Heat conducting pipe type wet material dryer and drying method thereof

A dryer and heat pipe technology, applied in the field of dryers, can solve the problems of potential safety hazards, low drying efficiency, and easy fire of materials, so as to eliminate potential fire hazards, good drying effect, and high drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

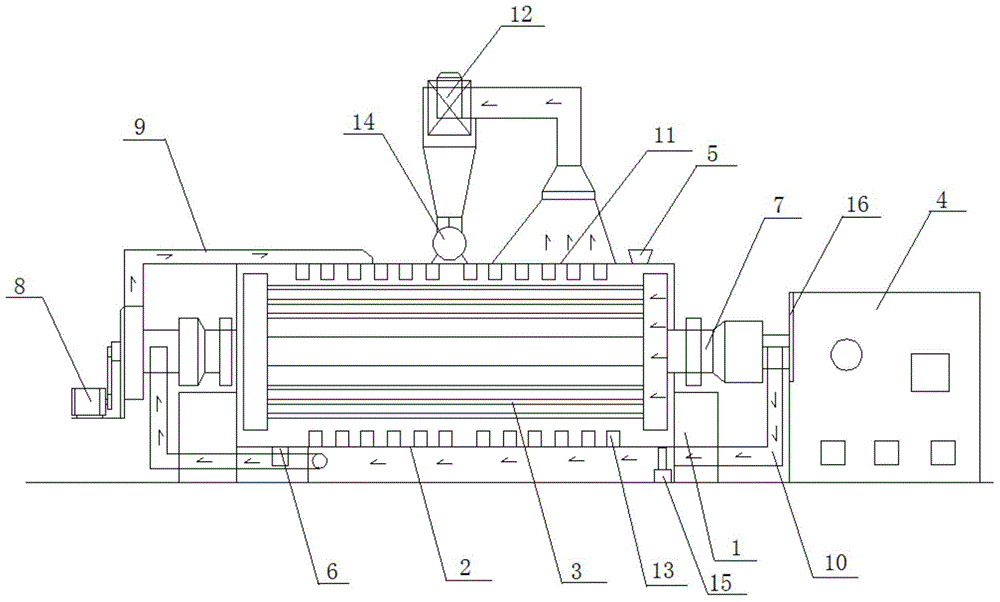

[0025] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0026] like figure 1 As shown, a heat-conducting tube type wet material dryer of the present invention includes a bracket 1, a heating drum 2 is arranged on the bracket 1, and a rotatable heat-conducting tube 3 is arranged in the heating drum 2; the whole bracket is installed obliquely, and the heating drum 2 The high end is connected with the hot blast stove 4, the heating drum 2 close to one end of the hot blast stove 4 is provided with a feeding port 5, and the other end of the heating drum 2 is provided with a drying material discharge port 6; the heat conduction pipe 3 passes through the first pipe 7 It communicates with the hot blast stove 4 .

[0027] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com