Patents

Literature

536results about How to "Improve discharge effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

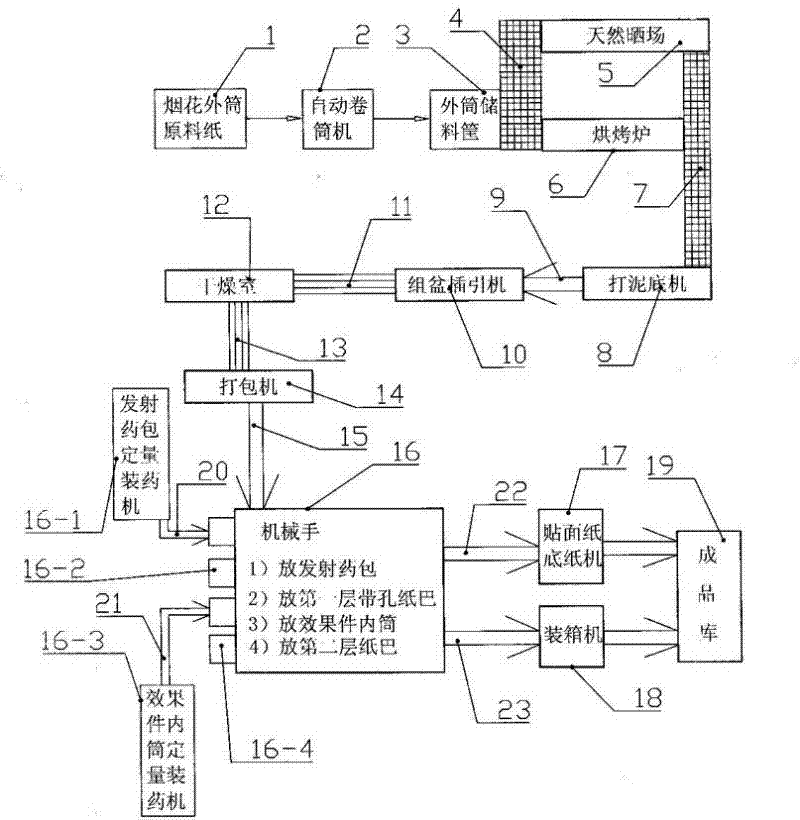

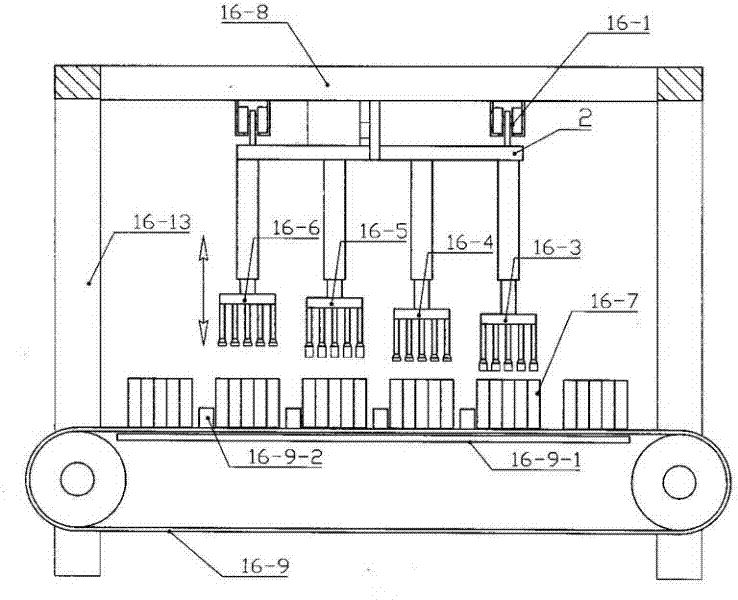

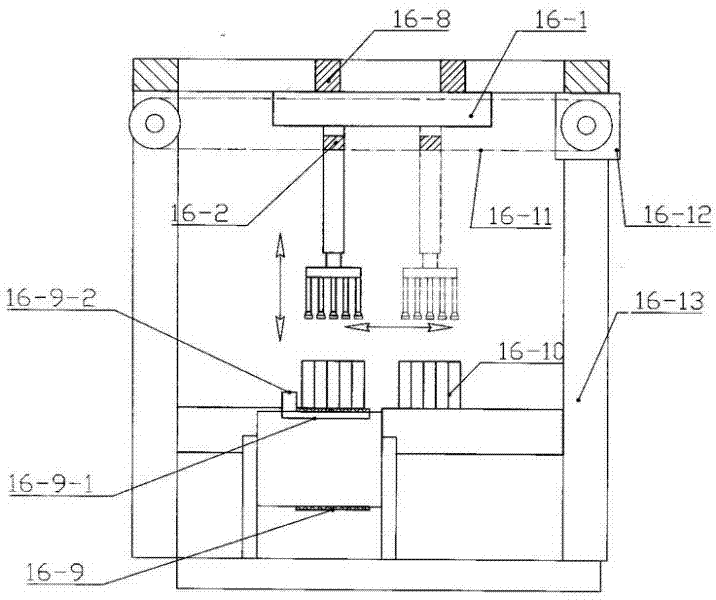

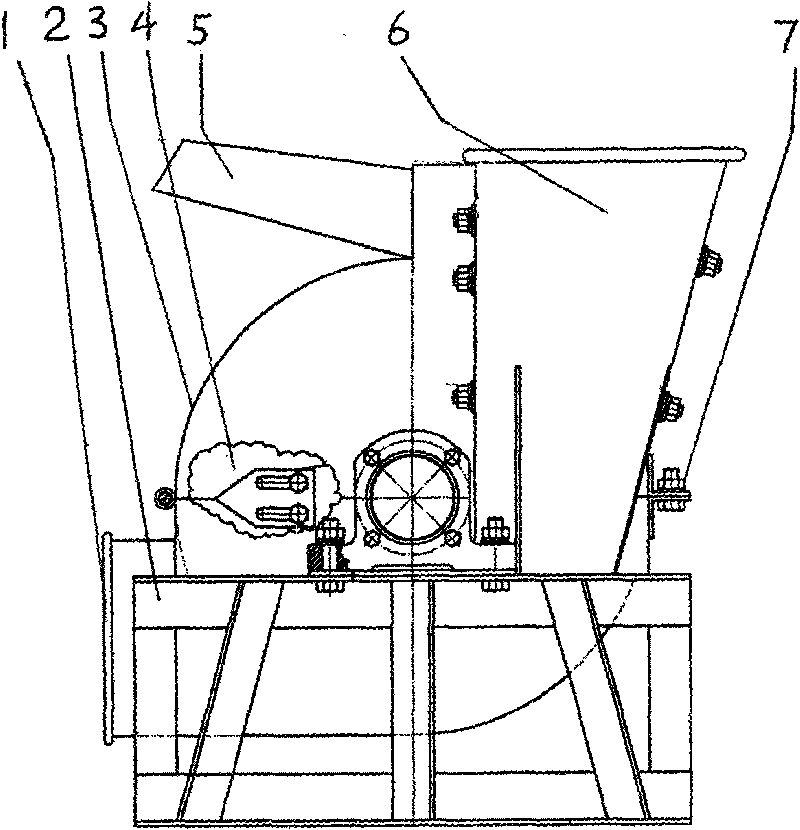

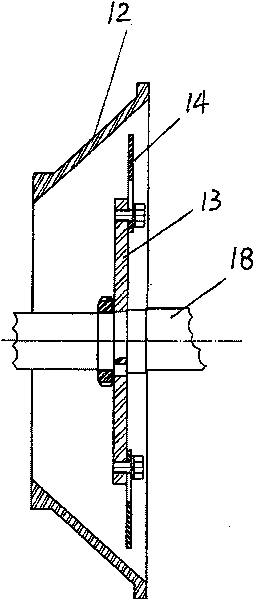

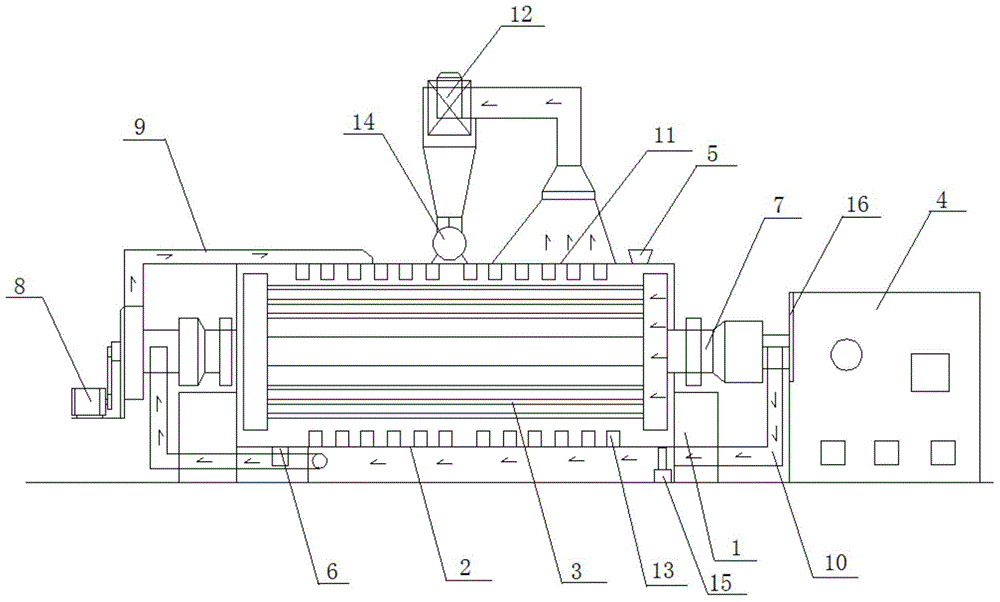

Flexible automatic production system for combined firework

InactiveCN102645135AAccurate and timely deliveryGuarantee quality and efficiencyFireworksFireworksPhotoelectric conversion

The invention relates to a flexible automatic production system for combined fireworks, which comprises an automatic tube rolling machine, a conveyer, a mud filling machine, a cake assembling and fuse inserting machine, a wrapping machine and a manipulator. The system is characterized in that firstly tubes are rolled through the automatic tube rolling machine and are stored in a tube storage basket, the tubes are fed to the mud filing machine for mud filling, cake assembling and fuse inserting after the tubes are dried, then the tubes are wrapped and reinforced by the wrapping machine, the tubes are righted and fed to the inlet port of the manipulator, propelling charges, effect part tubes, a first paper layer and a second paper layer are sequentially filled into the tubes after cake assembling, face paper and labels are stuck, products are boxed and sealed by a boxing and sealing machine and then the finished products are conveyed by the conveyer to a finished product warehouse; and materials among equipment of the entire system are conveyed by adopting the conveyer, and the loading position and the unloading position of each equipment are provided with photoelectrical conversion switches which are used for controlling the startup and the shutdown of the conveyer. Since the materials in the system are conveyed by the conveyer and the startup and shutdown of the conveyer are controlled by the photoelectric conversion switches, the materials are accurately conveyed in time, the product quality and the production efficiency are guaranteed, and the defects that manual handling in the past is time-consuming and labor-consuming and safety accidents are apt to occur are avoided.

Owner:柳真

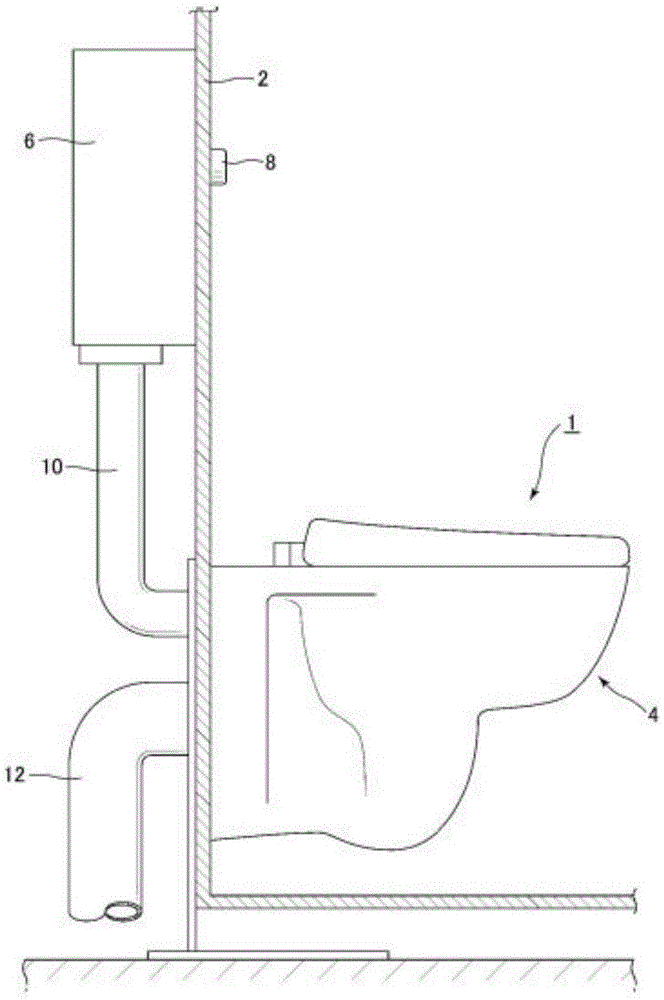

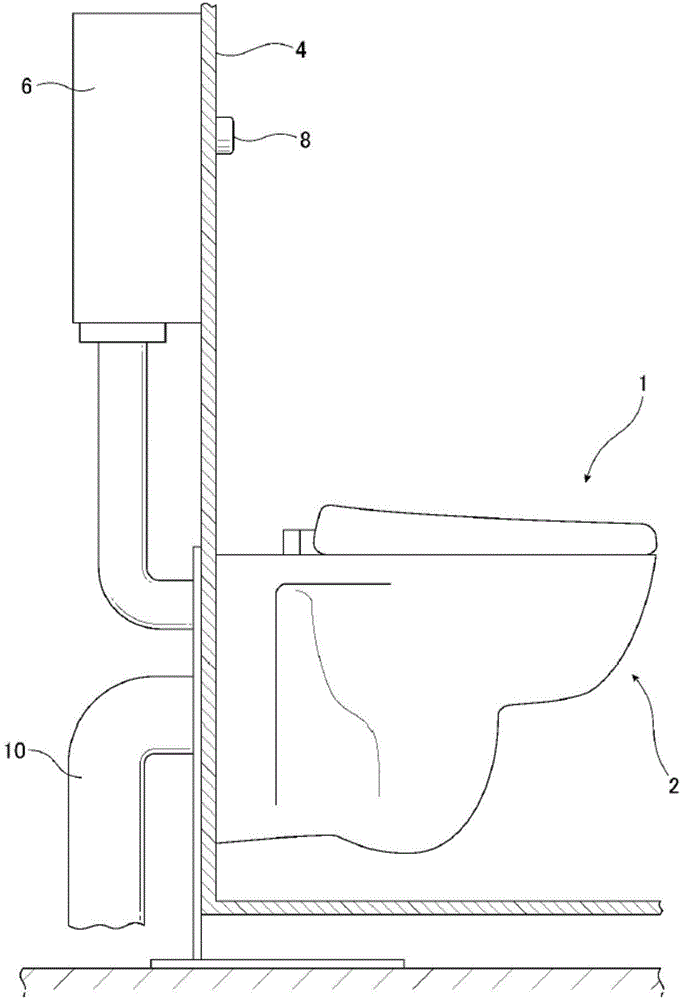

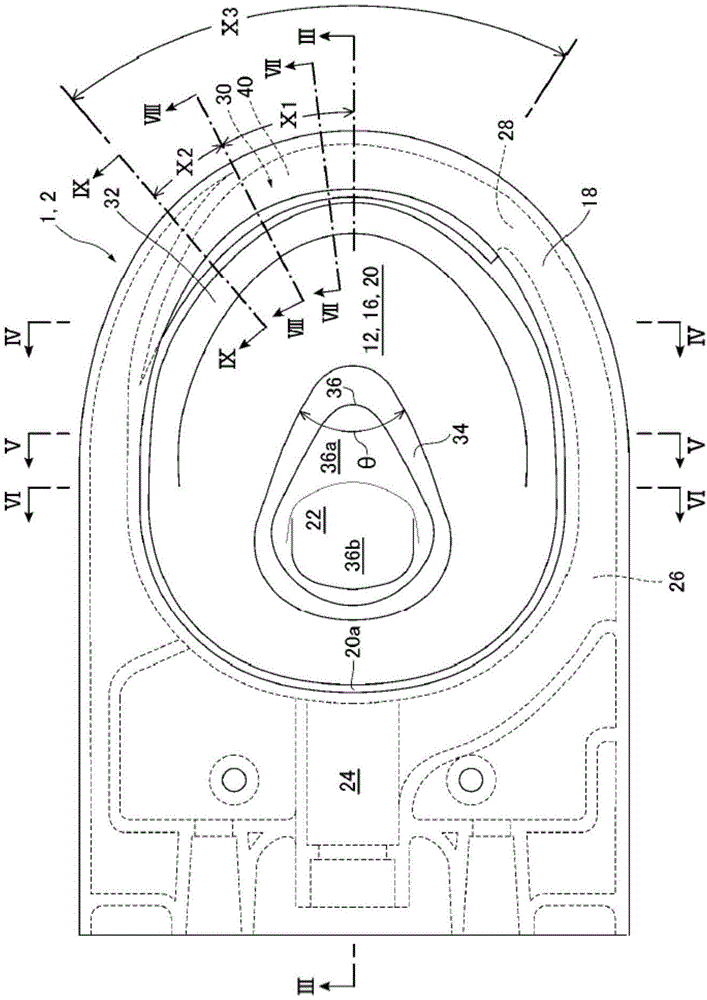

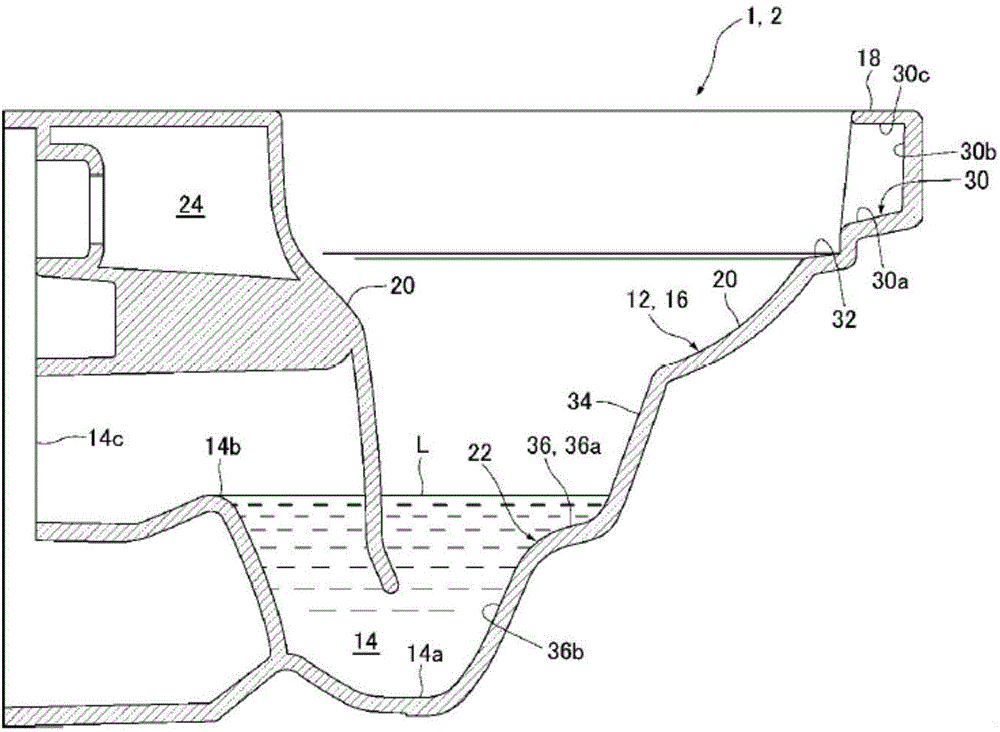

Flush toilet

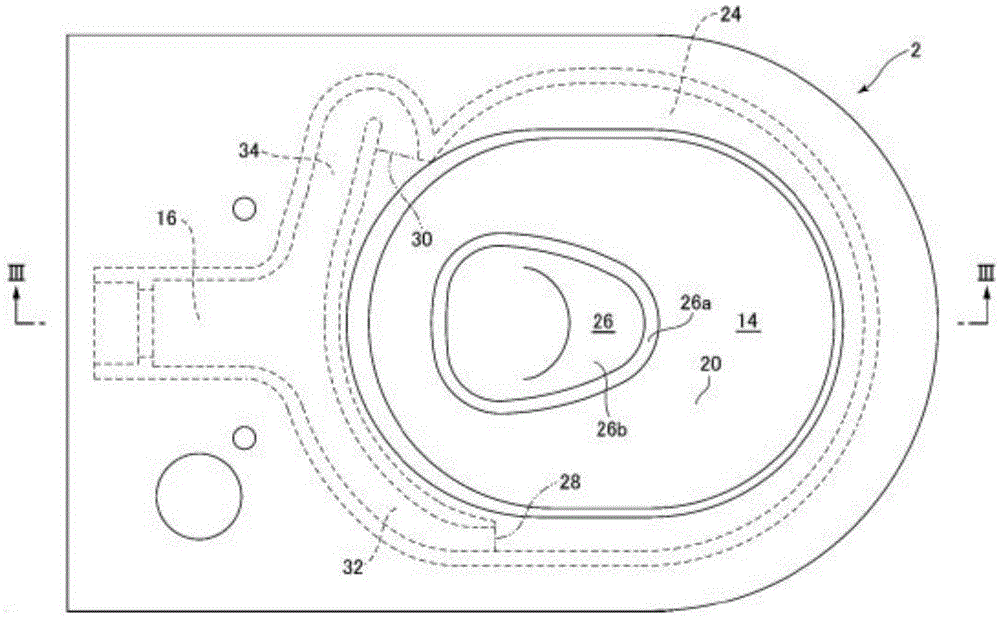

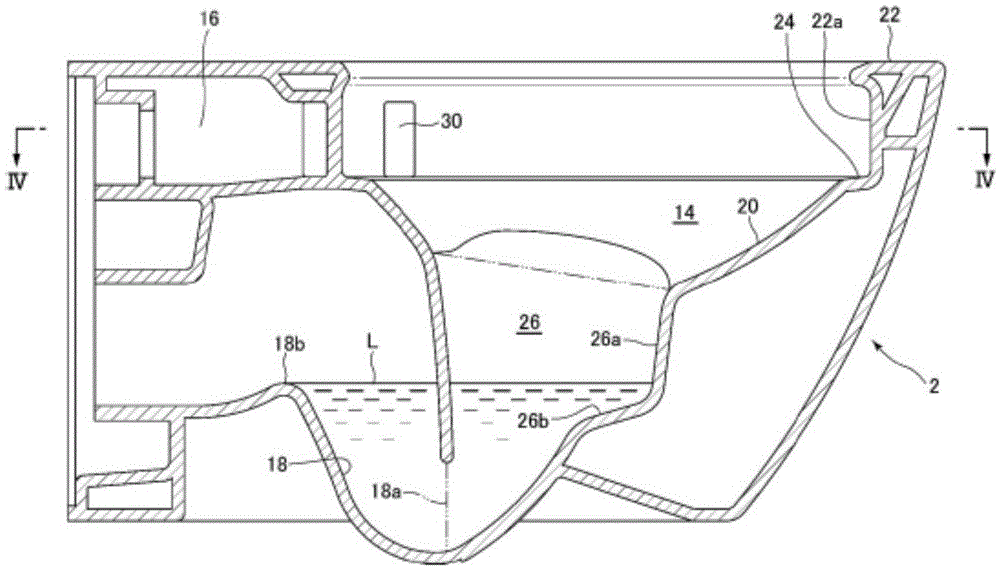

The flush toilet of the present invention has: a bowl portion (14) including a waste receiving surface (20), a rim portion (22), a shelf portion (24), and a concave portion (26); a discharge passage (18) for discharging waste; a first spout port (28) for spouting flush water on a shelf portion (24) of the bowl portion (14) to form a circulating flow; a second spout port (30) for spouting flush water in the same direction as the circulating direction of flush water spouted from a first spout port (28) and toward the rear of the bowl portion (14); a first water conduit (32) for supplying flush water to the first spout port (28); and a second water conduit (34) for supplying flush water to the second spout port (30). The first and second water conduits (32, 34) are formed so that the flow rate of flush water spouted from the second spout port (30) is greater than the flow rate of flush water spouted from the first spout port (28).

