Patents

Literature

279 results about "Cupronickel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cupronickel or copper-nickel (CuNi) is an alloy of copper that contains nickel and strengthening elements, such as iron and manganese. Despite its high copper content, cupronickel is silver in colour. Cupronickel is highly resistant to corrosion by salt water, and is therefore used for piping, heat exchangers and condensers in seawater systems, as well as for marine hardware. It is sometimes used for the propellers, propeller shafts, and hulls of high-quality boats. Other uses include military equipment and chemical, petrochemical, and electrical industries.

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

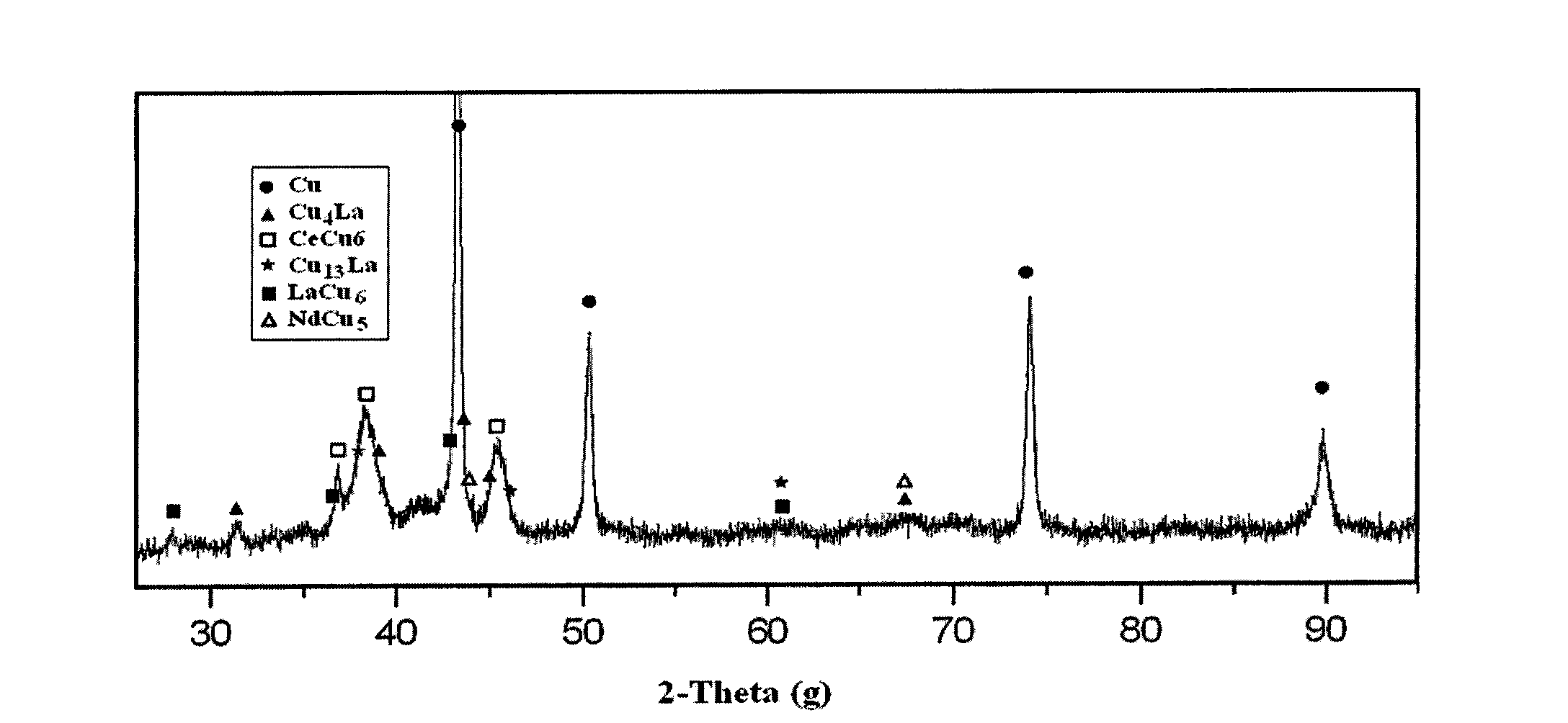

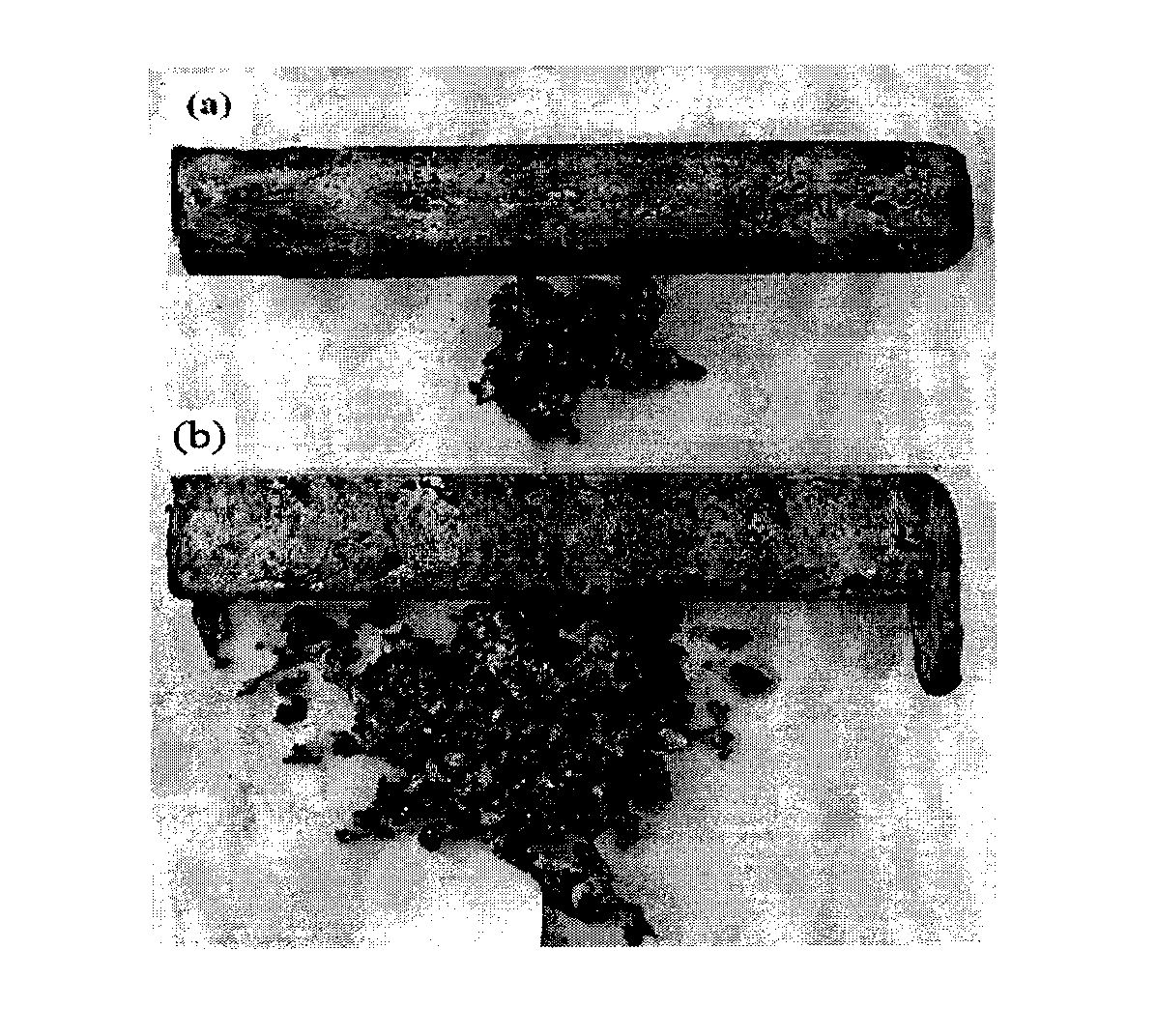

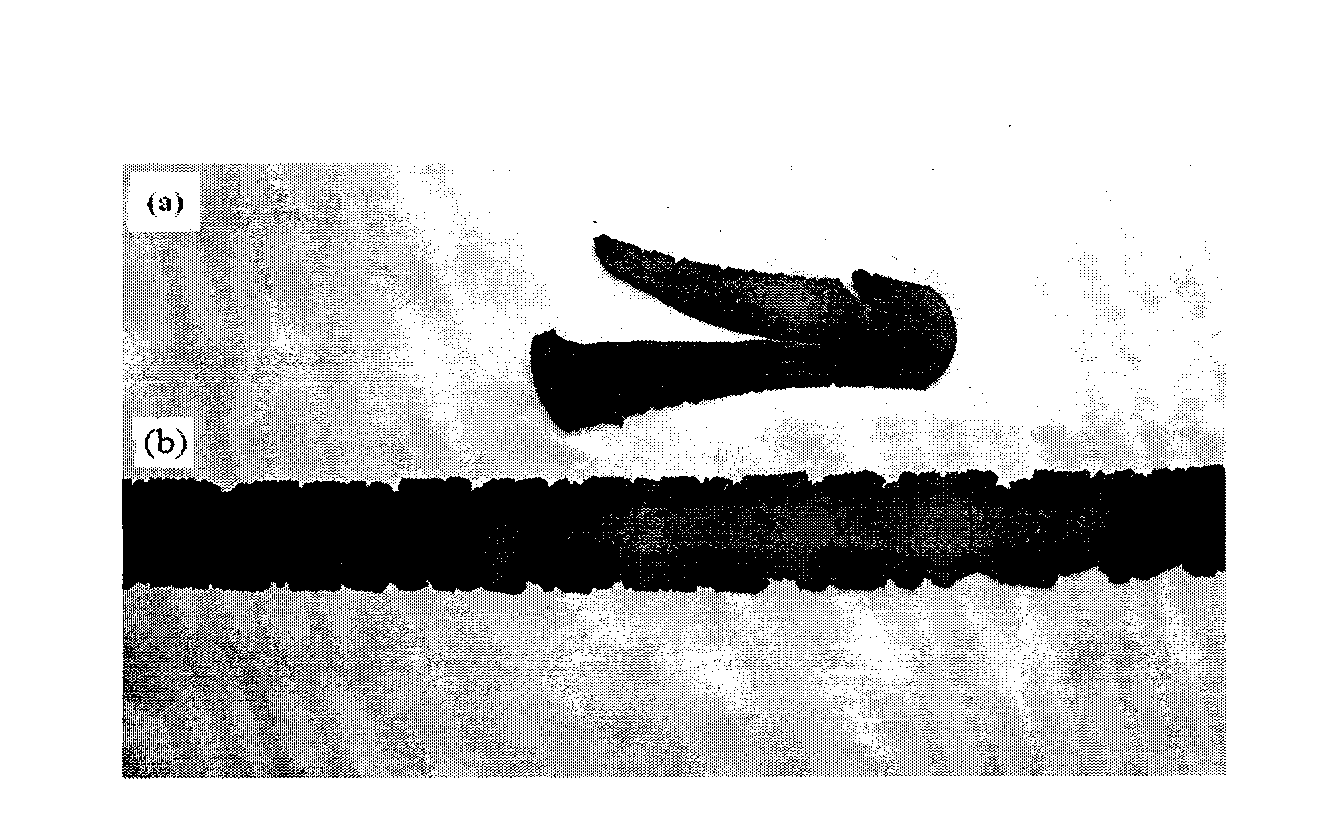

High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

The invention relates to a high Cu-RE refining agent which has high efficiency and low burning loss rate and can be used for copper and copper alloy, applied to mass refining of the copper and the copper alloy, especially applied to refining and modification of red impure copper and white impure copper. The Cu-RE interalloy refining agent is prepared by a vacuum melting method, wherein, rare earth content is up to 30-65%; and only 2-6g / kg refining agent is added while the Cu-RE interalloy refining agent is applied to remelting refining of scrap copper. The Cu-RE refining agent enhances slagging and deslagging of copper fused mass, reduces deleterious substances in the fused mass of the scrap copper, and improves texture and performance of the copper and the copper alloy, therefore, products prepared from the red impure copper as a raw material reach or exceed the quality of the products prepared from electrolytic copper as a raw material, and the white copper process waste can be used for directly producing high-quality products after remelting refined, thus promoting recycle and reutilization of the scrap copper, saving energy and resource, reducing environmental pollution and generating significant economic and social benefits.

