Reflective polarizer sheet

A polarizer, reflective technology, applied in the field of optical films, can solve problems such as color shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

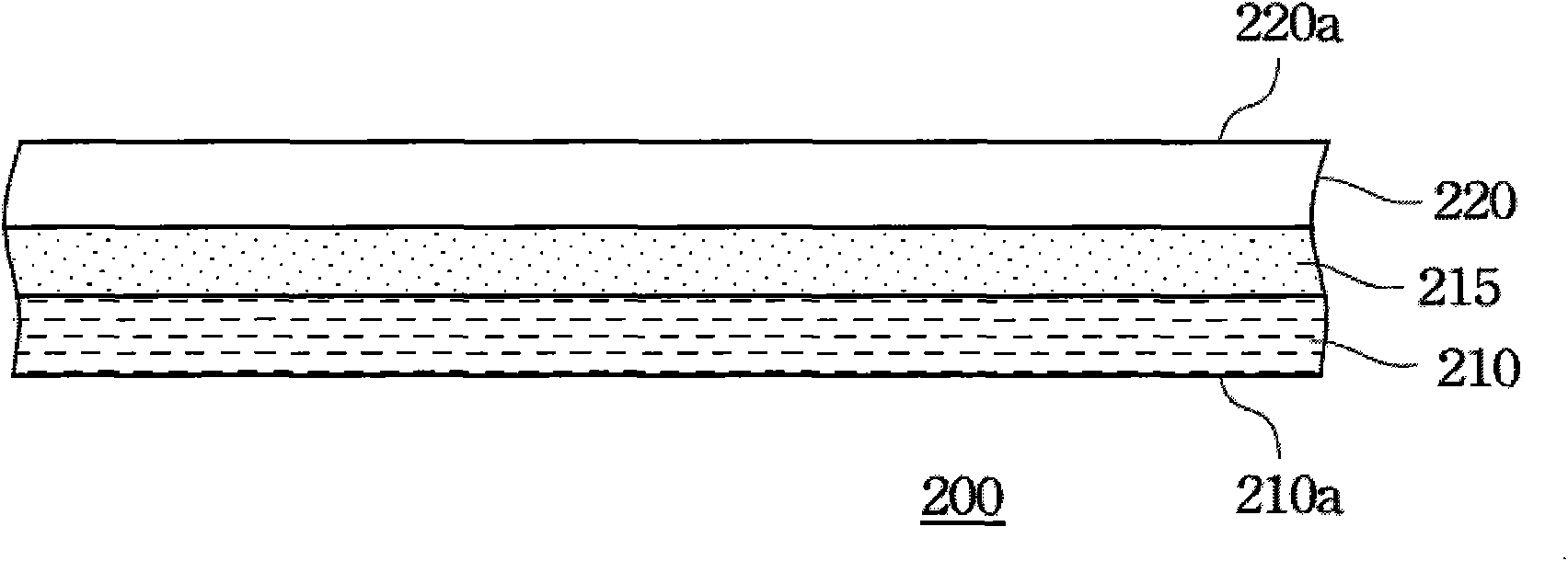

preparation example Construction

[0077] Here, experimental examples and comparative examples of preparation of adhesive layer compositions will be described. The adhesive layer composition is divided into three categories, namely, a composition without blue colorant, a composition with blue colorant added, and a composition with blue colorant and microbeads added. The preparation method is as follows:

[0078] 1. Composition without blue pigment (composition A):

[0079] Mix the adhesive (acrylic resin pressure-sensitive adhesive, AO-802, produced by Eternal Company) with the solvent (ethyl acetate) and stir evenly (solid content is 25%), and prepare the composition A of the adhesive layer, such as Table 1 shows.

