Heating apparatus, coating and development apparatus, and heating method

一种加热装置、加热方法的技术,应用在照明和加热设备、加热来干燥固体材料、炉子组件等方向,能够解决晶片弯曲程度大、位置偏移等问题,达到降低附着、防止位置偏移的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

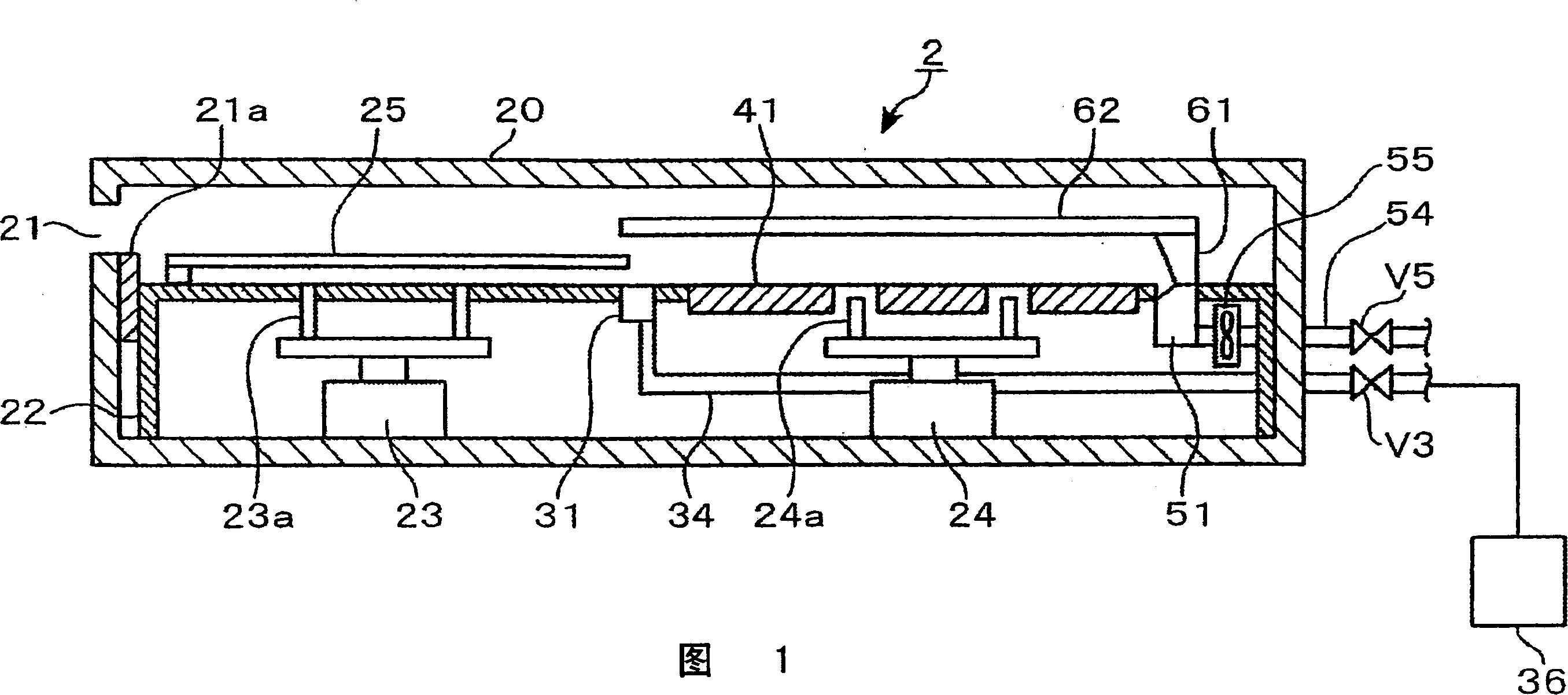

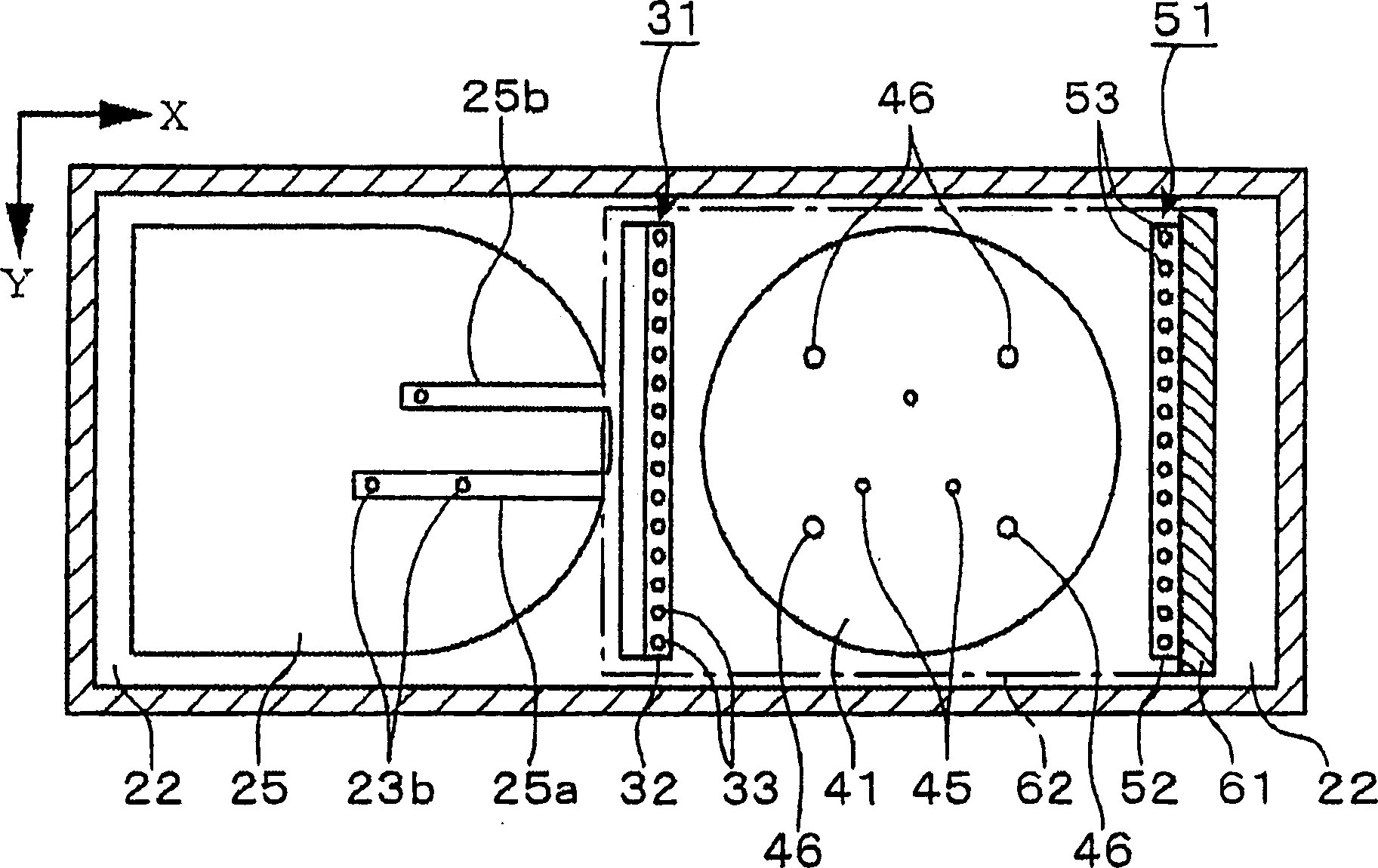

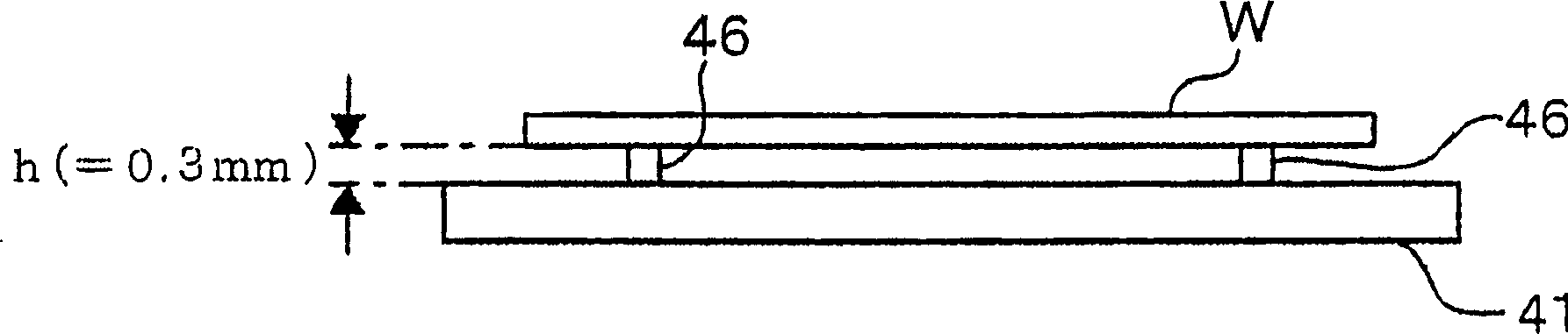

[0034] Hereinafter, as an example of an embodiment of the heating device according to the present invention, for example, a semiconductor wafer (hereinafter simply referred to as a wafer) W, on which a resist solution is applied as a coating solution on the surface, is subjected to heat treatment. The heating device 2 for forming a resist film on the surface of the wafer W will be described with reference to FIGS. 1 to 3 . In addition, as the size of the wafer W, for example, a size of 12 inches or more is used. This heating device 2 has a box body 20, and a transport port 21 for wafers W is opened on a side wall of the box body 20, and the transport port 21 is freely openable and closable by a shutter 21a. The shutter 21a is provided to prevent the airflow formed around the wafer W described later from being disturbed by outside air flowing into the housing 20 through the transfer port 21 when the wafer W is heated. 21, for example, an air curtain is provided in place of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com