Owner:CENT SOUTH UNIV

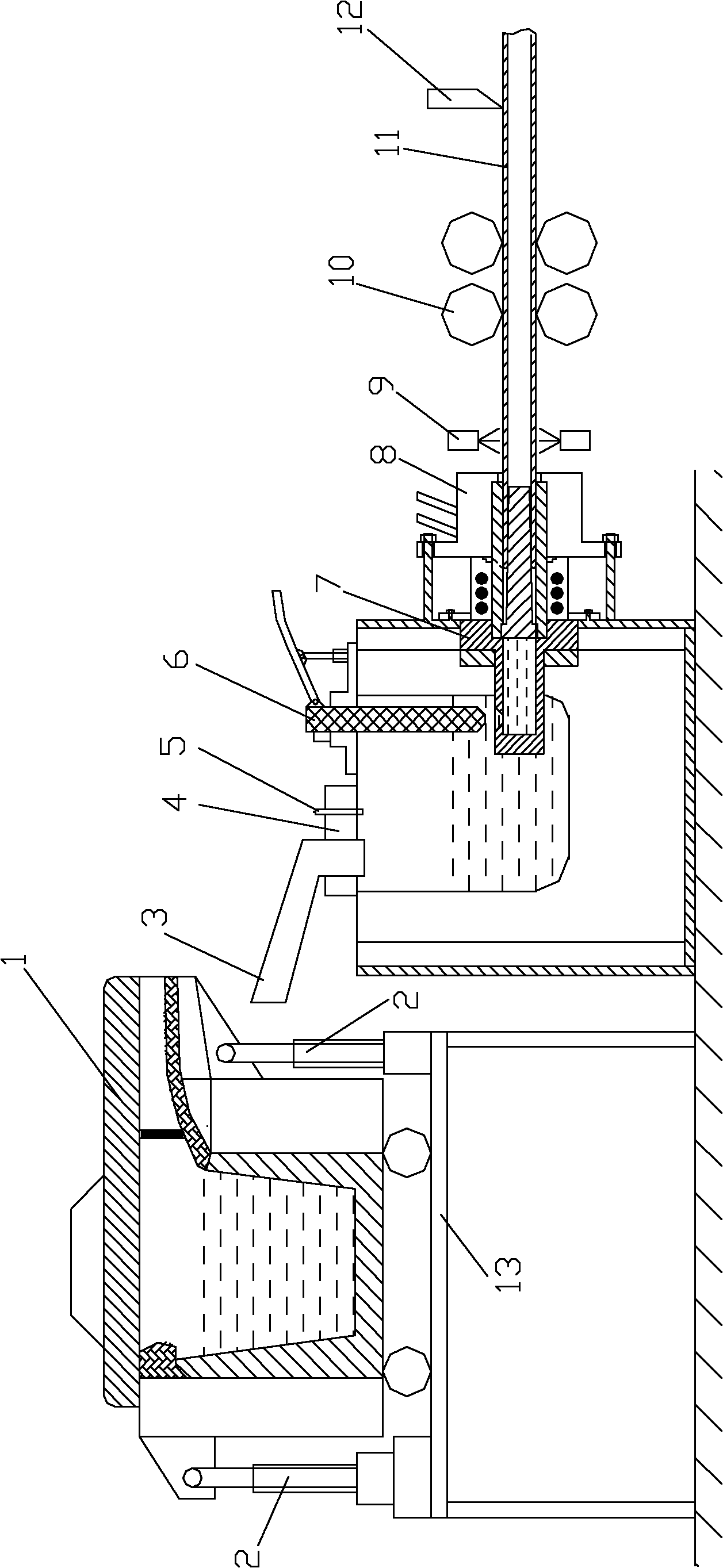

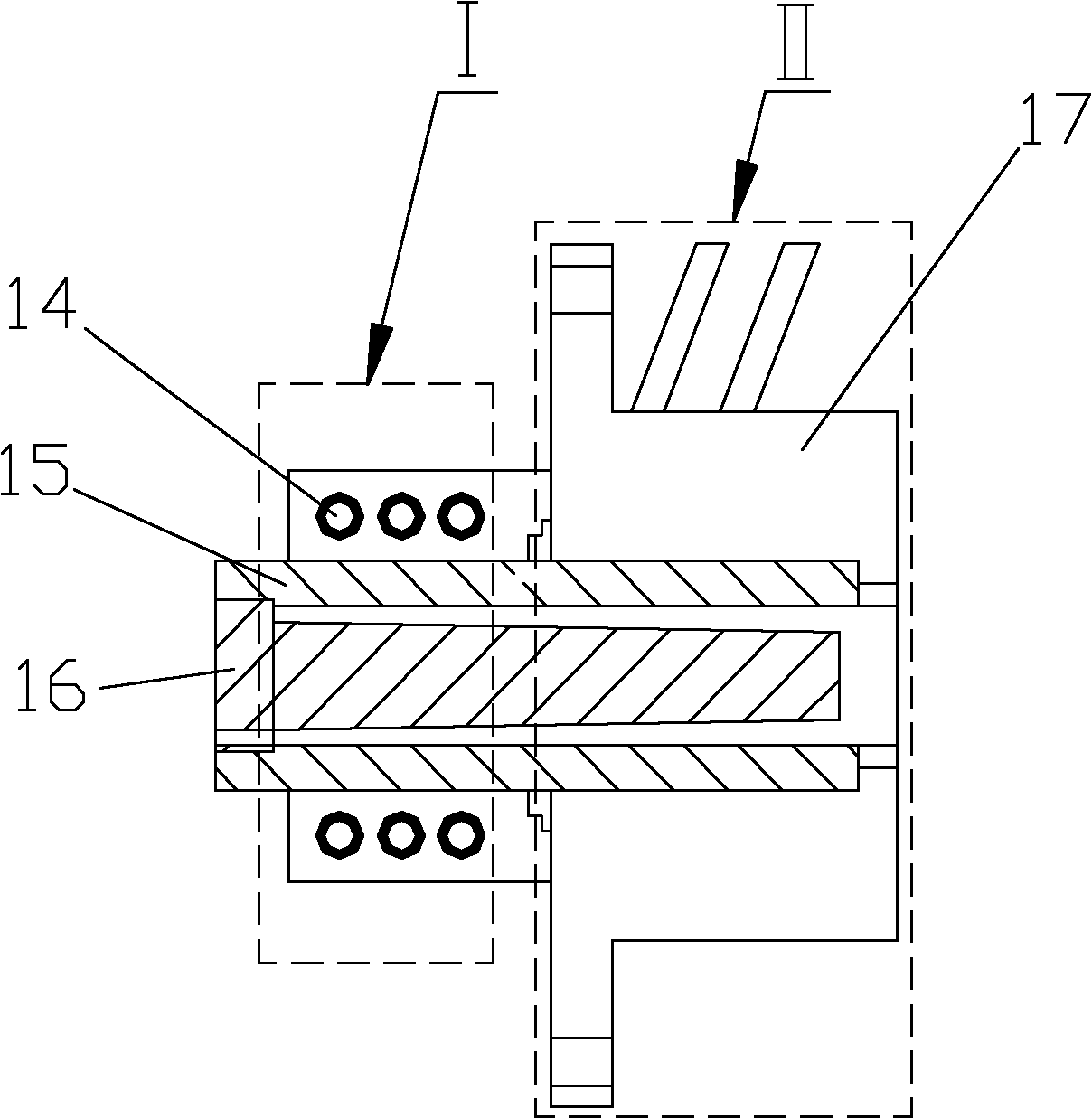

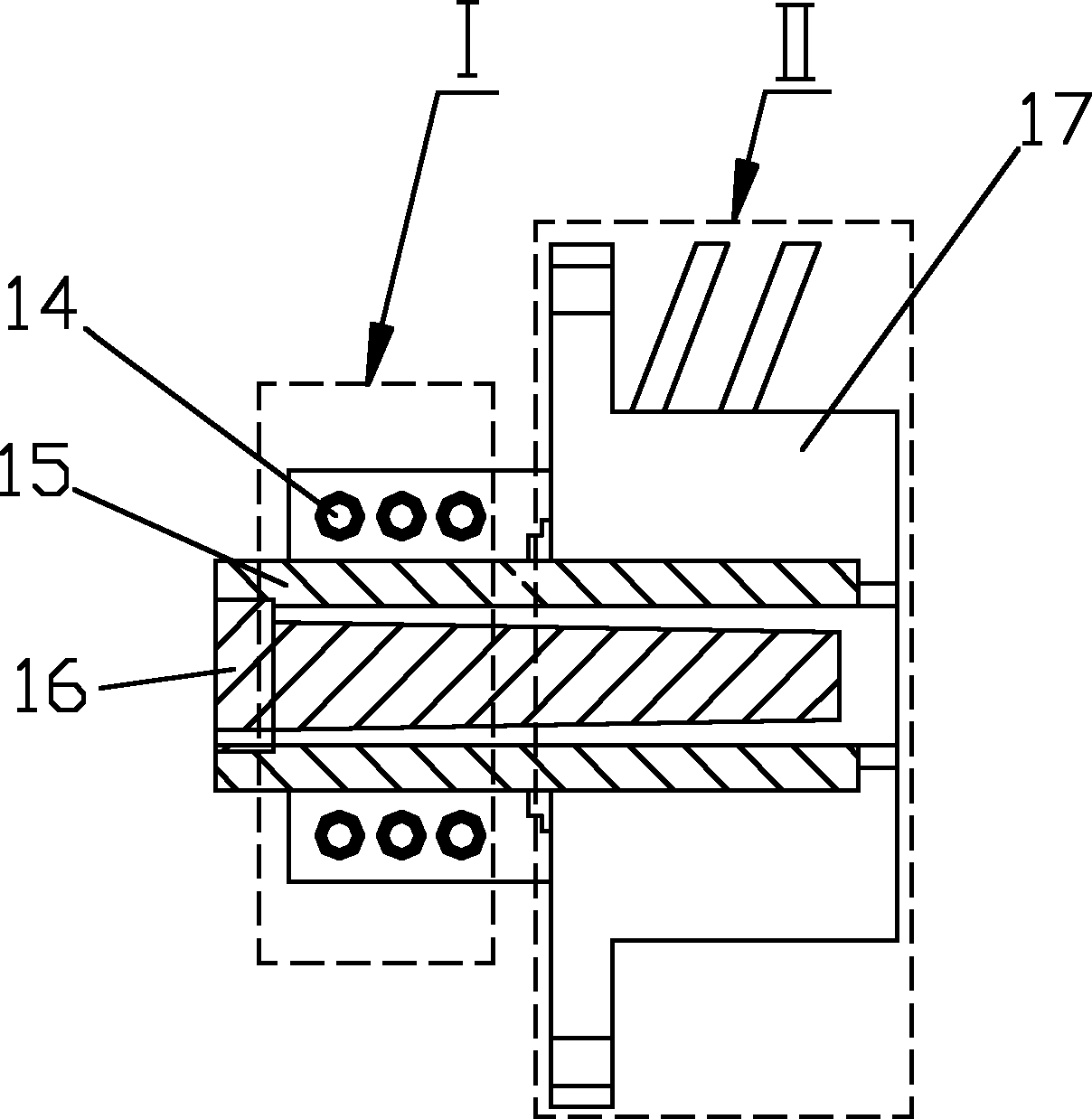

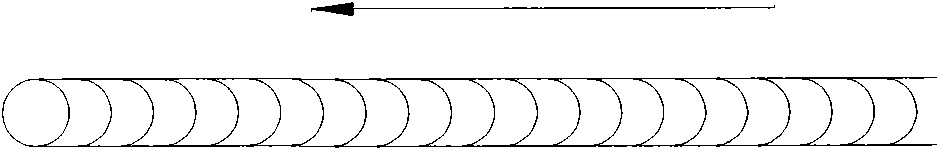

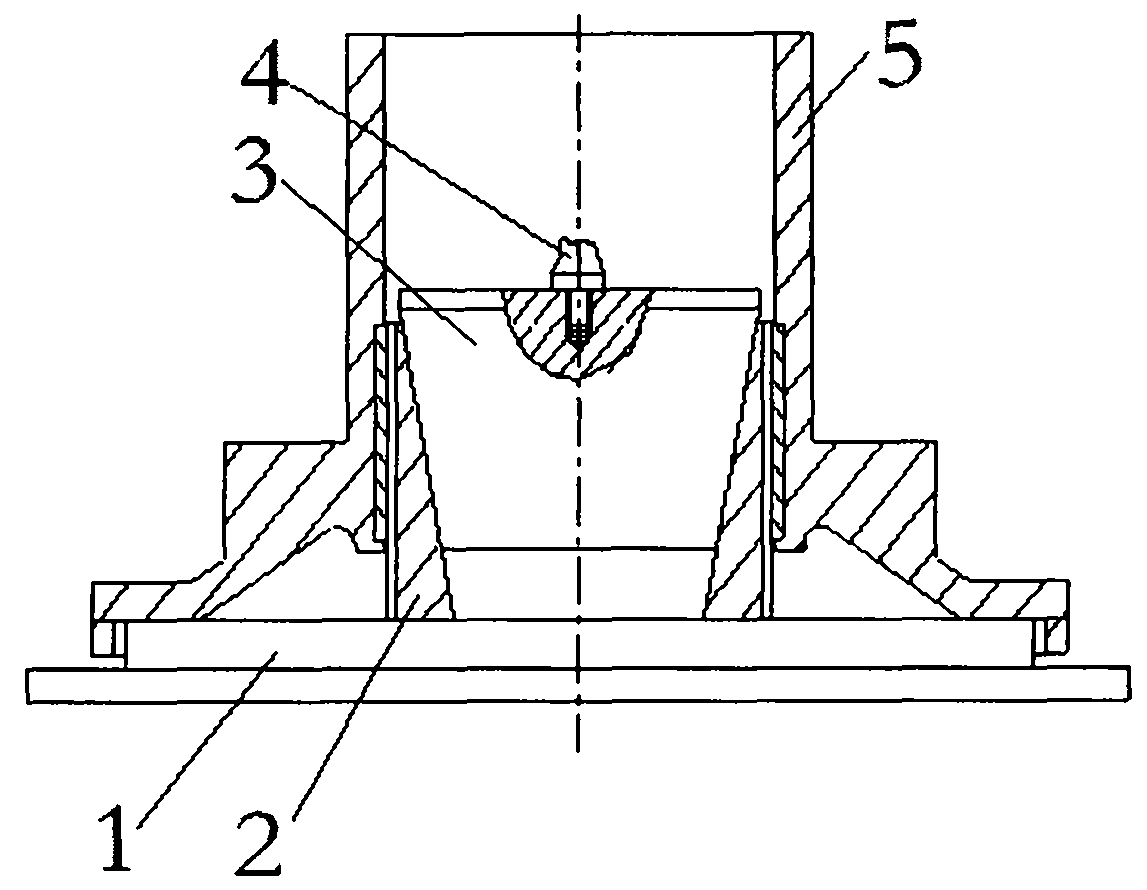

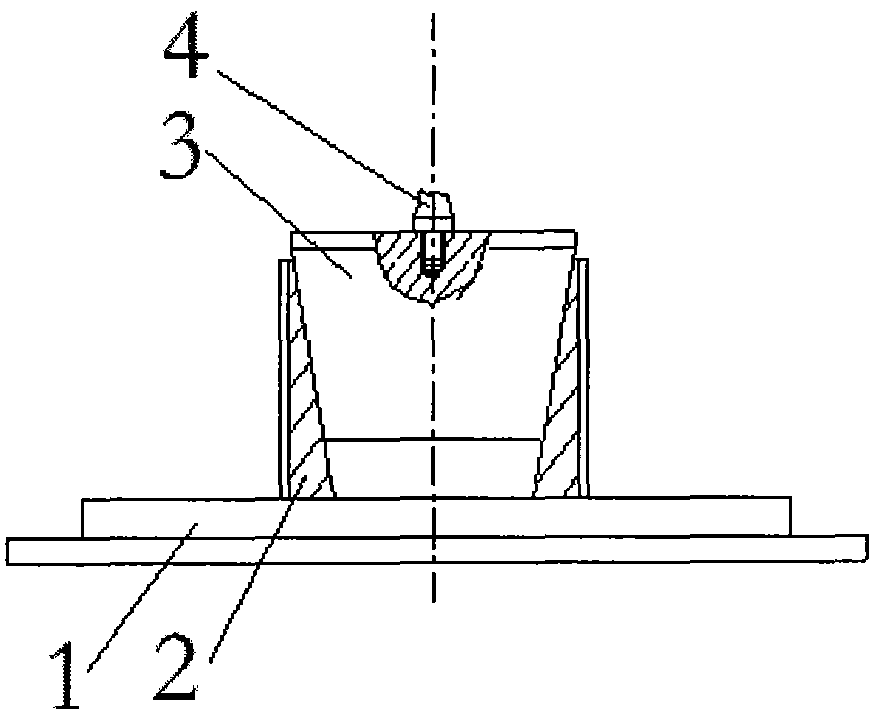

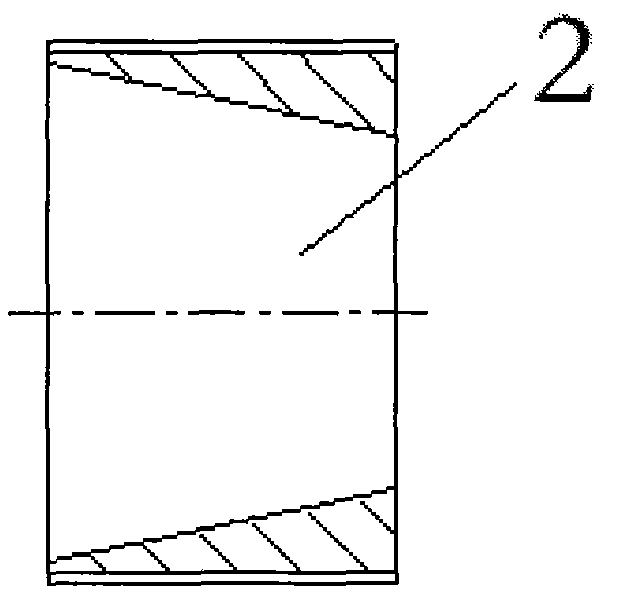

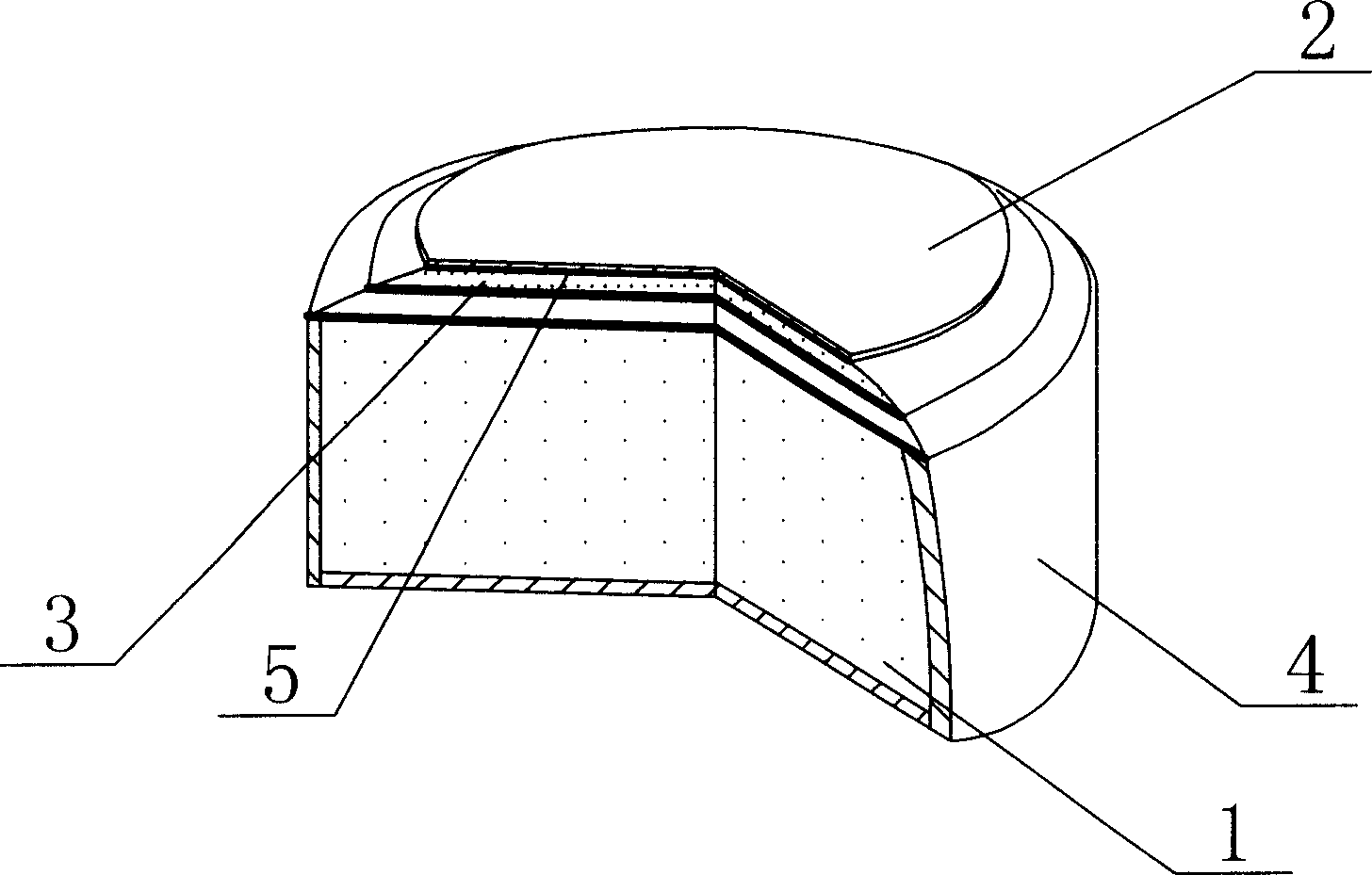

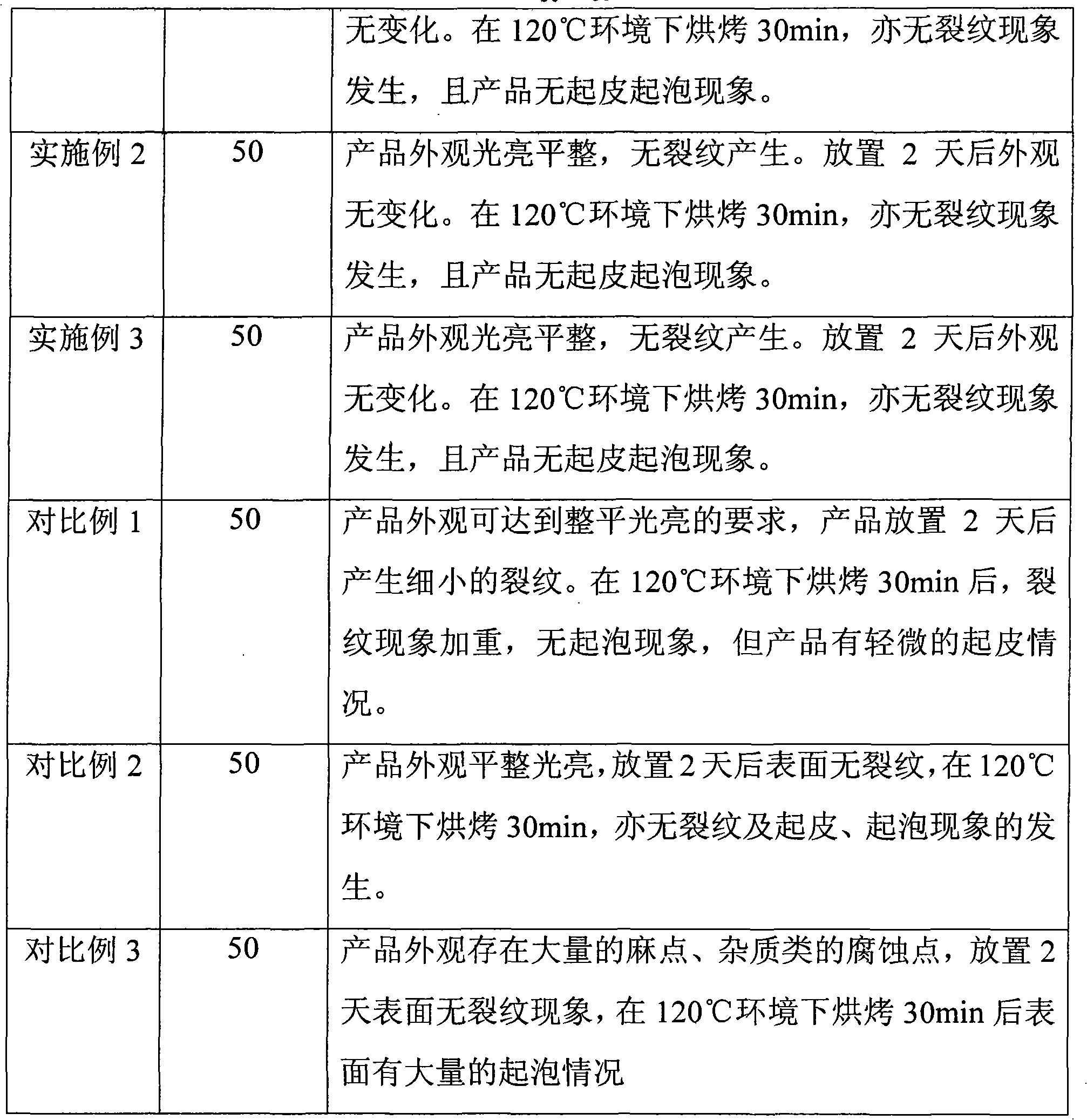

Hot-cold combined casting mould horizontal continuous casting equipment of cupronickel tubing and technology thereof

The invention provides hot-cold combined casting mould horizontal continuous casting equipment of cupronickel tubing and a technology thereof. The equipment comprises a smelting system for melting metal, a heat insulation system for storing molten metal, a horizontal continuous casting system for casting and shaping and an auxiliary system, wherein in the continuous casting system, the front end of a cold shaping section is provided with a hot shaping section so as to effectively control the solid-liquid interface of a tube billet to be located near the juncture of a cold section and a hot section; a shorter water-cooling copper bush and electromagnetic induction heating are adopted to reasonably design coil structure and the power and the frequency of a heating power supply, reduce electromagnetic constraint force to balance the hydrostatic pressure of a metal fusant, reduce friction between a primary kish and the casting mould, improve the surface quality of the tube billet and prolong the service life of the casting mould. Thus, the inner surface and the outer surface of the tube billet manufactured by the invention have good quality and no defects of orange peel, wrinkles, cracks and the like, net shape continuous casting is realized, the production efficiency and the metal yield are improved and the production cost is obviously lowered.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing copper and nickel alloy seamless copper tube

