Patents

Literature

37results about How to "Does not affect the composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

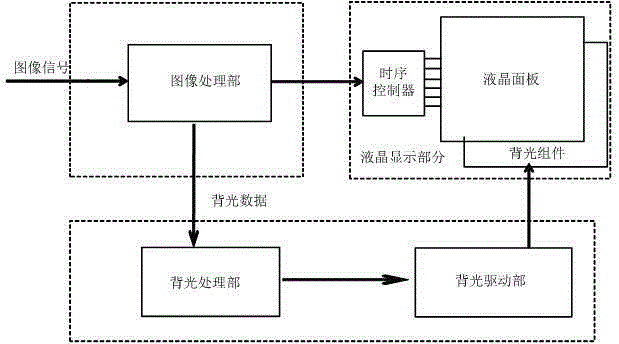

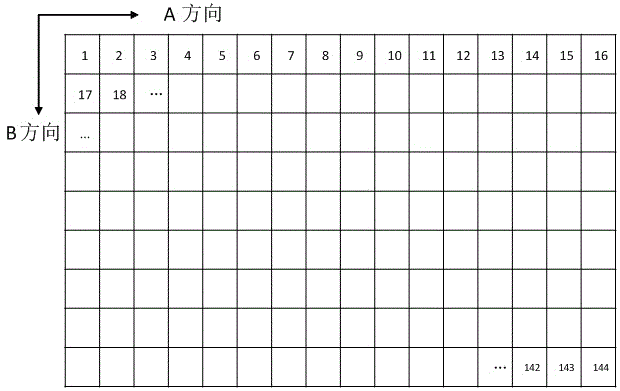

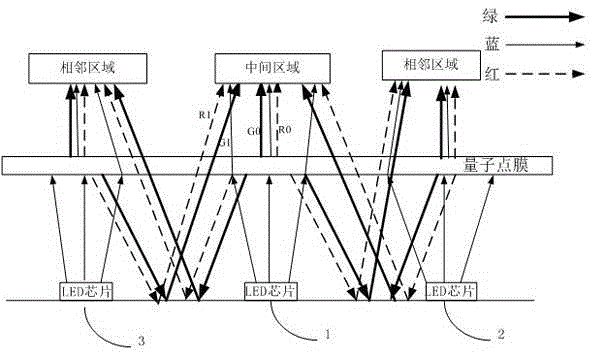

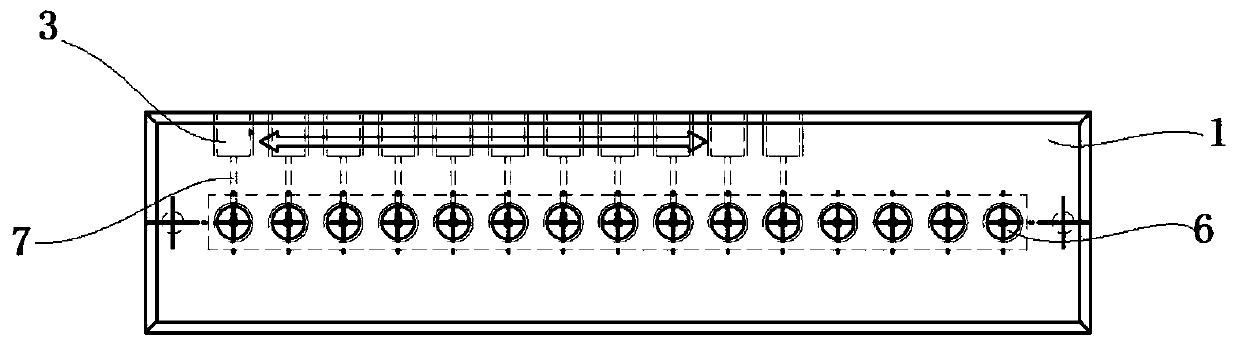

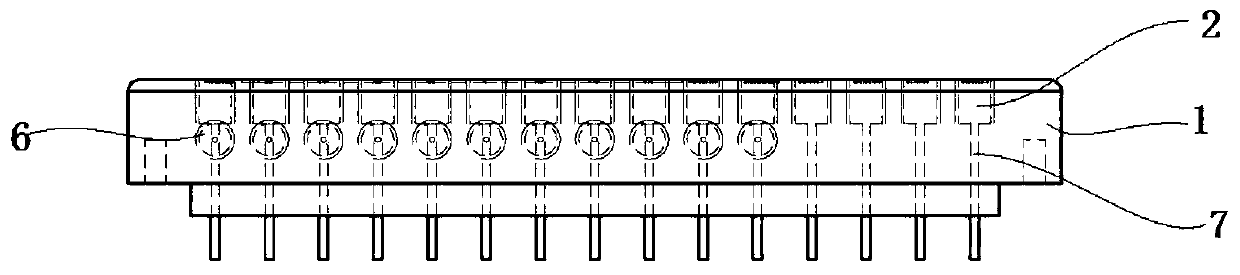

Backlight module and liquid crystal display device

InactiveCN105278162ADoes not affect the compositionSolve the problem of color castNon-linear opticsLiquid-crystal displayQuantum dot

The embodiments of the invention provide a liquid crystal display device, and relates to the technical field of liquid crystal displays. According to the embodiments of the invention, a liquid crystal display device is dynamically controlled within a backlight sub-area controlled dynamically by the sub-area backlight. A plurality of excitation-point light sources serve as excitation light sources of a surface light source and the quantum dot material in a quantum dot packaging part along the light emergent direction of the above light sources is excited. Between the plurality of excitation-point light sources and the quantum dot packaging part, a light selection part is arranged to select the transmission of the excitation light sources sent from the light sources and reflect the excitation light generated through exciting the quantum dot material. In this way, the back light reflected back by the quantum dot packaging part can be reflected by the light selection part, so that the interference of the back light on a white light source in the adjacent area can be avoided. Therefore, the white light of the white light source in the backlight sub-area is formed through only mixing up the excitation light generated by the point light sources in the backlight sub-area with the motivated light of the above point light sources generated through exciting the excitation light of the point light sources.

Owner:HISENSE VISUAL TECH CO LTD

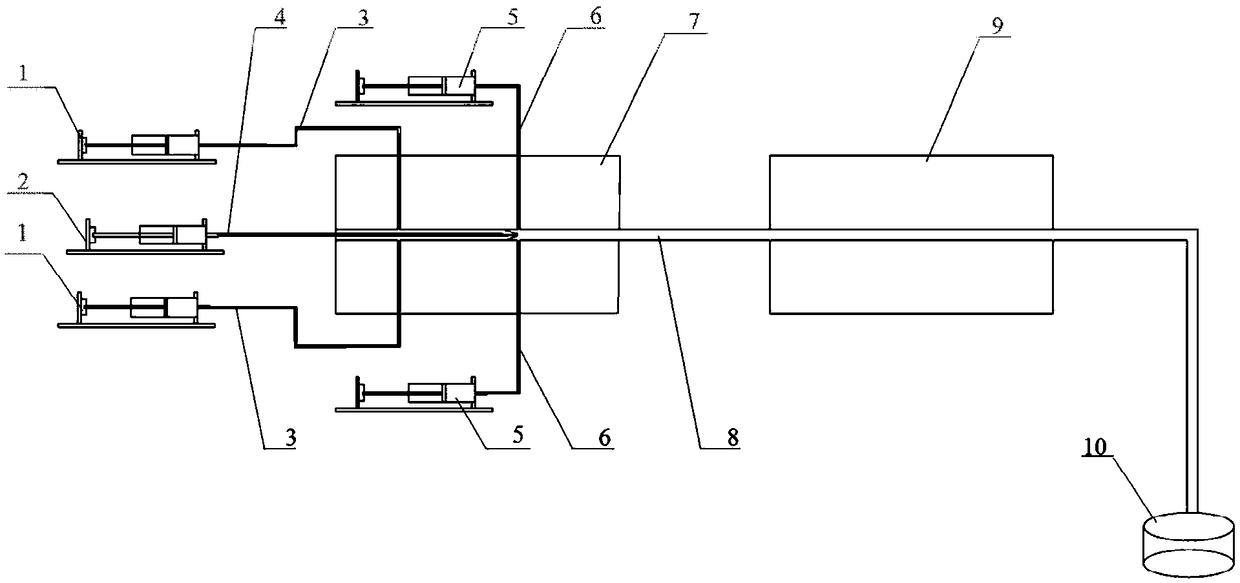

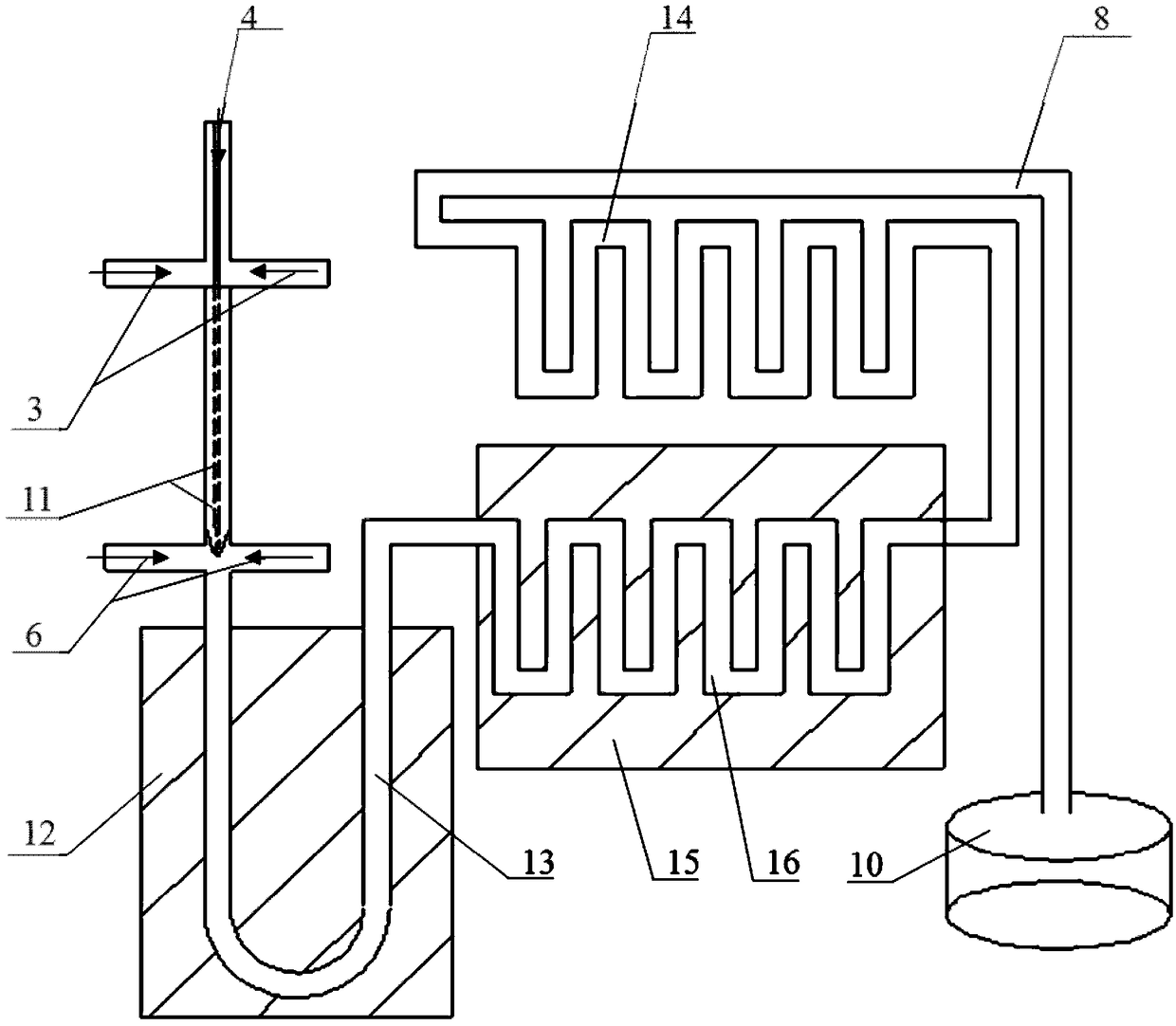

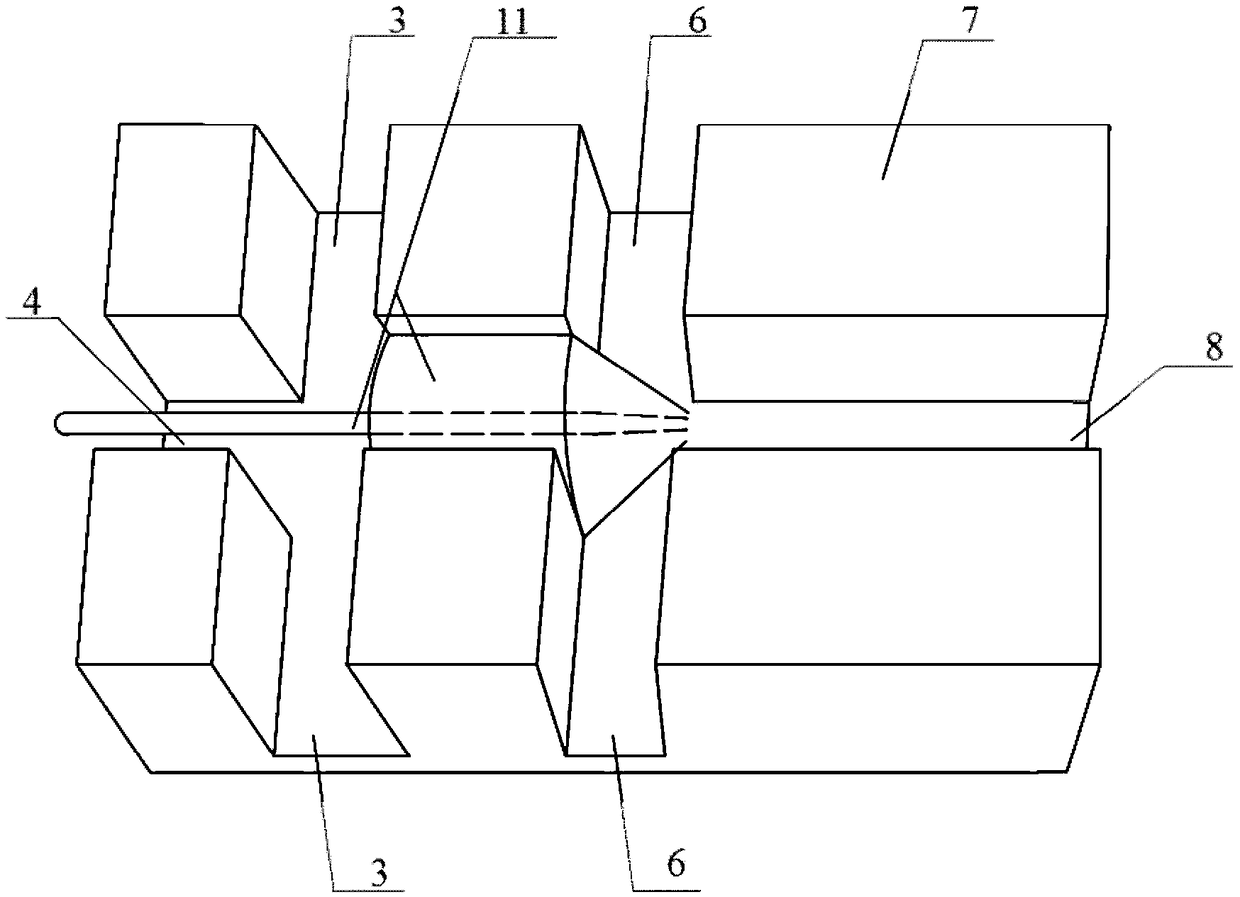

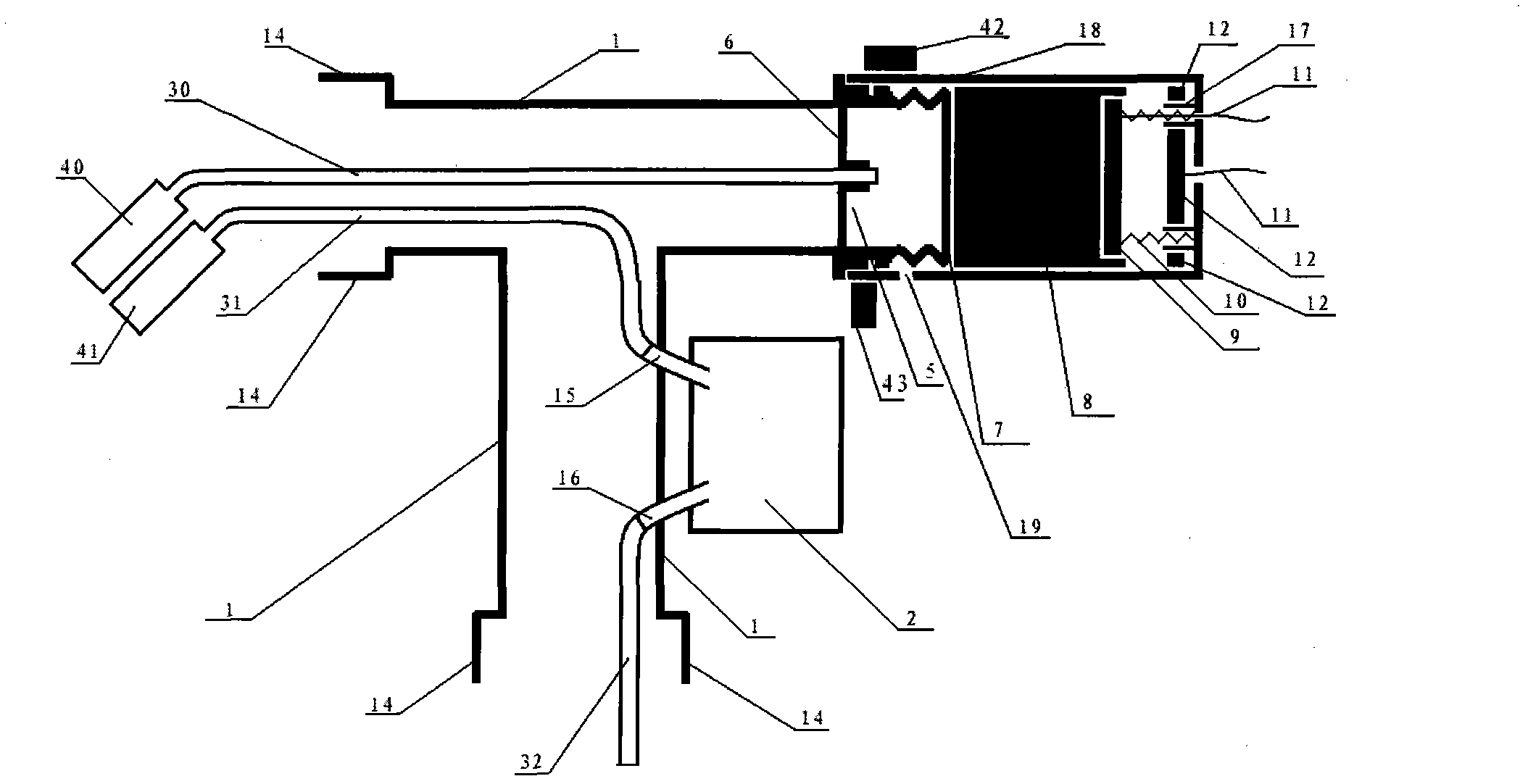

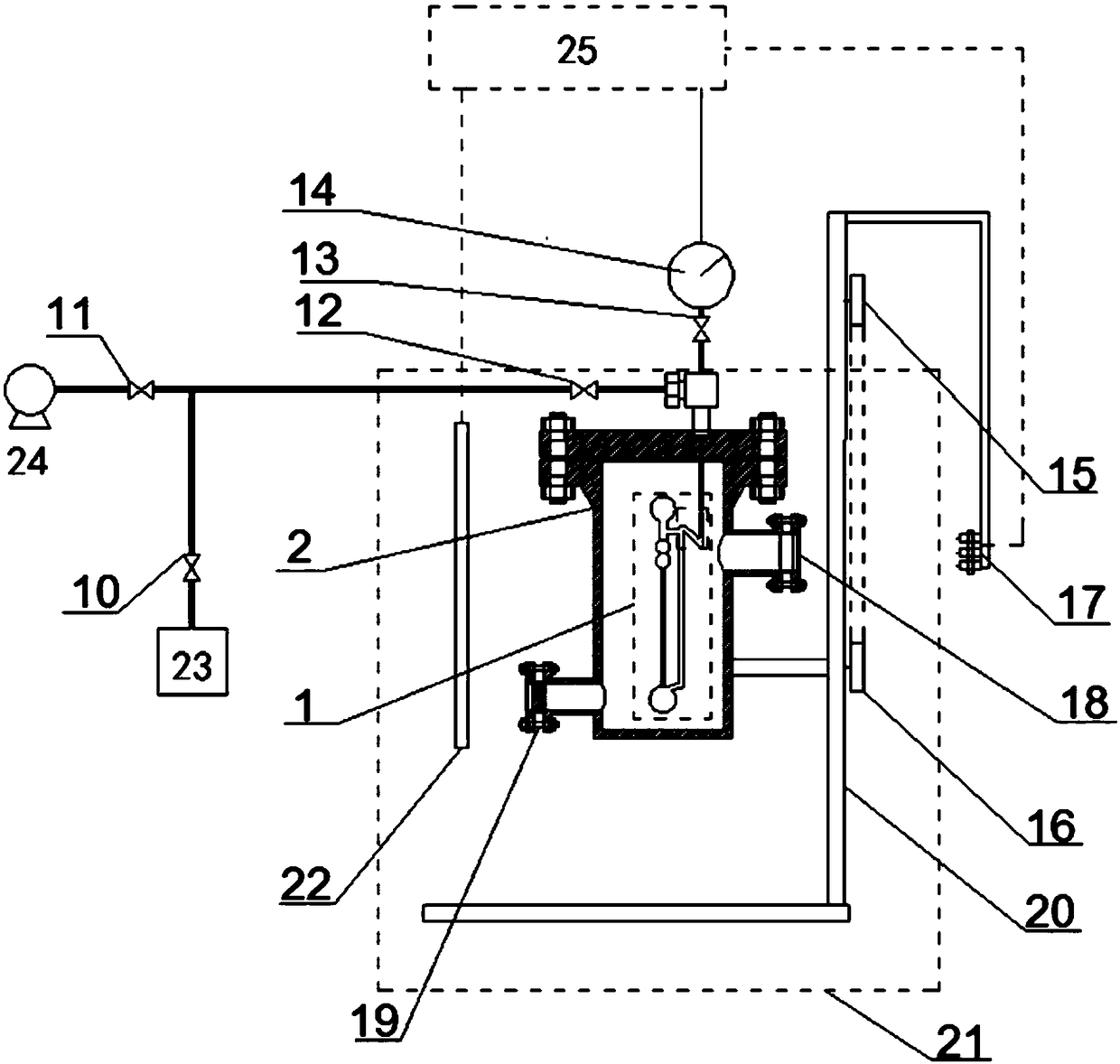

Preparation device of porous microspheres and method thereof

InactiveCN109289950AEasy to operateGood monodispersityLaboratory glasswaresMicroballoon preparationChemical reactionNanoparticle

The invention discloses a preparation device and a preparation method of porous microspheres. The preparation device comprises an external phase fluid injector, an intermediate phase fluid injector, an internal phase fluid injector and a microfluidic chip unit, wherein the microfluidic chip unit comprises an external phase input channel, an intermediate phase input channel, an internal phase inputchannel, a multinuclear double emulsion generating microstructure and a mainstream channel; the multinuclear double emulsion generating microstructure comprises a dual concentric glass capillary; a flow velocity controllable gas is introduced into the internal phase channel through the internal phase fluid injector; and a liquid containing nanoparticles is introduced into the external phase channel through the external phase fluid injector. Convenient control of the size and porous parameters of the porous microspheres is realized, and the nanoparticles help enhance the emulsion stability andcontrollability of the interfacial tension. According to the prepared porous microspheres, no components will be remained in the microspheres, thus not affecting the subsequent application. In addition, the porous microspheres for storing specific gases can be applied to chemical reactions.

