Patents

Literature

57 results about "Coloring problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-stage scheduling method of parallel test tasks facing spacecraft automation test

InactiveCN104239213AEasy to callEasy to handleConcurrent instruction executionSoftware testing/debuggingColoring problemDegree of parallelism

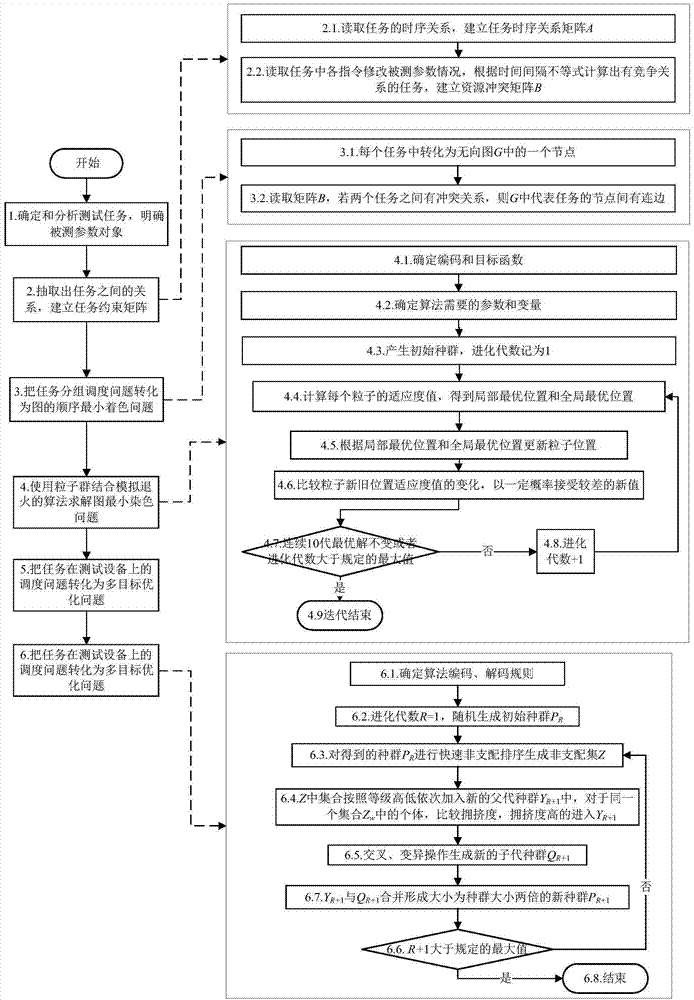

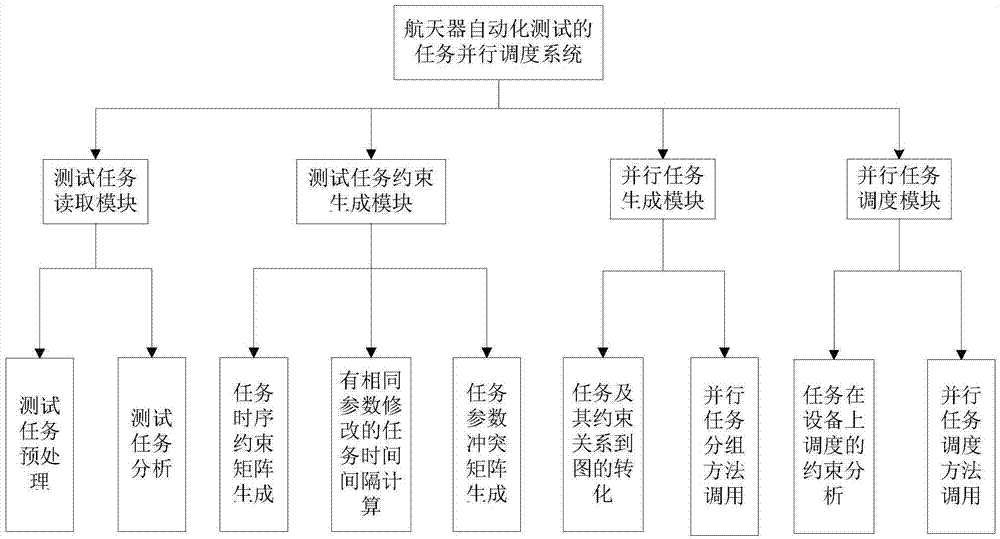

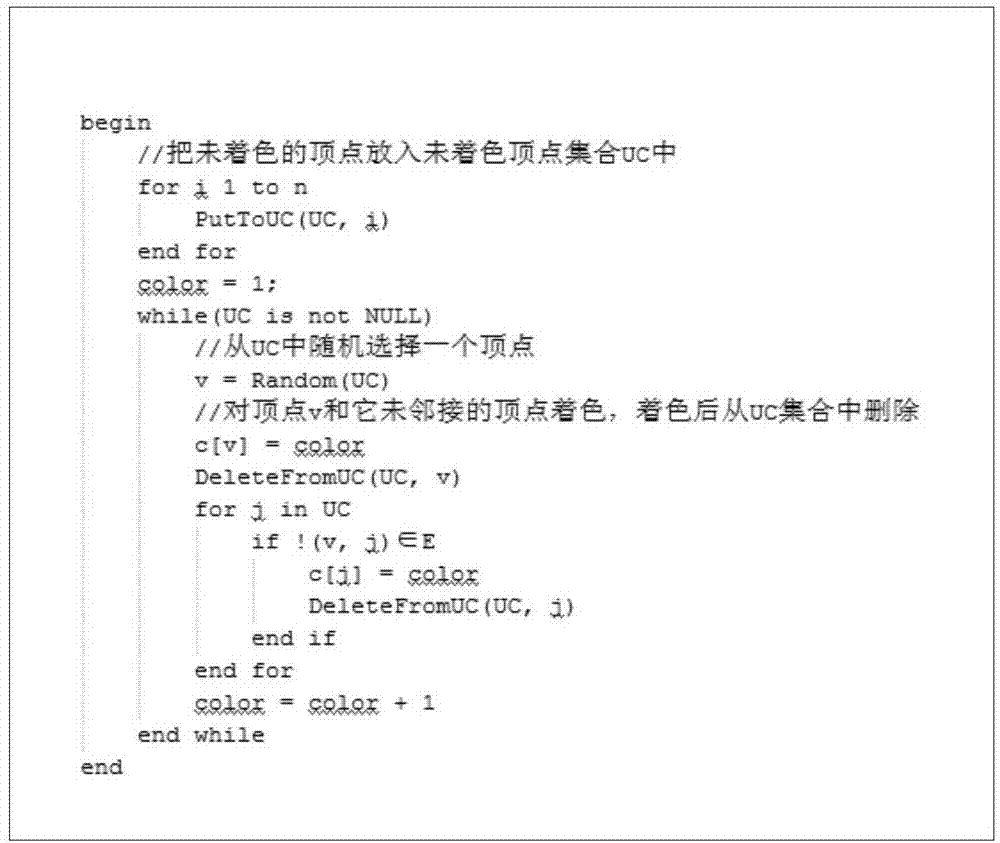

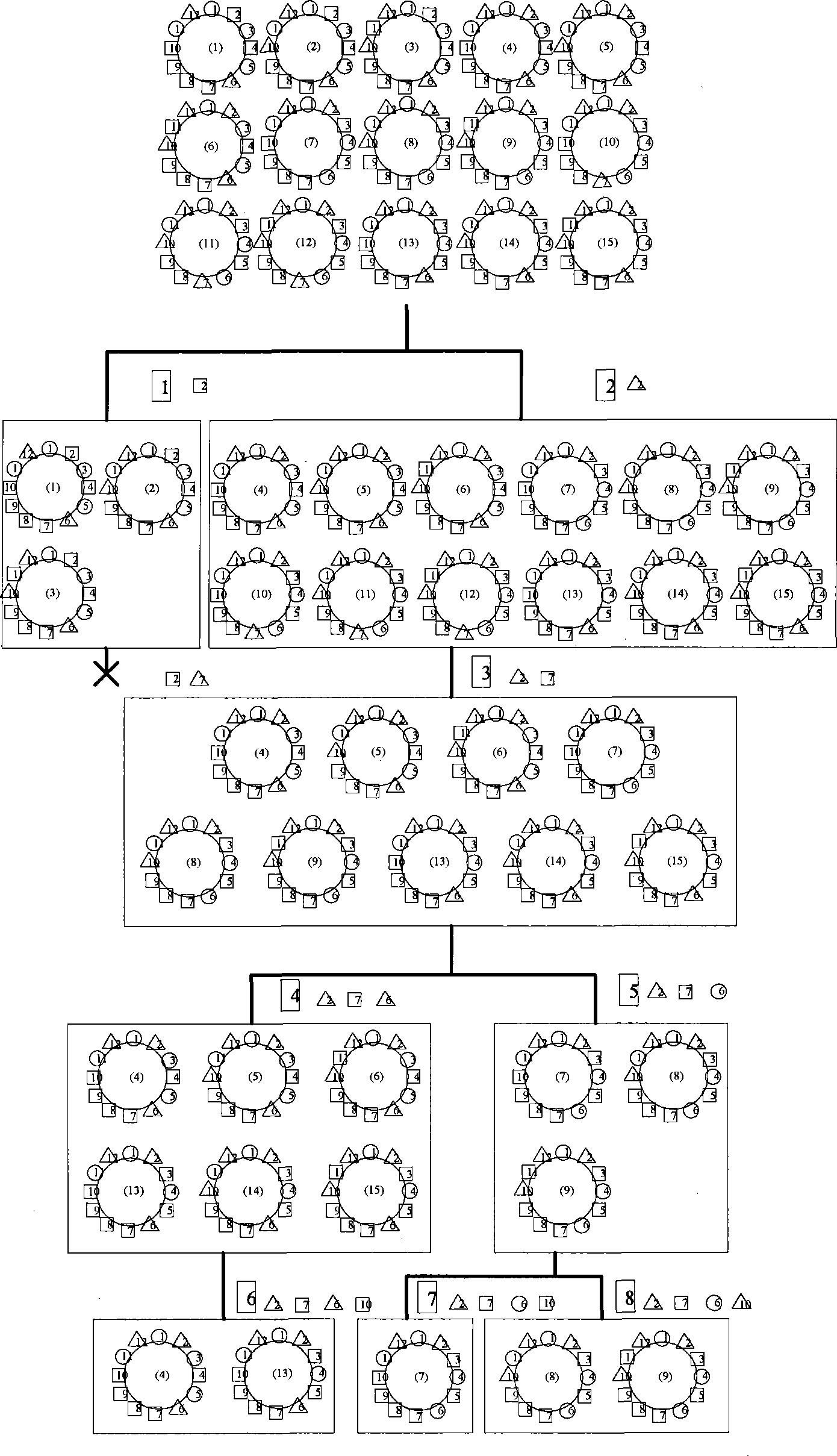

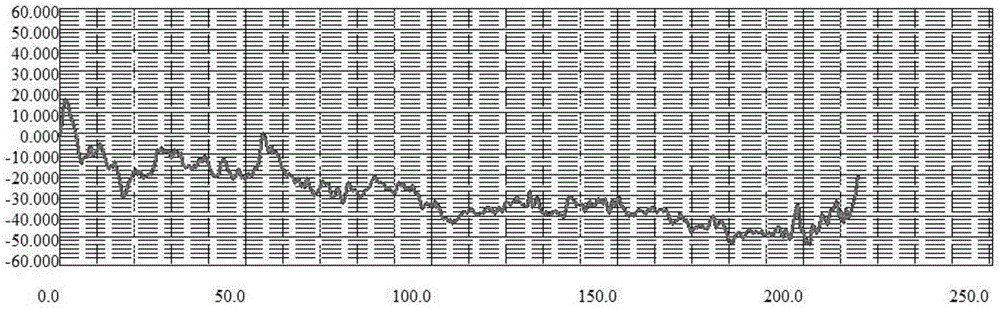

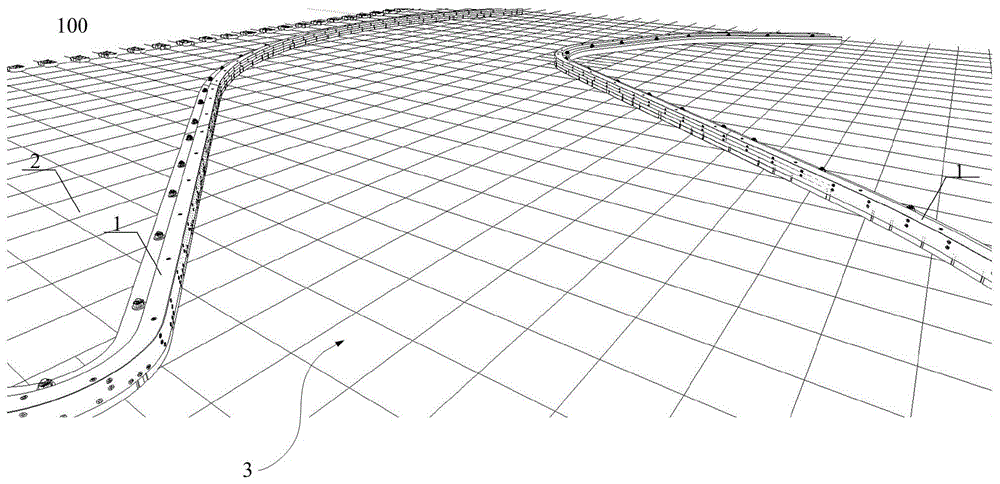

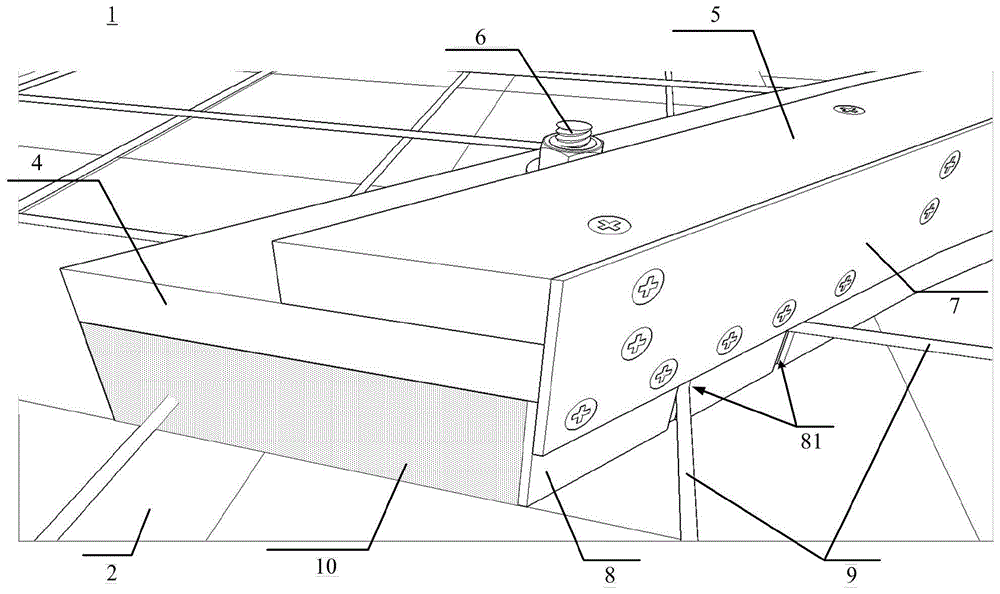

The invention relates to a two-stage scheduling method of parallel test tasks facing a spacecraft automation test, which belongs to the field of parallel tests. The method comprises the following stages: in the first stage, the test tasks, task instructions and tested parameters are analyzed and determined, a constraint relation between the tasks is defined, a time sequence constraint matrix and a parameter competitive relation matrix are established, the tasks and the constraint relation between the tasks are changed into undirected graphs, a parallel task scheduling problem is changed into a minimum coloring problem in the sequence of the tops of the graphs, a method based on the combination of a particle swarm and simulated annealing is used for solving, and then a test task group with the maximal degree of parallelism is obtained; in the second stage, the obtained test task group with the maximal degree of parallelism is distributed on limited test equipment, and then an optimal scheduling scheme is obtained. According to the two-stage scheduling method, the constraint relation among a plurality of test tasks is quickly established, the independence between the test tasks is analyzed, the degree of parallelism of the test tasks is increased, the optimal scheduling of the tasks on the equipment is realized when constraint conditions are satisfied, and the test efficiency is improved.

Owner:BEIHANG UNIV

7XXX aluminum alloy

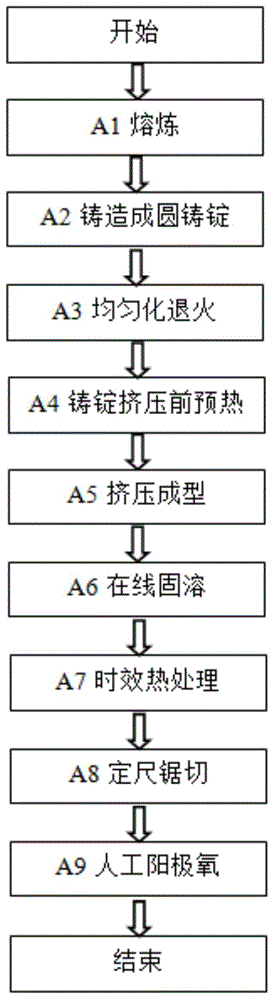

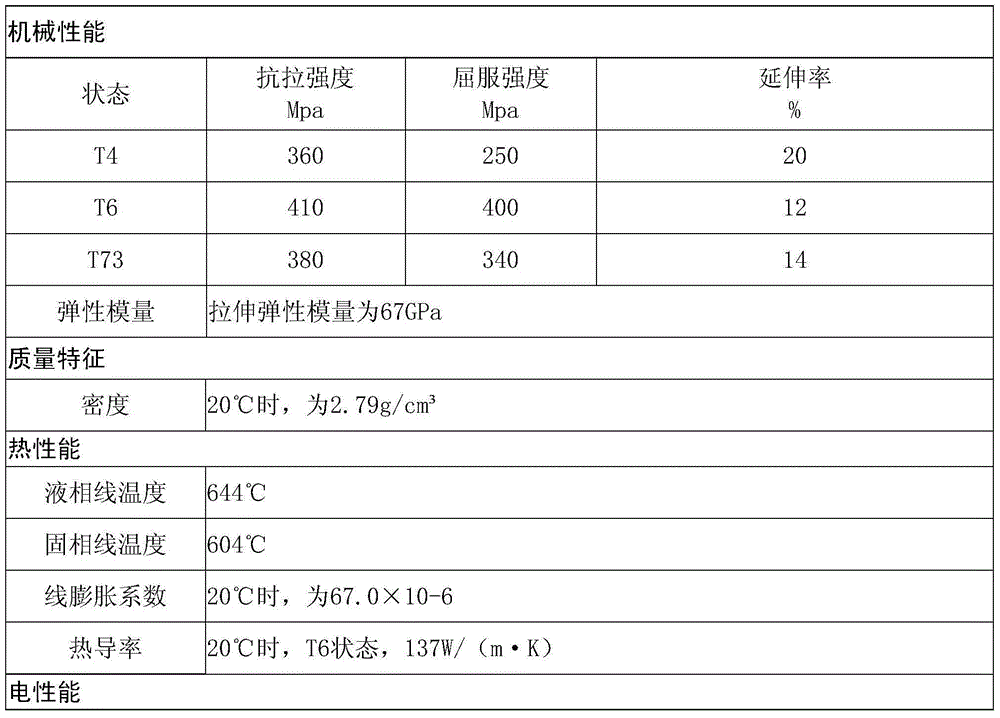

The invention relates to 7XXX aluminum alloy. The 7XXX aluminum alloy comprises the following components by weight percent: 6.6 to 7.6 percent of zinc, 1.25 to 1.80 percent of magnesium, 0.18 to 0.44 percent of copper, less than or equal to 0.06 percent of silicon, less than or equal to 0.16 percent of iron, , less than or equal to 0.03 percent of manganese, less than or equal to 0.03 percent of chromium, less than or equal to 0.02 percent of germanium, less than or equal to 0.02 percent of vanadium, less than or equal to 0.03 percent of titanium, less than or equal to 0.02 percent of zirconium, and less than or equal to 0.03 percent of total weight of manganese and chromium, less than or equal to 0.03 percent of each rest impurity element, less than or equal to 0.10 percent of total weight of rest impurity elements, and the balance of aluminum. On the basis of experiment, the material strength is improved by re-designing the mass fraction and a ratio of Zn to Mg; by re-designing the mass fraction of Cu, the alloy has excellent corrosion resistance, and the oxidation different color problem of silver white can be solved. By strictly controlling the weight percent of the impurity elements such as Mn and Cr, the crystal grains of the alloy material are uniform. Compared with the existing disclosed Al-Zn alloy system, the alloy has better comprehensive performance, and an oxidized membrane formed by oxidizing the material by virtue of anode is more delicate and beautiful.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

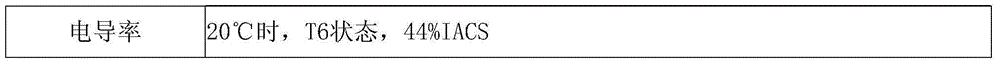

Carbodiimide composition with suppressed yellowing, a stabilizer against hydrolysis and a thermoplastic resin composition

ActiveUS7368493B2Improve heat resistanceNo coloring problemOrganic chemistryChemical inhibitorsHeat resistanceAntioxidant

A carbodiimide composition having an improved heat resistance which meets conventional requirements for a carbodiimide compound to be compounded in an ester-group-containing resin or a biodegradable plastic, and exhibiting no coloring problems due to yellowing, and having a superior stabilizing effect agains hydrolysis. The carbodiimide composition comprises a carbodiimide compound (A) and an antioxidant (B), having a 5% weight loss temperature not lower than 250° C. as determined by a thermogravimetric (TG) method, wherein an antioxidant (B) is dispersed and present in the composition by admixing during synthesis of a carbodiimide compound (A), a stabilizer against hydrolysis mainly comprising the carbodiimide composition and a thermoplastic resin composition containing the same.

