Patents

Literature

34 results about "Corrosion engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion engineering is the specialist discipline that requires application of scientific, technical and engineering knowledge along with natural laws and physical resources in order to design and implement materials, structures, devices, systems and procedures to manage the natural phenomenon known as corrosion.

Zinc-aluminum-magnesium-rare earth multi-element alloy material and preparation method thereof

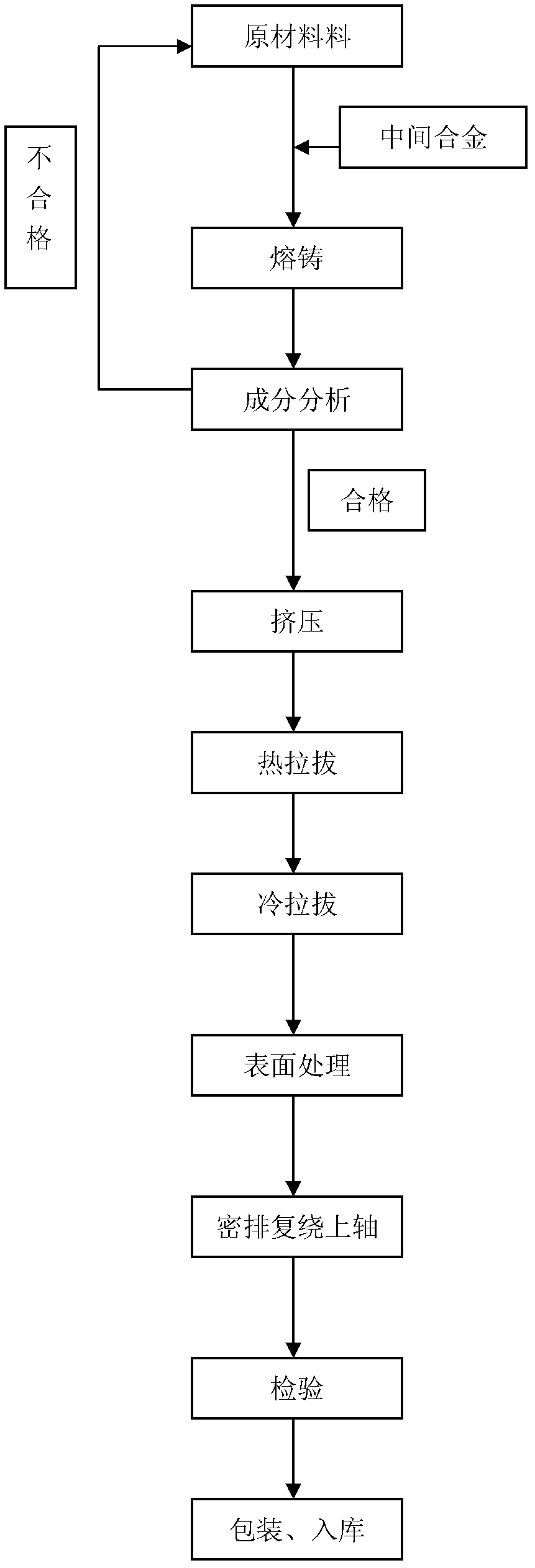

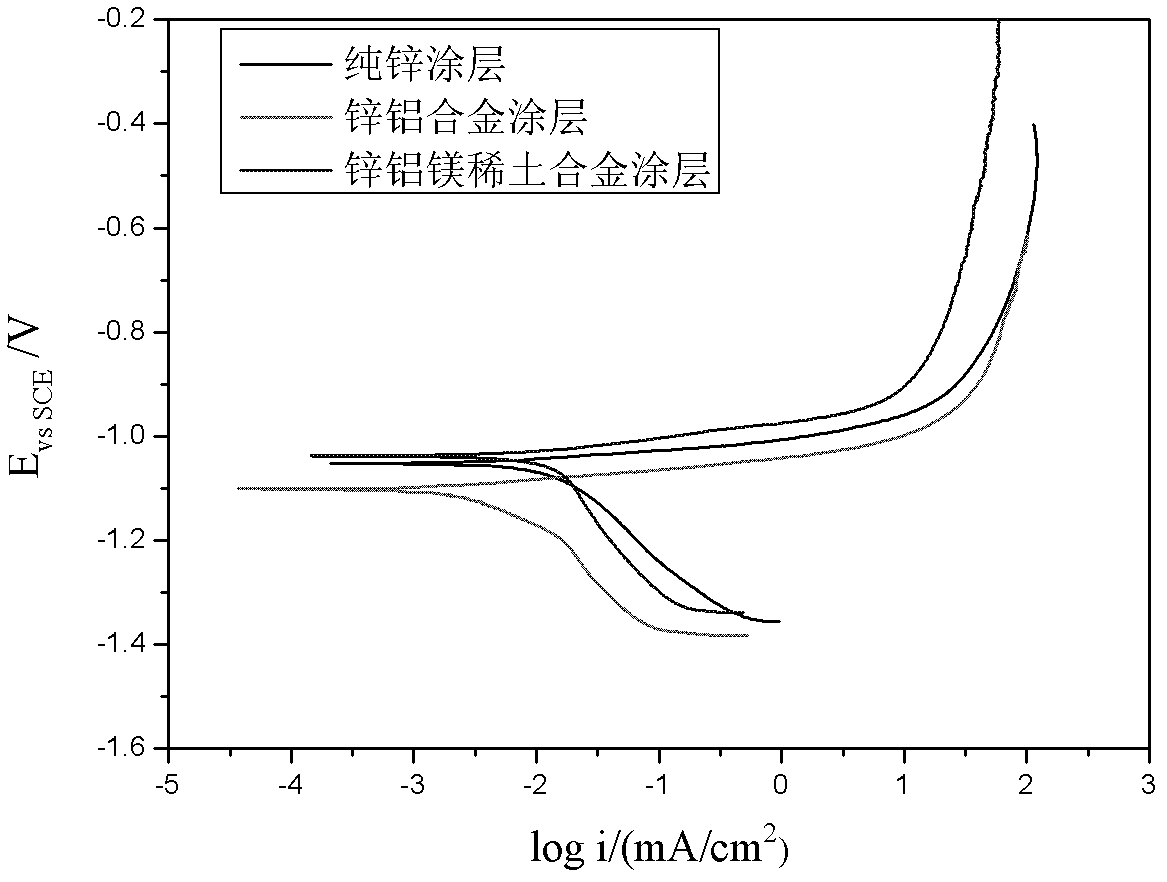

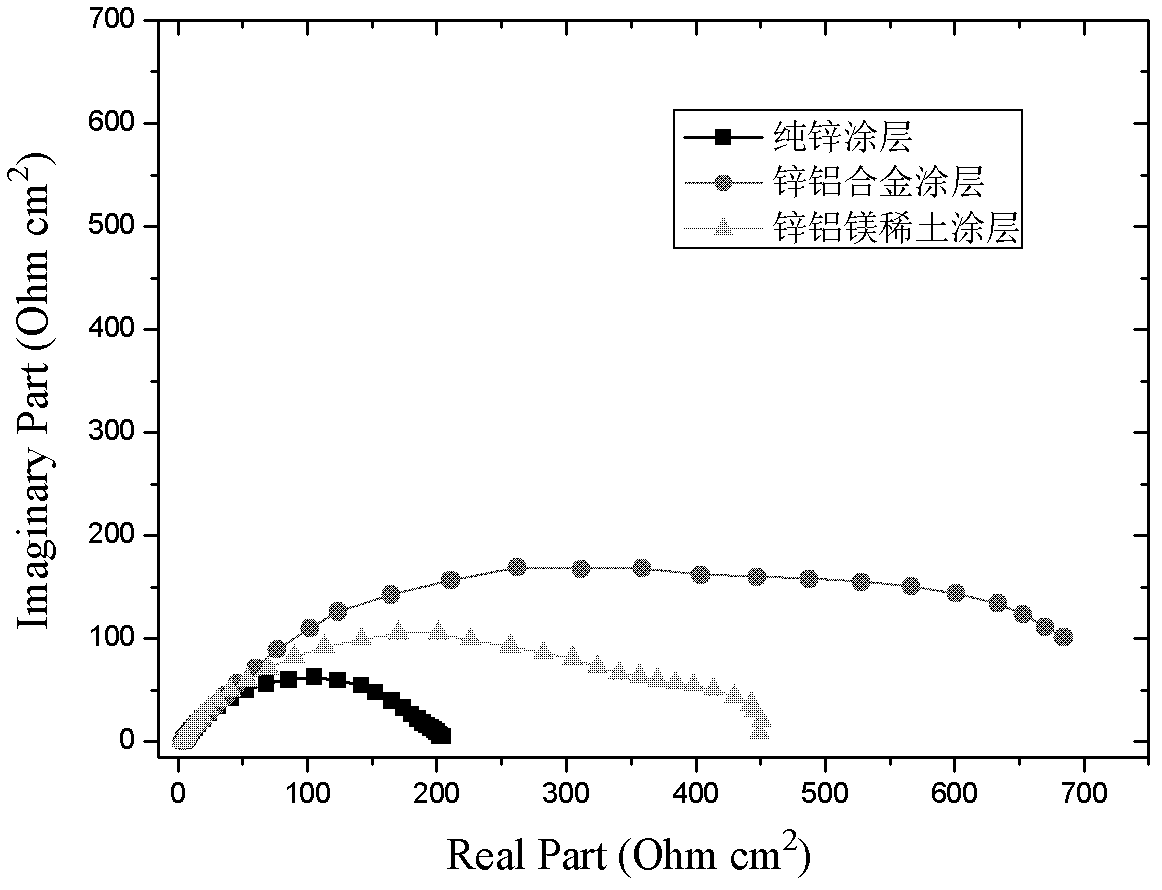

The invention relates to a composition design, a preparation method and application of a hot spraying zinc-aluminum-magnesium-rare earth multi-element alloy material, and belongs to the technical field of anti-corrosive metal anticorrosion. The zinc-aluminum-magnesium-rare earth multi-element alloy material comprises the following components in percentage by weight: 5.0 to 15.0 percent of aluminum, 0.1 to 1.0 percent of magnesium, 0.1 to 0.5 percent of rare earth (lanthanum and cerium), less than 1.0 percent of impurities and the balance of zinc. The preparation method comprises the following steps of: heating to smelt zinc ingots and aluminum ingots in an alloy smelting furnace, adding an intermediate alloy, stirring until the melt is clear, standing, slagging off, and casting; and performing homogenizing annealing on cast ingots, extruding to obtain zinc-aluminum-magnesium-rare earth multi-element alloy blank thick wires, and performing homogenizing annealing, drawing, diameter reducing, and wire surface cleaning to obtain zinc-aluminum-magnesium-rare earth multi-element alloy wire products. A corrosion resistant multi-element alloy coating prepared from the alloy wires prepared by the method through a hot spraying technology has the corrosion resistance obviously higher than that of a pure zinc coating, is suitable for protection construction of steel structural parts, and has important significance and wide application prospect for anti-corrosion engineering of water conservancy and hydropower, ports, bridges, ships and the like.

Owner:UNIV OF SCI & TECH BEIJING

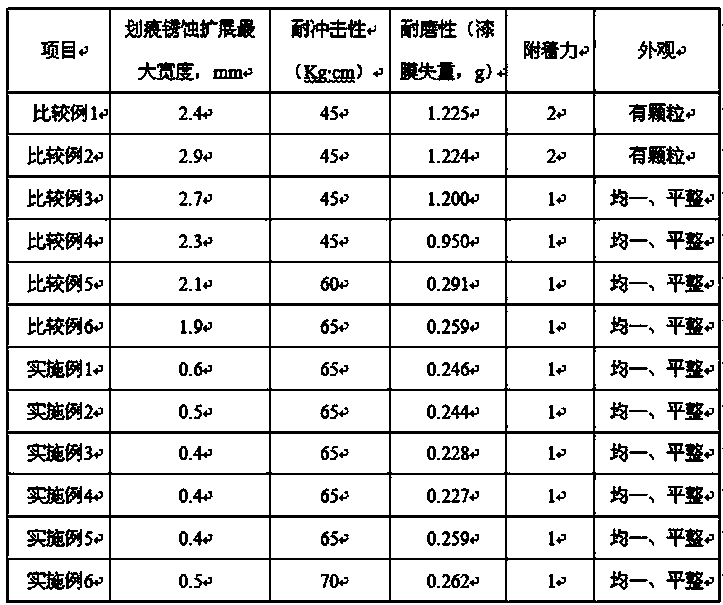

Aluminum oxide-containing polyaniline zinc powder flake epoxy heavy anti-corrosion coating and preparation method thereof

ActiveCN103834264AWith \"passivation\"Has a \"sustained release\" effectAnti-corrosive paintsEpoxy resin coatingsCoating systemFirming agent

The invention discloses aluminum oxide-containing polyaniline zinc powder flake epoxy heavy anti-corrosion coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises the following components in parts by mass: 35-85 parts of epoxy resin, 0.5-25 parts of polyaniline zinc powder flake, 0.1-10 parts of aluminum oxide, 0.1-5 parts of pigment, 1-15 parts of packing, 0.01-2 parts of anti-sag agent, 0.01-0.5 part of dispersant, 0.01-2 parts of flatting agent, 0.01-0.5 part of deforming agent and 5-40 parts of mixed solvent; and the component B comprises the following components in parts by mass: 40-90 parts of amine curing agent and 10-60 parts of solvent; and the coating is prepared by mixing and stirring the component A and the component B for 1-5 minutes according to a mass ratio being 1: (0.1-1):1. The corrosion resistance, seawater erosion and abrasion resistance, ageing resistance and anti-penetrating property of the coating system are obviously improved; and the coating can be applied to heavy anti-corrosion engineering in fields of petrochemical equipment, pipelines, offshore oil platforms, berthing facilities, ships and the like.