Owner:YANGZHOU UNIV

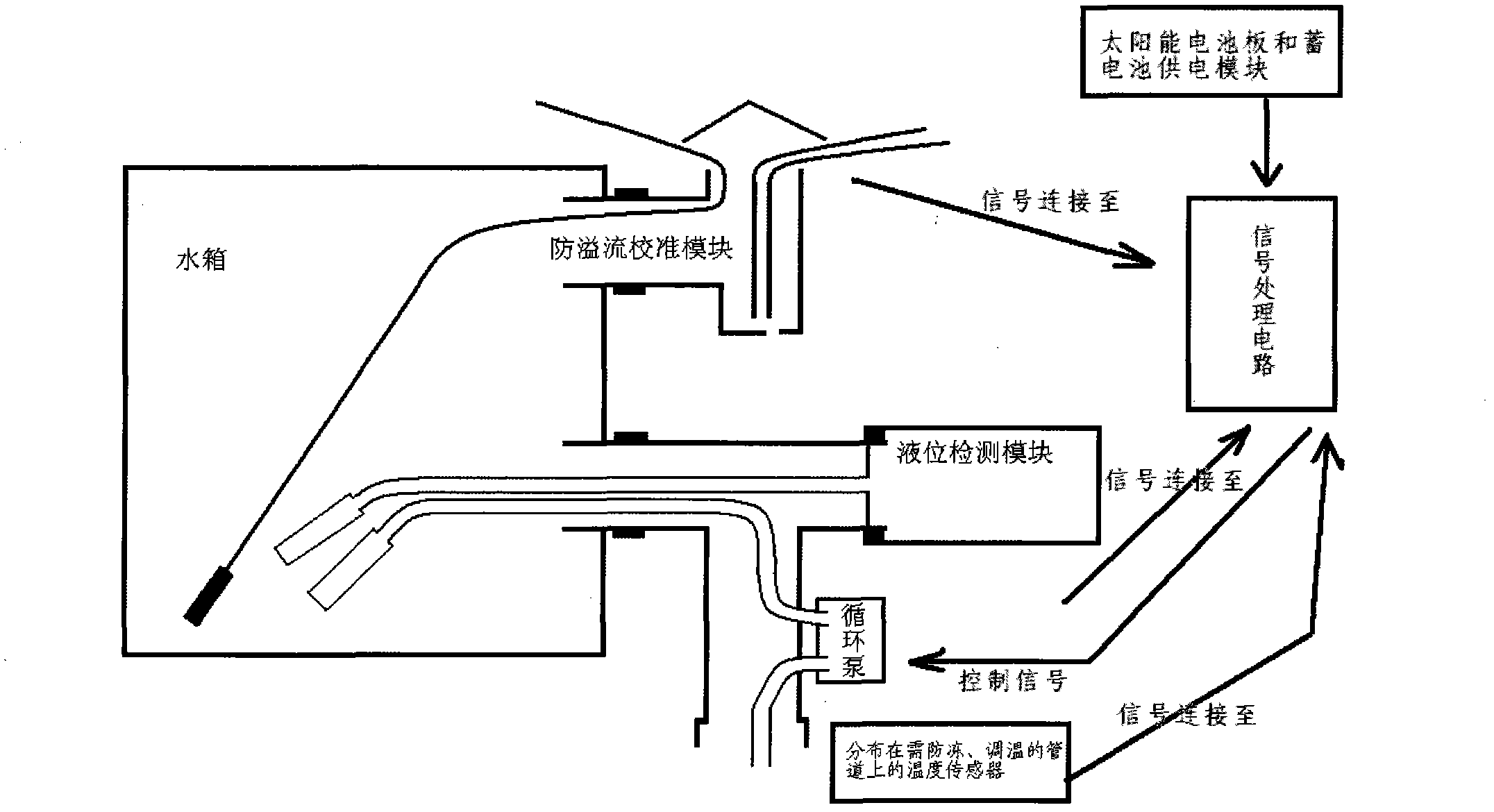

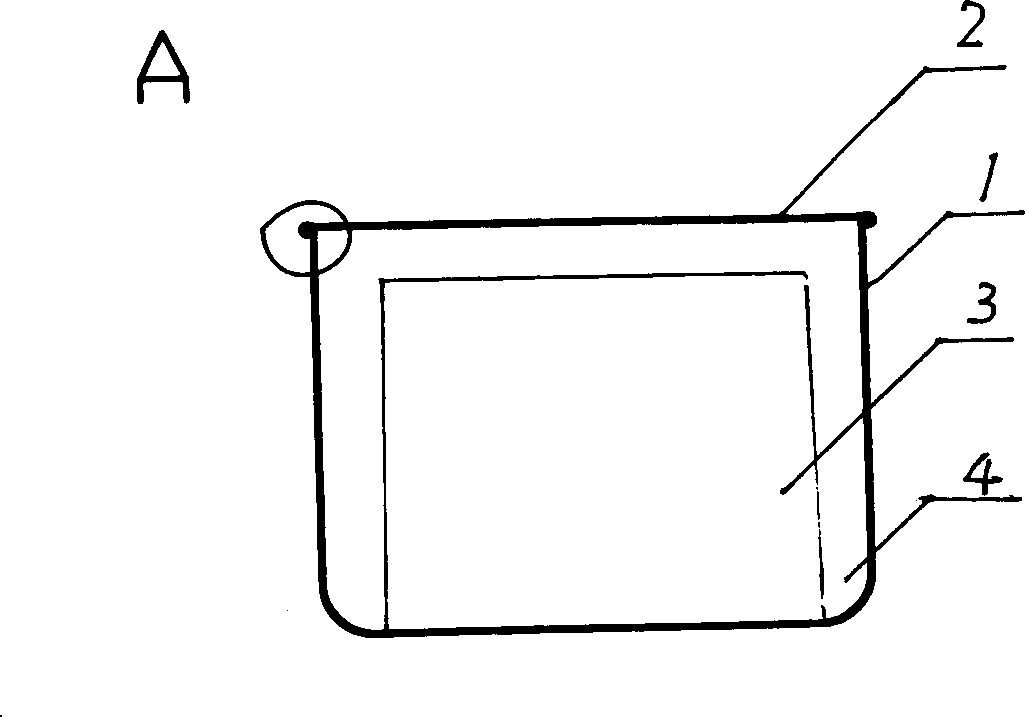

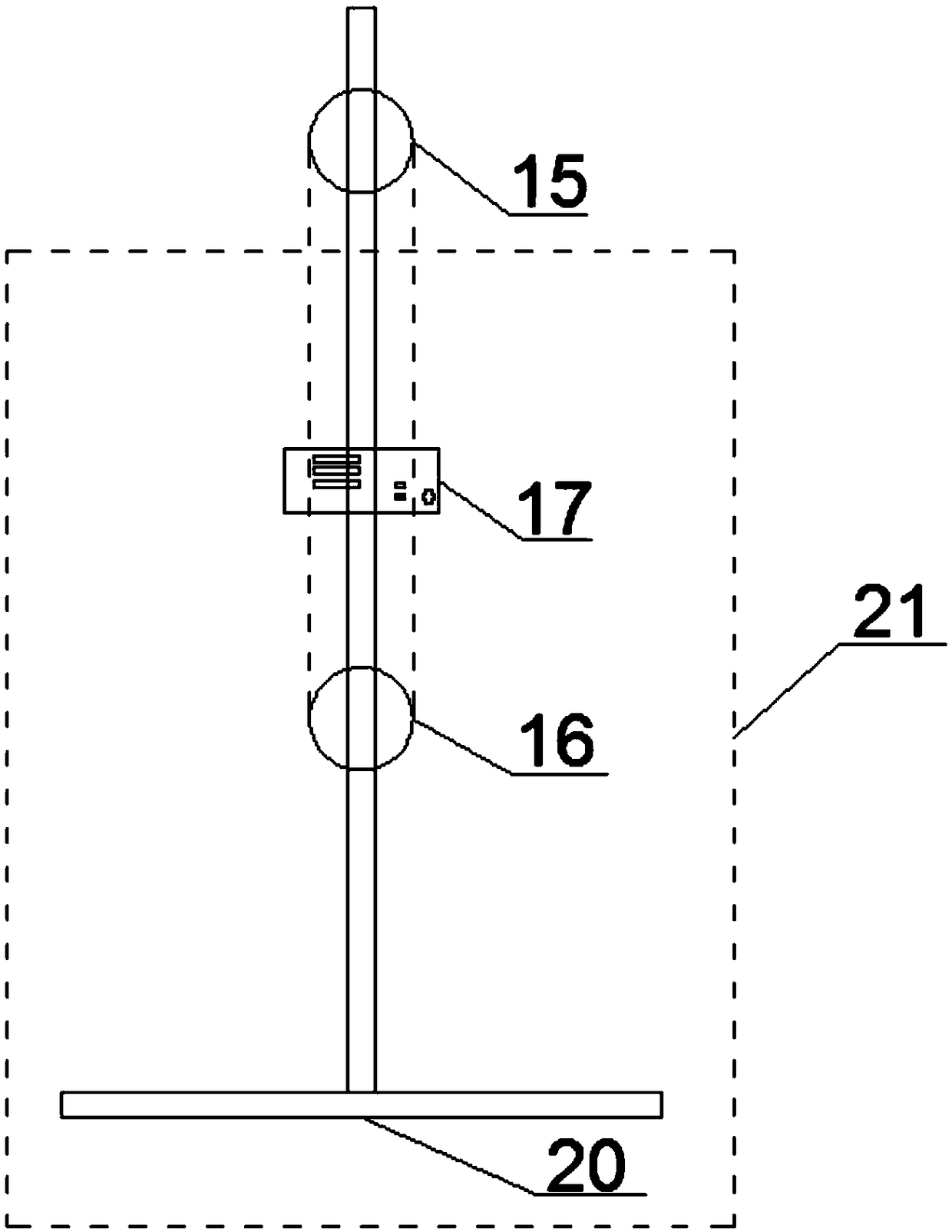

System for monitoring liquid temperature and liquid level

InactiveCN102494735AGuaranteed accuracyGuaranteed service lifeLevel indicators by physical variable measurementPistonLiquid temperature

The invention provides a system for monitoring a liquid temperature and a liquid level. The system comprises a main pipeline, a liquid level detection module, a partition board, and a pressure transmission pipe, wherein the front end of the pressure transmission pipe is immersed into a water tank and the pressure transmission pipe is connected with the partition board in a sealed manner; the liquid level detection module comprises a shell and the shell is internally provided with a deformation membrane, a guide piston and a capacitance assembly; the deformation membrane covers the back open end of a corrugated pipe and the front open end of the corrugated pipe is fixed to the main pipeline; a pressure cavity for sensing liquid level pressure is defined by the partition board, the corrugated pipe and the deformation membrane; the back end of the pressure transmission pipe is inserted into the pressure cavity; the capacitance assembly comprises a fixed capacitance plate fixed on the shell and a movable capacitance plate connected with the shell through a spring; the movable capacitance plate is close to or far away from the fixed capacitance plate under the deformation effect of the deformation membrane; a capacitive reactance between the fixed capacitance plate and the movable capacitance plate is output to a signal processor; and the capacitive reactance is converted into a water tank liquid level by the signal processor. The system for monitoring the liquid temperature and the liquid level, provided by the invention, has the advantages of application to various liquid, no influences on components of liquid to be detected, capability of realizing stepless continuous measurement on the liquid level, and long service life.

Owner:宋玉兴

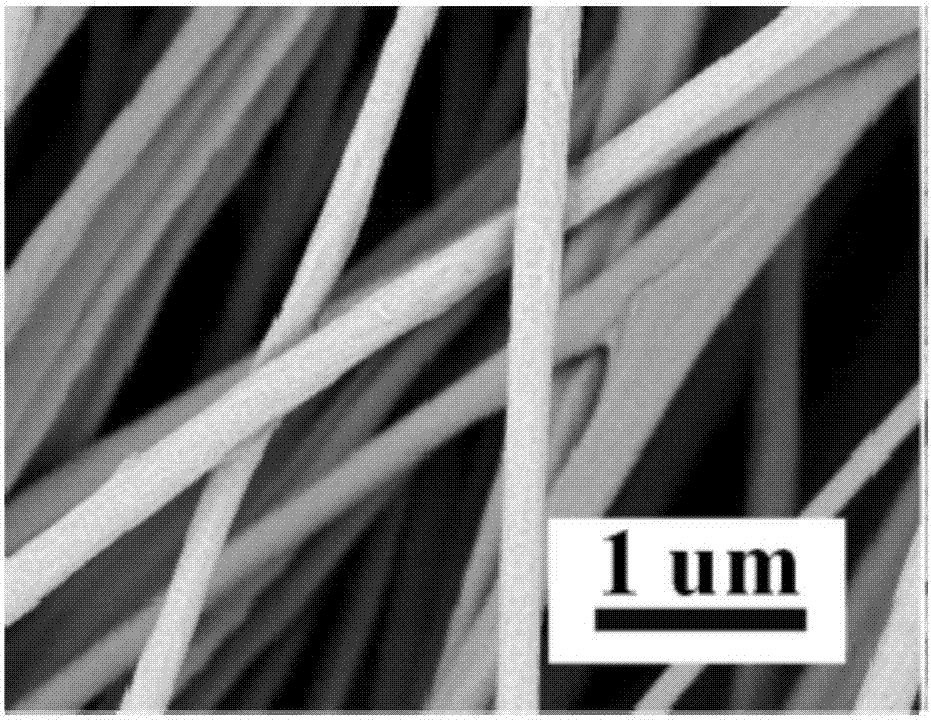

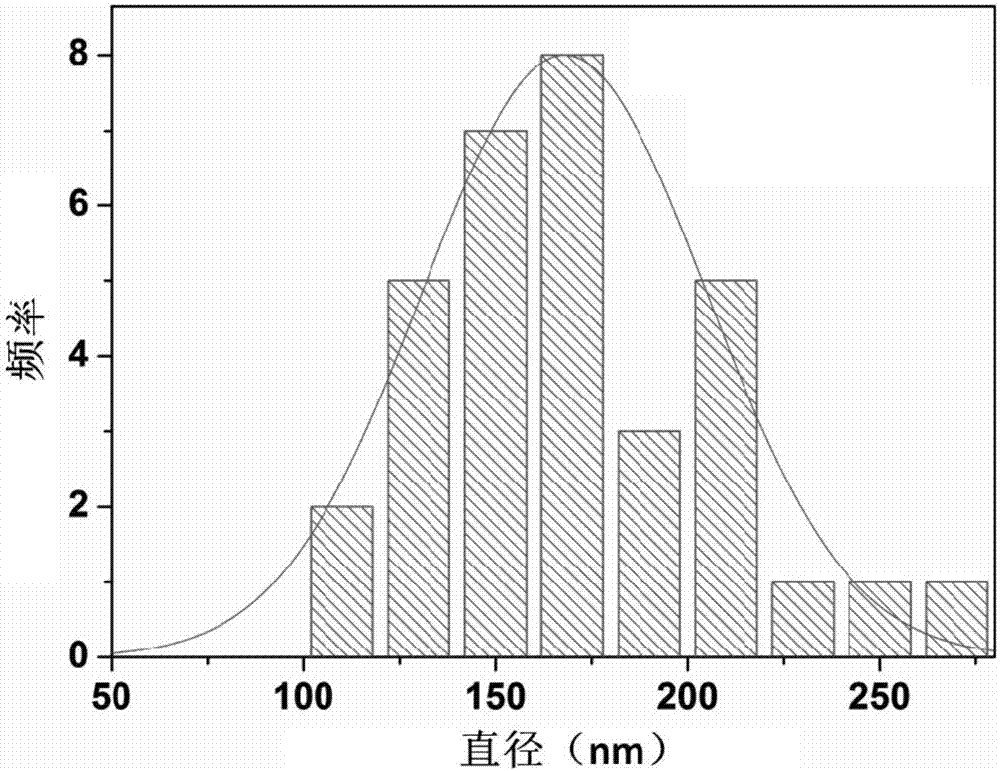

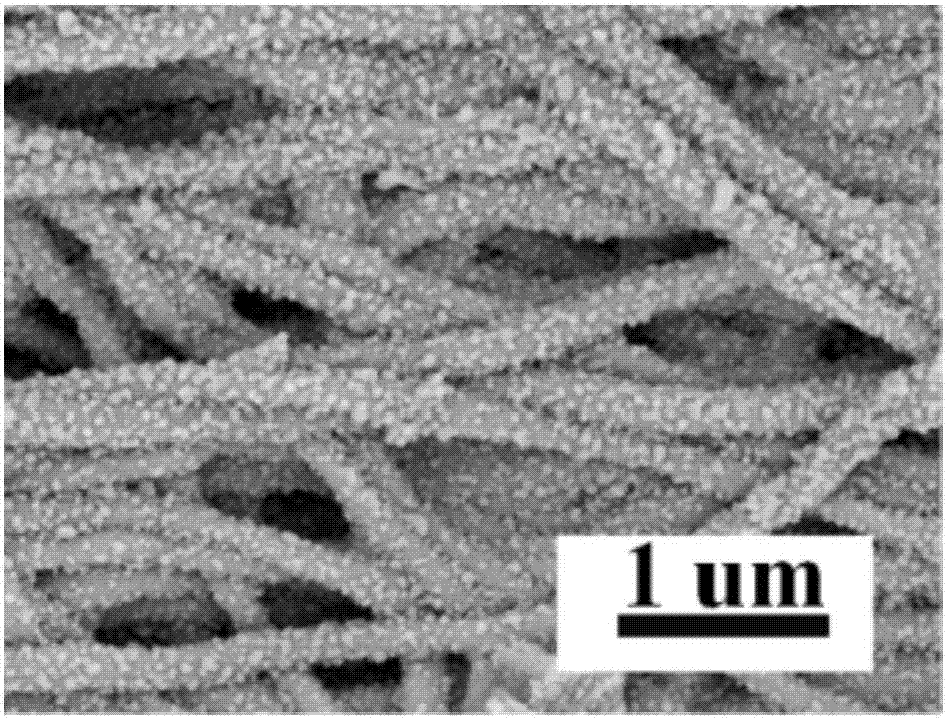

Alginic acid/nano-silver composite nanofiber and preparation method thereof

InactiveCN107385562AHigh content of silver nanoparticlesAvoid reunionBiochemical treatment with wool-protecting/anti-moth agentsFilament/thread formingComposite nanofibersIon exchange

The invention discloses an alginic acid / nano-silver composite nanofiber. The alginic acid / nano-silver composite nanofiber is acquired in the manner of preparing a silver alginate nanofiber after the ion exchange of a sodium alginate nanofiber acquired through an electrostatic spinning process and then reducing silver ions. Nano-silver grains are uniformly distributed on the inner and outer surfaces of the alginic acid / nano-silver composite nanofiber. A method for preparing the material successfully overcomes the limitation of the spinning property to the doping content of nano-silver grains and solves the problem of nano-silver grain conglobation in the electrostatic spinning process. The method can realize the large-scale production of the nano-silver containing composite fiber; the composite nanofiber is high in nano-silver grain content; the nano-silver grains are uniformly distributed on the material surface; and the fiber diameter is small, the specific surface area is large, the performance is excellent, the fiber is easy to be recycled and the cost is effectively saved.