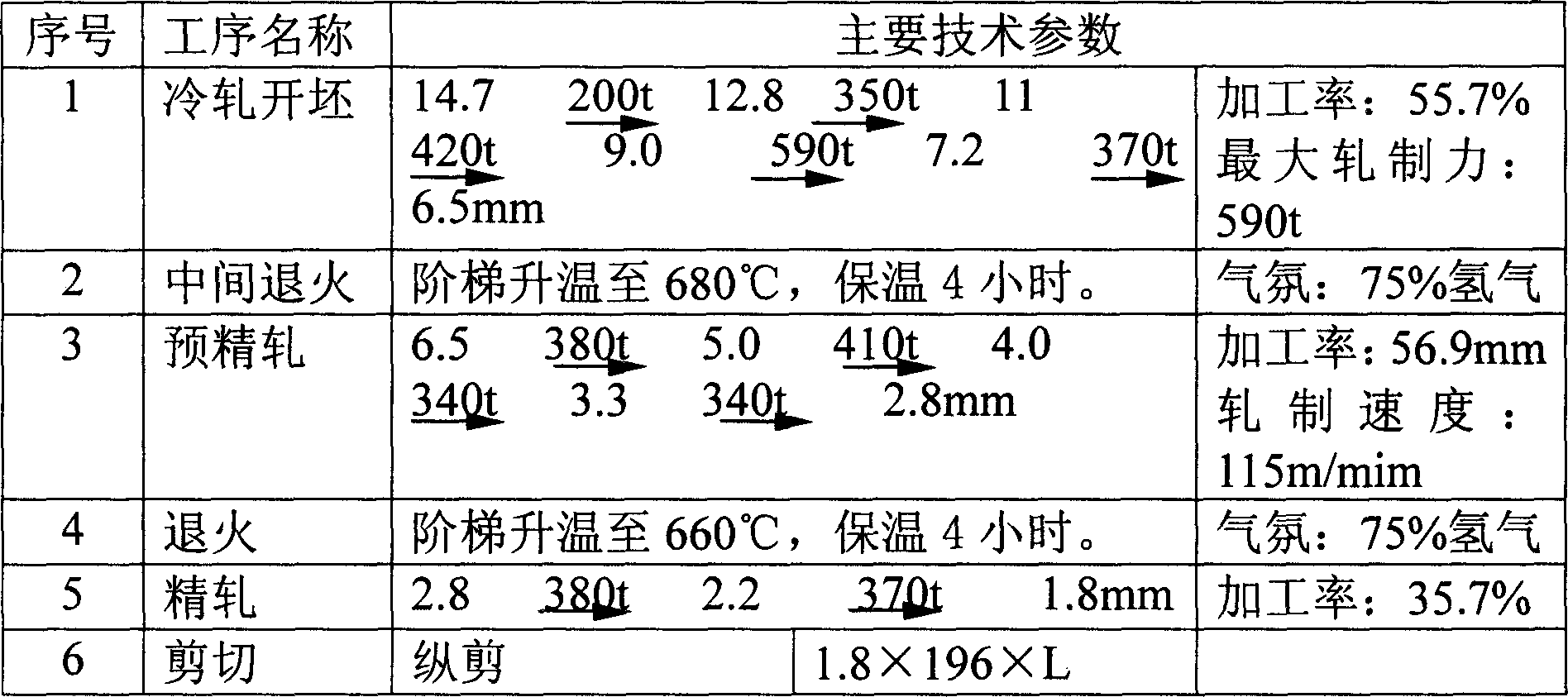

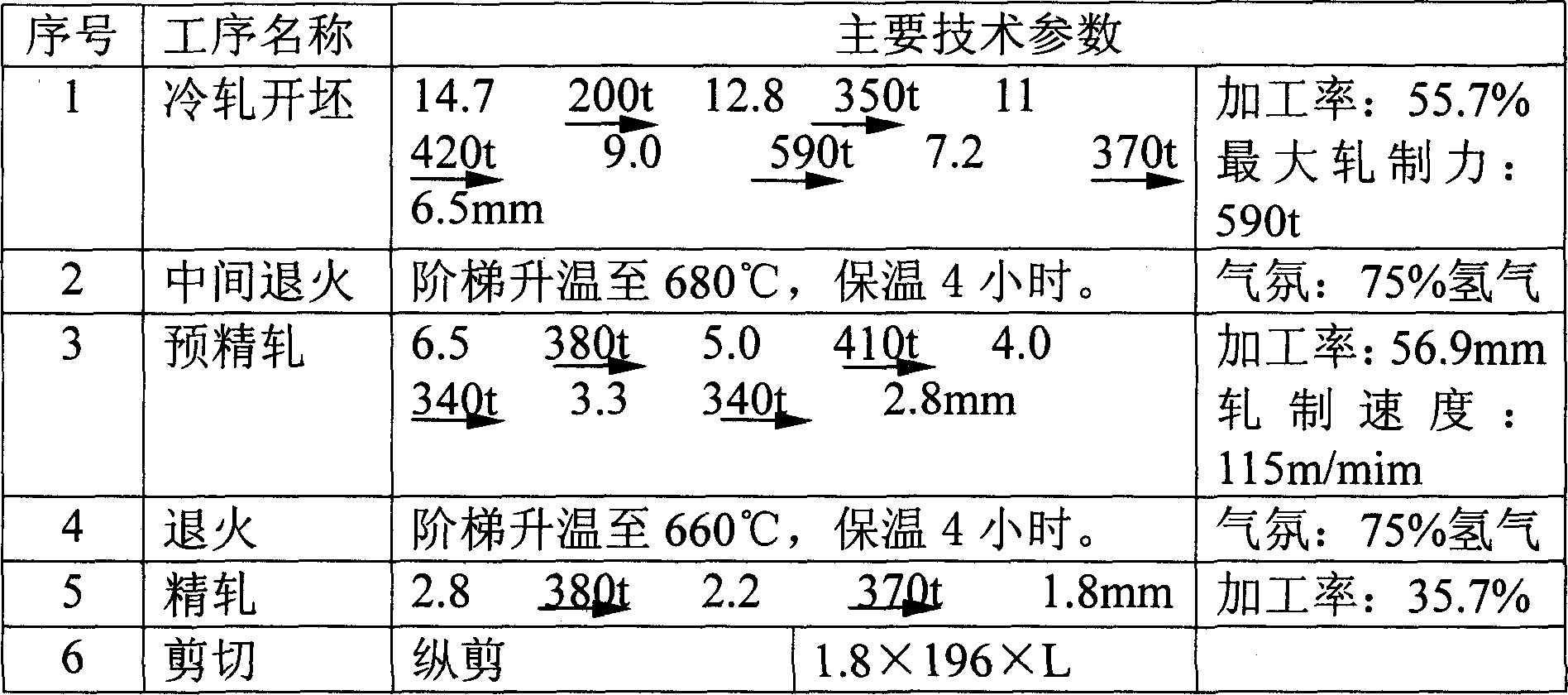

InactiveCN101058142AOptimize structure sizeImprove plastic deformation abilityRoll mill control devicesFurnace typesElectrolysisCupronickel

The invention relates to a copper nickel seamless copper tube with 92. 9-93. 6% copper and 6. 4-7. 1% nickel. It takes electrolytic copper and nickel to a low frequency electric oven to heat to 1320-1340deg.C, casting into solid ingot which is heated to 650-750deg.C for heat piercing to get the surface smooth ingot to heat to 650-750deg.C for squeezing to gross blank tube which is extended and peeled for cold reeling, to get the size of the product after annealing. Through calibration and rectification, cleaning and annealing, the product is inspected and put to stock. The content for nickel is 6. 4-7. 1%. It is better in processing feature due to the low nickel and better in corrosion resistant features than copper due to the content of nickel. It is also low in cost.

Owner:江阴和宏精工科技有限公司

Production process for packfong strips

The invention discloses a production process for packfong strips, which comprises the following process steps of: casting, milling, rough rolling, edge cutting, annealing, degreasing and cleaning, pre-finish rolling, annealing, finish rolling, annealing, degreasing and cleaning, stretch bending and straightening, cutting and packaging. The structure of a crystallizer, the temperature in a melting furnace, cooling temperature and the like are adjusted and controlled in the casting process, and the tension in the rolling process is controlled, so that the packfong strips with broad widths of 440 millimeters are produced. According to the test of produced packfong strips, the roll weight of unit millimeter is improved, and the yield of cupronickel is improved simultaneously. By measuring, the weight of unit millimeter of the packfong strips with the broad widths of 440 millimeters reaches 13 kilograms, and compared with the weight per unit millimeter of the strips with 330 millimeters, the weight per unit millimeter of the strips with 440 millimeters is improved by 2 to 3 kilograms; and the yield is improved by about 9 percent.

Owner:ANHUI XINKE NEW MATERIALS

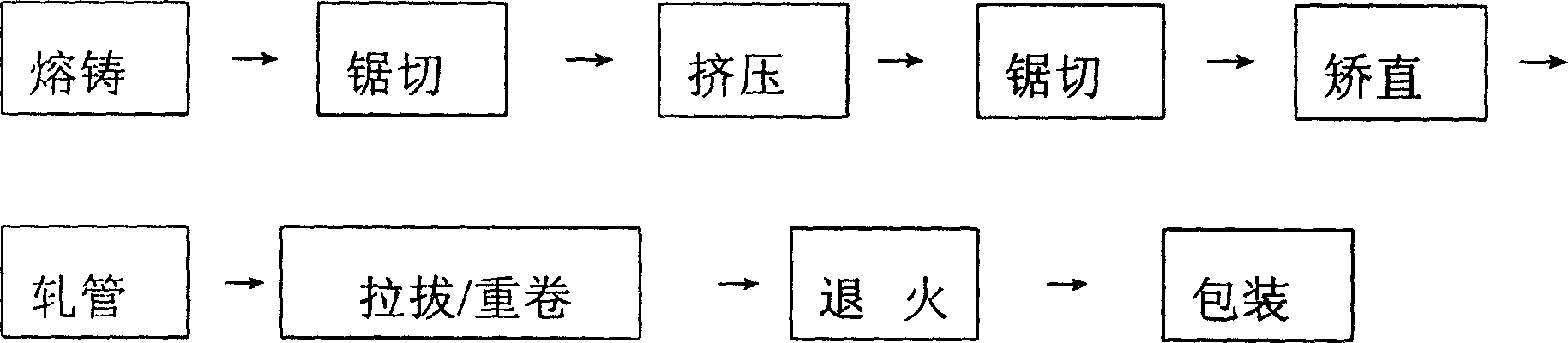

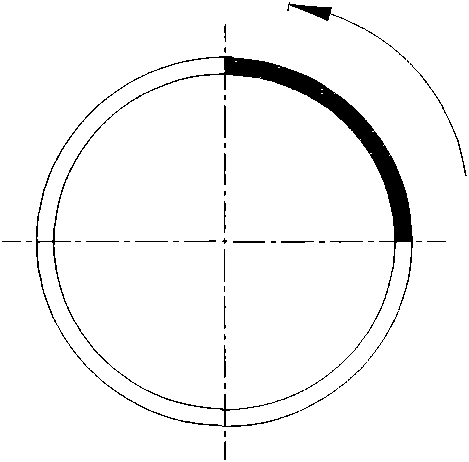

Cupronickel condensation tube production process using disk stretch

InactiveCN1754649AAchieve continuous stretchingMeet the length requirementCircular discProduction rate

This invention provides one process method by use of disc for ambrose alloy cold-finger, which comprises the following steps: melting to cutting to crushing to cutting to correction to grinding or rolling again to annealing to packing, wherein, the pulling process adopts multiple channel disc with pulling parameters in 1.30-1.45 and in and out mode oil moving viscosity of 400-900mm2 / s(40 DEG C) m wherein, Pulling mode angle of 9 degree-12 degree; motive core tamper degree of 6 degree -9 degree; pulling mode and motive core angle difference of 1 degree-3 degree.This invention adopts disc pulling process method to realize the continuous pulling to improve production rate to satisfy the market length need.

Owner:LUOYANG COPPER PROCESSING GROUP

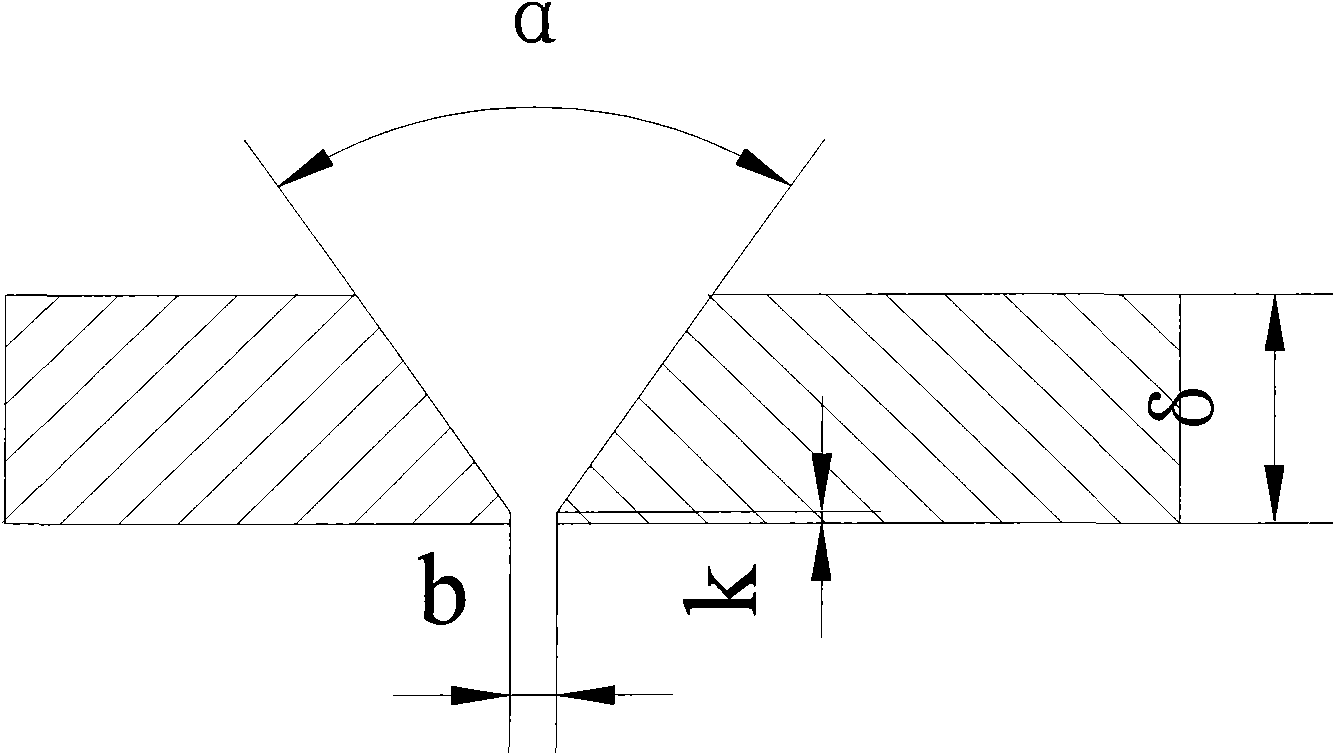

Welding method of cupronickel weldment

The invention relates to a welding method of a cupronickel weldment, comprising the following steps: (1) processing a welding joint groove of the weldment: determining a gap and an angle of the groove according to the width of the weldment; (2) determining the form of a fixing welding line during assembly; and (3) selecting welding wires, cleaning the welding wires and the surfaces thereof and welding according to a welding technology and operation requirements. The welding method has good economic benefits and social benefits.