Owner:HOHAI UNIV

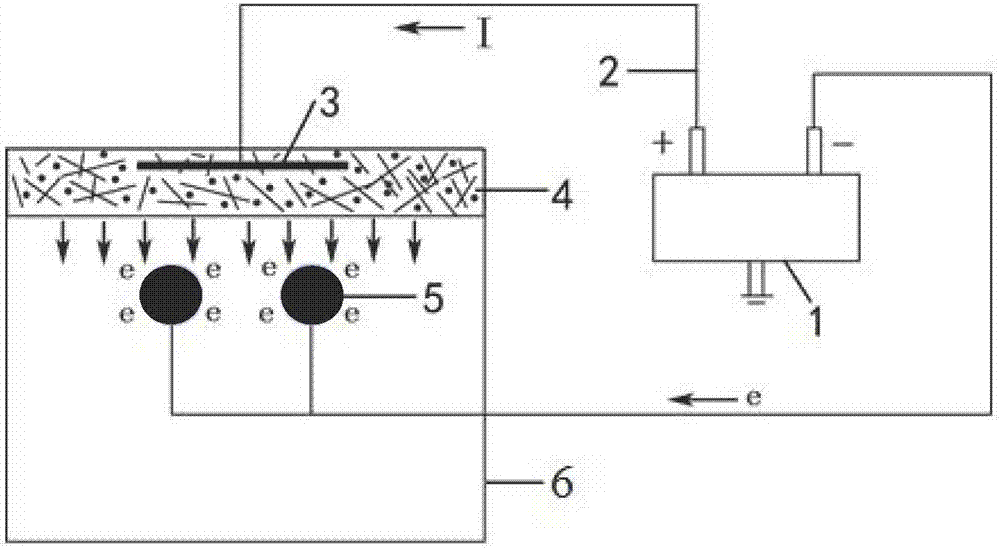

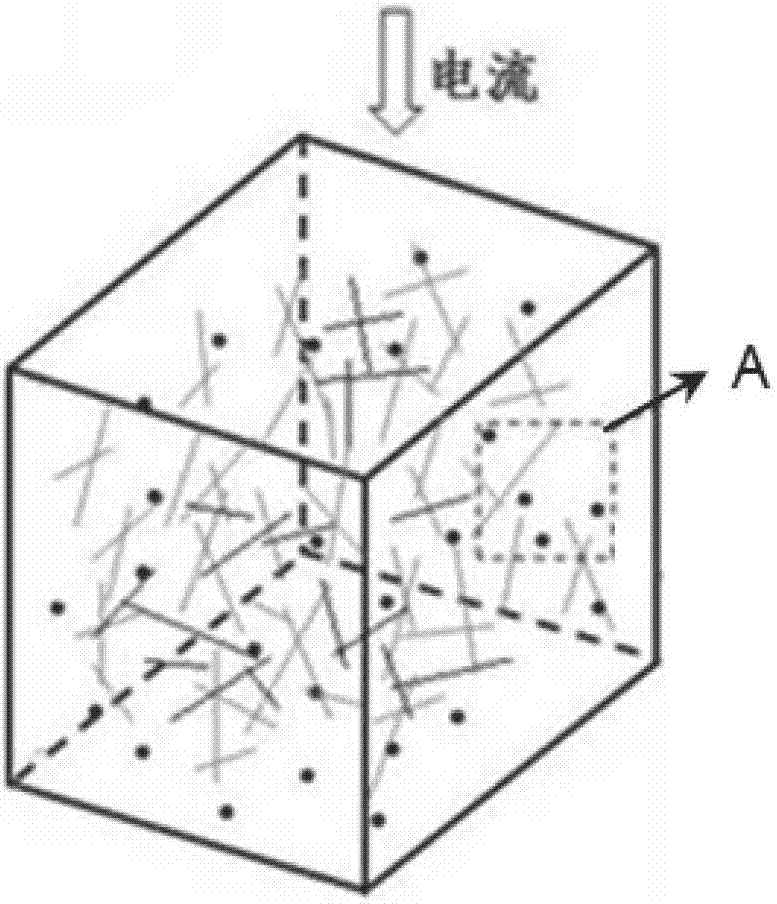

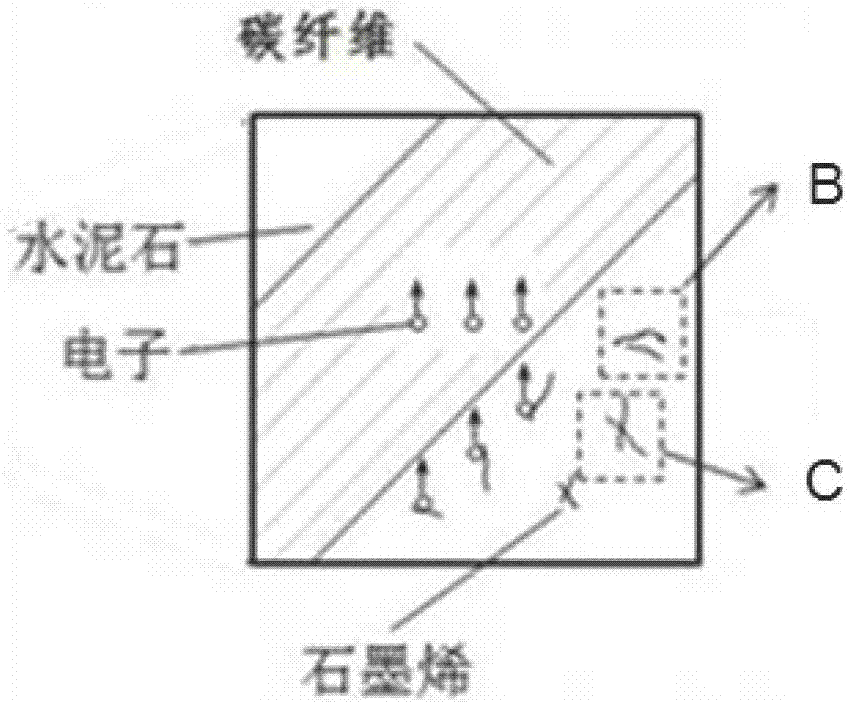

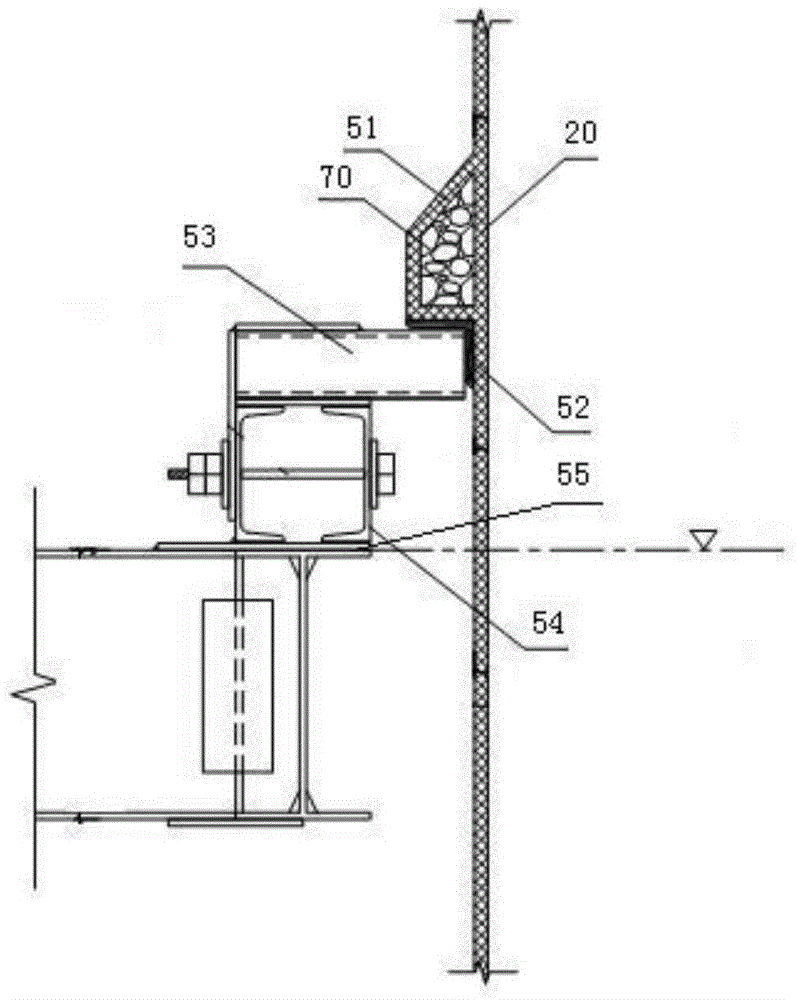

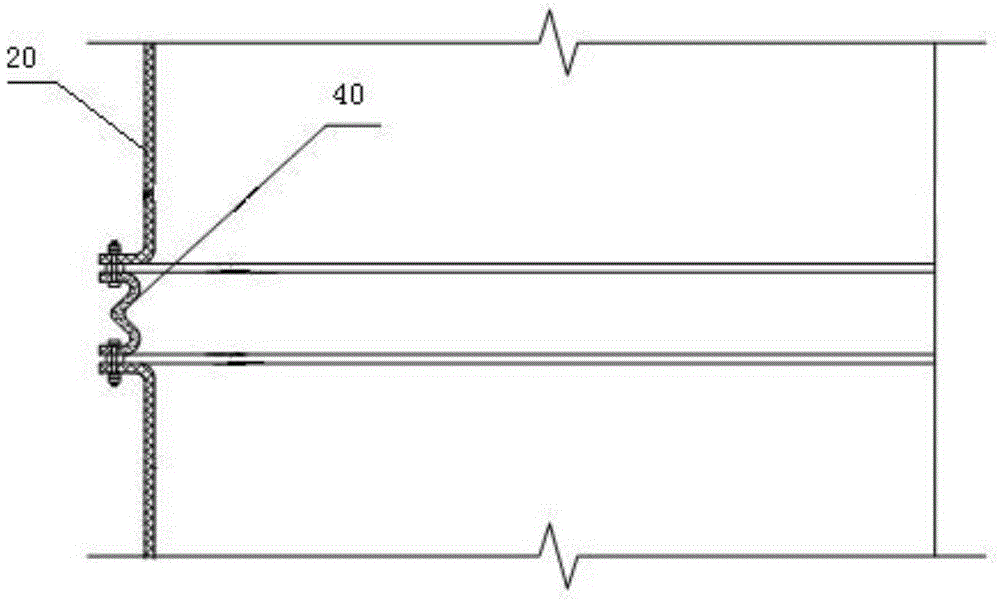

Reinforced concrete cathode protection system and method

The invention discloses a reinforced concrete cathode protection system and method. The reinforced concrete cathode protection system comprises reinforcing steel bars, concrete, a titanium net, a graphene / carbon fiber cement base material and a power source. The reinforcing bars are connected with the negative electrode of the power source to serve as cathodes; a hole solution of the concrete serves as an electrolyte; the titanium net is connected with the positive electrode of the power source to serve as a main anode; the graphene / carbon fiber cement base material serves as an auxiliary anode; and the reinforcing bars, the concrete, the titanium net, the graphene / carbon fiber cement base material and the power source form a loop of the cathode protection system. The reinforced concrete cathode protection system is low in cost, low in energy consumption and durable, an existing cathode protection technology is improved and optimized, an economical and effective corrosion protection technology is provided for domestic large-amount and large-range chlorine salt corrosion engineering, and obvious economic benefits and application prospects are achieved.