Owner:QINGDAO UNIV

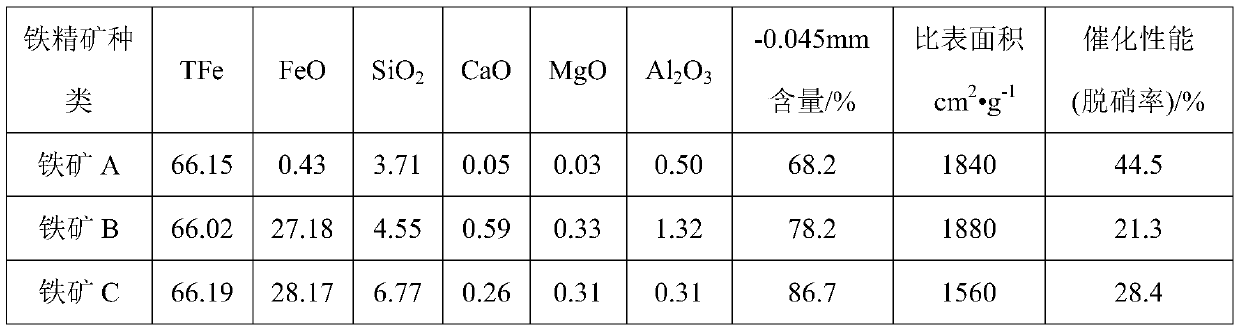

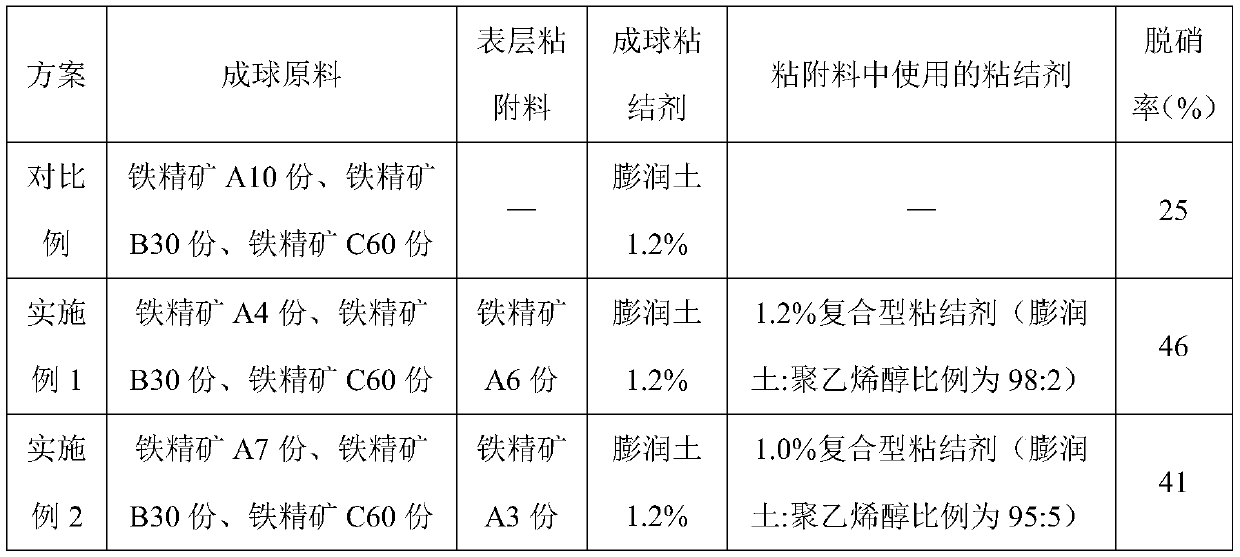

Strengthened ammonia injection denitration method based on surface catalytic performance of iron ore pellets

ActiveCN110904332AImprove denitrification effectRapid responseRotary drum furnacesPhysical chemistryRaw material

The invention relates to a strengthened ammonia injection denitration method based on surface catalytic performance of iron ore pellets. The method comprises the following steps of preparing green pellets by ingredients, drying and preheating a chain grate machine, and configuring ammonia injection denitration operation at an air draft drying section of the chain grate machine. The method is characterized by 1) determining pellet raw materials and a basic binder; 2) preparing a composite binder; 3) preparing green pellets with strong catalytic surfaces containing the composite binder; and 4) strengthening ammonia injection denitration on a pellet surface layer, decomposing and volatilizing the composite binder in a drying process to form rich pores in the pellet surface layer, increasing adsorption of NH3 and NOx on the pellet surface layer, accelerating a denitration reaction speed of the strong catalytic surface layer, and realizing strengthened ammonia injection denitration of thepellet surface layer. The method has advantages that a denitration rate is improved by more than 15 percent points compared with that of an existing ammonia spraying denitration technology; a pelletizing process does not need to be greatly changed, and only some improvements need to be made in the process of preparing the green pellets from the ingredients; and implementation and popularization are easy.

Owner:ANSTEEL GRP MINING CO LTD

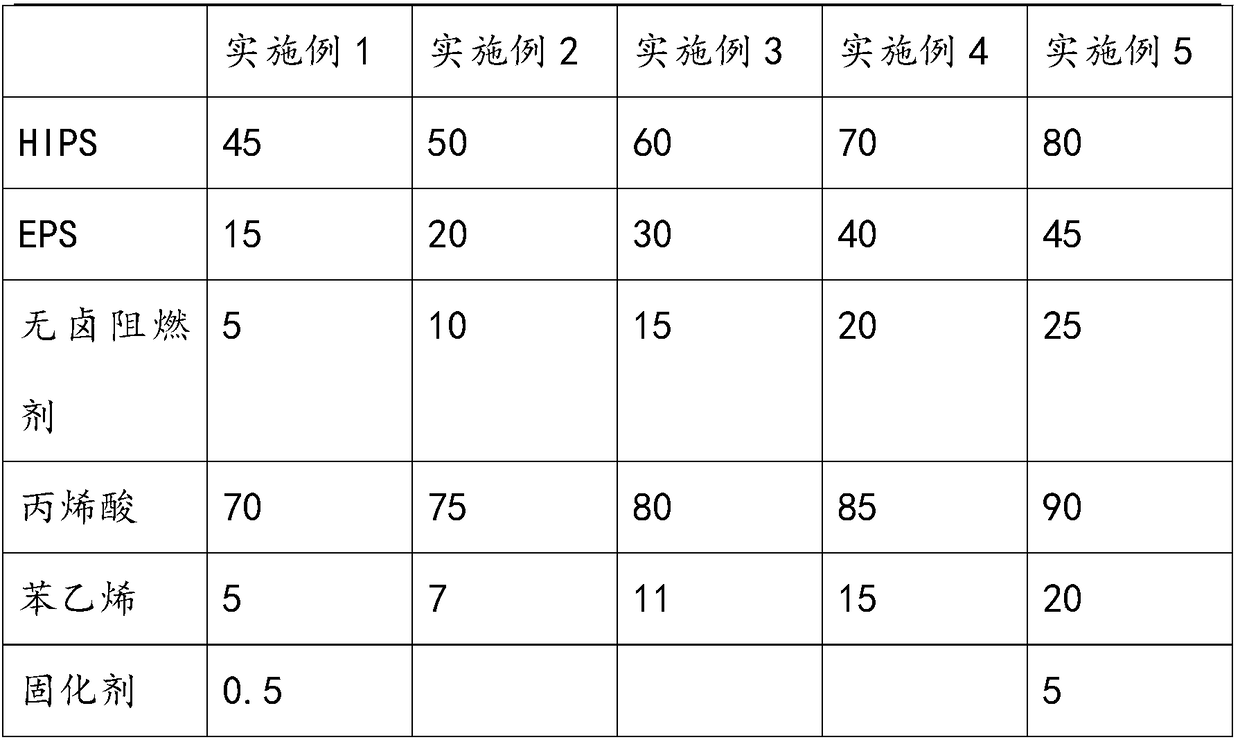

Flame retardant expanded double-sided tape and preparation process thereof

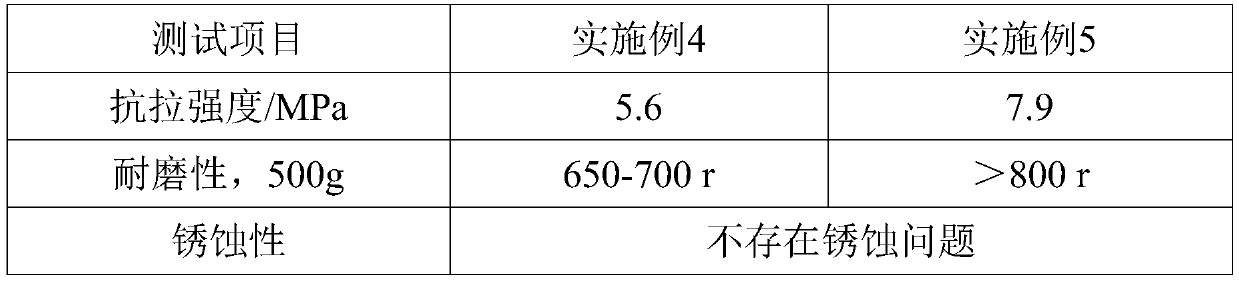

PendingCN109294463AGood bond strengthGood fixing performancePressure sensitive film/foil adhesivesFire retardantExpansion ratio

The invention relates to a flame retardant expanded double-sided tape. The flame retardant expanded double-sided tape comprises a first composite acrylic acid glue layer, a flame-retarded polystyrenesynthetic resin layer, a second composite acrylic acid glue layer and a double-sided release film layer which are sequentially arranged from top to bottom. Compared with the common flame-retardant expanded tape on the market, the product has high viscosity and strong fixing ability, so the an electrical core and an outer casing can be firmly fixed, the tape has the resistance to an electrolyte, does not affect the composition of the electrolyte, does not affect the performance of a battery, the expansion ratio of the tape exceeds 3 times, which is better to fill an assembly gap and reduce thepossibility of vibration displacement, and the double-sided tape has good safety.

Owner:太仓斯迪克新材料科技有限公司

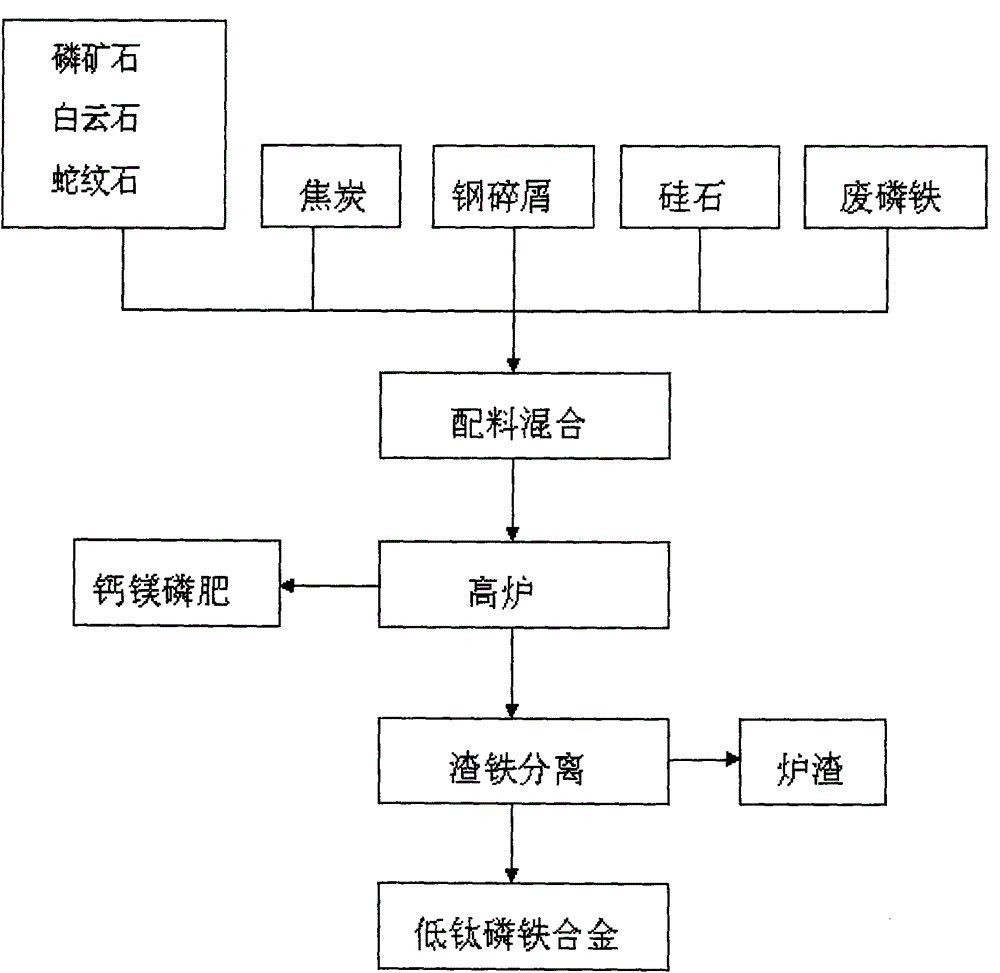

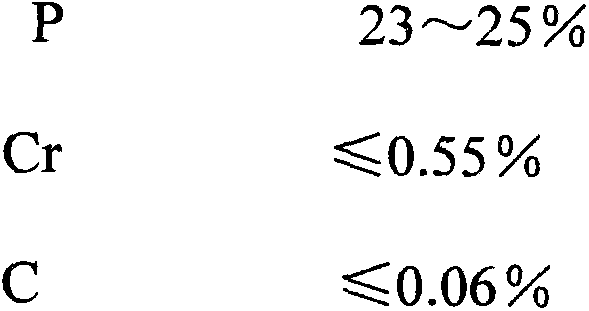

Iron alloy additive containing low titanium and phosphorus and use method of iron alloy additive

The invention discloses an iron alloy additive containing low titanium and phosphorus and a preparation method of the iron alloy additive. The iron alloy additive is specially designed for production of high-grade non-oriented and oriented silicon steel. The special iron alloy additive containing low titanium and phosphorus comprises 21%-25% of P, 0-0.08% of Cr, 0-3.0% of Si, 0-0.8% of C, 0-0.04% of S, 0-2.0% of Mn, 0-0.05% of Ti, 0-0.2% of V, 0-0.2% of Nb and 0-5% of screen underflow. The iron alloy additive containing low titanium and phosphorus has the characteristics of rich elements, lower content and moderate granularity, the impurity content in the steelmaking process can be effectively controlled, and particularly, the iron alloy additive has important function on enhancing steel strength and hardness during high-grade silicon steel production.

Owner:徐广哲

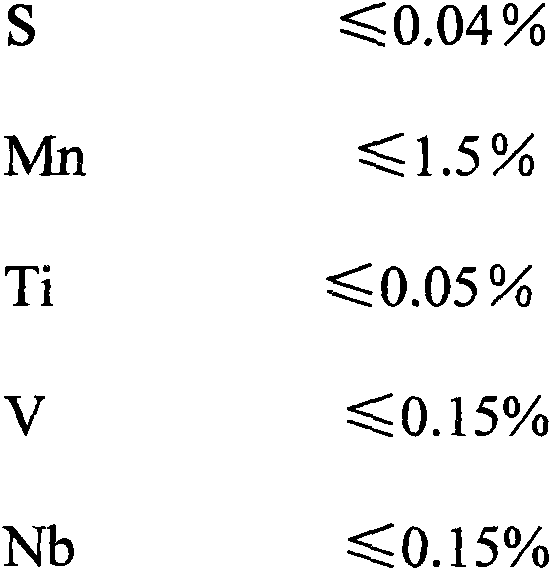

Protective method for hearth of vanadium titano-magnetite rotary hearth furnace used for coal-based direct reduction

The invention discloses a protective method for the hearth of a rotary hearth furnace used for the direct reduction of the vanadium titano-magnetite. A common refractory material is laid on the lower part of the hearth of the rotary hearth furnace; titanium slag obtained from a directly reduced metallic pellet which is subjected the electric furnace fusion and separation is crushed to 2 to 10mm and is laid on the refractory material on the surface of the hearth of the rotary hearth furnace. A soft hearth working surface is formed by the titanium slag between the refractory material on the surface of the hearth of the rotary hearth furnace and the reduced furnace charge; and then the preset thickness of the soft hearth working surface is reduced due to the loss, and the crushed titanium slag can be loaded into the hearth of the rotary hearth furnace. As the titanium slag has a higher fusion point, the vanadium titano-magnetite can be prevented from being atomized and sticking to the hearth in the 1,300 to 1,400 DEG C direct reduction process during use. As the hearth is a loose and soft hearth, the vanadium titano-magnetite does not stick to the hearth even with expansion. Therefore, the method has the advantages of protecting the hearth and a screw discharger, protecting the titanium slag from being polluted by the refractory material, bringing about the cycle use of the titanium slag, reducing the furnace maintenance cost, and having obvious economic and social benefits.

Owner:SICHUAN LOMON MINING & METALLURGY

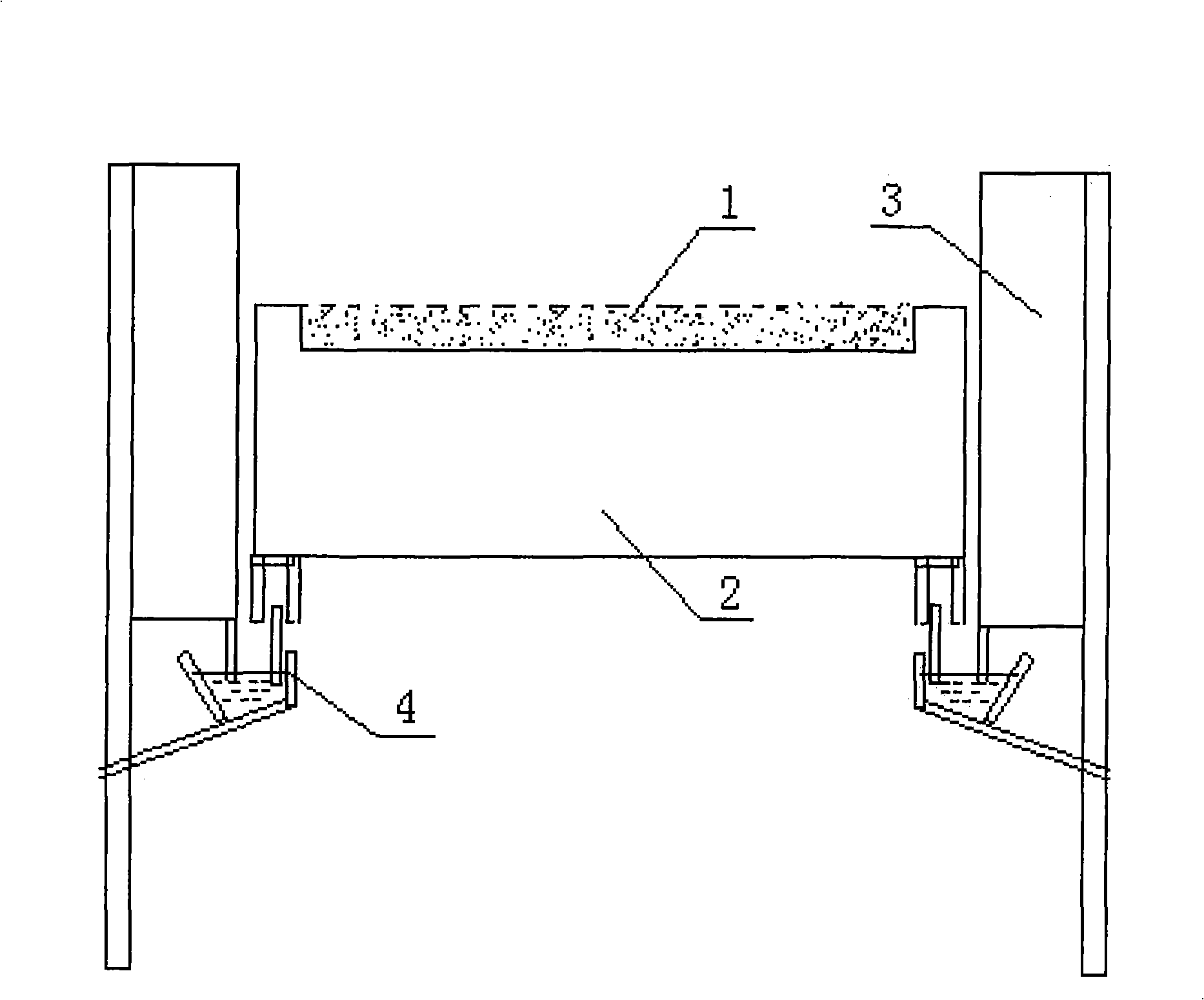

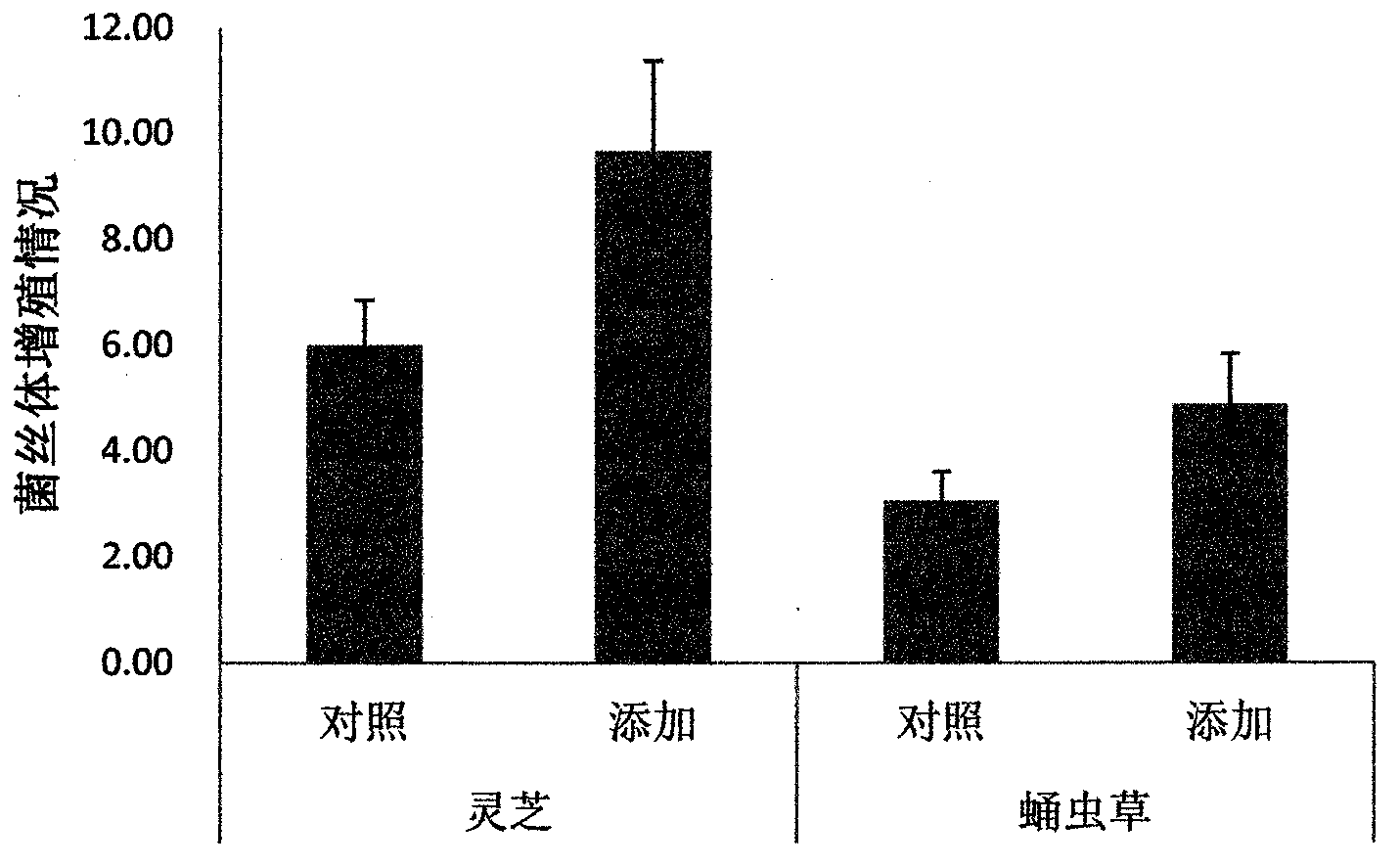

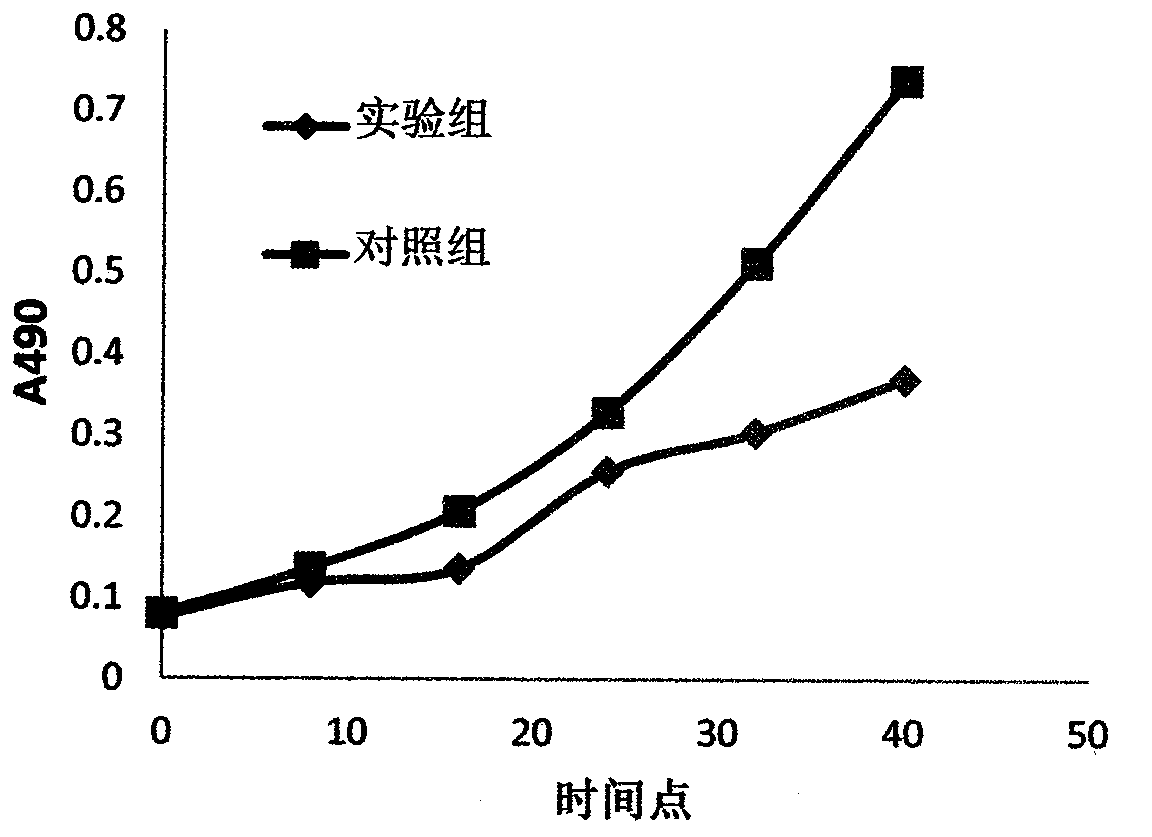

Special multi-element trace element additive for biological culture

The invention relates to a special multi-element trace element additive for biological culture. The multi-element trace element additive is especially suitable for the supplementation of multi-element trace elements in the culturing processes of a plurality of biologically active materials comprising plant cells, fungi and animals. The multi-element microbial element additive is named as a 'super power element', is obtained through chelating all trace elements required by organisms and ethylene diamine tetraacetic acid (EDTA) under high temperature reflux, and is a deep purple clear solution obtained after co-dissolving a ferrous salt, a magnesium salt, a zinc salt, a copper salt, a molybdenum salt, boric acid, a cobalt salt, a manganese salt, a cerium salt and a lanthanum salt and EDTA according to a certain ratio and carrying out boiling refluxing for 7h, and the clear solution is added to a biologic medium in a 0.01% proportion. The additive has the characteristics of high stability, wide pH tolerance characteristic, controlled release cell absorption and low cost, can effectively promote the healthy growth of cultured materials, improves the activities and the breeding speed, and has wide application values.

