Packaging technique with Sr-Al alloy can

A strontium aluminum can and metal technology, applied in the field of metal packaging, can solve the problems of unsealed packaging, loss, easy oxidation, etc., and achieve the effects of reducing specific surface area, simple and convenient operation, and reducing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

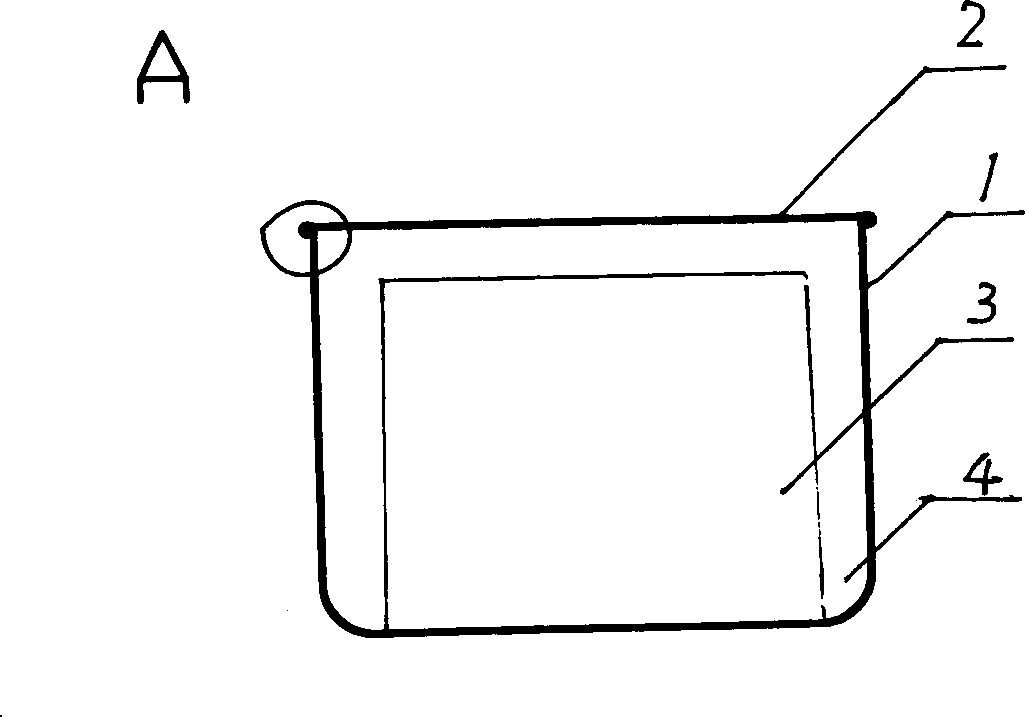

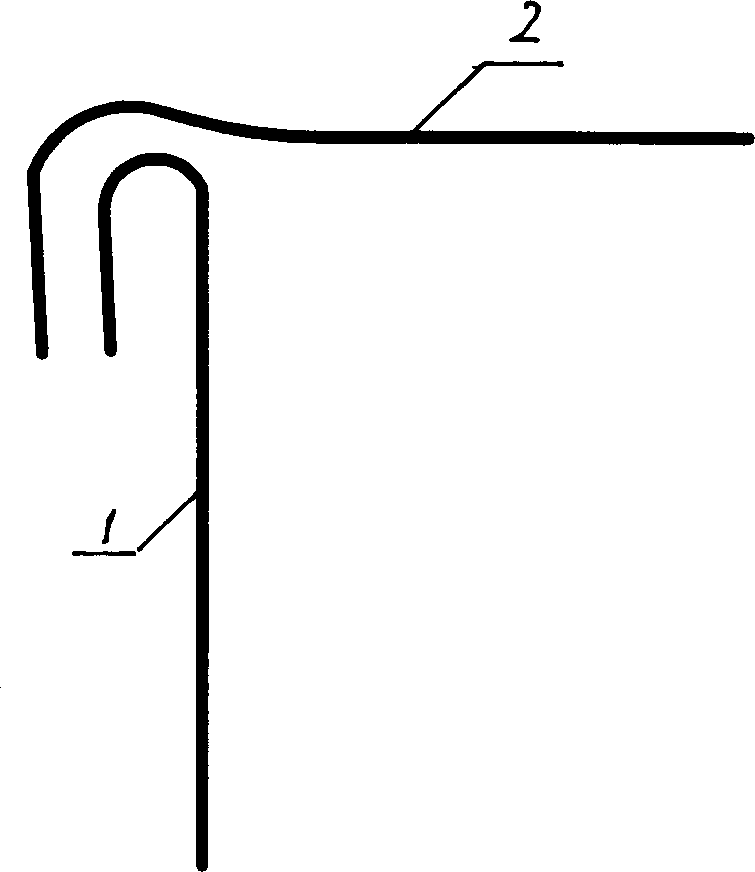

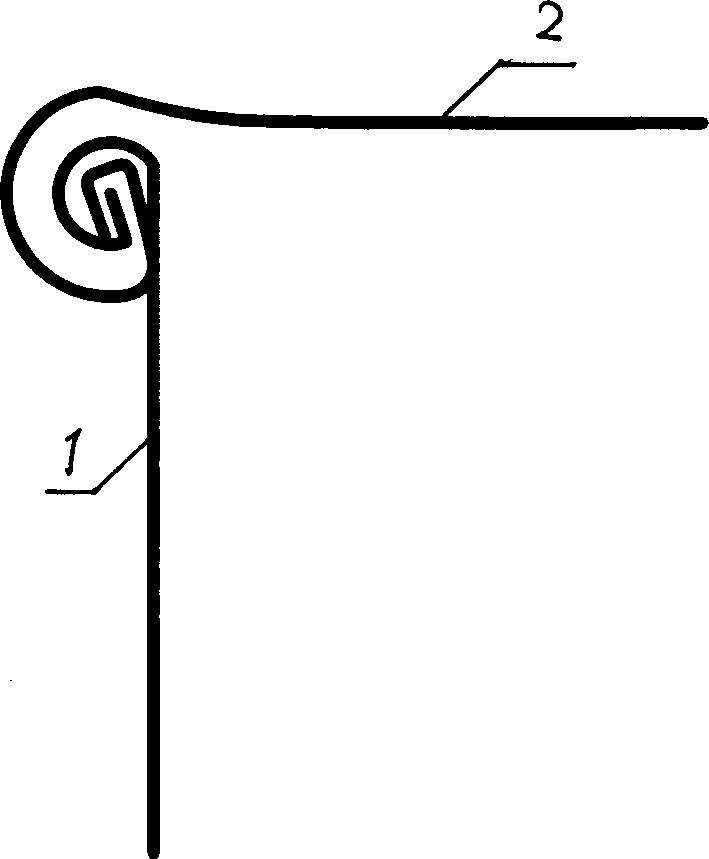

[0021] The crystalline small piece strontium is weighed (2.5 kilograms), packs into the pressing mold, forms metal strontium block (3) (round cake shape) with 315KN hydraulic press under 300KN pressure, then the metal strontium piece of round cake shape ( 3) Put it into the aluminum can body (1), fill it with argon gas (4) for 10 seconds, apply sealing glue in the groove on the edge of the aluminum can lid (2), and then cover the aluminum can lid (2) on the aluminum can On the can body (1), the edge of the aluminum can lid (2) is superimposed on the edge of the aluminum can body (1), and then the two edges are placed on a special sealing machine for five side seals. After the sides are sealed, the strontium aluminum can is Hermetically sealed strontium aluminum cans.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com