Owner:SHANGHAI CONSTRUCTION GROUP +3

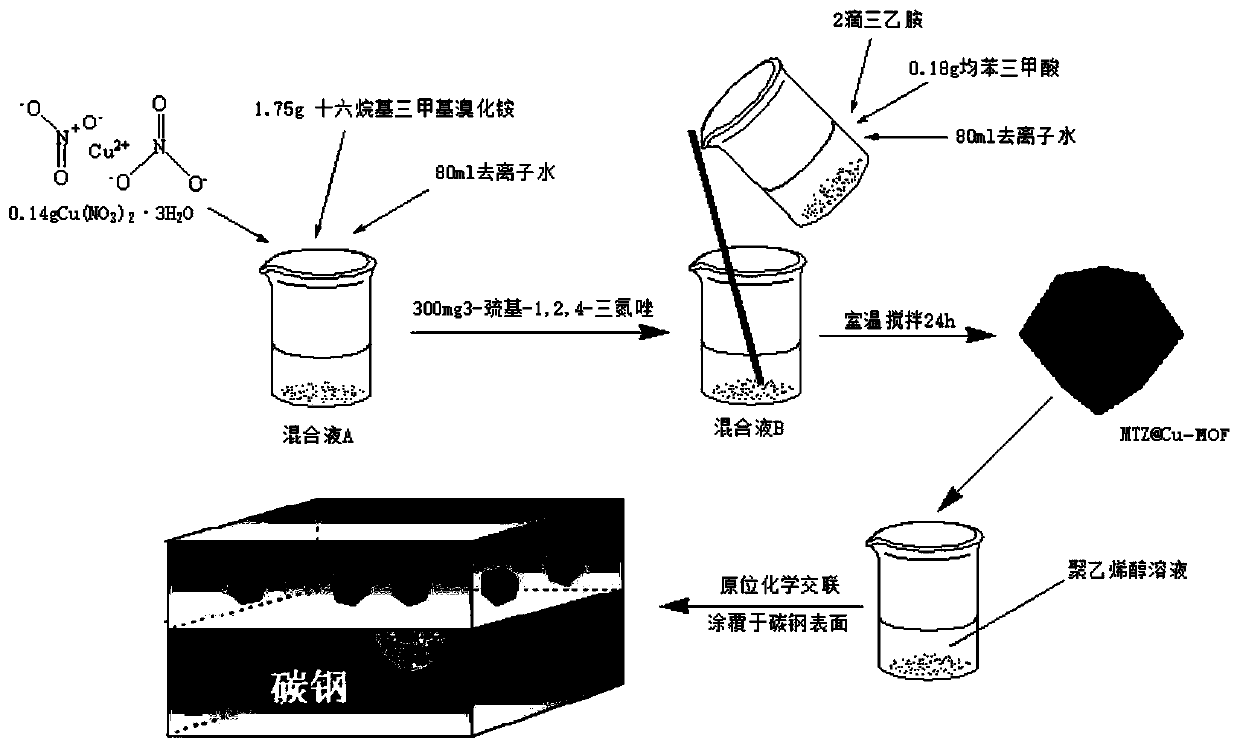

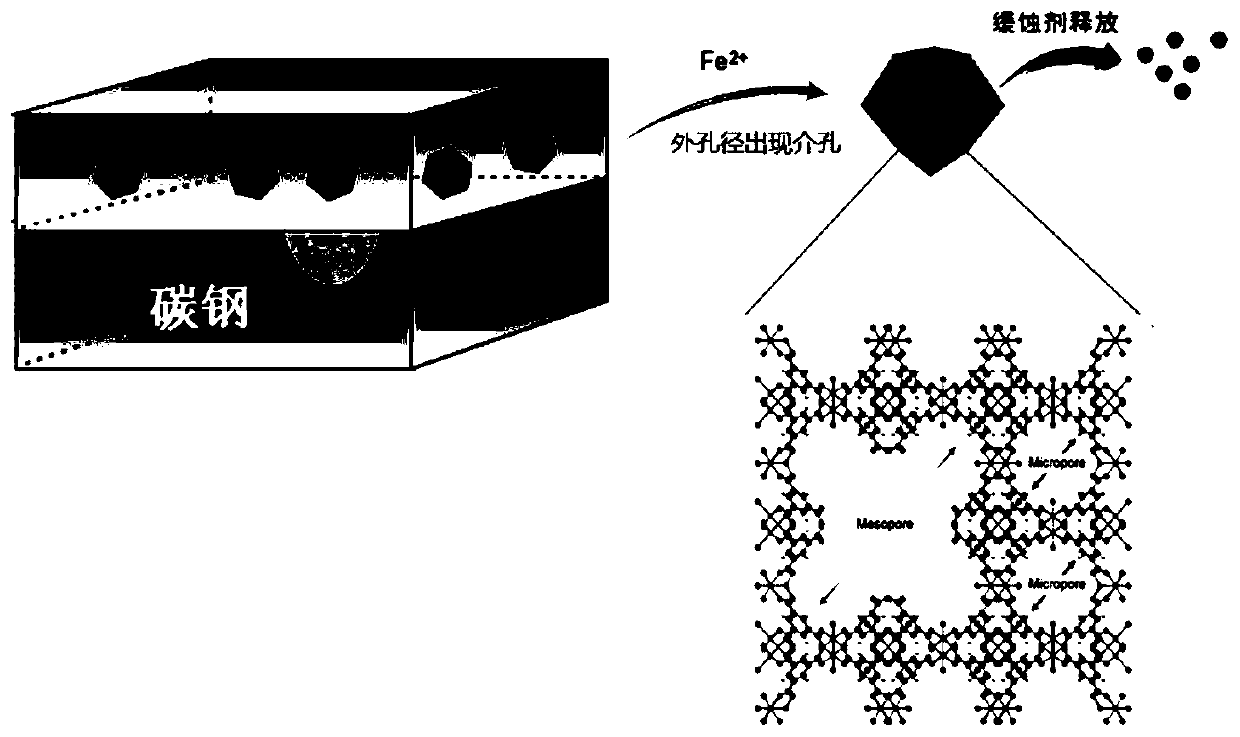

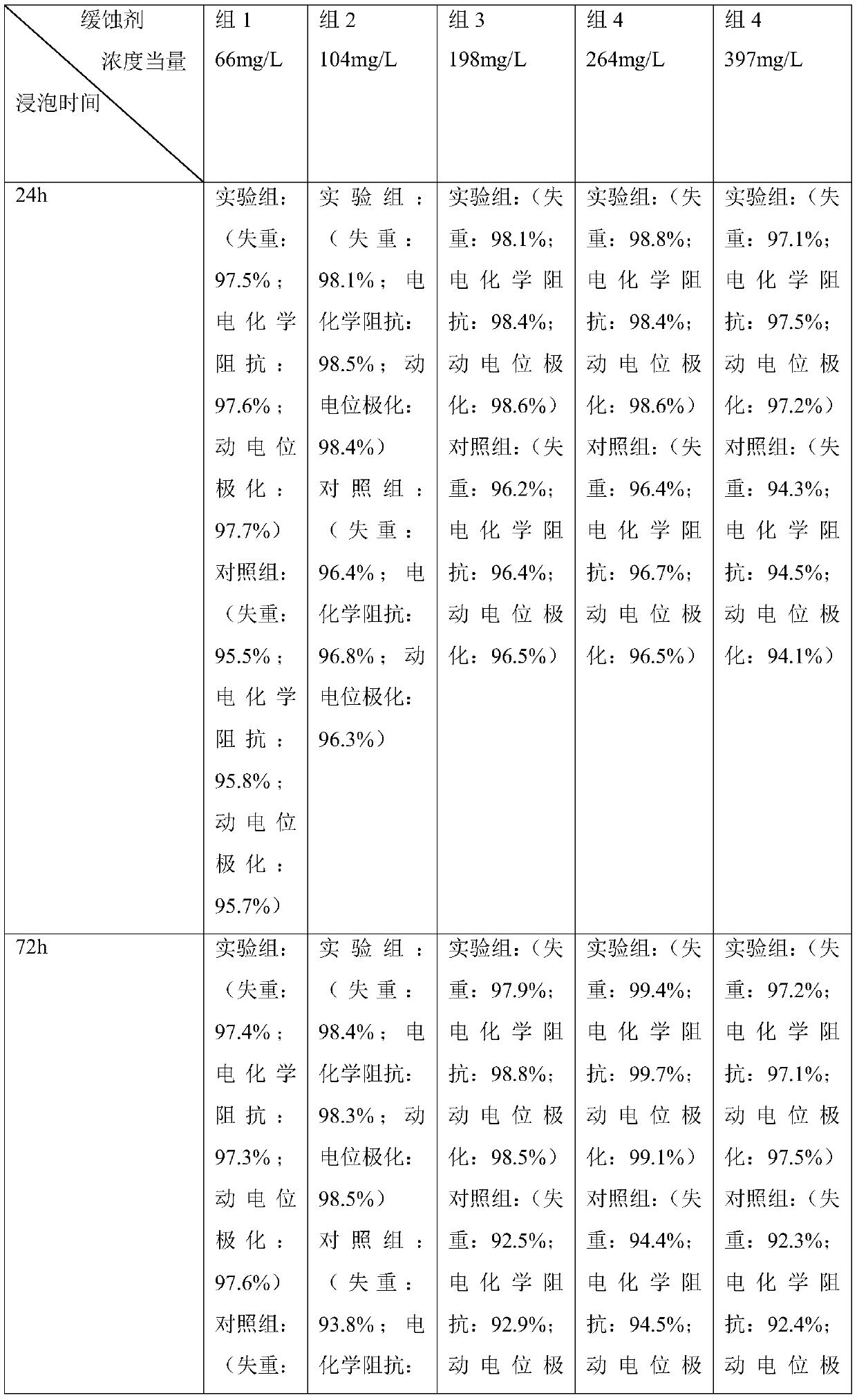

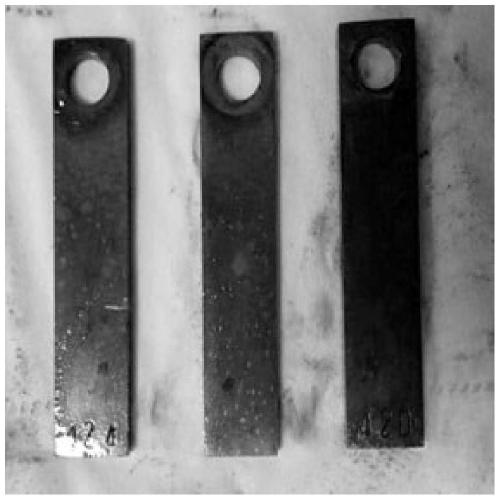

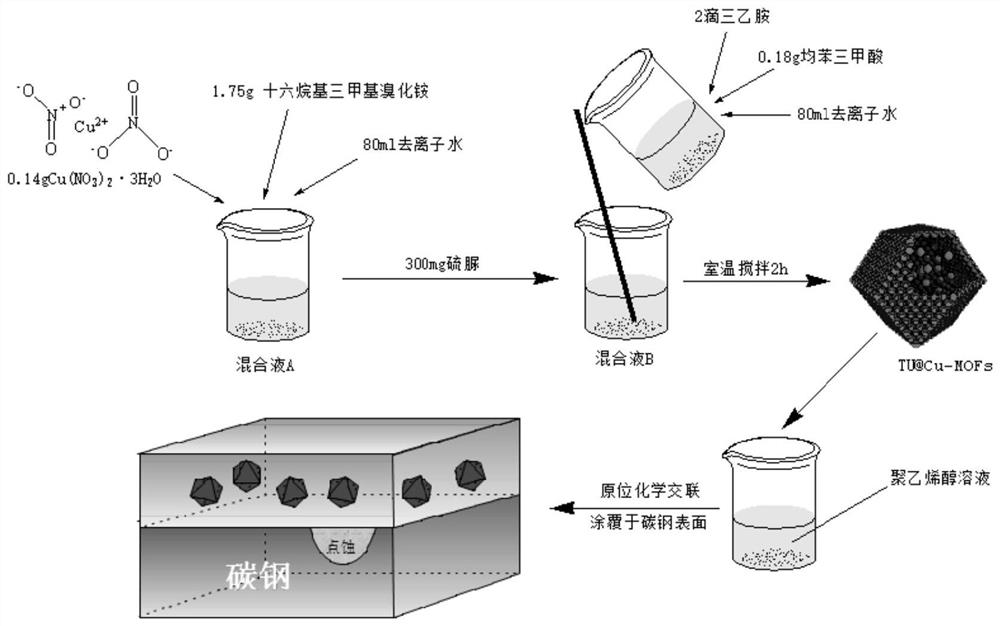

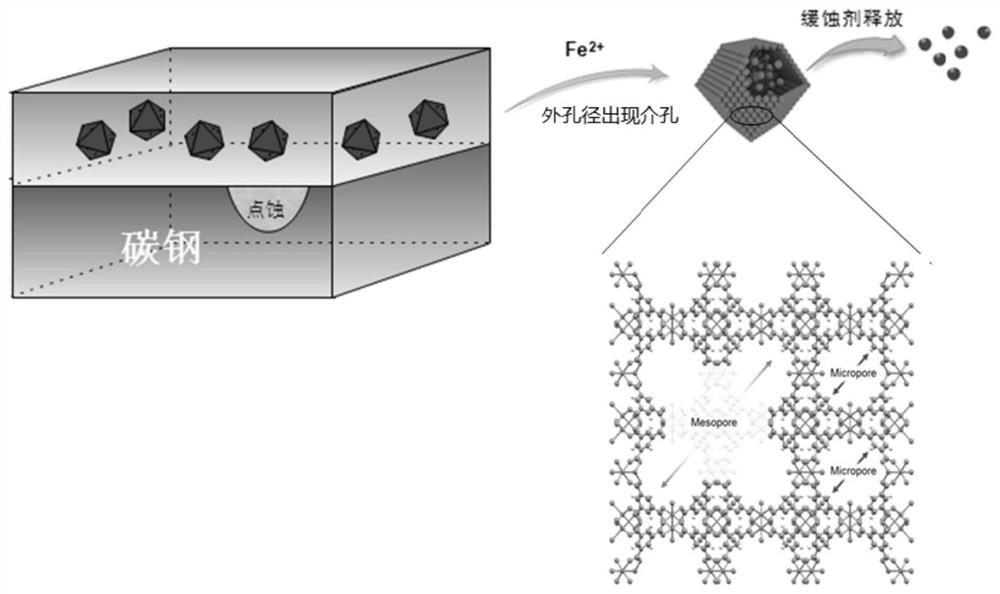

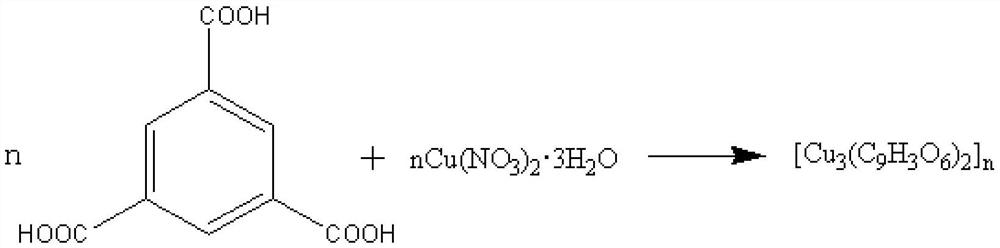

Metal organic formwork corrosion inhibitor-hydrogel compound with Fe2+ response characteristic, and preparation method and application thereof

ActiveCN110551398AGood dispersionImprove integrityAnti-corrosive paintsMetal-organic frameworkCarboxylic acid

The invention discloses a metal organic formwork corrosion inhibitor-hydrogel compound with a Fe2+ response characteristic, and a preparation method and application thereof. The metal organic formworkcorrosion inhibitor-hydrogel compound is composed of polyvinyl alcohol hydrogel and a copper-based carboxylic acid metal organic formwork doped in the hydrogel and encapsulated with a 1H-1,2,4-triazole-3-thiol corrosion inhibitor. The preparation method includes the steps that firstly, in-situ encapsulation of a corrosion inhibitor guest in a metal organic formwork encapsulation solution is achieved through a one-pot synthesis method, then an encapsulation precursor is doped into the polyvinyl alcohol hydrogel, the growth rate of a nanoshell is decreased through the coordination effect of a hydrogel monomer and a metal center in the metal organic formwork, thus the integration of a formwork structure is improved, high-capacity encapsulation of the corrosion inhibitor is achieved finally,and the high-load hydrogel compound of the metal organic formwork encapsulation corrosion inhibitor is formed. The corrosion inhibition compound can be applied to a seawater corrosion engineering structure, a main characteristic product of carbon steel corrosion in a seawater environment is free divalent iron ions, the ions are replaced with the center of cetyl trimethyl ammonium positive ions ofthe metal organic formwork, thus the outer surface hole diameter of a frame can be enlarged, the corrosion inhibitor encapsulated inside is released, and target protection of the corrosion area is achieved. By adopting a corrosion inhibition system, the targeting ability is high, the efficient and durable effects are achieved, cost performance is high, and significant application value and broad market prospects are achieved.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

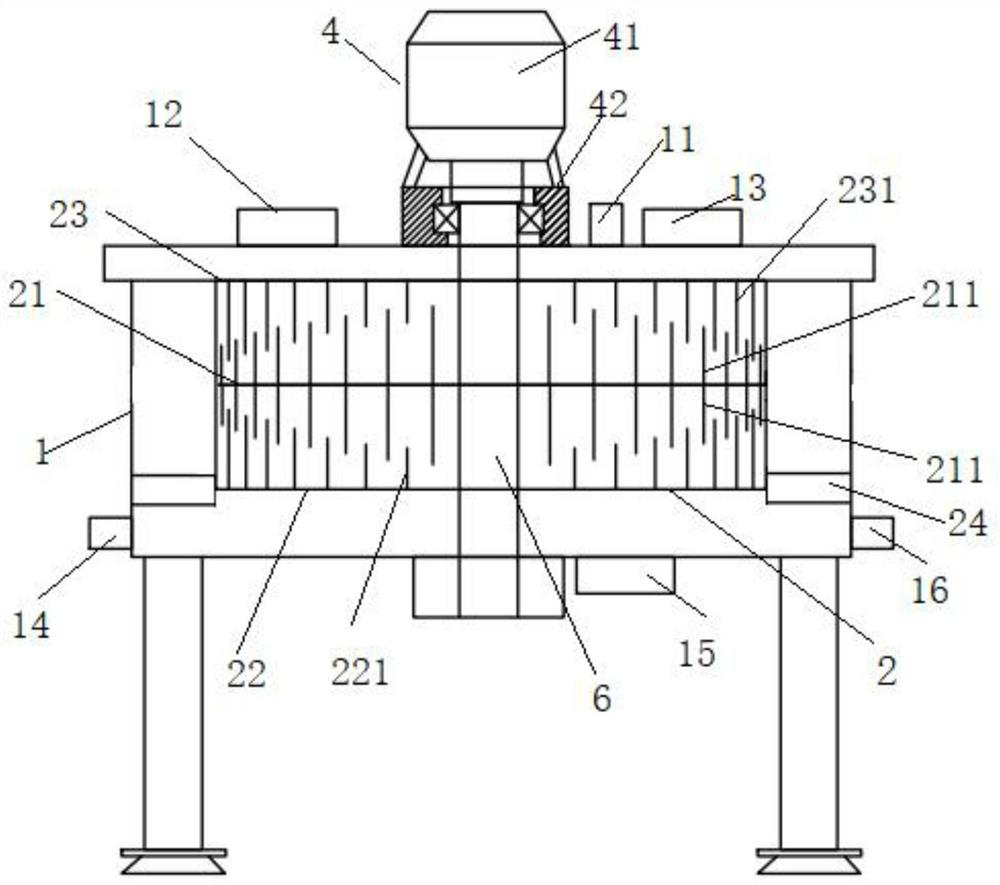

Method for evaluating corrosion inhibition performance of vapor-phase corrosion inhibitor

The invention relates to the technical field of anti-corrosion engineering and particularly discloses a method for evaluating corrosion inhibition performance of a vapor-phase corrosion inhibitor. Themethod for evaluating the corrosion inhibition performance of the vapor phase corrosion inhibitor comprises steps of (1) collecting corrosion working condition parameters of a to-be-applied field ofthe vapor phase corrosion inhibitor; (2) determining the water quality of a vapor phase corrosion inhibitor evaluation experiment; (3) determining parameters of the evaluation experiment according tofield working conditions; (4) selecting a dynamic evaluation reaction kettle according to the designed experiment parameters; and (5) carrying out multiple groups of vapor phase corrosion inhibitor evaluation experiments. The evaluation method for the corrosion inhibition performance of the gas-phase corrosion inhibitor is advantaged in that a situation that a subsea pipeline in the gas phase andthe liquid phase is corroded under various actual corrosion working conditions of pipeline transportation of natural gas is simulated, and thereby whether the selected corrosion inhibitor meets the field use requirement or not is scientifically judged.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