Owner:TIANJIN INT JOINT ACADEMY OF BIOTECH & MEDICINE +1

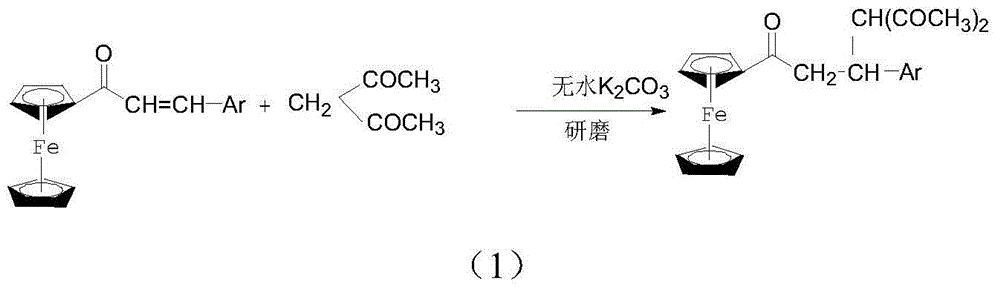

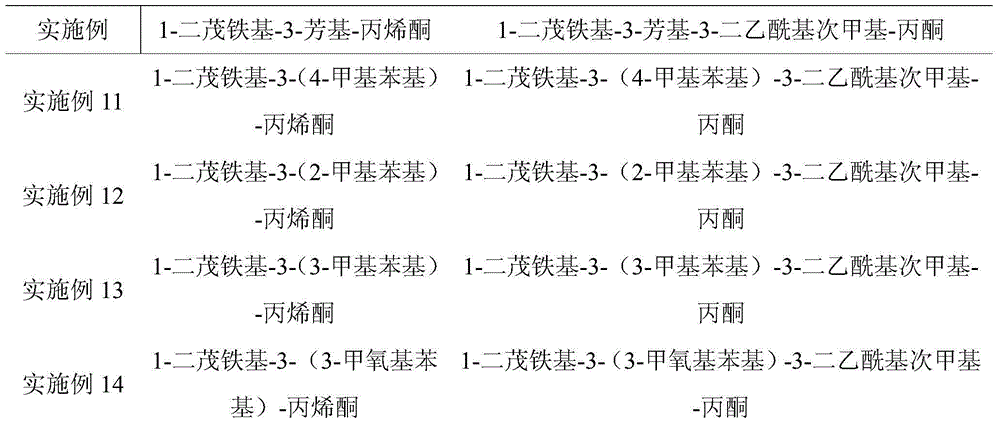

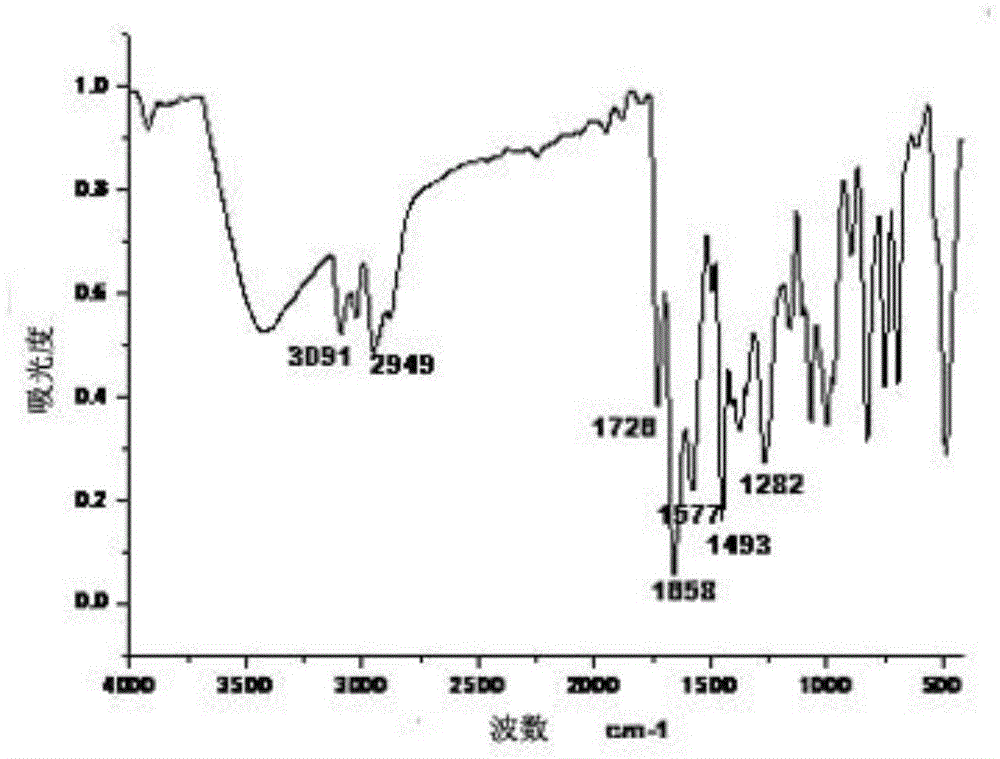

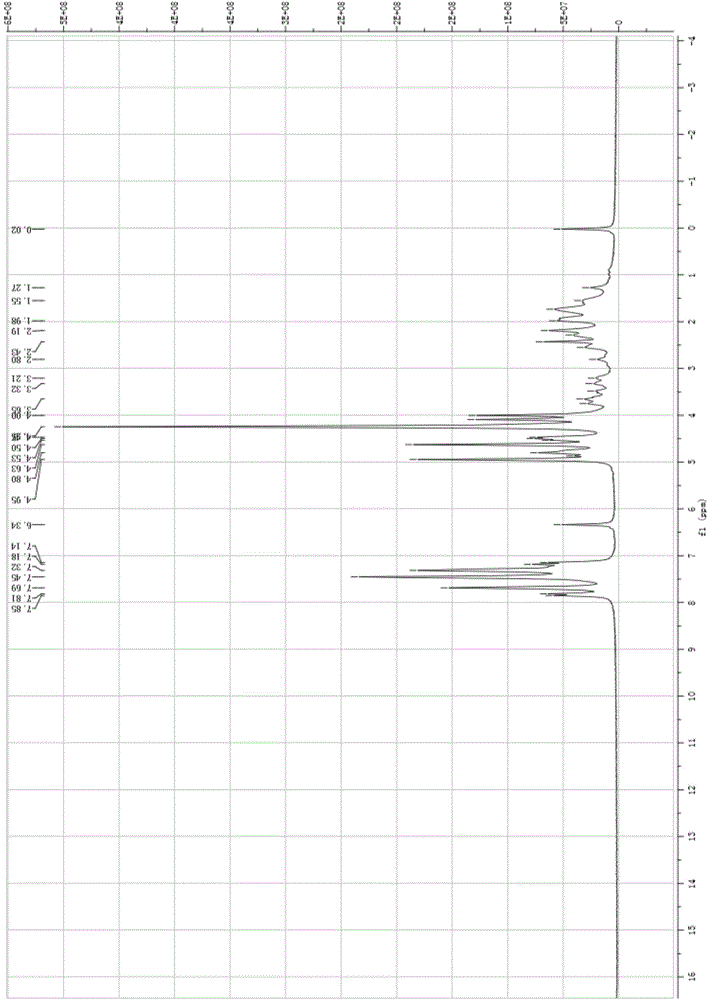

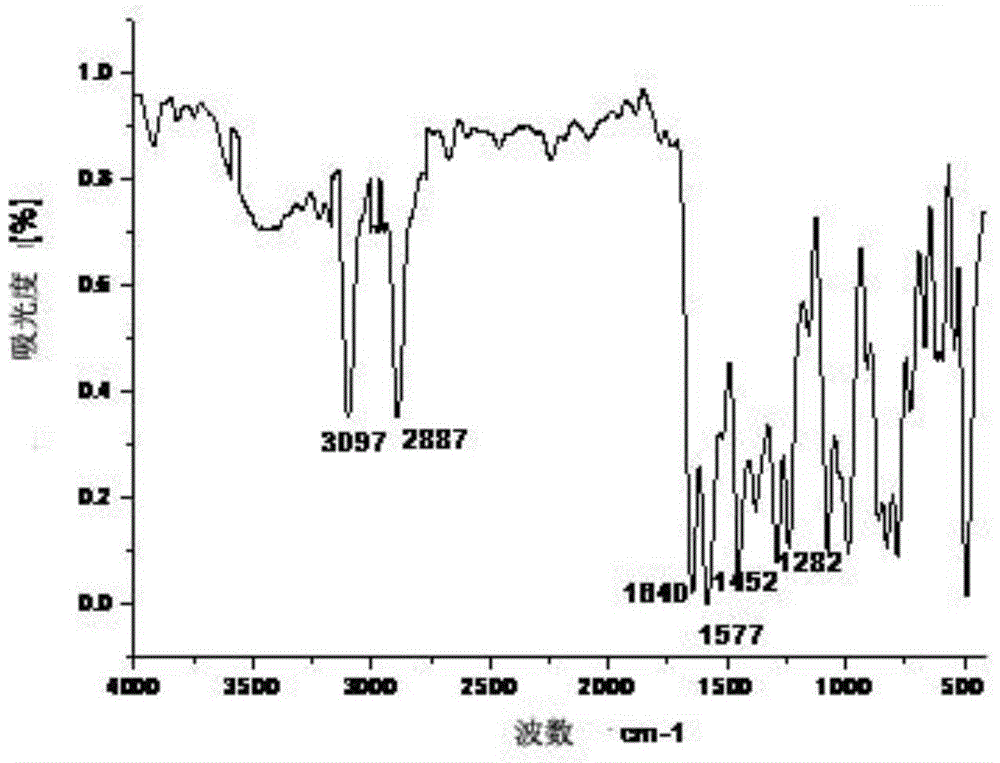

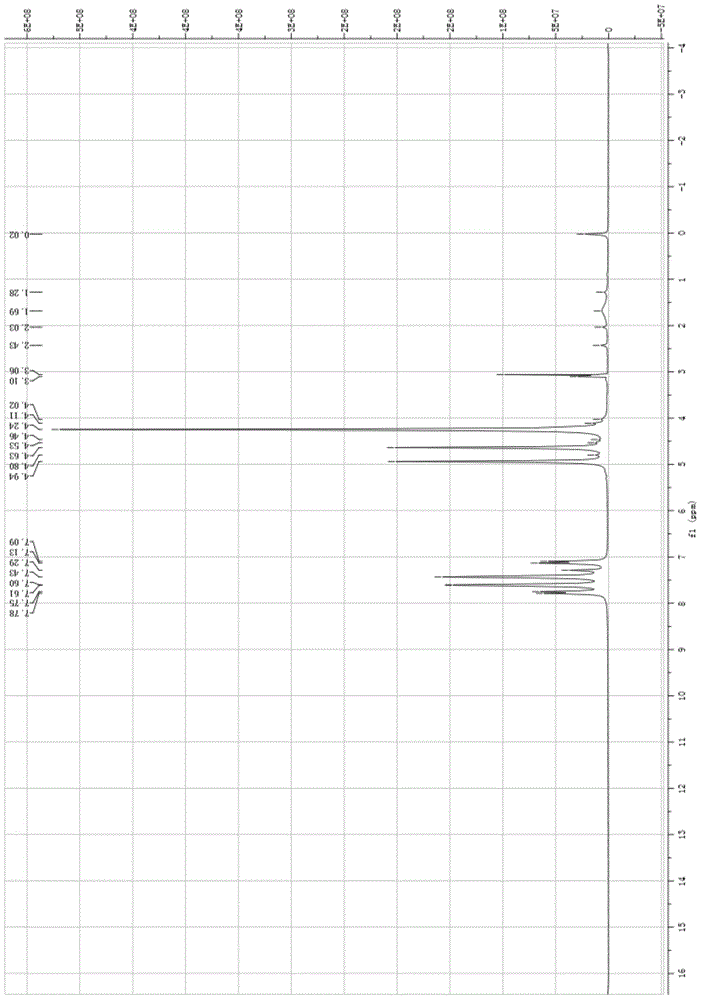

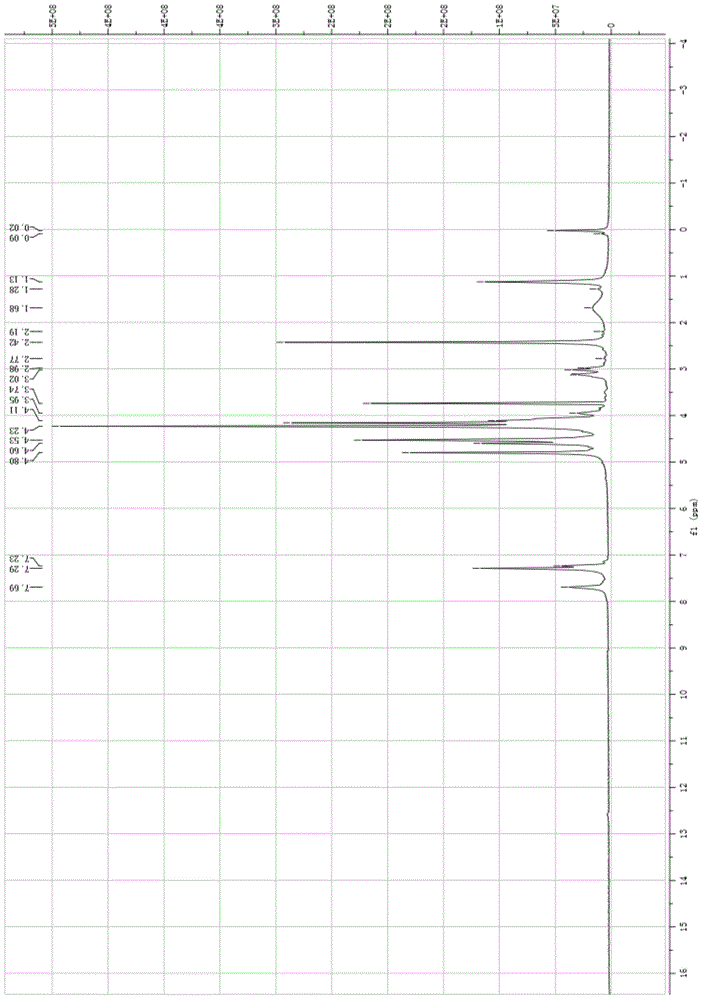

1-Ferrocenyl-3-aryl-3-diacetylmethylene-acetone and preparation method thereof

The invention discloses 1-ferrocenyl-3-aryl-3-diacetylmethylene-acetone and a preparation method thereof. The structural formula of the above compound is shown in the specification. The preparation method comprises the following steps: adding 1-ferrocenyl-3-aryl-acrylketone, anhydrous K2CO3 (or NaOH) and acetylacetone into a dry mortar, rapidly grinding, detecting the reaction process through TLC, washing with water after the reaction, carrying out pumping filtration, and carrying out vacuum drying to obtain 1-ferrocenyl-3-aryl-3-diacetylmethylene-acetone. The method has the advantages of simple operation, mild reaction conditions, simple post-treatment and high yield, and the product prepared in the invention is a brand new ketone, and can be used for in the fields of pesticides and medicines.

Owner:SHAANXI UNIV OF SCI & TECH

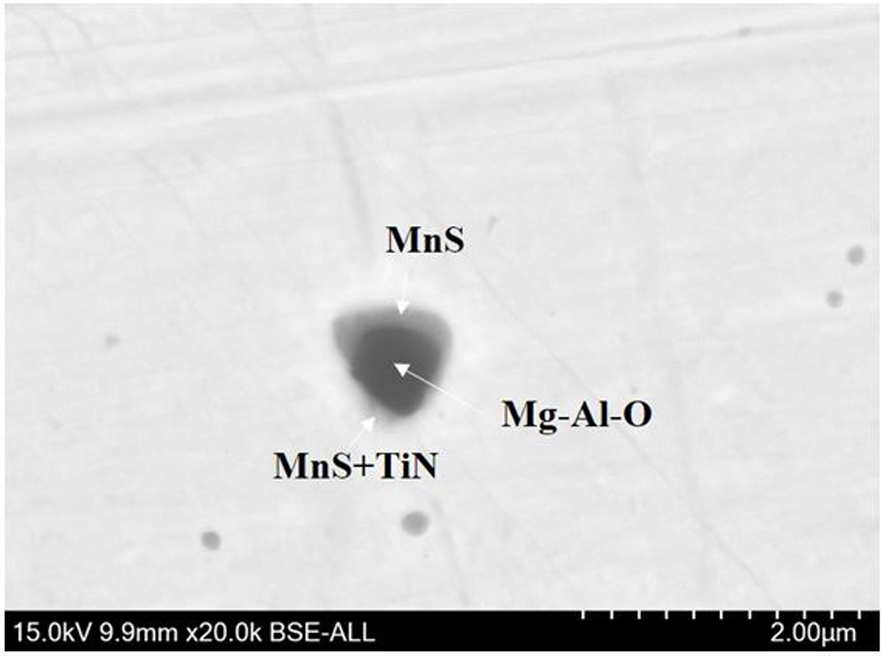

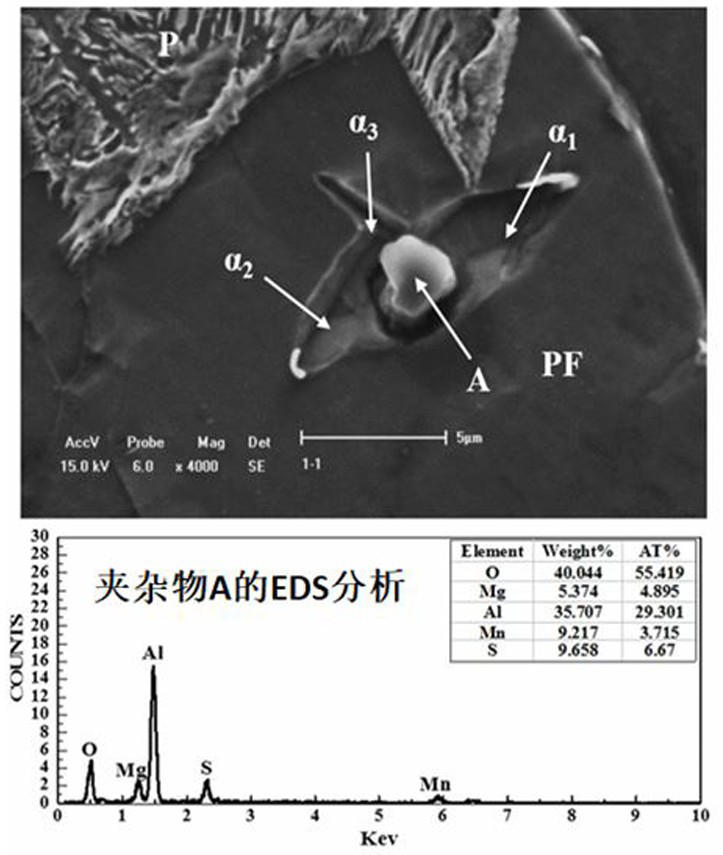

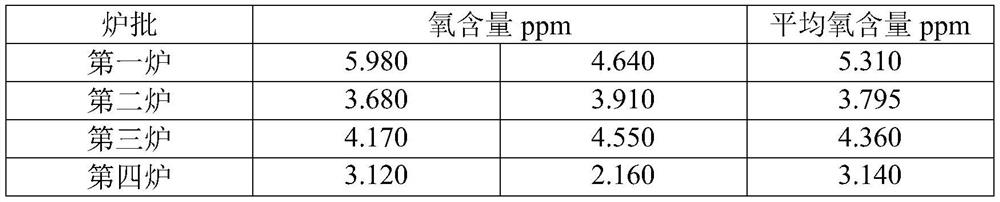

Low-cost magnesium-treated microalloyed steel and preparation method thereof

The invention discloses low-cost magnesium-treated microalloyed steel and a preparation method thereof. The preparation method for the low-cost magnesium-treated microalloyed steel comprises working procedures of steel smelting, alloying, cored wire feeding, continuous casting, rolling and the like. After Ruhrstahl-Heraeus (RH) refining is finished, a magnesium-aluminum-iron alloy is fed to moltensteel at a certain speed and used for partially replacing elements such as niobium, vanadium and titanium which are used for alloying in the refining working procedure. Large-amount precipitation ofsecond-phase particles of steel in solidifying and rolling processes can be promoted. The microalloying function of niobium, vanadium and titanium is replaced partially, and the structure and propertyof steel are improved. Because metal magnesium is lower in price, expensive alloying elements such as niobium, vanadium and titanium are replaced, and the production cost of steel can be effectivelylowered. The property of the magnesium-treated low-carbon microalloyed steel acquired with the preparation method is close to or exceeds the property of standard steel without addition of magnesium, the alloying cost of a ton of steel is lowered by more than twenty-five RMB, and the preparation method for the low-cost magnesium-treated microalloyed steel is a novel steel microalloying technology.