Owner:TOTO LTD

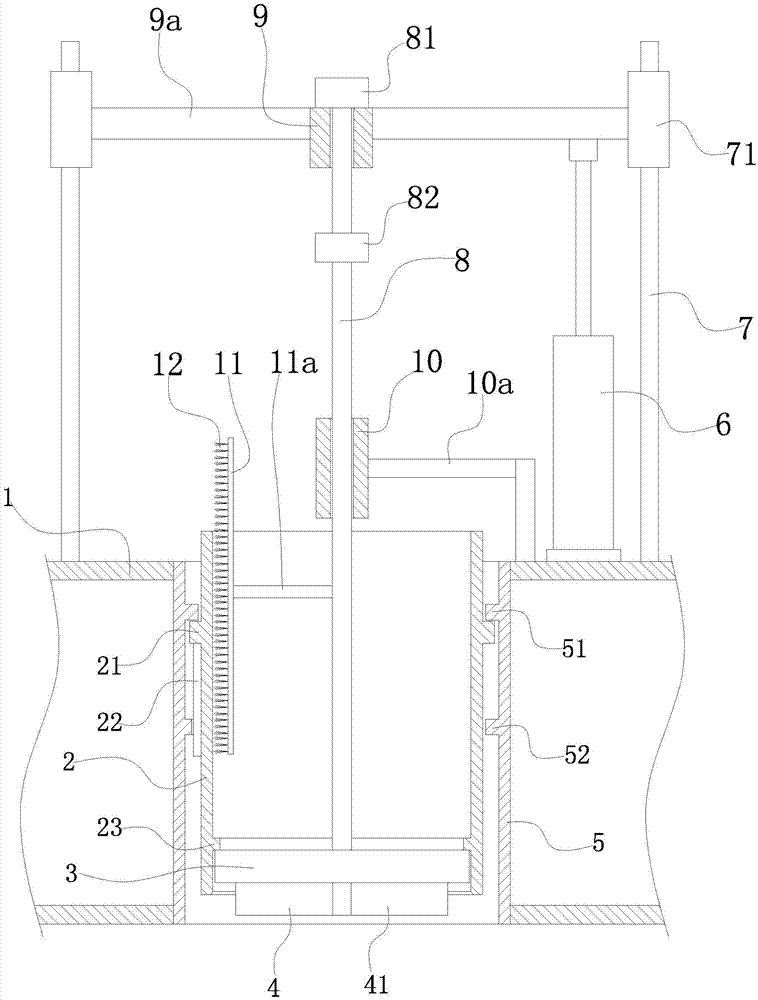

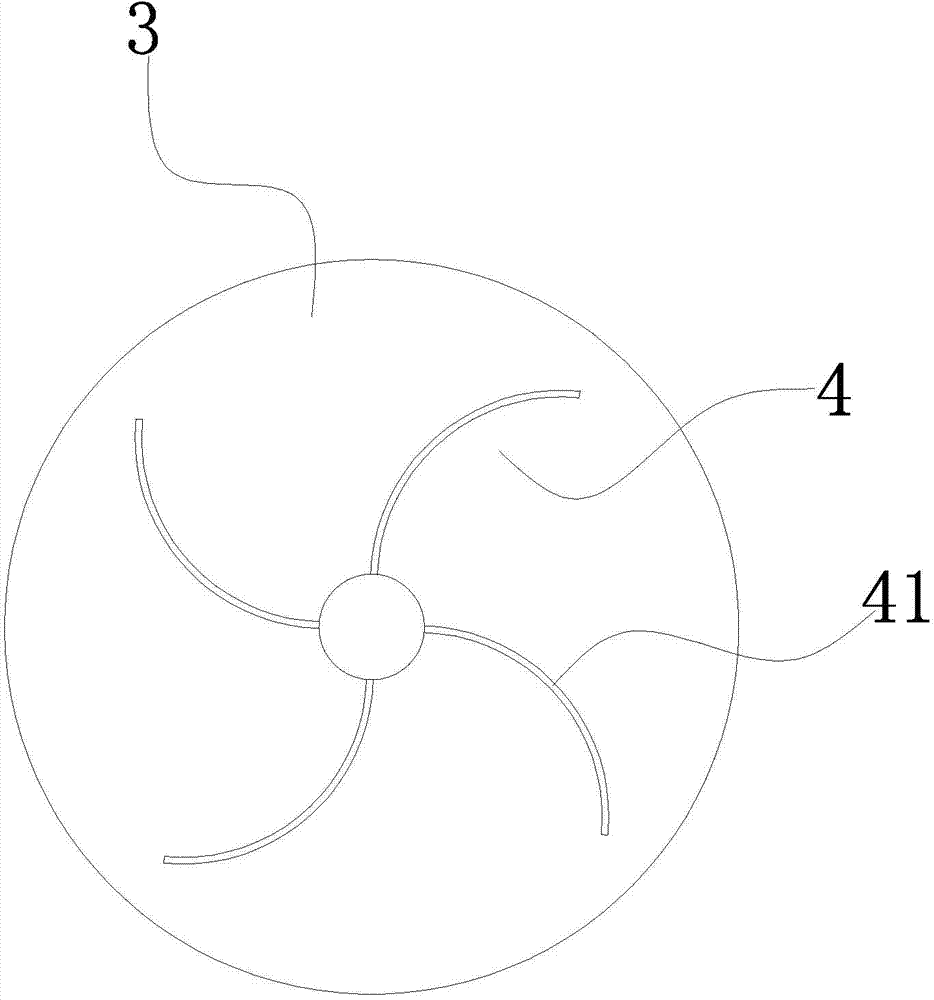

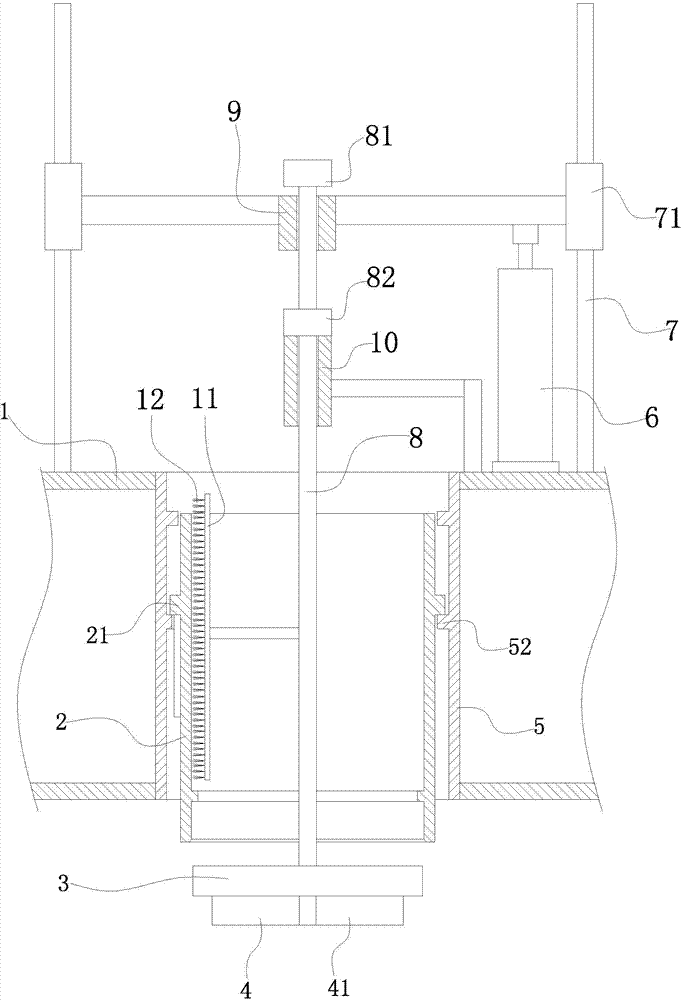

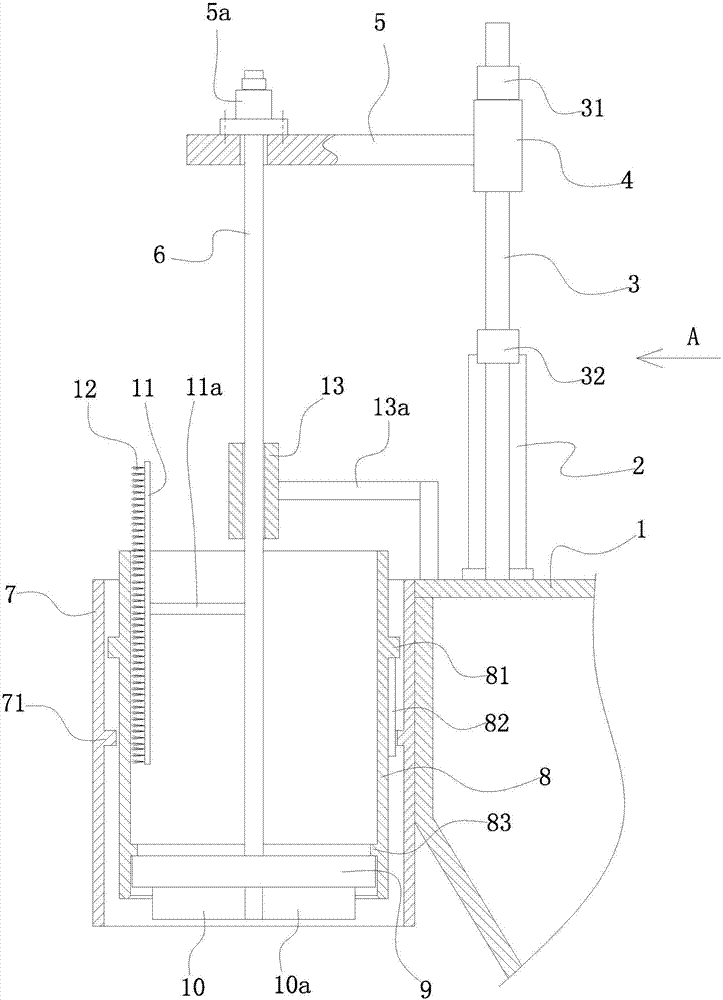

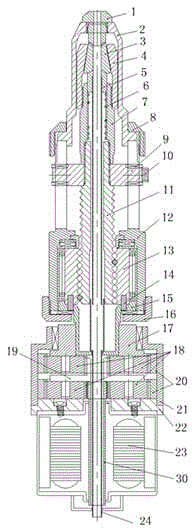

Shellfish discharge device for artificial breeding

InactiveCN104719192AImprove survival rateReduce labor intensityClimate change adaptationPisciculture and aquariaEngineeringUltimate tensile strength

The invention discloses a shellfish discharge device for artificial breeding. The shellfish discharge device is low in labor intensity, suitable for large-batch discharge, good in discharge effect and capable of improving the shellfish fry survival rate. The shellfish discharge device comprises a vertical guide rod, a guide sleeve, a vertical sleeve body, a placement barrel, a piston body, a connecting shaft rod, a connecting shaft sleeve and a lifting air cylinder, wherein the vertical guide rod is arranged on a boat body, the guide sleeve is arranged on the vertical guide rod in a slidable mode, the vertical sleeve body is arranged on the boat body, the placement barrel is arranged in the vertical sleeve body in a slidable mode, the piston body is arranged in the placement barrel in a slidable mode, the connecting shaft rod is coaxially arranged on the piston body, the upper portion of the connecting shaft rod is sleeved with the connecting shaft sleeve, and the lifting air cylinder is arranged on the boat body and used for lifting the connecting shaft sleeve.

Owner:舟山市应博水产科技有限公司

Medical waste treatment device convenient for residue medicine liquid separation

InactiveCN108326007AReduce volumeAvoid damageSolid waste disposalGrain treatmentsMedical wasteEngineering

The invention discloses a medical waste treatment device convenient for residue medicine liquid separation. The medical waste treatment device comprises a bottom plate and an extrusion crushing box, wherein two symmetrical rotating press plates are arranged inside the extrusion crushing boxes; the edge sides of the two rotating press plates are hinged to the inner wall of the extrusion crushing box; the upper end of the extrusion crushing box is provided with an opening; a crushing cutter blade is arranged on the outer side wall of the lower end of a rotating vertical shaft; two opposite extrusion plates are arranged inside the extrusion crushing box; pushing and pressing rods passing through the side wall of the extrusion crushing box are arranged at one opposite sides of the two oppositeextrusion plates; the upper end of the connecting seat is hinged to a pushing connecting rod; the top end of the pushing connecting rod is hinged to the outer side wall of a rotating sleeve arrangedon the outer side wall of the rotating vertical shaft. The medical waste treatment device has the advantages that the structure is simple; the compaction and crushing treatment is realized on the medical waste; meanwhile, the residue medicine liquid can be discharged; the environment pollution is avoided; the medical waste space is reduced; the transportation and the recovery are convenient; the practicability is higher.

Owner:GANZHOU YANSHUNFEI TECH CO LTD

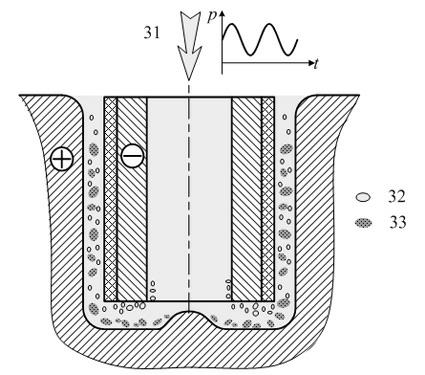

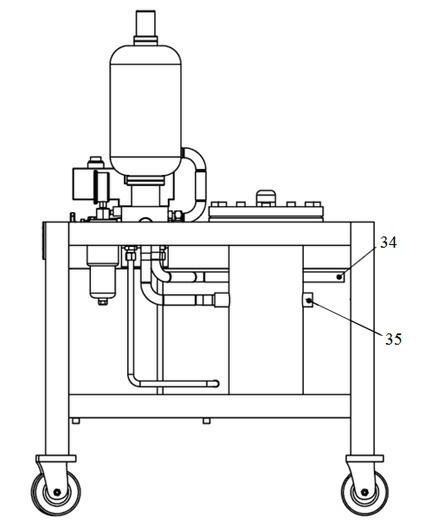

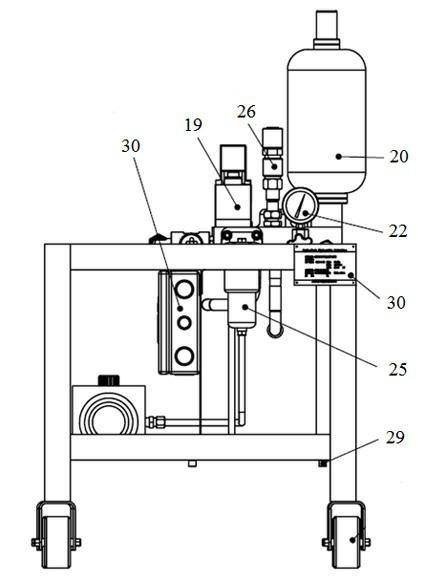

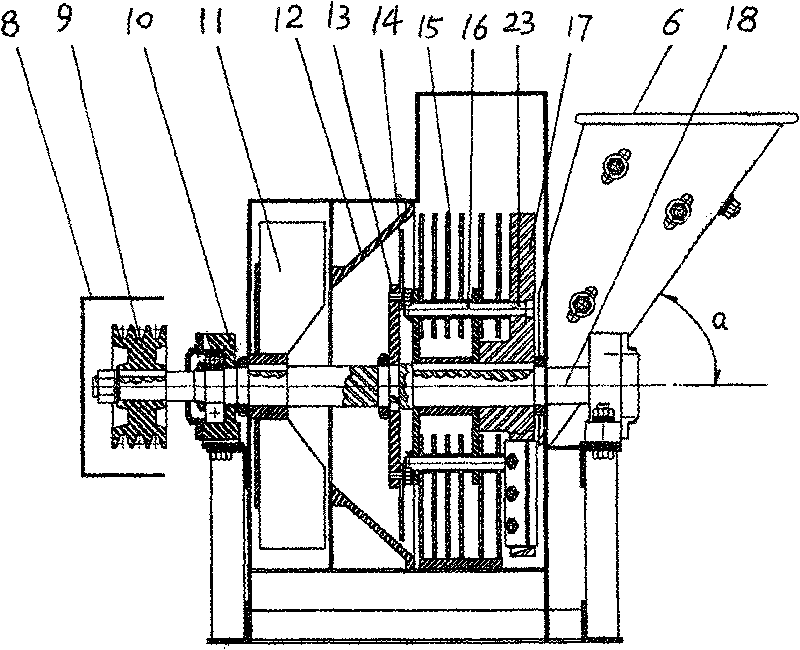

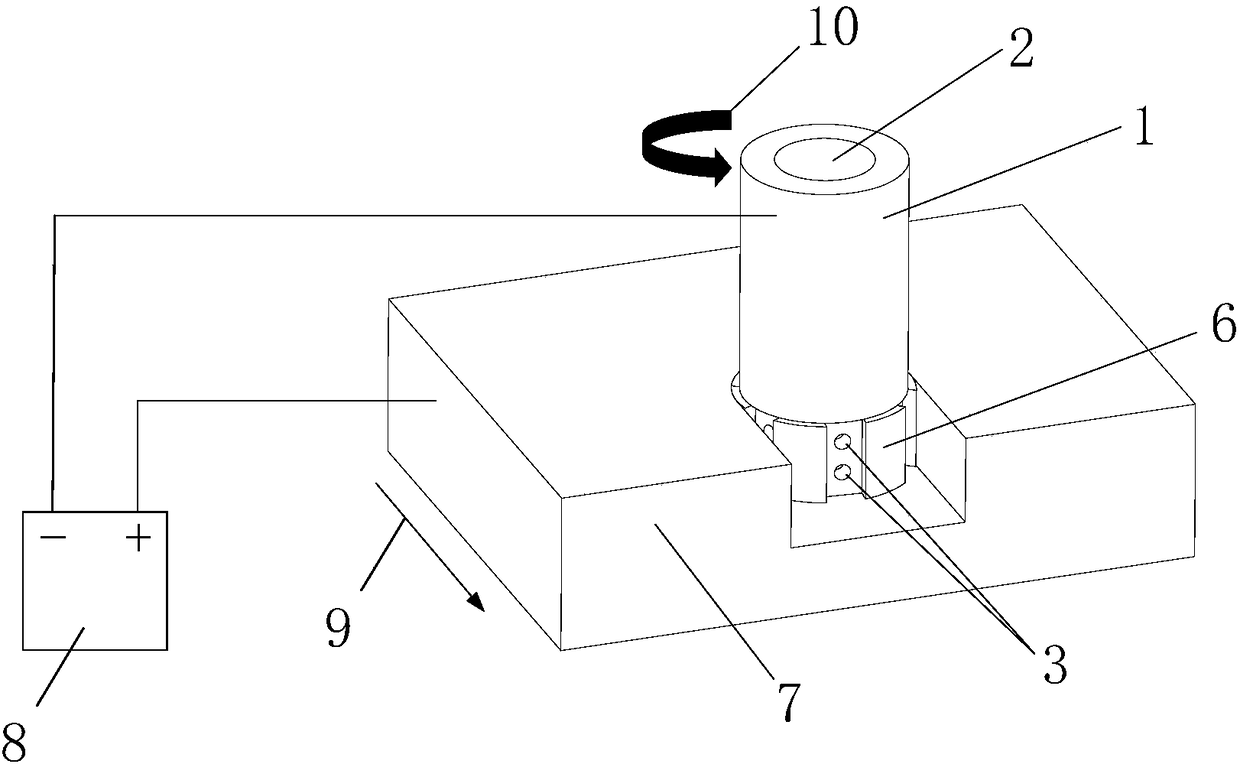

Electrochemical machining method and device for pulsating flow field tube electrode

ActiveCN102198549AReduce the "holding effect"Reduce the "squeeze effect"Machining working media supply/regenerationVoltage pulseElectrolysis

The invention relates to an electrochemical machining method and an electrochemical machining device for a pulsating flow field tube electrode, and belongs to the technical field of electrochemical machining. The method comprises the following steps of: 1, adjusting the flow and the pressure by controlling an action of a spool of a servo valve (9) by a pressure servo execution module (4), and outputting a pulsating electrolyte solution to an electrochemical machining area; 2, modulating a control instruction phase by using a control system of an electrochemical machining machine tool according to a pressure and voltage feedback signal, so that the pressure of the machining area is matched with the voltage pulse rhythm; and 3, dynamically adjusting a feeding speed and the machining voltage by using the control system of the electrochemical machining machine tool so as to machine a hole with a variable section in regular change. The method and the device provided by the invention have important meaning for increasing the flocculent product discharge rate and the machining stability of the electrochemical machining of a neutral saline solution deep hole tube electrode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

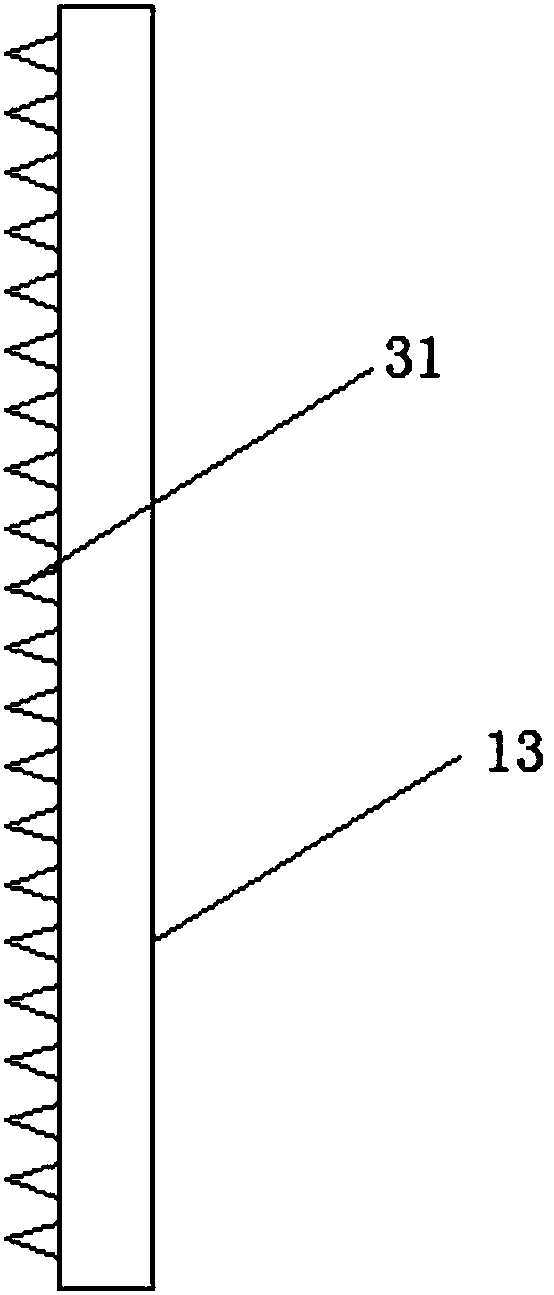

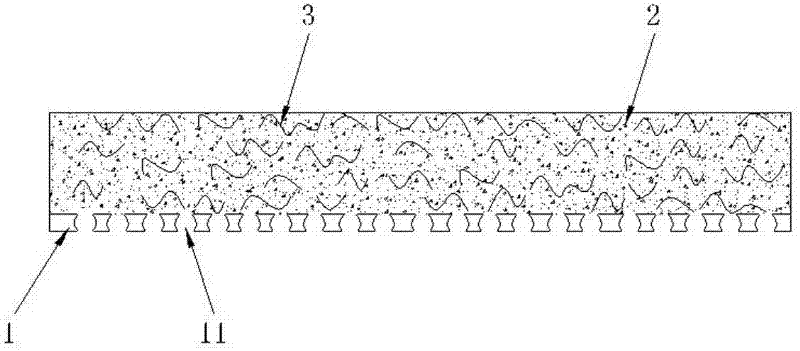

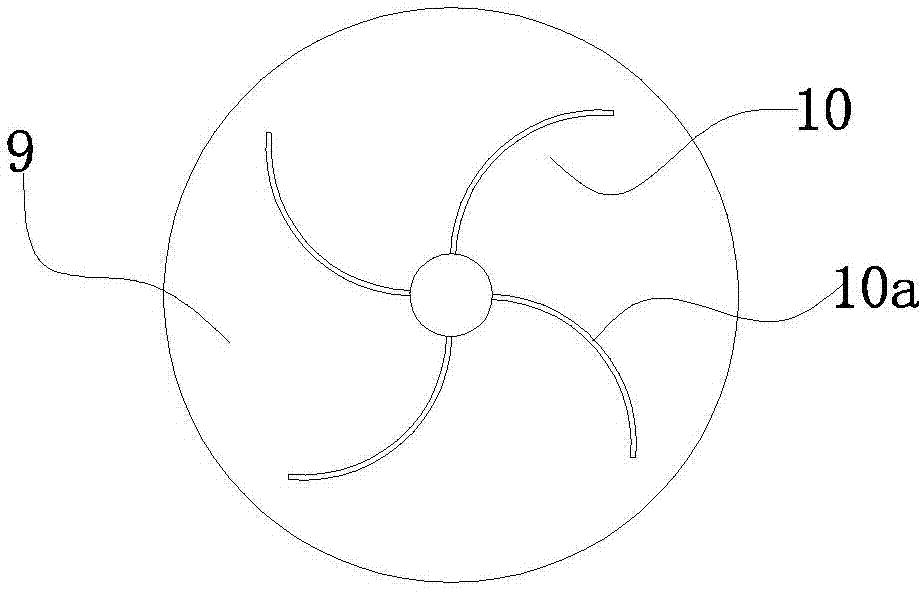

Plant material cutting pulverizer

InactiveCN101757961AImprove discharge effectIncrease productivityCuttersGrain treatmentsPulverizerEngineering

The invention relates to a plant material cutting pulverizer which comprises a stand, a casing, a discharge hole, a rotating cutterhead, a hammer group, a material suction fan, a main power shaft, an electric motor and a power transmission mechanism, wherein the rotating cutterhead is arranged on the main power shaft; the rotating hammer group is also arranged on the main power shaft; the side face of a hammer crushing chamber near the rotating cutterhead is provided with a lateral feed hole; and a circumference tangential feed hole is arranged above the casing. The plant material cutting pulverizer is characterized in that a particle size regulator for regulating the particle size of pulverized materials is arranged at the discharge side of the hammer crushing chamber; and the particle size regulator comprises a material suction fan blade, a regulator installation rack, a regulating piece and a horn-shaped material collecting cover, wherein the material suction fan blade, the regulator installation rack and the regulating piece are respectively arranged on the main power shaft; and the horn-shaped material collecting cover is arranged on the casing for regulating the size of a discharge channel of the pulverized materials. The traditional mode that the pulverizer filters particles through a screen stencil is changed to the mode of regulating the particle size of the pulverized materials by the regulator, both dry and wet raw materials can be pulverized and processed, the brush wood of woody plants and plant straws of herbaceous plants can be processed, and the output is enhanced by more than one time as comparison with common pulverizers.