[0080] 2. Add the composition of blue pigment (composition B-E):

[0081] Dissolve the blue dye (D-96, produced by Ciba Company) in the solvent (ethyl acetate), and then mix it with the adhesive (acrylic resin pressure-sensitive adhesive, AO-802, produced by Eternal Company) and mix evenly (solid...

experiment example 5

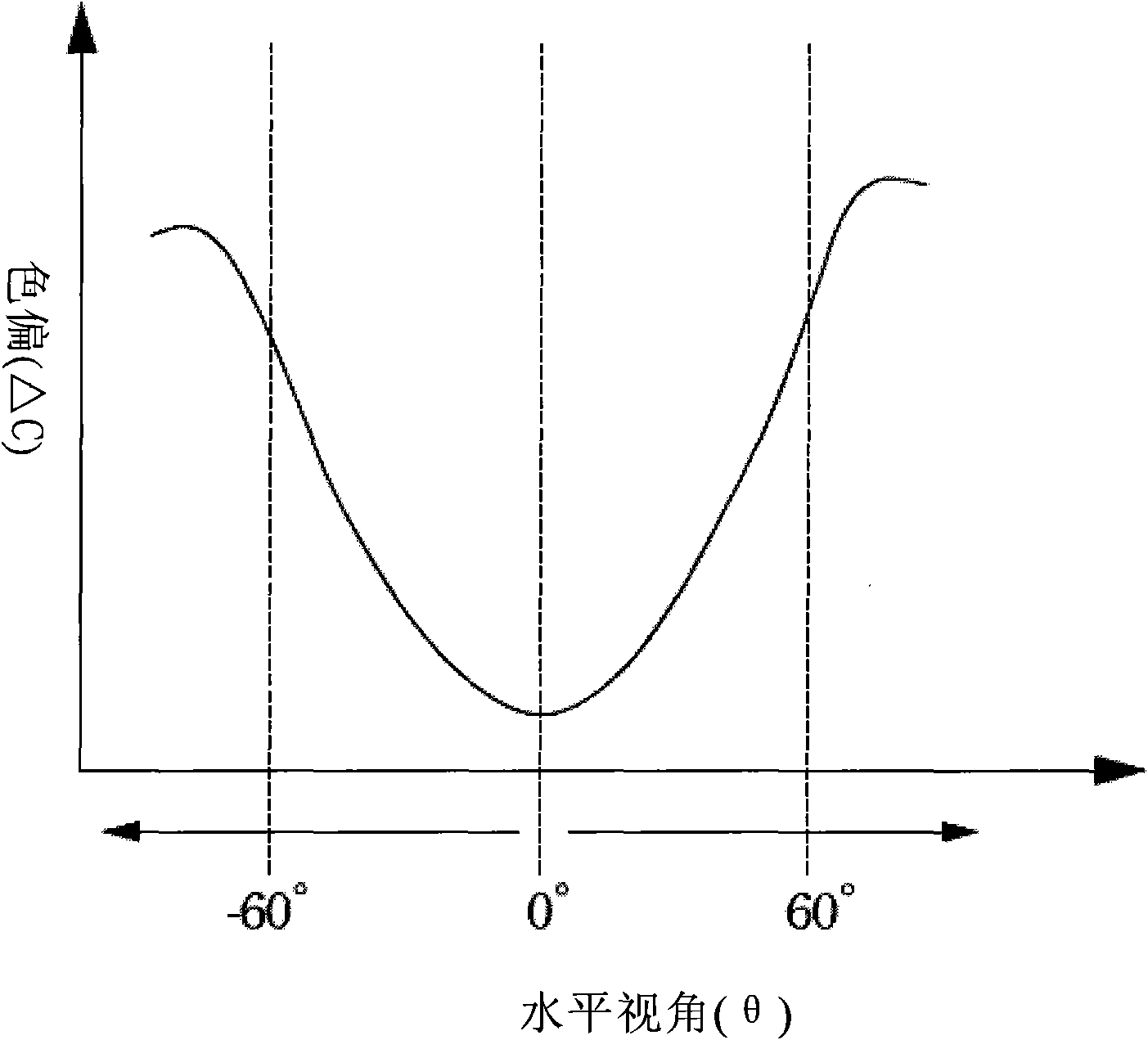

[0112] The values of ΔX0° and ΔX60° of Experimental Example 5 are significantly smaller than the values of ΔX0° and ΔX60° of Comparative Example 2. It shows that adding blue dye and microbeads to the adhesive layer at the same time can improve the effect of color difference comparable to the reflective polarizer with a large amount of blue dye added to the adhesive layer (Experimental Example 4).