Owner:SUZHOU UNIV

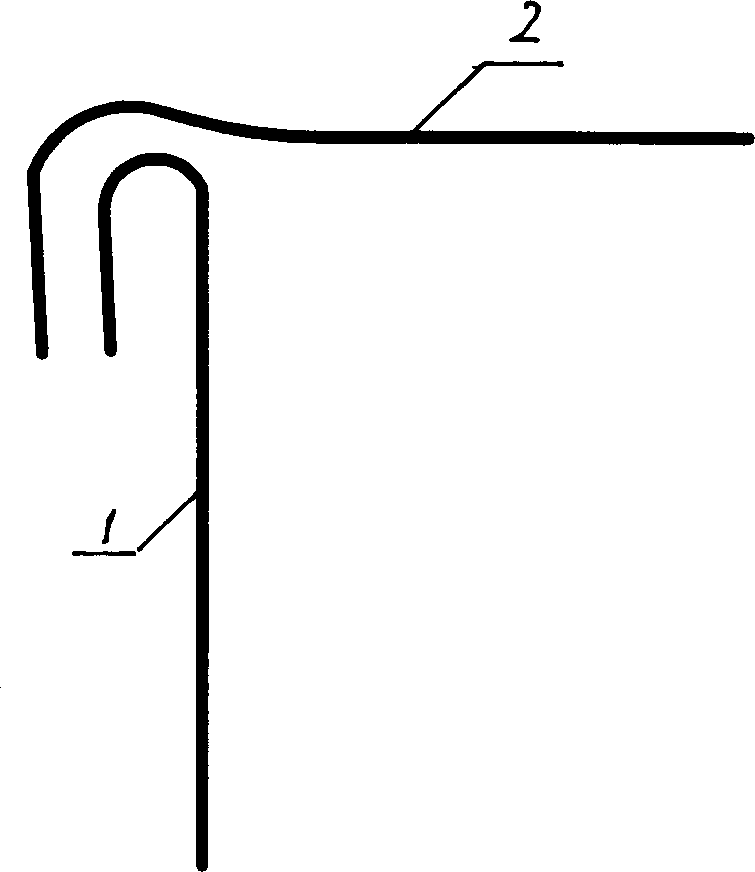

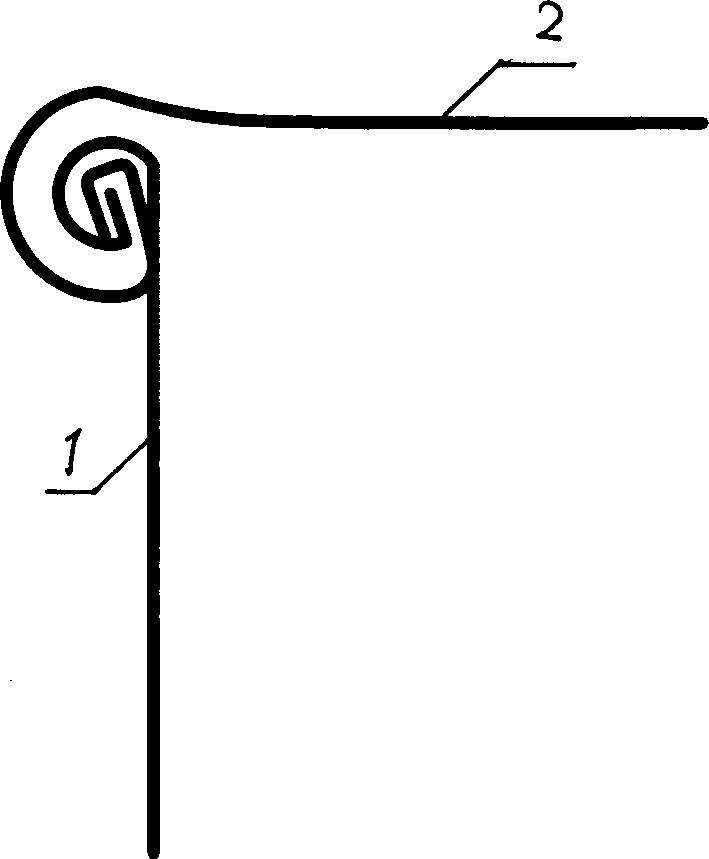

Packaging technique with Sr-Al alloy can

InactiveCN1382612AEasy to operateSmall specific surface areaWrapper twisting/gatheringPackaging under vacuum/special atmosphereAluminiumMetal

A technique for packing metal strontium with aluminium can features that argon gas is filled in the aluminium can and the can is sealed by curling its edge 5 times for preventing the strontium from being oxidized. If a Sr-Al alloy is prepared, the aluminium can can be directly used as its raw material.

Owner:NANJING YUNHAI SPECIAL METALS CO LTD

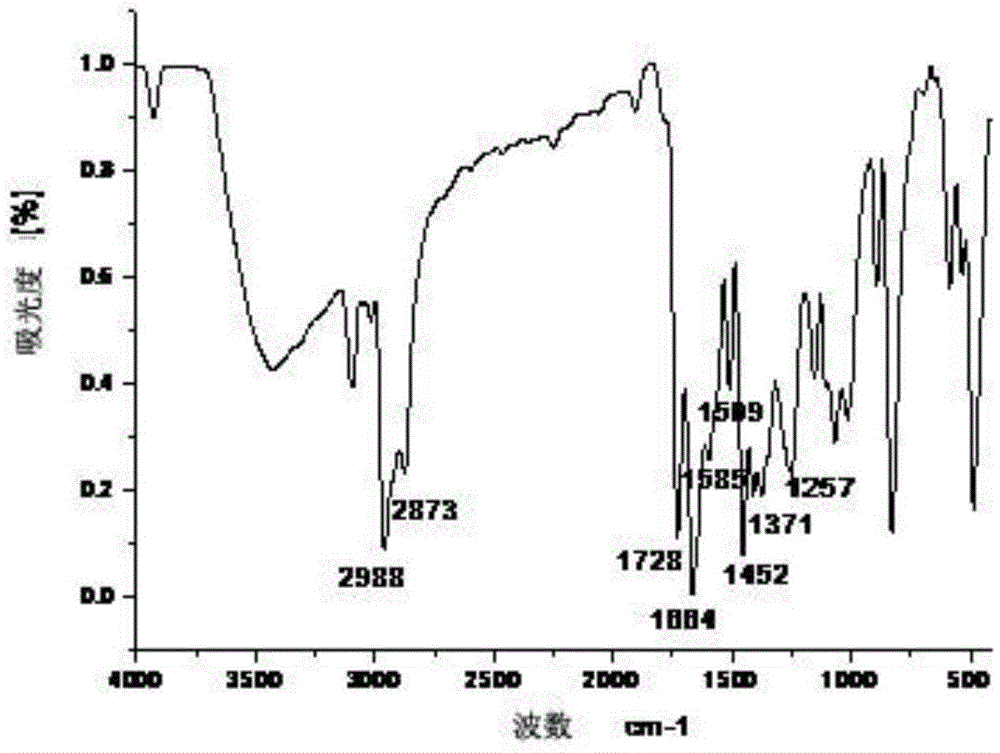

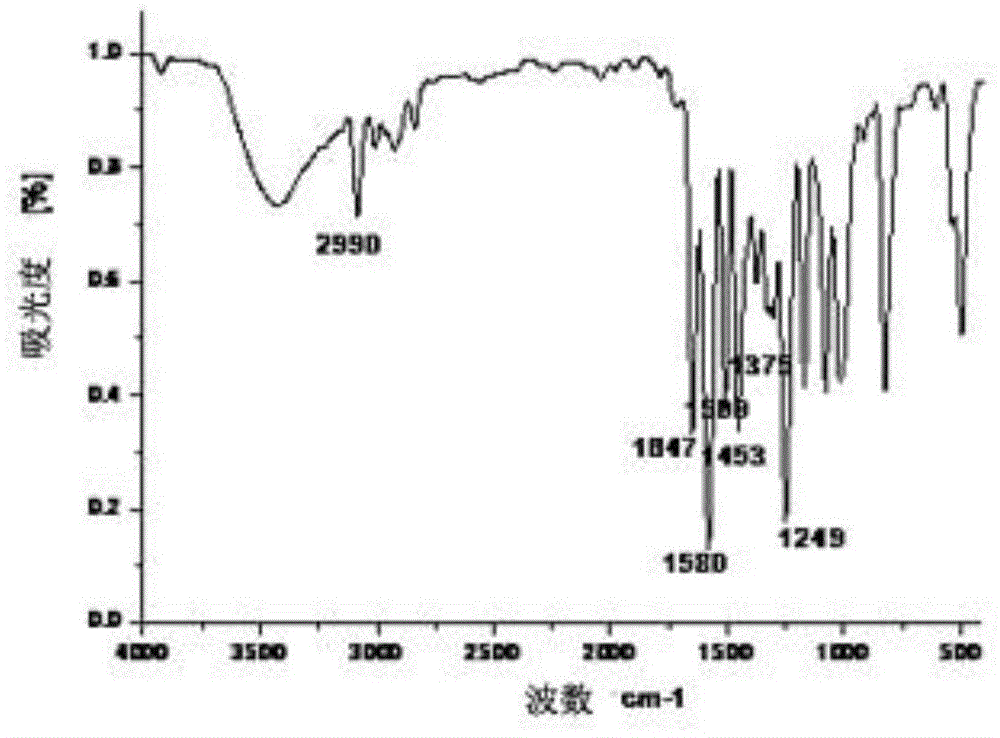

1-ferrocenyl-3-aryl-3-(2-cyclopentanon)-acetone and preparation method thereof

InactiveCN104447883AShort reaction timeEasy to operateIron organic compoundsMetallocenesSolventThin-layer chromatography

The invention discloses 1-ferrocenyl-3-aryl-3-(2-cyclopentanon)-acetone and a preparation method thereof. The structural formula of the 1-ferrocenyl-3-aryl-3-(2-cyclopentanon)-acetone is shown in the specification. The preparation method of the 1-ferrocenyl-3-aryl-3-(2-cyclopentanon)-acetone comprises the following steps: adding A mol of 1-ferrocenyl-3-aryl-acrylketone, B mol of anhydrous K2CO3 (or NaOH) and C mol of cyclopentanone into a dry mortar to quickly grind; performing TLC (Thin Layer Chromatography) monitoring until the reaction is complete; then washing, performing extraction filtration and drying to obtain the 1-ferrocenyl-3-aryl-3-(2-cyclopentanon)-acetone. The invention provides the1-ferrocenyl-3-aryl-3-(2-cyclopentanon)-acetone and the preparation method thereof. The method has the advantages of short reaction time, no need of solvent, environment friendliness, economy, easiness in operation, mild reaction condition, easiness in post-treatment and high yield.

Owner:SHAANXI UNIV OF SCI & TECH

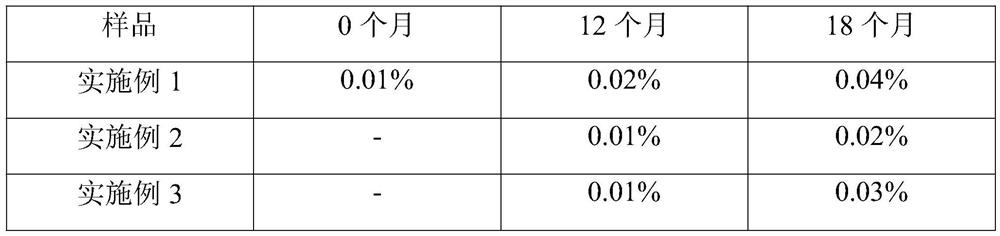

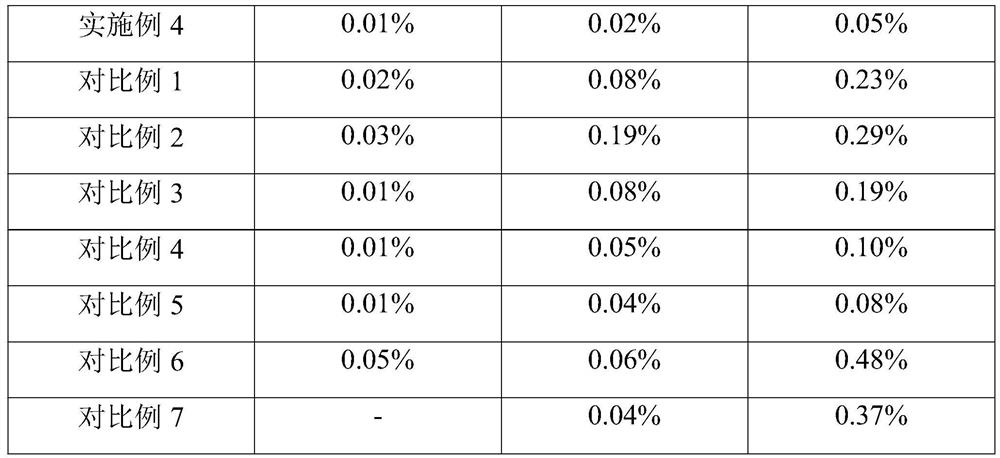

Salbutamol sulfate solution for inhalation and preparation method thereof

ActiveCN113476428AReduce the introductionSimple prescriptionOrganic active ingredientsPharmaceutical delivery mechanismDrug contentTherapeutic effect

The invention discloses a salbutamol sulfate solution for inhalation and a preparation method thereof. A formula of the salbutamol sulfate solution comprises salbutamol sulfate, lactose, an isotonicity regulator, a pH adjusting agent, an antioxidant and the balance of water for injection. In a preparation process, carbon dioxide is introduced as the antioxidant, so that the dissolved oxygen content and the residual oxygen content in the solution are reduced. The added lactose not only is beneficial to the flowability of the medicine component salbutamol sulfate, but also can be used for preventing the salbutamol sulfate from being agglomerated together, so that the salbutamol sulfate can be uniformly dispersed in a solution system. According to the salbutamol sulfate solution for inhalation, the impurity content is low, adverse effects of related substances on human health and drug effects are reduced, the stability is higher, the drug content distribution is uniform, and the treatment effect is facilitated.

Owner:朗天药业(湖北)有限公司 +1

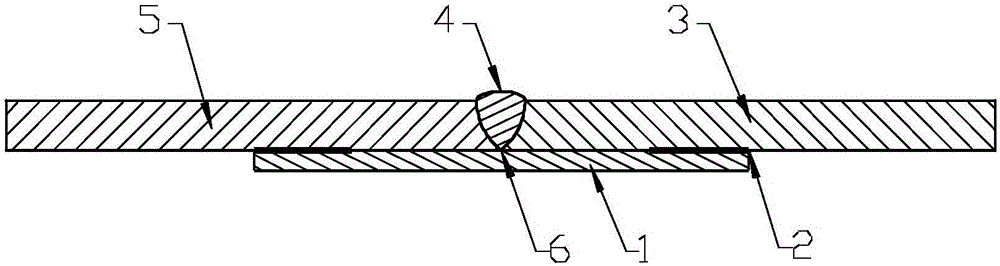

Welding protection method for improving welding quality

InactiveCN105965136AQuality improvementDoes not affect the compositionWelding accessoriesMetal foilOxygen

The invention belongs to the field of welding and particularly relates to a welding protection method for improving welding quality. When high-temperature alloy, titanium alloy, stainless steel and other materials are welded through argon arc welding, the front surfaces of welded seams are usually protected through a welding gun jetting inert gas, and the situation that the quality of the welded seams is reduced by oxygen and harmful gas is avoided; and generally, no universal welded seam protection method exists for the back surfaces of the welded seams. According to the welding protection method for improving the welding quality, metal foil belts are attached to the back surfaces of the welded seams, so that the welding quality is improved in a cheap and easy mode.