Owner:NISSHINBO IND INC

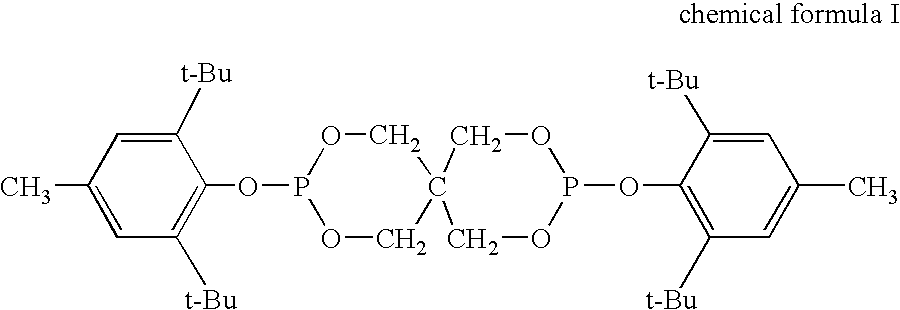

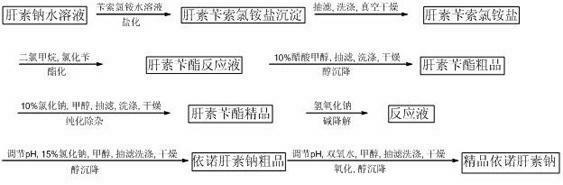

Enoxaparin sodium and production purification method thereof

InactiveCN102585037AReduce manufacturing costImprove product qualityBlood disorderExtracellular fluid disorderPurification methodsBenzyl chloride

The invention discloses enoxaparin sodium. The average molecular weight of the enoxaparin sodium is between 3500-5500 dalton, thrombolytic biological activity is 100-125IU / mg, and the ratio value of resistance to Xa and IIa resistance is between 3.3-5.3. A production purification method of the enoxaparin sodium comprises preparation of heparin benzyl chloride ammonium salt, preparation of heparin benzyl ester, purification of heparin benzyl ester, preparation of enoxaparin sodium and purification of enoxaparin sodium. By means of the enoxaparin sodium, the molecular weight and distribution range of a product are controlled, and the quality of a fine enoxaparin sodium product meets the quality standard of the european pharmacopoeia. The enoxaparin sodium adopts a crude product of heparin sodium as an initial raw material and can effectively reduce production cost. The refined heparin benzyl ester stabilizes the final quality of the product. Purification difficulties are simplified, the coloring problem in the production is effectively solved, and the product quality is improved.

Owner:麦科罗夫(南通)生物制药有限公司

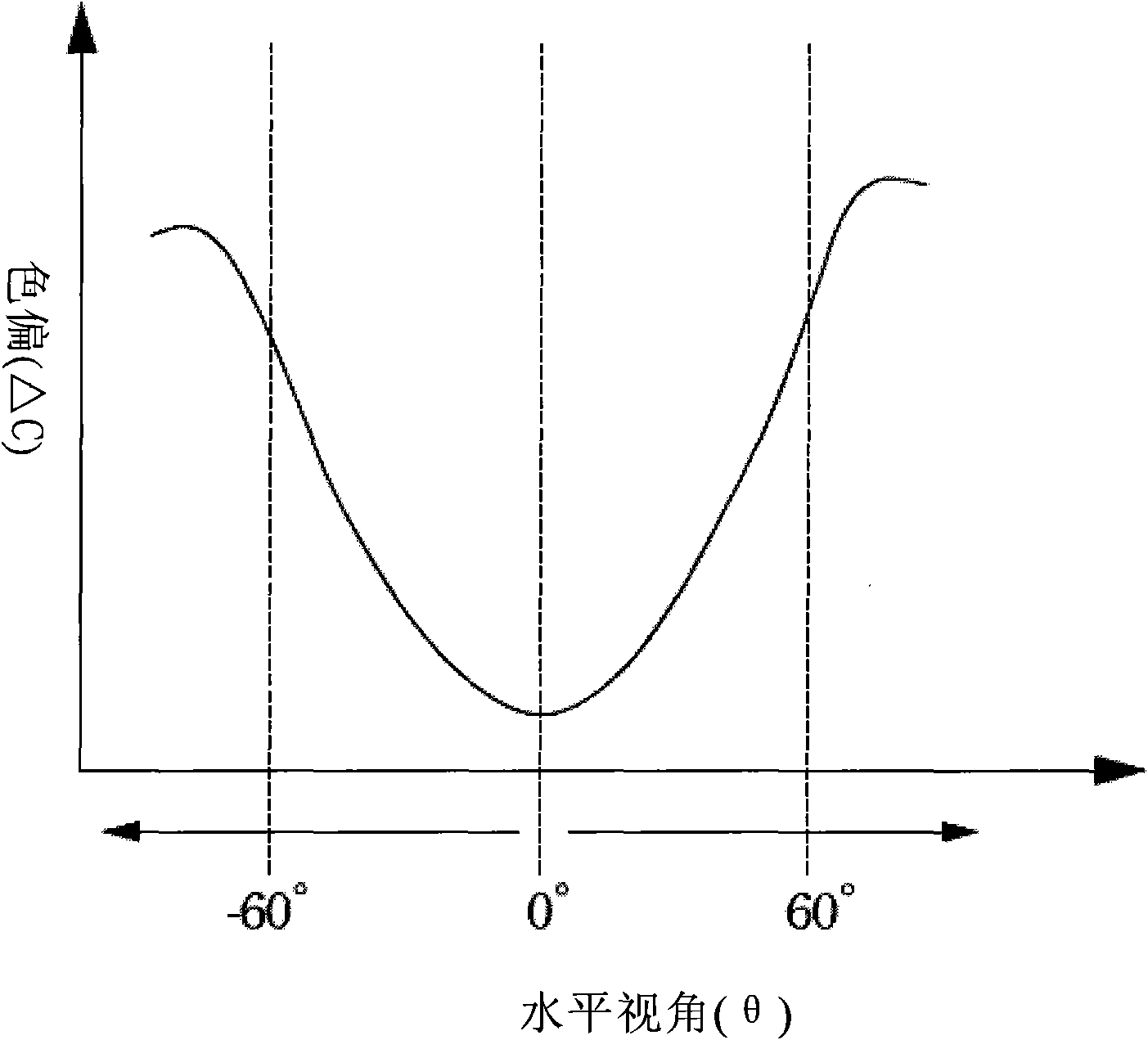

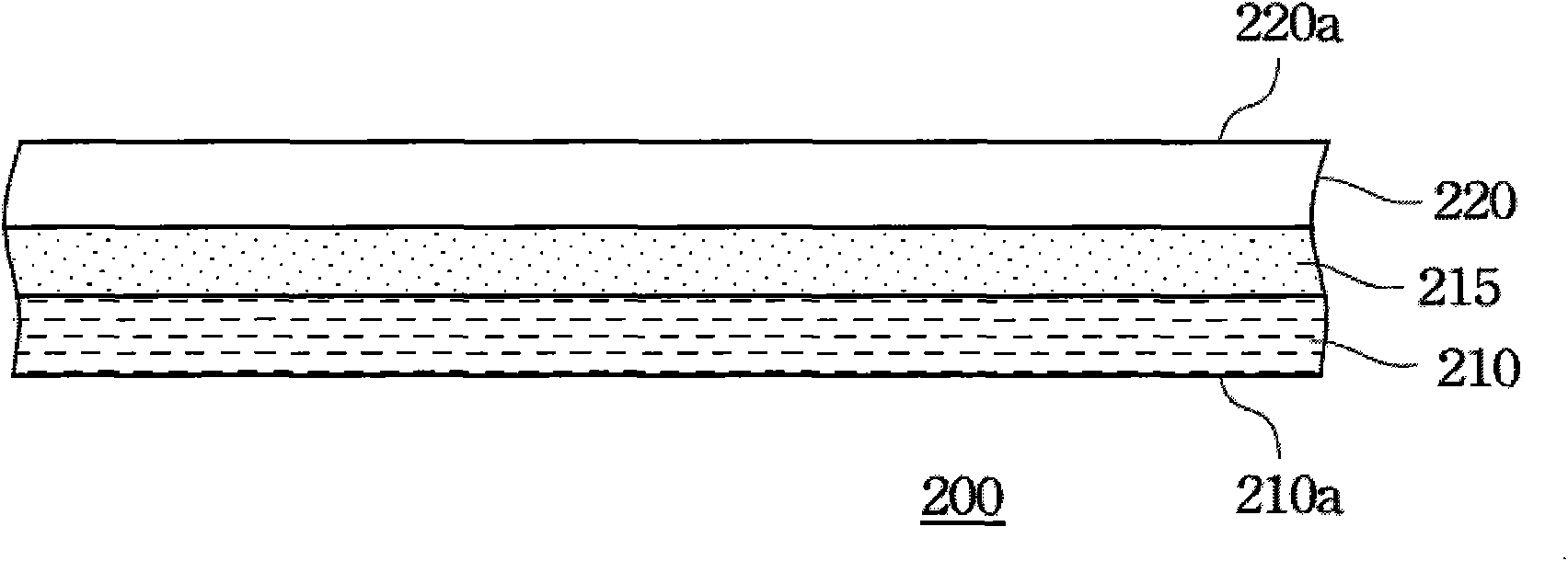

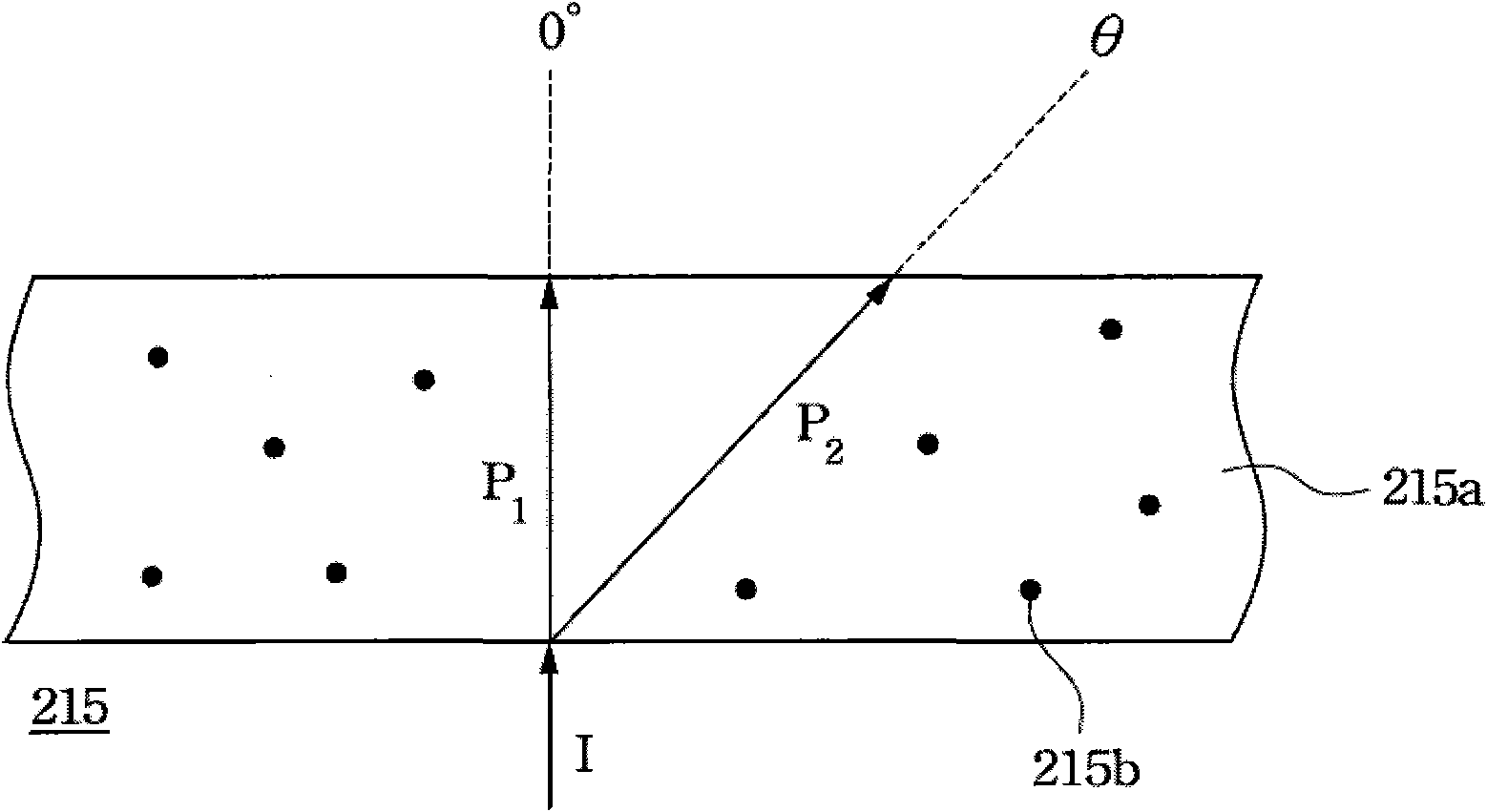

Reflective polarizer sheet

InactiveCN101630032ASolve the problem of color castMechanical apparatusPolarising elementsMicro structurePhase difference

The invention provides a reflective polarizer sheet which comprises a cholesterol liquid crystal layer, a phase difference membrane with a 1 / 4 wave length and a bonding layer. The bonding layer is positioned between the cholesterol liquid crystal layer and the phase difference membrane with the 1 / 4 wave length; and a jointing agent and blue pigment are included in the bonding layer. The blue pigment is added in the bonding layer of the reflective polarizer sheet so as to compensate the color problem caused by the reflective polarizer sheet self and a large horizontal viewing angle. A micro bead can be added in the bonding layer of the reflective polarizer sheet or a condenser micro-structure is configured on the outer side of the phase difference membrane with the 1 / 4 wave length so as to further improve the color problem caused by the reflective polarizer sheet self and the large horizontal viewing angle.