Owner:翁赐和

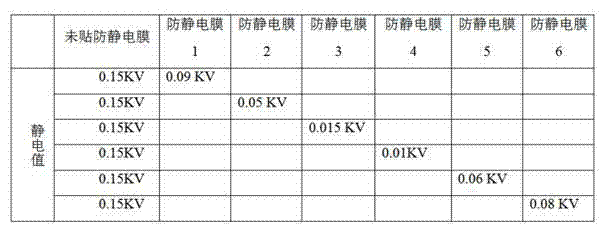

Anti-static film and preparation method thereof

ActiveCN102453446AGood discharge effectEasy to operateFilm/foil adhesivesPressure sensitiveChemistry

The invention provides an anti-static film, which comprises a substrate and a coating formed on the substrate, wherein micropores are formed on the surface of the substrate; the coating is made of a resin pressure-sensitive adhesive which contains a reticular structure formed by nano-wires. The invention also provides a preparation method of the anti-static film. According to the anti-static filmand the preparation method thereof, when the anti-static film is used, the anti-static film can be attached to the surface of a liquid crystal display screen by virtue of the resin pressure-sensitiveadhesive in the anti-static film, and static electricity can be directly discharged to the air by virtue of the reticular structure of the nano-wires formed in the resin pressure-sensitive adhesive and the phenomenon that the nano-wires discharge electricity at the tips in the micropores of the substrate. The anti-static film has an excellent discharge effect and is convenient in operation.

Owner:深圳市合力泰光电有限公司

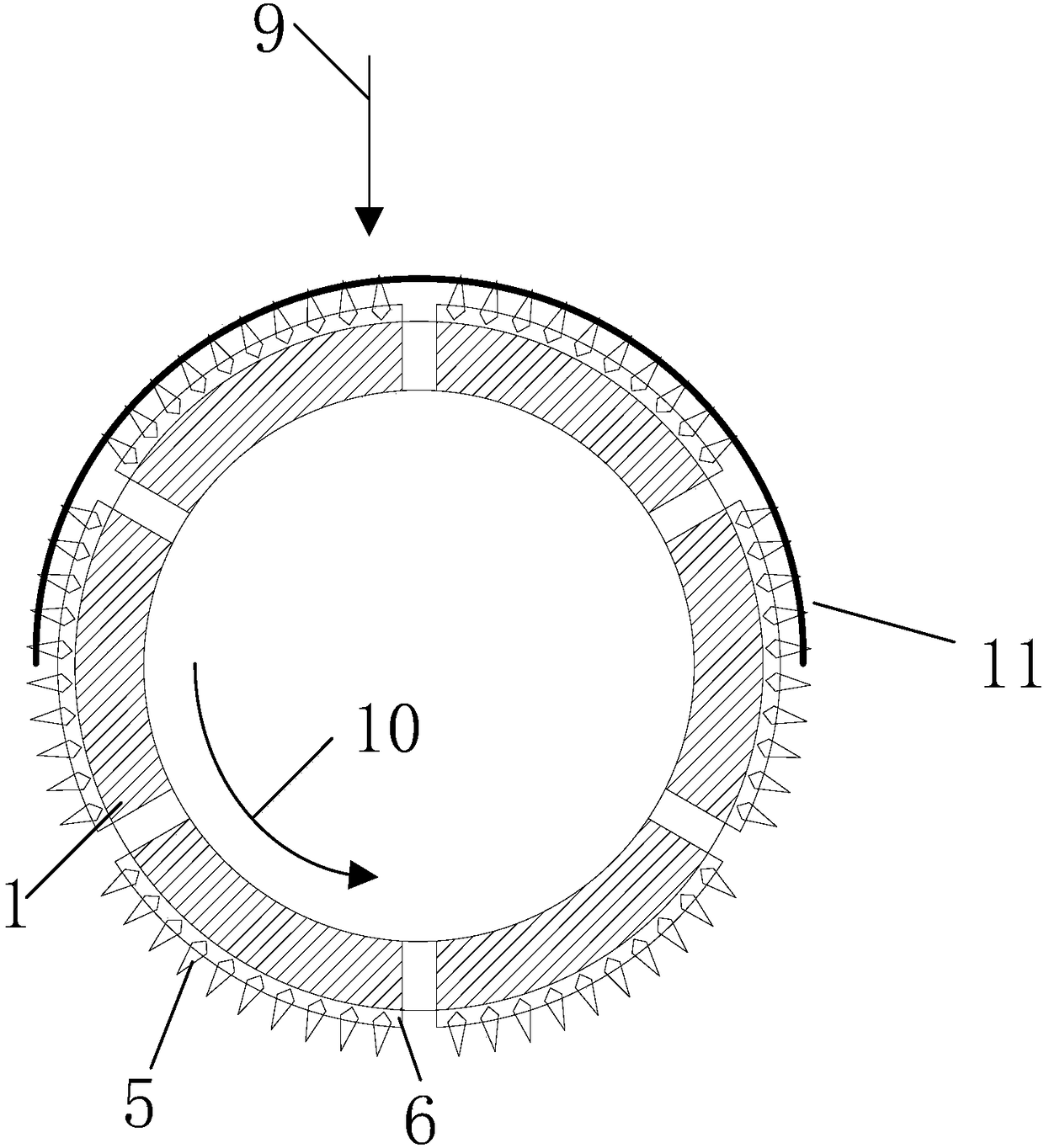

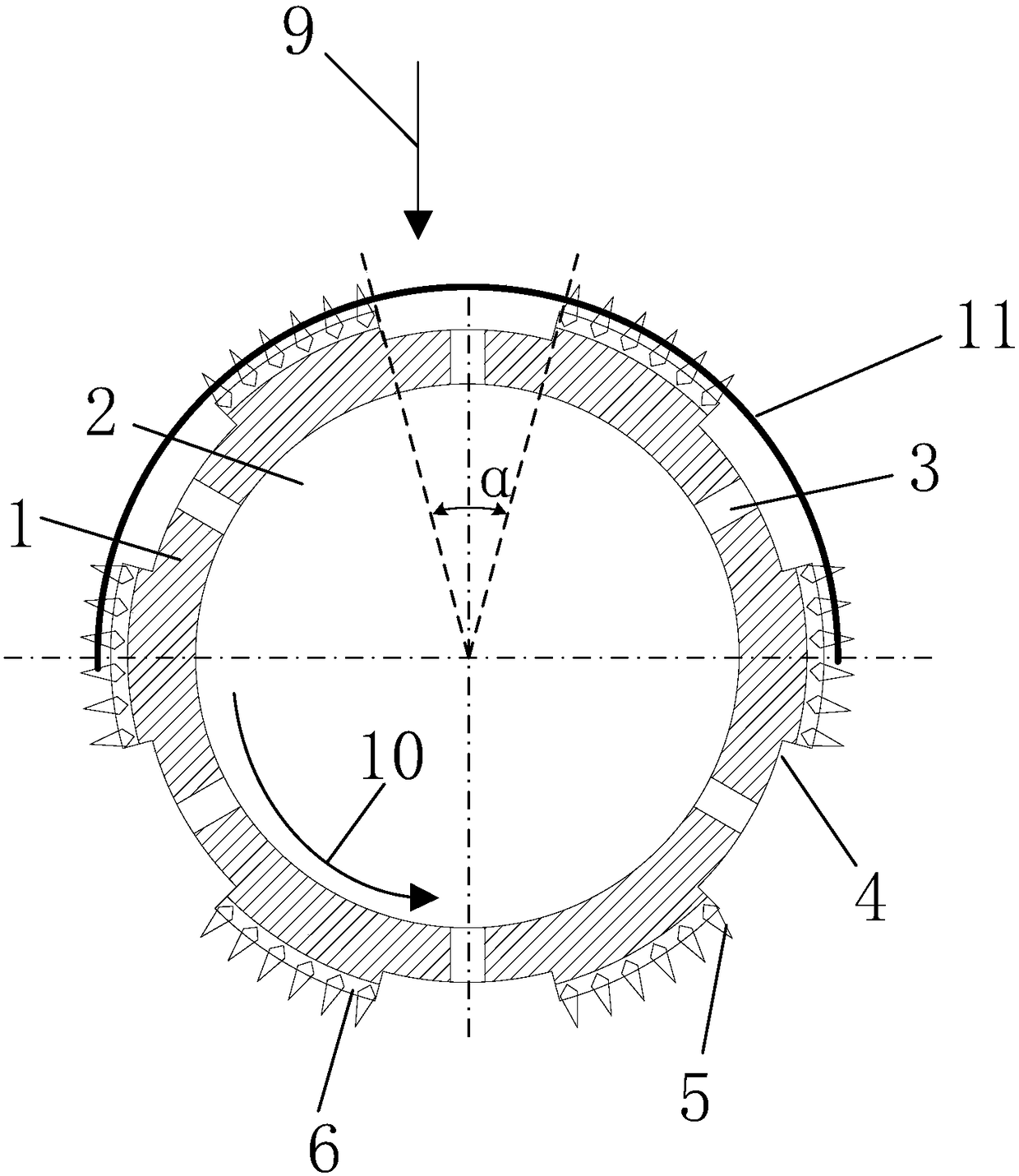

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cotton cloth reactive dye discharge printing process

InactiveCN101654876AImprove discharge/coloring effectImprove discharge effectDyeing processVinyl sulfoneEconomic benefits

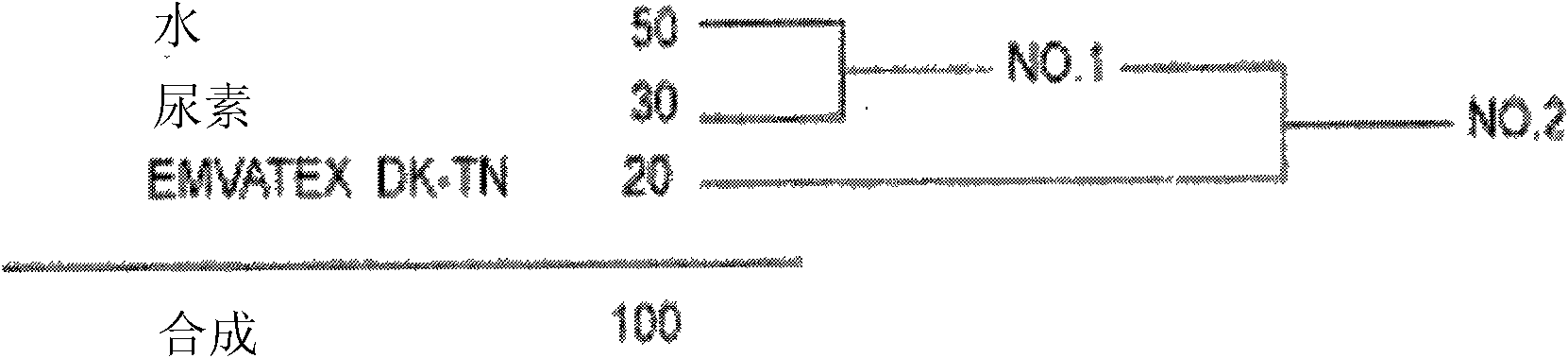

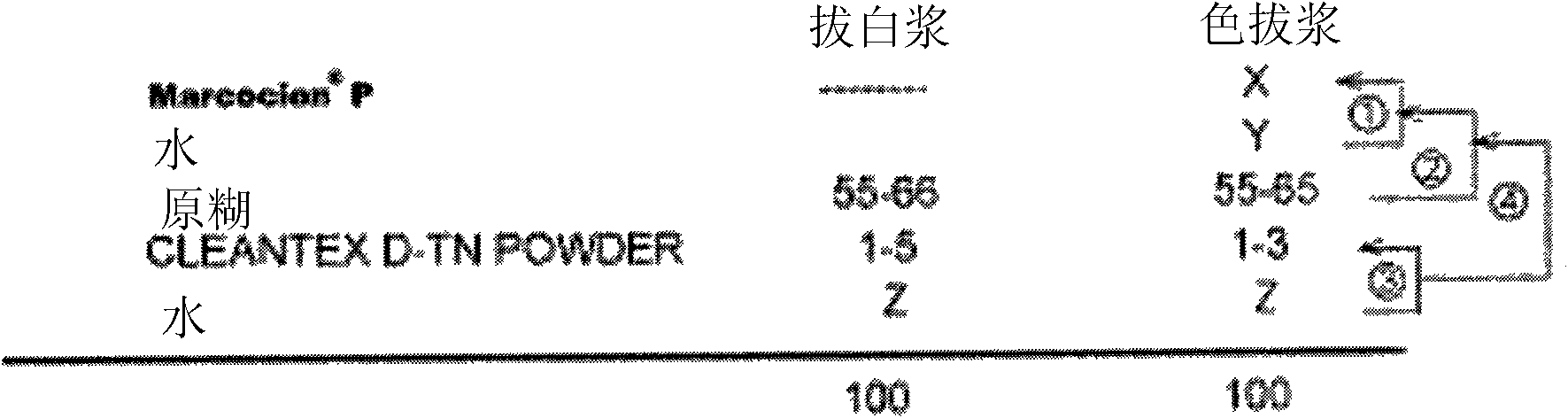

The invention relates to a cotton cloth reactive dye discharge printing process for use in textile dyeing and printing production, in particular to a reactive dye discharge printing process. The invention aims to substitute for the conventional reduction discharge process which is not environment-friendly and high in cost and has white discharge and poor red coloring in application by introducingthe cotton cloth reactive dye discharge printing process. The process comprises the following steps of: 1, ground dyeing of the cotton cloth with a vinyl sulfone reactive dye; 2, discharge printing ofthe cotton cloth with a color paste made from a discharge printing agent and an alkali-resisting P-type reactive dye; 3, baking for decolorization; 4, steaming of the cotton for color development; 5,water washing; and 6, drying. The formula thereof comprises: a primary paste containing 20 percent of discharge printing agent DK-TN, 20 to 30 percent of carbamide and the balance of water; a white discharging paste containing 50 to 60 percent of primary paste, 1 to 10 percent of leucotrope and water; and a color discharging paste containing Marcocion P dye stuff, 50 to 60 percent of primary paste, 1 to 8 percent of leucotrope D-TN and 2 to 4 percent of water / saleratus. The cotton cloth reactive dye discharge printing process has the advantages of updating the conventional process and the currently introduced discharge printing process, improving the discharge printing effect, reducing the printing cost, decreasing the added materials and reducing the amount of sewage generated in a process of water washing unfixed dyes. The reactive dye process is simple in technique, bright in color, soft in hand feeling and good in environment protection, belongs to innovation development, saves energy, improve efficiency and has enormous social and economic benefits.

Owner:董建圆

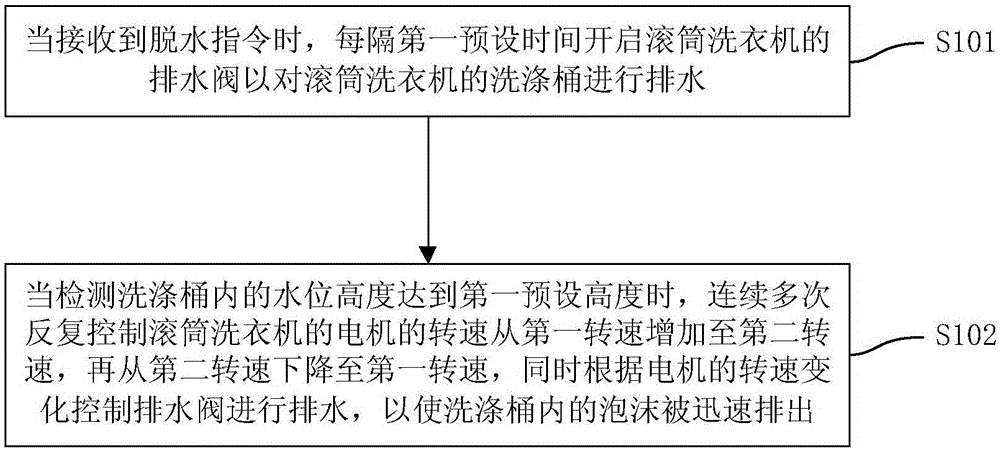

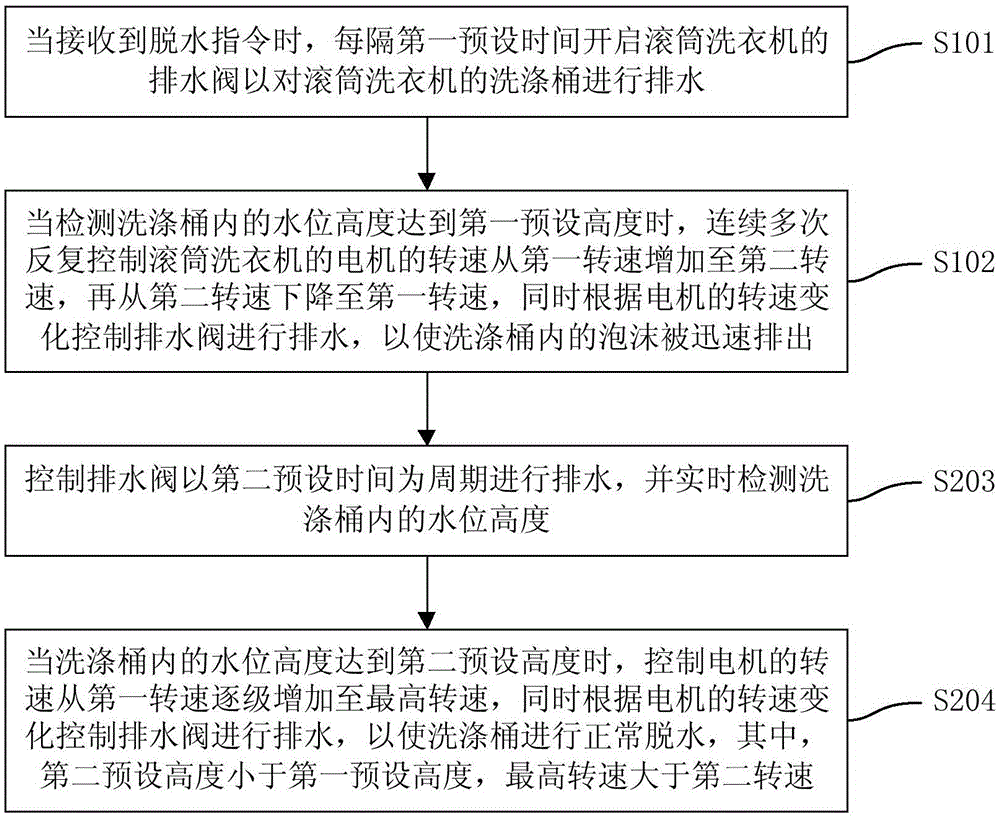

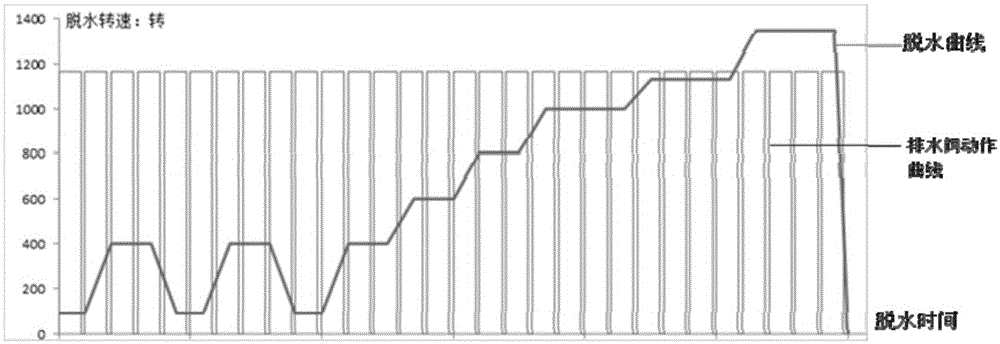

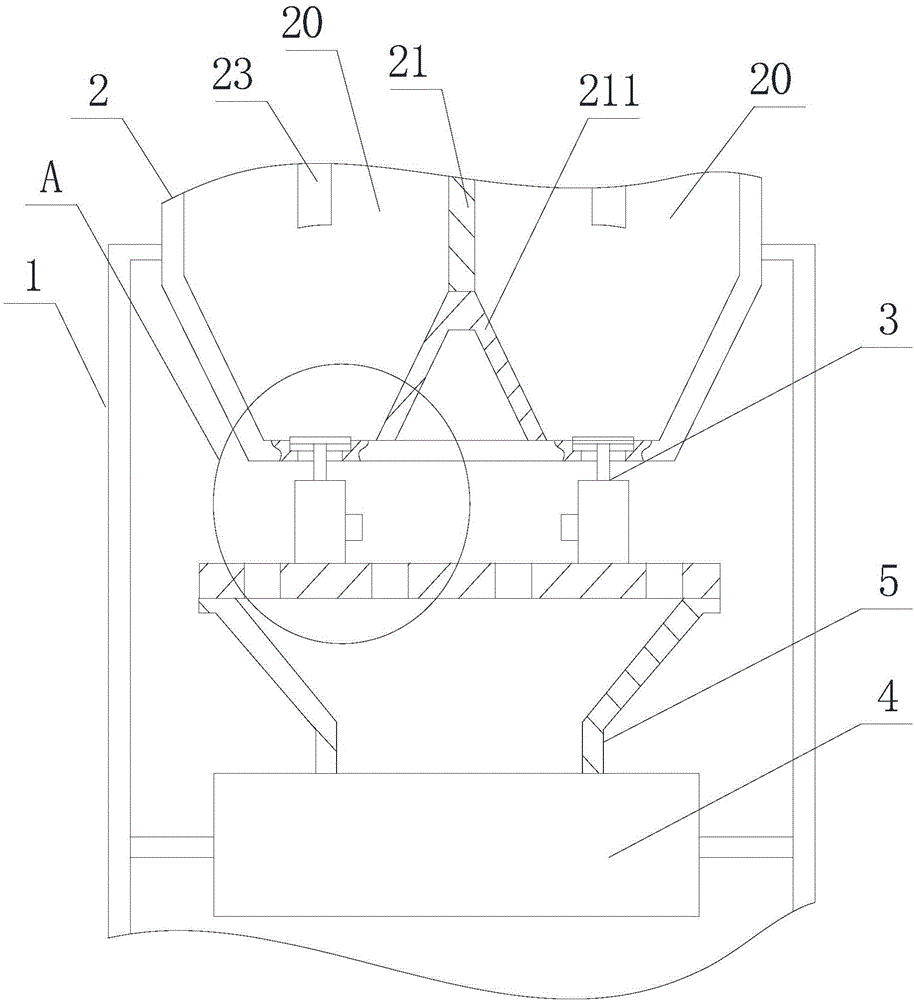

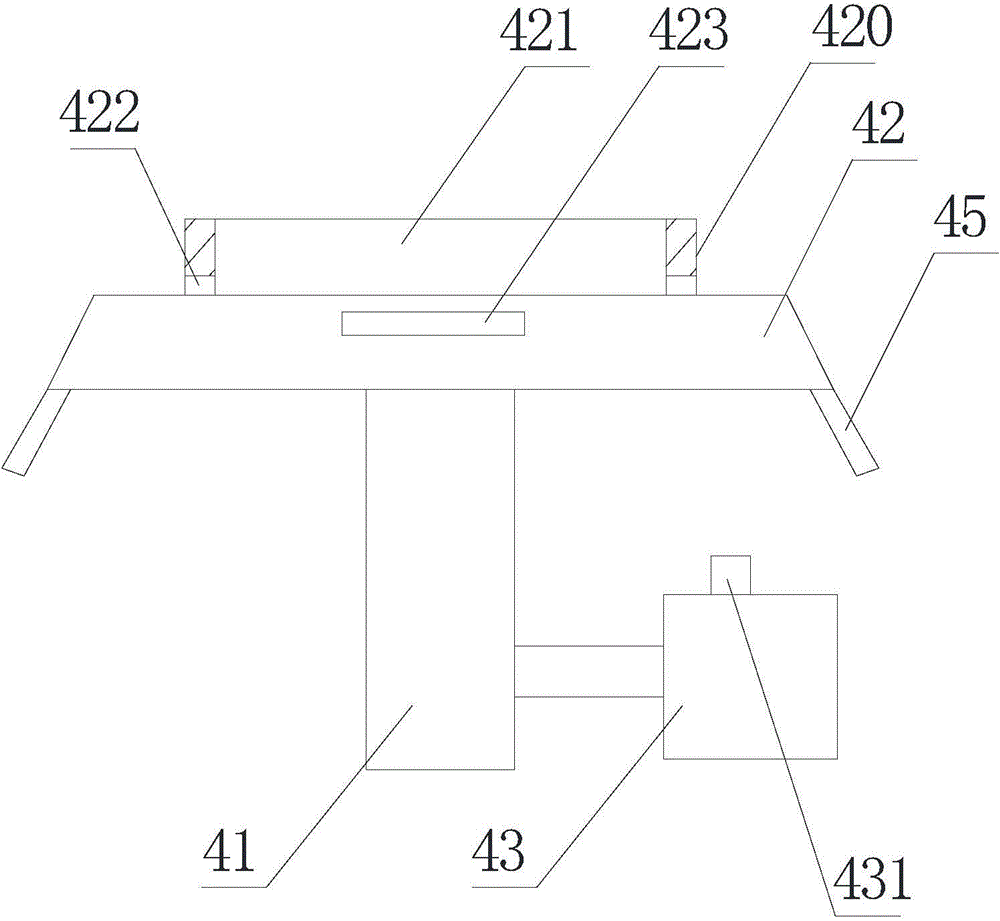

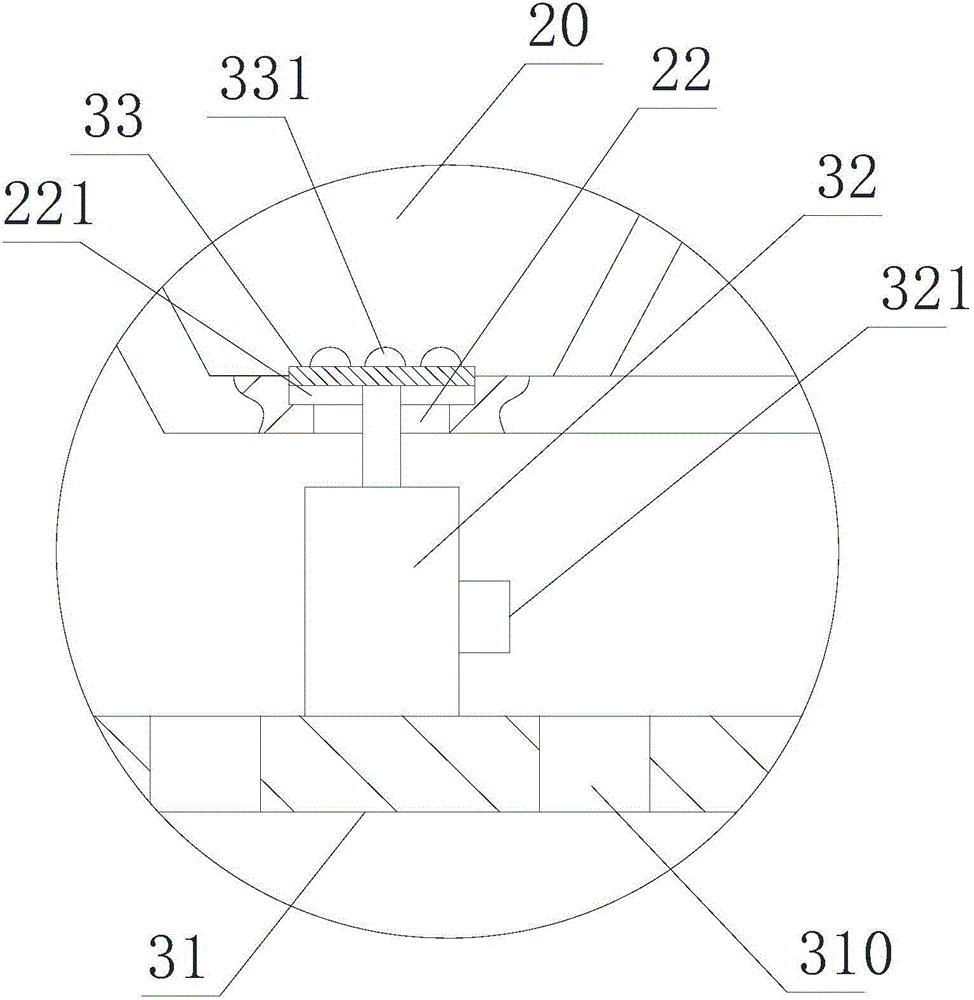

Control method and controlling device of front-loader washing machine and front-loader washing machine