Owner:HARBIN

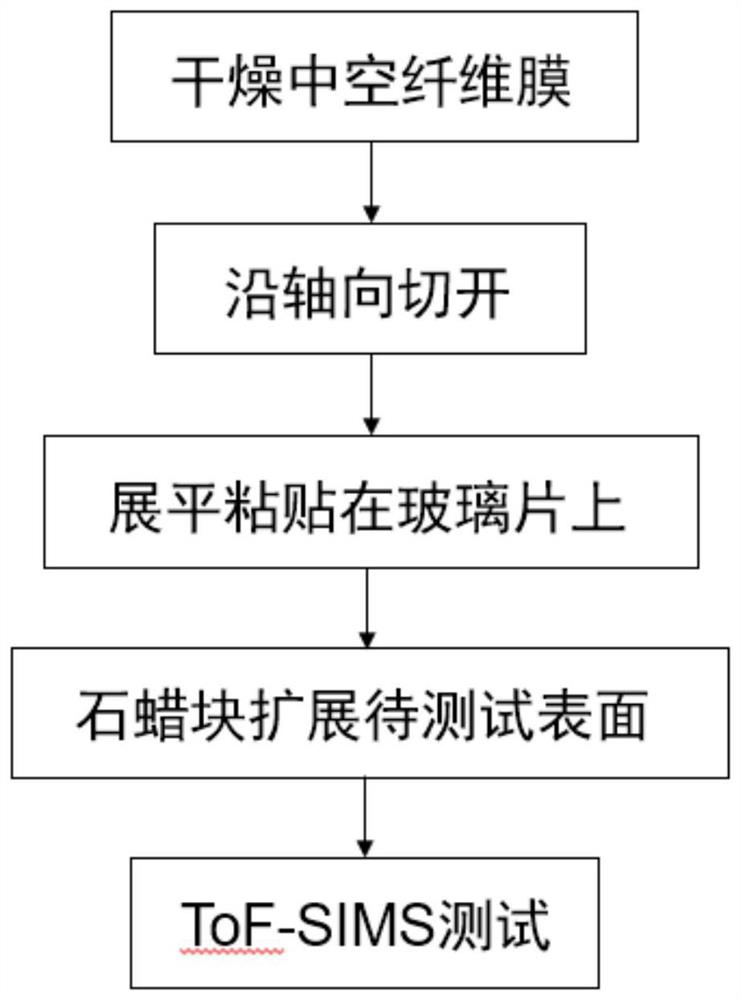

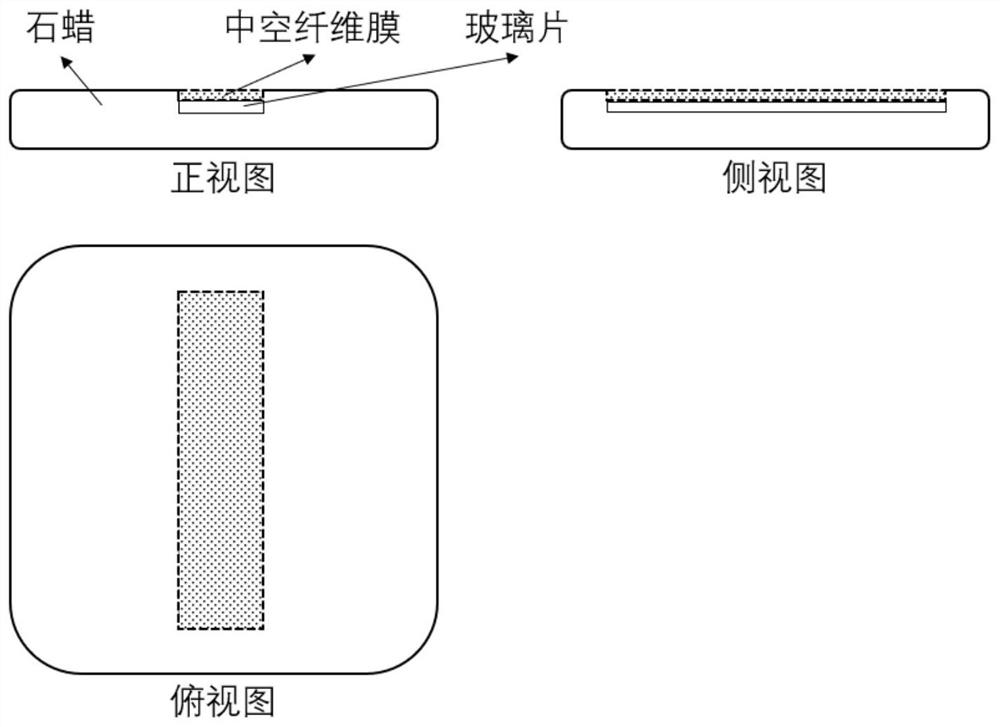

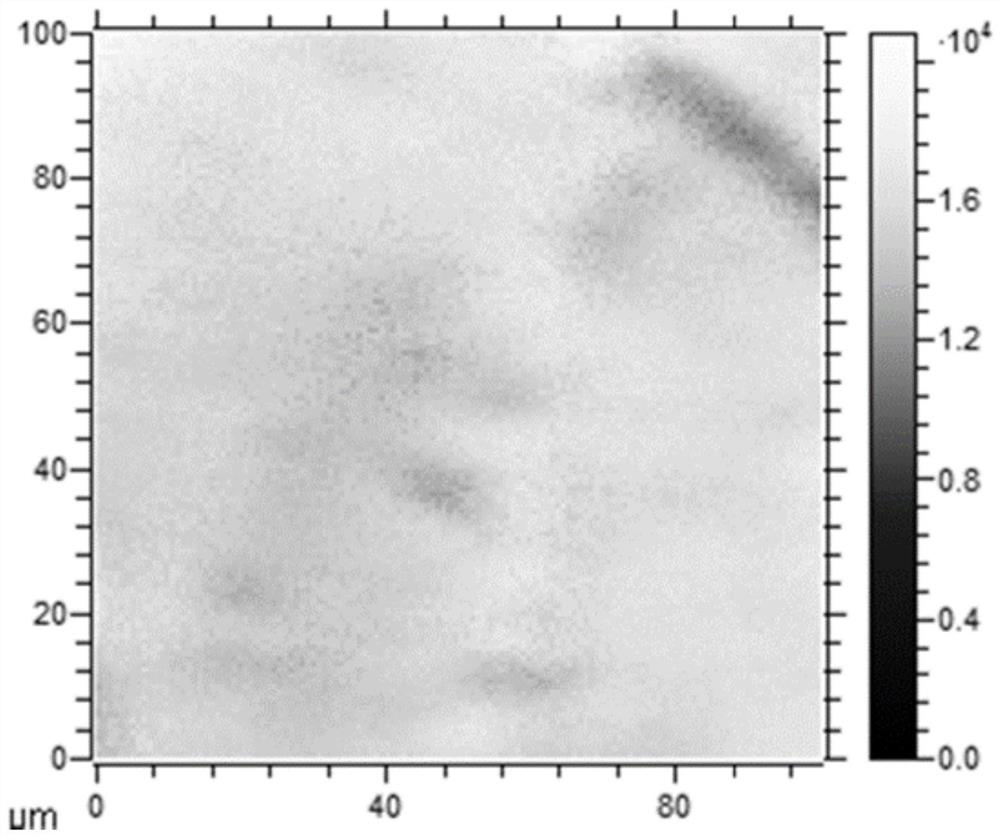

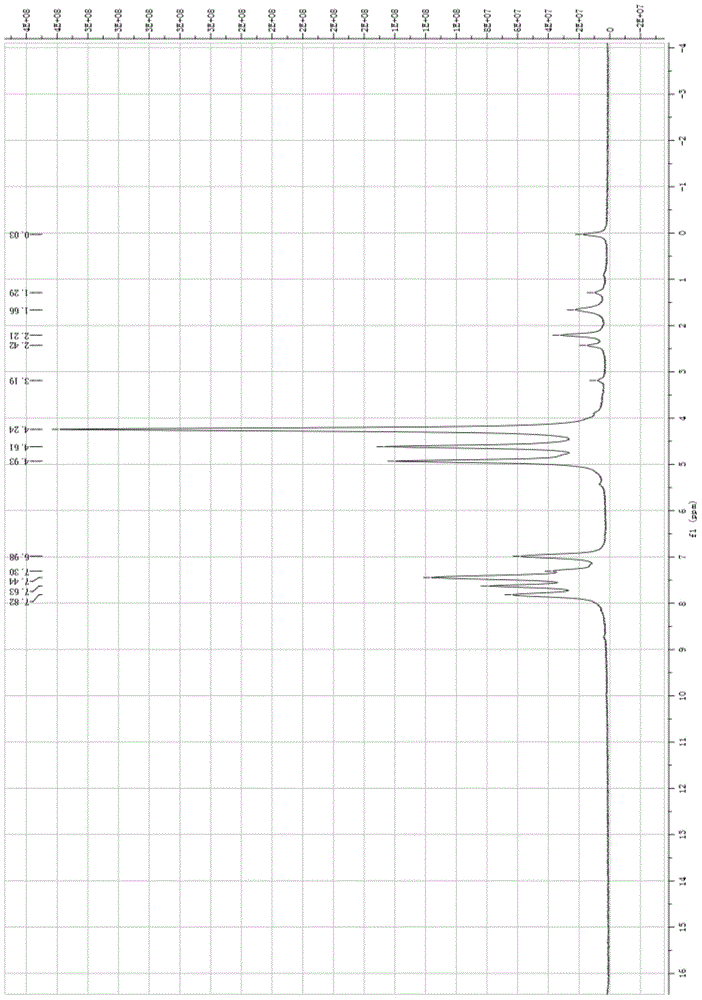

Sample preparation method for ToF-SIMS test of hollow fiber membrane

InactiveCN112505081AImplement analysis testsDoes not affect the compositionMaterial analysis using wave/particle radiationGlass chipComposition analysis

The invention provides a sample preparation method for ToF-SIMS test of a hollow fiber membrane, and belongs to the technical field of ToF-SIMS test. The method comprises the following steps: cuttinga hollow fiber membrane along the axial direction, flattening and pasting the hollow fiber membrane on a glass sheet, and expanding a to-be-tested surface by adopting a paraffin block. According to the method, the problem that the result is not credible due to the fact that the diameter of the hollow fiber membrane is too small, ToFSIMS cannot be effectively focused and the test signal is too pooris solved, the accurate and credible ToFSIMS test of the hollow fiber membrane is successfully achieved, the good test signal is obtained, operation is easy, and the method can be used for hollow fiber membrane surface filter cake layer composition analysis, membrane material composition analysis and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Copper-iron alloy and preparation method thereof

InactiveCN113005316AHigh purityGuaranteed purityPhotography auxillary processesBlast furnace detailsIron powderAlloy

The invention relates to the technical field of alloys, in particular to a copper-iron alloy and a preparation method thereof. The preparation method comprises the following steps that 1, raw material copper is refined, specifically, copper ore is subjected to air calcination, then a reducing agent is added for continuous calcination to obtain crude copper, and then wet copper extraction, crude copper leaching (leaching liquid), extraction, reverse extraction and electrodeposition are carried out to obtain electrolytic copper. According to the copper-iron alloy and the preparation method thereof, copper with high purity is obtained through cooperation of a calcination method and wet-process copper extraction, iron is obtained through high-temperature calcination, limestone can effectively absorb harmful gas generated during iron refining, copper-iron powder prepared through a high-pressure water atomization method is uniform in particle size, and does not influence components of copper and iron, the purity of the copper-iron alloy is guaranteed, and a V-shaped mixer is adopted for powder mixing and proportioning so that iron powder can be evenly mixed into copper powder, the uniformity of a precipitated phase of a finished product is improved, and the compactness of the copper-iron alloy can be improved by alternately conducting aging treatment and deformation machining treatment.

Owner:WUHU CHUJIANG ALLOY COPPER

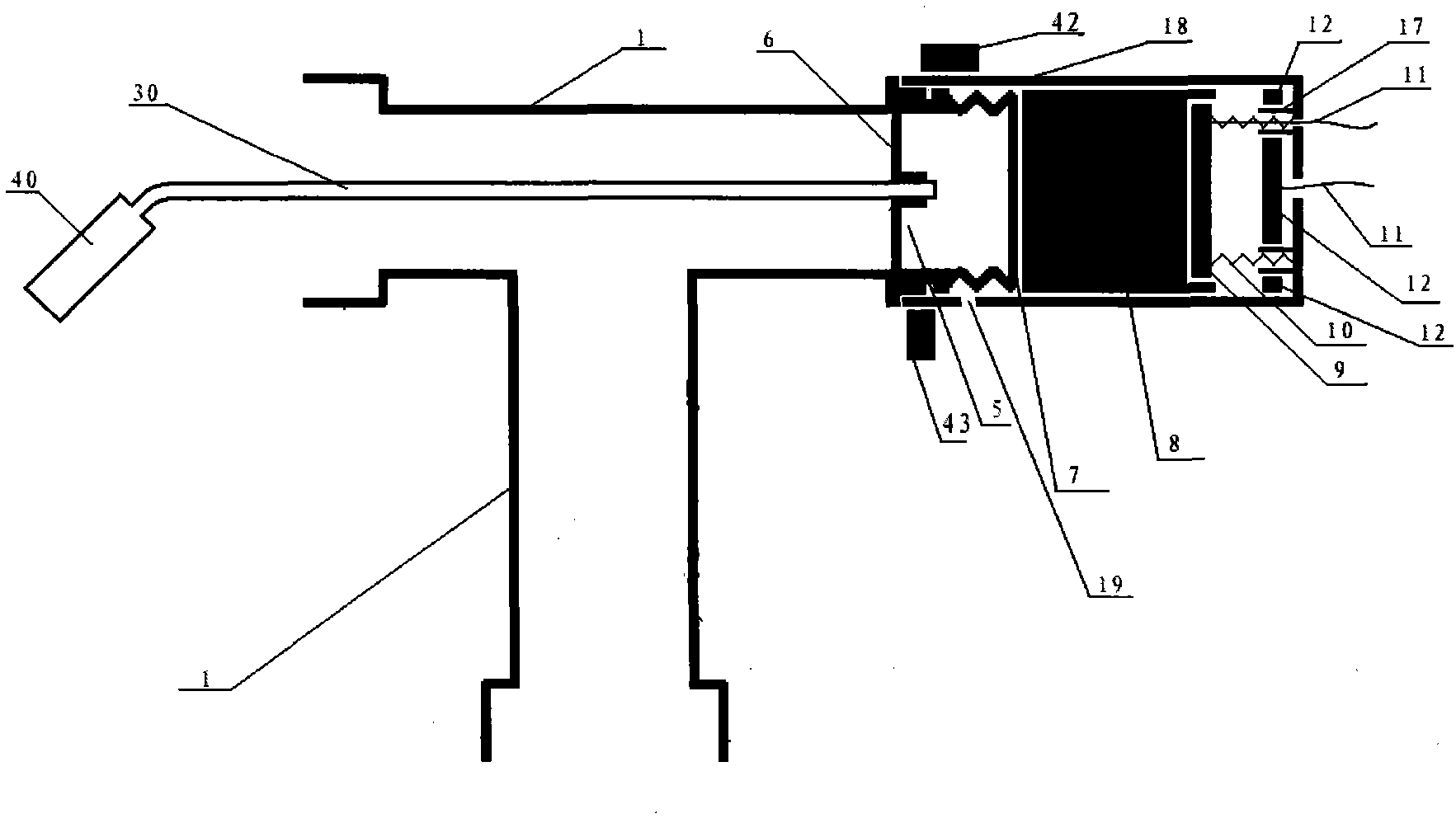

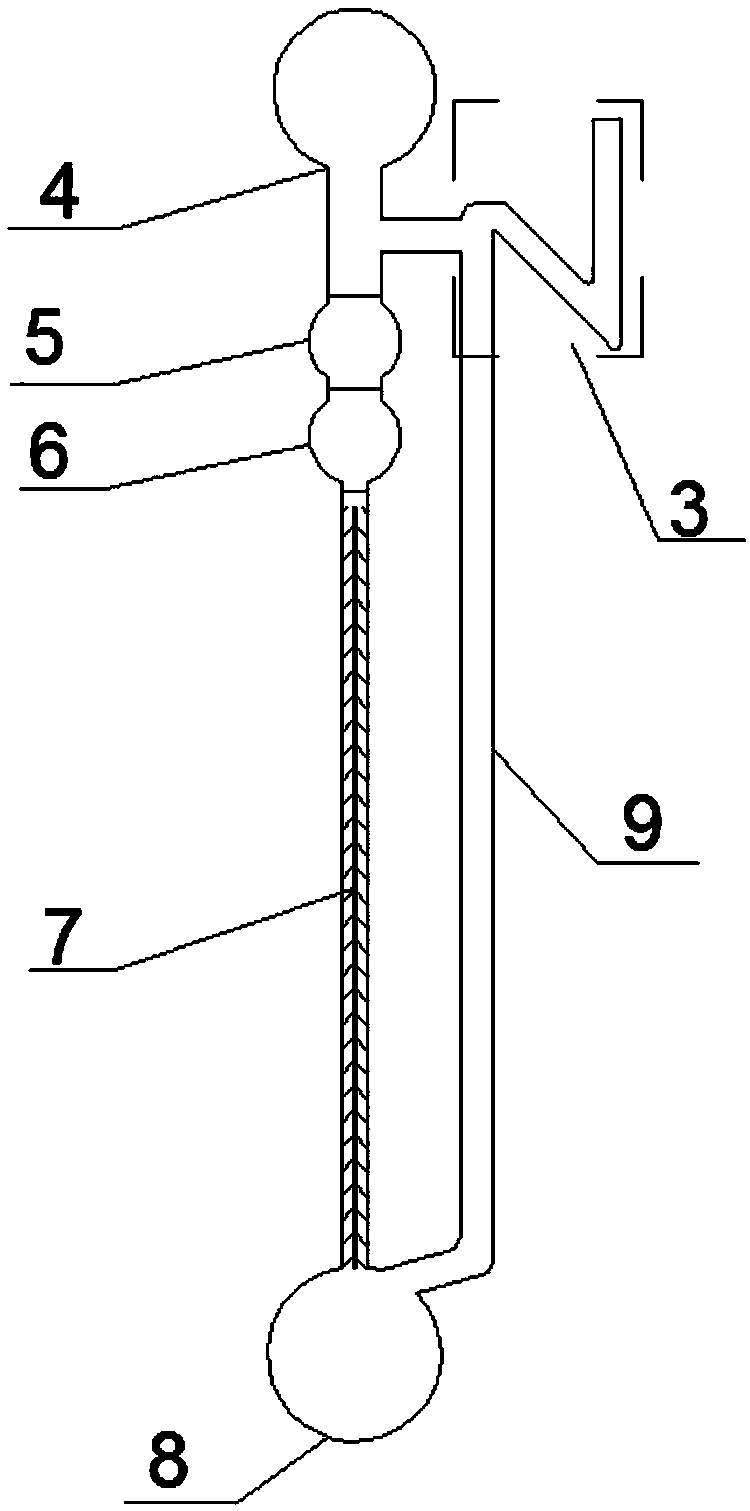

Capillary tube apparatus and method for automatically measuring viscosity of refrigerating fluid and lubricating oil

ActiveCN108776082ARealize measurementPrevent leakageEfficient regulation technologiesDirect flow property measurementCapillary TubingEngineering

The invention discloses a capillary tube apparatus and method for automatically measuring the viscosity of refrigerating fluid and lubricating oil. The capillary tube apparatus is composed of a fixingbracket, a laser sensor, a rotary transmission mechanism and a pressure vessel, wherein a capillary tube viscometer is fixedly arranged inside the pressure vessel and is composed of an upper liquid reservoir, an upper timing ball, a lower timing ball, a capillary tube, a lower liquid reservoir, a by-pass pipe and an N-shaped pipe; the upper liquid reservoir, the upper timing ball, the lower timing ball, the capillary tube and the lower liquid reservoir are communicated with one another in sequence from top to bottom; the upper liquid reservoir and the lower liquid reservoir are connected witheach other by virtue of the by-pass pipe; the volumes of the upper liquid reservoir and the lower liquid reservoir are the same and are larger than volumes of the upper timing ball and the lower timing ball; and the N-shaped pipe is arranged at the upper end of the by-pass pipe and is used for realizing two functions of injecting liquid and preventing turning and liquid leaking. With the adoptionof the design of the N-shaped pipe, the liquid can be conveniently injected, the liquid can be prevented from leaking into the pressure vessel via the liquid injection port in the process of turningto ascending feed, and to-be-measured liquid is prevented from being repeatedly filled.

Owner:TIANJIN UNIV

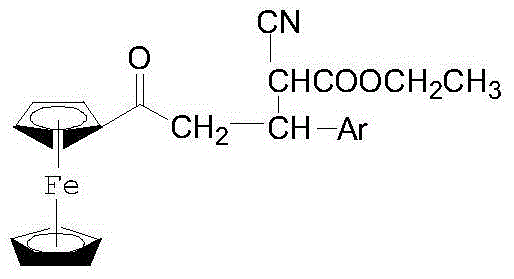

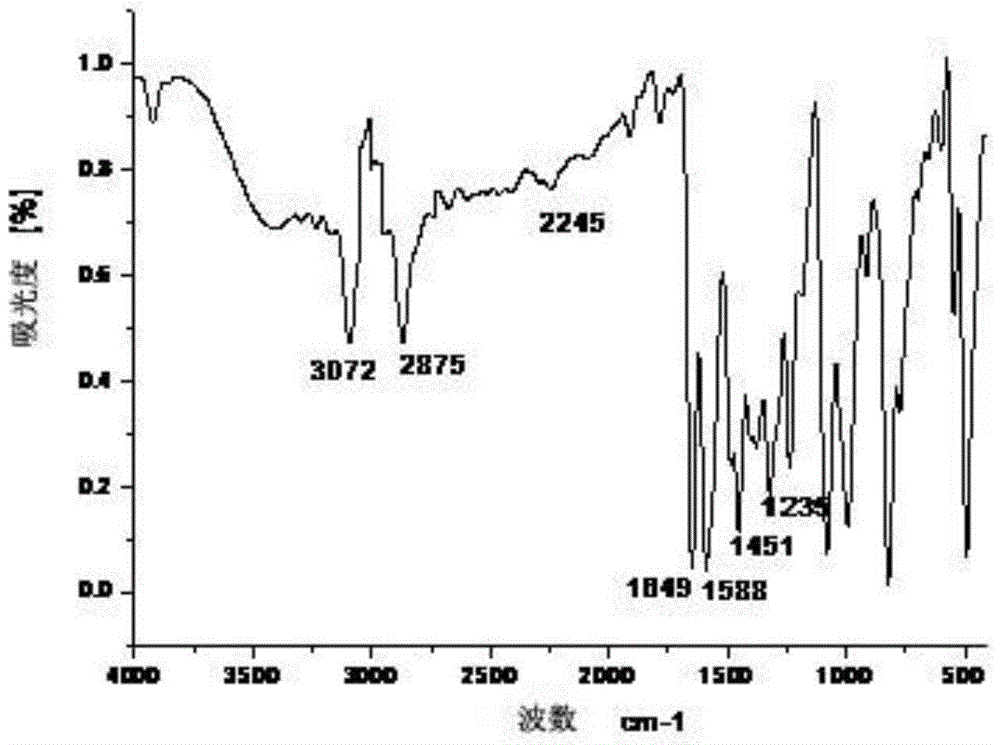

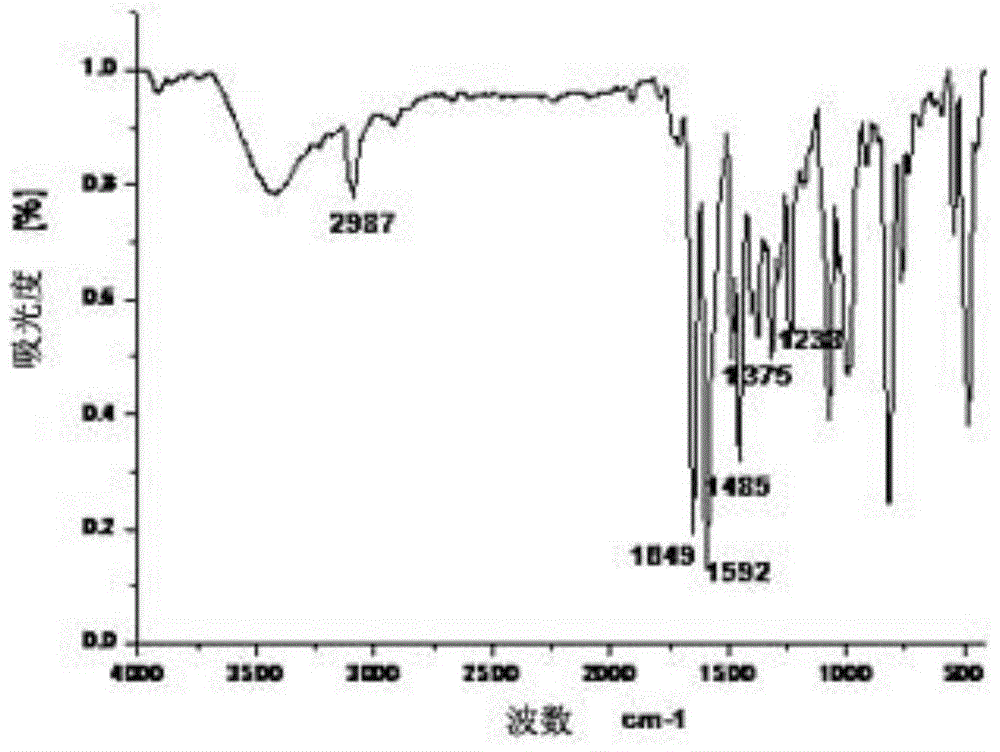

1-ferrocenyl-3-aryl-3-cyano-methylene-acetone and preparation method thereof

InactiveCN104478944AHigh yieldRaw materials are easy to getFungicidesDisinfectantsArylAfter treatment

The invention discloses 1-ferrocenyl-3-aryl-3-cyano-methylene-acetone and a preparation method thereof. 1-ferrocenyl-3-aryl-3-cyano-methylene-acetone has a structural formula described in the description. The preparation method comprises the following steps: adding A mol of 1-ferrocenyl-3-aryl-acrylketone, B mol of anhydrous K2CO3 (or NaOH) and C mol of acetonitrile into a dried mortar, quickly grinding, performing TLC (Thin Layer Chromatography) detection until complete reaction, washing with water, performing suction filtration, and drying to obtain 1-ferrocenyl-3-aryl-3-cyano-methylene-acetone. The preparation method has the advantages of being short in reaction time, free of solvent, environment friendly, good in economic property, simple in operation, mild in reaction conditions, simple in after-treatment and high in yield.

Owner:SHAANXI UNIV OF SCI & TECH

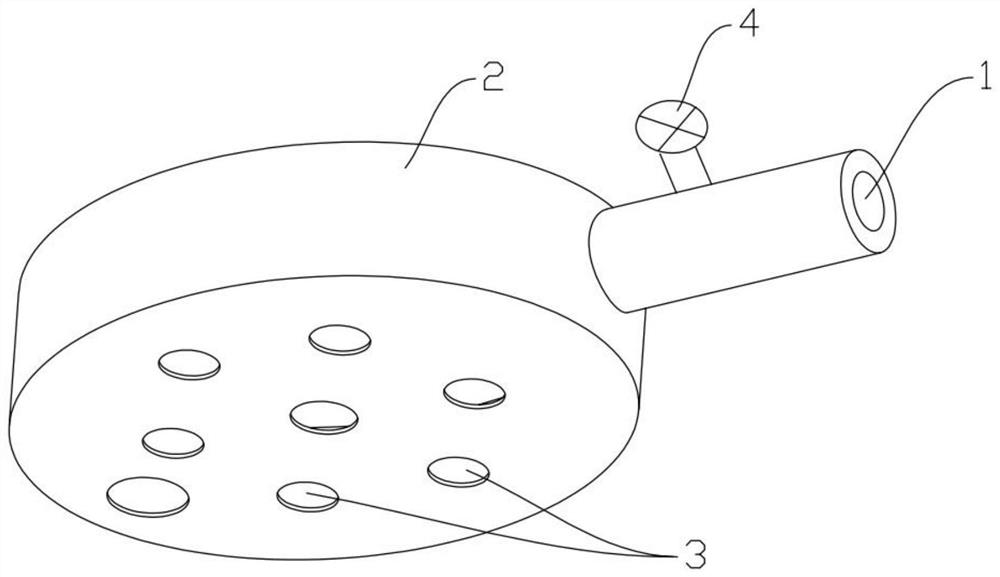

Common-passage liquid injection device

PendingCN110747105AGuaranteed premixedDoes not affect the compositionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

The invention relates to the technical field of biology, in particular to a common-passage liquid injection device. The common-passage liquid injection device comprises a main body plate, wherein a plurality of first liquid inlet parts penetrating through the main body plate are arranged on one surface of the main body plate; a plurality of second liquid inlet parts are arranged on the other surface adjacent to the surface; and the second liquid inlet parts extend to communicate with the first liquid inlet parts. Two reaction reagents of the common-passage liquid injection device can be injected into a composite column respectively through the first liquid inlet parts and the second liquid inlet parts; before the two reaction reagents are injected into the composite column, the premixing can be realized; the activation on the reagents can be further completed; the synthesis effects of RNA, LNA and DNA are improved to a certain degree; after the injection of the first group of reagentsis completed, the liquid injection device is moved; and then, the injection of the second group of reagents is performed, so that the injection of each group of reagents can be sequentially completedin a short time. In addition, by using a mode of simultaneously injecting the two reagents into the synthesis column, the liquid adding time is shortened to a certain degree; and the synthesis efficiency is improved.