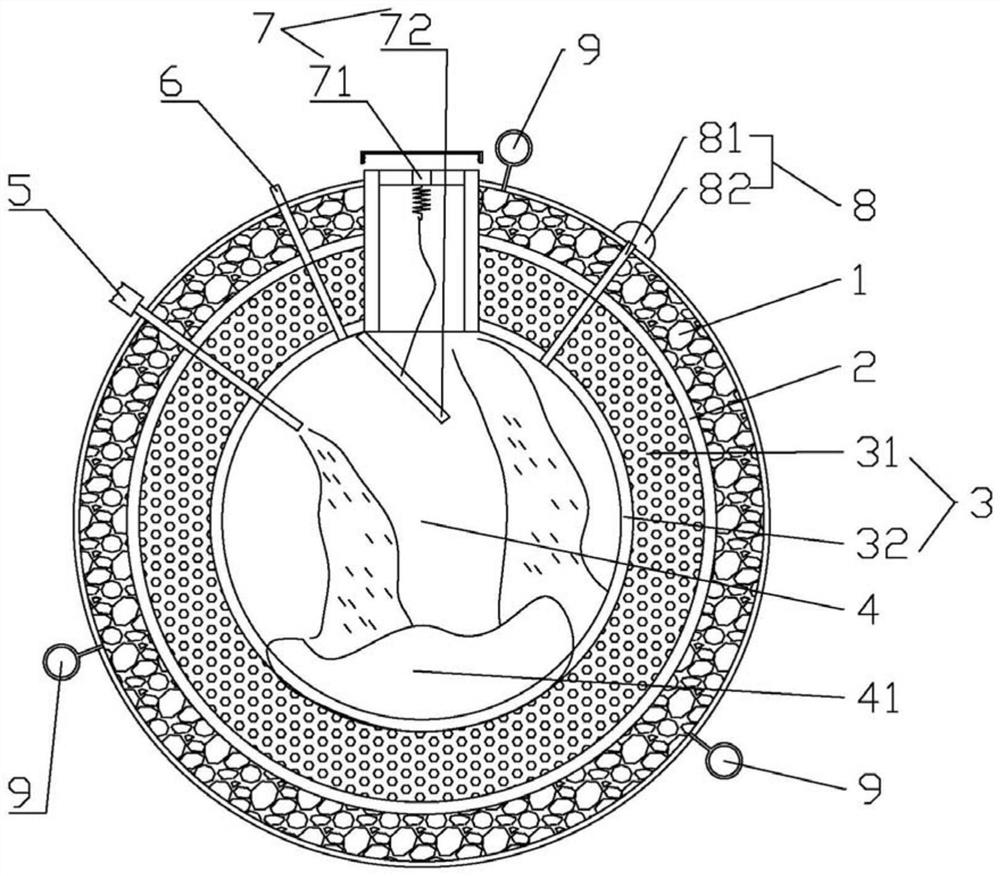

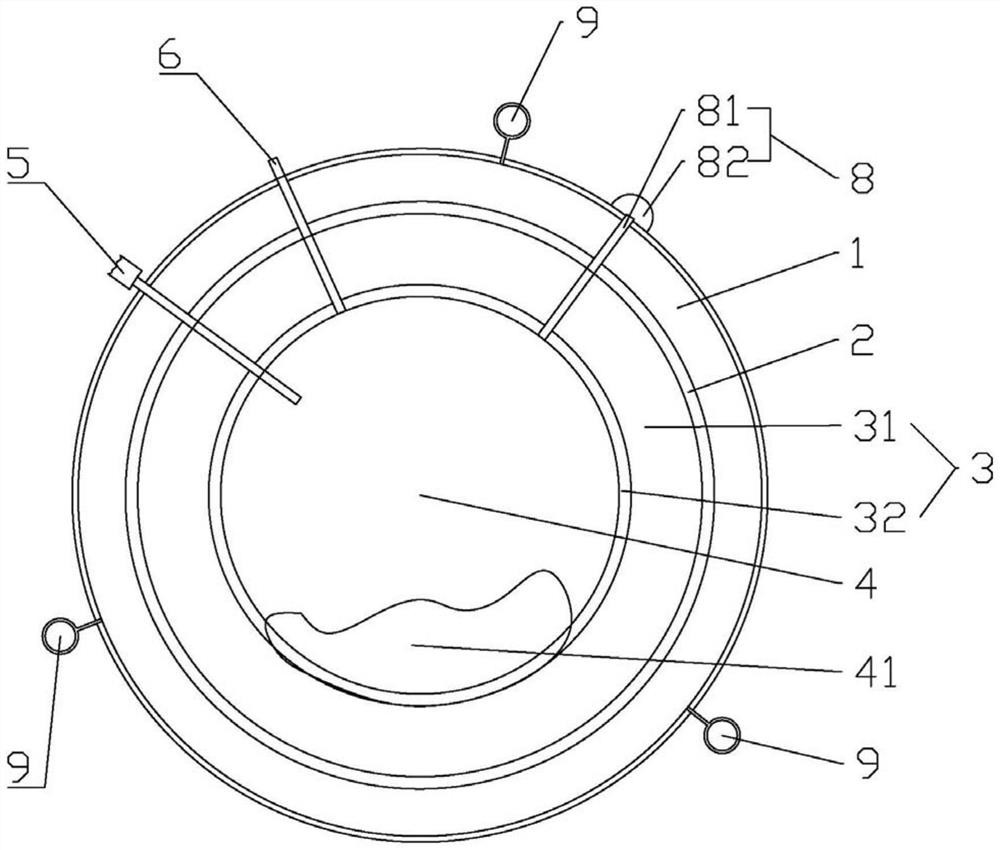

A high temperature resistant and anti-corrosion cyclone shear gas-liquid separator

ActiveCN111389106BRealize multiple mass transfer cyclesImprove work efficiencyDispersed particle separationVapor–liquid separatorAcid corrosion