ActiveCN105088646AProblems affecting useImprove usabilityOther washing machinesControl devices for washing apparatusEngineeringMechanical engineering

The invention discloses a control method and controlling device of front-loader washing machine and a front-loader washing machine. The method comprises starting a drain valve of a front-loader washing machine at first set intervals to drain water from a washing drum of the front-loader washing machine, when a spinning instruction is received; continuously and repeatedly controlling the rotational speed of a motor of the front-loader washing machine change into a second rotational speed from a first rotational speed and then change into the first rotational speed from the second rotational speed, when that the water level in the washing drum reaches up to a first preset height is detected, and controlling the drain valve to drain water according to a rotational speed of the motor, so as to quickly discharge foam in the washing drum. The control method is simple in control mode with no additional devices, the cost is reduced, the effect that foam can be normally discharged is distinctly improved, the problem that spilled foam influences a washing machine can be solved, and the availability of the washing machine can be raised.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Feed supply device for aquaculture

The invention relates to a feed supply device for aquaculture. The feed supply device comprises a machine frame and a feed storage box, wherein at least one vertical separating plate is arranged in the feed storage box, the bottom end of the feed storage box is provided with through holes, a control device is arranged on the machine frame, and comprises a retaining plate, a push rod and a control plate, and the bottom end of the retaining plate is provided with a control assembly. The feed supply device has the advantages that feed in the feed storage box is controlled by the control plate on the push rod to firstly pass through the through holes and then be discharged, and the feed is conveyed to a guide assembly through the retaining plate, and then is controlled to be uniformly dispersed and discharged, so the supply amount of the feed is effectively controlled according to the cultured species, the waste of the feed in culturing areas is avoided, the deterioration of water quality is reduced, and the labor intensity of a culturing person in the cleaning process is reduced; the interior of the feed storage box is separated into at least two material storage cavities by at least one vertical separating plate, the storage of the feed at different phases can be guaranteed, the discharging of the feed is controlled through different through holes, the discharging effect is good, the feed supply device is suitable for culturing different aquatic products, and the practicality is high.

Owner:浙江张老汉生态鳖业股份有限公司

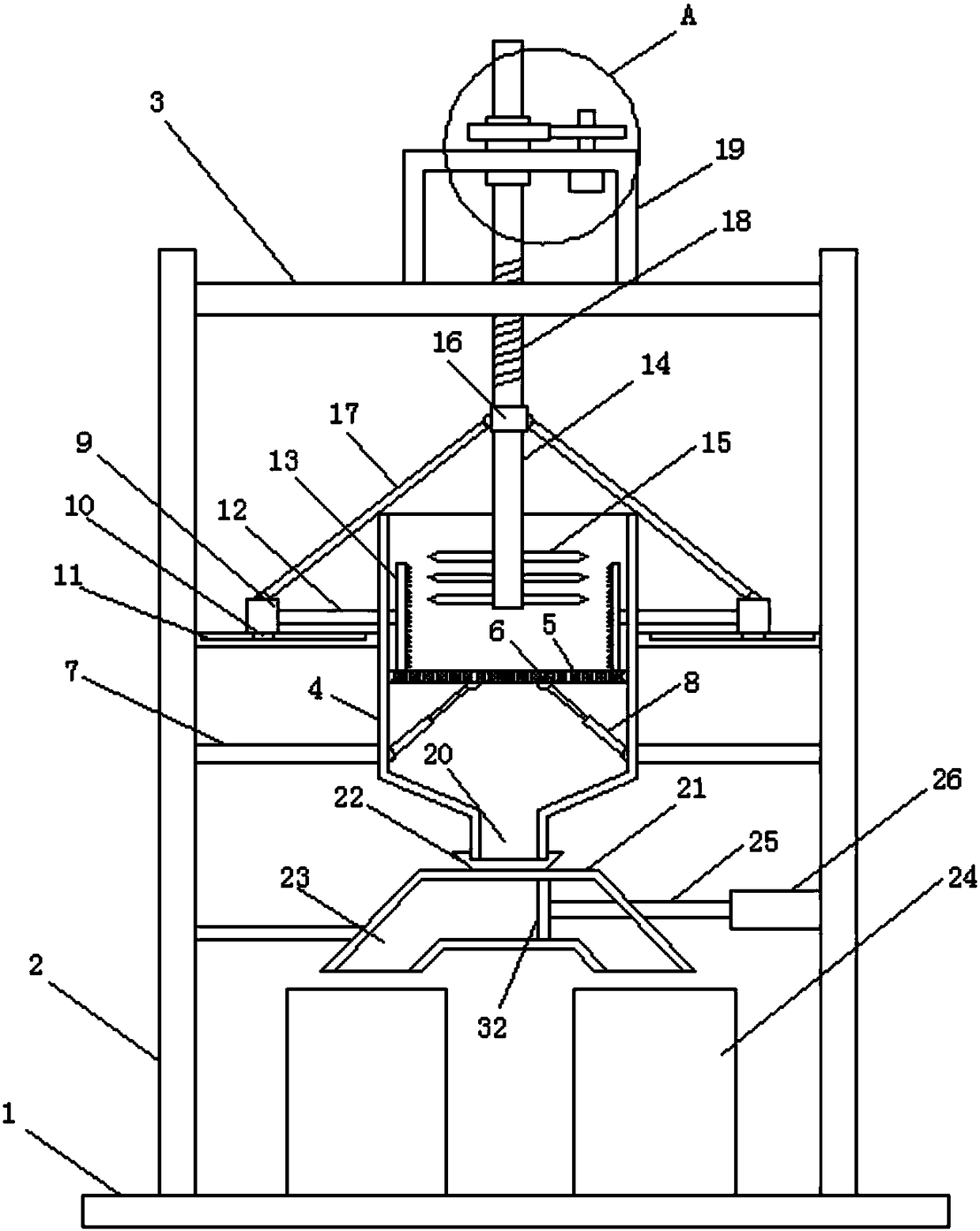

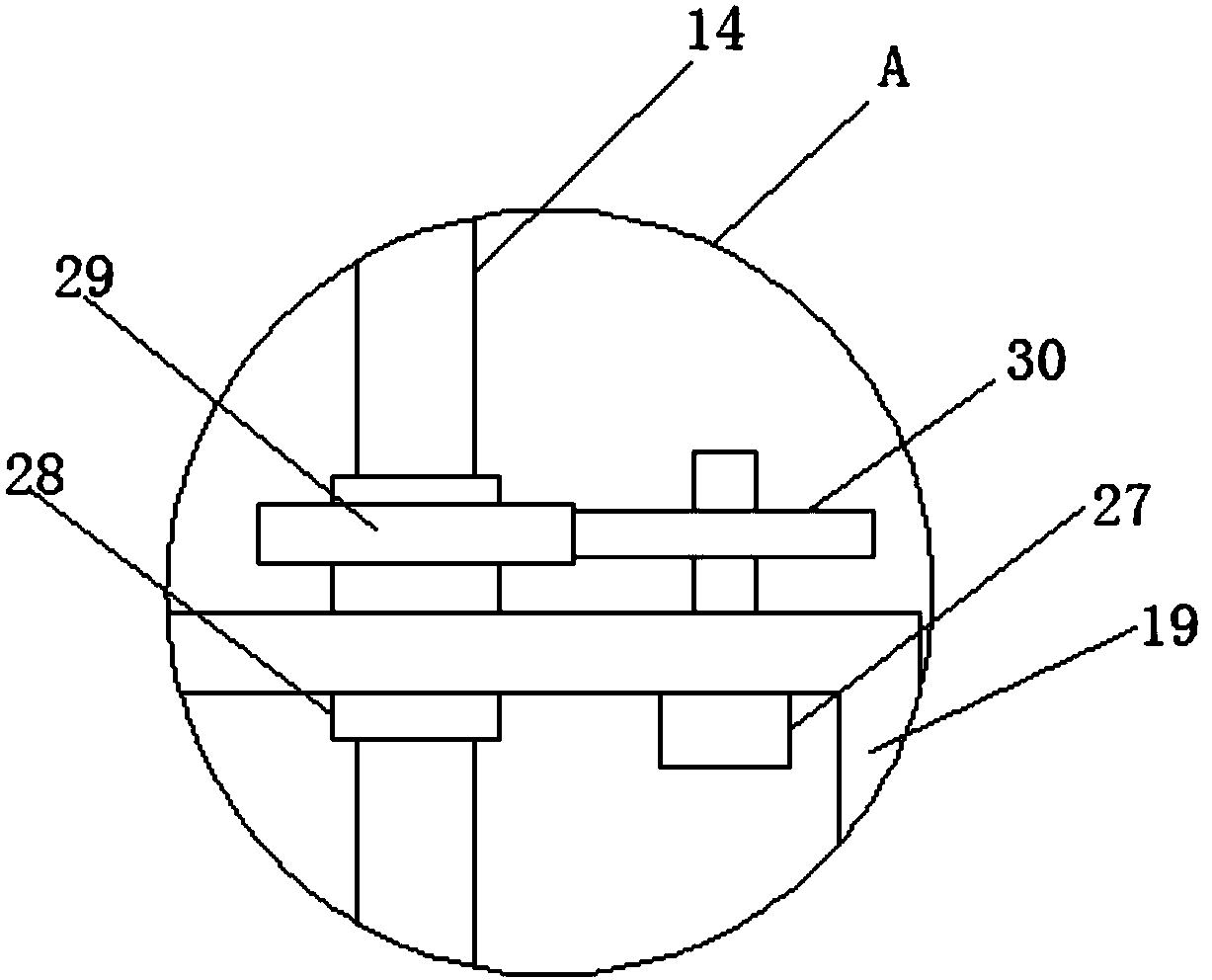

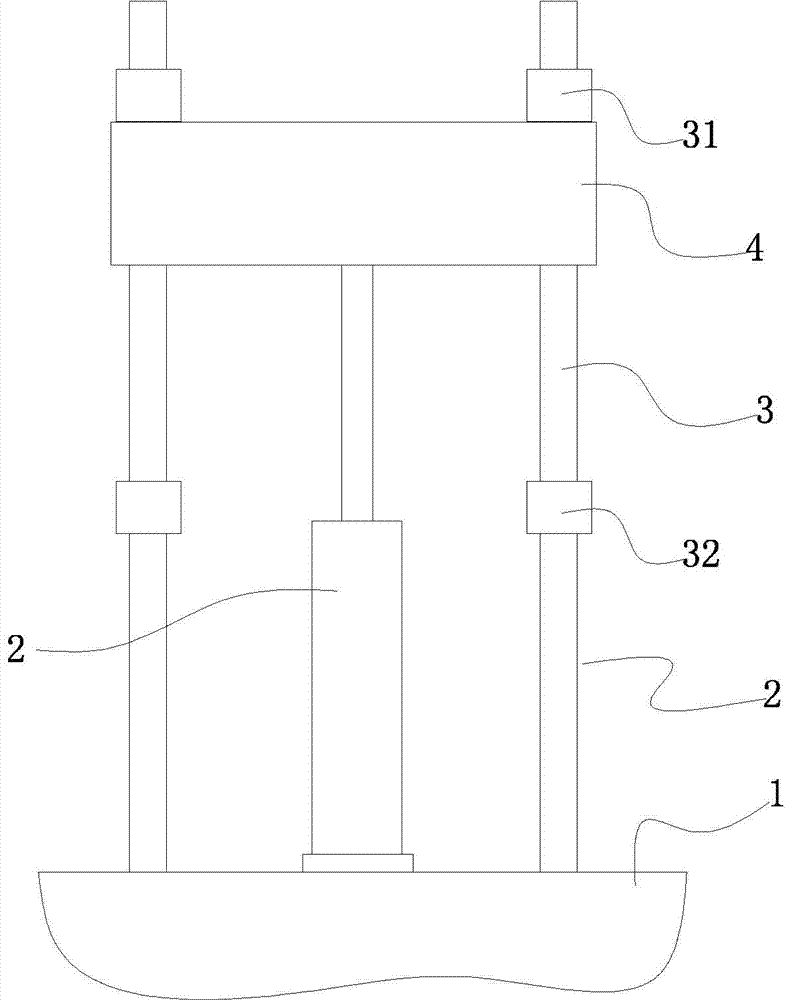

Enhancement and releasing system for snails

ActiveCN104719194AImprove survival rateReduce labor intensityClimate change adaptationPisciculture and aquariaMarine engineeringUltimate tensile strength

The invention discloses an enhancement and releasing system for snails. The enhancement and releasing system is low is labor intensity, suitable for large-scale releasing, good in releasing effect and capable of improving the survival rate of shellfish seedlings. The system comprises a vertical sleeve, a connecting shaft rod, a storing barrel arranged in the vertical sleeve in a slidable mode, a piston arranged in the storing barrel in a slidable mode, a vertical guiding rod arranged on a boat, a lifting sliding seat capable of sliding up and down along the vertical guiding rod and a lifting execution device arranged on the boat and used for driving the lifting sliding seat.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

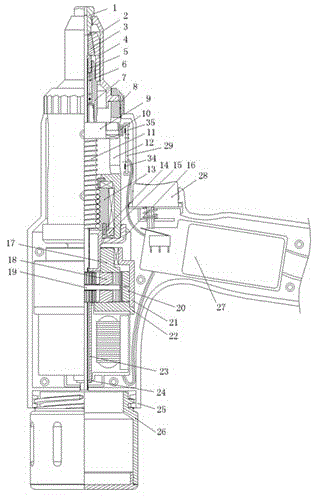

Electric riveting tool

ActiveCN104439022AUnlimited sizeImprove discharge effectToothed gearingsTransmission elementsControl lineInductor

The invention relates to an electric riveting tool used in the technical field of machines. The tool is composed of an outer cover, a trigger, a rivet pulling system, a lead screw transmission system, a planetary gear speed-reducing system and a power motor assembly. A spring sleeve is connected with the front end of a ball lead screw, the planetary gear speed-reducing system is fixed to a lead screw nut through a connection shaft, the power motor assembly is connected with the planetary gear speed-reducing system, a nail collecting cylinder is arranged at the rear end of the power motor assembly, a discharging pipe penetrates through a motor shaft and the planetary gear speed-reducing system and then is arranged outside a core ejector pipe in a sleeving mode, the outer cover is provided with a circuit board, the trigger and a stroke control plate, the circuit board is connected with a motor and the stroke control plate through control lines, the stroke control plate is provided with an inductor, a rolling wheel positioning block is provided with a magnet, and the inductor is located on the lower portion of the magnet. The tool is strong in power, can be used for work indoors and outdoors, is used in a handheld mode, accords with the principle of ergonomics, makes full use of tool space, can be used for pulling rivets of different specifications and is high in applicability, and waste nail rod discharging is easy.

Owner:昆山铆足劲工具有限公司

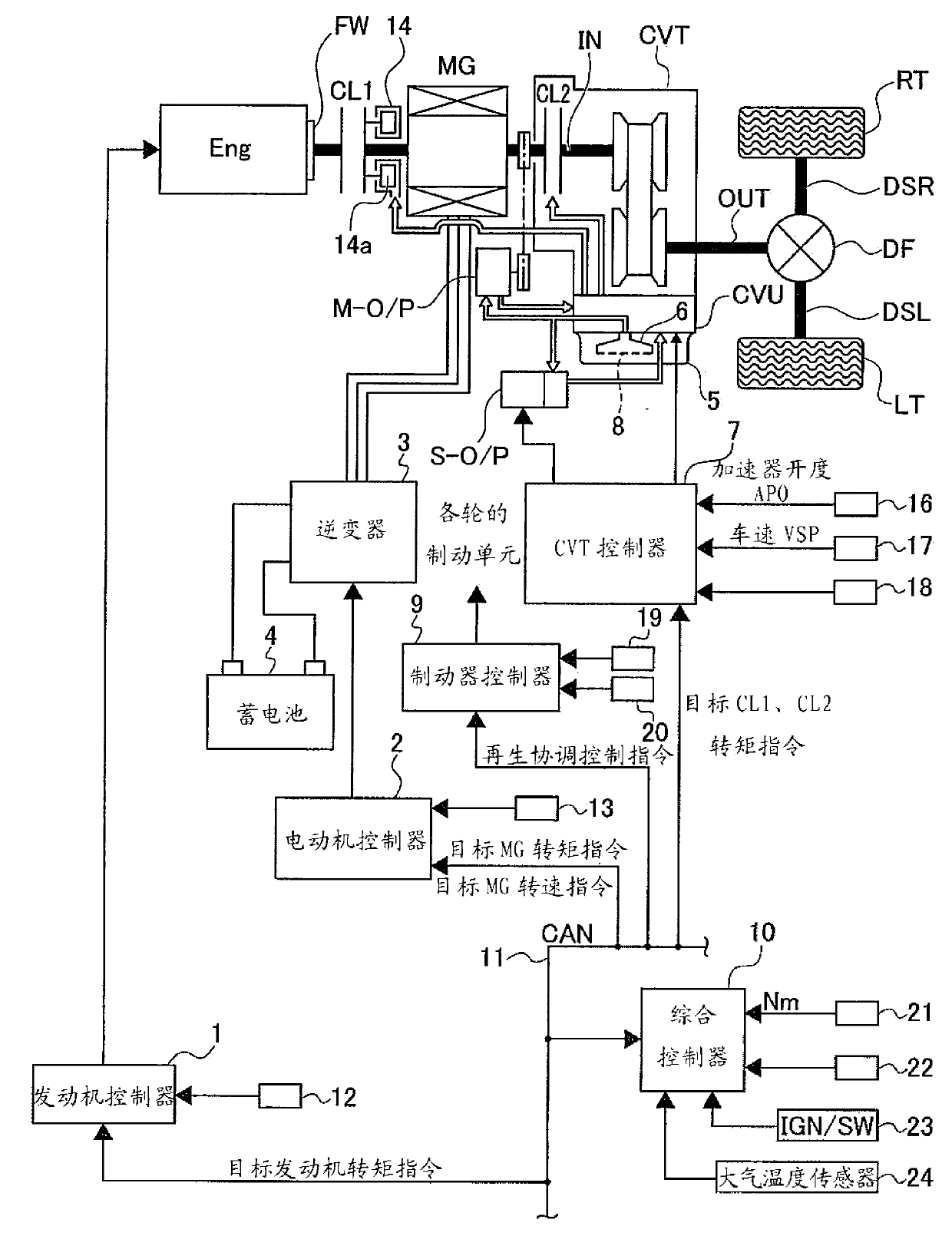

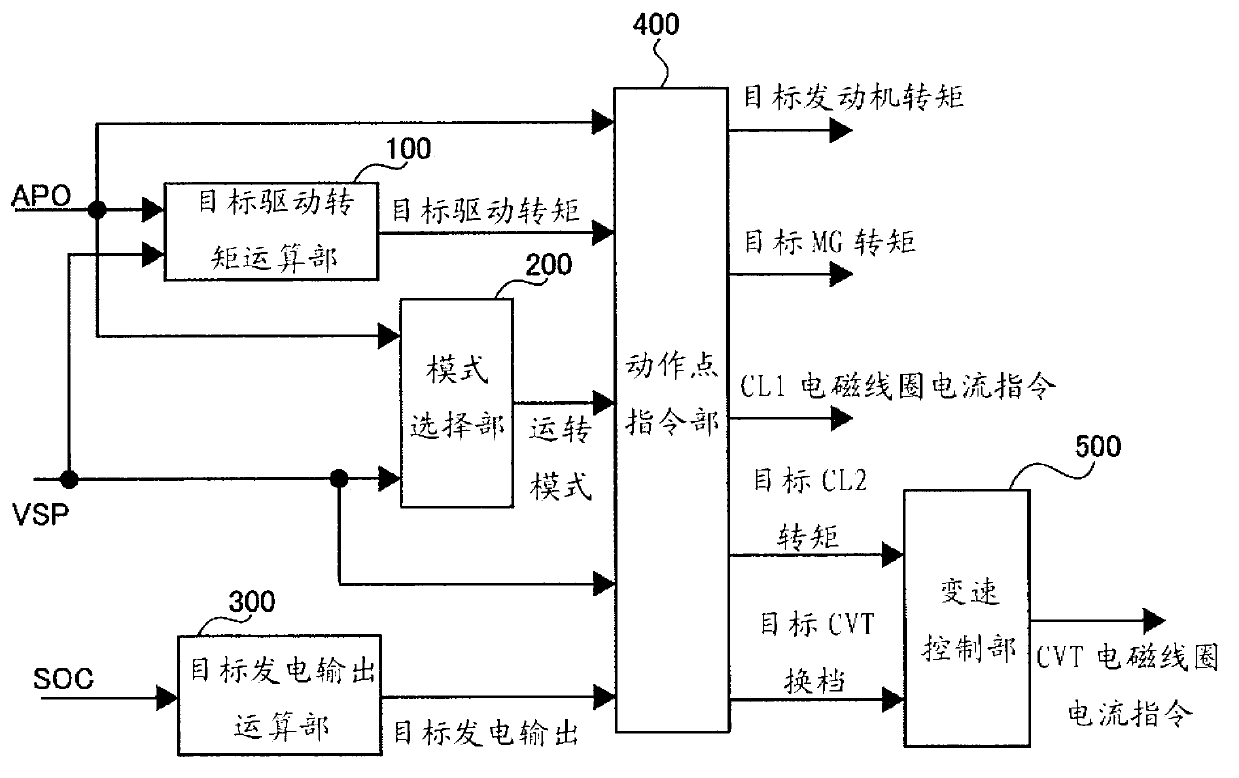

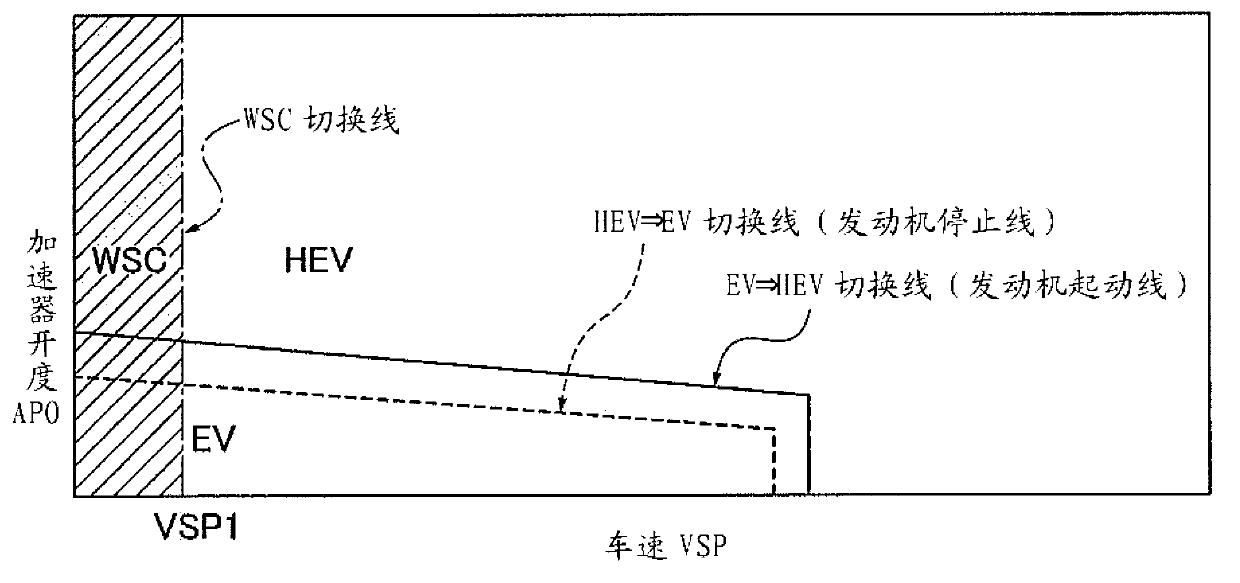

Engine start control apparatus for hybrid electrical vehicle

InactiveCN103213500AIncrease temperatureLow viscosityHybrid vehiclesElectrical controlHybrid electrical vehicleEngine power