Owner:CHINA NAT CHEM ENG NO 14 CONSTR

Anticorrosion white Cu-Mn alloy and method for making its wire material

An anticorrosion white Cu-Mn alloy contains Mn (9-15 wt.%), Zn (4-15 wt.%), Al (0.5-1.5 wt.%), Sn (0-1.5 wt.%) rare-earth element (less than 0.2 wt.%), and Cu (the rest). Said alloy can be used to make wire material through non-vacuum smelting, horizontal conticasting and cold drawing or cold rolling. Its advantages are high machinability and anticorrosion nature and stable lustre. It can replace Ni-contained white Zn-Cu alloy.

Owner:中铜(上海)铜业有限公司 +1

Environmentally-friendly lead-free free-machining zinc white copper and preparation method thereof

The invention discloses an environmentally-friendly lead-free free-machining zinc white copper and a preparation method thereof. The zinc white copper comprises the following components in percentage by weight: 27.0-44.0% of zinc, 6.0-25.0% of nickel, 0.05-2.5% of silicon, 0.03-0.1% of cerium, 0.03-1.5% of phosphorus and the balance of copper and inevitable impurity, wherein lead content in the impurity is less than 0.01%. The preparation method comprises the steps of smelting, horizontal continuous casting, cold machining, heat treating and the like. The copper alloy of the invention also has high strength (sigma b=700-750 MPa) and favorable machining performance which is more than 70% of lead brass C36000. Hot extrusion shaping and horizontal continuous casting shaping can be adopted; the zinc white copper has favourable cold and hot pressure processing performance, is an environmentally-friendly novel material, can completely replace lead and zinc white copper to prepare various free-machining elements, can be processed into copper alloy products, such as lines, rods, plates, strips, sections, tubes, cast and the like, can be widely applied to the manufacturing industry, such as pen points, eyeglass accessories, instrument accessories and the like and is an ideal substitute for lead and zinc white copper.

Owner:NINGBO POWERWAY ALLOY MATERIAL

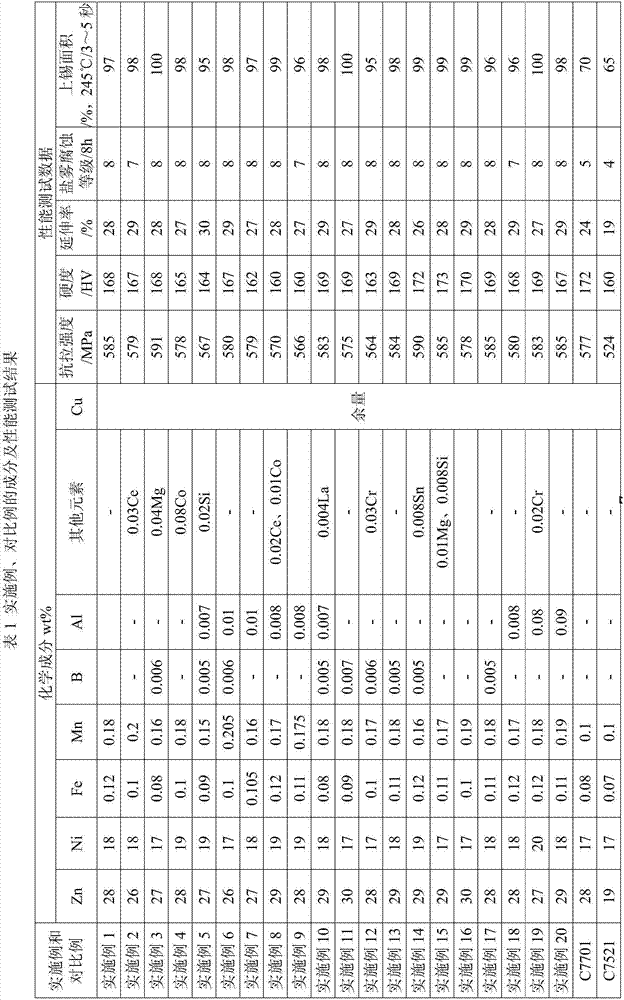

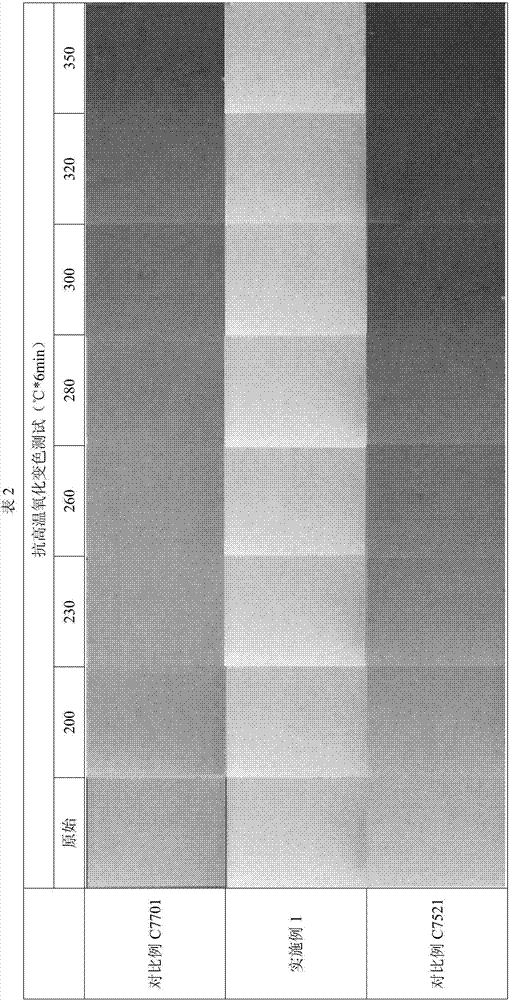

Zinc-copper-nickel alloy and preparation method and application thereof

ActiveCN107151750AImprove high temperature oxidation resistanceImprove solderabilityHot-dipping/immersion processesCupronickelSoldering

The invention discloses a zinc-copper-nickel alloy. The zinc-copper-nickel alloy comprises the following components in percentages by weight: 13-25% of Ni, 15-40% of Zn, 0.01-0.25% of Fe, 0.01-0.5% of Mn and the balance of Cu and inevitable impurities. The zinc-copper-nickel alloy has excellent high-temperature oxidation resistance, salt-spray corrosion resistance and soldering performance. The zinc-copper-nickel alloy cannot oxidize when baked for 5-15 minutes at the high temperature of 280 DEG C; the non-corrosive duration of the zinc-copper-nickel alloy in a 5% NaCl salt mist atmosphere is longer than or equal to 8 hours; and if the zinc-copper-nickel alloy is soaked in tin liquor at the temperature of 245+ / - 5 DEG C and then is taken out 3-5 seconds later, the tinplated area is 95% or above. The zinc-copper-nickel alloy can be applied to electronic and electrical products such as shielding covers, and can also be used as raw materials of other electronic and electrical products with high requirements on comprehensive properties including high-temperature oxidation resistance, salt-spray corrosion resistance and soldering performance.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

Brazing filler metal for welding of high-temperature alloy and cupronickel and preparation method thereof

ActiveCN102009284AImprove mechanical propertiesExtend working lifeWelding/cutting media/materialsWelding/soldering/cutting articlesCupronickelManganese

The invention discloses brazing filler metal for welding of high-temperature alloy and cupronickel and a preparation method thereof. The brazing filler metal is a foil-shaped copper, manganese, cobalt and nickel brazing filler metal consisting of 26 to 35 percent of manganese, 8 to 14 percent of cobalt, 1.5 to 3.0 percent of nickel, 0.03 percent of phosphorus, 0.02 percent of tin, 0.02 percent of silicon, 0.01 percent of aluminum, 0.01 percent of zinc and the balance of copper. By rolling blanks of the copper, manganese, cobalt and nickel brazing filler metal by using a rolling mill, a platinum-shaped brazing filler metal with the thickness of 0.1mm is obtained. The brazing filler metal is applied to rotating working components bearing high temperature, high pressure and large torque. The brazing filler metal is used for welding of stainless steel and stainless steel, stainless steel and high-temperature alloys, the high-temperature alloys and the cupronickel, and the high-temperature alloys and the high-temperature alloys, and can enhance the mechanical properties of welding pieces and prolong the service life of the welding pieces.

Owner:AECC AVIATION POWER CO LTD

Method and fixture for welding high temperature alloy and cupronickel

ActiveCN101983819AHigh strengthImprove corrosion resistanceSoldering auxillary devicesCupronickelManganese

The invention discloses a method and fixture for welding high temperature alloy and cupronickel. A brazing filler metal consisting of powdery gold 20, nickel, chromium, iron, silicon and boron, or consisting of platinoid copper, manganese, cobalt and nickel is used for welding. The brazing filler metal is coated or arranged between a cupronickel piece and high temperature alloy, and the peripheryof the bonding surface of the cupronickel piece and the high temperature alloy is coated with a red stop-off agent and is pressed tightly by a fixture. A brazing filler metal welding piece which is pressed tightly by the fixture is put in a vacuum furnace, and then the processes of vacuumizing, heating and brazing are performed. Since the brazing filler metal consisting of copper, manganese, cobalt and nickel has the characteristics of high strength, good corrosion resistance, low price and high weld joint quality, and the brazing filler metal consisting of gold 20, nickel, chromium, iron, silicon and boron has the characteristics of good ductility and strong wetting function, respective pressing is omitted the process of brazing, thereby achieving good molding quality of the weld joint. Since the brazing elements of the two brazing filler metals used in the brazing process have the alloying effect on the two materials to be connected, the brazing joint has large spreading area, the joint is high in strength, and the quality of the brazing joint meets the requirement.

Owner:AECC AVIATION POWER CO LTD

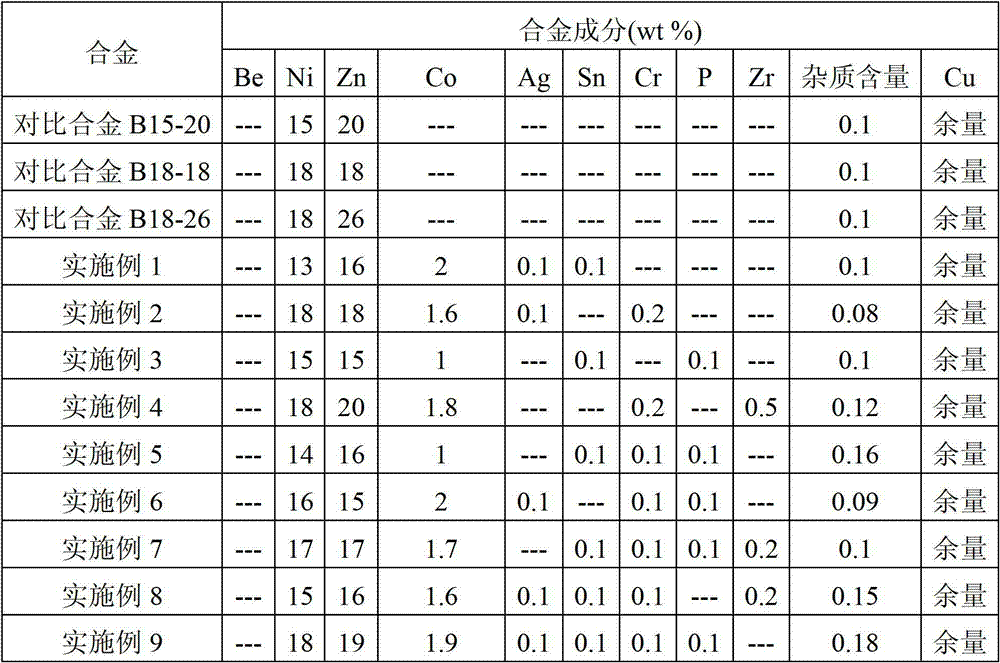

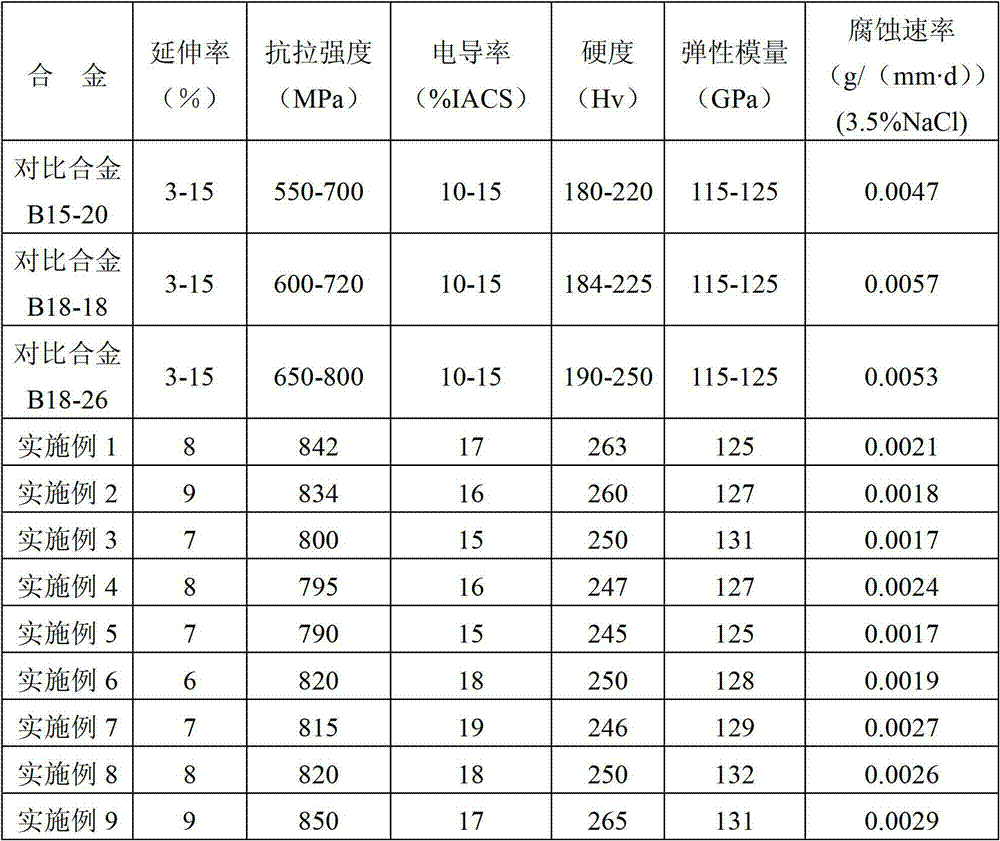

High-strength high-elasticity zinc-copper-nickel alloy and processing method thereof