Owner:苏州汇博龙环保科技有限公司

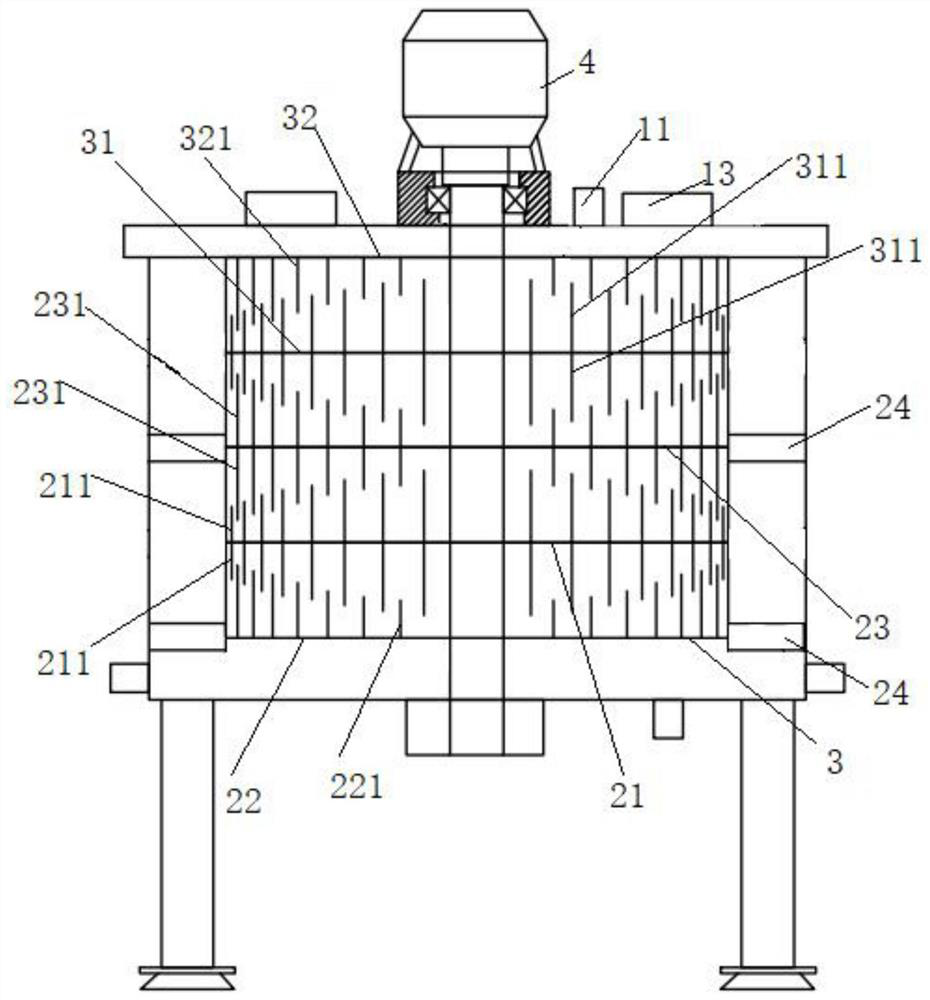

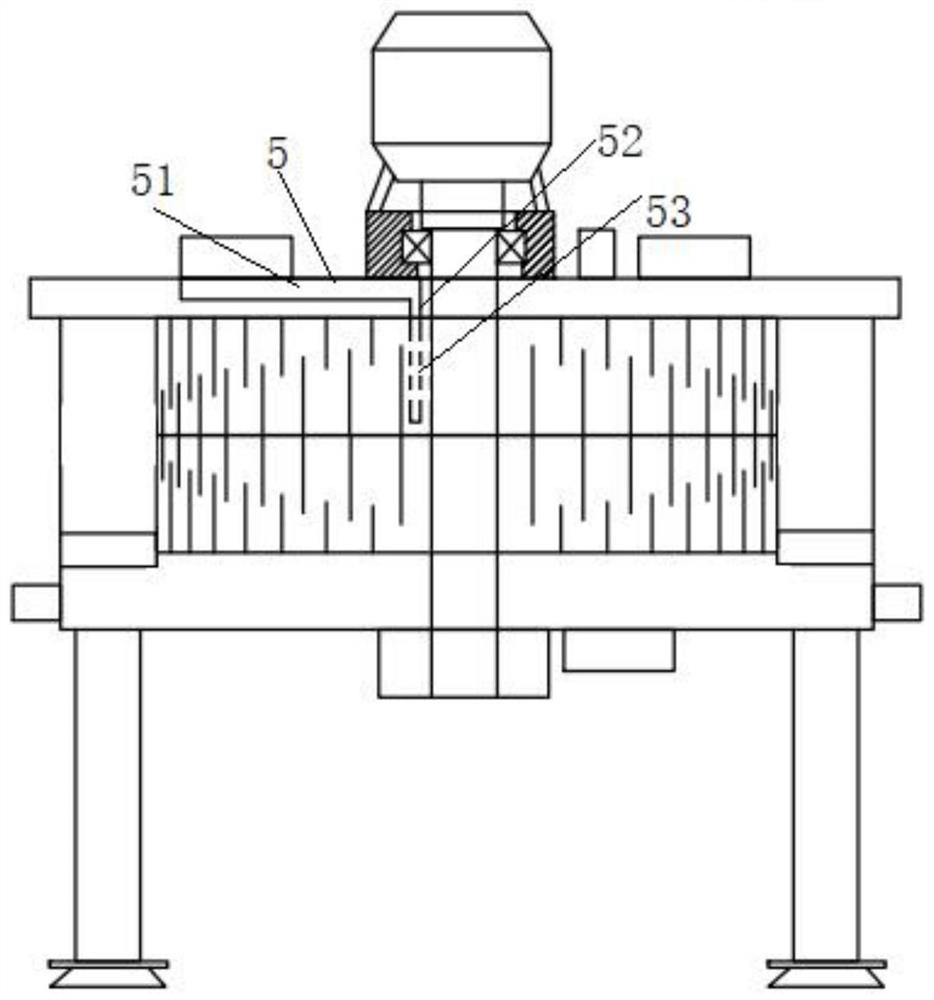

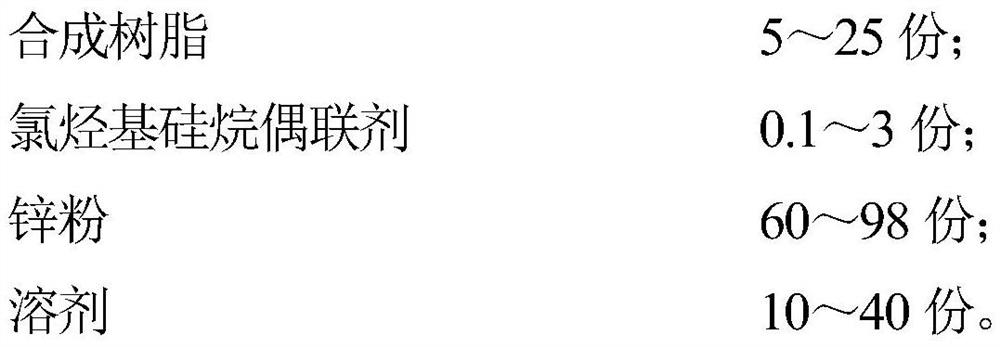

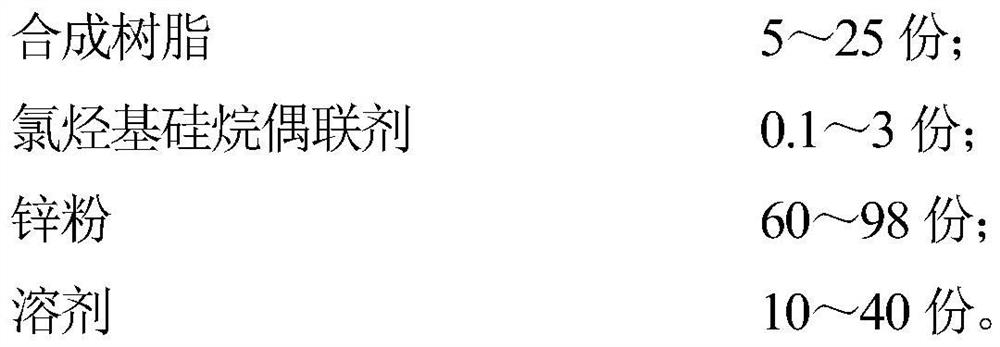

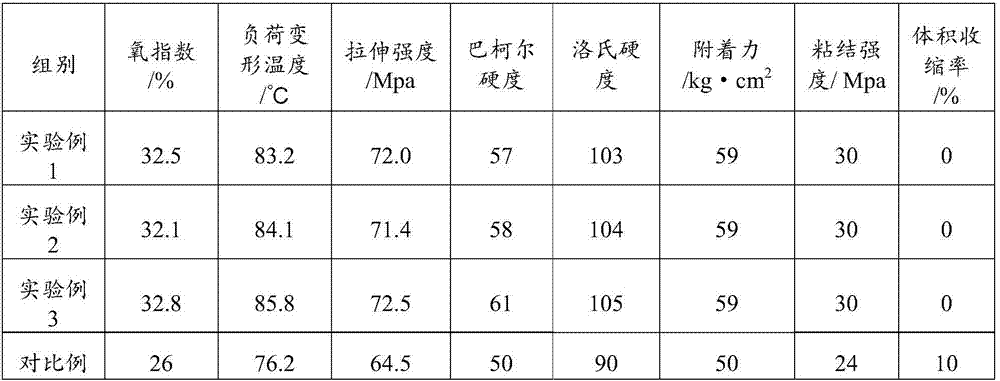

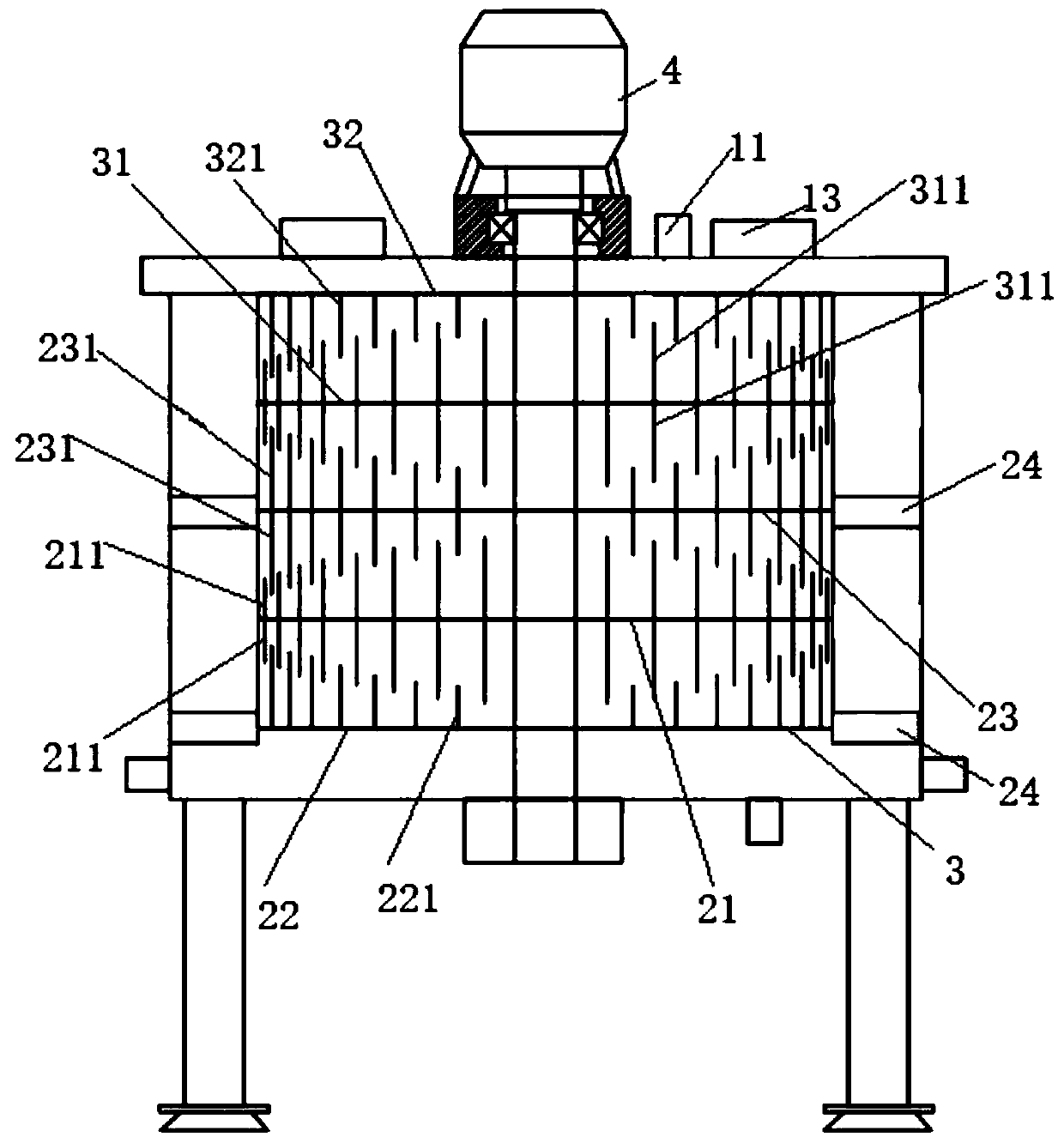

Chlorohydrocarbyl silane coupling agent modified cold-coating zinc coating and preparation method thereof

InactiveCN112961559AImprove adhesionImprove wettabilityAnti-corrosive paintsSynthetic resinCorrosion resistant

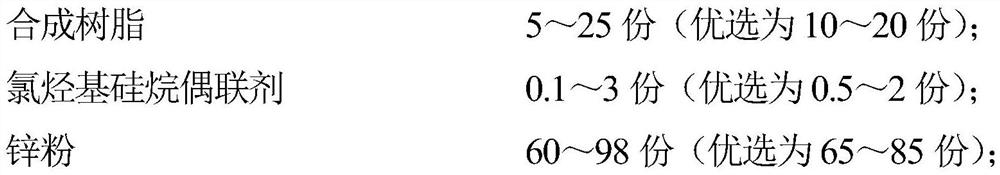

The invention relates to a chlorohydrocarbyl silane coupling agent modified cold-coating zinc coating and a preparation method thereof, and belongs to the field of coatings. The cold-coating zinc coating is prepared from the following components in parts by mass: 5 to 25 parts of synthetic resin, 0.1 to 3 parts of a chlorohydrocarbyl silane coupling agent, 60 to 98 parts of zinc powder and 10 to 40 parts of a solvent. The preparation method comprises the following steps: firstly, sequentially adding synthetic resin, a chlorohydrocarbyl silane coupling agent and a solvent into a reaction kettle, and dispersing for 15-50 minutes at the rotating speed of 300-1500 rpm; and then adding the modified zinc powder, dispersing for 30-100 minutes at the speed of 300-1500 rpm, filtering, and discharging, so as to obtain the chlorohydrocarbyl silane coupling agent modified cold-coating zinc coating. After the chlorohydrocarbyl silane coupling agent is added into the cold-coating zinc coating, the adhesive force of a coating and a hot-dip galvanized base material can be greatly improved, and the corrosion resistance of the coating on hot-dip galvanized steel is improved. The modified cold-coating zinc coating can be widely applied to anti-corrosion engineering of outdoor steel structures, and can conveniently and quickly solve the problem of corrosion protection of power transmission and transformation facilities, high-speed rail facilities, highway facilities and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

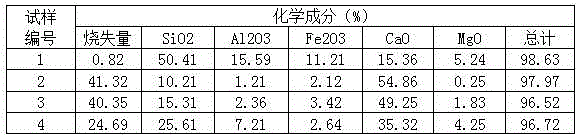

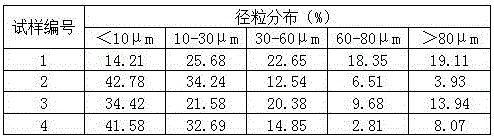

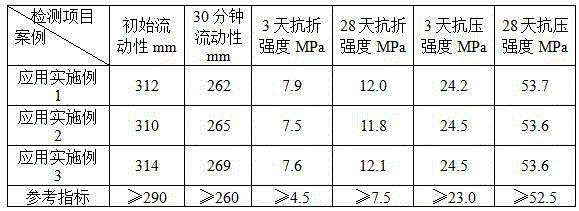

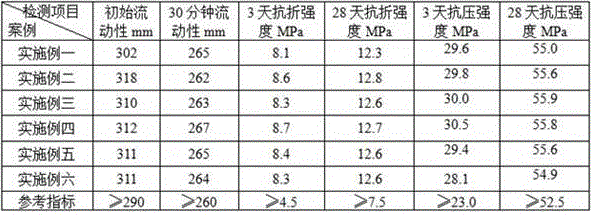

Method for producing green ecological cement resistant to seawater corrosion with stone waste

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from stone waste, which comprises the following raw materials in parts by weight: 30-40 parts of stone waste; 40-50 parts of sulphoaluminate cement clinker; 0.03-0.05 parts of activator; 2-4 parts of early strength agent; 0.3-0.5 parts of water reducing agent; 0.005-0.007 parts of air-entraining agent; The salt cement clinker, composite activator and early strength agent are crushed separately, pulverized, homogenized, then mixed and homogenized according to the proportion, and then added with water reducer, air-entraining agent and retarder, mixed and homogenized to obtain the product. The seawater corrosion-resistant green ecological cement of the present invention, in addition to the performance of ordinary cement, also has excellent characteristics such as high strength, seawater erosion resistance, seawater erosion resistance, etc., and is especially suitable for underground projects, ports, wharves and other erosive media. project.

Owner:广西云燕特种水泥建材有限公司

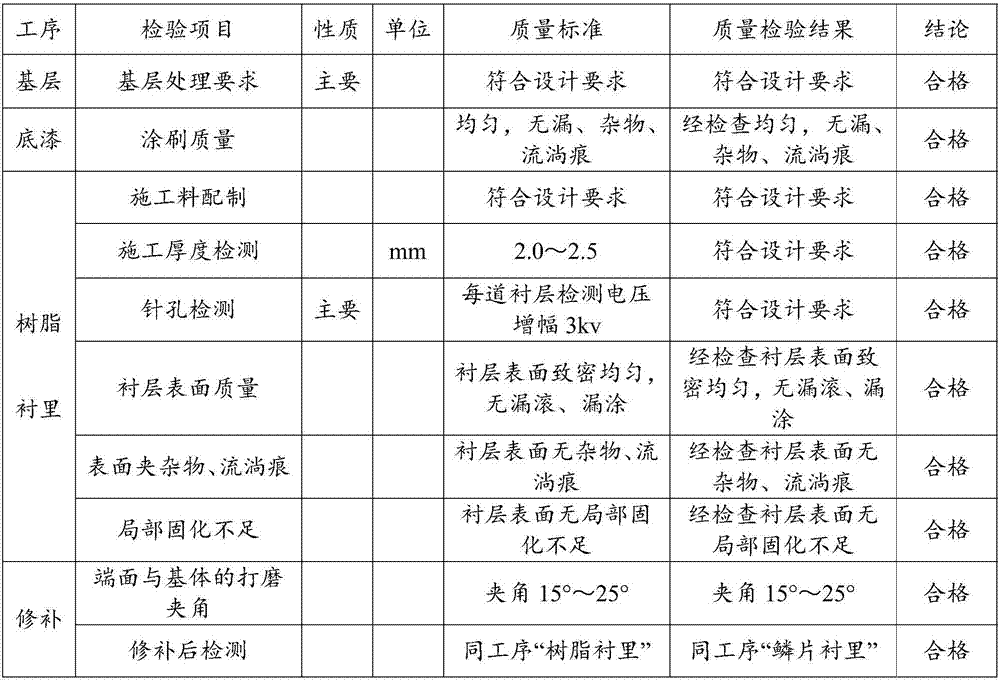

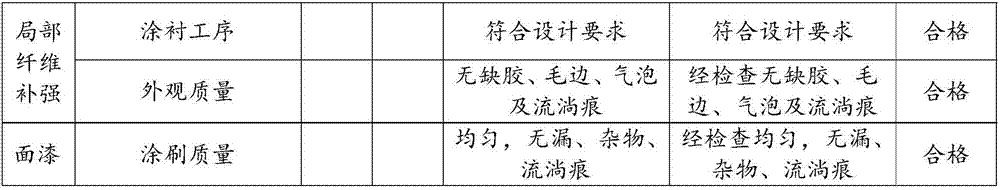

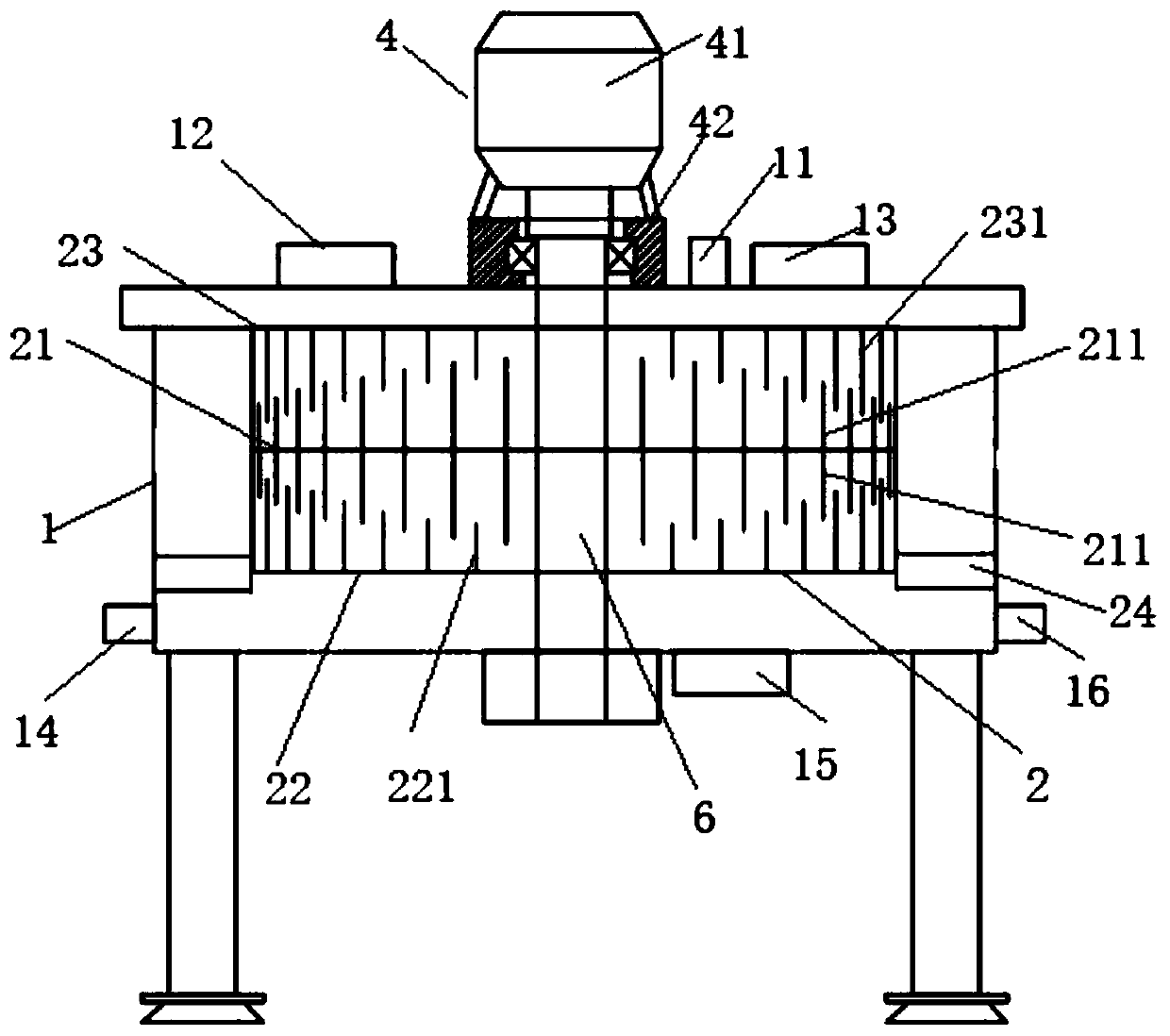

Application of a kind of resin ceramic material in anticorrosion engineering of wet desulfurization absorption tower

ActiveCN106883734BEliminate fire hazardsHigh bonding strengthPretreated surfacesAnti-corrosive paintsOrganic solventHigh wear resistance

The invention provides an application of a resin ceramic material in anti-corrosion engineering of a wet desulfurizing absorption tower and aims at solving the problem that glass flake resin adopted by the anti-corrosion engineering of an existing wet desulfurizing absorption tower is poor in effect and has a potential safety hazard. The resin ceramic material is adopted by the application; and the resin ceramic material has the advantages of being easy to mold, free of water and zero in shrinkage after being solidified. The resin ceramic material is compact in surface and high in bonding strength with carbon steel after being molded, and has the advantages of high wear resistance, decay resistance and relatively good erosion resistance. Furthermore, the resin ceramic material is free of an organic solvent, and is safe and environmentally friendly. In addition, the construction method of the material is convenient, simple and easy to construct, and is suitable for actual production and application.

