Anti-corrosive treatment method of welded junction part of construction process pipe of heavy caliber push pipe

A technology for large-diameter pipelines and construction technology, which is applied in the field of anti-corrosion treatment of pipeline welding joints in large-diameter pipe jacking construction process, and can solve the problems of complicated operation, low bonding strength, and inability to guarantee the bonding between the filling material and the epoxy coating. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

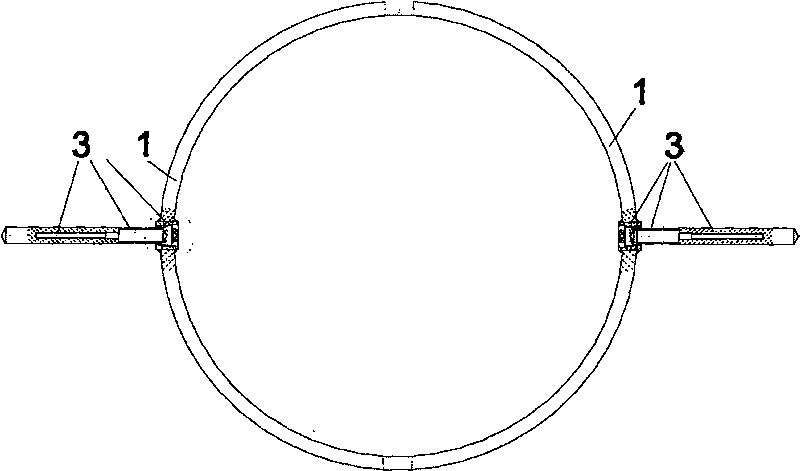

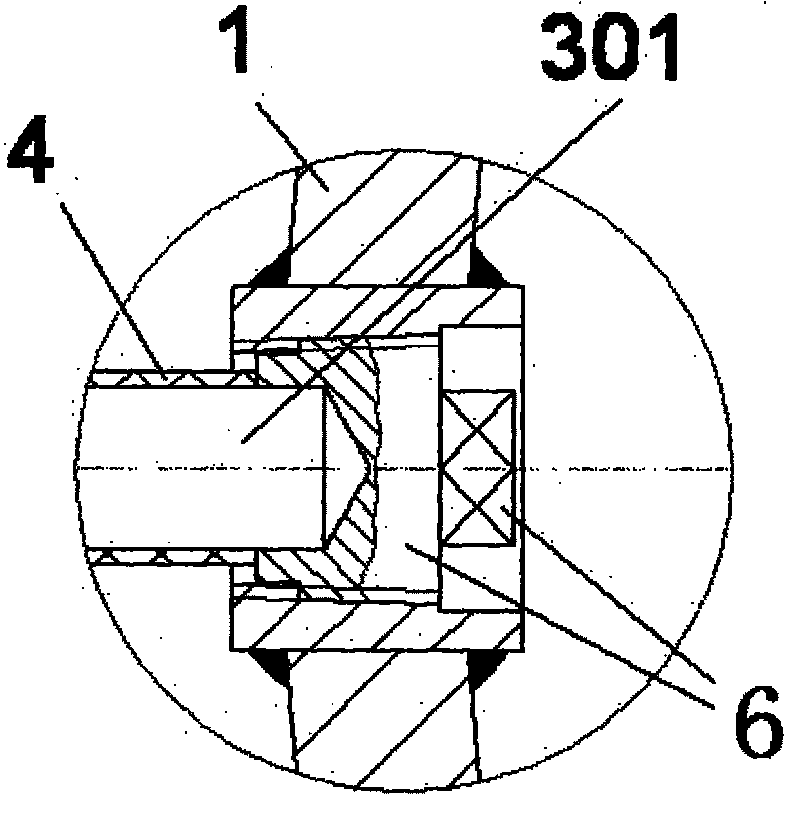

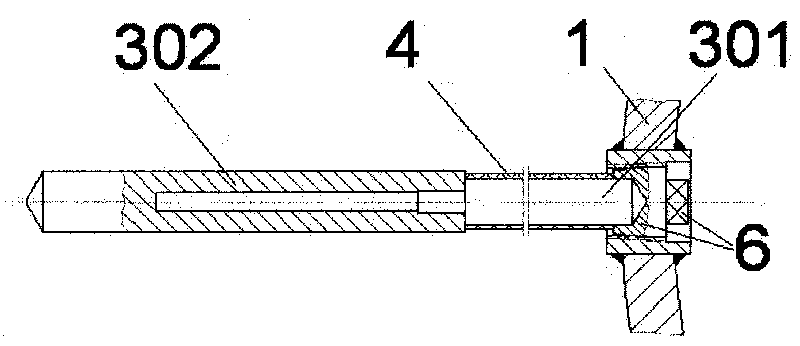

[0089] An anti-corrosion treatment method for pipe welding joints in a large-diameter pipe jacking construction process, which specifically applies an open excavation construction or a pipe jacking construction process for pipeline installation; the process pipeline is a segmented pipe jacking construction pipeline, and each section The pipes are fixed together by welding; the outside of the pipeline is provided with a sacrificial anode protection device 3 fixedly connected to the outer wall of the pipeline, and the entire outside of the pipeline is provided with a protective coating;

[0090] The material of the sacrificial anode protection device 3 is magnesium alloy or zinc alloy; the specific requirements respectively meet the "4 technical conditions" in the "People's Republic of China Petroleum and Natural Gas Industry Standard. Design Code for Sacrificial Anode Cathodic Protection of Buried Steel Pipelines" SY / T0019-97 Provisions.

[0091] The anti-corrosion treatment method ...

Embodiment 2

[0107] The anti-corrosion treatment method for the welded joints of the large-diameter pipe jacking construction process adopts the open excavation construction or the pipe jacking construction process for pipeline installation; the process pipeline is a segmented pipe jacking construction pipeline, and the sections are welded Fixed together; the outside of the pipeline is provided with a sacrificial anode protection device 3 fixedly connected to the outer wall of the pipeline, and the entire outside of the pipeline is provided with a protective coating; its characteristics are:

[0108] The anti-corrosion treatment method for the pipe weld joint of the large-diameter pipe jacking construction process specifically uses a solvent-free liquid epoxy coating to perform a quick coating repair operation on the pipe outer wall weld joint to quickly form an overall protective coating on the outside of the pipe , The coating performance of the solvent-free liquid epoxy meets the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com