Chlorohydrocarbyl silane coupling agent modified cold-coating zinc coating and preparation method thereof

A technology of chlorocarbon-based silane coupling agent and cold coating zinc, which is applied in the direction of anti-corrosion coatings and coatings, can solve the problems of weak adhesion and short cathodic protection time, and achieve high adhesion, high cathodic protection efficiency, Good wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

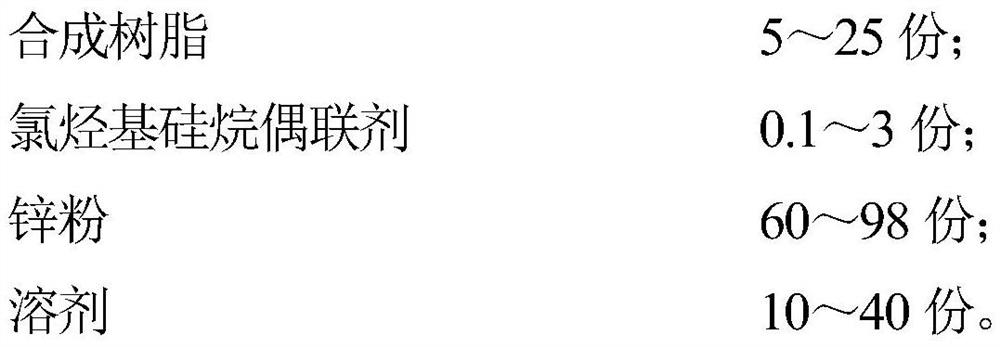

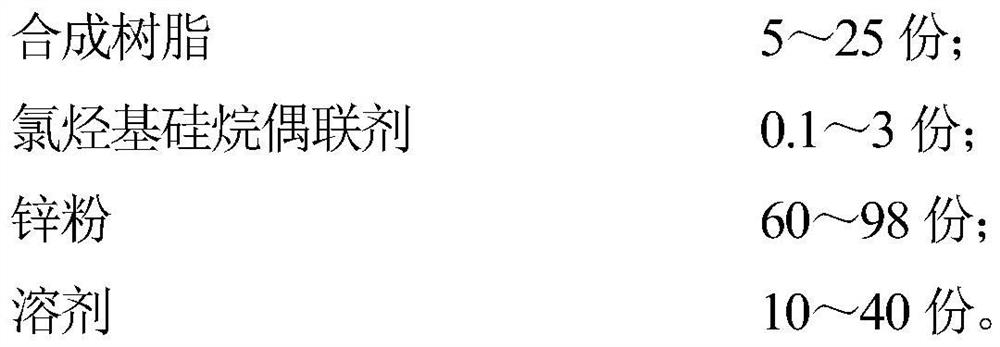

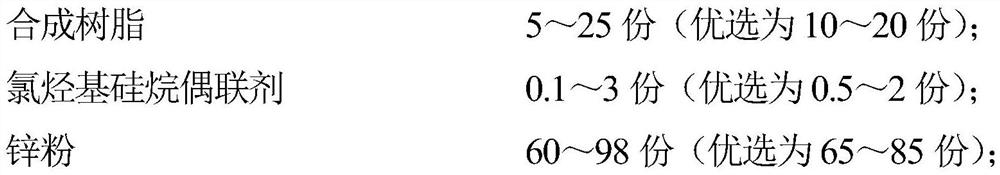

Method used

Image

Examples

Embodiment 1

[0029] In this example, firstly, 17.1g of acrylic resin, 0.5g of γ-chloropropyltriethoxysilane, and 14.0g of xylene were sequentially added to the reaction kettle, and dispersed at 1000rpm for 20min; then slowly added 68.4g of 500 The target zinc powder is dispersed at a high speed of 1500rpm for 30 minutes, filtered and discharged to make a chlorohydrocarbon-based silane coupling agent-modified cold-coated zinc coating.

Embodiment 2

[0031] In this example, firstly, 17.1g of acrylic resin, 1.0g of γ-chloropropyltriethoxysilane, and 13.5g of xylene were sequentially added to the reaction kettle, and dispersed at 800rpm for 40min; then slowly added 68.4g of 1000 The target zinc powder is dispersed at 800 rpm for 90 minutes at high speed, filtered and discharged to make a chlorohydrocarbon-based silane coupling agent-modified cold-coated zinc coating.

Embodiment 3

[0033] In this example, firstly, 17.1g of acrylic resin, 1.5g of γ-chloropropyltriethoxysilane, and 13.0g of xylene were sequentially added to the reaction kettle, and dispersed at 1200rpm for 30min; then slowly added 68.4g of particle size 800 Target zinc powder (50g) and particle size 1200 mesh zinc powder (18.4g) were dispersed at high speed for 60min at 1200rpm, filtered and discharged to make chlorohydrocarbon-based silane coupling agent-modified cold-coated zinc coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com