Owner:北京擎科生物科技股份有限公司

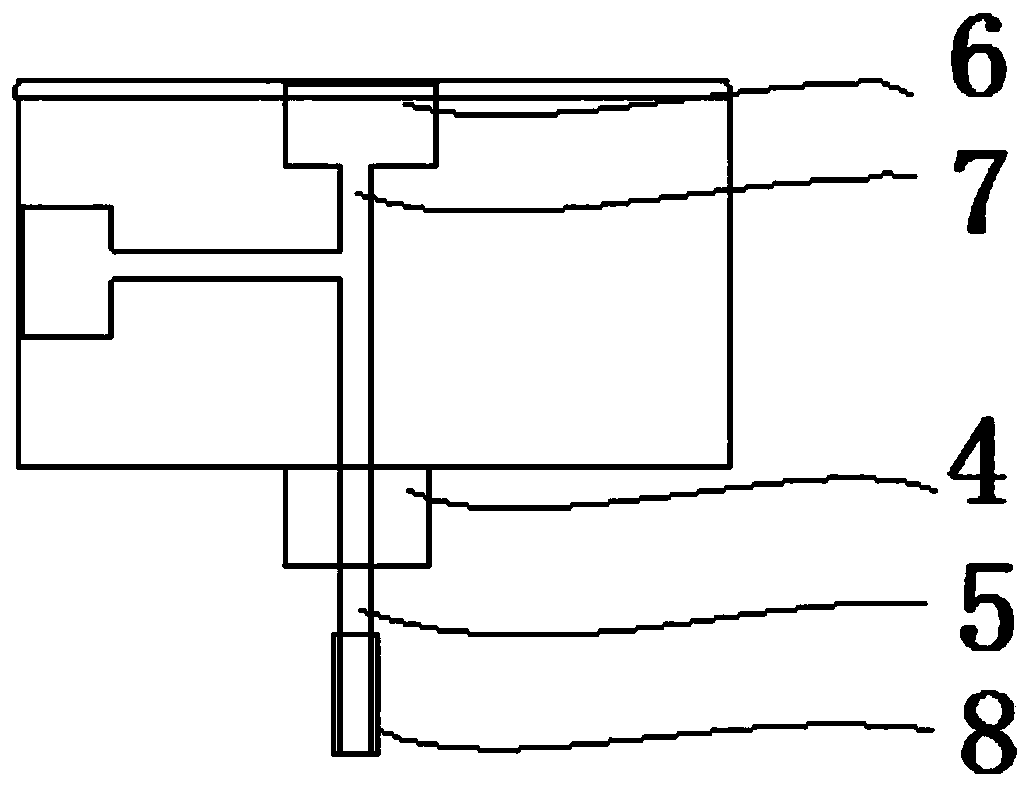

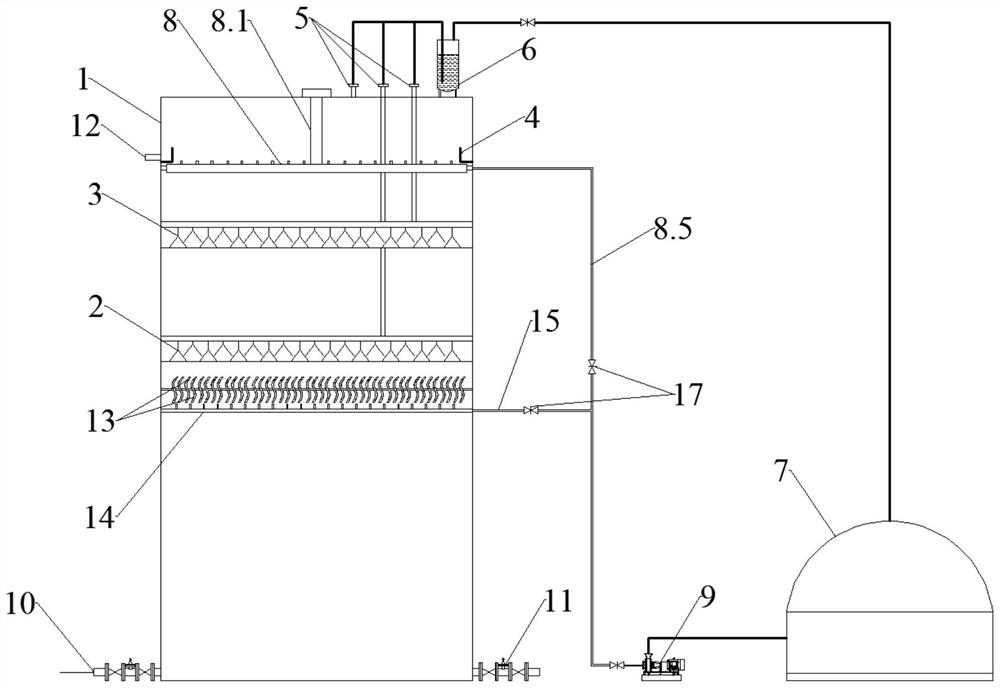

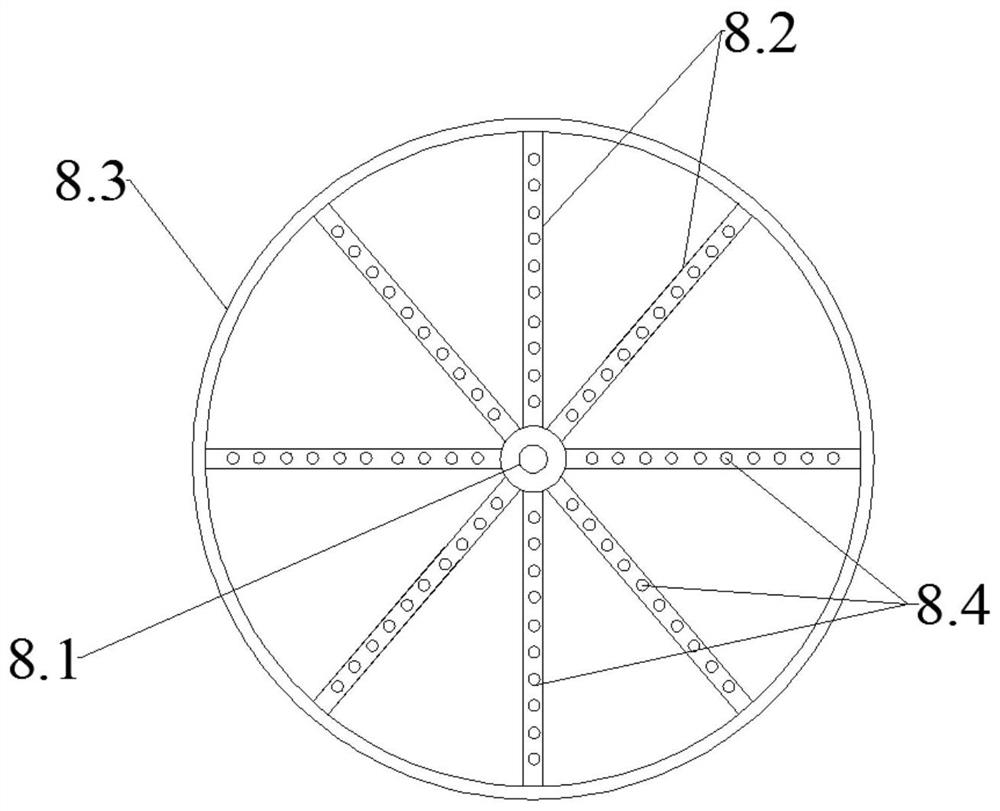

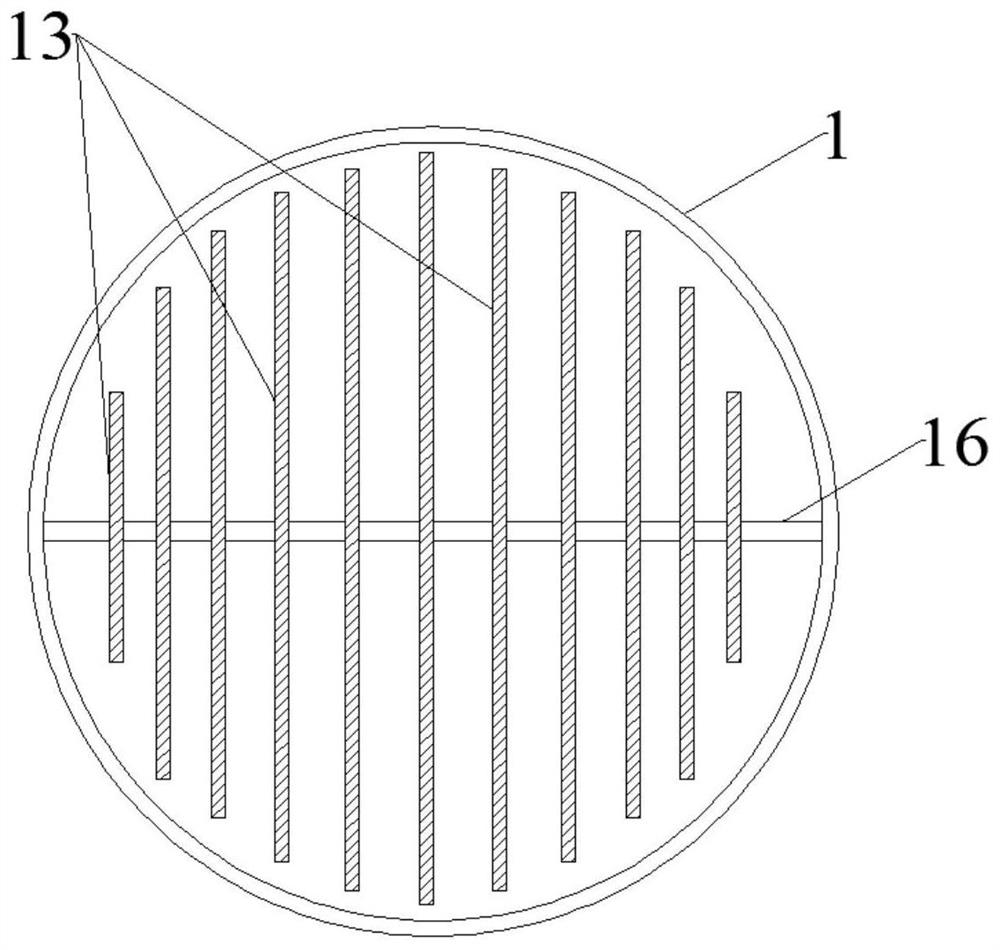

Sewage treatment anaerobic reactor with scum and crusting eliminating function

ActiveCN113354081ADoes not affect the compositionRealize the use of the nearestSpecific water treatment objectivesWater contaminantsAnaerobic reactorExhaust pipe

The invention discloses a sewage treatment anaerobic reactor with a scum and crusting eliminating function, the reactor comprises a reactor body, the lower part of the reactor body is provided with a water inlet and a sludge outlet, and a lower-layer three-phase separator and an upper-layer three-phase separator are sequentially fixed in the inner cavity of the reactor body from bottom to top. An overflow weir is fixed on the upper-layer three-phase separator in the inner cavity of the reactor body, and a water outlet is formed in the overflow weir. The lower-layer three-phase separator and the upper-layer three-phase separator are both communicated with an exhaust pipe, the exhaust pipe is connected with a liquid seal device fixed on the top surface of the reactor body, and the liquid seal device is connected with a biogas cabinet outside the reactor body. A pneumatic shell breaking mechanism is fixed between the upper-layer three-phase separator and the overflow weir, is provided with a plurality of upward air nozzles, and is connected with the biogas cabinet through a pressure pump. The reactor not only can utilize the generated biogas to break scum or crusts at the upper part of the reactor, but also has the characteristic of improving the solid-liquid separation effect.

Owner:山东杨帆环保工程股份有限公司

1-ferrocenyl-3-aryl-3-(2,4,6-pyrimidinetriketo)-acetone and preparation method thereof

The invention discloses 1-ferrocenyl-3-aryl-3-(2,4,6-pyrimidinetriketo)-acetone and a preparation method thereof. 1-ferrocenyl-3-aryl-3-(2,4,6-pyrimidinetriketo)-acetone has a structural formula as shown in the description. The preparation method comprises the following steps: adding A mol of 1-ferrocene-3-aryl-propenone, B mol of anhydrous K2CO3 (or NaOH) and C mol of barbituric acid into a dried mortar, rapidly grinding, detecting with TLC until the reaction is completed, washing with water, carrying out suction-filtration and drying to obtain 1-ferrocenyl-3-aryl-3-(2,4,6-pyrimidinetriketo)-acetone. The 1-ferrocenyl-3-aryl-3-(2,4,6-pyrimidinetriketo)-acetone and the preparation method thereof have the advantages that the method is simple in operation and post-treatment, mild in reaction conditions and high in yield.

Owner:SHAANXI UNIV OF SCI & TECH

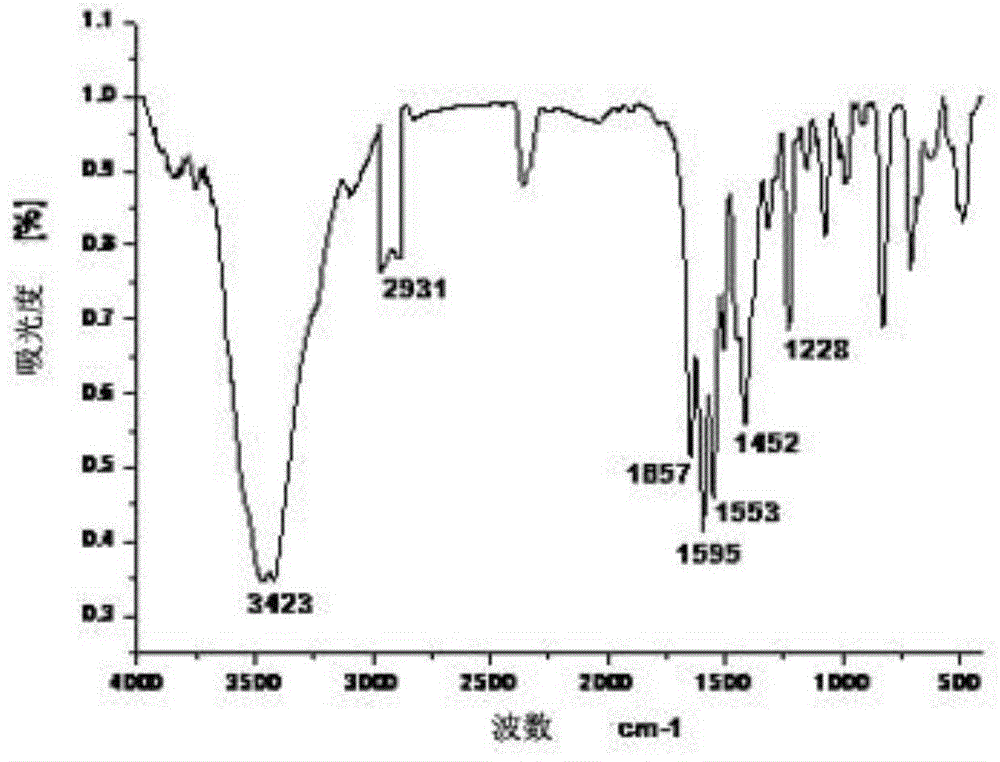

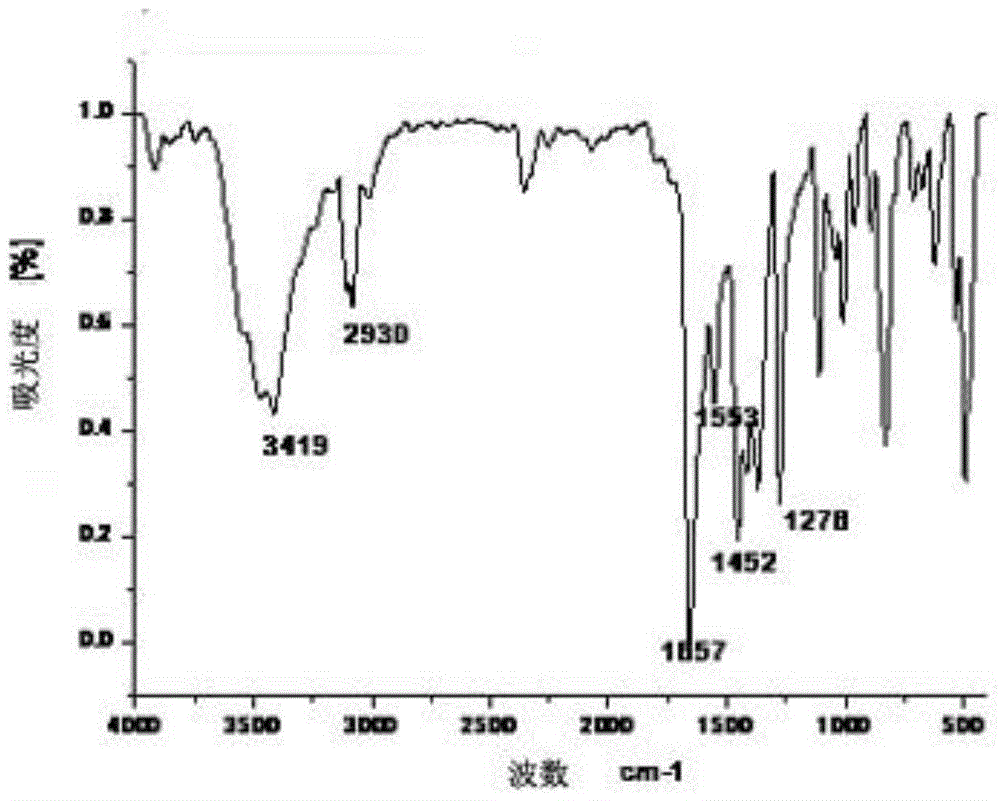

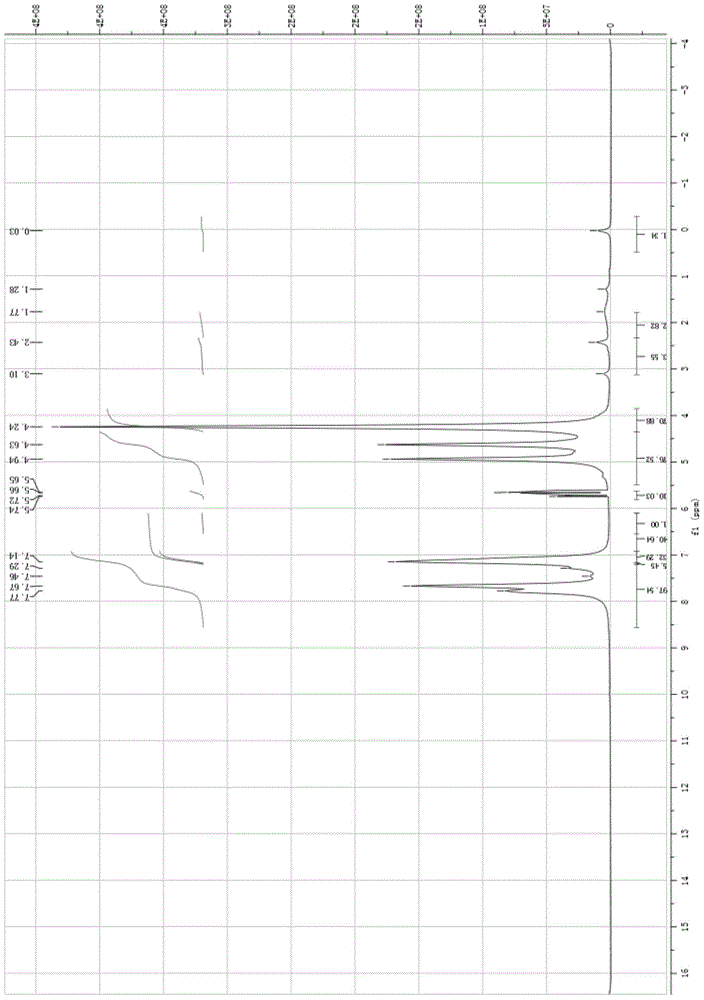

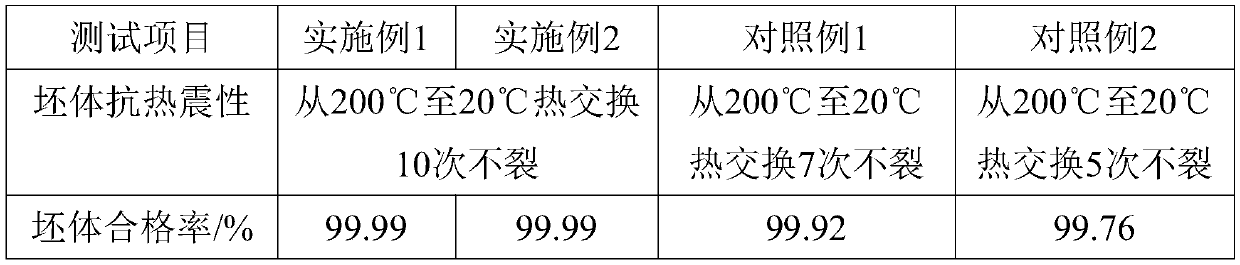

A processing technology of ceramic tableware body for daily use

ActiveCN107573023BImprove thermal shock resistanceImprove pass rateFibre typesYarnMechanical engineeringNanostructured titanium

The invention discloses a technology for processing a green body of daily ceramic tableware and relates to the technical field of daily ceramics. The technology comprises the following steps: (1) preparing raw materials; (2) preparing mud; (3) filtering and dewatering the mud; (4) performing vacuum pugging; (5) cutting the mud; (6) forming the green body; (7) pre-drying the green body. According to the technology disclosed by the invention, by virtue of a manner of adding a small amount of nano titanium dioxide and crude molecular sieve powder into the raw materials, the thermal shock resistance of the prepared green body is obviously improved, and the problem that the green body produces cracks even fissures under continuous high-temperature raise conditions when immediately transferred into a kiln from a room temperature environment is solved; therefore, the yield of the fired green body is improved. Due to two-stage pre-drying treatment of the green body, the contained moisture is slowly volatilized, and the condition that the green body is directly transferred into the kiln to produce deformation due to sudden drop of the moisture content is avoided, so that the yield of the fired green body is further improved.