Owner:JATCO LTD

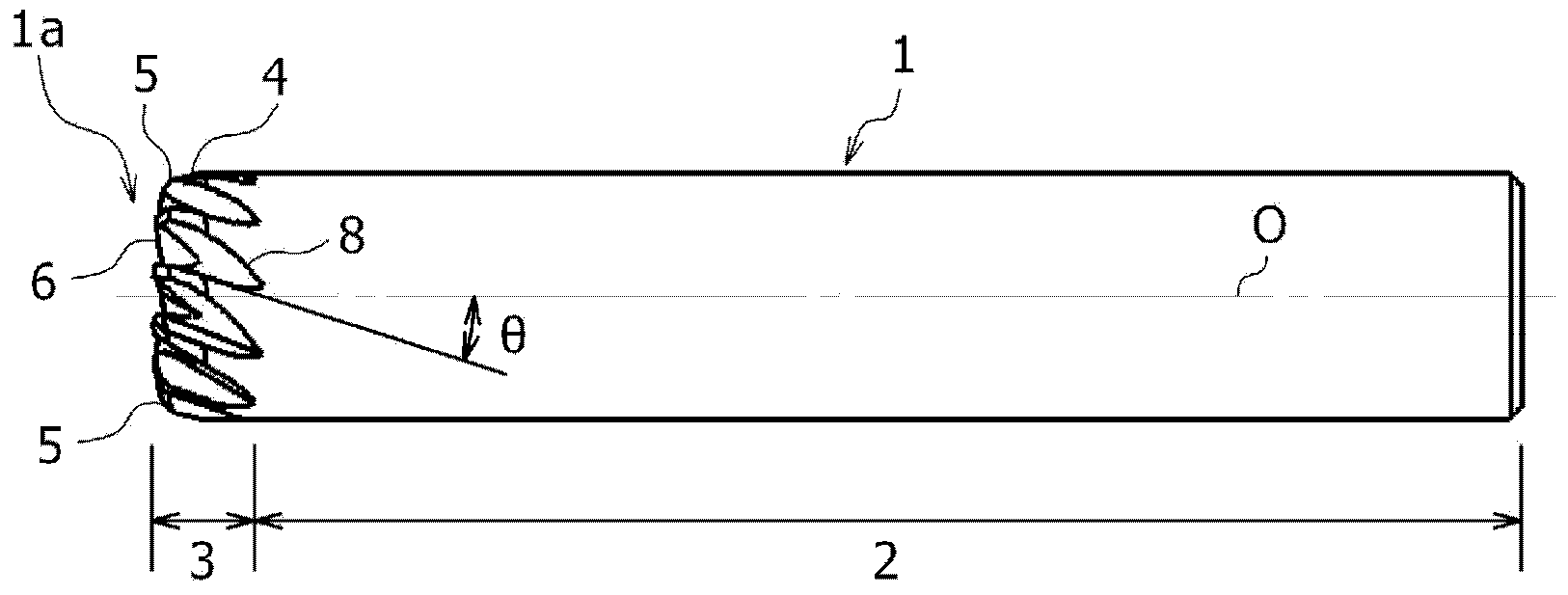

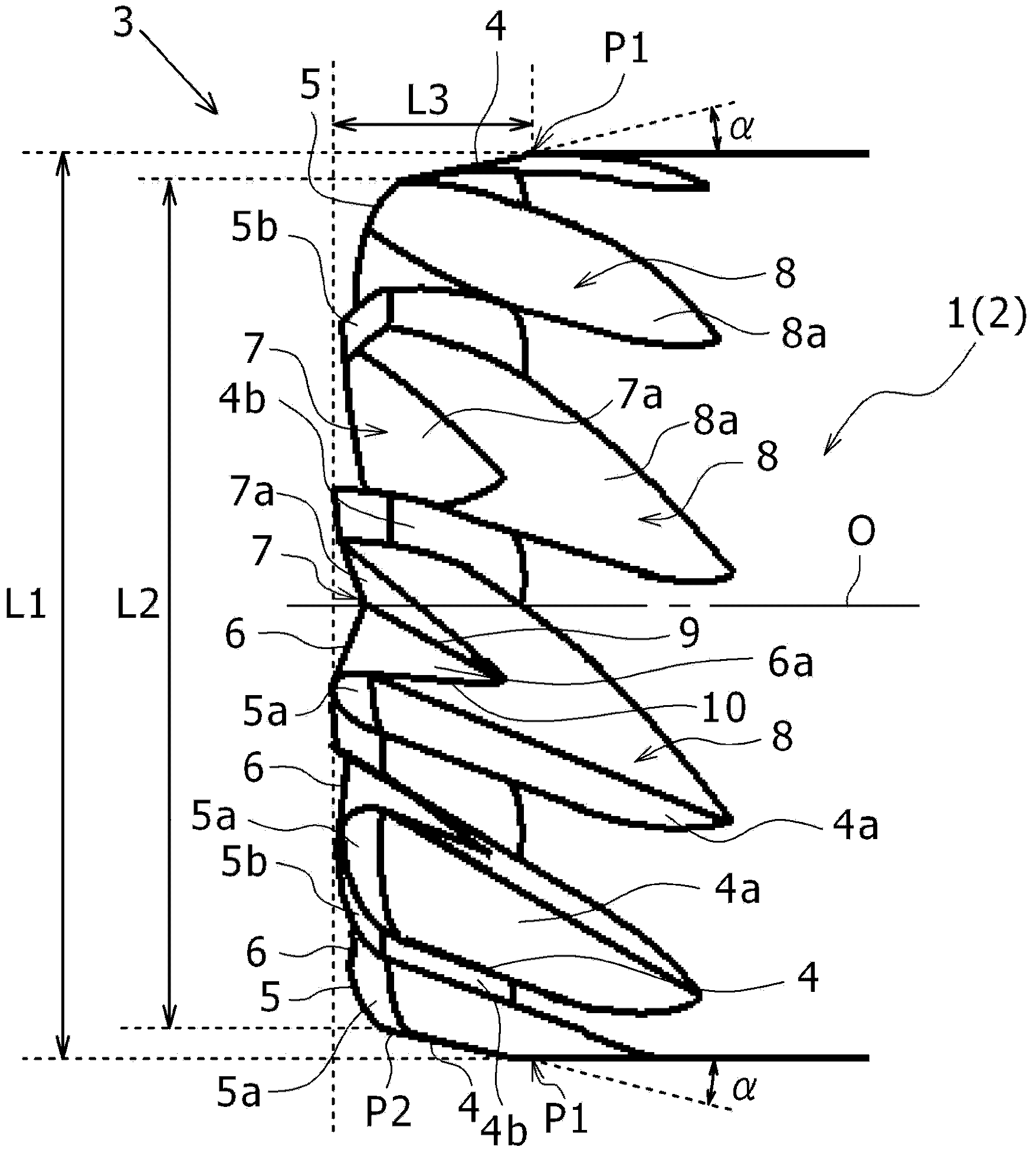

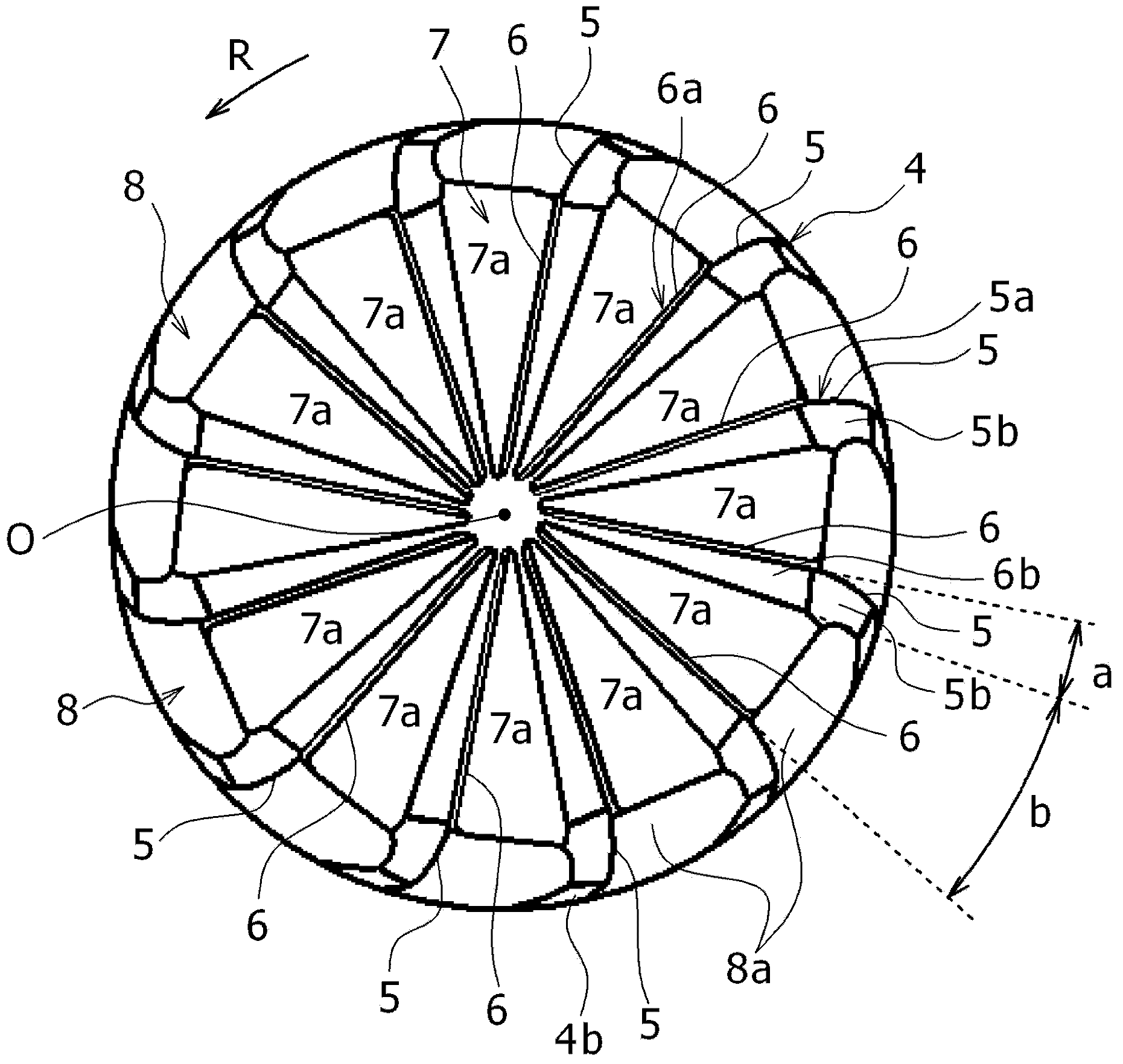

Multi-edge endmill

To improve removal of chips generated when performing high feed processing of thin-walled materials such as impellers using a multi-edge endmill. In a multi-edge endmill (1) having a cutting edge part (3) provided with multiple cutting edges and flutes (8) formed between cutting edges that are adjacent in the direction of rotation around the tool axis (O), the rake face of the cutting edge is configured from: the rake face (6a) of an end cutting edge (6) from the tool axis (O) to the outer circumference of the shank (2); the adjacent rake face (5a) of a corner R edge (5) that forms a surface different from the rake face (6a) of the end cutting edge (6); and the adjacent rake face (4a) of a peripheral cutting edge (4) that forms a surface different from the rake face (5a) of the corner R edge (5). Between the rake face (6a) of an end cutting edge (6) and the flank (6b) of the end cutting edge (6) that is adjacent on the forward side thereof in the direction of rotation (R), a gash (7), which configures a space that is continuous with the flute (8), is formed, and one surface that configures the gash (7) also serves as the rake face (6a) of the end cutting edge (6).

Owner:HITACHI TOOL ENG LTD

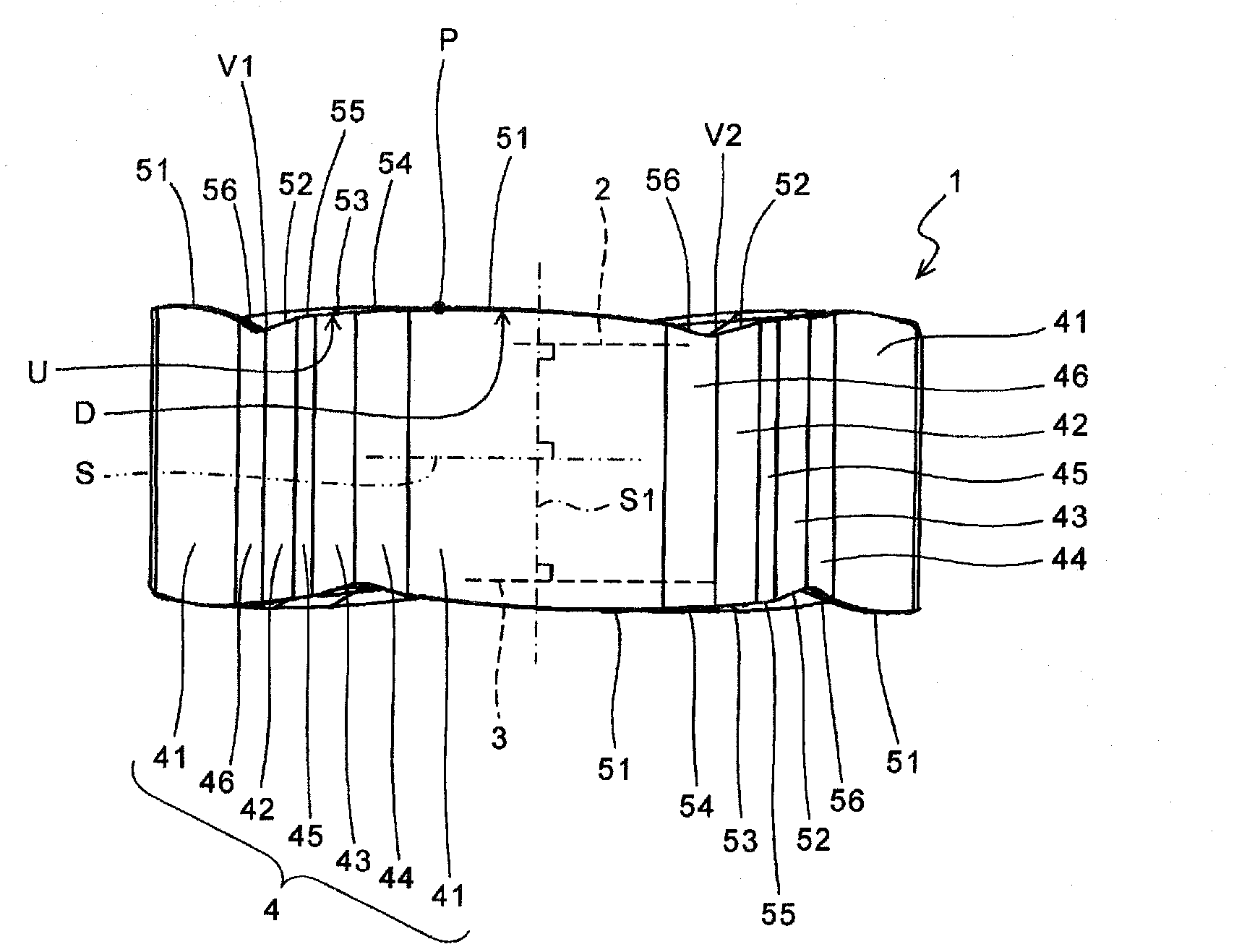

Fireworks product

The invention relates to a fireworks product, which comprises an outer cylinder with a sealed end, and an inner cylinder arranged in the outer cylinder, wherein the sealed end of the outer cylinder is provided with a small hole for an outer igniter cord; the inside of the outer cylinder is provided with propellant powder; the inner cylinder is provided with a small hole for an inner igniter cord; the inner igniter cord is contacted with the propellant powder; and the inside of the inner cylinder is provided with propellant powder. The fireworks product contains effective powder comprising red light powder, unpacking powder, igniting powder, sounding powder and black powder, wherein the red light powder comprises 43 percent of potassium perchlorate, 30 percent of powered alloy, 20 percent of strontium carbonate, 7 percent of hexachlorobenzene and 7 percent of phenolic resin; the unpacking powder comprises 50 percent of potassium perchlorate, 30 percent of powered alloy and 20 percent of aluminum powder; the igniting powder comprises 18 percent of potassium perchlorate, 7 percent of powered alloy, 12 percent of brimstone, 47 percent of potassium nitrate and 16 percent of charcoal; the sounding powder comprises 18 percent of powered alloy, 3 percent of brimstone, 5 percent of potassium nitrate, 52 percent of minium and 22 percent of copper oxide; and the black powder comprises 7 percent of potassium perchlorate, 6 percent of powered alloy, 9 percent of brimstone, 60 percent of potassium nitrate and 18 percent of charcoal. The fireworks product can generate flowery red light when set off, and simultaneously has high safety.

