Application of a kind of resin ceramic material in anticorrosion engineering of wet desulfurization absorption tower

A ceramic material, wet desulfurization technology, applied in epoxy resin coatings, anti-corrosion coatings, devices for coating liquid on the surface, etc., can solve the problems of poor effect of flake glass resin, hidden safety hazards, high bonding strength, etc., to achieve Ease of application, high bonding strength, and good erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

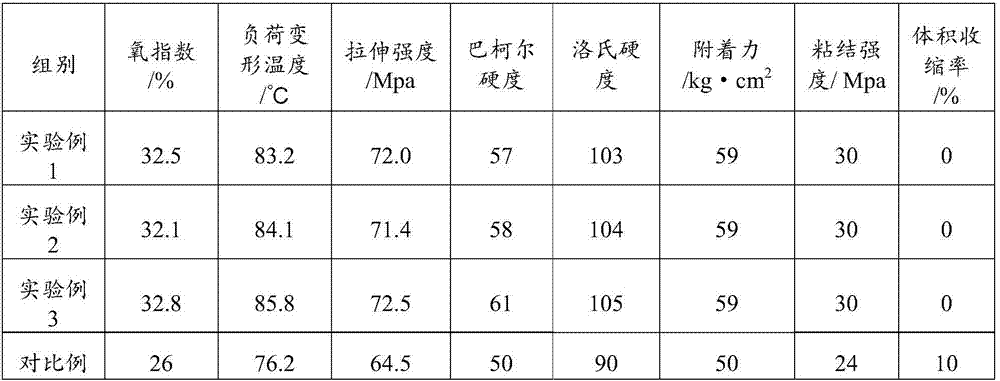

Embodiment 1

[0090] The resin material provided in this embodiment includes component A and component B with a mass ratio of 3:1;

[0091] Wherein, component A specifically comprises the following components:

[0092] Acrylic modified epoxy resin 800kg, 320# silicon carbide 150kg, 320# brown corundum 40kg, titanium dioxide 22.5kg, talcum powder 58kg, white carbon black 31.8kg, black pigment 1.2kg and silicon dioxide 28kg.

[0093] Component B specifically includes the following components:

[0094] 651.190kg of curing agent, 593.40kg of curing agent, 8kg of accelerator triethanolamine and 520g of yellow dye.

Embodiment 2

[0096] The resin material provided in this embodiment includes component A and component B with a mass ratio of 3:1;

[0097] Wherein, component A specifically comprises the following components:

[0098] Acrylic modified epoxy resin 150kg, 120# silicon carbide 108kg, 320# silicon carbide 57kg, 240# brown corundum 195kg, talcum powder 25kg, white carbon black 1kg, asbestos wool 800g, titanium dioxide 1.25kg and silicon dioxide 1.8kg.

[0099] Component B specifically includes the following components:

[0100] Curing agent 651 190kg, curing agent 593 40kg, accelerator EP-184 4kg, yellow dye 520g and silicon dioxide 59.5kg.

Embodiment 3

[0102] The resin material provided in this embodiment includes component A and component B with a mass ratio of 3:1;

[0103] Wherein, component A specifically comprises the following components:

[0104] Acrylic modified epoxy resin 150kg, 120# silicon carbide 108kg, 320# silicon carbide 57kg, 240# brown corundum 195kg, talcum powder 25kg, white carbon black 1kg, asbestos wool 800g, titanium dioxide 1.25kg, dye phthalocyanine blue 650g and Silicon dioxide 1.8kg.

[0105] Component B specifically includes the following components:

[0106] Curing agent 651.190kg, curing agent 593.40kg, accelerator DMP-30 8kg and yellow dye 520g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com