Owner:ETERNAL MATERIALS CO LTD

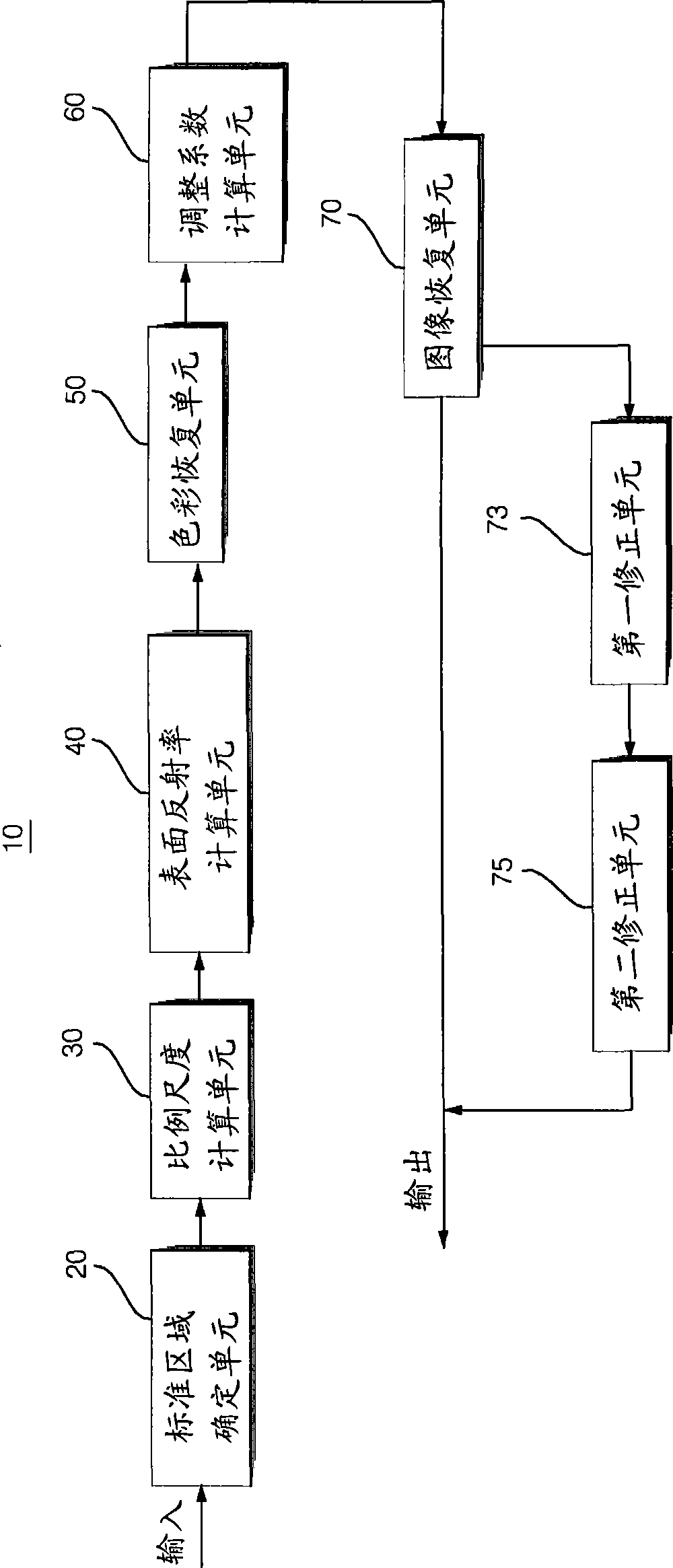

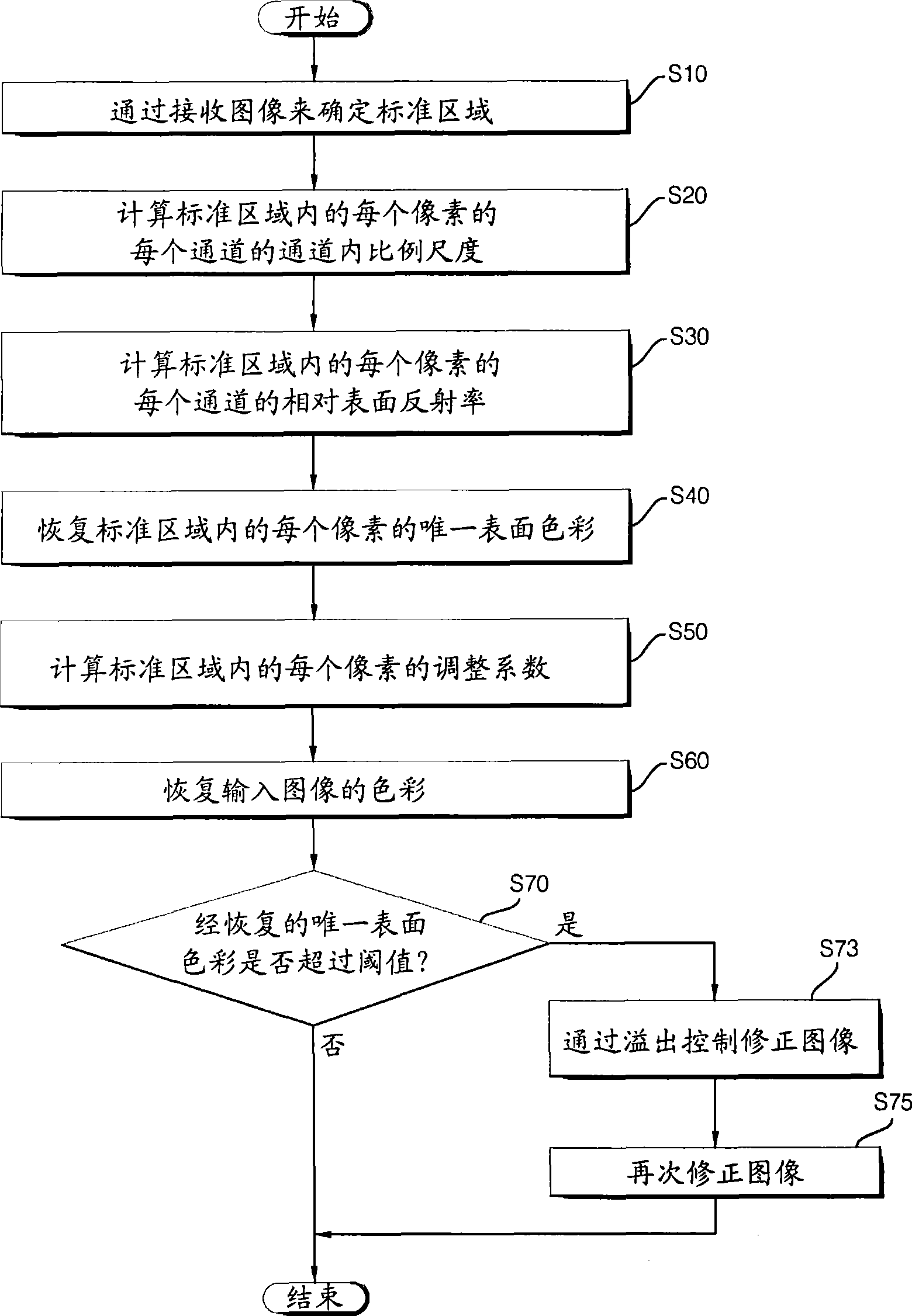

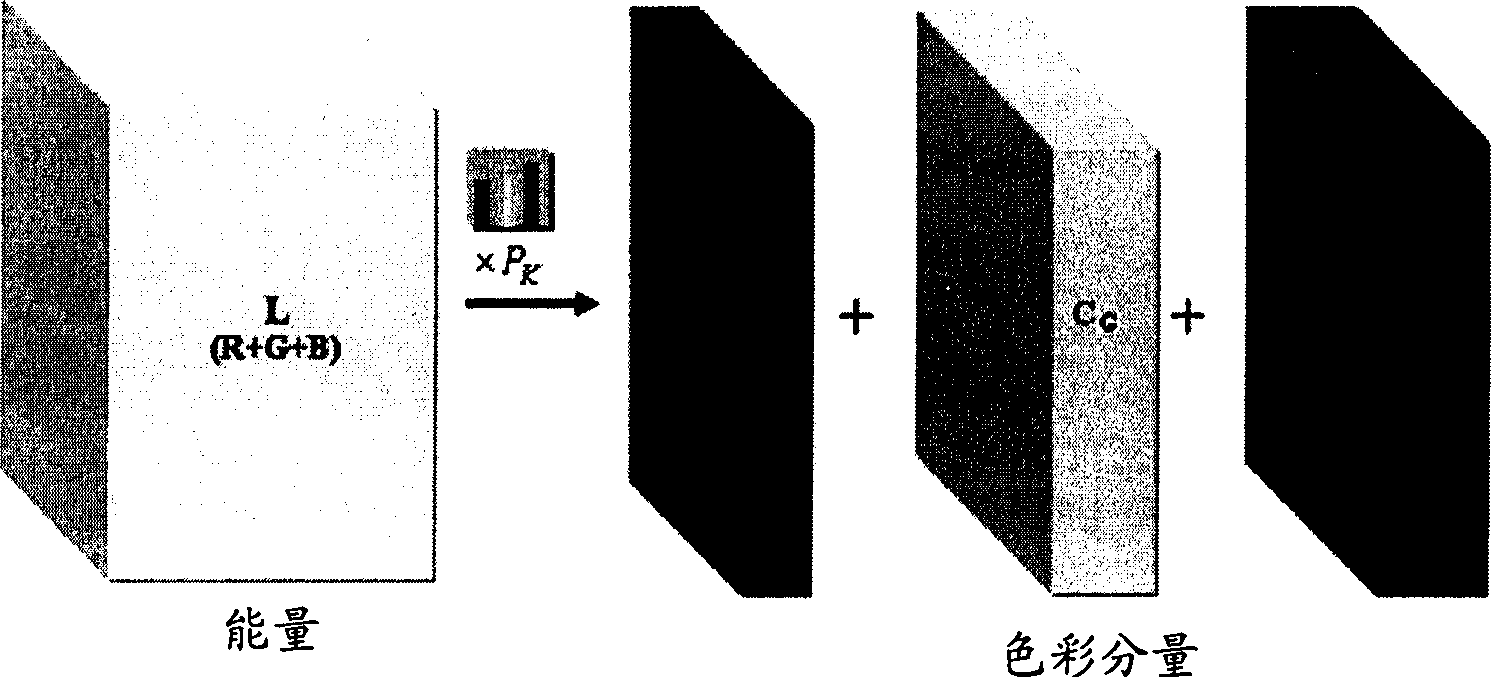

Color recovery method and system

The present invention relates to a color recovery method and system, and more specifically, to a color recovery method and system that recovers colors of digital images distorted due to lighting by using a principle of implementing color constancy based on a human vision system. The present invention comprises: a) determining criterion region in consideration of variance values for each color channel of images to be recovered; b) computing relative surface reflectance for the determined criterion regions and computing adjustment coefficients for excluding distortion effects of a light source using the computed relative surface reflectance; and c) recovering the colors for the images by using the adjustment coefficient. With the present invention, the distorted colors of digital images due to the spectral bias of a light source can be easily recovered in a very fast single step operation free from the unique color problem, one of the worst problems in the field of color correction technology so-far known as impossible to solve, if and only if there is a sub-region in a digital image containing sufficient number of surface elements of different reflectance.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

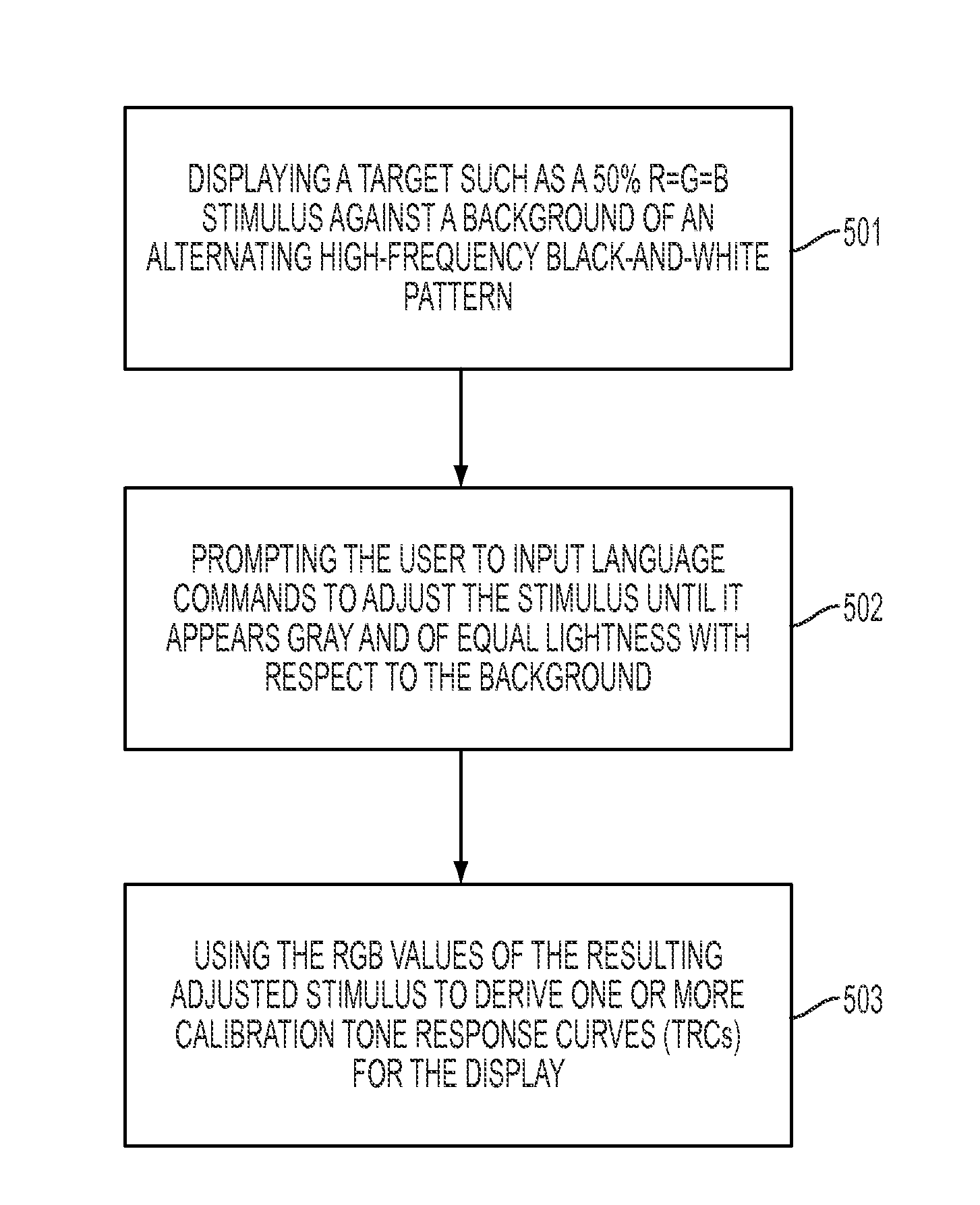

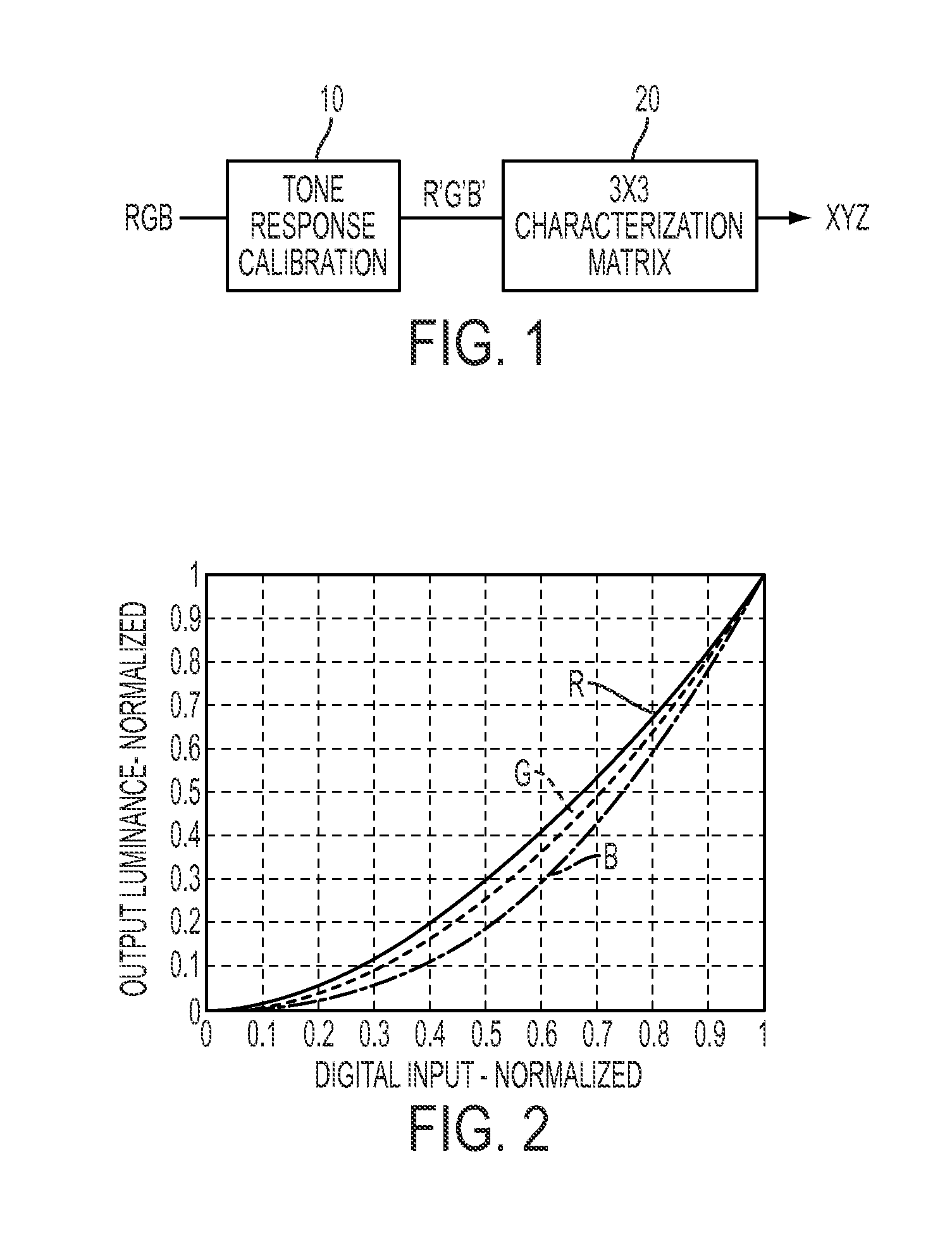

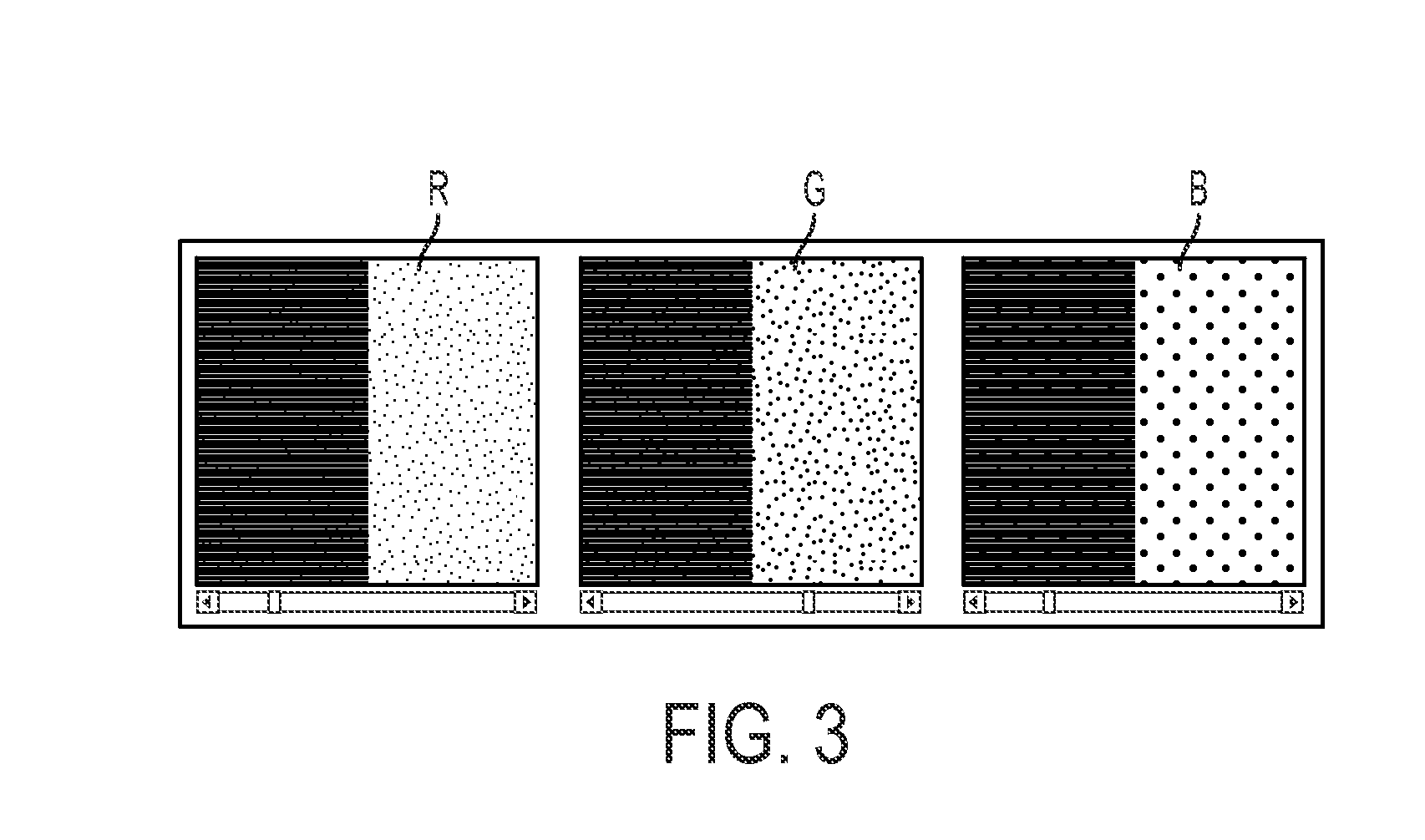

Language-based color calibration of displays

ActiveUS20130027421A1High expressionThe process is simple and fastColor signal processing circuitsCathode-ray tube indicatorsDisplay deviceColor calibration

Described herein is a method of calibrating displays (or printers) using Natural Language-based commands. The exemplary method provides an easy-to-use solution to the common methods of color calibrating a display. Instead of using sliders or manual controls for the individual dimensions of a three-dimensional color problem, the user is able to make adjustments via natural language commands, such as “make reference patch less purple.” The method does not require the user to understand color mixing technology when making separate R, G, and B adjustments to match a specified patch. A user can easily express the necessary color adjustment in natural language terms, making the process simpler and faster.