Owner:王生宝

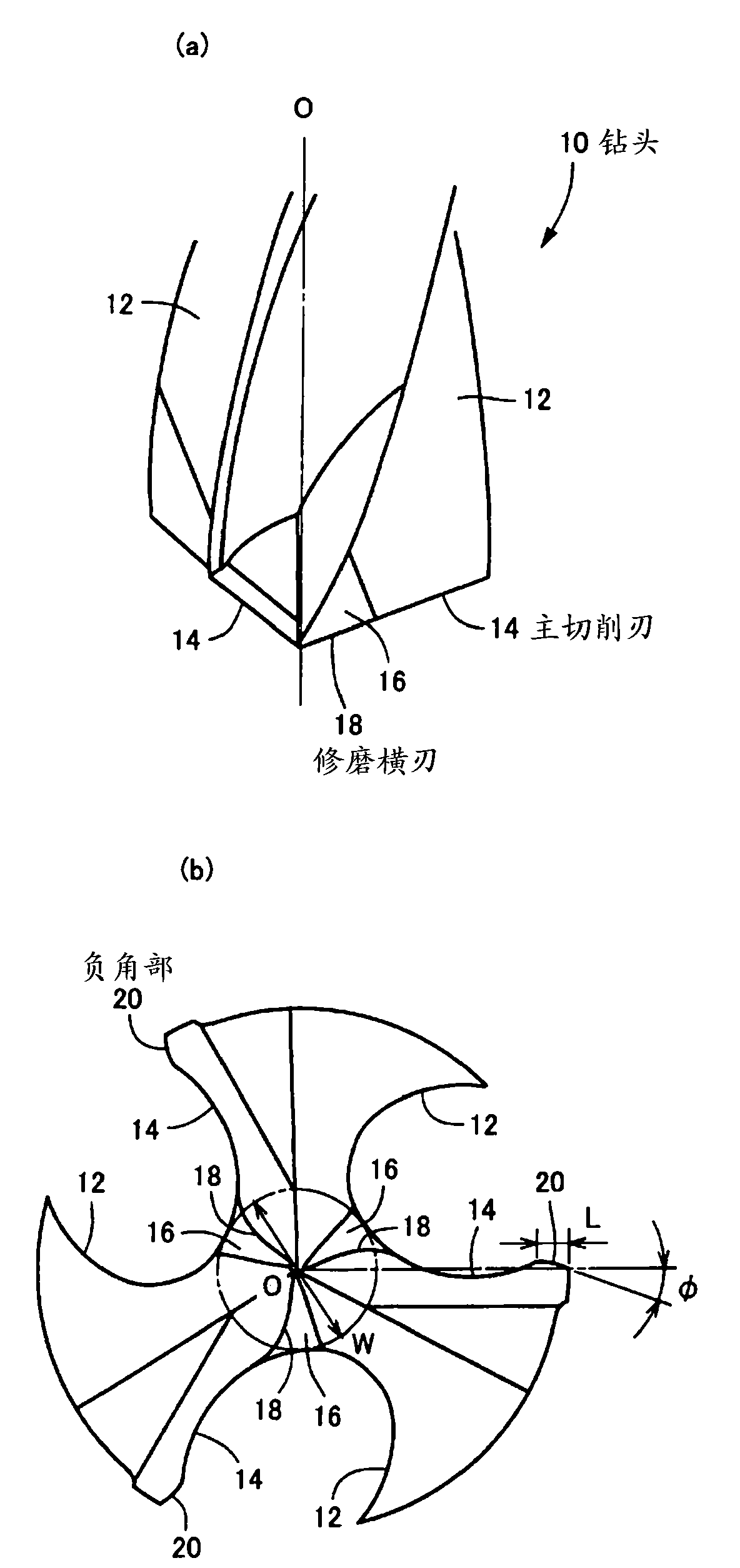

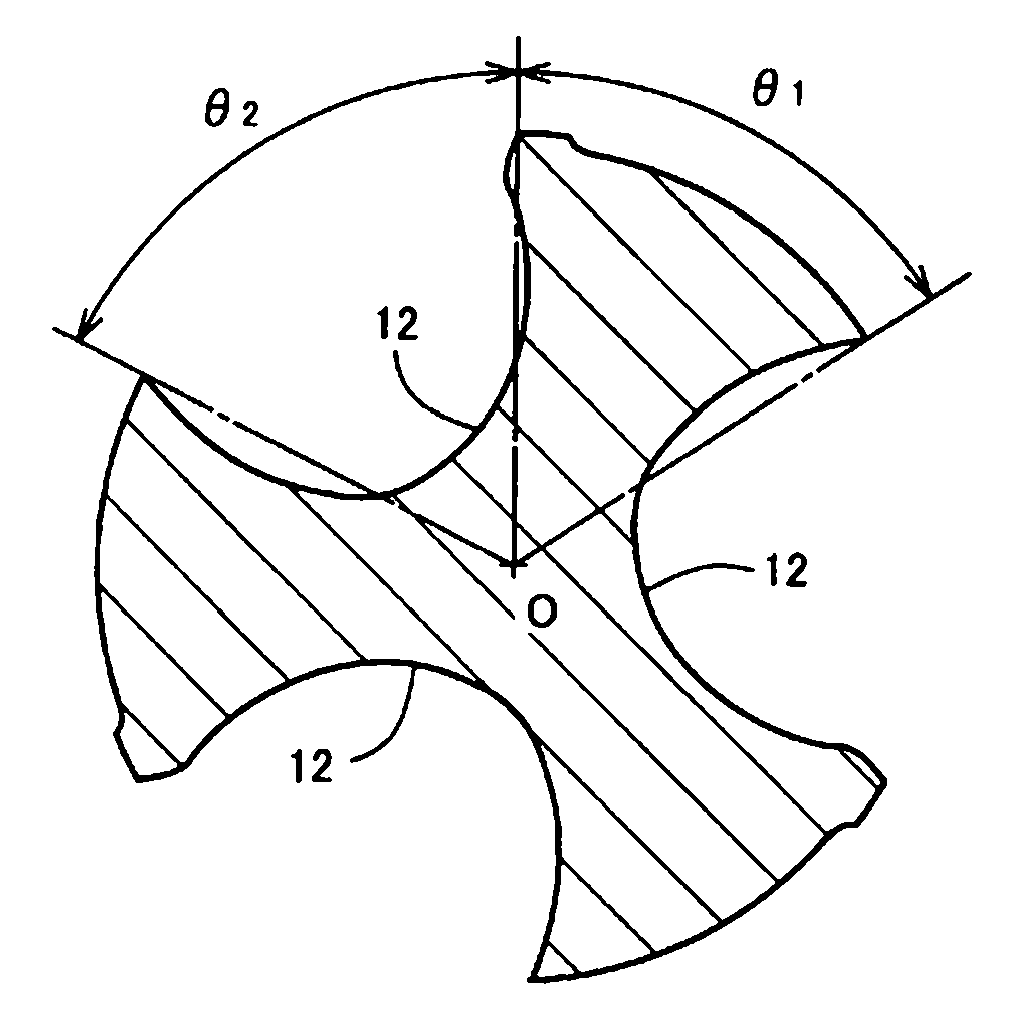

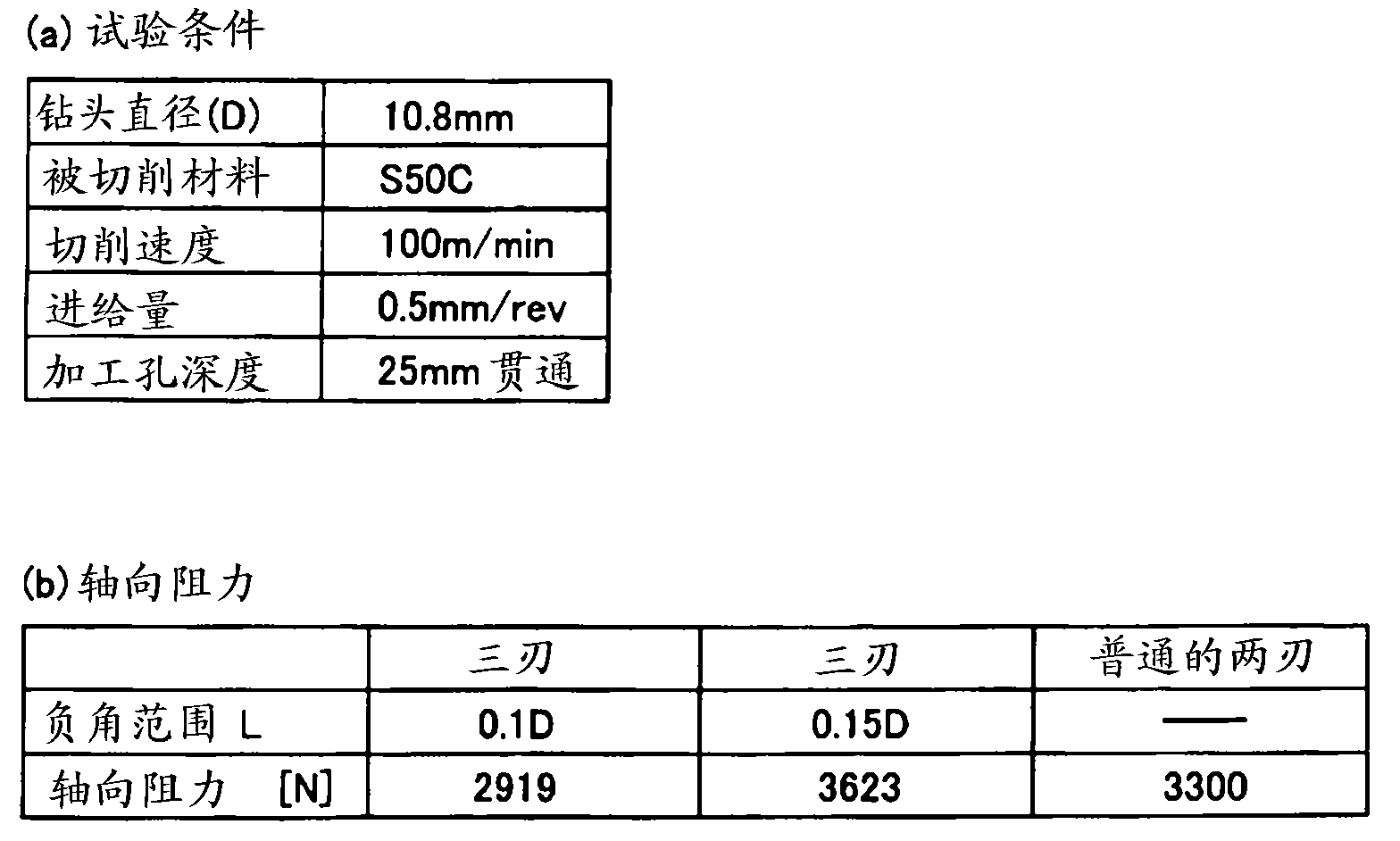

Drill

InactiveCN102170989AEasy to curlImprove discharge effectTransportation and packagingWorkpiecesEdge strengthEngineering

Owner:OSG

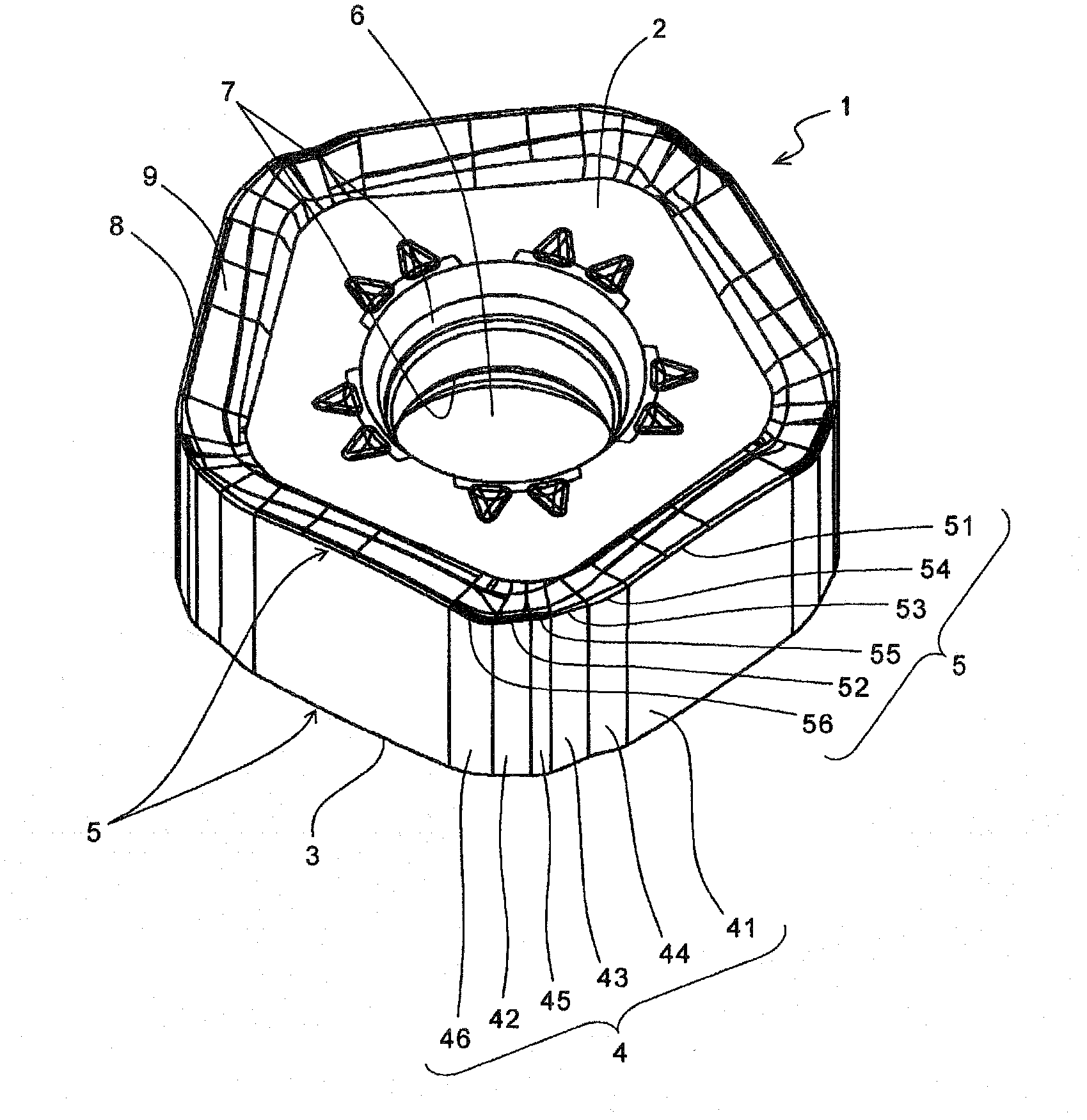

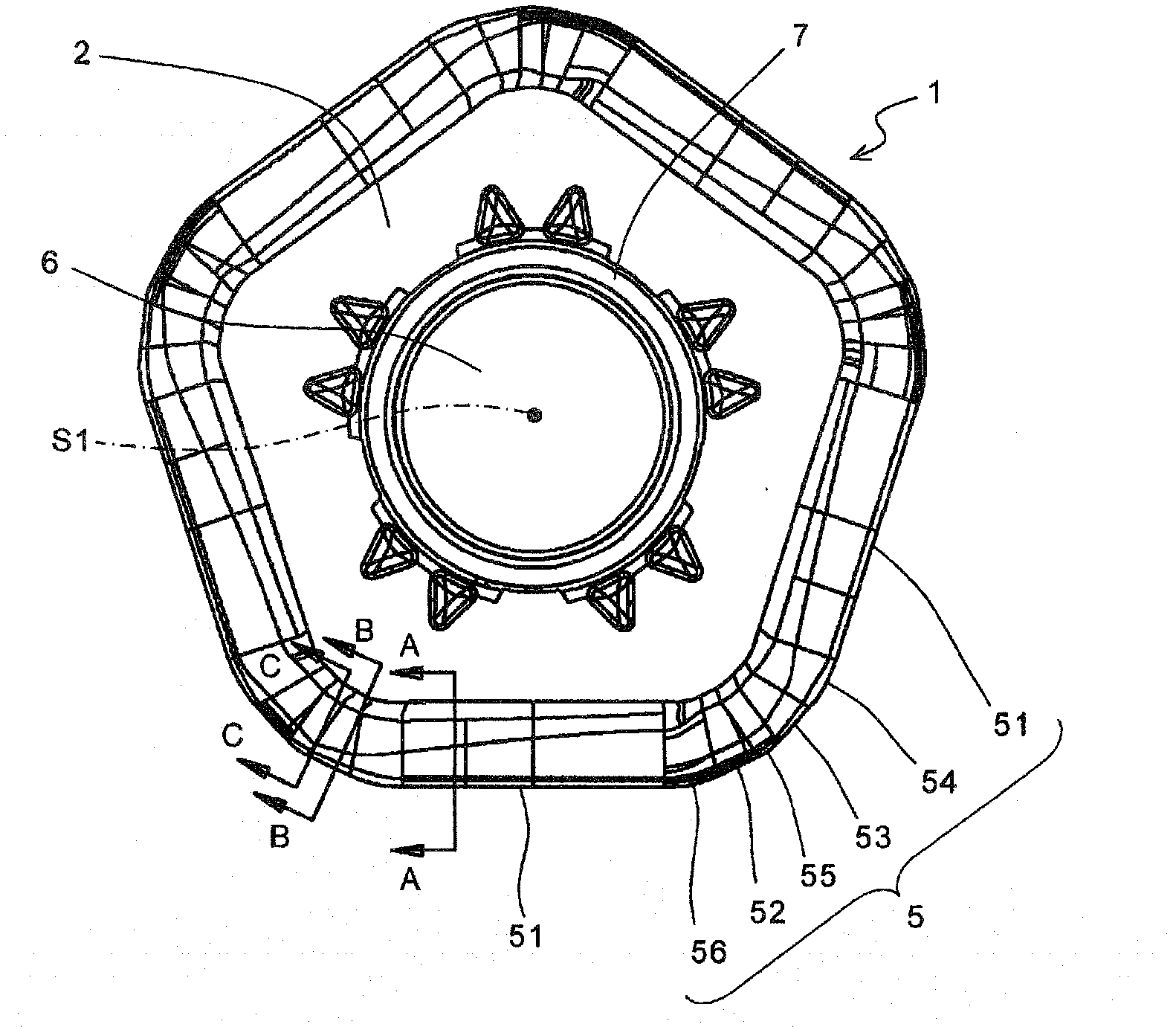

Cutting insert, cutting tool, and method for producing cut product using said cutting insert and cutting tool

ActiveCN103118822AStable discharge directionImprove discharge effectMilling cuttersCutting insertsEngineeringBiomedical engineering

The invention provides a cutting insert, a cutting tool, and a method for producing cut product using said cutting insert and cutting tool. The cutting insert according to the embodiments of the present application is provided with an upper surface, side surfaces, and a first cutting blade positioned at the intersection line of the upper surface and the side surfaces, wherein: the upper surface is provided with a pair of ridges positioned so as to face one another with the perpendicular bisector of the first cutting blade therebetween; the top portion of each ridge has at least two protrusions oriented in the direction along the aforementioned perpendicular bisector when viewed from above; and the aforementioned protrusions are provided with a first protruding section positioned the closest to the aforementioned perpendicular bisector, and a second protruding section positioned further away from the aforementioned perpendicular bisector than the first protruding section and at a higher position than the first protruding section. Also provided are a cutting tool provided with the aforementioned cutting insert and a method for producing a cut product by using said cutting tool.

Owner:KYOCERA CORP

Cutting insert and cutting tool, and cut workpiece manufacturing method using same

ActiveCN102548694ASuitable for curlImprove discharge effectMilling cuttersMilling equipment detailsMechanical engineeringReference plane

A cutting insert is provided with an upper surface, a lower surface, side surfaces, and cutting edges located respectively at the intersection lines between the upper surface and the side surfaces, and comprises a main cutting edge, a flat cutting edge, and an auxiliary cutting edge that is located between the main cutting edge and the flat cutting edge. In a side view, the cutting edge inclines upward with respect to a reference plane perpendicular to the center axis of the cutting insert, starting from the flat cutting edge toward the main cutting edge, until a top section is reached, whereupon the cutting edge inclines downward with respect to the reference plane, and the outer peripheral cutting edge angle of the auxiliary cutting edge is larger than the outer peripheral cutting edge angle of the main cutting edge. Provided are a cutting tool equipped with the cutting insert, and a cut workpiece manufacturing method using the cutting tool.

Owner:KYOCERA CORP

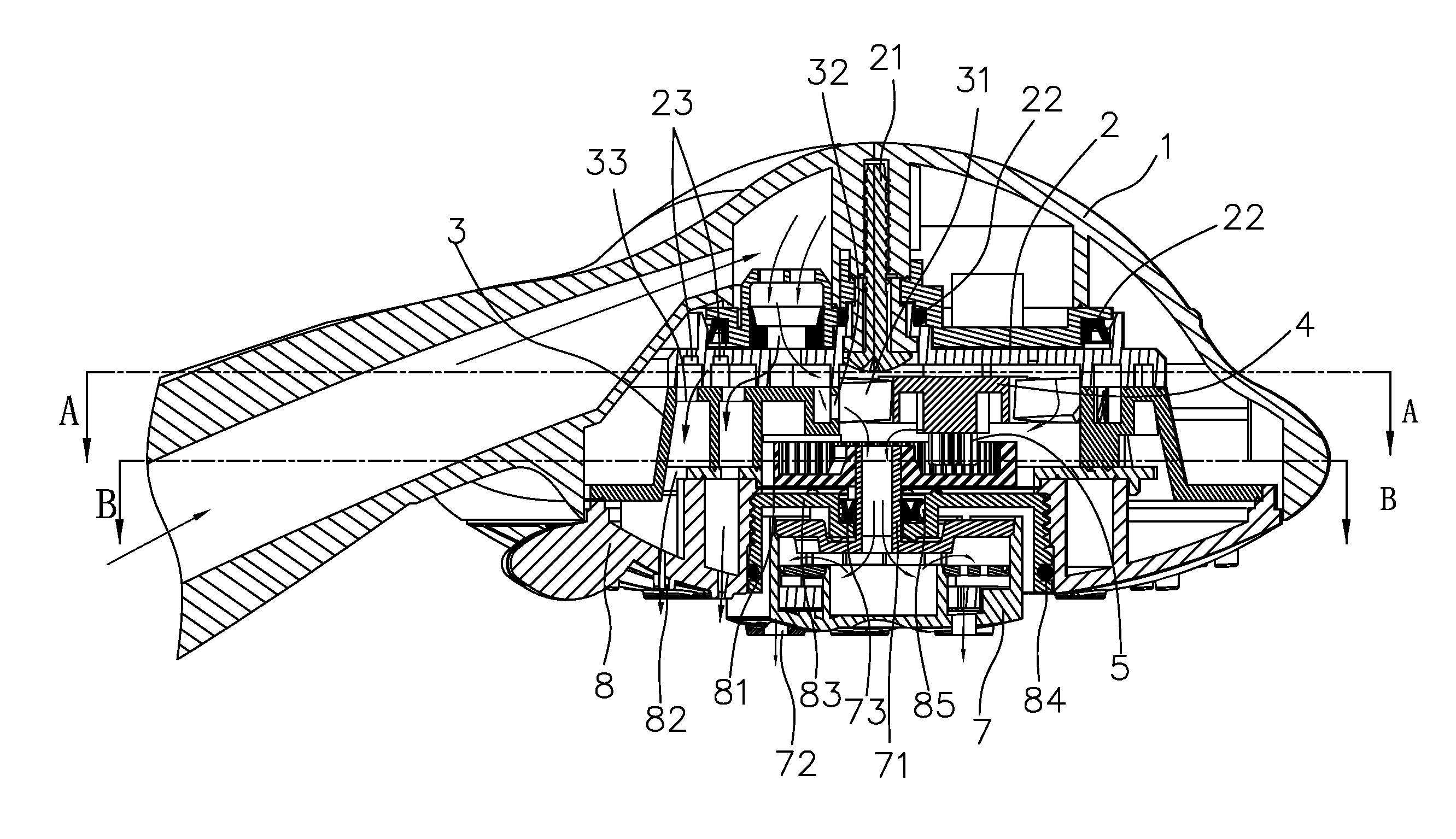

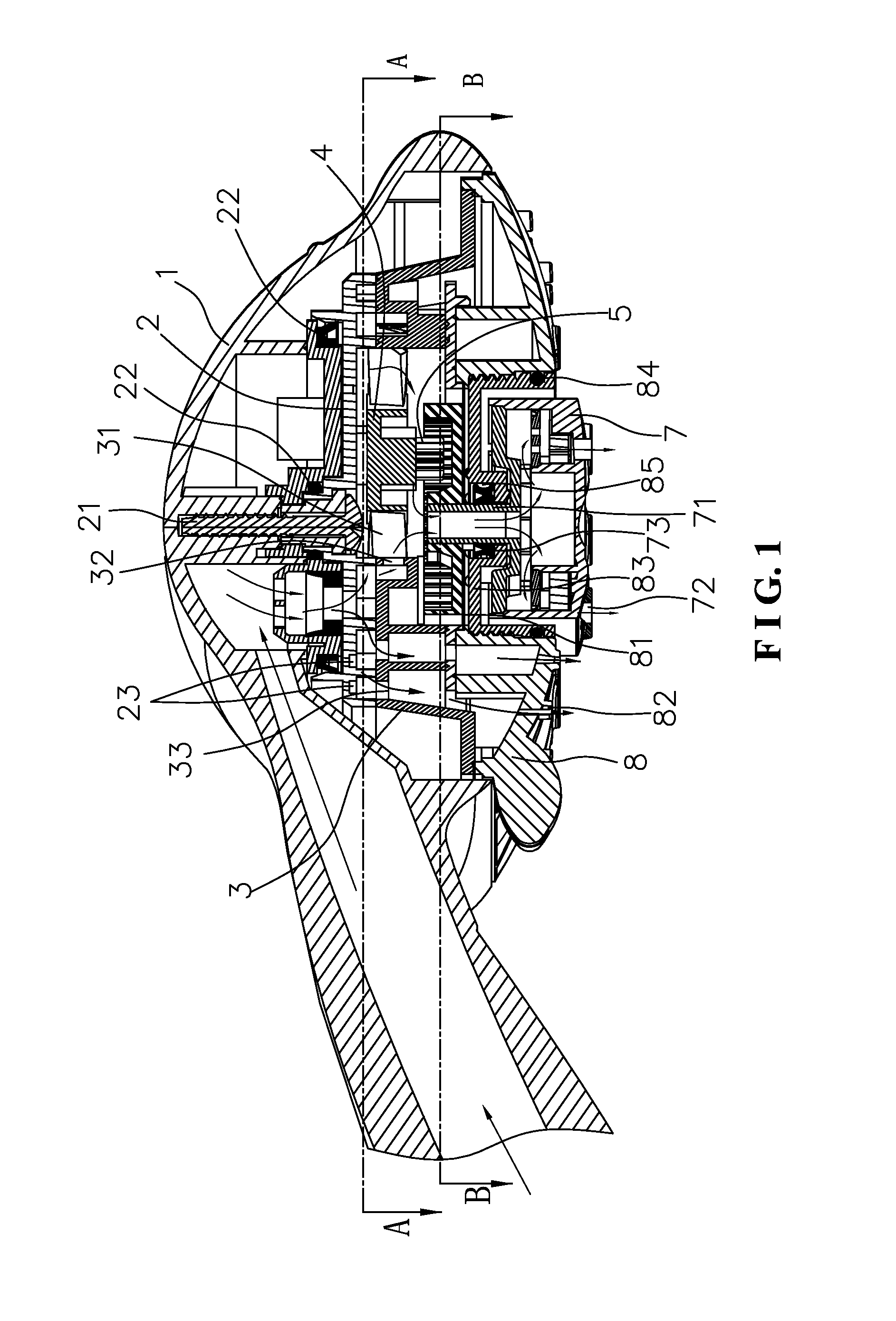

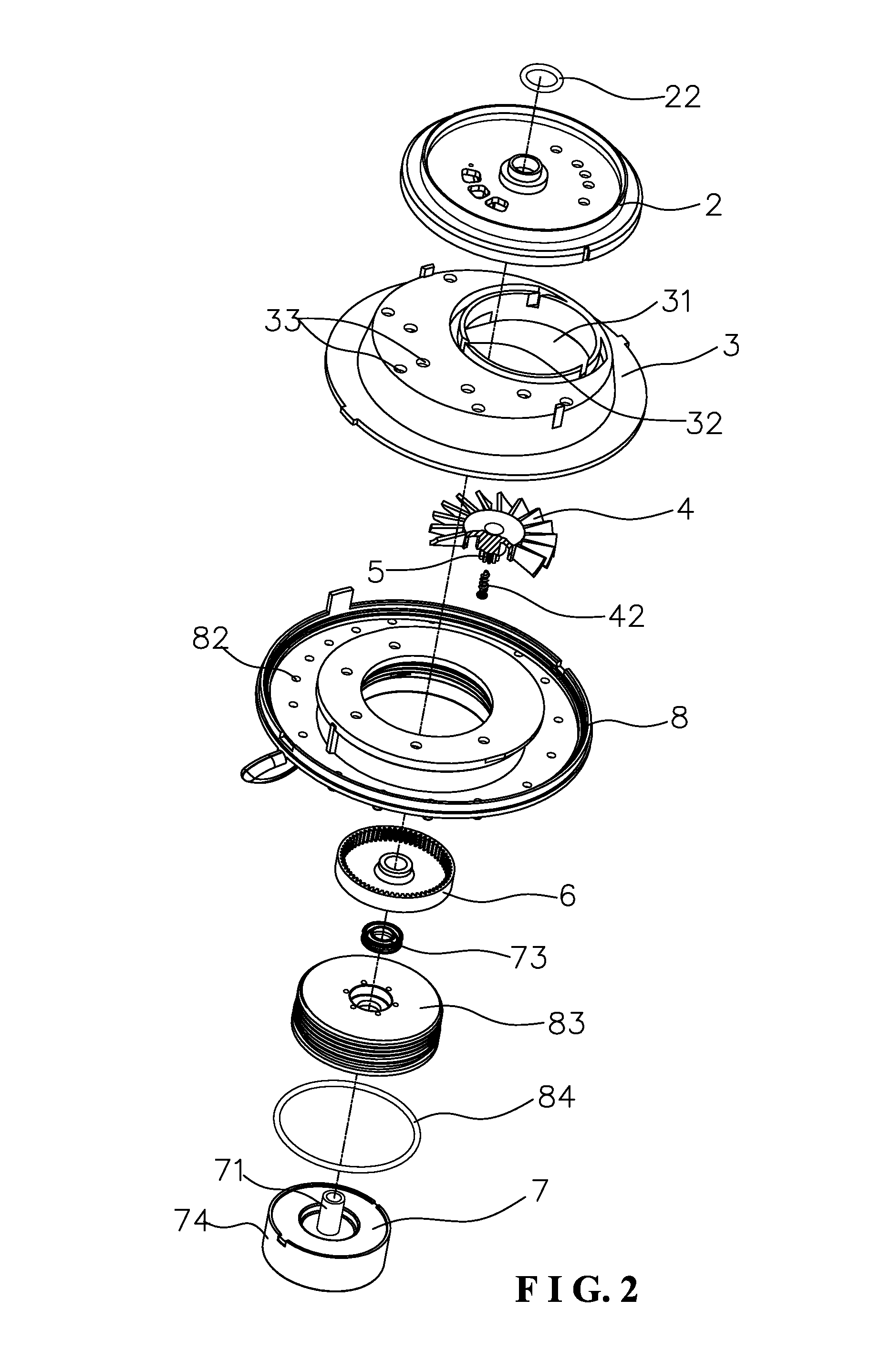

Rotary spray shower head

ActiveUS20140110502A1Simple structureSpeed controllableMovable spraying apparatusSpray nozzlesReduction driveGear wheel

A rotary spray shower head includes a main body, a water distributing plate, a rear faceplate, an impeller, a pinion, a driven gear, a water outlet head assembly and a discharge faceplate. The present invention is simple in structure. When in use, one portion achieves an ordinary discharge function of the shower head, and another portion achieves a rotary discharge function. The present invention uses the pinion and the driven gear to constitute a planet deceleration. The rotating speed can be controlled, and the rotary spray discharge effect is good.