Owner:瑞通(山东)新材料科技有限公司

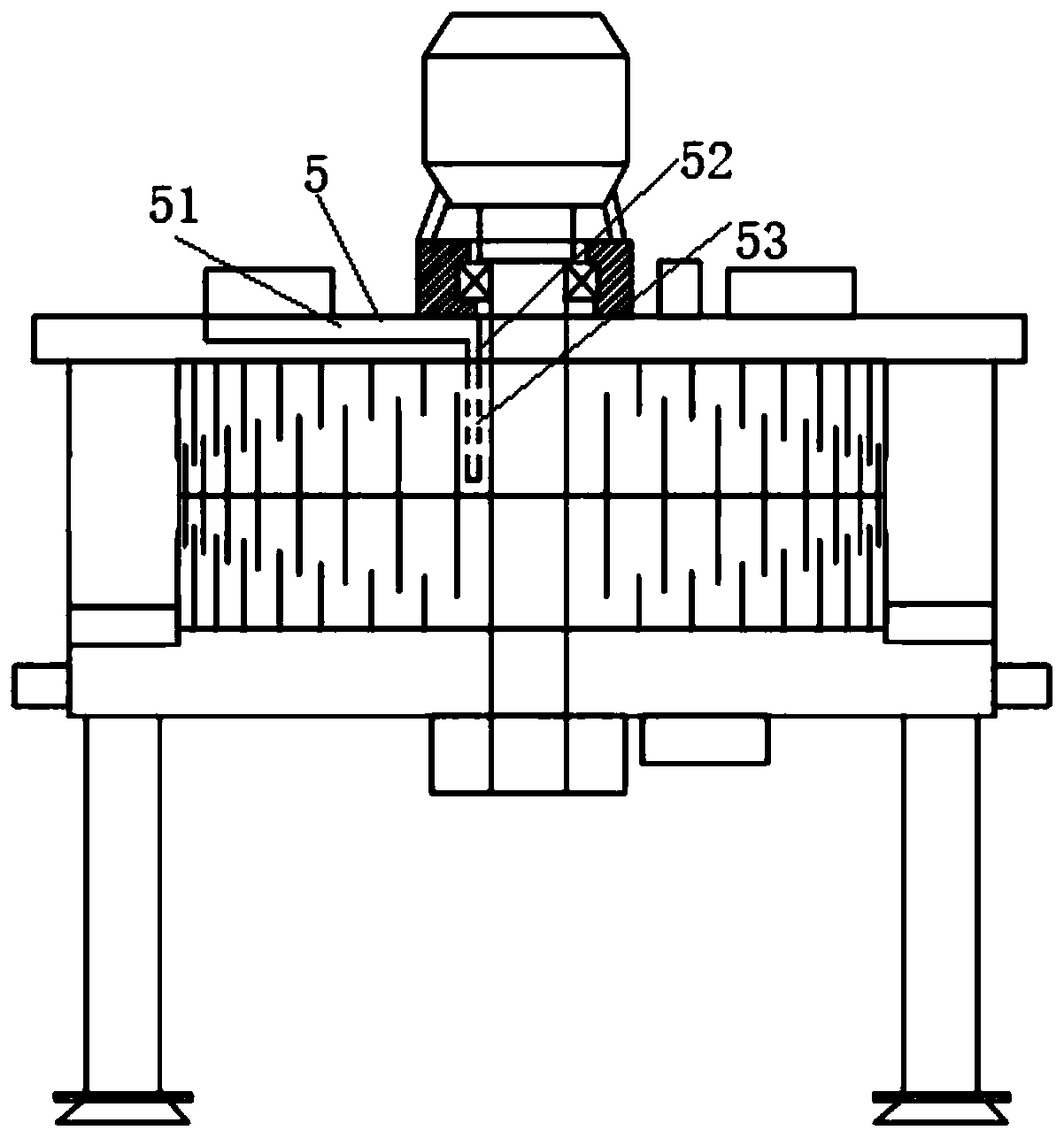

High-temperature-resistant anti-corrosion rotational flow shear type gas-liquid separator

ActiveCN111389106ARealize multiple mass transfer cyclesImprove work efficiencyDispersed particle separationVapor–liquid separatorEngineering

The invention provides a high-temperature-resistant anti-corrosion rotational flow shear type gas-liquid separator. The gas-liquid separator comprises first rotational flow shearing type separation standard module assemblies or second rotational flow shearing type separation standard module assemblies, each first rotational flow shearing type separation standard module assembly comprises a first tray body, a second tray body and a third tray body, or each second rotational flow shearing type separation standard module assembly comprises a first tray body, a second tray body, a third tray body,a fourth tray body and a fifth tray body; the first rotational flow shearing type separation standard module assemblies or the second rotational flow shearing type separation standard module assemblyassemblies are connected to a main shaft at intervals in the axial direction of the main shaft; when the rotating separator rotates at a high speed, liquid is continuously and circularly impacted bythe centrifugal force of the rotating separator and gas countercurrent, a solute and a solvent are separated efficiently and efficiently, the disc bodies, a main body and the main shaft of the gas-liquid separator are all made of corresponding anti-corrosion engineering materials, and the gas-liquid separator has the advantages of being good in anti-corrosion performance, easy to operate, low in energy consumption and the like, and is a novel efficient rotational flow shearing type gas-liquid separator suitable for resisting high temperature and preventing corrosion of various acid types.

Owner:苏州汇博龙环保科技有限公司

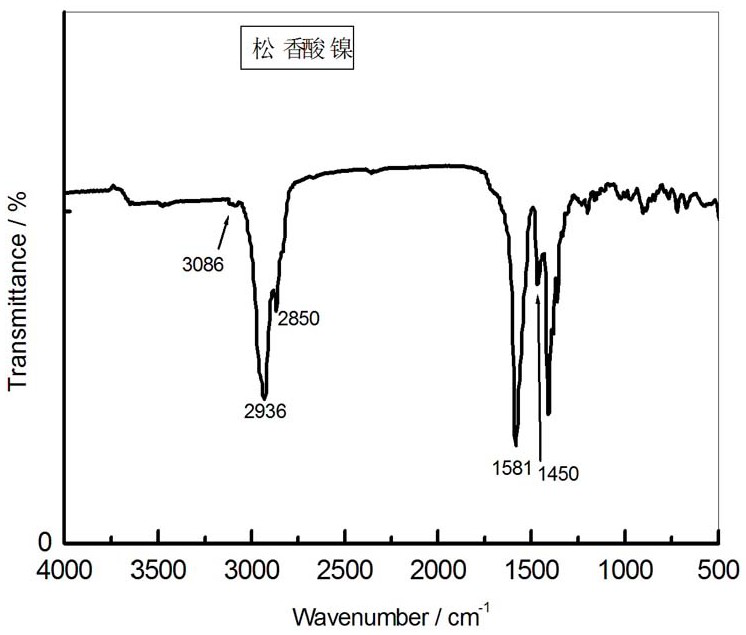

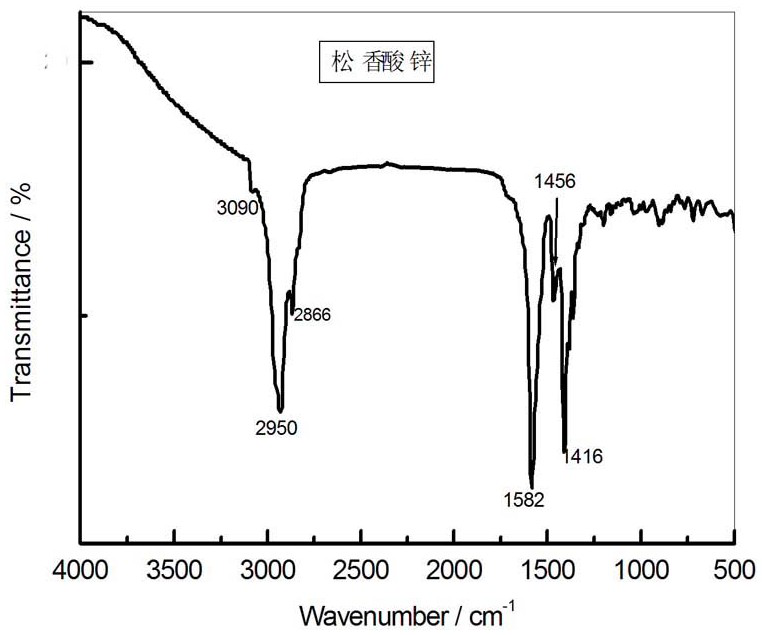

Simple preparation method of rosin-based short-oil alkyd resin anticorrosive enamelpaint

InactiveCN112500771AHigh resistance to localized corrosionIncreased corrosion potentialRosin coatingsAnti-corrosive paintsPolymer scienceManganese

The invention discloses a simple preparation method of rosin-based short-oil alkyd resin anticorrosive enamel paint, which comprises the following steps: by using dry short-oil alkyd resin and nickelabietate prepared by hot melting reaction as film-forming substances and o-xylene as a solvent, then adding activated calcium carbonate, kaolin, carbon black, leveling agent polyether modified polydimethylsiloxane copolymer and a manganese salt of a drier naphthenic acid, and stirring at a high speed to obtain the rosin-based short-oil alkyd resin anticorrosive enamel paint. The enamel paint has high corrosion potential, low corrosion current and high electrochemical impedance, has good local corrosion resistance, and can be applied to heavy anti-corrosion engineering in the fields of house balcony iron-based railings, petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, ships and the like.

Owner:GUANGXI UNIV FOR NATITIES

Marine corrosion resistant coating material containing nickel-manganese

InactiveCN104140703ASolving Marine Corrosion ProblemsAnti-corrosive paintsIndustrial equipmentManganese

The invention discloses a marine corrosion resistant coating material containing nickel-manganese. The marine corrosion resistant coating material containing the nickel-manganese is prepared from the following raw materials in parts by weight: 50-60 parts of nickel-manganese alloy powder, 5-12 parts of organic solvent, 5-15 parts of nano oxide particle reinforcing agent, 1-5 parts of leveling agent, 1-5 parts of epoxy solid enhancer, 10-15 parts of defoamer, 3-8 parts of deionized water, 1-5 parts of binder, 1-5 parts of corrosion inhibitor, 1-5 parts of dispersant and 1-5 parts of thickener. The marine corrosion resistant coating material containing the nickel-manganese has the advantage of meeting the urgent need of solving the problem of marine corrosion of engineering parts, and has an important application prospect in the corrosion engineering of industrial equipment of ocean engineering, offshore wind power and the like.

Owner:QINGDAO UWELL INFORMATION TECH

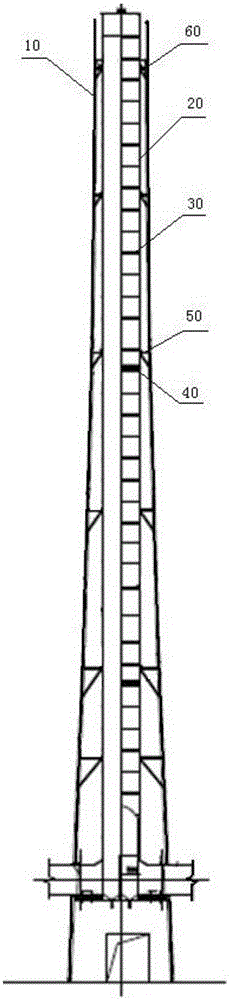

An installation method of a thermal power plant wet chimney with a flame-retardant and anti-corrosion glass-steel structure

InactiveCN103924820BSolve difficult problems of leakage and corrosionAnti-corrosion advantageTowersTechnology developmentEngineering

Disclosed is a mounting method for a thermal power plant wet chimney with a flame retardant anti-corrosion glass fiber reinforced plastic structure. The mounting method is characterized by including the steps of 1), calculating, designing and determining structural parameters of parts of the wet chimney; 2), manufacturing a glass fiber reinforced plastic lining in segmentation; 3), independently mounting the chimney with the glass fiber reinforced plastic lining in segmentation in a reinforced-concrete external barrel or a steel-structured support frame, setting connecting and supporting nodes at positions of designed supporting nodes, and configuring non-metallic expansion joints at the upper end of each supporting node; setting and connecting shake stopping points at positions according to the designed shake stopping points. The wet chimney with the glass fiber reinforced plastic lining and the mounting method are major technical innovation in anti-corrosion engineering of the wet chimney. The puzzling problem about leakage corrosion during the anti-corrosion engineering of the wet chimney is solved, which is the major technical innovation of the anti-corrosion engineering of the wet chimney and the next-step smoke extraction technology development direction of thermal power plants.

Owner:BEIJING DATANG HENGTONG MECHANICAL TRANSPORT

Polyurea external corrosion prevention paint for pipe line and its manufacturing method

ActiveCN100513499CExtended service lifeIncreased shear strengthAnti-corrosive paintsPolyurea/polyurethane coatingsComposition BSpray coating

The invention relates to a polyurea external anti-corrosion coating for pipelines and a manufacturing method thereof, which is prepared by heating and prepolymerizing diphenylmethane diisocyanate, carbodiimidized diisocyanate, polyether diol and polyether triol. Polymer liquid A, composed of amino-terminated polyoxyethylene ether, dimethylthiotoluenediamine, diethyltoluenediamine, isopropyl titanate solution, polyacrylate solution, carbon black, titanium dioxide and light carbonic acid Calcium-based Liquid B is composed of Liquid A and Liquid B, which are heated to 65°C and mixed, and then quickly sprayed and solidified to form a coating. The coating has excellent construction performance and fast curing speed, and the coating has excellent shear performance, cathodic stripping resistance, abrasion resistance, impact resistance and corrosion resistance. It can be used in the external anti-corrosion project of the pipeline, which can resist the corrosion of the pipeline by the corrosive medium and improve the service life of the pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Marine corrosion resistant coating material containing nickel-manganese

InactiveCN104177898ASolving Marine Corrosion ProblemsAnti-corrosive paintsManganeseIndustrial equipment

The invention discloses a marine corrosion resistant coating material containing nickel-manganese. The marine corrosion resistant coating material containing nickel-manganese is prepared from the following raw materials in parts by weight: 50-60 parts of nickel-manganese alloy powder, 5-12 parts of organic solvent, 5-15 parts of nano oxide particle reinforcing agent, 1-5 parts of leveling agent, 1-5 parts of epoxy solid enhancer, 10-15 parts of defoamer, 3-8 parts of deionized water, 1-5 parts of binder, 1-5 parts of corrosion inhibitor, 1-5 parts of dispersant and 1-5 parts of thickener. The marine corrosion resistant coating material containing nickel-manganese has the advantage of meeting the urgent need of solving the problem of marine corrosion of engineering parts, and has an important application prospect in the corrosion engineering of industrial equipment of ocean engineering, offshore wind power and the like.

