Iron-free and manganese-free copper-nickel b10 production process

A production process, manganese-nickel-nickel technology, applied in the field of iron-free and manganese-free nickel-nickel copper B10 production process, can solve the problem of low temperature coefficient of resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the embodiments of the present invention are explained and described below, but the following embodiments are only preferred embodiments of the present invention, not all of them. Based on the examples in the implementation manners, other examples obtained by those skilled in the art without making creative efforts all belong to the protection scope of the present invention.

[0022] Iron-free and manganese-free copper-nickel B10 production process, copper-nickel B10 is produced through an open power frequency induction furnace, including the following steps:

[0023] S10: Bake the furnace when starting the furnace, remove iron impurities before using the charcoal, and bake the crystallizer and stopper before using;

[0024] S20: Add cupronickel regrind, electrolytic copper and electrolytic nickel to the furnace, cover the surface with the first insulation layer, and add deoxidizing materials for deoxidation;

[0025] S30: the raw materials i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

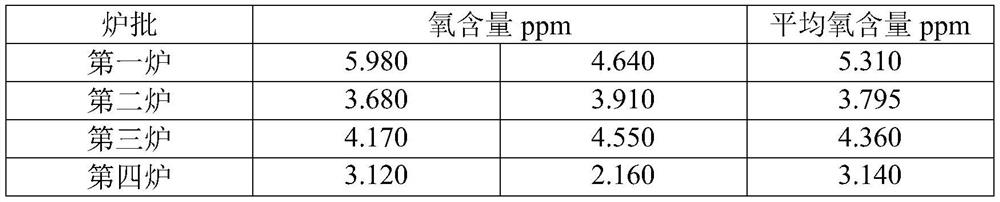

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com