Owner:XEROX CORP

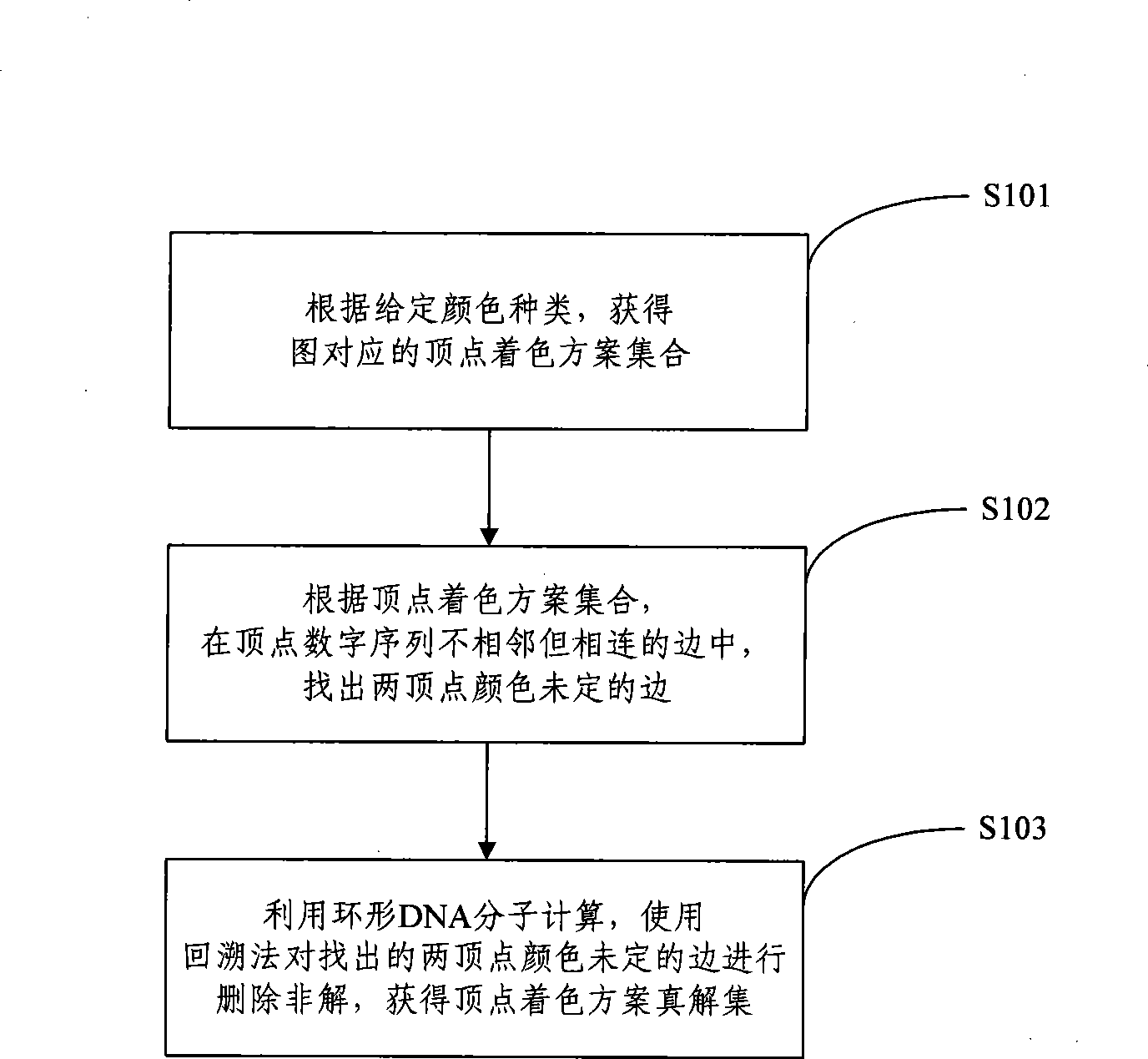

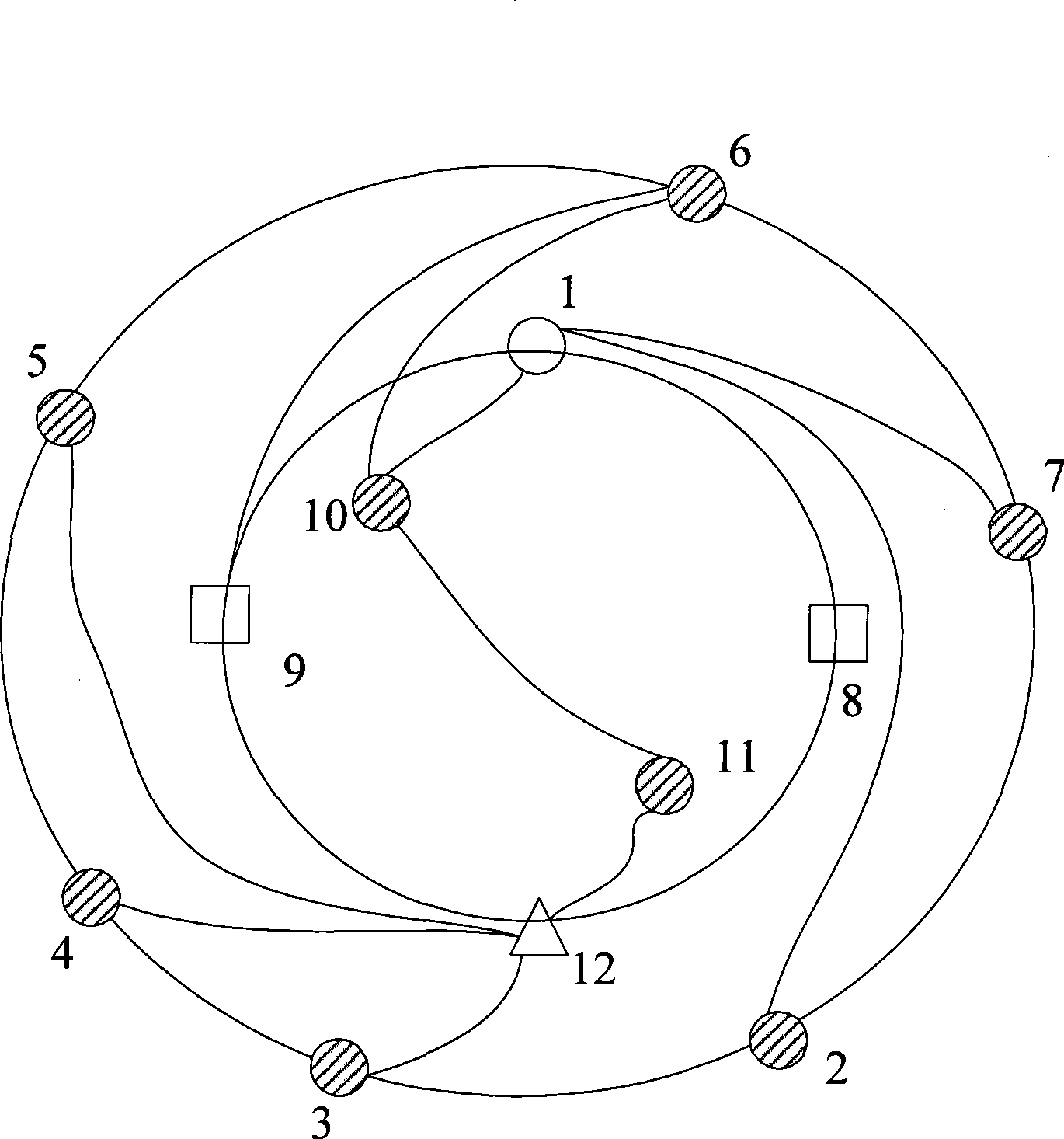

Graph coloring computing method based on annular DNA and its DNA computing system

InactiveCN101488197AAvoid reorganizationImprove solution efficiencyMicrobiological testing/measurementGenetic modelsAlgorithmGraph coloring

The invention relates to a graph coloring node operation method based on the ring-shaped DNA, comprising the following steps of obtaining the coloring scheme congregation of a vertex corresponding to a graph according to given color kinds; finding out two edges with undetermined vertex colors from edges with nonadjacent but connected vertex digit sequences according to the coloring scheme congregation of the vertex; and deleting and untying the two edges with undetermined vertex colors by the operation of the ring-shaped DNA and a backtracking method to obtain the true solution set of vertex coloring schemes. The technical proposal of the invention is to explain graphs, avoids the molecule recombination by concurrency of the life-form operation of the DNA operation and based on the characteristic of the operation of the ring-shaped DNA, and gradually obtains the vertex coloring scheme congregation for a coloring graph, thereby organically combining an optimized operation method, DNA sequence codes, various biochemistry operations, solution detection problems, solution space scales and the like, and enhancing the solving rate of the coloring problem of a graph.

Owner:PEKING UNIV

Concrete, pathway terrace and template system and construction method

ActiveCN104829198AImprove flatnessPrevent discolorationIn situ pavingsRoads maintainenceLow noiseSurface layer

The invention provides a concrete, pathway terrace and template system and a construction method, aiming at solving a series of problems in the prior art that a pathway terrace cannot meet ultra-flat, ultra-hard, anti-sliding, low-noise and de-coloring requirements and the like. A concrete formula used in the pathway terrace is improved so that the problem that the early strength of the concrete of the pathway terrace is low is solved, a bleeding phenomenon in an initial set process of the concrete of the pathway terrace is avoided, and the deformation degree of the concrete pathway terrace is controlled. Meanwhile, the whole strength of the concrete of the pathway terrace is greatly improved, and the ultra-hard and wear-resisting use function requirements of the pathway terrace are met. A concrete construction process is improved, a special ultra-flat pathway terrace system is developed, and the high flatness can be kept when the pouring of the pathway terrace is finished, so that the ultra-flat target is realized. Furthermore, the concrete formula is further improved and the decoration effect is improved; and colored concrete is used for pouring the pathway terrace, so that the de-coloring problem does not occur even if the terrace is abraded. Meanwhile, a surface layer is arranged on the surface of the concrete terrace, so that the ultra-hard and wear-resisting effects are enhanced, and the anti-sliding and low-noise effects are realized.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

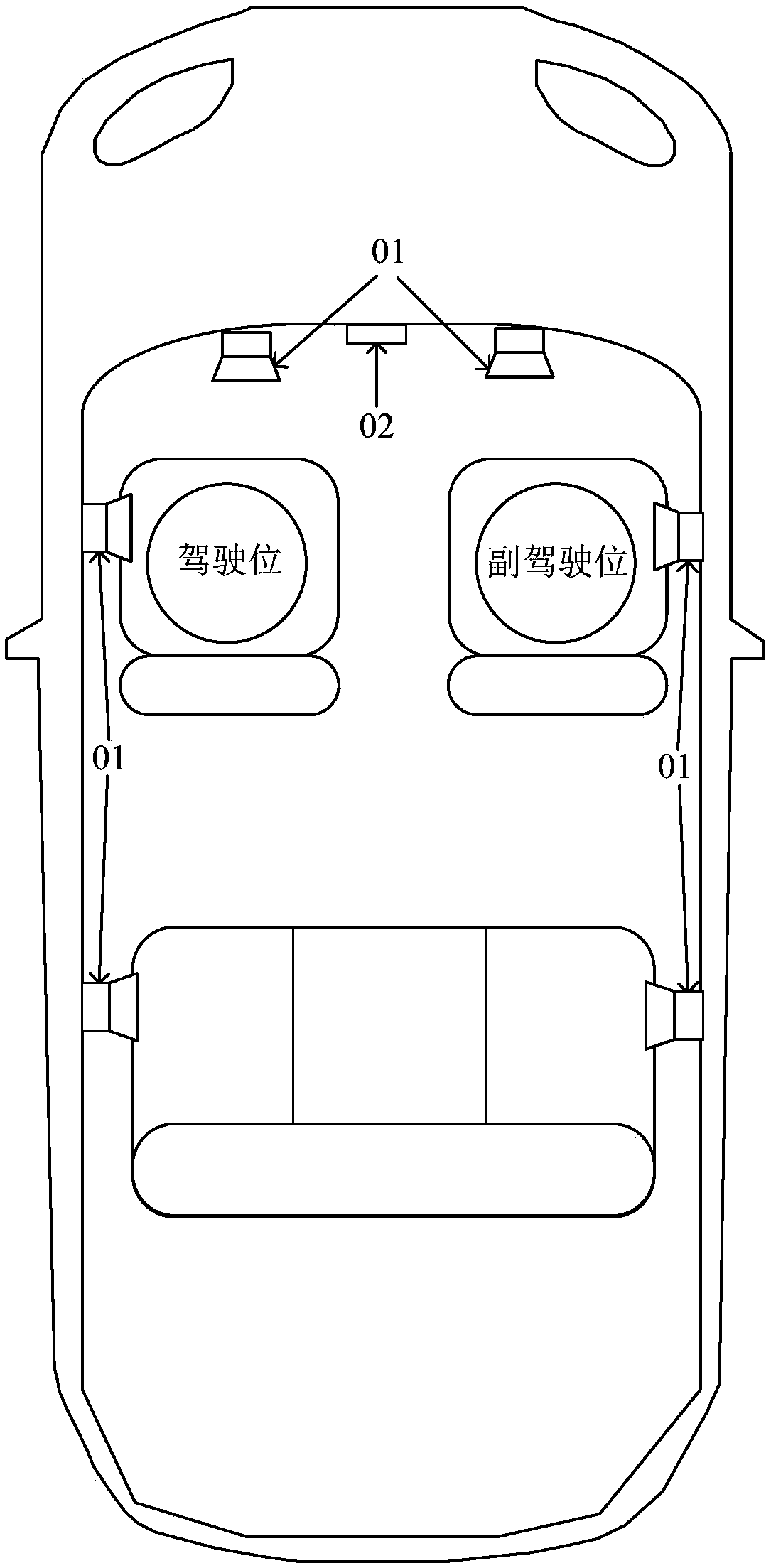

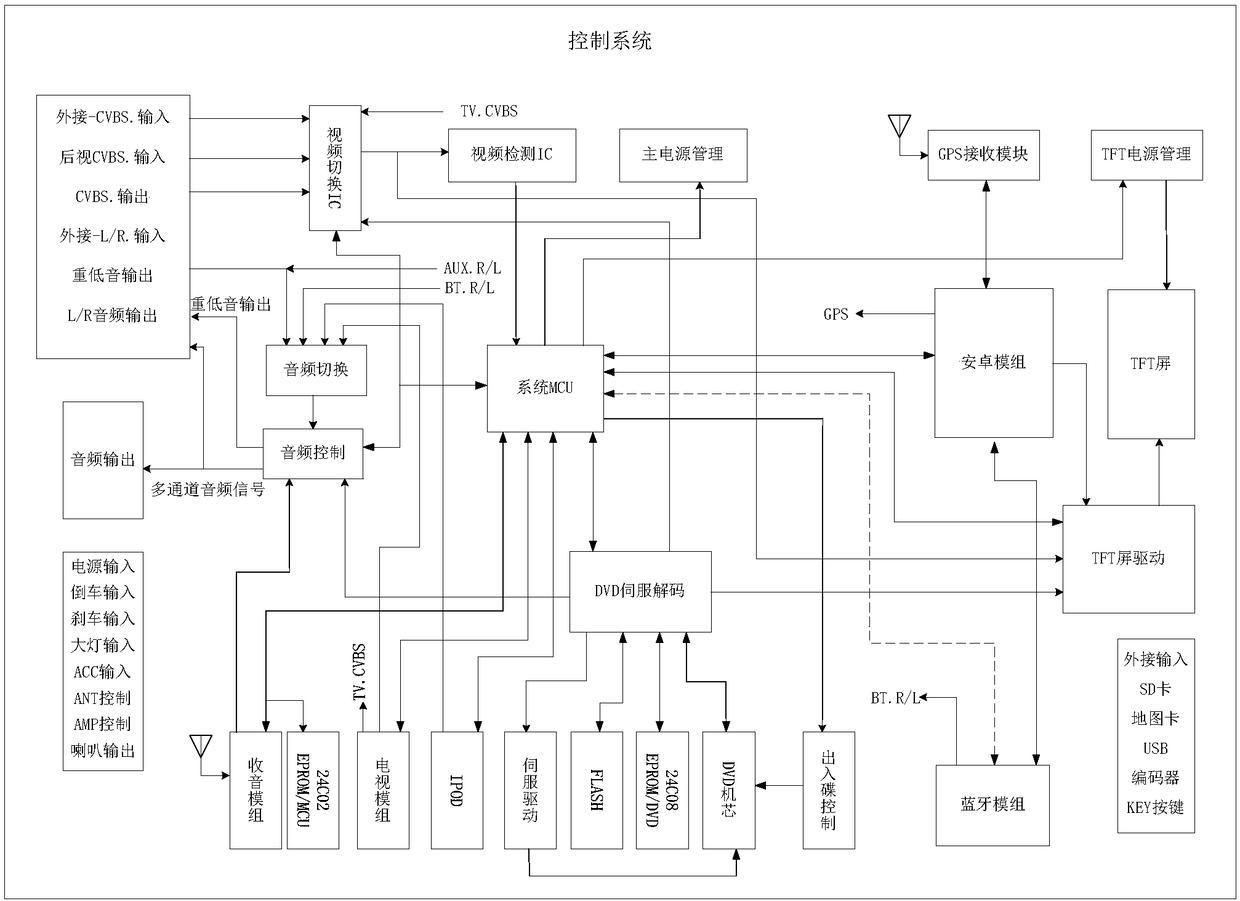

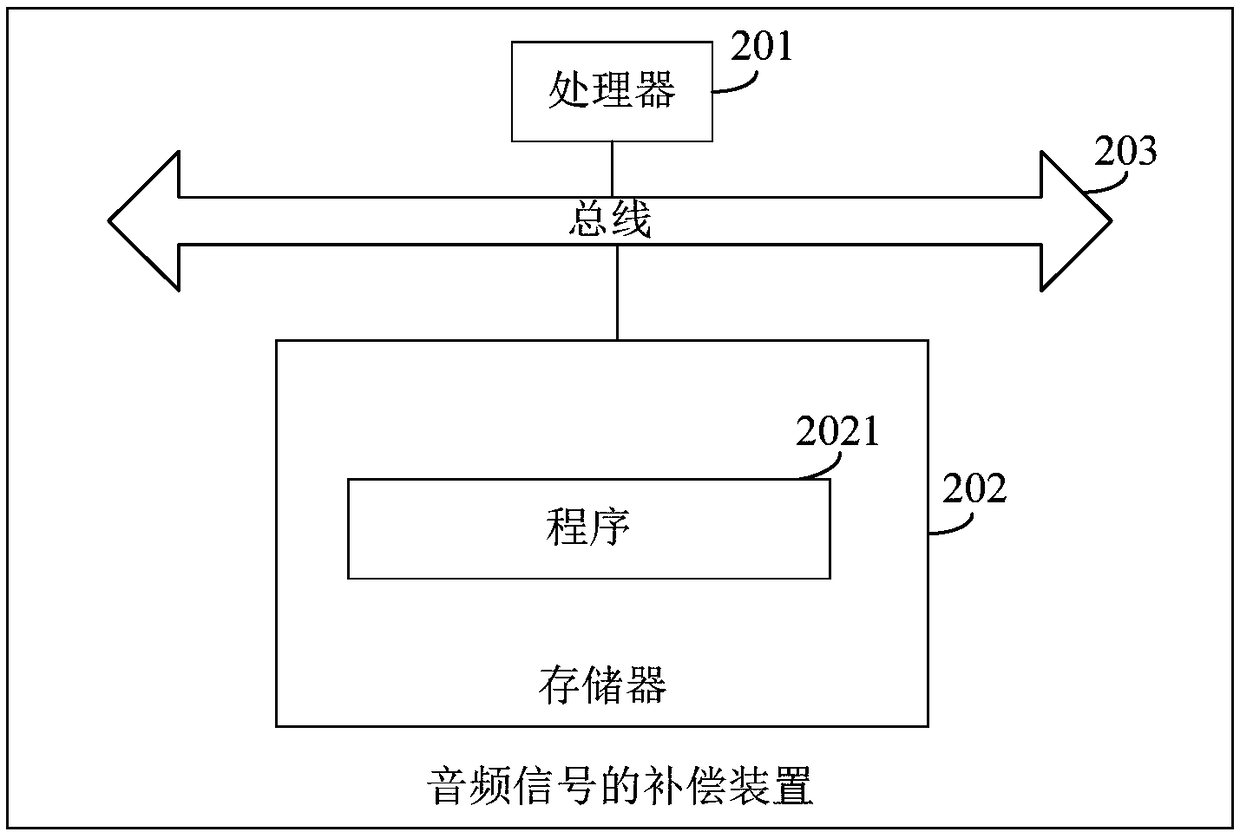

Audio signal compensation method, device and system

ActiveCN109302660AImprove the sound effectEliminate sound coloration problemsSignal processingTransducer circuitsImpulse responseLoudspeaker

The invention discloses an audio signal compensation method, device and system, and belongs to the technical field of acoustics. The method comprises the following steps: acquiring M loudspeakers arranged in an audio play space and a room impulse response matrix of the audio play space between L receiving points in the audio play space; calculating a theoretical sound pressure value at each of theL receiving points of the sound played by each of the M loudspeakers to obtain an ideal sound field matrix; calculating a filter coefficient based on the room impulse response matrix and the ideal sound field matrix; and compensating M paths of audio signals by adopting the filter coefficient to obtain M paths of compensation signals. According to the audio signal compensation method provided bythe invention, the audio signals are compensated by using the calculated filter coefficient, so that the actual sound field of the audio signals output by the loudspeakers can be approximated to the ideal sound field to a certain extent, and an acoustic coloring problem caused by the reflected sound in the audio play space is eliminated, thereby effectively improving the sound effect of a sound system in the audio play space.