Owner:SINYU TECH FUJIAN

Environment-friendly paste discharge agent for textile printing and preparation method thereof

ActiveCN102704292ANon-oxidizingNon-reducibleTransportation and packagingMixingSolubilityTextile printer

The invention discloses an environment-friendly paste discharge agent for textile printing and a preparation method thereof. The environment-friendly paste discharge agent comprises the following components in parts by weight: 30-60 parts of decamethyl cyclopentasiloxane, 40-70 parts of thiourea dioxide, 1-3 parts of surfactant and 3-6 parts of glycerin. The preparation method comprises the steps: putting the decamethyl cyclopentasiloxane into a ball grinder container; adding the surfactant to be uniformly dispersed or dissolved and uniformly agitated; and then adding the thiourea dioxide into the ball grinder container to blend and grind for 1-3 hours. Specific liquid compound decamethyl cyclopentasiloxane as a disperse medium and the thiourea dioxide are not subjected to chemical reaction; With the environment-friendly paste discharge agent provided by the invention, contact of the thiourea dioxide with the external water and air is isolated; the stability of the thiourea dioxide is improved; the discharge effect is excellent; and the problems of low solubility, poor dispersible uniformity in discharge pulp, poor net permeability and insufficient development of the discharge action caused by common thiourea dioxide used as the discharge agent are overcome.

Owner:HAINING GREEN SHIELD TEXTILE TECH CO LTD

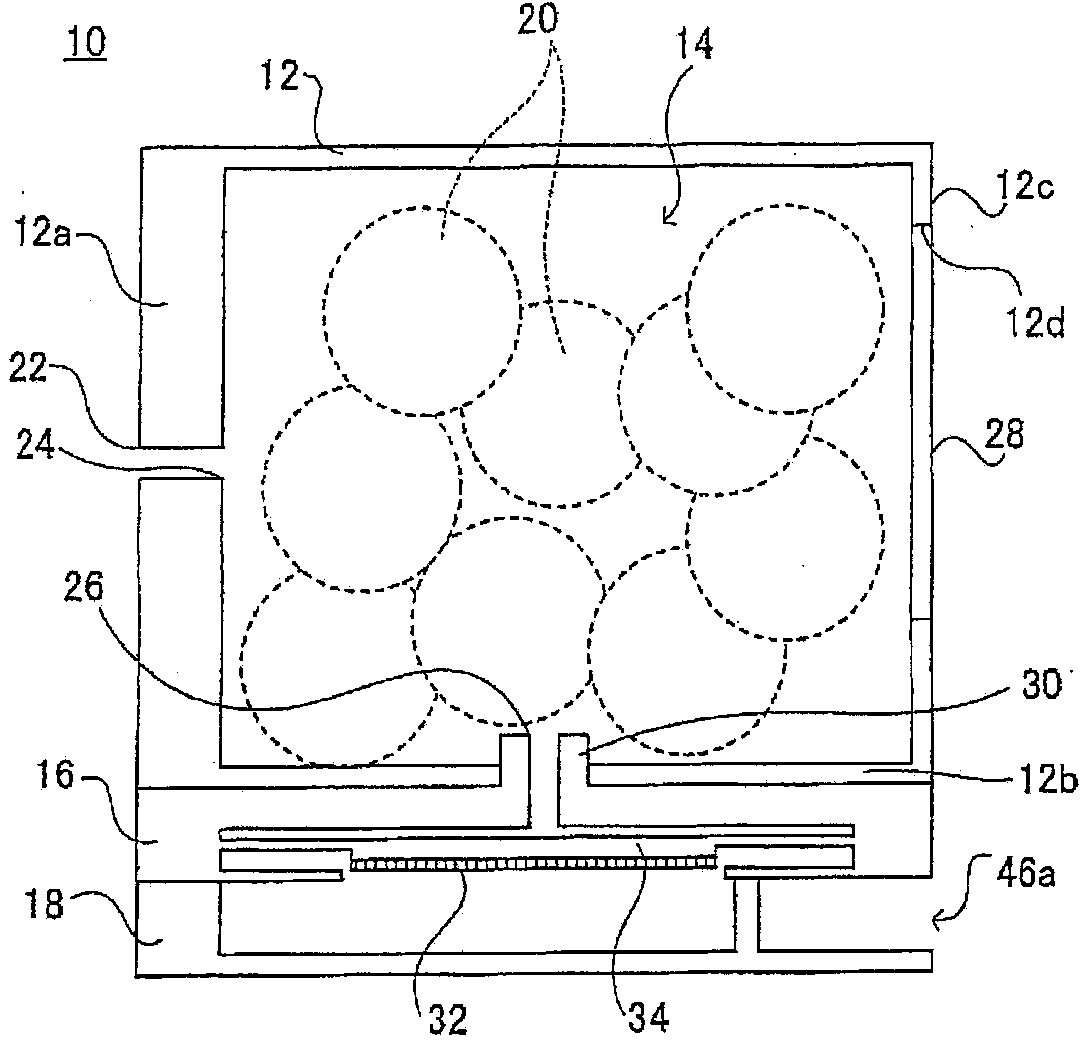

Olfactory display

ActiveCN103403785AImprove responsivenessEasy to useTransportation and packagingFlexible member pumpsDisplay deviceEngineering

The present invention provides an olfactory display (10) which includes a housing (12) that has a spray opening (22) and presents aromas in a temporally and spatially limited range. An aroma chamber (14) that has an in-draft opening (26) and an aroma outlet (24) linked to the spray opening (22) is formed in the housing (12), and an aroma source (20) in a solid form is accommodated in this aroma chamber (14). In addition, a blowing force source (16) provided with a diaphragm (34) to which a piezoelectric element (32) is attached is provided in the aroma chamber (14). When an aroma is presented, air inside the aroma chamber (14), which includes an aroma component in a gaseous form volatized from the aroma source (20) by the blowing force source (16) blowing air into the aroma chamber (14) from the in-draft opening (26), passes through the aroma outlet (24) and is sprayed from the spray opening (22).

Owner:NAT INST OF INFORMATION & COMM TECH

Calcium sulfate composite oxidant for fireworks and crackers and preparation method thereof

The invention relates to a calcium sulfate composite oxidant for fireworks and crackers and a preparation method thereof, belonging to the technical field of chemical raw materials of the industry of the fireworks and crackers. The oxidant takes calcium sulfate and iron oxide as a main body assisted by barium nitrate, takes potassium permanganate and potassium perchlorate as initiators, and is added a small amount of an active agent. The preparation method comprises the following steps: roasting gypsum (calcium sulfate dihydrate), smashing, adding a mixed powder body of potassium permanganate and potassium perchlorate, grinding, smashing iron oxide, adding the active agent into the iron oxide powder, and then adding barium nitrate and grinding; and uniformly mixing the two types of ground powder. One of main raw materials of the invention is calcium sulfate which is non-toxic and has low price, and after being roasted the calcium sulfate, the calcium sulfate is not only an oxidant but also a moisture-proof agent and a leavening agent and also is a mechanical sensitivity buffer which is fine and smooth and slippery. Since the composite oxidant of the invention is prepared into the fireworks and crackers according to the traditional method, the fireworks and crackers has the advantages that the burning property is good, the safety is strong, the friction sensitivity and impact sensitivity are zero, and the production cost is greatly reduced.

Owner:谢新佑

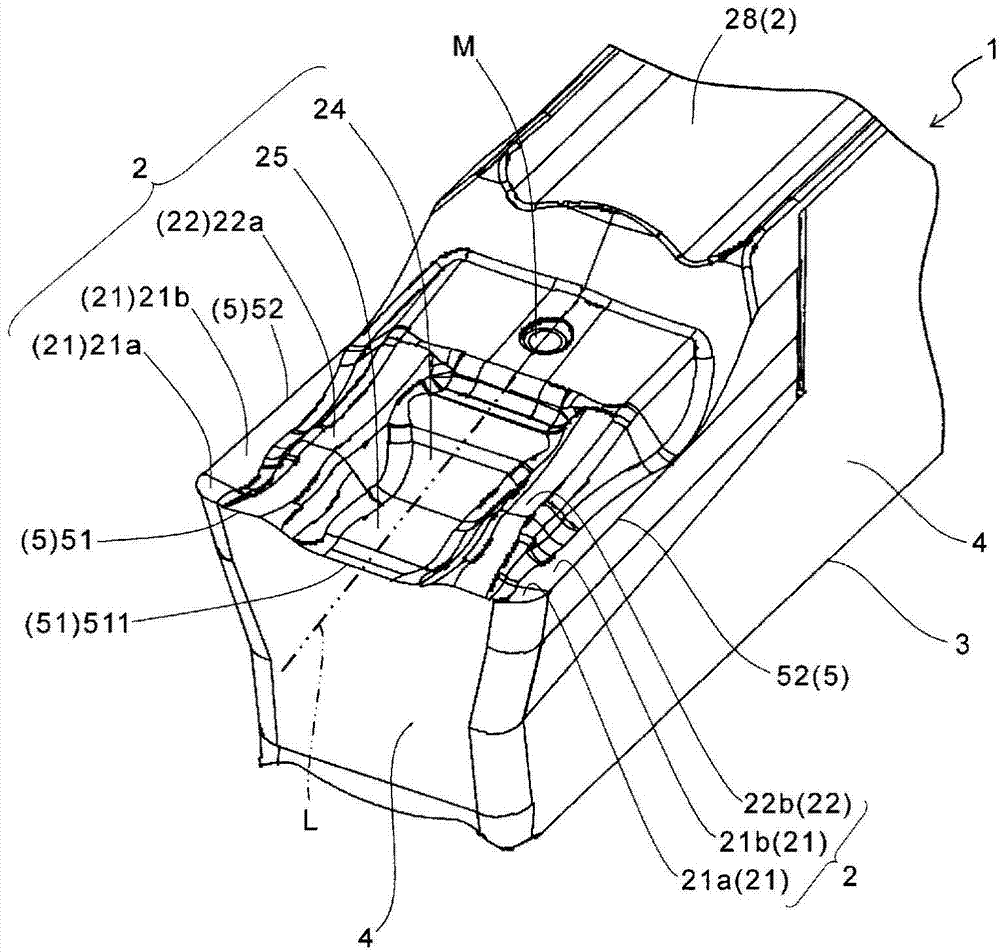

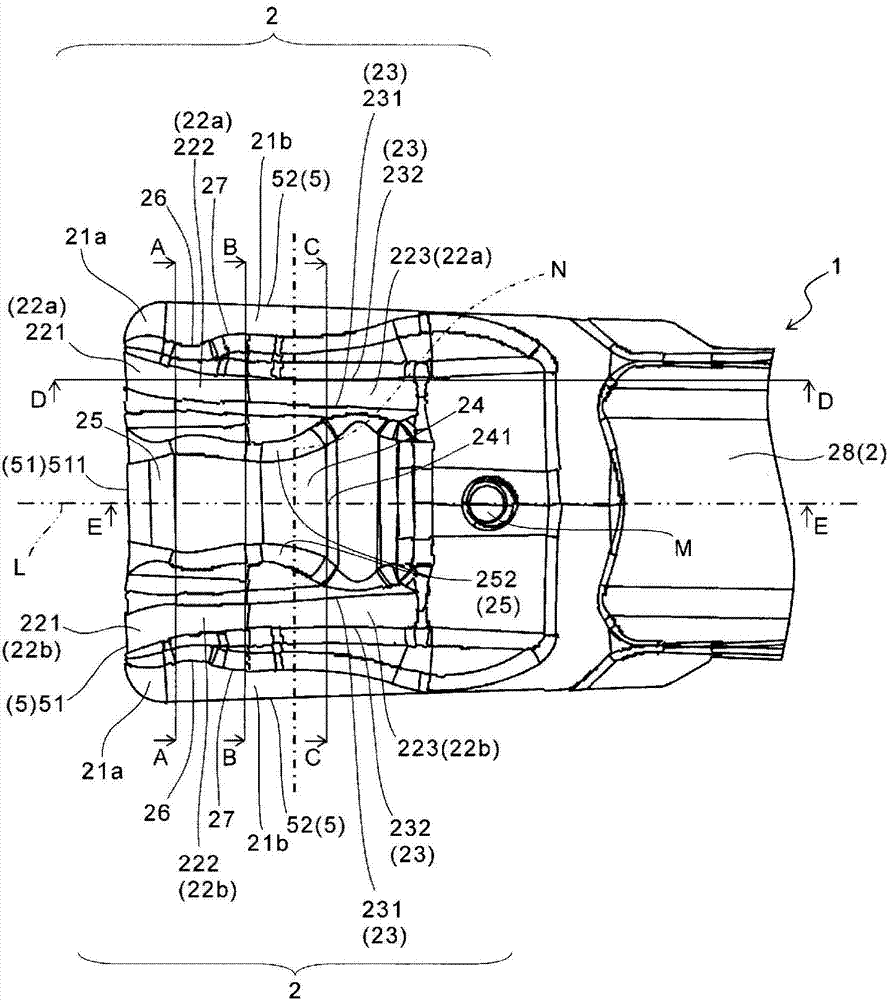

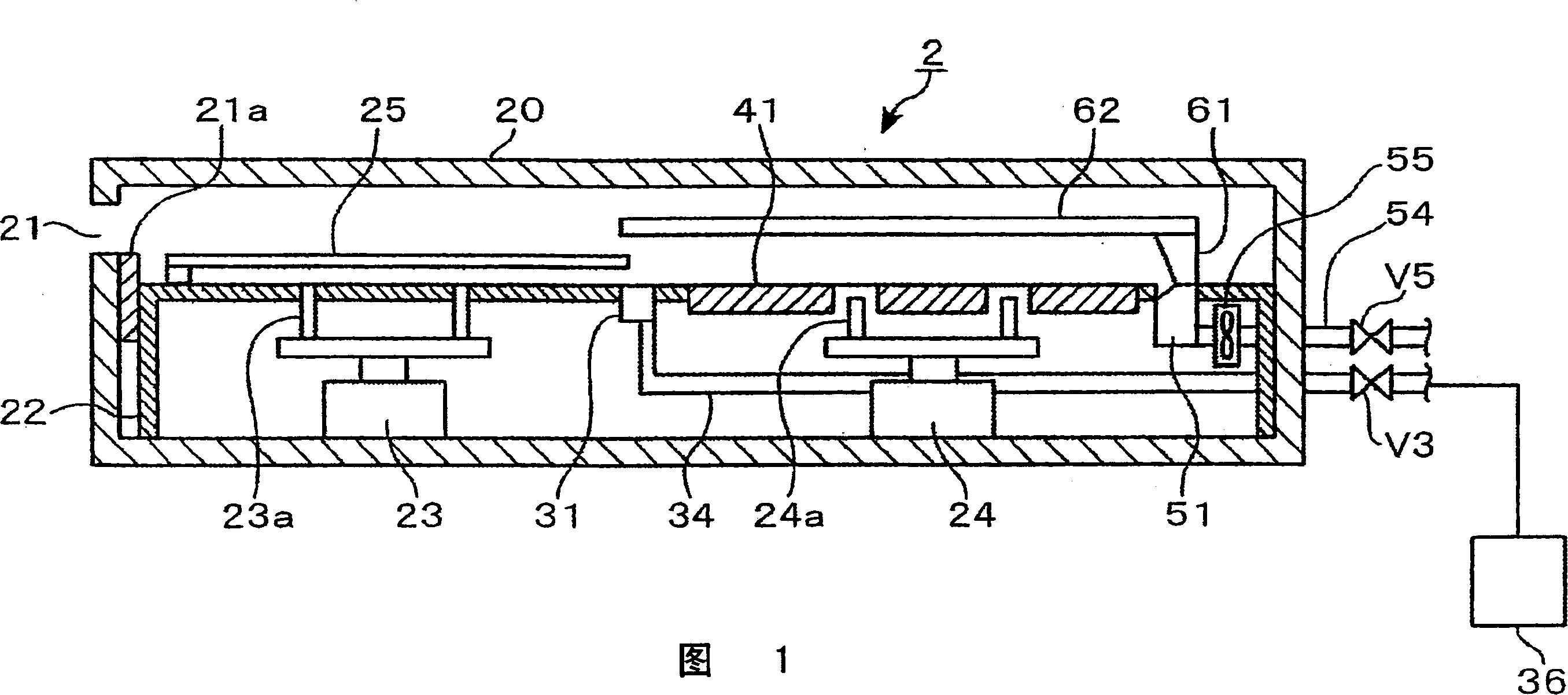

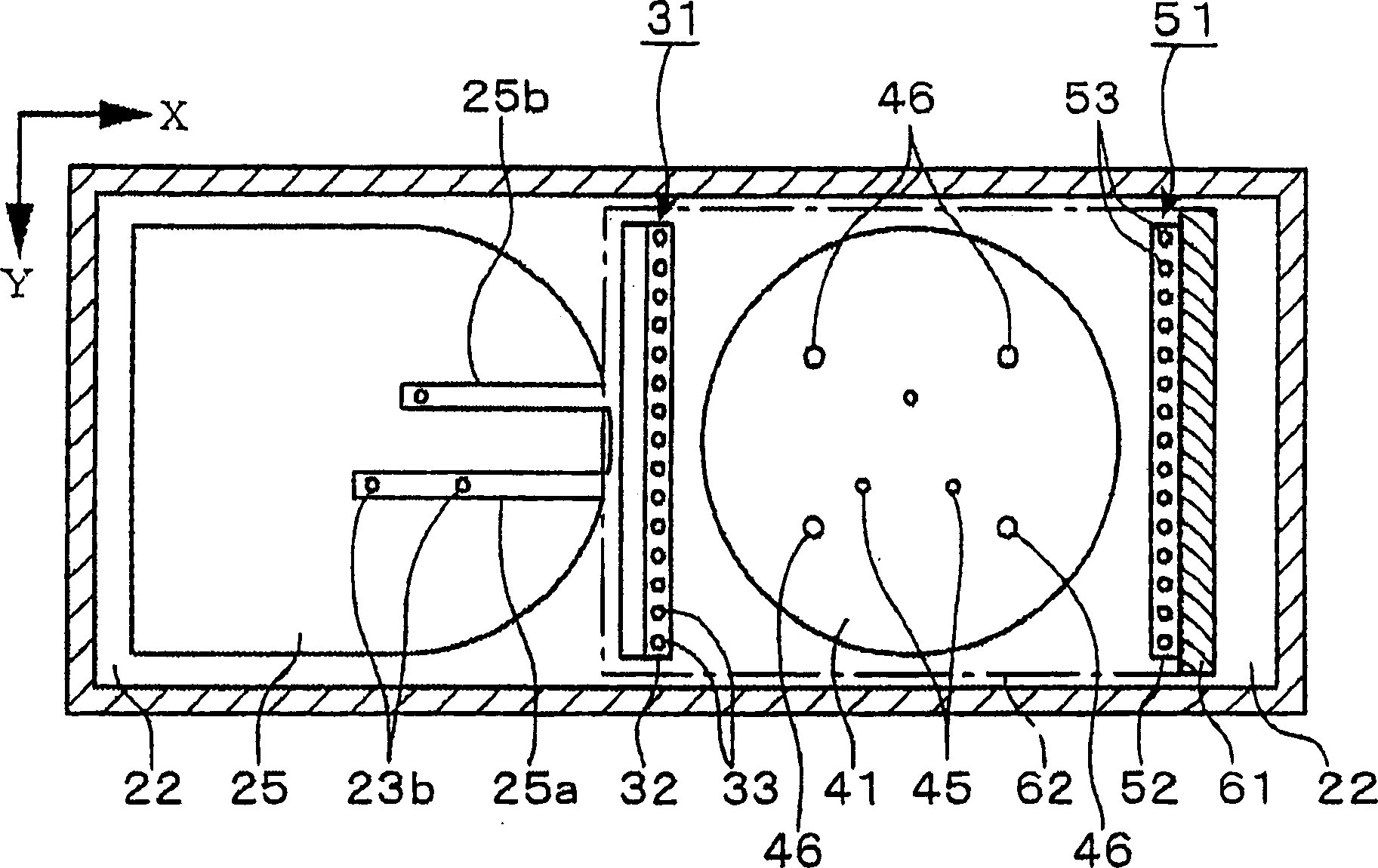

Flushing toilet

The invention provides a flushing toilet capable of truly forming a beamed main stream facing an inlet of a drain elbow portion, thus improving sewage discharge performance; specifically, the flushing toilet (1) comprises the following elements: a basin portion (12) having basin sewage bearing surface (16) and an inner edge (18) positioned in the upper edge and having an inner periphery; a drain elbow pipe (14) discharging the sewage; an inner edge water sprayer portion (28) spraying cleaning water from the inner edge water sprayer along the inner periphery of the inner edge, thus forming a convolution flow. The inner edge portion allows the inner periphery to expose to an inner space of the basin portion, thus forming a suspension shape; the inner periphery (30) comprises the bottom face (30a), a side face (30b) extending from the outer end of the bottom edge to an upper portion, and an upper surface (30c) extending from the top of the side face to the inner space; guide portions (40, 50) are formed in the basin portion and used for guiding the cleaning water, sprayed from the inner sprayer portion, to the top of the inner edge portion, to the water can fall to a set position of the basin portion.

Owner:TOTO LTD

Heat conducting pipe type wet material dryer and drying method thereof

InactiveCN105115265AImprove drying efficiencyEliminate fire hazardsDrying gas arrangementsDrying machines with non-progressive movementsHeat conductingWater vapor

The invention discloses a heat conducting pipe type wet material dryer which comprises a support. A heating drum is arranged on the support, rotatable heat conducting pipes are arranged in the heating drum, and scraper plates are arranged on the peripheral heat conducting pipes. The whole support is obliquely arranged, the higher end of the heating drum of the dryer is connected with a hot blast furnace, the end, close to the hot blast furnace, of the heating drum is provided with a feeding inlet, and the other end of the heating drum is provided with a dried material discharging outlet. The heat conducting pipes are communicated with the hot blast furnace through a first pipeline. High-temperature hot air generated by the hot blast furnace flows through the heat conducting pipes, wet materials to be dried are completely isolated from the high-temperature hot air, and therefore the potential hazard of fires of the materials is eliminated; the wet materials to be dried enter from the high-temperature end close to the hot blast furnace, vapor outlets are formed in the high-temperature end, and when the wet materials enter the high-temperature end, a large amount of generated vapor is directly exhausted from the vapor outlets through a vapor exhaust fan and a cyclone separator; the vapor exhausting effect is good, the material drying effect is good, and the drying efficiency is high.