The invention relates to a high-strength high-elasticity zinc-copper-nickel alloy and a processing method thereof, belonging to the field of nonferrous metal processing. The high-strength high-elasticity zinc-copper-nickel alloy comprises the following components in percentage by weight: 13-18% of Ni, 15-20% of Zn, 1-2% of Co, 0.01-1% of at least one of Ag, Sn, Cr, P and Zr, and the balance of Cu, wherein (a) 15%<=Ni+Co<=20%, and (b) 6.5<=Ni / Co<=15. The high-strength high-elasticity zinc-copper-nickel alloy is subjected to draw casting by a horizontal continuous casting technique. The tensile strength sigma b of the copper alloy is 790-850 MPa, the plastic elongation percentage delta is 4-15%, the electric conductivity is 12-25% IACS, the corrosion resistance is good, and thus, the copper alloy can be widely used for manufacturing precision components and the like in the fields of instruments, meters, medical appliances, daily necessities, communications and the like.

Owner:NINGBO XINGYE SHENGTAI GROUP

Novel wood grain gold and production method thereof

The invention discloses a novel wood grain gold. The novel wood grain gold is prepared from a red copper compound, a brass compound and a white copper compound. The production method of the wood graingold comprises the steps of: uniformly saw cutting a material, then fixing and placing the material with a steel plate and heating and melting the material in an electric kiln furnace, cooling to room temperature, back forging, and finally producing a different texture. The raw material used in the invention have high ductility and moulding, and is easy to process, and can reduce considerable production cost under a condition that products and performances are not changed. Due to an oxidizing property of metal and contact with a skin for a long time, color of finished products produced by replacing silver with the white copper compound can be more and more quaint with time. At the same time, subtle changes in color occur under influence of different external temperatures, making the colormore unique and aesthetically pleasing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Corrosion resistant cupronickel alloy material for plate heat exchanger and processing technique thereof

ActiveCN101100715AMeet the requirements of corrosion resistanceLow costPlate heat exchangerCupronickel

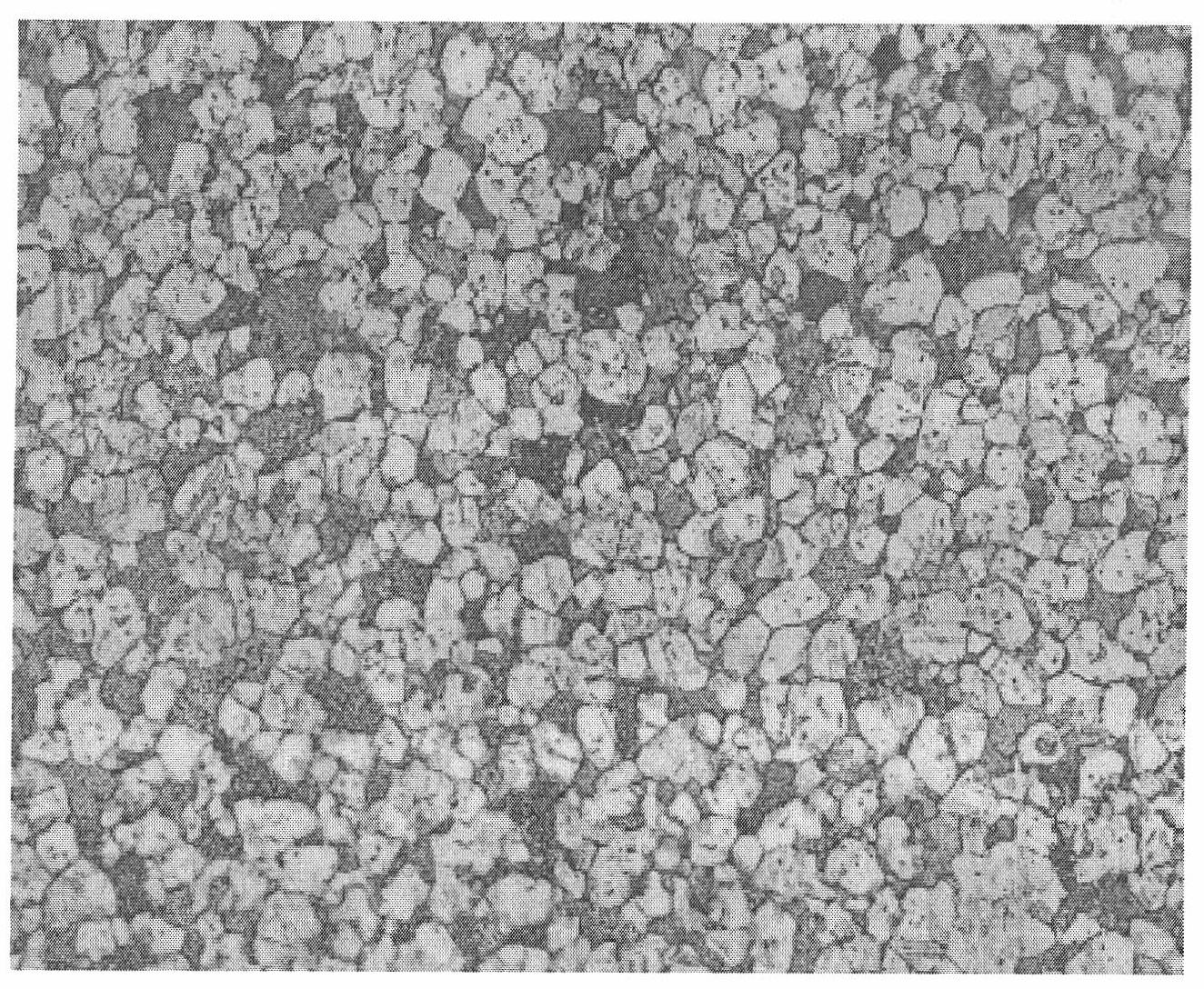

A corrosion-proof German silver band for plate heat exchanger and its production are both disclosed herewith. It contains (wt%): Ni 9.0-11.0, Mn 0.5-1.0, Fe 1.0-1.8, Ce 0.05-0.2, and waste Cu alloy with Cu balanced, and with impurity not more than 0.7. It is produced by: weighing, smelting, casting, hot rolling, end-surface milling, primary rolling, inter-annealing, cold rolling, inter-annealing, edge cutting, pre-rolling, inter-rolling, fine rolling, final annealing, surface treating, cutting, and packing. It is of size (0.4-8.5mm)X(300-1000mm)X(500-3000mm), performance of Rm not less than 320MPa, A11.3 not less than 30%, Hv1 not less than 85, grain 0.015-0.045mm, and Ra larger than 0.2um without scratches, and can meet demands of PHE and bactericidal washing machine.

Owner:中铝洛阳铜加工有限公司

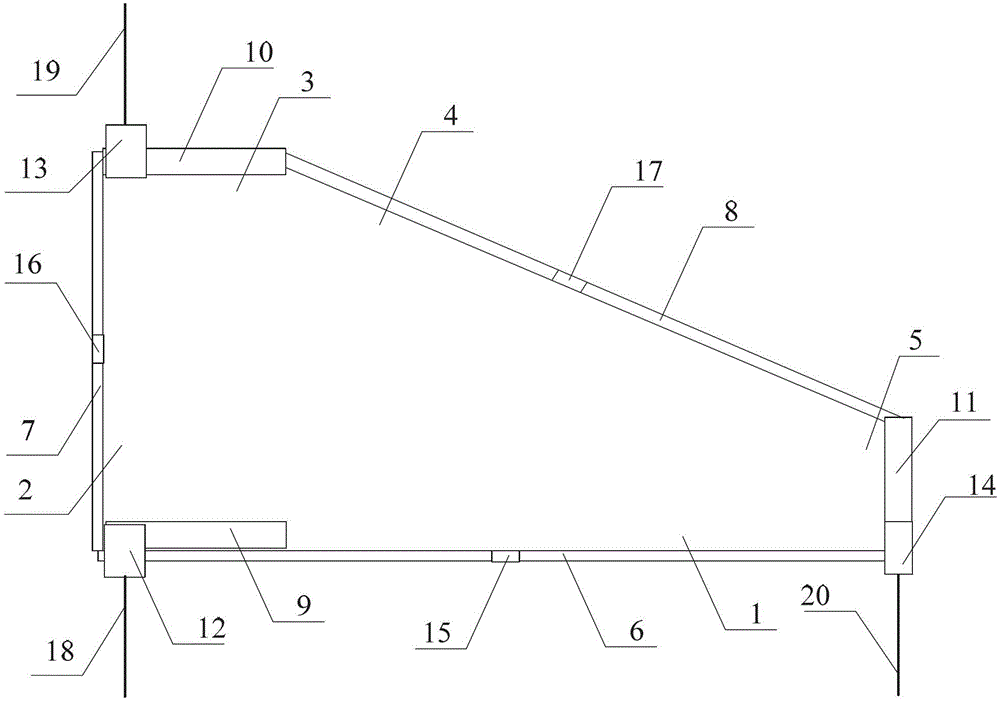

Large-diameter thin-wall cupronickel tube short process production method

The invention discloses a large-diameter thin-wall cupronickel tube short process production method and belongs to the technical field of metal materials. Specific to the problems that large-scale extrusion equipment up to 5000 tons is needed to produce large-diameter thin-wall cupronickel tubes through a traditional technique of semi-continuous casting solid ingot casting, punching, extruding, acid pickling, drawing and annealing, the finished product rate is low and the cost is high, the invention provides a method for producing the large-diameter thin-wall cupronickel tubes. Hot and cold combination casting horizontal continuous casting is adopted to producing large-size cupronickel tube blanks, and then a hole enlargement or / and hole shrinkage drawing is adopted to machining and forming the large-diameter thin-wall cupronickel tubes. The method has the advantages of being small in equipment investment, short in technical process, free of acid pickling and the like. The outer diameter of horizontal continuous casting tube blanks is 110-350 mm, the wall thickness is 5-30 mm, the elongation coefficient of hole enlargement drawing pass is 0.80-1.0, and the elongation coefficient of hole shrinkage drawing pass is 1.1-1.5; the outer diameter of machined products is 100-320 mm, and the wall thickness is 3-20 mm.

Owner:UNIV OF SCI & TECH BEIJING

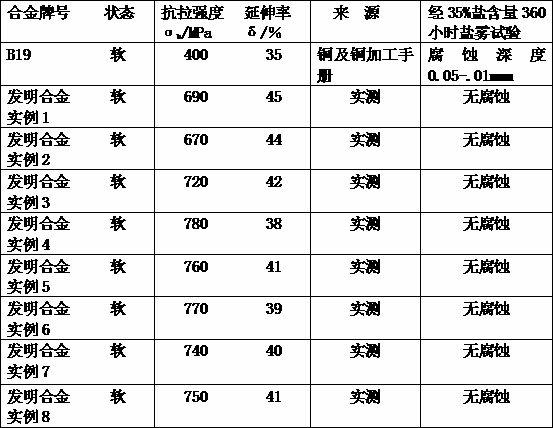

High-strength and high-corrosion-resistance cupronickel alloy and manufacturing method thereof

The invention relates to a high-strength and high-corrosion-resistance cupronickel alloy and a manufacturing method thereof. The high-strength and high-corrosion-resistance cupronickel alloy is characterized by comprising cathode copper and electrolytic nickel as main components, less zirconium sponge and metallic silicon powder, and less than or equal to 2.0% of impurities. According to the manufacturing method provided by the invention, a soft alloy end-product is formed by performing the steps of electrically smelting, refining, condensing and crusting, casting and molding, in a vacuum induction furnace, and the like. The high-strength and high-corrosion-resistance cupronickel alloy has high strength and high corrosion resistance, 670-770 MPa tensile strength and 38-45% extension property, so that the property is 40% higher than B19 property, the corrosion resistance is increased by 3 times and the machining property is excellent. The high-strength and high-corrosion-resistance cupronickel alloy has the characteristics of wide application, long service life and the like, and can be used for producing plates, belts, pipes, bars, lines and forging pieces. The high-strength and high-corrosion-resistance cupronickel alloy is widely applied to the industries, such as shipbuilding, chemical industry, manufacturing and metallurgy. The manufacturing method provided by the invention also has the advantages of simple steps of the cupronickel alloy processing technology, low processing cost, easiness in production, and meeting the demands of various application fields on the high-strength and high-corrosion-resistance cupronickel alloy.