Owner:HUAWEI TECH CO LTD +1

Bactericidal property treatment technique for fibre or fibre products

This invention relates to the processing technology of the sterilizing product, it concretely relates to the sterilizing technology for a fibre and fibre product. This invention need to solve the product coloring problem and the effectiveness of sterilizing is not ideal by current technology. To solve the current problem, the technical project of this invention is that the fibre and fibre product sterilizing processing technology consists of approaches such as the fibre and fibre product directly infusing with AgNO3 the concentration of which is larger than 0, smaller or equal to 1.5%, after infusing completely, the fibre is take out and centrifugal drying. Comparing to the current technology, the advantage of this invention is that it solve the coloring problem, the sterilizing effectiveness is good, the process is simple, there dose not need complicate instrument, the application are is large, the cost is low, it is safe and reliable, the usage is convenient, and the lifetime is long.

Owner:陈凡

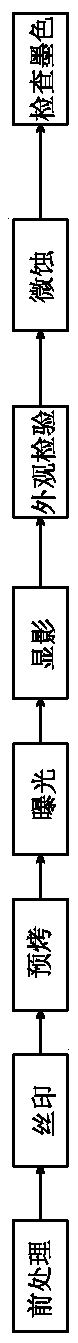

Solder mask manufacturing process for PCBs applied to LED display screens

ActiveCN109413882AImprove flatnessGood colorNon-metallic protective coating applicationCooking & bakingLED display

The invention discloses a solder mask manufacturing process for PCB applied to LED display screens. The process comprises the following steps of: (1) preprocessing: processing the surface of a PCB byadoption of a browning process; (2) silk printing: carrying out silk printing on a copper surface of the PCB, strictly controlling an ink opening viscosity of printing ink, an angle of a doctor blade,an ink scraping amount of the doctor blade and a speed of the doctor blade in the silk printing process, and carrying out standing for 15-30 min after the silk printing; (3) pre-baking; (4) exposure;(5) development; (6) appearance inspection; (7) micro erosion; and (8) ink color check. According to the process, the solder mask preprocessing manner is the browning process, so that the copper surface can be uniformly coarsened; silk printing parameters, exposure parameters and development parameters are controlled at optimum values, so that solder mask windowing analysis is smooth after the development of the PCB; and after the development, the browned layer on the windowed copper surface is removed through micro erosion, so that the copper surface is better is flatness and color, the appearance ink color of the PCB is consistent, and the ink color problems caused by unfavorable solder mask exposure and bad solder mask analysis can be effectively solved.

Owner:东莞市若美电子科技有限公司

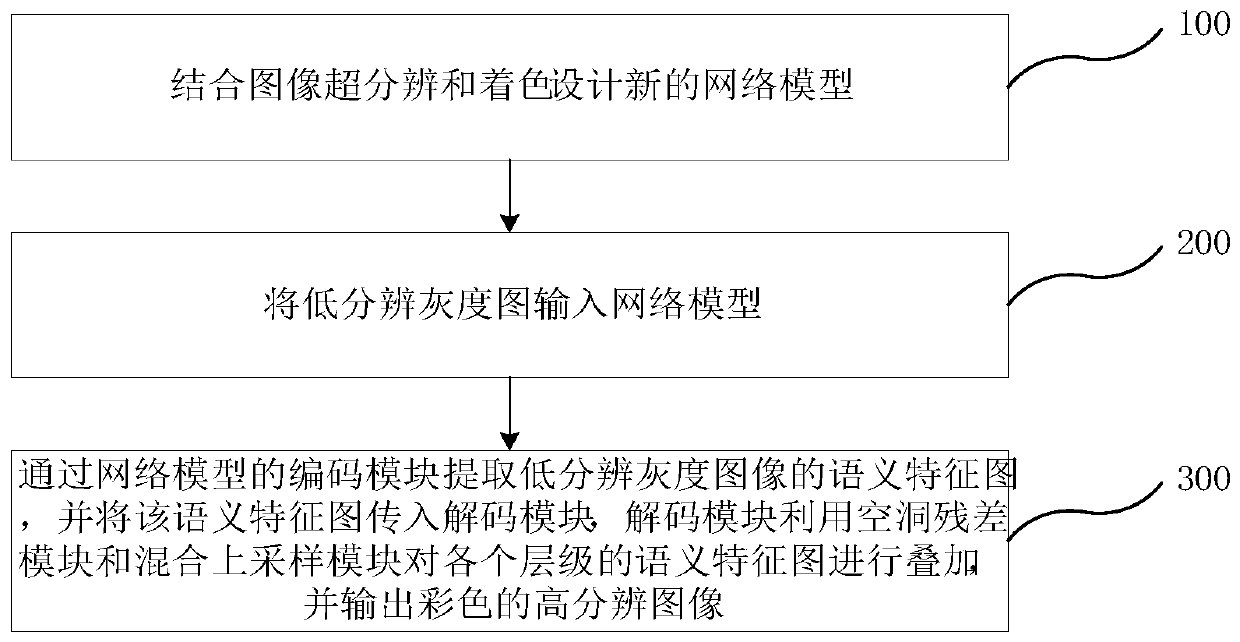

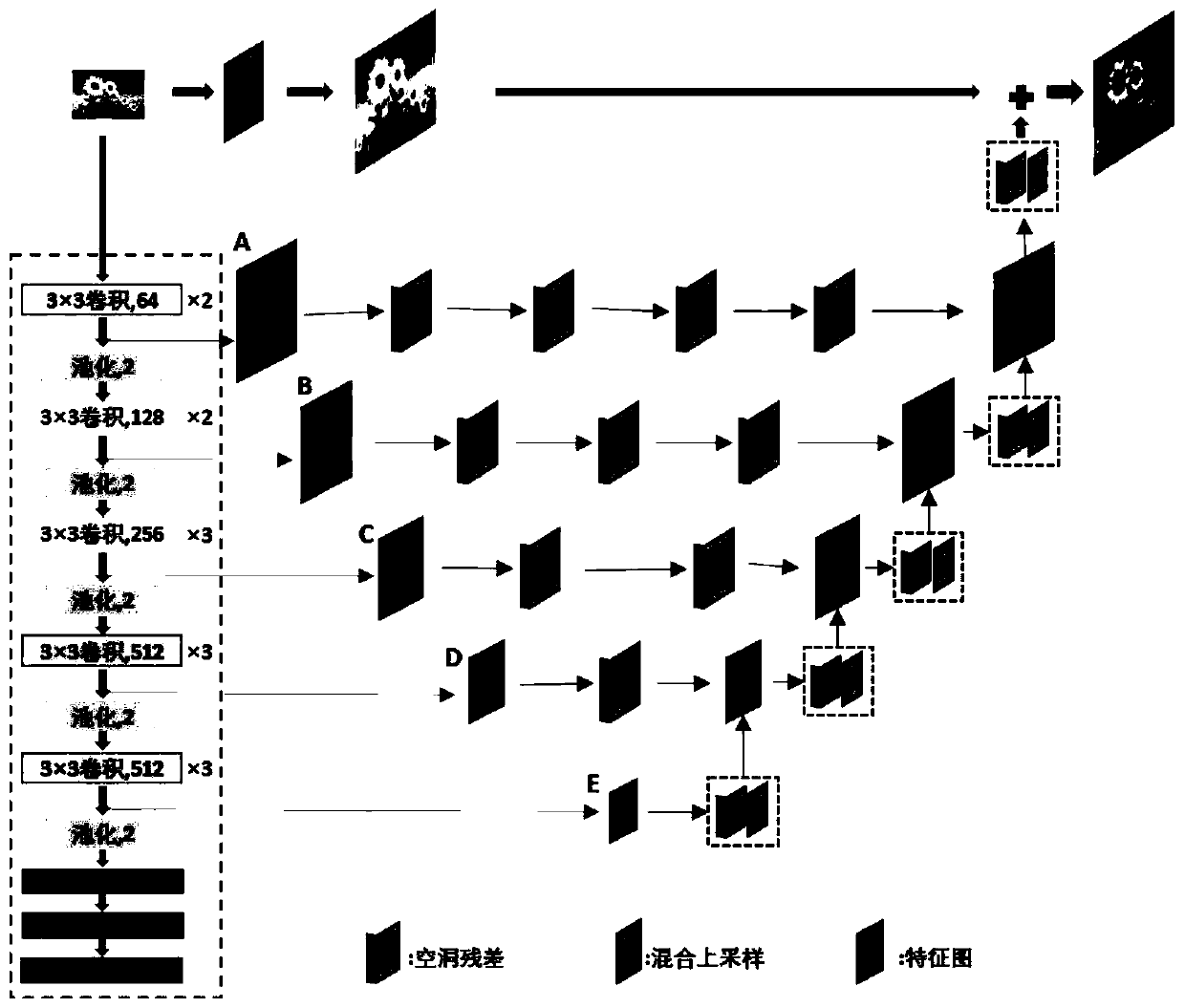

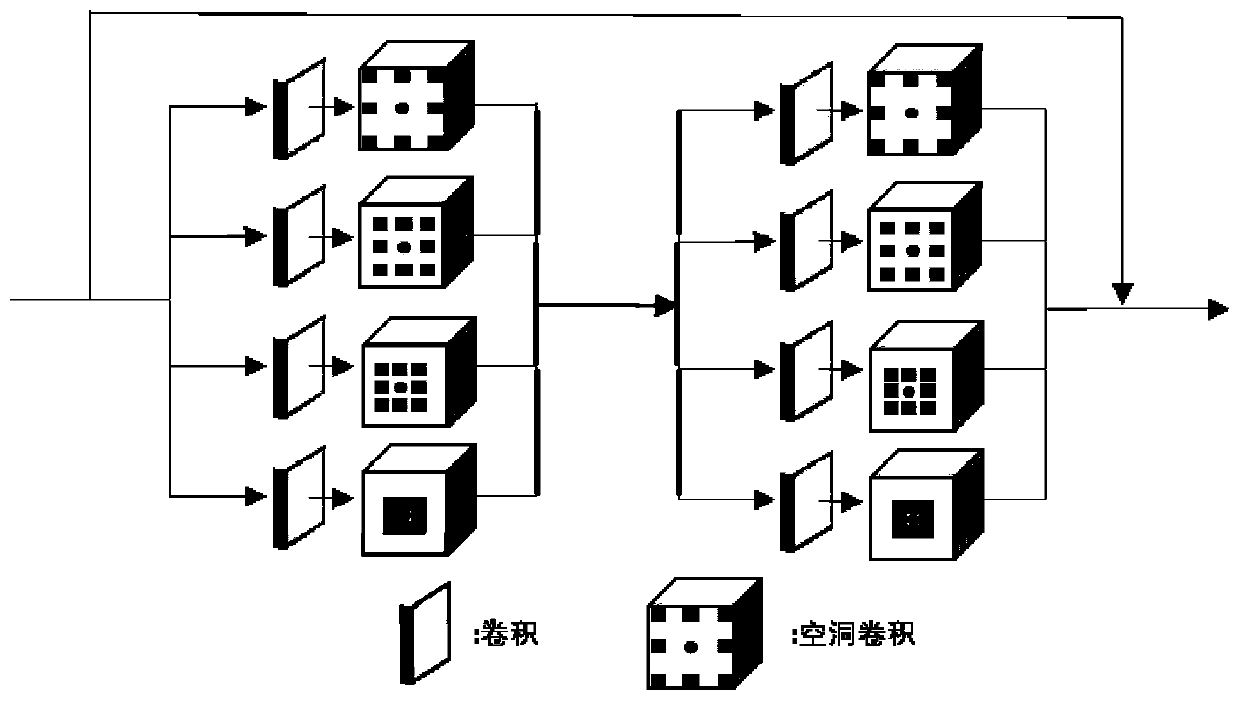

Image super-resolution and coloring method and system and electronic equipment

ActiveCN110163801AImprove visual effectsSave resourcesTexturing/coloringGeometric image transformationNetwork modelSemantic feature

The invention relates to an image super-resolution and coloring method, an image super-resolution and coloring system and electronic equipment. The method comprises the following steps: step a, designing a new network model by combining image super-resolution and coloring, wherein the network model comprises an encoding module and a decoding module; b, inputting the low-resolution grayscale imageinto a network model; and step c, extracting the semantic feature map of the low-resolution grayscale image through the encoding module, transmitting the semantic feature map to a decoding module, superposing the semantic feature maps of all levels by the decoding module, and outputting a high-resolution color map. The new network model is designed for the super-resolution and coloring problems, the super-resolution and coloring tasks are processed together, the low-resolution grey-scale map is directly mapped to the high-resolution color map, the visual impression of people is improved, and resources and time are saved.

Owner:SHENZHEN INST OF ADVANCED TECH

Immunohistochemical staining method and applications of immunohistochemical staining method in cervical tumorous lesion screening

InactiveCN105241726ALower cost per capitaReduce workloadPreparing sample for investigationAntigenStaining

The present invention relates to the technical field of cytologic screening of tumorous lesions, particularly to an immunohistochemical staining method and applications of the immunohistochemical staining method in cervical tumorous lesion screening. The method comprises: obtaining a precipitate containing sample cells; obtaining a suspension containing sample cells; obtaining a cell smear or cell chip; and taking the cell smear or cell chip, immobilizing with an immobilize liquid, carrying out water washing on the cell chip with gradient alcohol, adding a repair liquid to carry out antigen repair, adding antibody or probe, adding a blocking solution to block the background, and carrying out immunohistochemical staining. According to the present invention, the false negative and false positive problem of the tumorous lesion cytologic screening can be solved, the workload and the burden of the pathologists can be significantly reduced, the immunochemistry and in situ hybridization staining background and non-specific coloring problem in the cell smear can be solved, and the per capita cost of the tumor screening can be significantly reduced.

Owner:黄小军

Whitening process of PE (Polyethylene) stretch film

InactiveCN103613833AHigh transparencyIncrease brightnessSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention provides a whitening process of a PE (Polyethylene) stretch film. In a production process, a whitening agent is added, a mixed color problem of the stretch film produced by a reclaimed material is solved, transparency and brightness of the stretch film are improved, and product appearance is improved. The whitening process can respectively adopt a single-layer extruding process, a double-layer extruding process and a three-layer extruding process. In the single-layer extruding process, the stretch film is prepared by mixing 88.9wt%-55wt% of LLDPE (Linear Low Density Polyethylene) or MLLDPE (Metallocene Linear Low Density Polyethylene), 10%-35% of a reclaimed material which is at least one of PE reclaimed material or PP (Polypropylene) reclaimed material, 0.1%-3% of a whitening agent, and 1%-7% of a tackifier which is polyisobutene PIB or very low density polyethylene VLDPE. As for either the single-layer extruding process or the double-layer extruding process or the three-layer extruding process, product tensile strength is not less than 7 N in longitudinal direction and is not less than 3.5 N in transverse direction. The whitening process disclosed by the invention improves the mixed color problem of the stretch film produced by the reclaimed material, improves the transparency and brightness of the stretch film and improves the product appearance.

