Cotton cloth reactive dye discharge printing process

A technology of discharge printing and reactive dyes, applied in the field of cotton reactive dye discharge printing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] By adjusting the process formula, improve the deficiencies, and improve the effect of discharge dyeing.

[0026] 1. Process flow:

[0027] Conventional dyeing process of CDR dye exhaust or pad dyeing→machine printing→drying→baking machine / setting machine baking→flower steaming machine steaming→washing→soaping→washing→drying→setting→rolling

[0028] 2. Formula:

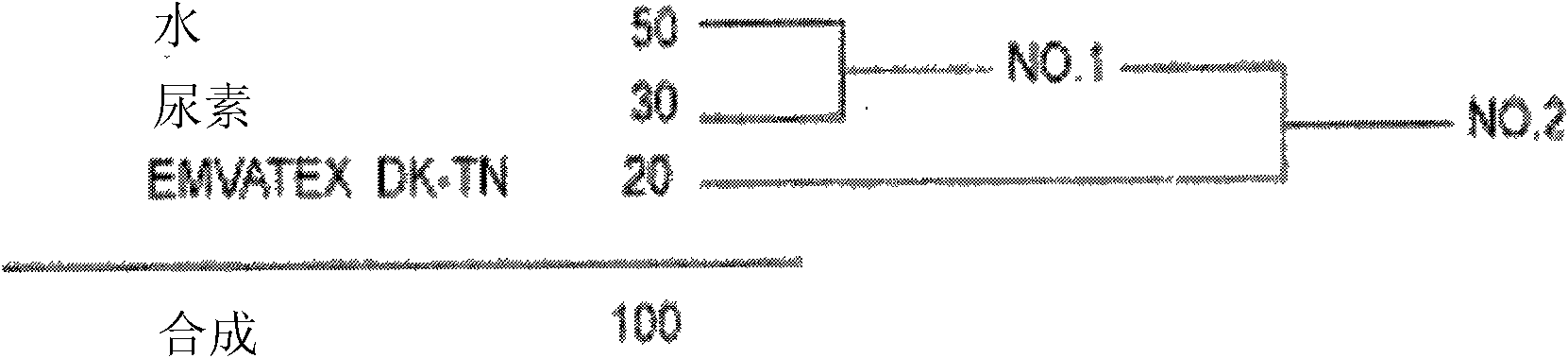

[0029] Original paste: dye discharge agent DK-TN 20% + urea 20-30% + hydration synthesis 100%

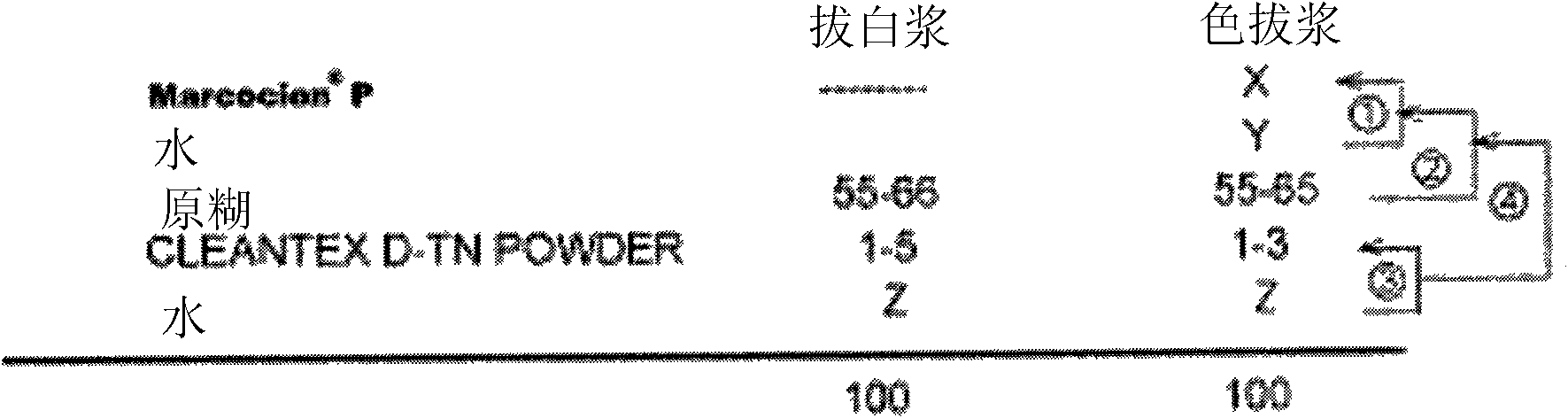

[0030] White pulp: original paste 50-60% + pulling agent 1-10% + water

[0031] Color pulling paste: Marcocion P dye + original paste 50-60% + pulling agent D-TN 1-8% + water / +baking soda 2-4%

[0032] Implementation key notes:

[0033] 1. Whitening problem: Appropriately increase the pulling agent to improve the whitening effect, and increase the whiteness during washing.

[0034] 2. Coloring problem: Appropriately add baking soda to improve coloring rate, fixation rate and color fastness to washing.

[0035] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com