Owner:沈阳有色金属研究所有限公司

Environment-friendly alkaline button cell

InactiveCN1838457AReduce outgassingInhibit swellingAlkaline accumulatorsPrimary cell electrodesIndiumCupronickel

This invention relates to an environment-friendly alkaline buckle battery, which includes anode substance, cathode cover, cathode substance, seal glue ring, anode hull, electrolyte and dissepiment paper, the character of which is that the battery cathode cover inner is plating with a layer of white copper or copper alloy, the cathode substance includes pure zinc powder, and it uses high pure hydroxides indium and indium oxide as inhibitor to lower electric potential where the zinc powder separates hydrogen, the cathode substance also includes thickening agent, zinc oxide and so on. The advantage in this invention is that it can prevent from swelling from the gas produced by the zinc contacting with other materials or metals, and it reduces the gas separating quantity of the hydrogen cathode to satisfy the environmental protection.

Owner:黄圣赐

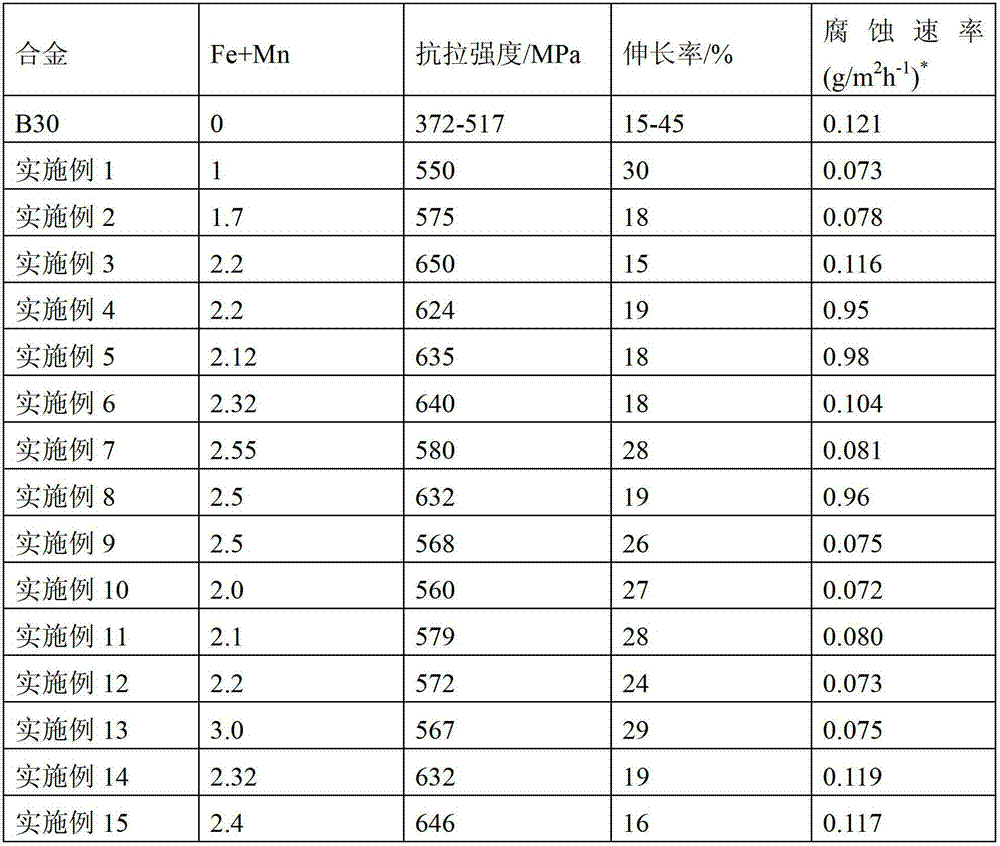

Novel erosion resistant cupronickel alloy and preparation method thereof

InactiveCN102732746AImprove mechanical propertiesImprove corrosion resistanceCupronickelNonferrous metal

The invention relates to a novel erosion resistant cupronickel alloy and a preparation method of the novel erosion resistant cupronickel alloy, belonging to the field of nonferrous metal processing. The novel erosion resistant cupronickel alloy comprises the following components in percentage by weight: 11-13% of Ni, 0.5-2.0% of Fe, 0.5-2% of Mn and the balance of Cu, wherein the summation of the weight percentages of the Fe and the Mn is more than or equal to 1.0 and less than or equal to 3. Through the procedures of fusion casting, cold rolling, intermediate annealing, cold rolling, final annealing and final hardening, the tensile strength of the alloy can reach 550-650MPa, and the elongation is 18-30%, so the novel erosion resistant cupronickel alloy can be used for replacing B30 alloy in the market and applied to the fields of instruments, shipbuilding, petrochemical industry, medical apparatus and instruments and the like and has a wide application prospect.

Owner:NINGBO XINGYE SHENGTAI GROUP

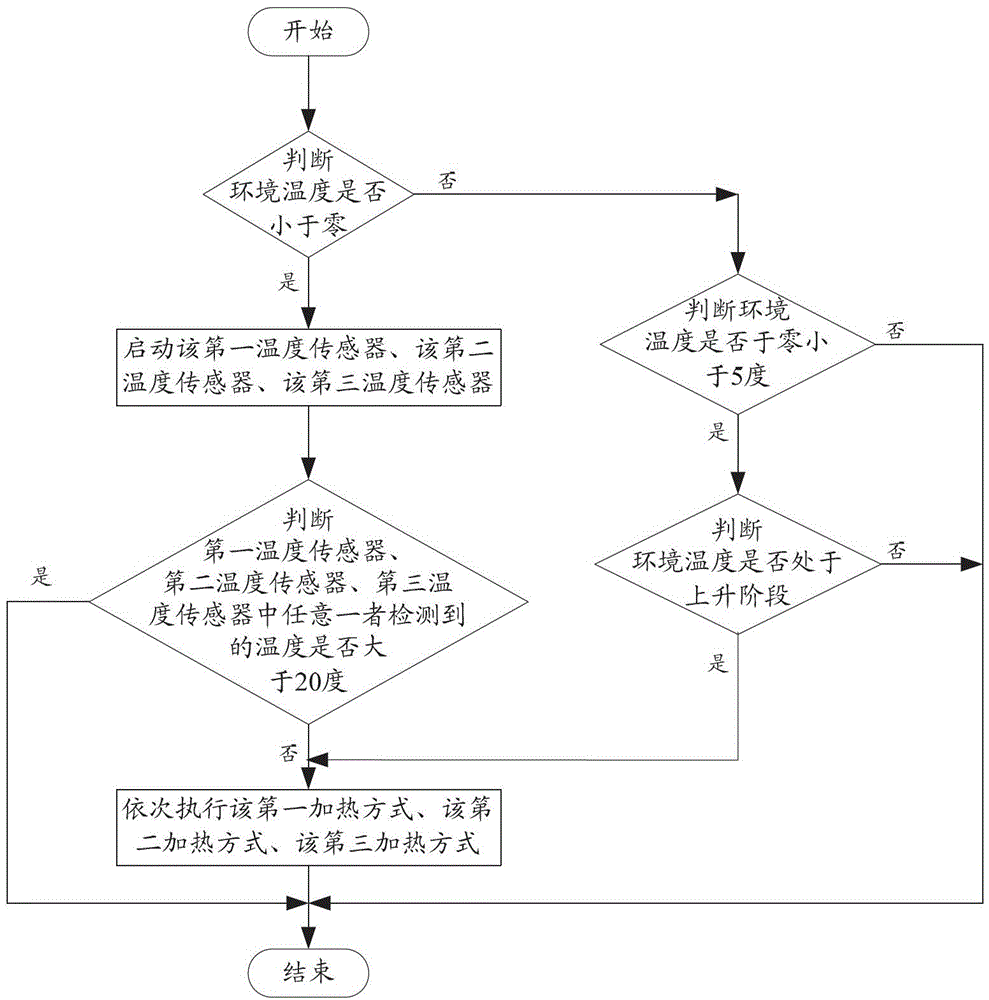

Heater as well as shaped liquid crystal display with same and heating method thereof

ActiveCN102879933AEvenly distributedEffective control of heating timeStatic indicating devicesTemperatue controlSilver pasteLiquid-crystal display

The invention discloses a heater applied to a shaped liquid crystal display and a heating method thereof, and the shaped liquid crystal display with the heater and a heating method thereof. The heater is in a pentagonal structure with a first edge, a second edge, a third edge, a fourth edge and a fifth edge, which are connected end to end in order; the first edge is parallel to the third edge; the second edge is parallel to the fifth edge; and the first edge, the second edge and the fourth edge are longer than the third edge and the fifth edge. The heater is provided with first, second and third electrodes, first, second and third conductive silver pastes, first, second and third cupronickel sheets, first, second and third temperature sensors, and first, second and third electrode lead wires, wherein the first, the second and the third electrodes are respectively fixedly arranged at the first edge, the second edge and the fourth edge; the first, the second and the third conductive silver pastes are respectively fixed at the first, the third and the fifth edges; the first, the second and the third cupronickel sheets are respectively fixed on the first, the second and the third conductive silver pastes; the first, the second and the third temperature sensors are respectively fixed at the first, the second and the fourth edges; and the first, the second and the third electrode lead wires are respectively leaded out from the first, the second and the third cupronickel sheets. The heater provided by the invention has the advantages in that energy can be uniformly distributed on the shaped liquid crystal display, so that the display has good display effect at a low temperature.

Owner:中航华东光电有限公司

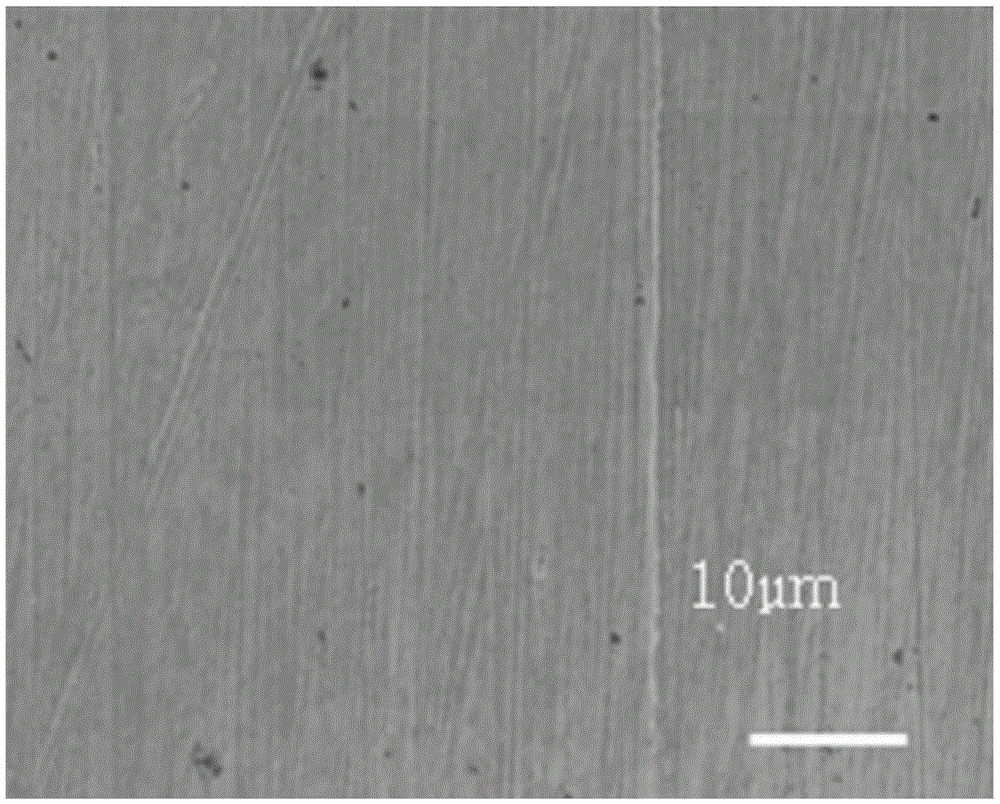

Preparation method for cupronickel super-hydrophobic surface

ActiveCN105220155AImprove corrosion resistanceImprove anti-corrosion performanceMetallic material coating processesCupronickelFiltration

The invention relates to a preparation method for a cupronickel super-hydrophobic surface. According to the preparation method, firstly, an ammonia-water solution serves as an etchant, and cupronickel is pretreated to remove oil contamination and grease on the surface; afterwards, the pretreated cupronickel is subjected to chemical etching through the etchant; then calcination treatment is conducted, and the cupronickel surface with a rough structure is prepared; and finally, the cupronickel surface is put in an ethanol solution of stearic acid for soaking, a super-hydrophobic film is generated on the rough cupronickel surface in a self-assembly mode, afterwards, the cupronickel super-hydrophobic surface is prepared after filtration, washing and drying. Compared with the prior art, the preparation method combining chemical etching with the high-temperature calcination treatment is adopted, the surface roughness is constructed on the cupronickel surface so that stearic acid molecules can be adsorbed strongly; the preparation process is simple, mild in condition, low in cost, high in stability and environmentally friendly. The contact angle of the prepared cupronickel super-hydrophobic surface can be up to 153 degrees, and the prepared cupronickel super-hydrophobic surface has good corrosion resistance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Nickel silver alloy and processing technique

This invention relates to a zincum-white copper alloy and its processing technique. It comprises of 67~69wt% of Cu, 14~16wt% of Ni and 15~19wt% of zincum. Due to the creativity in weight percentage of the Cu-Ni-Zn ternary alloy in this invention, the alloy shows a considerably silvery color, an outstanding strength, wear resistance, corrosion resistance and discoloration resisting properties. This invention stressed a raw materials cost as low as possible, meanwhile assures excellent founding properties, corrosion resisting properties and coin processing properties.