Owner:XIAMEN JUFU PLASTIC PRODS

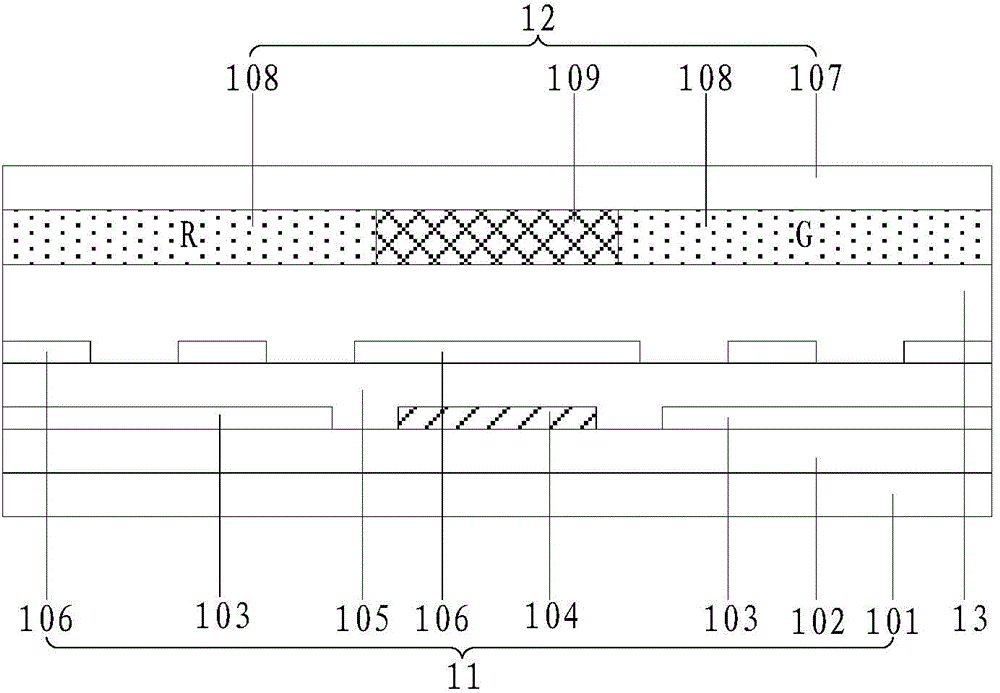

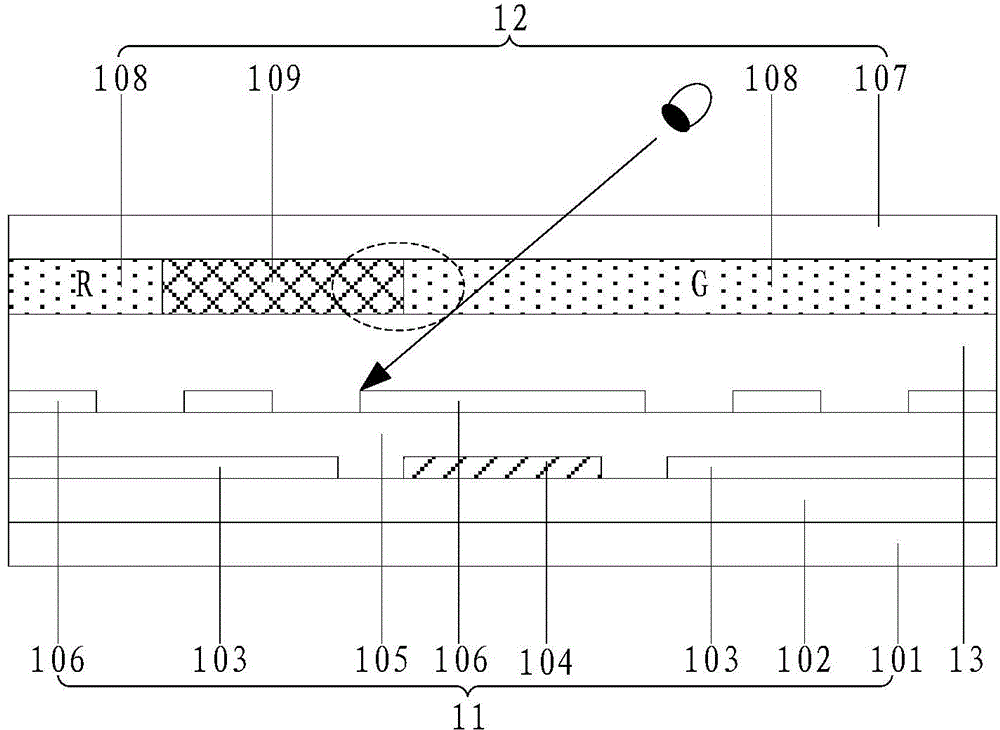

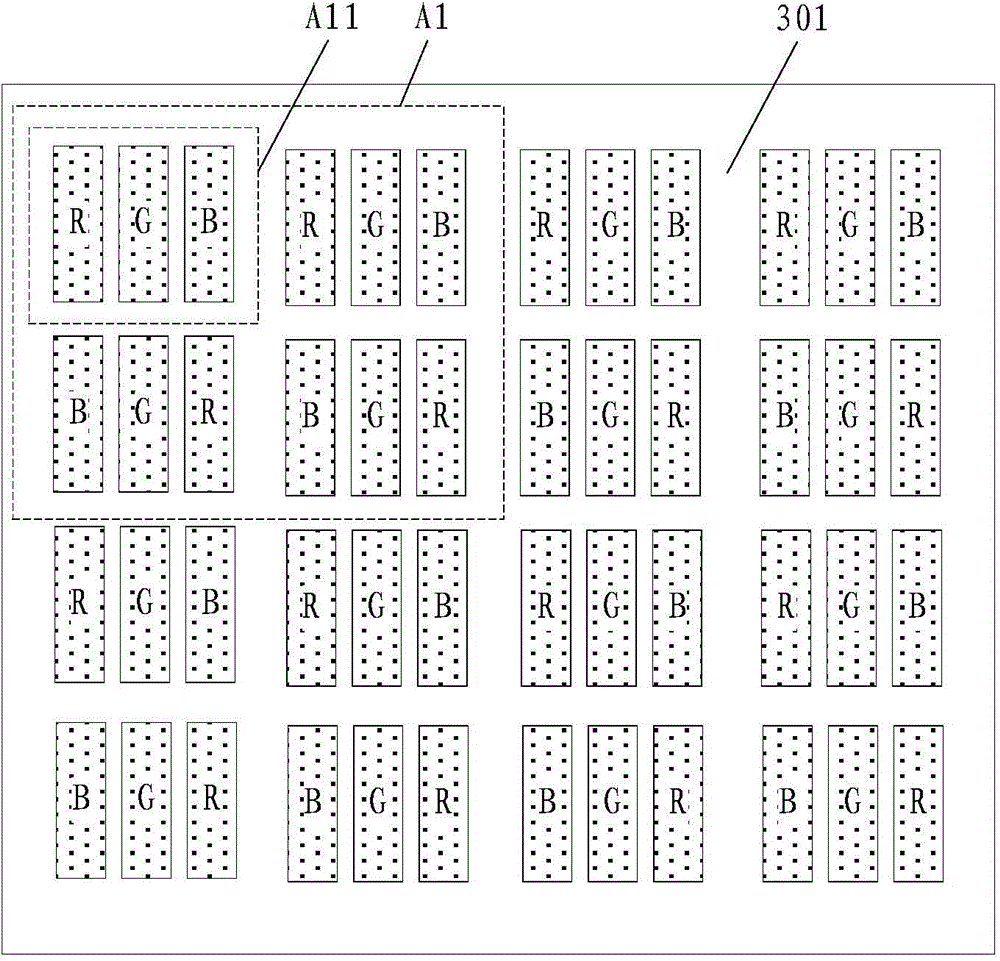

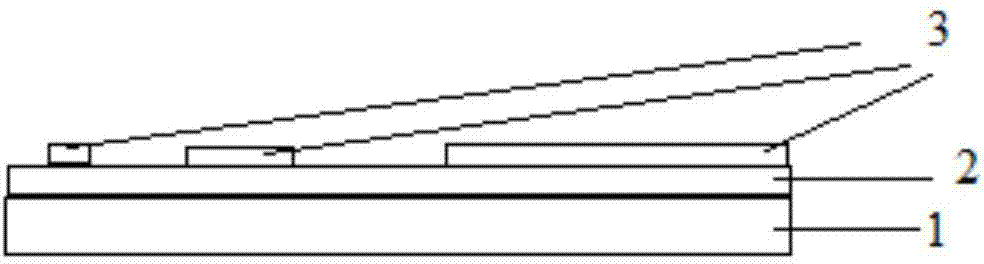

Color-film substrate and display device

The invention provides a color-film substrate and a display device. The color-film substrate comprises a plurality of pixels distributed in an array mode, each pixel comprises three color photoresists with different colors, one pixel comprises three side-by-side color photoresist rows, the color photoresist rows on the two sides comprise color photoresists of two colors, and the color photoresists of two colors are distributed at intervals. According to the color-film substrate, in a pixel unit formed by four pixels, color photoresists of one color on the left side or the right side are always adjacent to the color photoresists of two colors, when the color-film substrate deviates leftwards and rightwards relative to an array substrate or a user observes a picture along an inclined visual angle, two colors will be added into sub pixels of one color, and the influence of overlaying of the two added colors and the original color of the sub pixels on the color, needing to be displayed, of the sub pixels is far smaller than the influence caused by adding one color, so that the cross-color problem caused by poor alignment of the color-film substrate and the array substrate is solved, and picture quality is improved.

Owner:BOE TECH GRP CO LTD +1

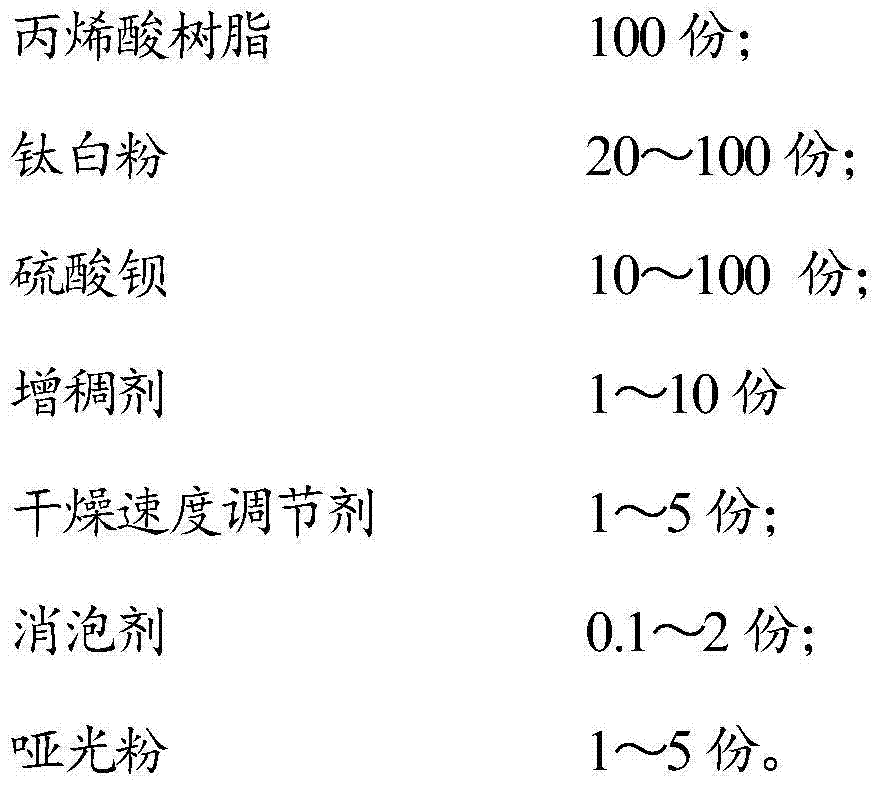

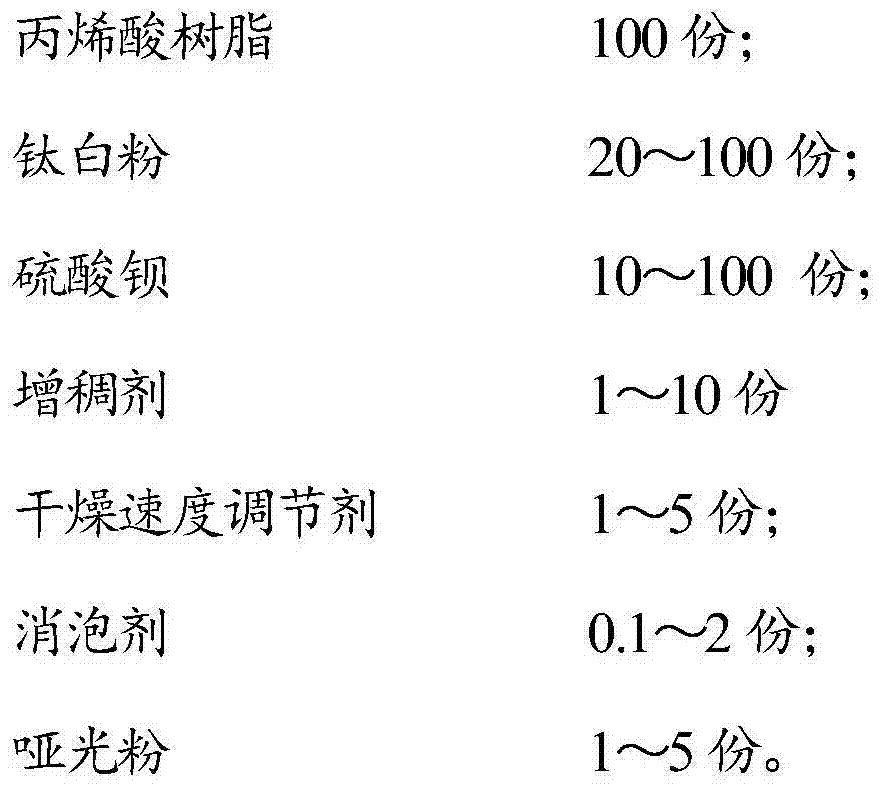

Wallpaper with hand-painting effect and manufacturing process of wallpaper

InactiveCN103483910AAvoid color distortionWith the effect of hand paintingCovering/liningsInksWater basedAcrylic resin

The invention discloses wallpaper with a hand-painting effect. The wallpaper comprises a bottom layer, an underpainting layer and a pattern layer, wherein the underpainting layer is formed on the bottom layer; the pattern layer is formed on the underpainting layer and formed by printing ink; and the printing ink is formed by adding organic coloring pigments to water-base resin, and the water-base resin comprises components in parts by weight as follows: 100 parts of acrylic resin, 20-100 parts of titanium dioxide, 10-100 parts of barium sulfate, 1-10 parts of a thickening agent, 1-5 parts of a drying rate conditioning agent, 0.1-2 parts of a defoaming agent and 1-5 parts of matte powder. According to the wallpaper, the printing ink used in the pattern layer is formed by adding the organic coloring pigments into the water-base resin, and the water-base resin is prepared with from proper raw materials, so that when the pattern layer is formed by the printing ink, pattern color distortion caused by secondary color and composite color problems during printing can be avoided, partial pattern surfaces are smooth and fine, the wallpaper is vividly and has the hand-painting effect, patterns can be formed through industrial production such as printing, the production efficiency is high, and the labor cost is low.

Owner:GUANGDONG YULAN GRP

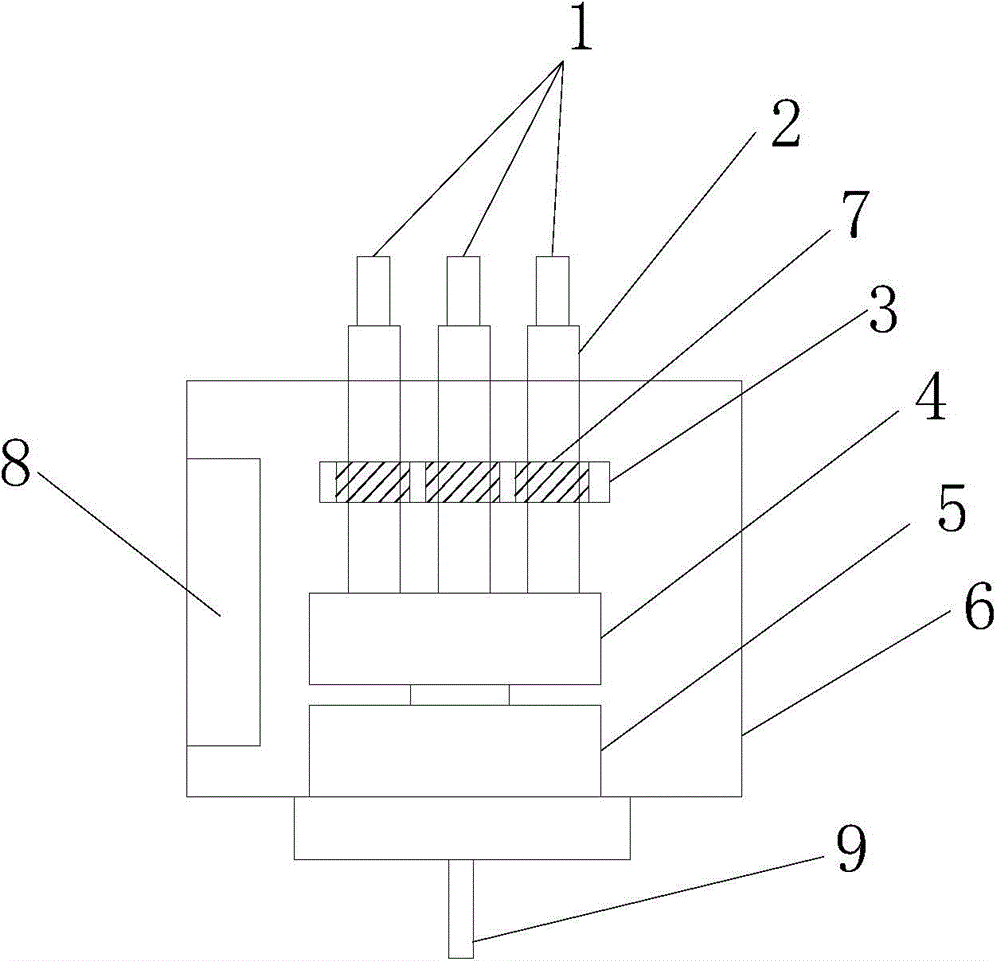

Three-color 3D printer head

The invention provides a three-color 3D printer head. The three-color 3D printer head is composed of a shell, three feed holes, a feed adjusting device, a melting device, a stirring device, a discharge outlet and a printer head controller, wherein the three feed holes are feed inlets respectively in three colors, are located above the shell and extend to the melting device, the discharge outlet is arranged below the shell, and the feed adjusting device, the melting device, the stirring device and the printer head controller are arranged in the shell. Through the improvement on the internal structure of the printer head, a three-color raw material is inputted for carrying out matching on the color so as to realize multicoloured 3D product printing. The three-color 3D printer head is simple in technique operation and easy to implement, and can effectively solve the pure color problem of printing products.