Owner:QINGDAO UWELL INFORMATION TECH

Marine corrosion resistant coating material containing magnesium-manganese

InactiveCN104177897ASolving Marine Corrosion ProblemsAnti-corrosive paintsIndustrial equipmentManganese

The invention discloses a marine corrosion resistant coating material containing magnesium-manganese. The marine corrosion resistant coating material containing the magnesium-manganese is prepared from the following raw materials in parts by weight: 50-60 parts of magnesium-manganese alloy powder, 5-12 parts of organic solvent, 5-15 parts of nano oxide particle reinforcing agent, 1-5 parts of leveling agent, 1-5 parts of epoxy solid enhancer, 10-15 parts of defoamer, 3-8 parts of deionized water, 1-5 parts of binder, 1-5 parts of corrosion inhibitor, 1-5 parts of dispersant and 1-5 parts of thickener. The marine corrosion resistant coating material containing the magnesium-manganese has the advantage of meeting the urgent need of solving the problem of marine corrosion of engineering parts, and has an important application prospect in the corrosion engineering of industrial equipment of ocean engineering, offshore wind power and the like.

Owner:QINGDAO UWELL INFORMATION TECH

Preparation method of long-oil alkyd resin anticorrosive enamel paint with high corrosion potential

InactiveCN112409896AImprove corrosion resistanceIncreased corrosion potentialSiccativesMagnetic paintsPolymer scienceKaolin clay

The invention discloses a preparation method of long-oil alkyd resin anticorrosive enamel paint with high corrosion potential, which comprises the steps of by taking dry long-oil alkyd resin and zincabietate synthesized by the method as film-forming substances and isobutanol as a solvent, adding organic kaolin, organic bentonite, carbon black, simethicone and aluminum naphthenate serving as a drier, and stirring at a high speed to obtain the simple rosin-based long-oil alkyd resin anticorrosive enamel paint. The enamel paint has low corrosion current, high corrosion potential and large electrochemical impedance, that is, the enamel paint has good local corrosion resistance, and can be applied to anti-corrosion engineering in the fields of house balcony metal base railings, petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, ships and the like.

Owner:GUANGXI UNIV FOR NATITIES

Marine corrosion resistant coating containing magnesium-nickel

InactiveCN104164103ASolving Marine Corrosion ProblemsAnti-corrosive paintsOrganic solventIndustrial equipment

The invention discloses a marine corrosion resistant coating containing magnesium-nickel. The coating is prepared from the following raw materials in parts by weight: 50-60 parts of magnesium-nickel alloy powder, 5-12 parts of organic solvent, 5-15 parts of nano oxide particle reinforcing agent, 1-5 parts of levelling agent, 1-5 parts of epoxy curing agent, 10-15 parts of defoaming agent, 3-8 parts of deionized water, 1-5 parts of binding agent, 1-5 parts of corrosion inhibitor, 1-5 parts of dispersing agent and 1-5 parts of thickening agent. The coating meets the urgent need for solving the problem of marine corrosion of engineering parts, and has important application prospects in marine engineering and corrosion engineering of industrial equipment such as offshore wind farms and the like.

Owner:QINGDAO UWELL INFORMATION TECH

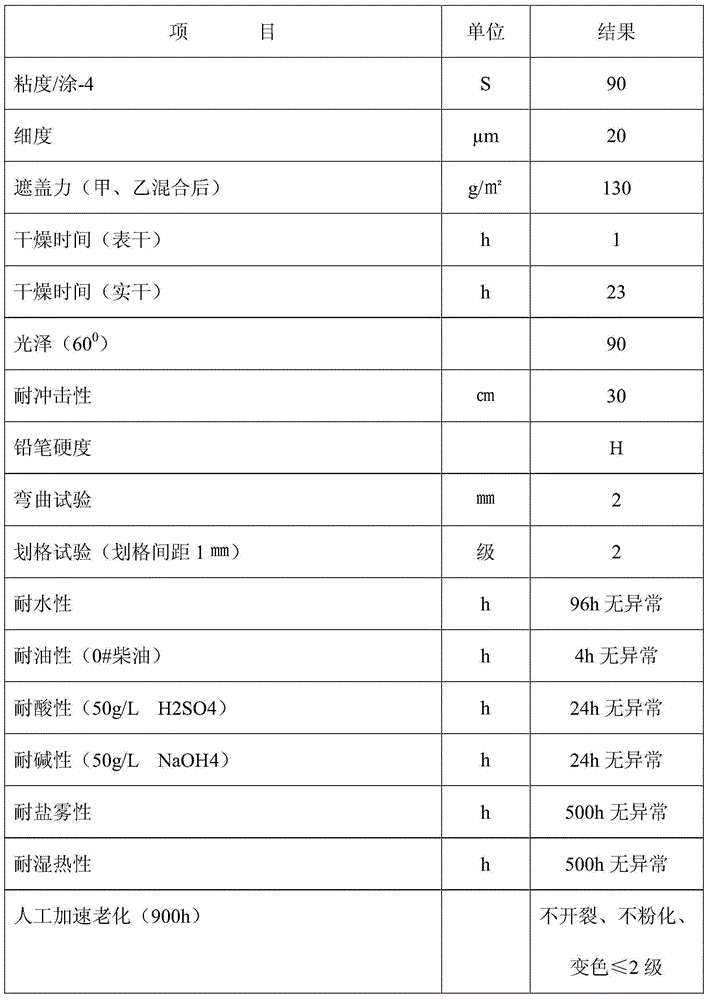

A two-component construction machinery anticorrosion decorative finish paint and preparation method thereof

ActiveCN103555176BGuaranteed quantityHigh reactivityAnti-corrosive paintsPolyurea/polyurethane coatingsDibasic esterMaterials science

The invention provides double-component anti-corrosive decorative finishing coat for engineering machinery. The finishing coat is formed by mixing 72-75 parts of BC (Folic Acid)-1 resin, 0.3-0.5 part of a wetting dispersant, 0.2-0.4 part of organic bentonite, 18-20 parts of pigments, 0.2-0.9 part of an assistant, 1-2 parts of a metal drying agent, 9-11 parts of a modifying filler, 1-3 parts of a DBE (Dibasic Ester) solvent and 2-3 parts of butyl acetate. Compared with the conventional acrylic polyurethane coating, the finishing coat disclosed by the invention has high coating fullness, good fresh imaging performance, low toxicity and low price, satisfies or exceeds technical requirements of HG / T4339-2012 (other finishing coat), and is functional double-component coating.

Owner:ANQING LINGHU PAINT

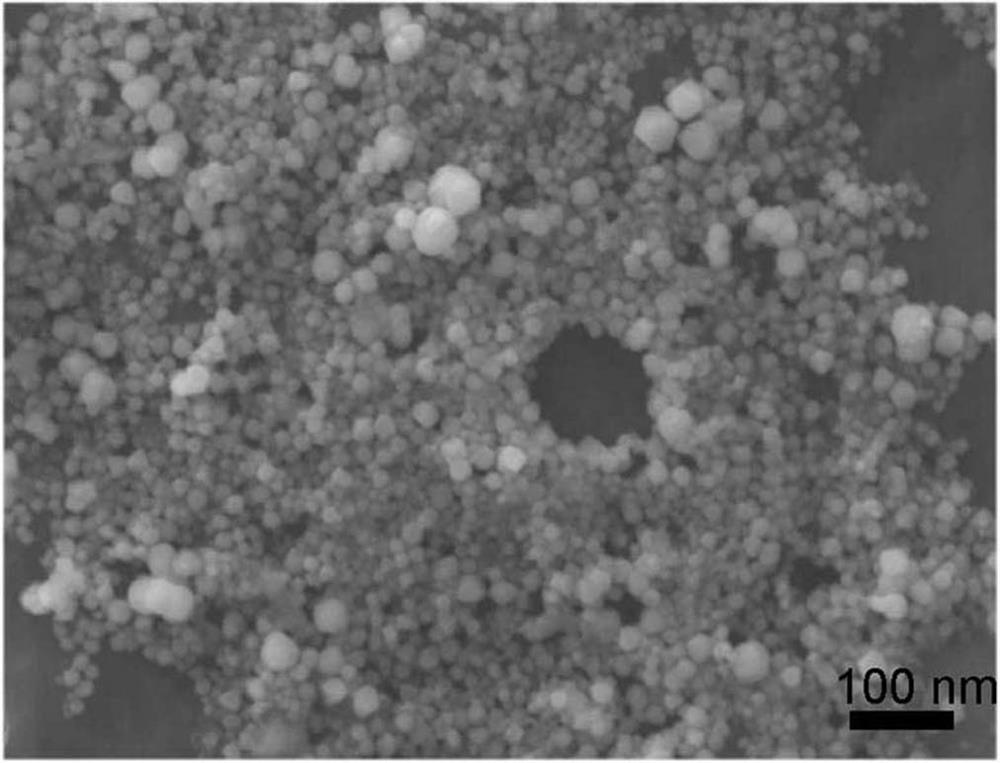

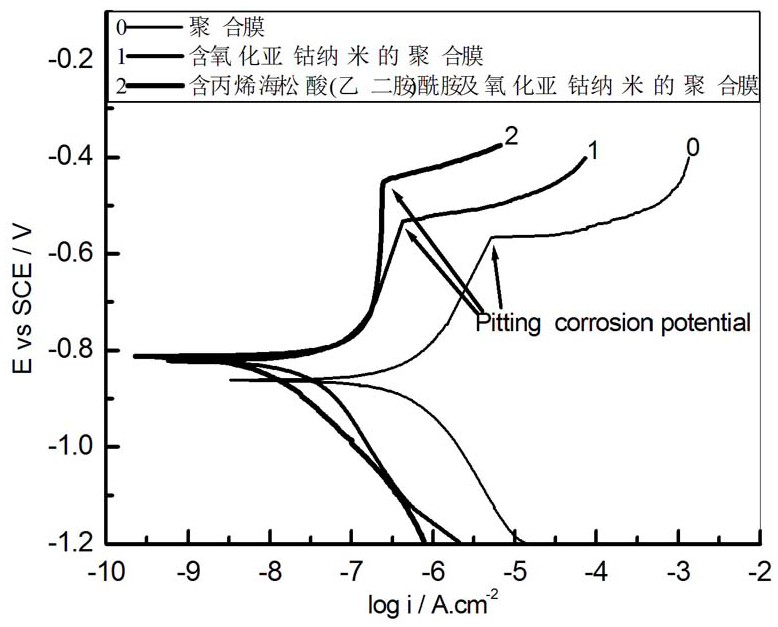

Preparation method of rosin-based thermal polymerization anti-corrosion film doped with cobaltous oxide nanoparticles with high pitting potential

The invention discloses a preparation method of a rosin-based thermally polymerized anticorrosion film doped with cobaltous oxide nanoparticles with high pitting potential. Acrylamide is used as a monomer, azobisisobutyronitrile is used as an initiator, and cobaltous oxide nanoparticle The particles are used as dopants, and propylene pimaric acid (ethylenediamine) amide is used as crosslinking agent. A rosin-based thermally polymerized anticorrosion film doped with cobaltous oxide nanoparticles with high pitting corrosion potential is prepared by thermal polymerization. The film The layer has high pitting potential, good pitting corrosion resistance, simple and practical, and overcomes the shortcomings of low corrosion potential of the previous anti-corrosion film layer. The film layer can be applied to the anti-corrosion engineering of metal parts of electrical equipment such as air conditioners, electric water heaters, air conditioners, and refrigerators, and mechanical equipment such as tractors and cranes.

Owner:GUANGXI UNIV FOR NATITIES

Marine corrosion resistant coating containing aluminium-manganese-graphite

InactiveCN104164117ASolving Marine Corrosion ProblemsAnti-corrosive paintsIndustrial equipmentManganese

The invention discloses a marine corrosion resistant coating containing aluminium-manganese-graphite. The coating is prepared from the following raw materials in parts by weight: 50-60 parts of aluminium-manganese-graphite alloy powder, 5-12 parts of organic solvent, 5-15 parts of nano oxide particle reinforcing agent, 1-5 parts of levelling agent, 1-5 parts of epoxy curing agent, 10-15 parts of defoaming agent, 3-8 parts of deionized water, 1-5 parts of binding agent, 1-5 parts of corrosion inhibitor, 1-5 parts of dispersing agent and 1-5 parts of thickening agent. The coating meets the urgent need for solving the problem of marine corrosion of engineering parts, and has important application prospects in marine engineering and corrosion engineering of industrial equipment such as offshore wind farms and the like.

Owner:QINGDAO UWELL INFORMATION TECH

Marine corrosion resistant coating material containing rare earth

InactiveCN104140695ASolving Marine Corrosion ProblemsAnti-corrosive paintsRare earthIndustrial equipment

The invention discloses a marine corrosion resistant coating material containing rare earth. The marine corrosion resistant coating material containing the rare earth is prepared from the following raw materials in parts by weight: 50-60 parts of rare-earth alloy powder, 5-12 parts of organic solvent, 5-15 parts of nano oxide particle reinforcing agent, 1-5 parts of leveling agent, 1-5 parts of epoxy solid enhancer, 10-15 parts of defoamer, 3-8 parts of deionized water, 1-5 parts of binder, 1-5 parts of corrosion inhibitor, 1-5 parts of dispersant and 1-5 parts of thickener. The marine corrosion resistant coating material containing the rare earth has the advantage of meeting the urgent need of solving the problem of marine corrosion of engineering parts, and has an important application prospect in the corrosion engineering of industrial equipment of ocean engineering, offshore wind power and the like.

Owner:QINGDAO UWELL INFORMATION TECH

Metal corrosion resistant coating and its manufacturing process

InactiveCN100506935CGood weather resistanceAccelerated corrosionAnti-corrosive paintsBituminous coatingsWeather resistanceFirming agent

The invention discloses a long-acting metal anti-corrosion coating for metal structural parts and metal equipment anti-corrosion and its manufacturing process, which consists of modified polymer organic compound coal tar pitch, organic polymer modified resin, active anti-rust Blending agent 3 or 4 or 5 and additives, after stirring, grinding and adjusting viscosity, adding curing agent. This kind of metal anti-corrosion coating uses the electrochemical mechanism of metal corrosion and adopts a new preparation process. It has extremely excellent super weather resistance and corrosion resistance. It can work under the conditions of rust, water and oil, and can be widely used. Anti-corrosion engineering such as metal structural parts, equipment, buildings (structures), underground engineering and ships in various environments.

Owner:刘赞成

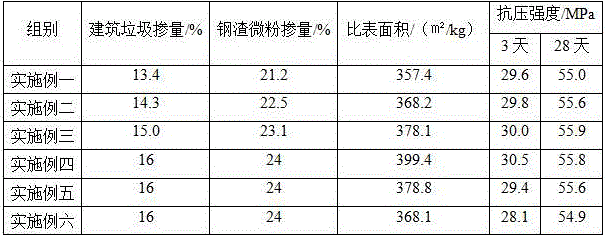

Method for producing seawater corrosion-resistant green ecological cement with construction waste

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from construction waste, which comprises the following raw materials in parts by weight: 40-50 parts of sulphoaluminate cement clinker; 5-20 parts of construction waste; steel slag fine powder 20-25 parts; 0.06-0.08 parts of composite activator; 2-5 parts of early strength agent; 0.3-0.5 parts of water reducing agent; 0.005-0.007 parts of air-entraining agent; Construction waste, sulphoaluminate cement clinker, composite activator and early strength agent are crushed separately, milled, homogenized, mixed and homogenized according to the proportion, and then mixed and homogenized by adding water reducing agent, air-entraining agent and retarder get the product. The seawater corrosion-resistant green ecological cement of the present invention, in addition to the performance of ordinary cement, also has excellent characteristics such as high strength, seawater erosion resistance, seawater erosion resistance, etc., and is especially suitable for underground projects, ports, wharves and other erosive media. project.