Owner:宜兴市凯世达科技有限公司

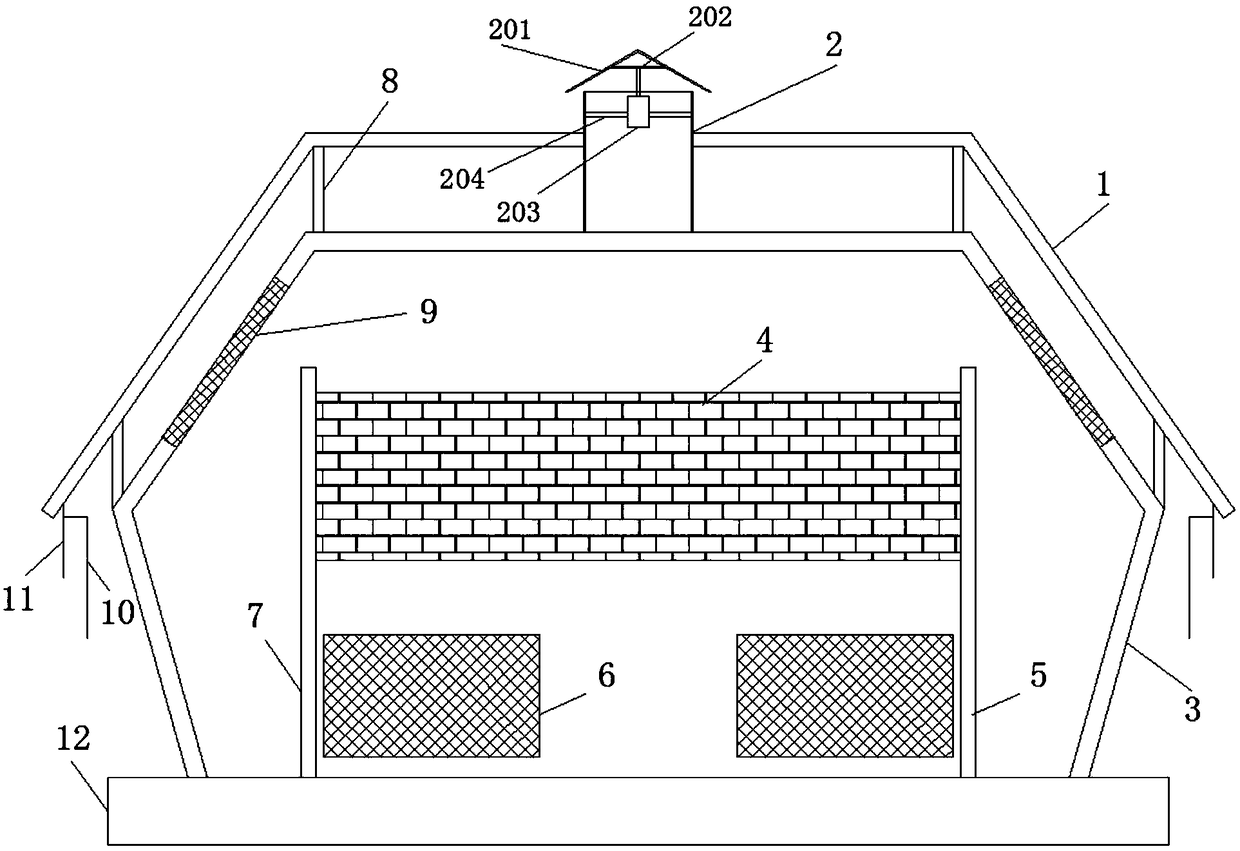

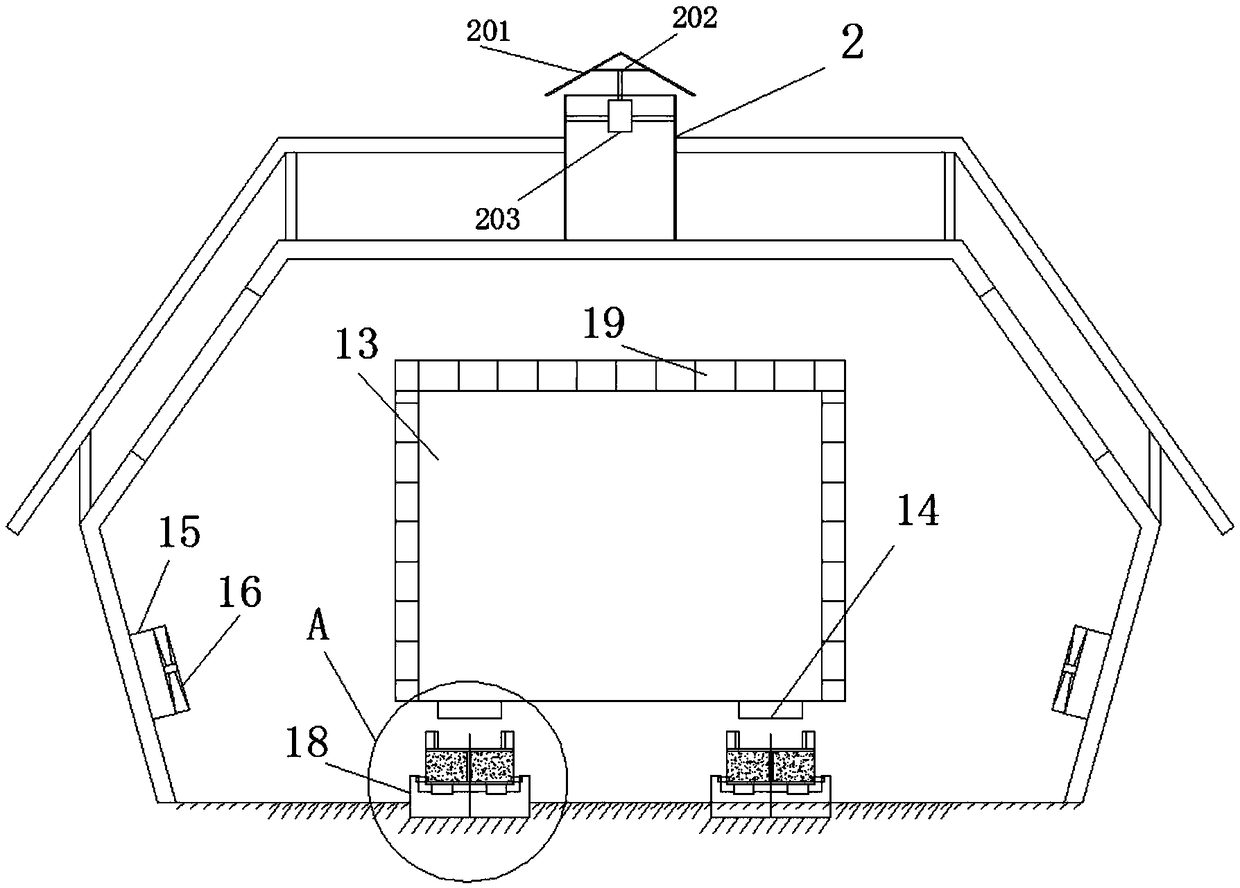

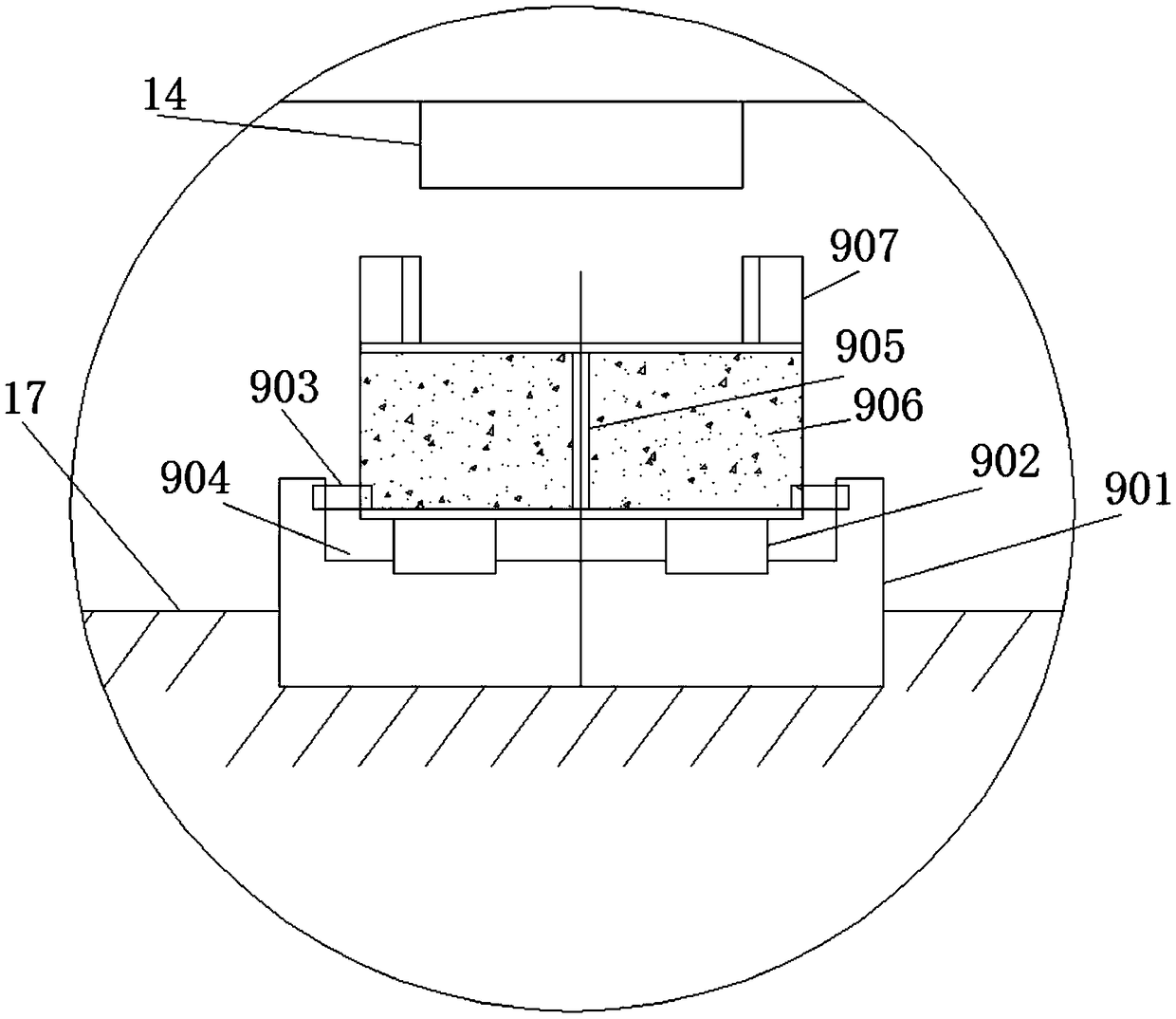

An outdoor box-type transformer device

ActiveCN109193417ARealize the big cycleImprove cooling effectTransformers/inductances coolingTransformers/inductances casingsTransformerEngineering

The invention discloses an outdoor box-type transformer device, which can circulate airflow in a large area of the box body, the box body structure is more reasonable, and is more conducive to the promotion of heat dissipation effect. The invention comprises a box body and a transformer body arranged in the box body; a lid is arranged on that top of the box body; the box body is installed on the base, and the box body comprises a left side and a right side and two front and rear end faces; an end face is provided with a door plate, an air inlet is arranged at a position close to the bottom ofat least one end face, and an air inlet assembly is installed on the air inlet; the two sides are symmetrically arranged and each side comprises an upper side plate and a lower side plate, and the included angle between the upper side plate and the lower side plate is an obtuse angle; the top plate of the box body is provided with an air exhaust outlet, and the air exhaust outlet is provided withan air exhaust component; the exhaust assembly passes upward through the box cover; the case cover includes a horizontal portion for covering the top plate of the case and an inclined portion arrangedon both sides of the horizontal portion for covering the upper side plates on both sides of the case. The distance between the lid and the box is L, and L is greater than 0.

Owner:国网新疆电力有限公司和田供电公司 +1

Pre-dispersed master batch particle for rubber vulcanization cross-linking and preparation method of pre-dispersed master batch particle

ActiveCN104844856AImprove vulcanization efficiencyIncrease the degree of cross-linkingRubber materialDispersity

The invention discloses a pre-dispersed master batch particle for rubber vulcanization cross-linking and a preparation method of the pre-dispersed master batch particle. The pre-dispersed master batch particle comprises, by weight, 30-50 parts of trithiocyanuric acid, 20-40 parts of 1, 1'-dithiobiscaprolactam, 3-10 parts of coupling agents, 3-10 parts of inorganic fillers, 5-10 parts of softening oil, 2-5 parts of processing agents and 5-40 parts of rubber carriers. By the preparation method of the pre-dispersed master batch particle, dispersity of active components is improved, the master batch particle is uniformly discharged, the surface of the particle is smooth, the master batch particle has fine processing performance and is used for preparing rubber materials, vulcanization time is shortened, and the mechanical property of vulcanized rubber is effectively improved.

Owner:NINGBO ACTMIX POLYMER

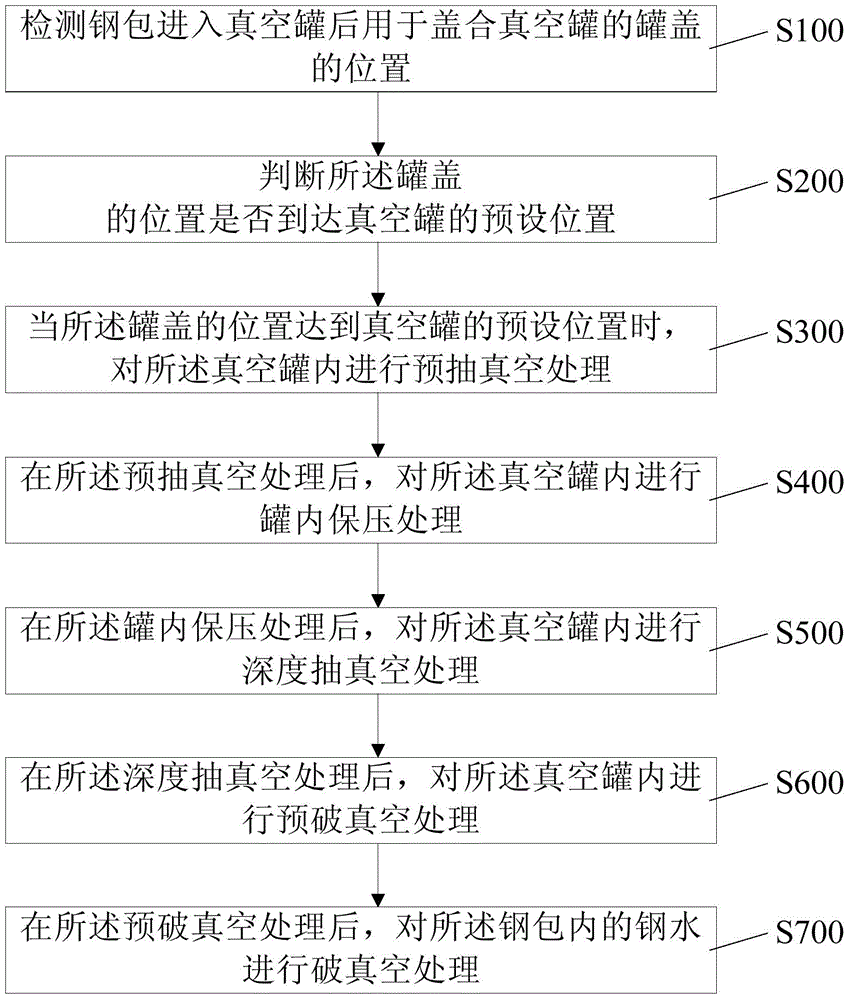

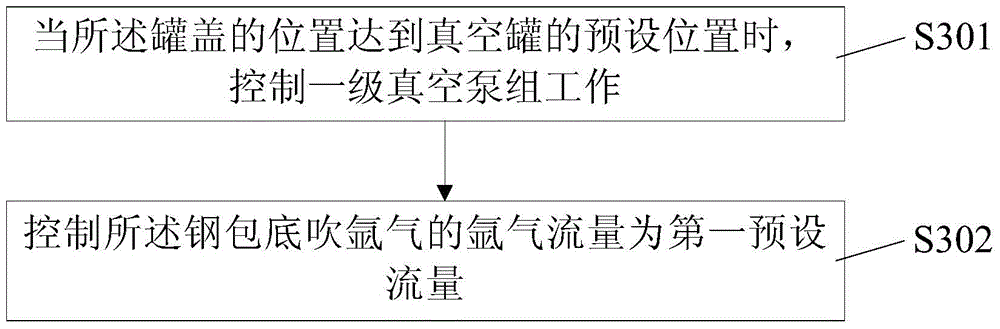

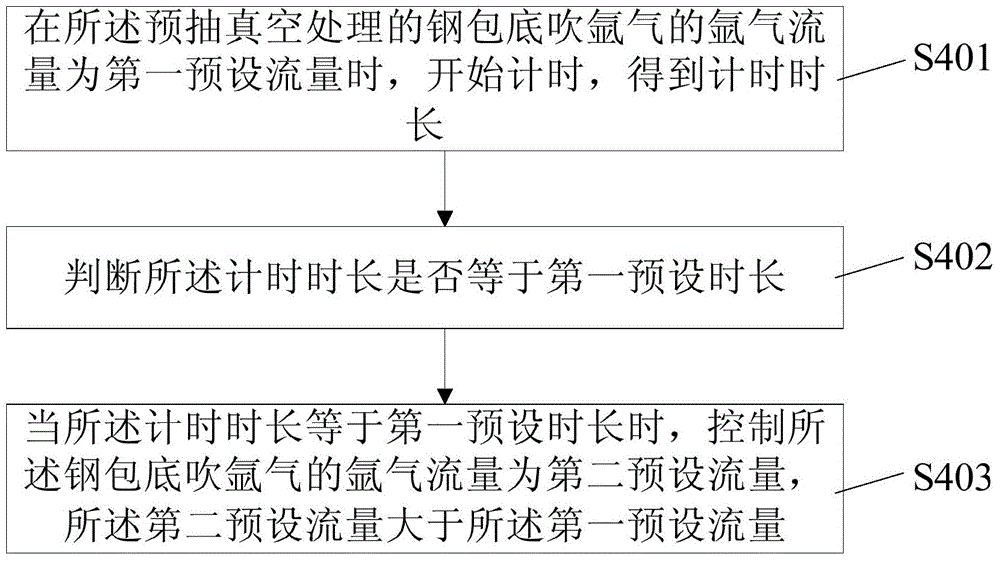

Vacuumizing control method and system of VD mechanical pump

The embodiment of the invention discloses a vacuumizing control method and system of a VD mechanical pump. The vacuumizing control method of the VD mechanical pump comprises the following steps: detecting a position of a tank cover used for covering a vacuum tank after a steel ladle enters the vacuum tank, judging whether the tank cover reaches a preset position in the vacuum tank, when the tank cover reaches the preset position in the vacuum tank, performing pre-vacuumizing treatment in the vacuum tank, and orderly performing in-tank pressure-holding treatment, deep vacuumizing treatment, pre-vacuum-breaking treatment and vacuum-breaking treatment in the vacuum tank after the pre-vacuumizing treatment. The vacuumizing treatment is performed on the molten steel in the steel ladle in the vacuum tank through the vacuumizing control method of the VD mechanical pump, the equipment damage caused by molten steel slag-overflow in the steel ladle is effectively avoided, the impurities and a large amount of gas in the molten steel can be effectively removed, the cleanliness of the molten steel and the quality of the manufactured steel can be effectively improved.

Owner:SHANDONG IRON & STEEL CO LTD

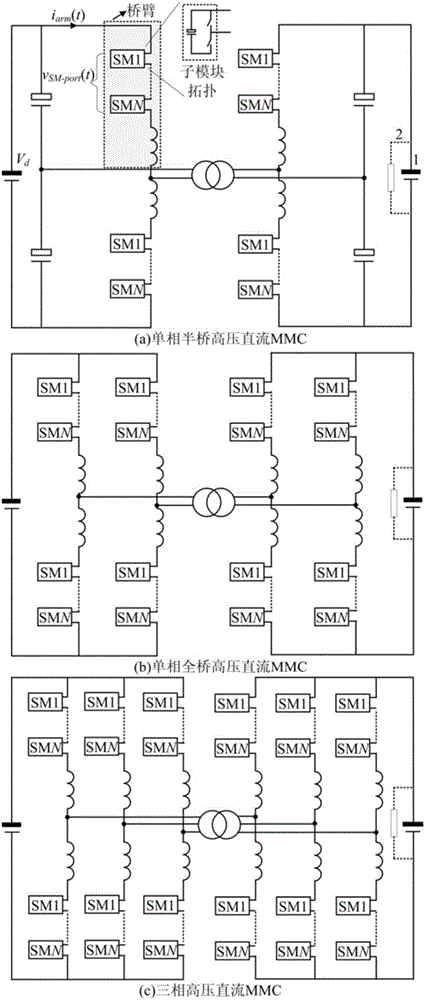

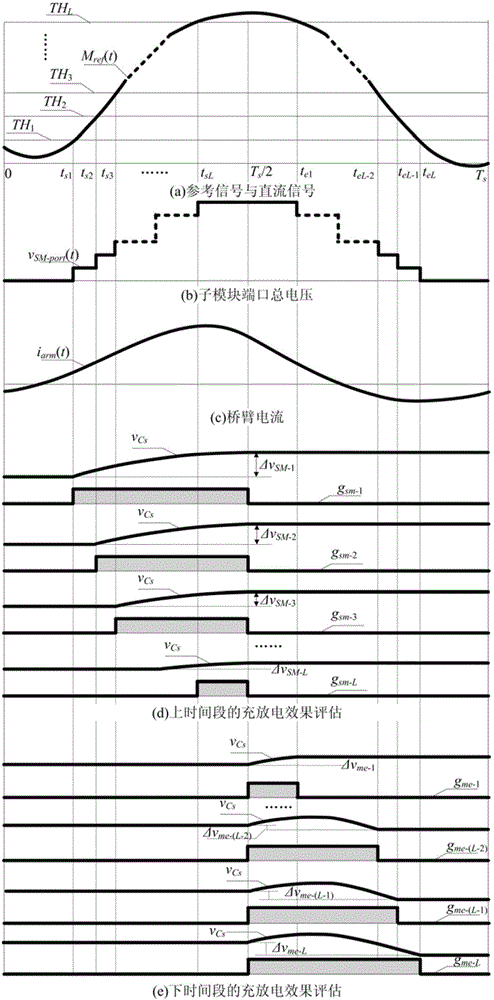

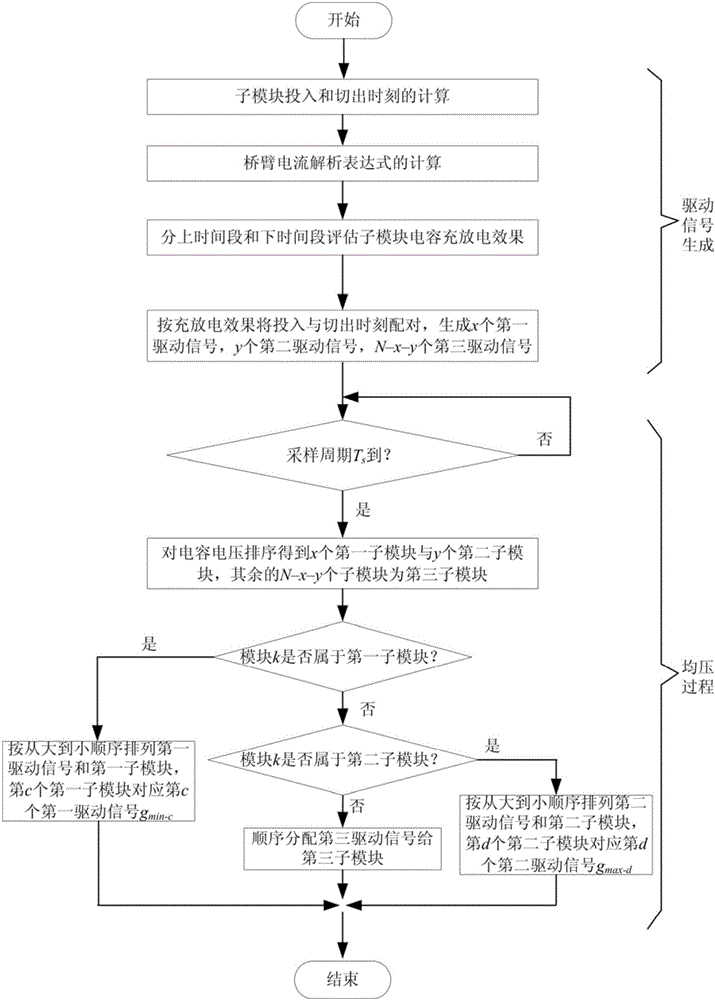

Voltage balancing method of high-voltage DC modular multilevel converter (MMC) in fundamental frequency modulation

InactiveCN105006972AReduce the number of sortsImprove discharge effectApparatus without intermediate ac conversionElectric variable regulationWave periodVIT signals

The invention discloses a voltage balancing method of a high-voltage DC modular multilevel converter (MMC) in fundamental frequency modulation. The voltage balancing method comprises the steps of S1, acquiring capacitor voltage of N sub-modules at the starting time of an i-th fundamental wave period, and selecting x first sub-modules with relatively large capacitor voltages and y second sub-modules with relatively small capacitor voltages in the N sub-modules, and using the residual sub-modules as third sub-modules; S2, controlling for making the capacitor voltages of the first sub-modules at the ending time of the current fundamental wave period smaller than the capacitor voltage of the first sub-modules at the starting time through a first driving signal, controlling for making the capacitor voltage of the second sub-modules at the ending time of the current fundamental wave period larger than the capacitor voltage of the second sub-modules at the starting time through a second driving signal, and controlling for making the capacitor voltage of the third sub-modules at the ending time of the current fundamental wave period equal with the capacitor voltage of the third sub-modules at the starting time; and S3, performing i=i+1, and returning to the S1. The voltage balancing method can remarkably reduce an ordering calculation load in operation of a system and is suitable for any modular multilevel converter in fundamental frequency modulation. When the number of sub-modules in a bridge arm increases, the voltage balancing method has a particularly remarkable advantage in reducing the ordering load.

Owner:STATE GRID CORP OF CHINA +3

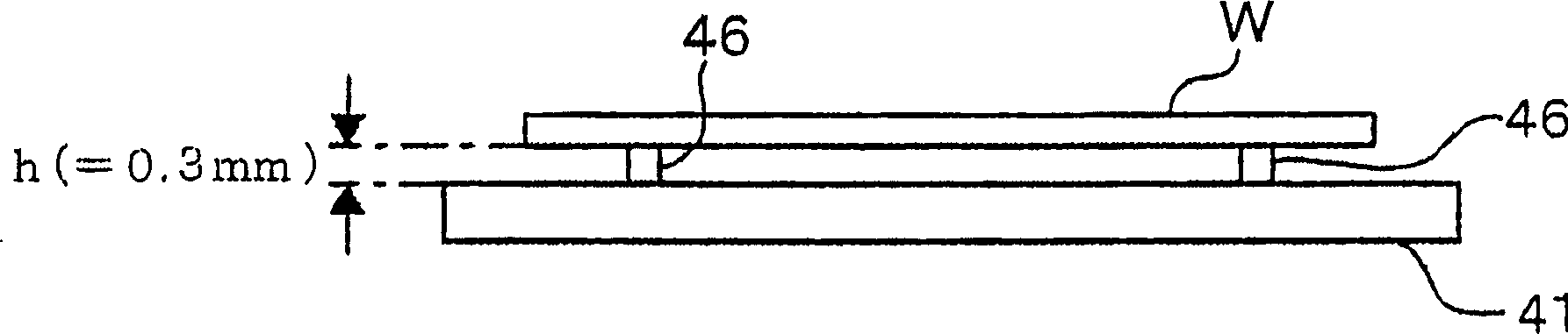

Heating apparatus, coating and development apparatus, and heating method

ActiveCN1837731AInhibition retentionUneven flow rateDrying solid materials with heatMuffle furnacesEngineeringCoating

A heating apparatus is configured to include a hot plate at which a substrate is placed, a top plate opposed to the substrate, a gas discharging part provided on one end side of the hot plate for discharging gas between the hot plate and the top plate, an exhaust part provided to be opposed to the gas discharging part with the hot plate interposed therebetween, and a heating part independently heating a first region and a second region of the substrate. A heating process is performed with good within-wafer uniformity by forming an unidirectional flow to heat the first region and the second region at different temperatures.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com