Owner:XIAN SHANGSHANG ELECTROMECHANICAL

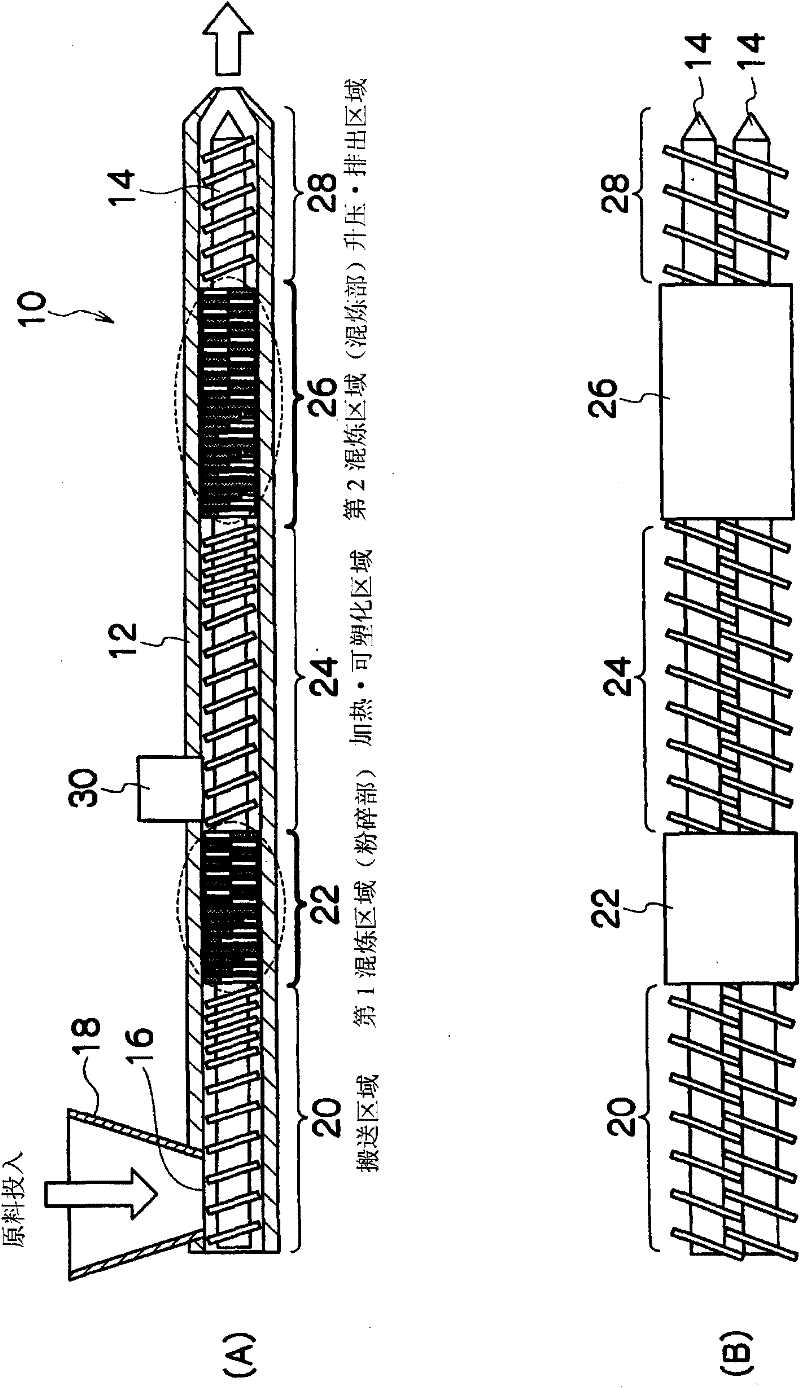

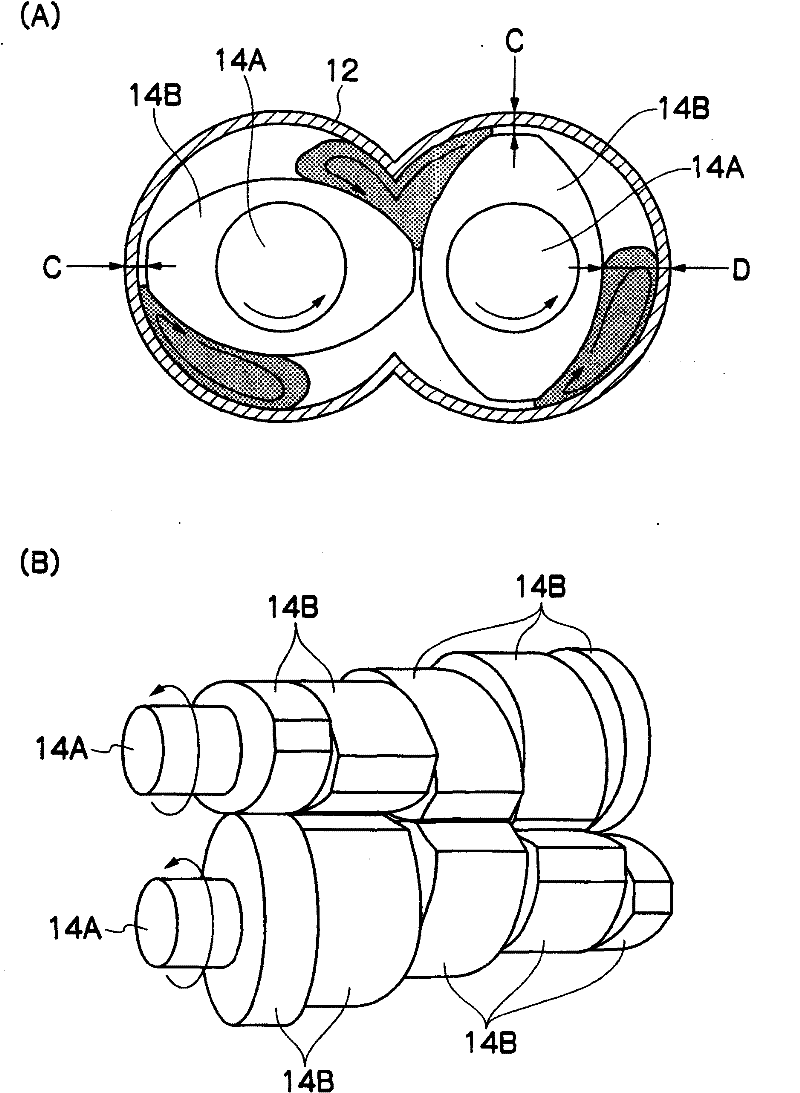

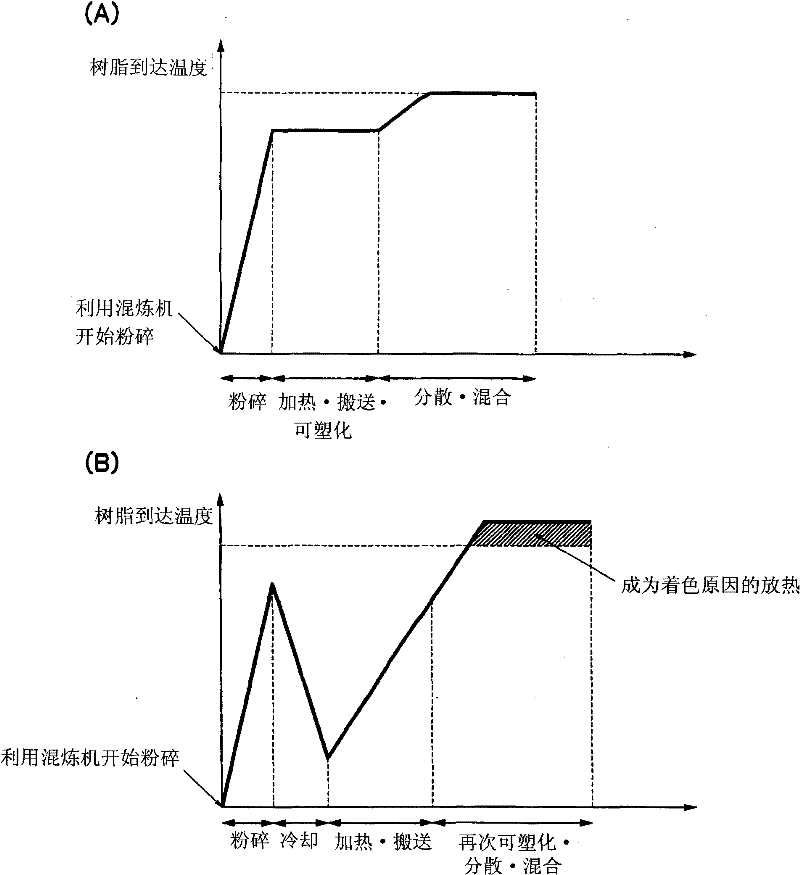

Manufacturing method of cellulose resin compositions

A manufacturing method of cellulose resin compositions can settle total problems of coloring problem, low modular weight, remaining of unmelted object and incapability of obtaining required physical performance when a mixing roll is used for manufacturing the cellulose resin compositions. According to the manufacturing method of the cellulose resin compositions, the mixing roll squeeze a raw material which comprises a resin material and a plasticizing agent for manufacturing the resin composition, wherein the resin material at least comprises particle-shaped cellulose resins. The manufacturing method of the cellulose resin compositions is characterized in that: a double-shaft mixing mill (10) which is provided with two mixing mill parts on a screw (14) and can adjust a shearing speed of the mixing mill part to a range of 140-436 sec<-1> is used as the mixing roll; in the two mixing roll parts, through setting a temperature of a roller at the mixing roll part at an inlet side to less than a softening temperature of the resin material and setting a temperature of a roller at the mixing roll part at an outlet side to above the softening temperature of the resin material; the mixing roll part at the inlet side is used as a crushing material (22) of the raw material, and simultaneously the mixing roll part at the outlet side is used as a mixing area (26) of the raw material; and one mixing roll is used for performing crushing, dispersing and mixing of the raw material.

Owner:FUJIFILM CORP

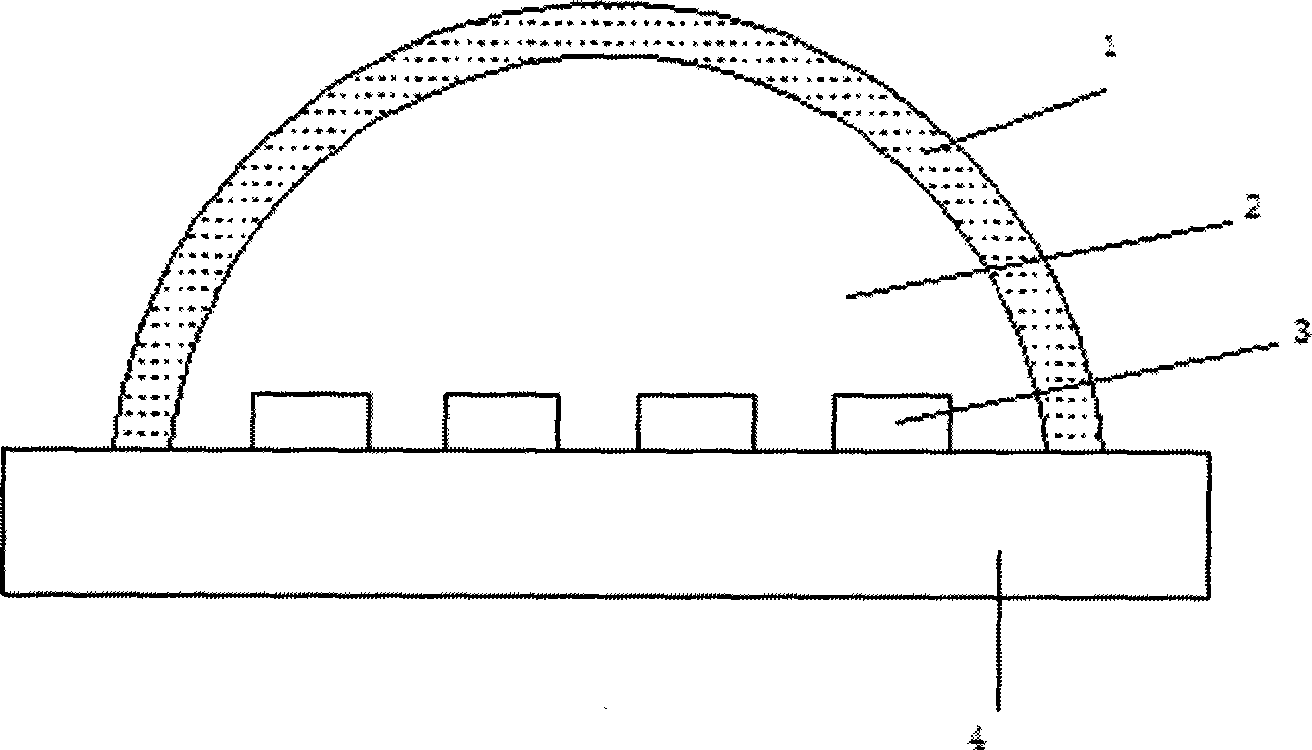

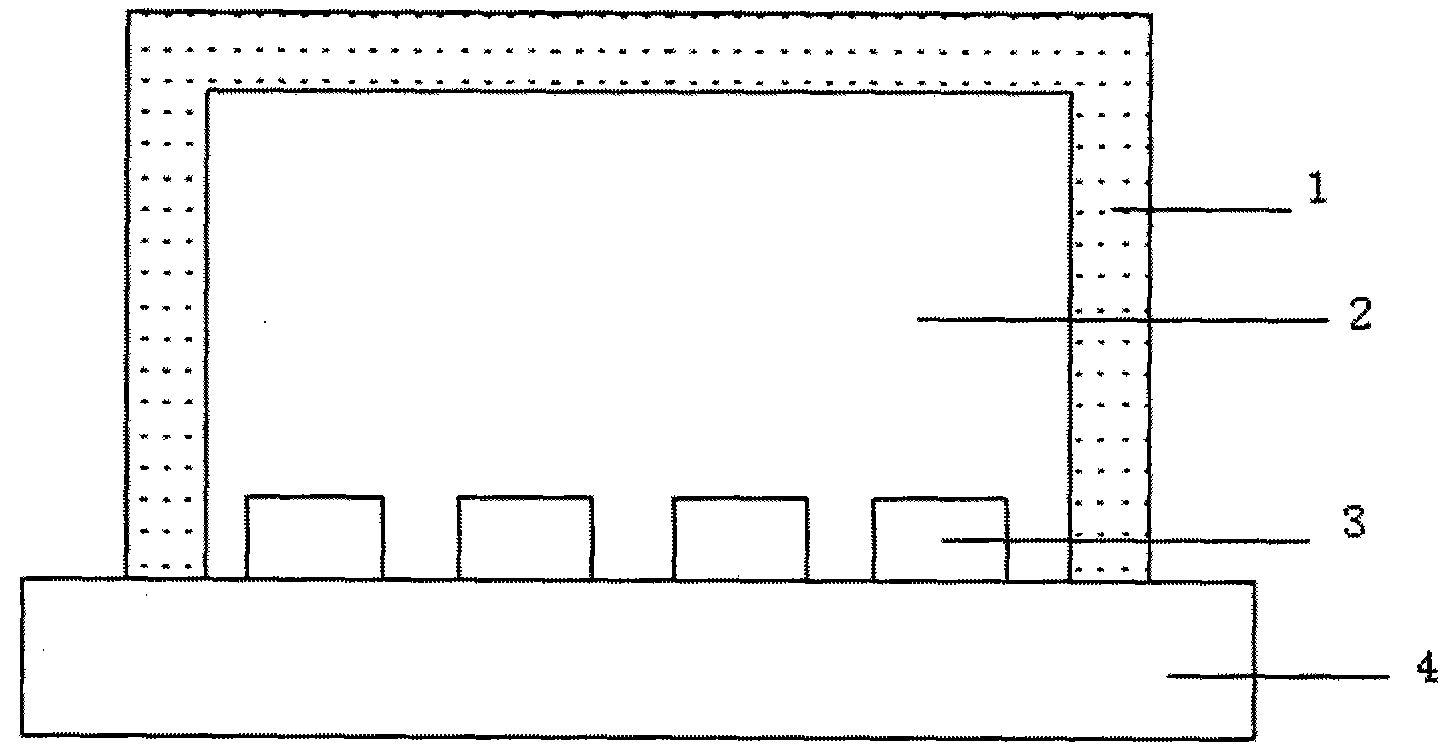

LED light source packaged with thin-wall ceramic lens

InactiveCN103824850AAvoid crackingEliminate yellow edgesSolid-state devicesSemiconductor devicesEffect lightOptical pathlength

The invention provides an LED light source packaged with a thin-wall ceramic lens. The LED light source packaged with the thin-wall ceramic lens comprises an LED chip, an electrode connection wire, an LED support, a packing material and the thin-wall ceramic lens. The thin-wall ceramic lens is fixed to the support, and the chip is completely covered with the thin-wall ceramic lens. The support and the thin-wall ceramic lens form a hollow inner cavity, and the inner cavity can be filled with the packing material at the time of packaging. The thickness of the thin-wall ceramic lens ranges from 0.05 mm to 2 mm. The thin-wall ceramic lens can be in the shape of a hemisphere or a semi-ellipsoid or a square box or a rhombus or an angle or a hyper-hemisphere or a Fresnel lens according to the packaging requirement of the LED light source. According to the LED light source packaged with the thin-wall ceramic lens, the LED light source is packaged in the form of the thin-wall ceramic lens, so that the optical paths of chip light to all parts of the lens are identical, and edge chromatic aberration of yellow edges, red edges, green edges and the like and the five-color problem of the packaged LED light source can be effectively eliminated; meanwhile, since the chip light is completely sealed in the lens, harm of blue light can be effectively avoided; by the selection of the packing material, the phenomenon that ceramic cracks due to a thermal gradient can be effectively prevented, and the lighting effect is enhanced.