Owner:潮州市乐盈弘陶瓷有限公司

1-ferrocenyl-3-aryl-3-(1-acetyl-1-formylcarbethoxyl-methenyl)-acetone and preparation method thereof

InactiveCN104447884ARaw materials are easy to getShort reaction timeMetallocenesFiltrationEthyl acetate

The invention discloses 1-ferrocenyl-3-aryl-3-(1-acetyl-1-formylcarbethoxyl-methenyl)-acetone and a preparation method thereof. The general structural formula of the 1-ferrocenyl-3-aryl-3-(1-acetyl-1-formylcarbethoxyl-methenyl)-acetone is shown in the specification, wherein the aryl group is phenyl group, halogenbenzyl group, methyl phenyl group, ethyl phenyl group, propyl phenyl group, methoxy phenyl group, nitrophenyl group, hydroxyphenyl group, aminophenyl group, styryl group, five-membered heterocyclic group or six-membered heterocyclic group. The preparation method of the 1-ferrocenyl-3-aryl-3-(1-acetyl-1-formylcarbethoxyl-methenyl)-acetone comprises the following steps: adding A mol of 1-ferrocenyl-3-aryl-acrylketone, B mol of anhydrous K2CO3 (or NaOH) and C mol of ethyl acetoacetate into a dry mortar to quickly grind; performing TLC (Thin Layer Chromatography) monitoring until the reaction is complete; then washing, performing extraction filtration and drying to obtain the 1-ferrocenyl-3-aryl-3-(1-acetyl-1-formylcarbethoxyl-methenyl)-acetone. The method has the advantages of short reaction time, no need of solvent, environment friendliness, economy, easiness in operation, mild reaction condition, easiness in post-treatment and high yield.

Owner:SHAANXI UNIV OF SCI & TECH

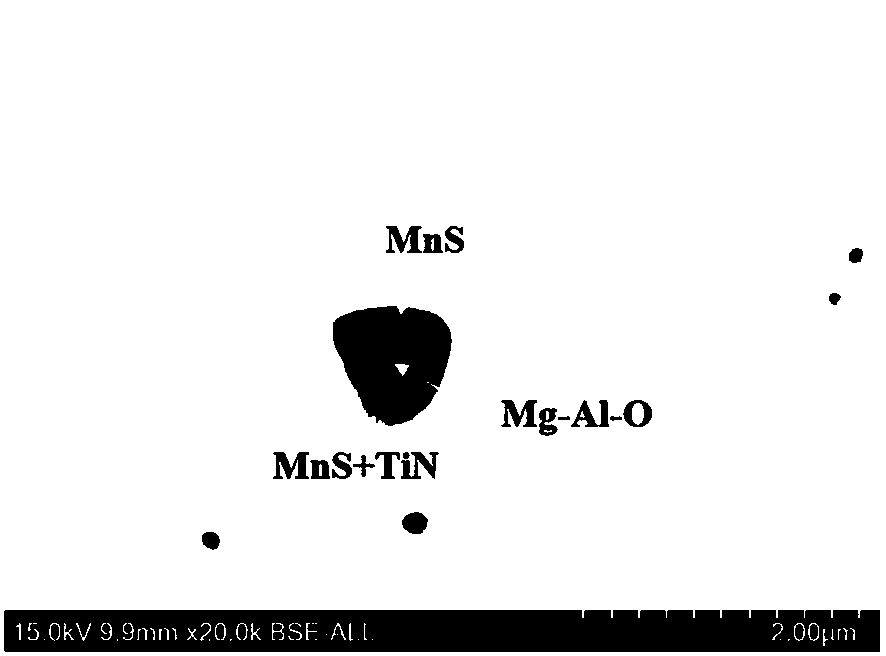

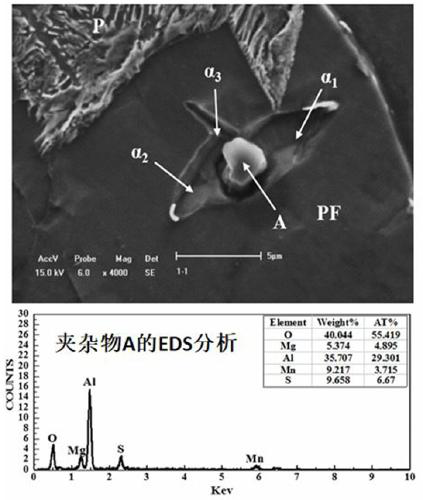

A low-cost magnesium-treated microalloyed steel and its preparation method

The invention discloses a low-cost magnesium-treated micro-alloy steel and a preparation method thereof, including steel smelting, alloying, cored wire feeding, continuous casting, rolling and the like. After RH refining is finished, Mg-Al-Fe alloy is fed into molten steel at a certain speed, which is used to partially replace Nb, V, Ti and other elements used for alloying in the refining process, which can promote the solidification and rolling process of steel A large amount of precipitation of the second phase particles in the medium partially replaces the microalloying of Nb, V, Ti, and improves the structure and performance of the steel; due to the low price of metal magnesium, replacing the expensive alloying elements Nb, V, Ti reduces the energy efficiency of the steel production cost. The performance of the magnesium-treated low-carbon microalloy steel obtained by the invention is close to or exceeds that of the reference steel without adding magnesium, and the alloying cost per ton of steel is reduced by more than 25 yuan, which is a new steel microalloying technology.

Owner:SUZHOU UNIV

Iron-free and manganese-free copper-nickel b10 production process

Owner:上海海亮铜业有限公司 +1

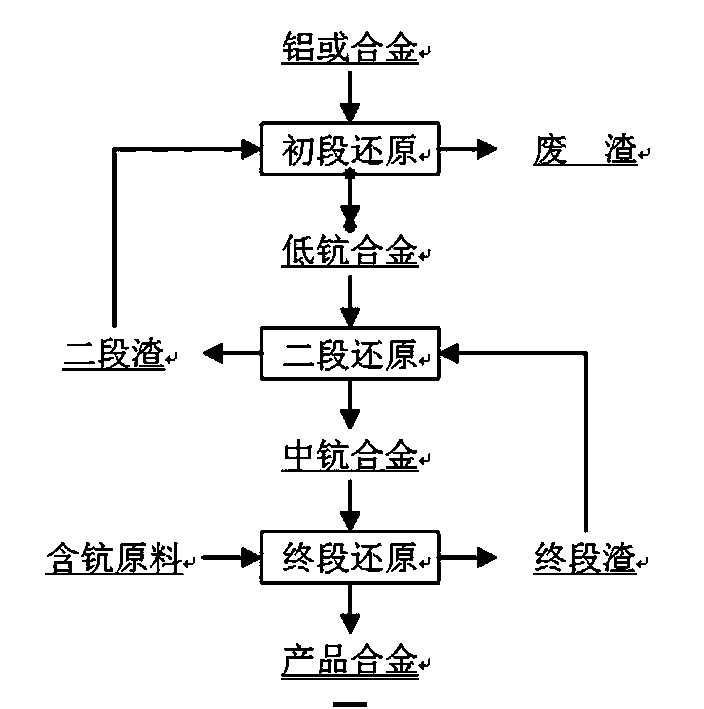

Method for preparing aluminum-scandium alloy by segmental countercurrent reduction method

Owner:ZHENGZHOU UNIV

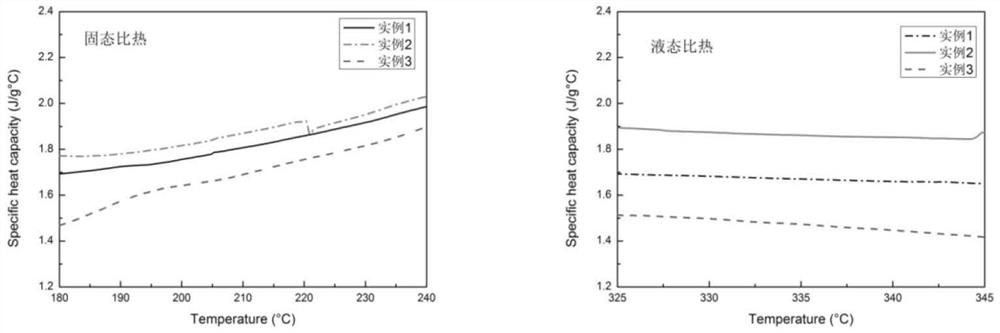

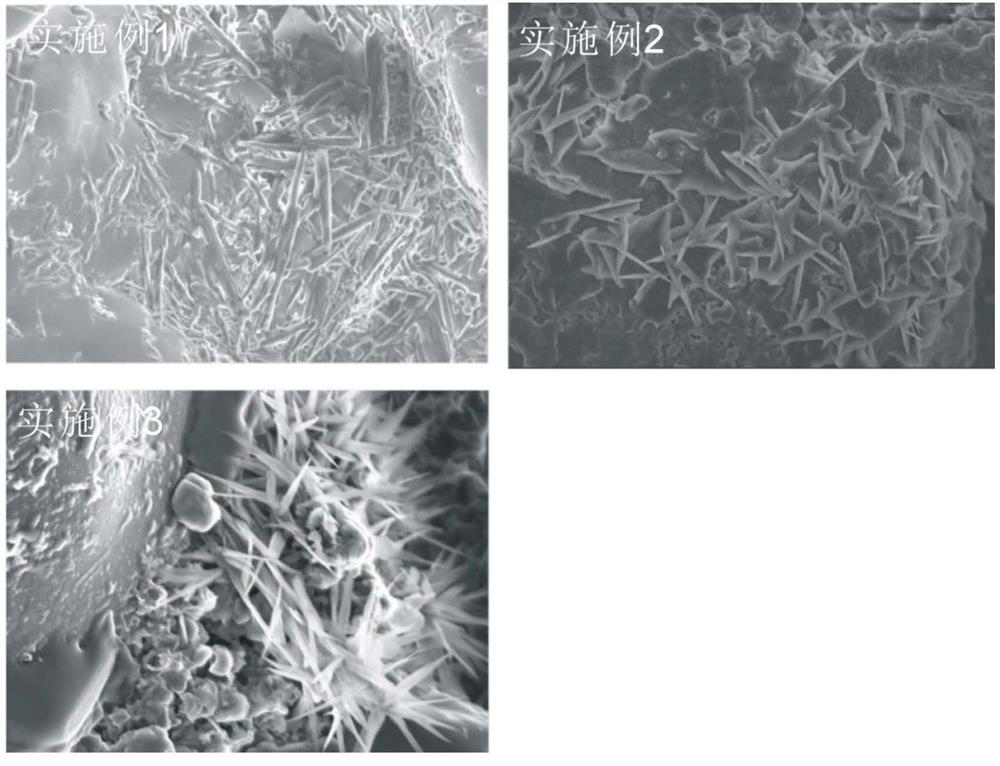

A nano with high specific heat capacity 3 Phase change heat storage material and preparation method thereof

ActiveCN110172332BHigh specific heat capacitySimple methodHeat-exchange elementsLiquid stateMolten salt

The invention discloses a NaNO3 heat storage material high in specific heat capacity. The material is prepared with NaNO3 as a raw material and urea as fuel through modification by using a solution combustion method. The stoichiometric ratio of the raw material NaNO3 to the fuel urea is 2:(1-4). The phase of the NaNO3 heat storage material obtained through the method is still NaNO3, linear structures, needle-shaped structures, spherical structures and other special structures grow on the surface of the material and in the material, the solid-state specific heat capacity can be increased to 1.87 J / (g DEG C) and is increased by 43.8% compared with that of ordinary NaNO3, and the liquid-state specific heat capacity can be increased to 1.86 J / (g DEG C) and is increased by 51.2% compared with that of the ordinary NaNO3. The NaNO3 heat storage material has the advantages of being high in specific heat capacity, special in structure and the like, a modification method is simple, and a new idea is provided for modification of the molten salt heat storage material.

Owner:WUHAN UNIV OF TECH

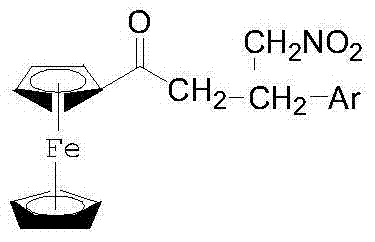

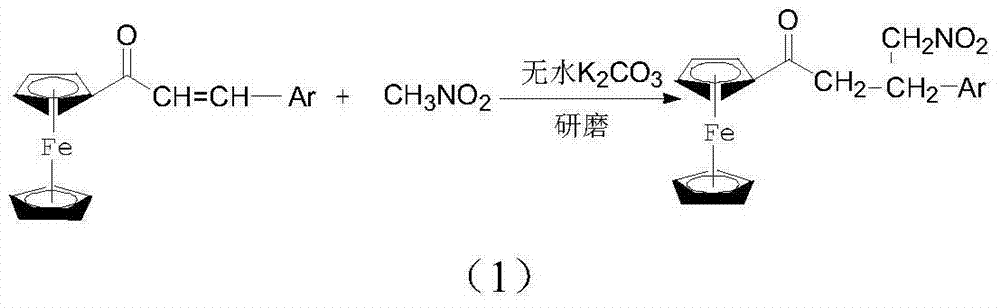

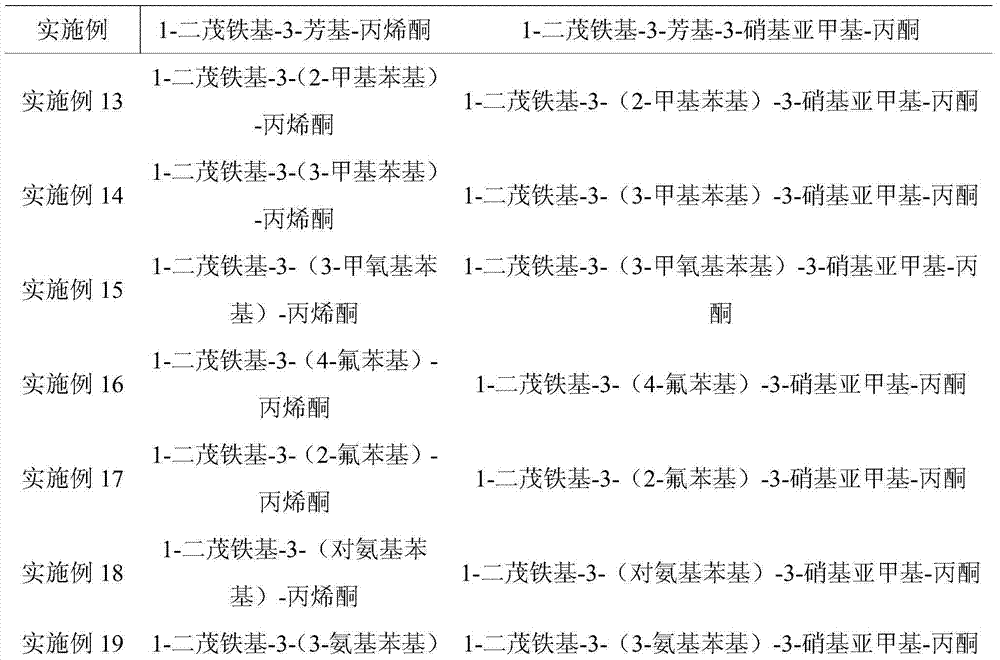

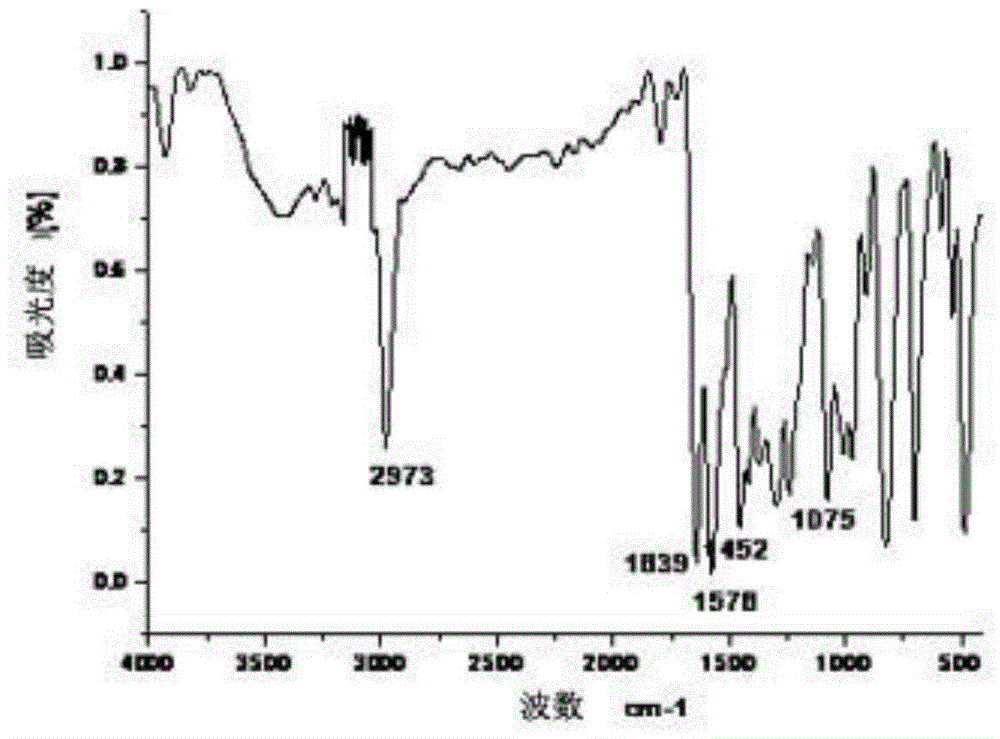

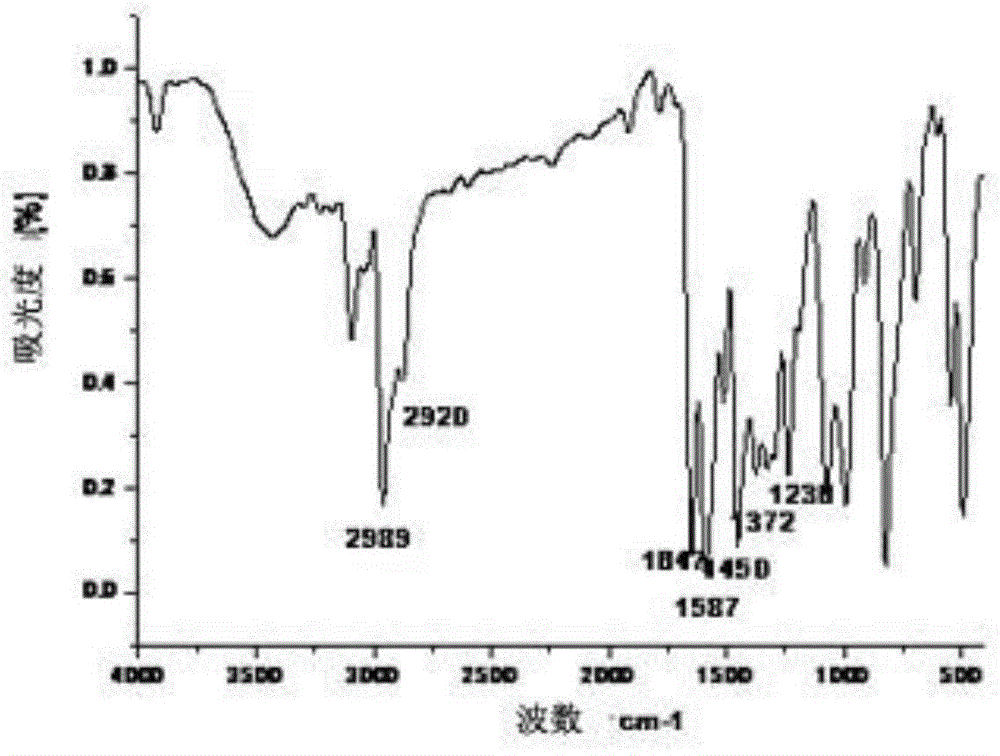

1-ferrocenyl-3-aryl-3-nitromethylene-acetone and preparation method thereof

The invention discloses a 1-ferrocenyl-3-aryl-3-nitromethylene-acetone and a preparation method thereof. The structural formula of the compound is disclosed in the specification. The preparation method comprises the following steps: quickly grinding 1-ferrocenyl-3-aryl-propenylketone, anhydrous K2CO3 (or NaOH) and nitromethane in a dry mortar, and detecting the reaction progress by TLC (thin layer chromatography); and after the reaction is completely finished, washing with water, carrying out vacuum filtration and vacuum drying to obtain the 1-ferrocenyl-3-aryl-3-nitromethylene-acetone. The invention provides the 1-ferrocenyl-3-aryl-3-nitromethylene-acetone and the preparation method thereof. The method is simple to operate, and has the advantages of mild reaction conditions, simple after-treatment, no need of solvent, high economy and high yield; and the prepared product is a brand-new ketone and can be used in the fields of pesticides, medicines and the like.

Owner:SHAANXI UNIV OF SCI & TECH

1-ferrocenyl-3-aryl-3-(2,6-dicarbonyl-4-thiopyrimidinyl)-acetone and preparation method thereof

InactiveCN104530139AShort reaction timeEasy to operateAntiinfectivesDisinfectantsThio-Biochemical engineering

The invention discloses 1-ferrocenyl-3-aryl-3-(2,6-dicarbonyl-4-thiopyrimidinyl)-acetone and a preparation method thereof. The structural formula of the 1-ferrocenyl-3-aryl-3-(2,6-dicarbonyl-4-thiopyrimidinyl)-acetone is shown in the specification. The preparation method comprises the following steps: adding A mol of 1-ferrocenyl-3-aryl-acrylketone, B mol of anhydrous K2CO3 (or NaOH) and C mol of thiobarbituric acid into a dried mortar, grinding the materials fast, performing TLC tests till complete reaction, and then performing washing, suction filtration and drying to obtain the 1-ferrocenyl-3-aryl-3-(2,6-dicarbonyl-4-thiopyrimidinyl)-acetone. The invention has the advantages that the 1-ferrocenyl-3-aryl-3-(2,6-dicarbonyl-4-thiopyrimidinyl)-acetone and the preparation method thereof are provided, and the method has short reaction time, does not need a solvent, is green, environment-friendly and economic, is simple to operate, moderate in reaction condition and simple in after-treatment and has high yield.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com