Capillary tube apparatus and method for automatically measuring viscosity of refrigerating fluid and lubricating oil

An automatic measurement and refrigerant technology, applied in the direction of DC flow characteristics measurement, etc., can solve the problems of reducing the accuracy of the results, low stability, difficult automatic measurement, etc., to improve the accuracy and stability, avoid repeated charging, Achieve the effect of repeated measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

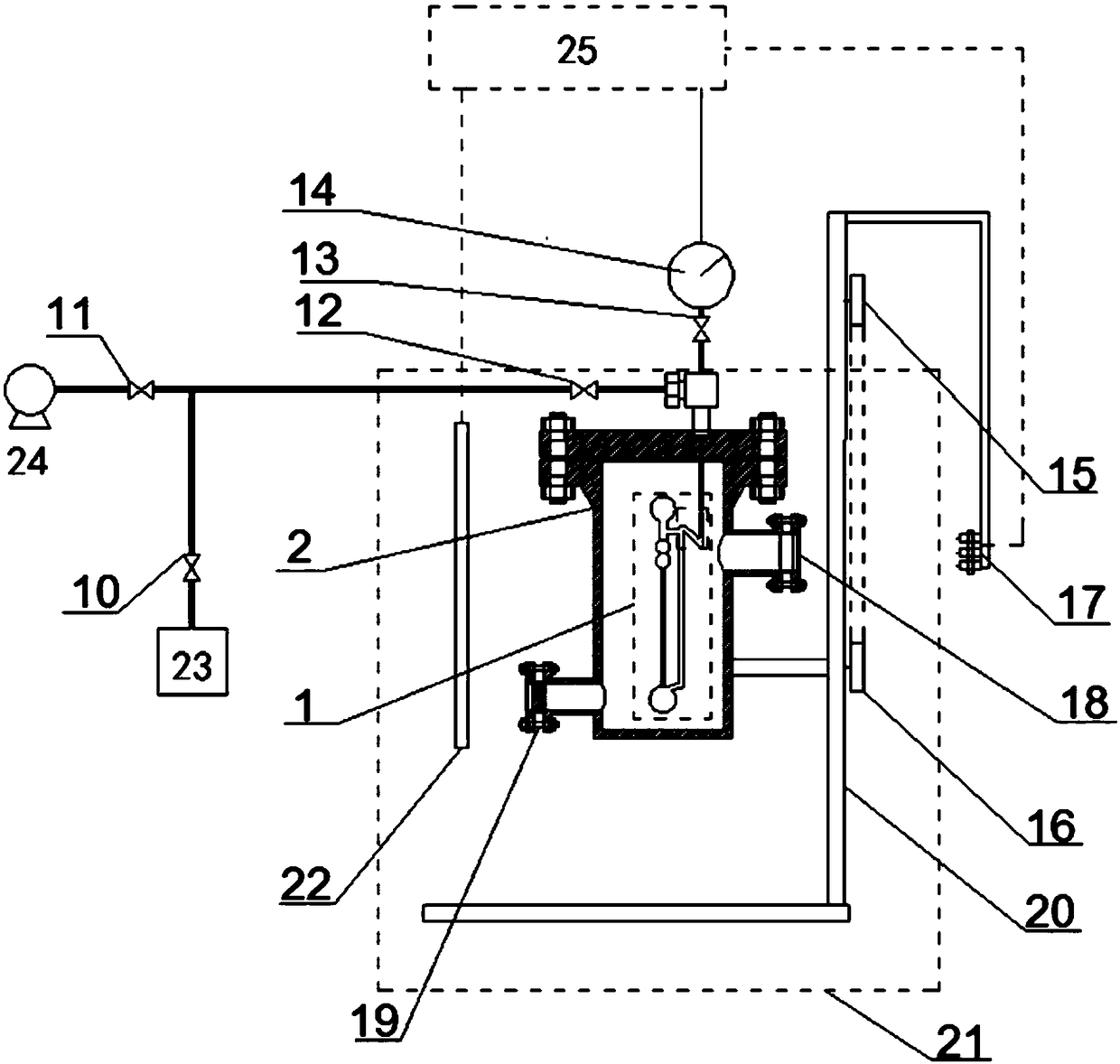

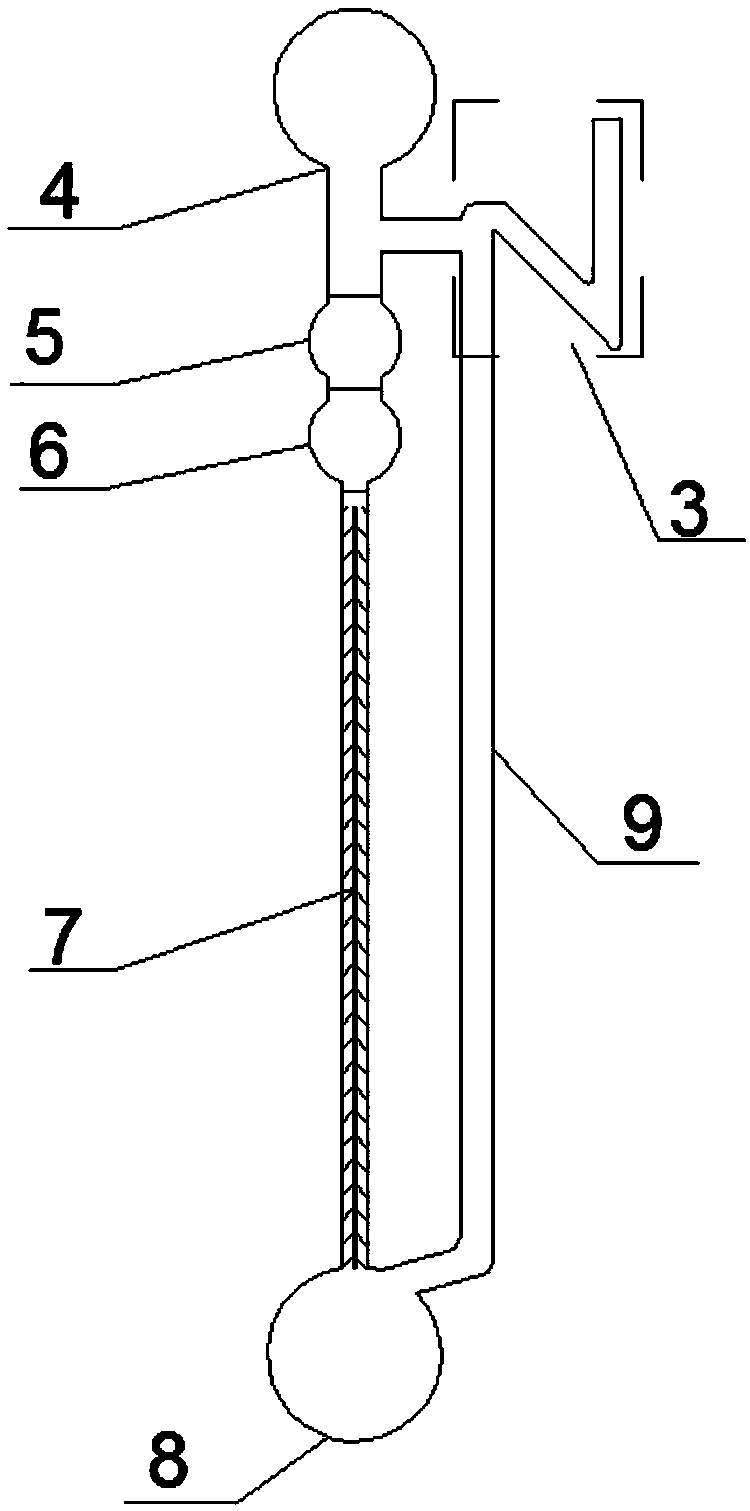

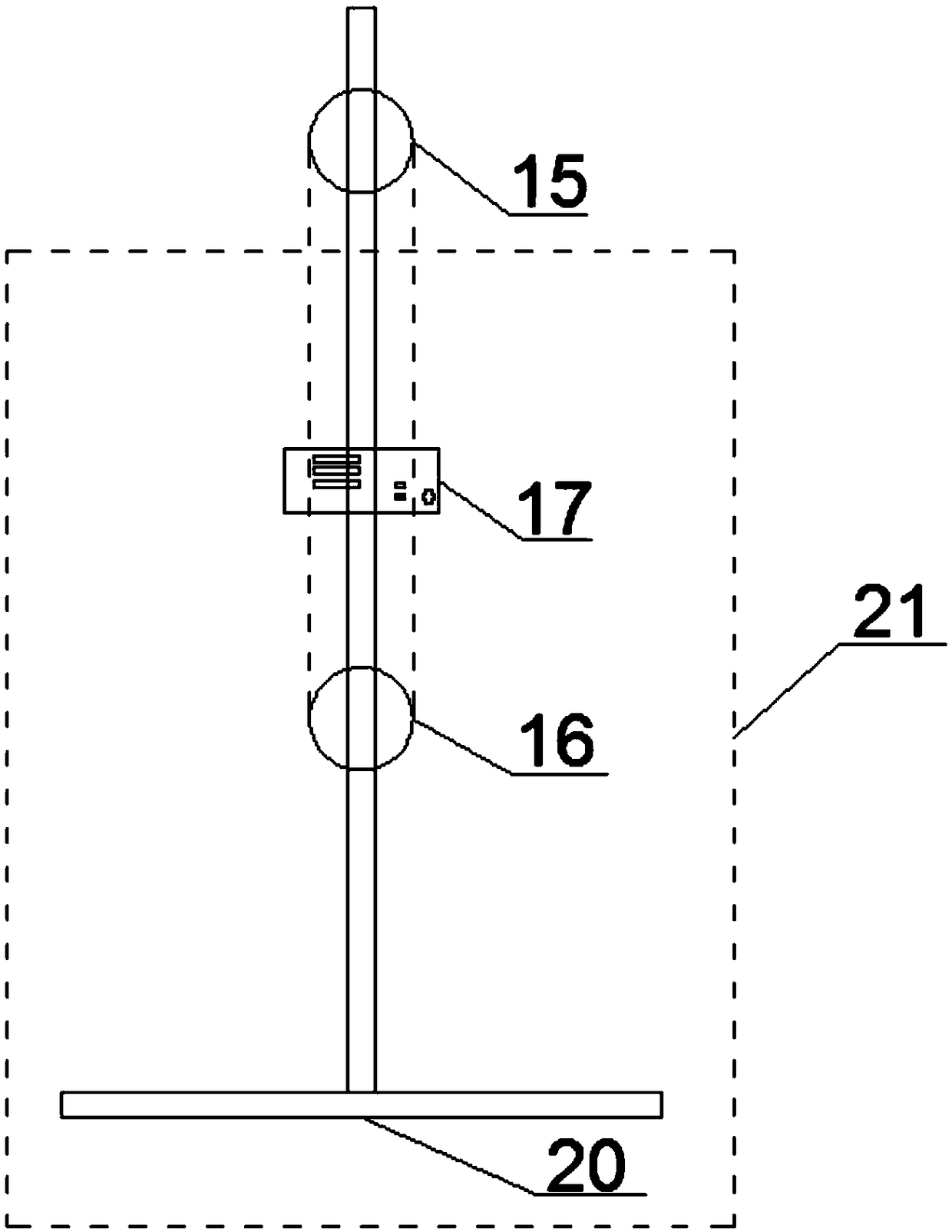

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the method, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0027] Such as Figure 1 to Figure 3 As shown, the present invention provides a capillary device for automatically measuring the viscosity of refrigerant and lubricating oil, which is arranged in a constant temperature tank 21, and the top of the pressure vessel 2 is connected with a vacuum pump 24 and a refrigerant tank 23 through a connecting pipe. The connection between the vacuum pumps 24 is controlled by the main valve 12 and the second valve 11, the connection between the pressure vessel 2 and the refrigerant tank 23 is controlled by the main valve 12 and the first valve 10, and the connection between the pressure vessel 2 and the pressure sensor 14 is controlled by The third valve 13 controls. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com