Owner:张红卫

Optical element of liquid crystal display and manufacturing method thereof

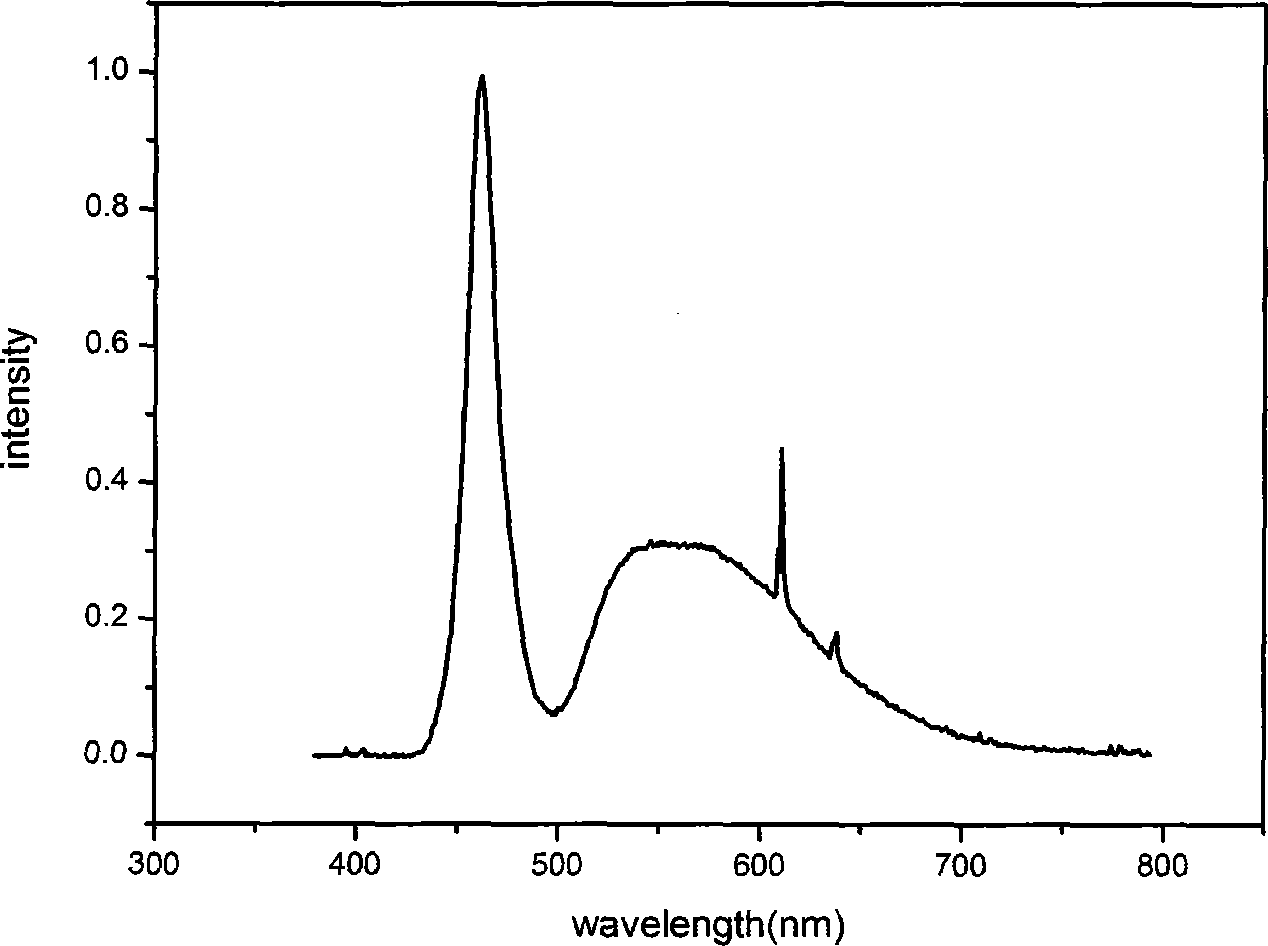

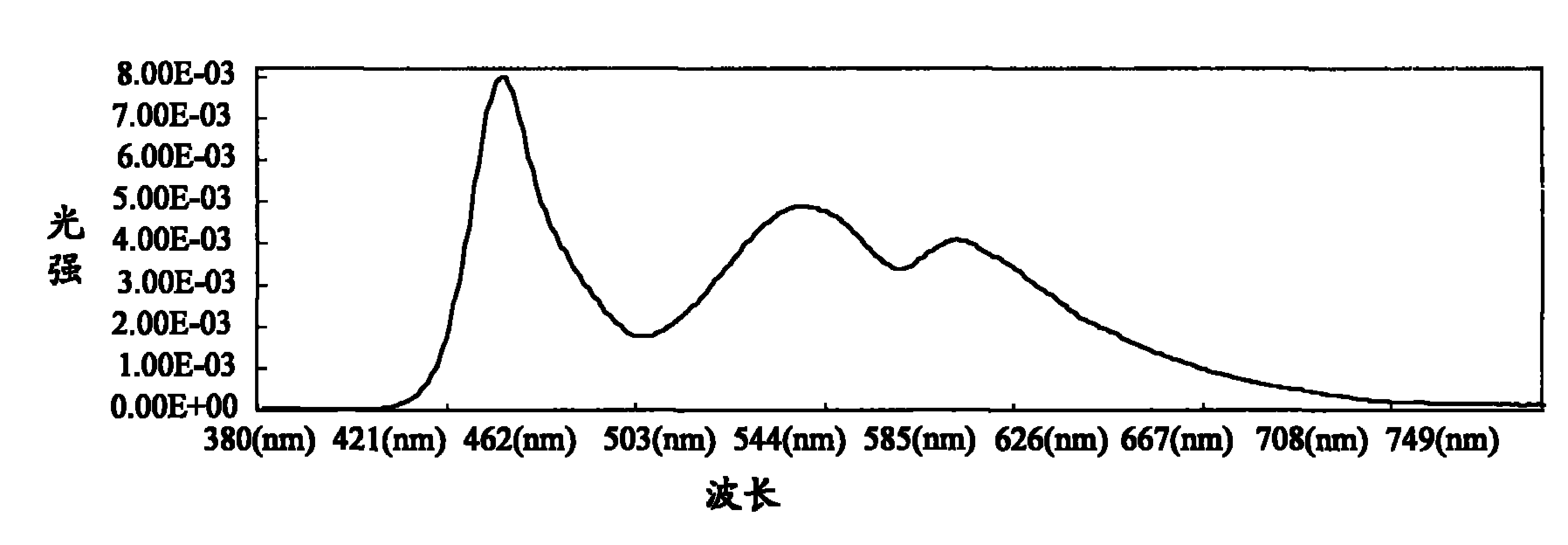

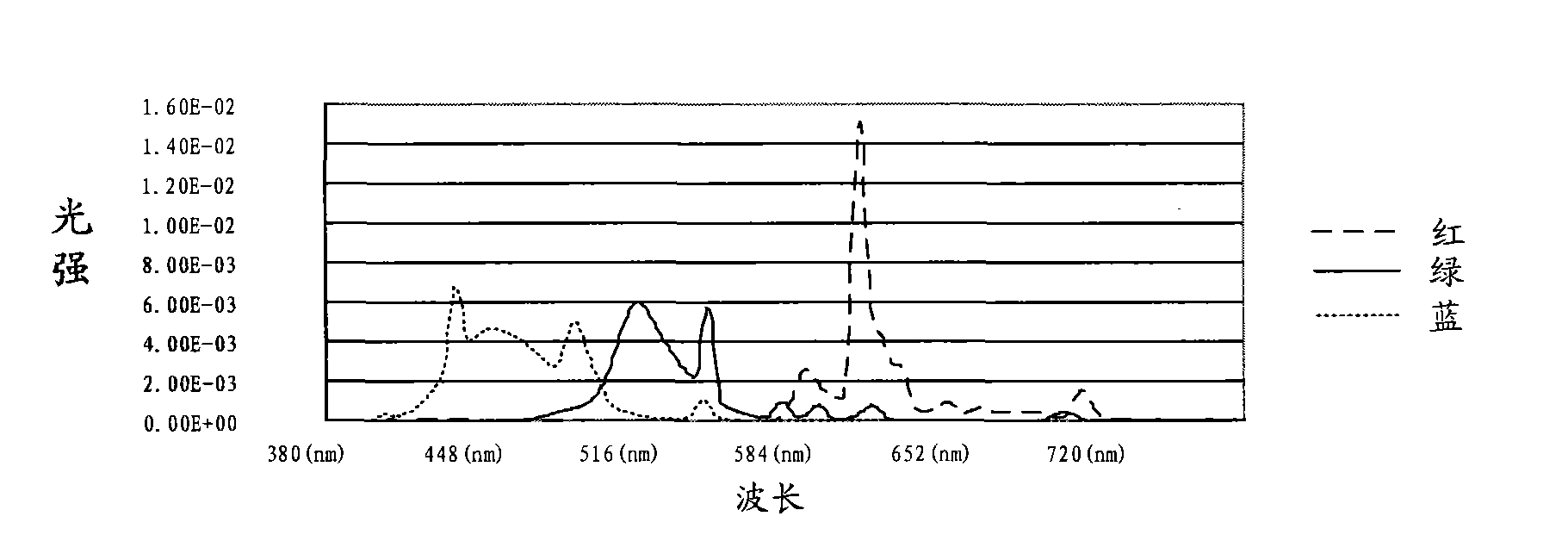

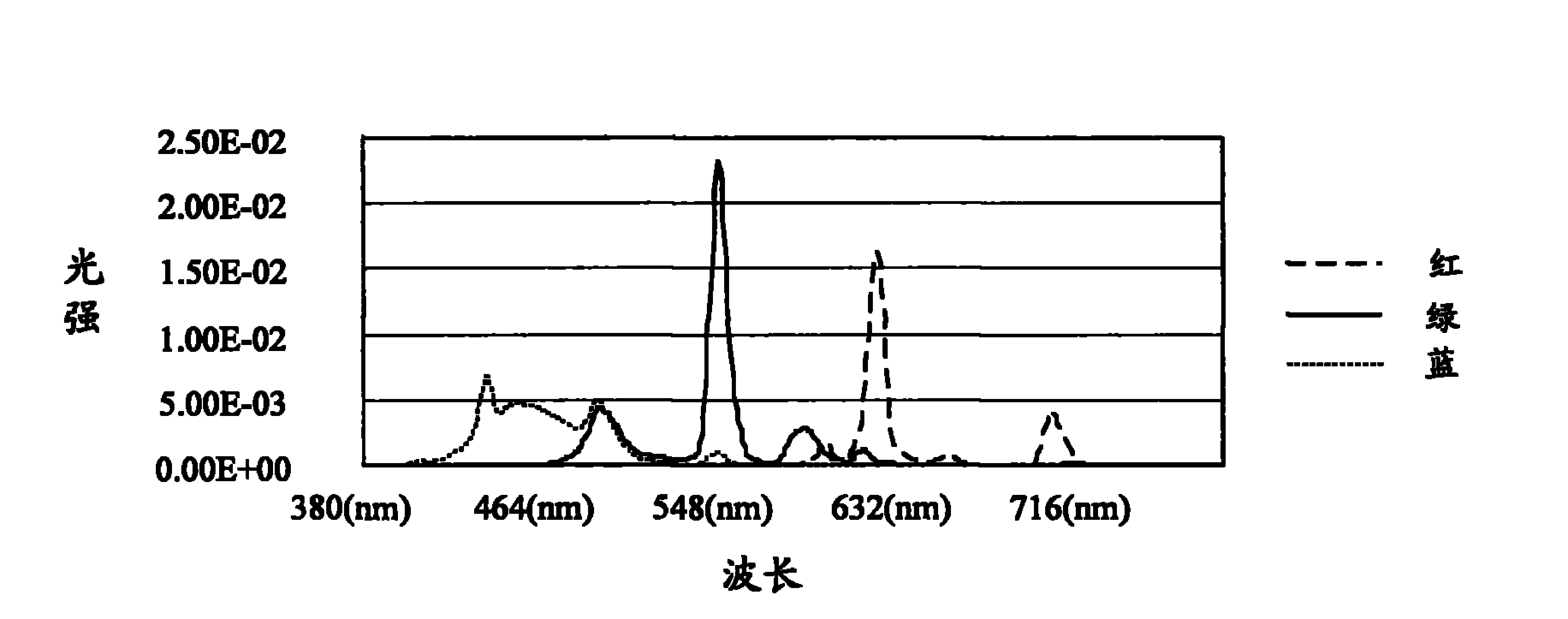

ActiveCN102116959AImprove picture qualityReduce transmittanceNon-linear opticsOptical elementsLiquid-crystal displayLight guide

The invention provides an optical element of a liquid crystal display and manufacturing method thereof, wherein the optical element of the liquid crystal display is an optical element positioned between a white light backlight source and a color film substrate and is distributed red particles. The invention further provides a liquid crystal display, comprising the white light backlight source andthe color film substrate, wherein the optical element of the liquid crystal display is arranged between the white light backlight source and the color film substrate. The invention further provides amethod for manufacturing a light guide plate and an optical film of the liquid crystal display. The optical element of the liquid crystal display and manufacturing method provided by the invention can change intensity ratio of the red light, the green light and the blue light penetrating through the optical element in backlight, increase the proportion of the red light by adding the red particlesin the optical element so as to solve the partial color problem of the white light as the backlight source which is obtained by means of exciting the yellow fluorescent powders by the blue light, andimprove the picture quality of the liquid crystal display using the white light backlight source.

Owner:BOE TECH GRP CO LTD +1

Slurry special for modified floating beads and preparation method of slurry special for modified floating beads

ActiveCN103937314AFix color problemsImprove adhesionReflecting/signal paintsThermal isolationThermal insulation

The invention relates to a coating for photo-thermal reflection and photo-thermal isolation, and in particular relates to a preparation method of slurry special for modified floating beads, and the slurry special for the modified floating beads, belonging to the technical field of building coatings. A reflective thermal-insulation coating comprises a reflective coating and modified floating beads, wherein the modified floating beads are uniformly dispersed in the reflective coating. From economic considerations, ceramic hollow micro beads are replaced by fly-ash floating beads, and good technical effects are obtained; the price of the fly-ash floating beads is much lower than that of the ceramic hollow micro beads; and although the fly-ash floating beads have strong thermal insulation capacities, the color of the fly-ash floating beads is not pure white enough, and the photo-thermal reflection performance of the coating is influenced. According to the slurry disclosed by the invention, the color problems of the floating beads are solved by adopting a titanium dioxide spraying process; moreover, the adhesion of the floating beads to the wall surface is much stronger than that of the ceramic hollow micro beads, thus having technical advantages; the reflective coating disclosed by the invention not only can be used independently, but also can be matched with the modified floating beads; and the reflective coating has a photo-thermal reflection effect when being used independently, and has a reflective thermal-insulation effect when being matched.

Owner:HUZHOU GREEN BUILDING MATERIALS DEV

Bamboo vegetable carbon black biscuit and preparation method thereof

InactiveCN107156227AFood safetySolve the problem of coloringDough treatmentModified nutritive productsFlavorBaking powder

The invention discloses a bamboo vegetable carbon black biscuit and a preparation method thereof and belongs to the field of food processing. The bamboo vegetable carbon black biscuit is processed from raw materials in parts by weight as follows: 180-210 parts of flour, 50-70 parts of eggs, 15-30 parts of milk powder, 0-80 parts of cereal flour, 0-80 parts of vegetable powder, 0-80 parts of mushroom powder, 1-4 parts of table salt, 50-70 parts of sugar, 80-110 parts of cream, 3-6 parts of baking powder and 0.5-1.5 parts of bamboo vegetable carbon black. According to the bamboo vegetable carbon black biscuit obtained with the preparation method, the coloring problem of the biscuit is solved, and the biscuit has uniform and reliable quality, is safe to eat and has the unique flavor. The biscuit has the advantages of being good in product quality, simple and convenient to operate, prone to industrialization and the like and has bright popularization and application prospects.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

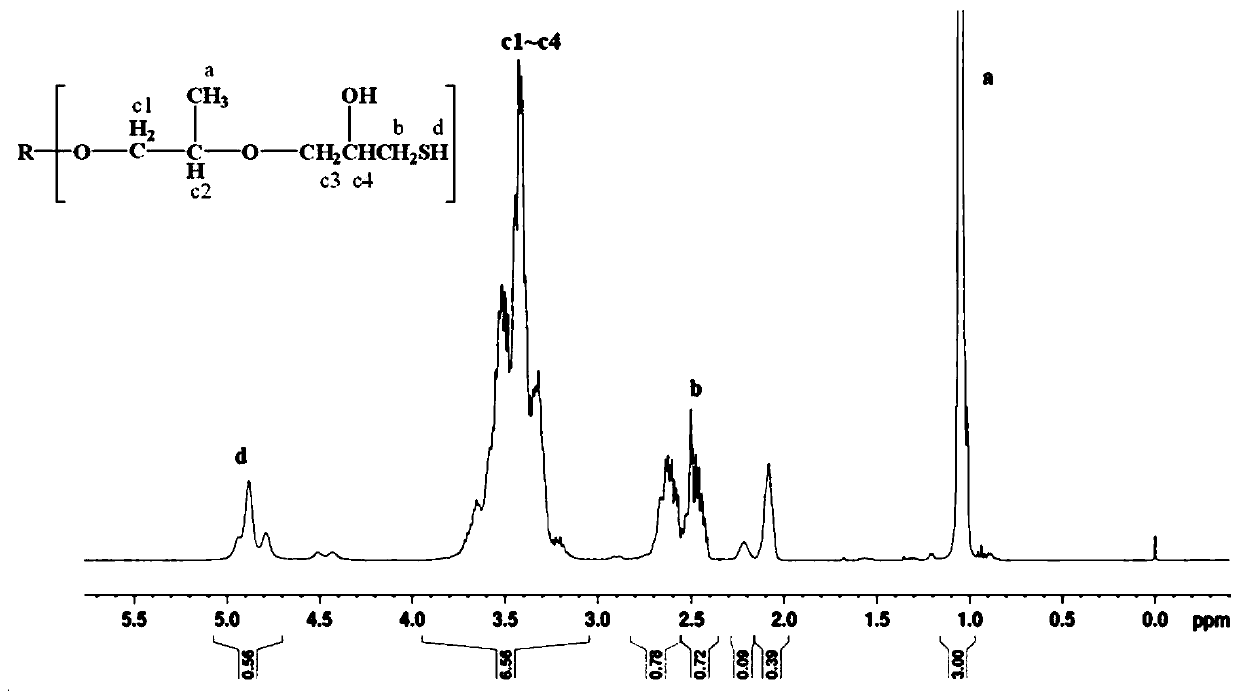

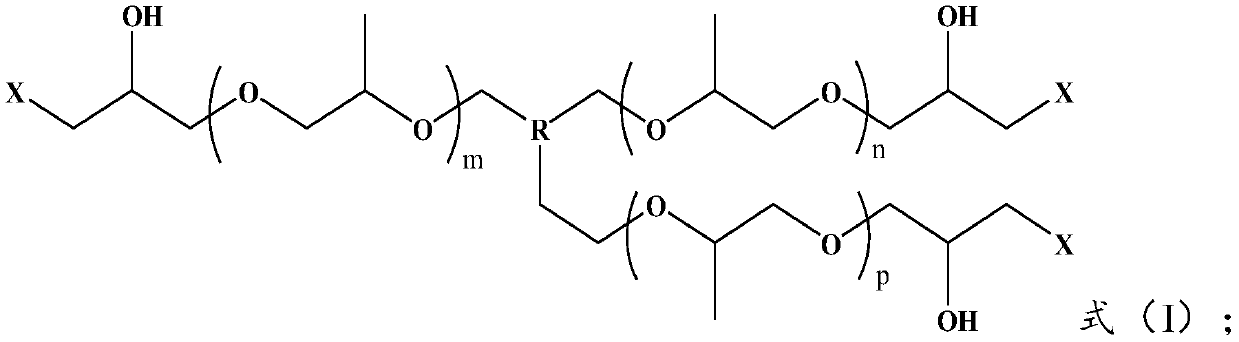

Polymercaptan curing agent, and preparation method and application thereof

The invention provides a preparation method of a polymercaptan curing agent. The preparation method comprises the following steps: a) carrying out reacting on NaSH, a phase transfer catalyst, organicpolyhalogenated polyether and water in the presence of H2S to obtain a crude product, wherein the iron content of NaSH ranges from 0.005 wt% to 1 wt%; and b) sequentially washing the crude product obtained in the step a) by water, and carrying out drying to obtain the polymercaptan curing agent. Compared with the prior art, the preparation method has the advantages that the iron content of the rawmaterial NaSH is strictly controlled, the high-quality polymercaptan curing agent is obtained through a specific preparation process, and the product is colorless and transparent, is low in halogen content and meets the requirements of a novel green environment-friendly curing agent. When the polymercaptan curing agent is applied to preparation of optical materials such as lenses with good optical physical properties, the coloring problem cannot be caused. Experimental results show that the chromaticity of the polymercaptan curing agent obtained by the preparation method provided by the invention is 16-27, and the halogen content is within 700ppm.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Milk white or colorful magnetic fiber filament meeting textile color requirement and preparing method thereof

InactiveCN108286085AColor is full and richGuaranteed long-term effectivenessFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolyester

The invention relates to a milk white or colorful magnetic fiber filament meeting the textile color requirement and a preparing method thereof. The milk white or colorful magnetic fiber filament is characterized in that the magnetic fiber filament is of a skin-core structure, and a skin layer material and a core layer material of the magnetic fiber filament adopt polyamide / polyester chips which are different in polarity respectively, wherein the skin layer material of the magnetic fiber filament comprises color master batches, and the core layer material of the magnetic fiber filament comprises magnetic master batches. According to the milk white or colorful magnetic fiber filament meeting the textile color requirement and the preparing method thereof, a milk white or colorful magnetic fiber effectively isolates air and water of the magnetic master batches in the core layer material through the polyamide / polyester chips with the different polarities in the core layer material and the skin layer material, the long-term effect of filter magnetism is guaranteed, and the single color problem in the existing magnetic fiber preparing technology is solved by adding the color master batches into the skin layer material.

Owner:ZHOUSHAN XINXIN CHEM FIBER +1

Preparation method of modified special slurry for floating beads and modified special slurry for floating beads

ActiveCN103937314BFix color problemsImprove adhesionReflecting/signal paintsThermal isolationThermal insulation

The invention relates to a coating for photo-thermal reflection and photo-thermal isolation, and in particular relates to a preparation method of slurry special for modified floating beads, and the slurry special for the modified floating beads, belonging to the technical field of building coatings. A reflective thermal-insulation coating comprises a reflective coating and modified floating beads, wherein the modified floating beads are uniformly dispersed in the reflective coating. From economic considerations, ceramic hollow micro beads are replaced by fly-ash floating beads, and good technical effects are obtained; the price of the fly-ash floating beads is much lower than that of the ceramic hollow micro beads; and although the fly-ash floating beads have strong thermal insulation capacities, the color of the fly-ash floating beads is not pure white enough, and the photo-thermal reflection performance of the coating is influenced. According to the slurry disclosed by the invention, the color problems of the floating beads are solved by adopting a titanium dioxide spraying process; moreover, the adhesion of the floating beads to the wall surface is much stronger than that of the ceramic hollow micro beads, thus having technical advantages; the reflective coating disclosed by the invention not only can be used independently, but also can be matched with the modified floating beads; and the reflective coating has a photo-thermal reflection effect when being used independently, and has a reflective thermal-insulation effect when being matched.

Owner:HUZHOU GREEN BUILDING MATERIALS DEV

A kind of silica sand colorant, colored silica sand and preparation method of colored silica sand

The invention provides a silica sand colorant, which contains iron yellow powder and titanium dioxide, wherein, based on the total weight of iron yellow powder and titanium dioxide, the content of iron yellow powder is 1-99% by weight, and the content of titanium dioxide is The colored silica sand using the silica sand coloring agent and the preparation method of the colored silica sand are also provided. The present invention uses the silica sand coloring agent prepared by mixing iron yellow powder and titanium dioxide in a certain proportion to overcome the problems of difficulty in coloring silica sand and poor long-term stability of the color after coloring in the prior art, and can easily dye silica sand to different degrees of yellow , and the colored silica sand has excellent long-term color stability.

Owner:BEIJING RECHSAND SCI & TECH GRP

Polyvinyl chloride color masterbatch suitable for high-speed production of automobile wires and cables and preparation method of polyvinyl chloride color masterbatch

InactiveCN109096652AMix evenly and stablyHigh degree of polymerizationPolyvinyl chlorideColoring problem

The invention relates to polyvinyl chloride color masterbatch suitable for high-speed production of automobile wires and cables and a preparation method of the polyvinyl chloride color masterbatch. The active components of the polyvinyl chloride color masterbatch consist of the following raw materials in parts by weight: 45-55 parts of polyvinyl chloride, 5-12 parts of titanium dioxide, 4-8 partsof a brightening agent, 3-6 parts of a calcium zinc stabilizer, 1-3 parts of oxidized polyethlene wax, 1-3 parts of a surface treating agent, 1-3 parts of zinc stearate, 1-3 parts of a coupling agentand 25-35 parts of pigment. The polyvinyl chloride and the oxidized polyethlene wax are pre-stirred, so that substrate materials are stable and uniform when being mixed, the polymerizing degree is higher, when the temperature of masterbatch substrates is lower than that of squeezed materials, diverging and coloring of masterbatch are facilitated, the fusion degree of the masterbatch substrate materials and the squeezed materials is increased, and high-speed squeezing is facilitated; and through measures of added materials and a production technology, the masterbatch materials are more suitablefor high-speed squeezing of automobile wires and cables, the production efficiency is greatly improved, and unnecessary losses caused by color problems are reduced.

Owner:山东寰宇线缆有限公司

Production process for attaching color shine on platinum surface

InactiveCN105015243ASolve single colorFunction increaseDecorative surface effectsSpecial ornamental structuresPlatinumPt element

The present invention relates to a production process for attaching color shine on the platinum surface. The production process steps comprise: 1, melting small platinum through a melting furnace; 2, pouring the molten platinum liquid raw material into a strip mold to form a platinum strip raw material; 3, pressing the platinum strip raw material into a platinum sheet raw material by using the upper pressing roller and the lower pressing roller of a sheet pressing machine; 4, carrying out annealing treatment on the platinum sheet raw material through an annealing process, wherein the platinum sheet raw material is baked and softened into a soft platinum sheet; and 5, taking laser aluminum sheet raw materials with different color shine forms, cutting, and adhering the laser aluminum sheet raw material with the color shine and the soft platinum sheet so as to obtain the mixed soft platinum sheet raw material. With the process of the present invention, the original traditional white color of the platinum is changed into various colors, such that the platinum is faddish while the quality of the platinum is not affected, the single color problem of the platinum is solved, and the function of the platinum is expanded so as to expand the use range of the platinum, increase the added value of the platinum, form the new color shine platinum.

Owner:深圳市冠华珠宝有限公司

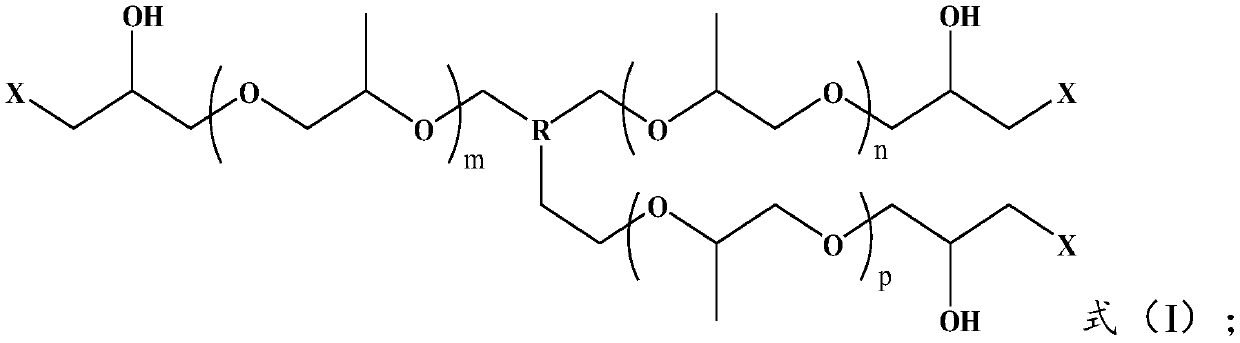

Image processing method and device

InactiveCN107172406AGuaranteed picture qualityImprove wrong color problemBrightness and chrominance signal processing circuitsImaging processingImaging quality

The embodiment of the present invention proposes an image processing method and an image processing device, which improve the wrong color problem existing in the traditional method of restoring YUV444 from YUV422. For the missing UV component, the current pixel point calculates the weight according to the brightness component information and then calculates its recovery. After the UV component, the image quality is guaranteed as much as possible while reducing the bandwidth.

Owner:XIAN NOVASTAR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com