Owner:广西云燕特种水泥建材有限公司

Marine corrosion resistant coating containing graphite

InactiveCN104164119ASolving Marine Corrosion ProblemsAnti-corrosive paintsOrganic solventIndustrial equipment

The invention discloses a marine corrosion resistant coating containing graphite. The coating is prepared from the following raw materials in parts by weight: 50-60 parts of graphite alloy powder, 5-12 parts of organic solvent, 5-15 parts of nano oxide particle reinforcing agent, 1-5 parts of levelling agent, 1-5 parts of epoxy curing agent, 10-15 parts of defoaming agent, 3-8 parts of deionized water, 1-5 parts of binding agent, 1-5 parts of corrosion inhibitor, 1-5 parts of dispersing agent and 1-5 parts of thickening agent. The coating meets the urgent need for solving the problem of marine corrosion of engineering parts, and has important application prospects in marine engineering and corrosion engineering of industrial equipment such as offshore wind farms and the like.

Owner:QINGDAO UWELL INFORMATION TECH

a fe 2+ Metal-organic framework corrosion inhibitor-hydrogel composite with responsive properties and its preparation method and application

ActiveCN110698931BWith targeted protectionHigh sensitivityAnti-corrosive paintsThioureaMetal-organic framework

Owner:SUN YAT SEN UNIV

Environment-friendly polyaniline modified mica iron oxide anticorrosion coating and preparation method thereof

ActiveCN101643620BAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPhytic acidPetrochemical

The invention relates to paint technology, in particular to an environment-friendly polyaniline-modified mica iron oxide anti-corrosion paint and a preparation method thereof, which solves the problem that the existing mica iron oxide paint has poor anti-corrosion performance and must use harmful lead and chromium in the manufacturing process. Salt paint problem. The environment-friendly polyaniline modified mica iron oxide anticorrosion coating is composed of film-forming substances, polyaniline modified mica iron oxide, etc. The polyaniline coating layer is formed on the surface of mica iron oxide by oxidative polymerization. The treated mica iron oxide has a passivation effect on metals, and the phytic acid coating layer on the surface of mica iron oxide also acts as a corrosion inhibitor for metals. Environmentally friendly polyaniline modified mica iron oxide anti-corrosion coating has strong corrosion resistance and anti-permeability, and can be applied to anti-corrosion projects of petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, ships, etc.

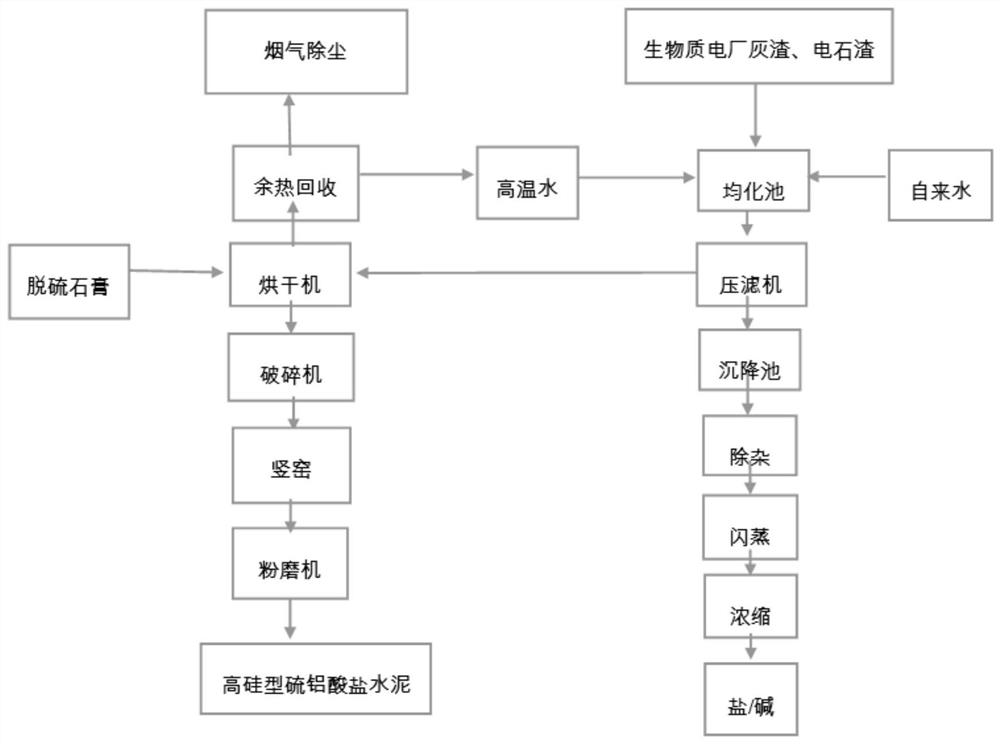

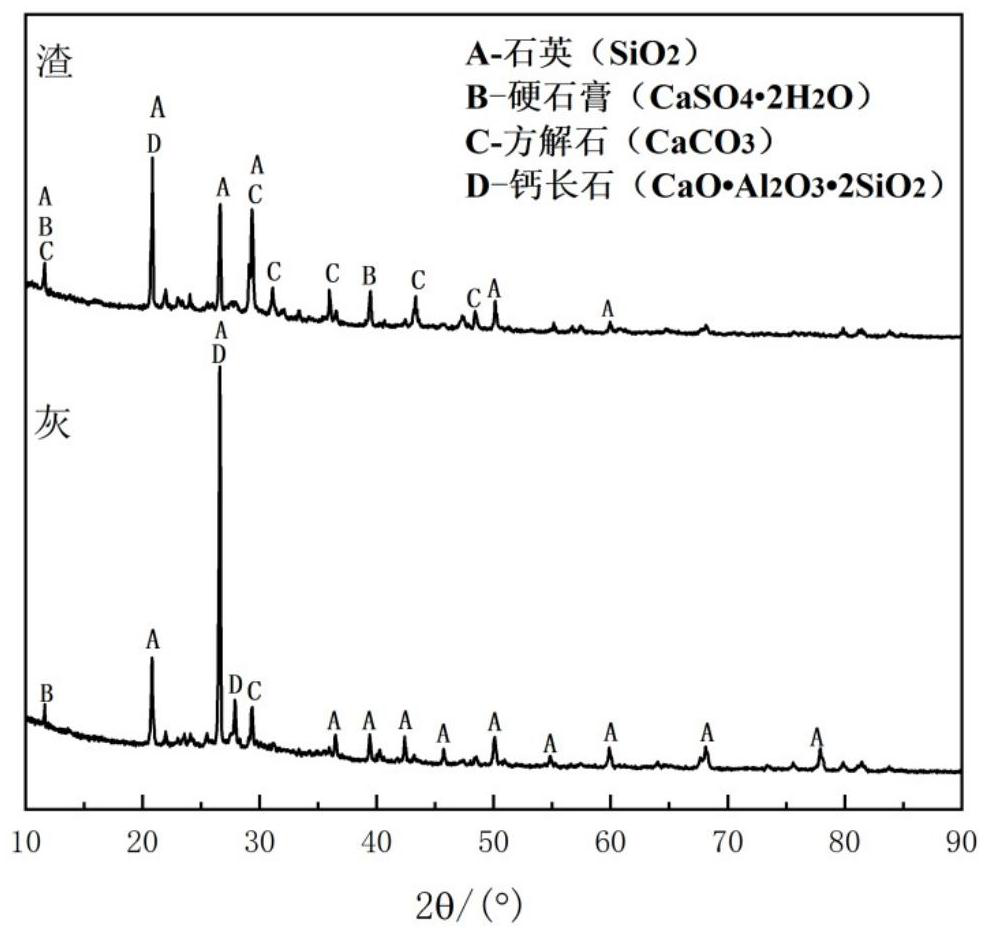

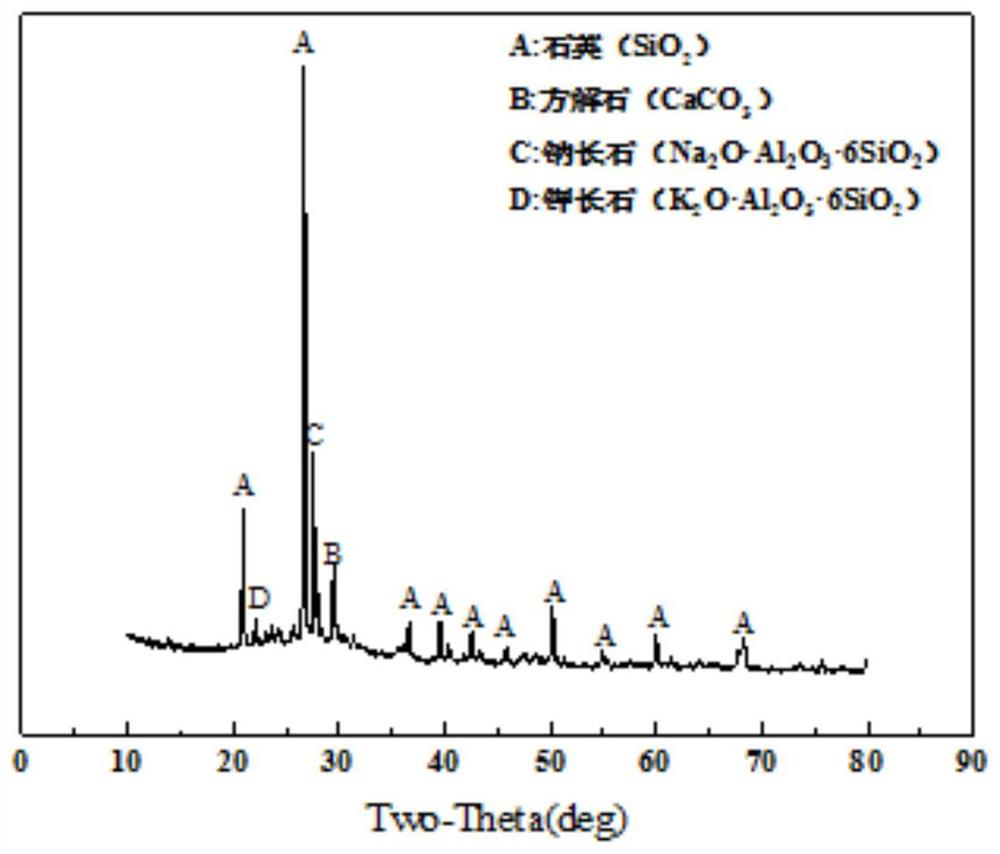

System and method for producing high-silicon sulphoaluminate cement by utilizing biomass ash

Owner:国能生物发电集团有限公司 +1

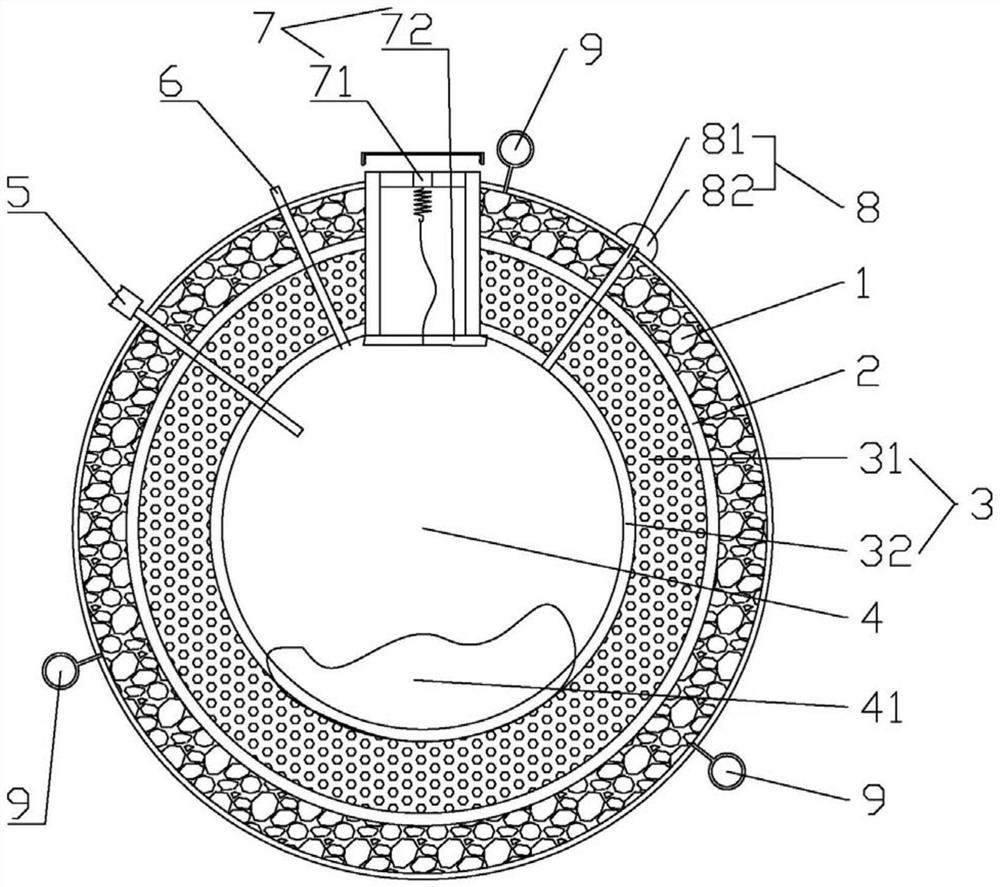

A reclamation unit with adjustable internal water pressure

InactiveCN109162252BSolving Engineering Resource IssuesGuaranteed sturdinessFoundation engineeringLand reclamationReinforced concreteEngineering

The invention discloses a reclamation unit capable of adjusting internal water pressure, which belongs to the technical field of land reclamation. At present, land reclamation projects are mainly faced with the shortage of filling materials, small material mass-to-weight ratio, difficult material transportation, many metal reclamation structures are prone to corrosion, difficult engineering construction, and costly and expensive. The present invention comprises an outer shell and an inner tank by constructing a hollow inner cavity inside the inner tank, the hollow inner cavity is used to accommodate a pressurized medium, the inner tank includes an elastic support outer layer and an elastic waterproof inner layer; the outer shell It includes a reinforced concrete layer, and the outer shell covers the inner tank; the outer shell is provided with a number of pipelines for filling the pressurized medium that can communicate with the hollow inner cavity of the inner tank and the outside world; the pipelines are provided with valves, and the valves can The pipeline is selectively opened and closed. The use of cheap manufacturing materials aims to provide a reclamation building material with a large body-to-weight ratio, a simple structure, saving material resources by using hydraulic pressure, easy handling, less difficulty in construction, and less corrosion.

Owner:XIANGSHAN SHANGBO E COMMERCE CO LTD

Marine corrosion resistant coating containing magnesium

InactiveCN104164118ASolving Marine Corrosion ProblemsAnti-corrosive paintsOrganic solventIndustrial equipment

The invention discloses a marine corrosion resistant coating containing magnesium. The coating is prepared from the following raw materials in parts by weight: 50-60 parts of magnesium alloy powder, 5-12 parts of organic solvent, 5-15 parts of nano oxide particle reinforcing agent, 1-5 parts of levelling agent, 1-5 parts of epoxy curing agent, 10-15 parts of defoaming agent, 3-8 parts of deionized water, 1-5 parts of binding agent, 1-5 parts of corrosion inhibitor, 1-5 parts of dispersing agent and 1-5 parts of thickening agent. The coating meets the urgent need for solving the problem of marine corrosion of engineering parts, and has important application prospects in marine engineering and corrosion engineering of industrial equipment such as offshore wind farms and the like.

Owner:QINGDAO UWELL INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com