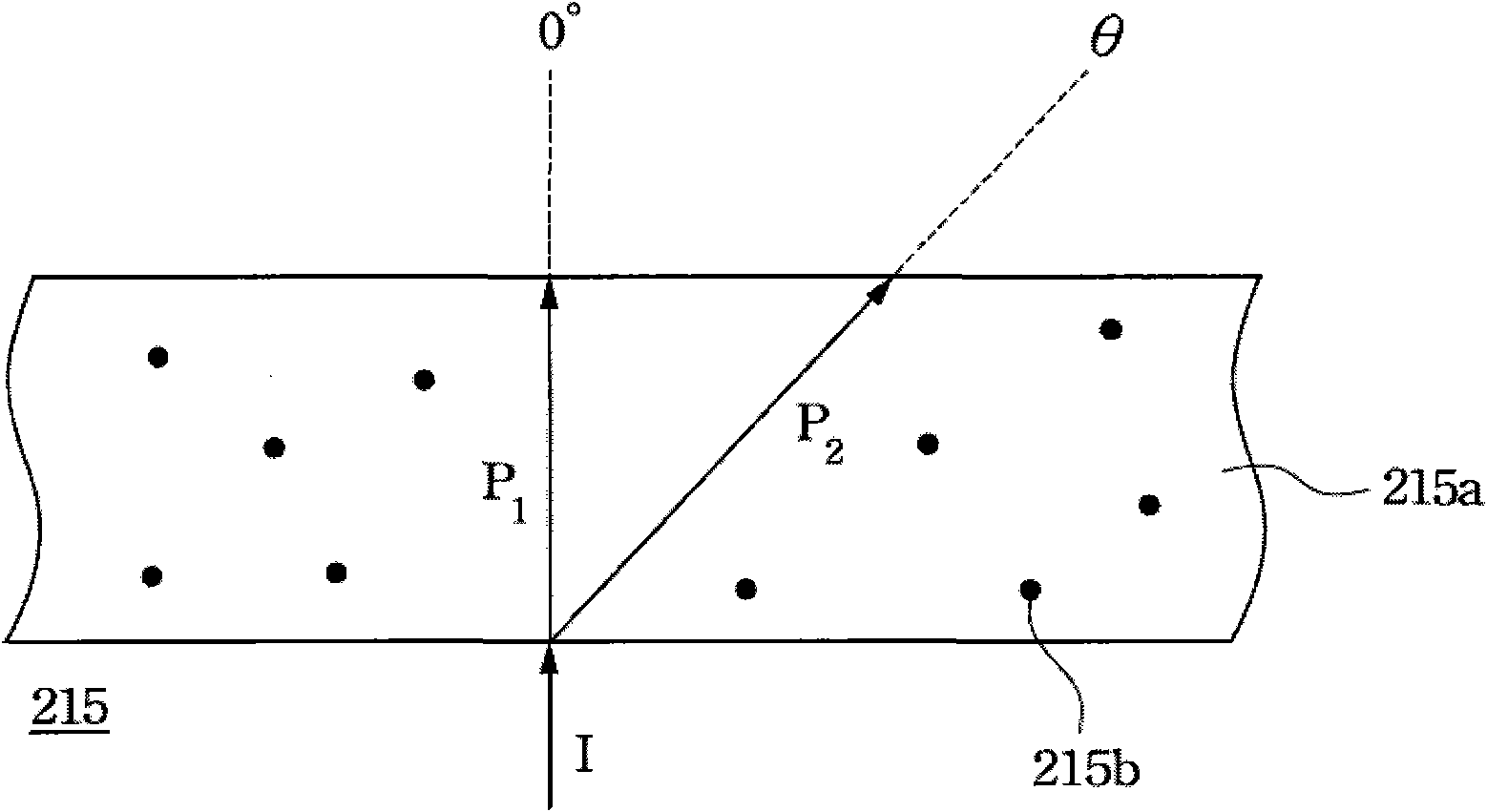

[0113] From the values of ΔX0° and ΔX60° in Experimental Examples 6-8, it can be known that the formation of light-condensing microstructures on the surface of the reflective polarizer can further reduce the chromaticity difference caused when the reflective polarizer is applied to the backlight module, and Reduce the chromaticity difference between large horizontal viewing angle (60°) and normal viewing angle (0°). Especially in reducing the chromaticity difference between normal viewing angles (0°), its performance is particularly remarkable.

[0114]It can be seen from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com