Owner:CHINA BANKNOTE PRINTING & MINTING

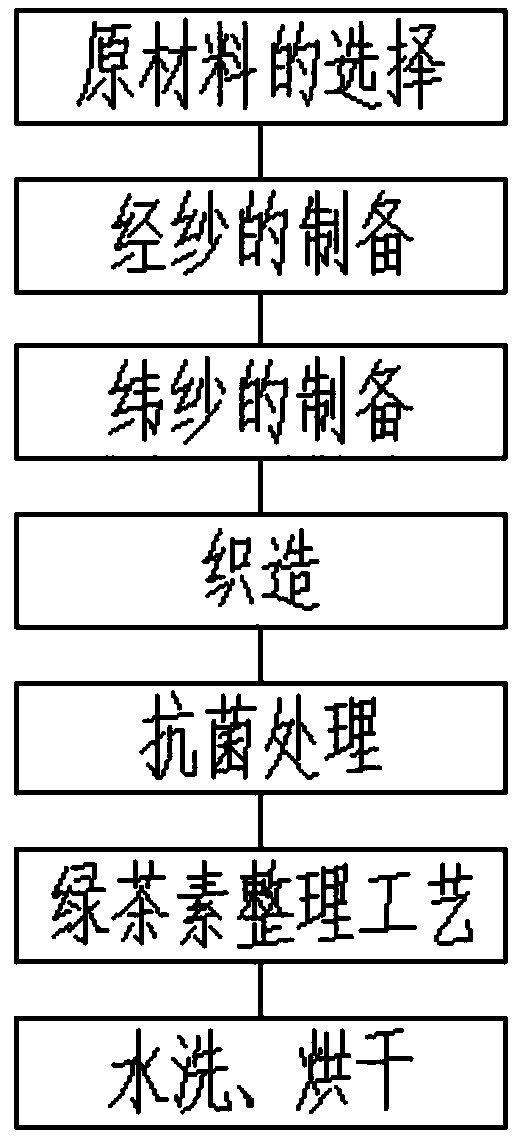

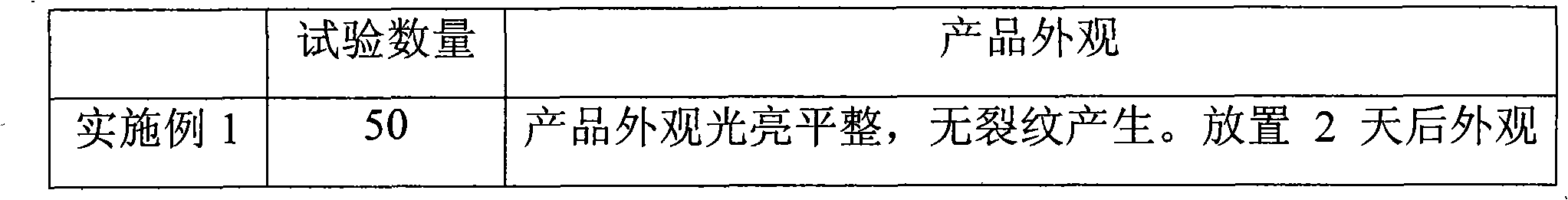

Antibacterial blended textile and preparation technology thereof

InactiveCN109385729AImprove antibacterial propertiesFriendlyCarbon fibresBiochemical fibre treatmentPolyesterCarbon fibers

The invention discloses an antibacterial blended textile and a preparation technology thereof. The textile is prepared from, by weight, 16-22 parts of staple fiber silks, 2-8 parts of nano bamboo carbon fibers, 1-5 parts of silver ion fibers, 4-8 parts of aloe fibers, 40-60 parts of cotton fibers, 22-32 parts of polyester fibers, 10-16 parts of cupronickel fibers and 20-40 parts of lyocell fibers.The preparation technology of the antibacterial blended textile is completed through the steps of raw material selection, warp preparation, weft preparation, weaving, antibacterial treatment, green tea extract finishing technology, washing and drying. According to the blended textile, the weaving of the blended textile is conducted by adopting an antibacterial raw material, the woven textile hasa better antibacterial function, secondary antibacterial treatment is conducted on the textile by adopting a natural antibacterial agent, there exists no pollution, the textile is purely natural, thetextile can be effectively suitable for different skins, there exist no pollutant in the preparation of the natural antibacterial agent, which is environmentally friendly and helps production popularization, and the economical benefit is high.

Owner:南通欣颐家纺有限公司

Electroplating method

InactiveCN101899664ASolve the technical problem of high stress and prone to dynamic embrittlementImprove wear resistanceLiquid/solution decomposition chemical coatingSuperimposed coating processCopper platingCupronickel

The invention relates to an electroplating method, which belongs to the field of electroplating, and the method comprises the following steps: (a) copper preplating; (b) acid bright copper plating; (c) chemical immersion tin; and (d) white copper tin electroplating. An electroplated product obtained by using the electroplating method with concentration can well solve the phenomena of greater stress of an electroplated white copper tin layer and easy production of dynamic embrittlement, and effectively improve the wear resistance and the anti-salt spray corrosion performance of the plated layer. The electroplating method can be widely applied in decoration of surfaces of metal products.

Owner:BYD CO LTD

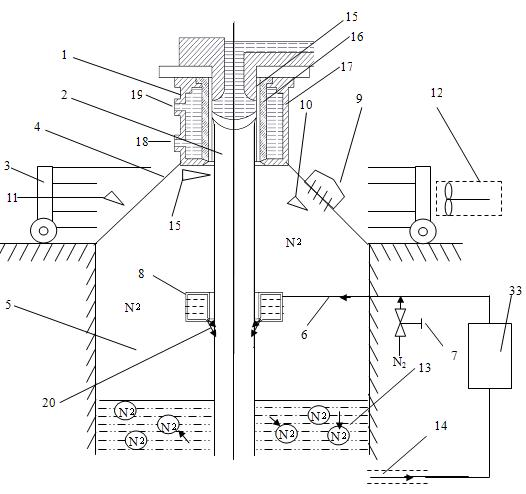

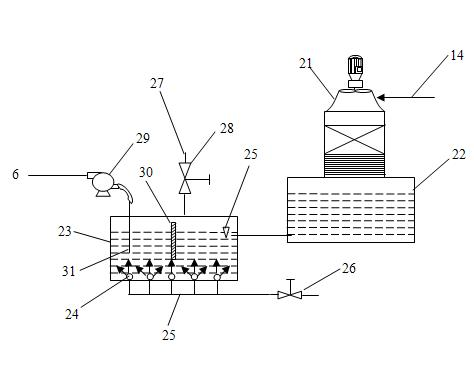

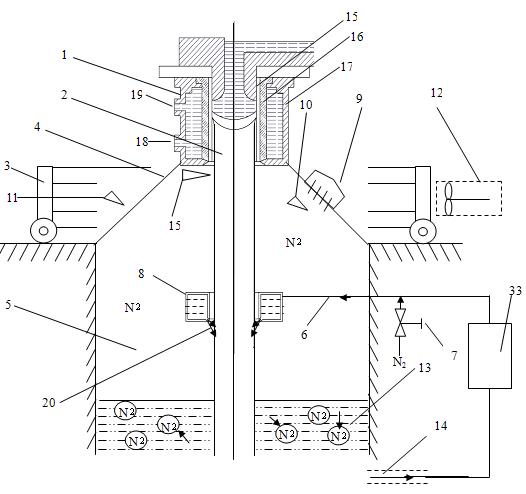

Copper and copper alloy casting equipment under protection of nitrogen

The invention discloses copper and copper alloy casting equipment under the protection of nitrogen. The equipment comprises a crystallizer assembly, and a secondary water cooling device and a casting well which are positioned below the crystallizer assembly. The equipment is characterized in that: an airtight protective cover is arranged between the crystallizer assembly and the casting well; the secondary water cooling device is connected to a secondary water cooling-deoxidizing device through a secondary cooling water pipe which is connected with a nitrogen injection pipe and a valve; and the bottom of the casting well is provided with a cooling water return pipe. Under the sealing protection of the nitrogen, outside air is prevented from entering the casting well so as not to contact high-temperature copper ingots in the casting process, the copper ingots are prevented from being oxidized by the air, the surface non-oxidation casting of industrial pure copper, high copper and a white copper alloy is realized, and the aims of reducing the oxidation loss of copper metal and production cost are fulfilled.

Owner:JINCHUAN GROUP LIMITED

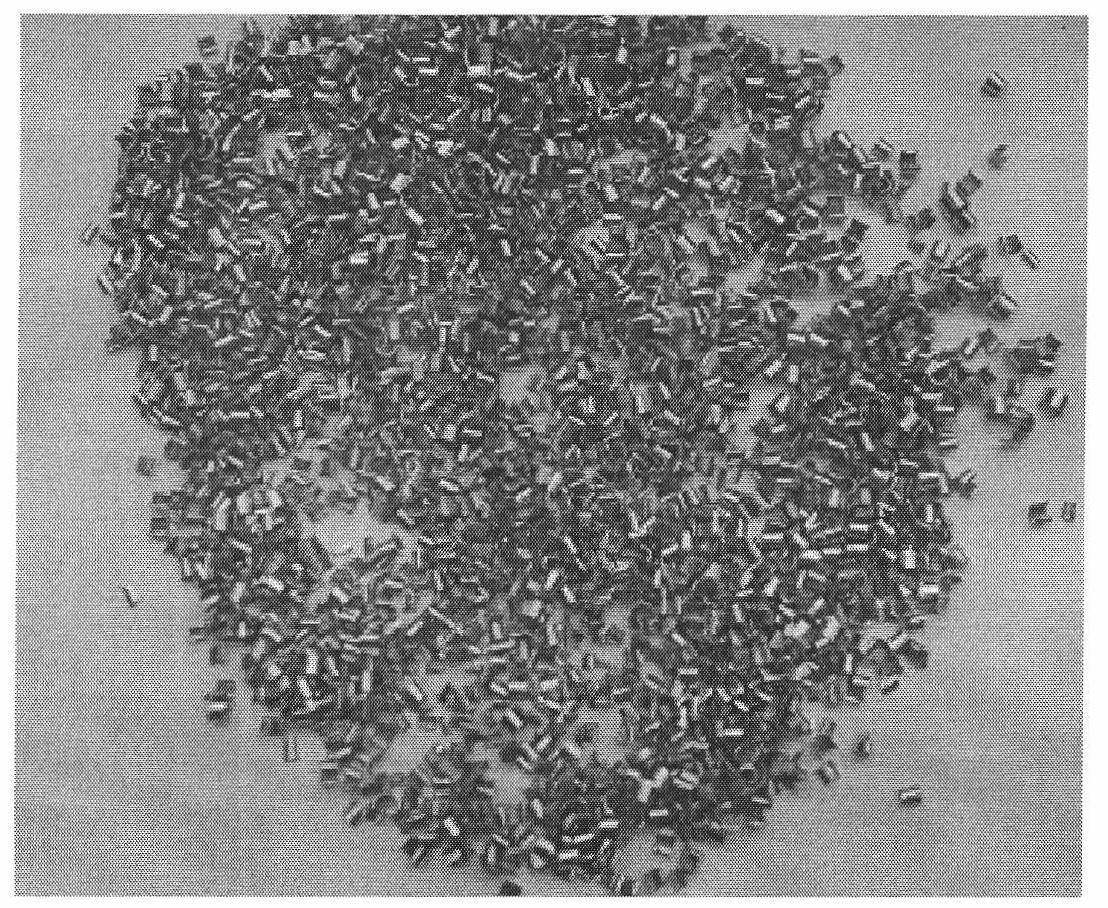

Manufacturing process of cupronickel pipe

The invention provides a manufacturing process of a cupronickel pipe. The process comprises the steps: mixing a metal copper raw material, a nickel raw material and other trace alloy elements according to the ratio requirement of the cupronickel material, continuously smelting the mixture in a smelting furnace, continuously feeding the molten alloy liquid into a heat preserving furnace through a connection through hole, continuously upwards casting the molten alloy liquid entering the heat preserving furnace to form a copper-nickel alloy pipe blank after the molten alloy liquid passes through a continuous casting crystallizer, clamping and drawing the continuously-cast alloy pipe blank through the pressure of pair rolls on a vertical casting and drawing machine stander, continuously drawing out the pipe blank upwards , cutting off the drawn-out pipe blank according to a given length, primarily straightening the pipe blank, and drawing the straightened pipe blank in one step or multiple steps to form a finished product after the straightened pipe blank is rolled in one step through a primary cold roll mill and annealed in one step. According to the process, the traditional extruding production process is simplified to a novel production process of one-step continuous casting, one-step continuous cold rolling and one-step or multi-step drawing process. The process is an advanced process which is free from smoke and dust pollution and capable of improving the rate of finished products.

Owner:高玉树

A kind of titanium and titanium alloy pre-plating solution and electroplating method

The invention provides a titanium and titanium alloy pre-plating solution. The pre-plating solution includes sodium gold sulfite, a conductive salt, a complexing agent, a brightener and a pH buffer; the pH of the electroplating solution is 9-11. The present invention also provides a method for electroplating titanium and titanium alloys, which includes placing titanium and titanium alloys in a pre-plating solution for pre-plating and then electroplating cyanide-free cupronickel tin; wherein the pre-plating solution is the The pre-plating solution. The present invention replaces pre-nickel plating with cyanide-free pre-plating gold, increases the bonding force between titanium and titanium alloys and the coating, reduces pitting, and uses the cyanide-free white copper-tin system to replace the commonly used nickel plating process to solve the human body's allergy to nickel. Cyanide pollutes the environment.

Owner:BYD CO LTD

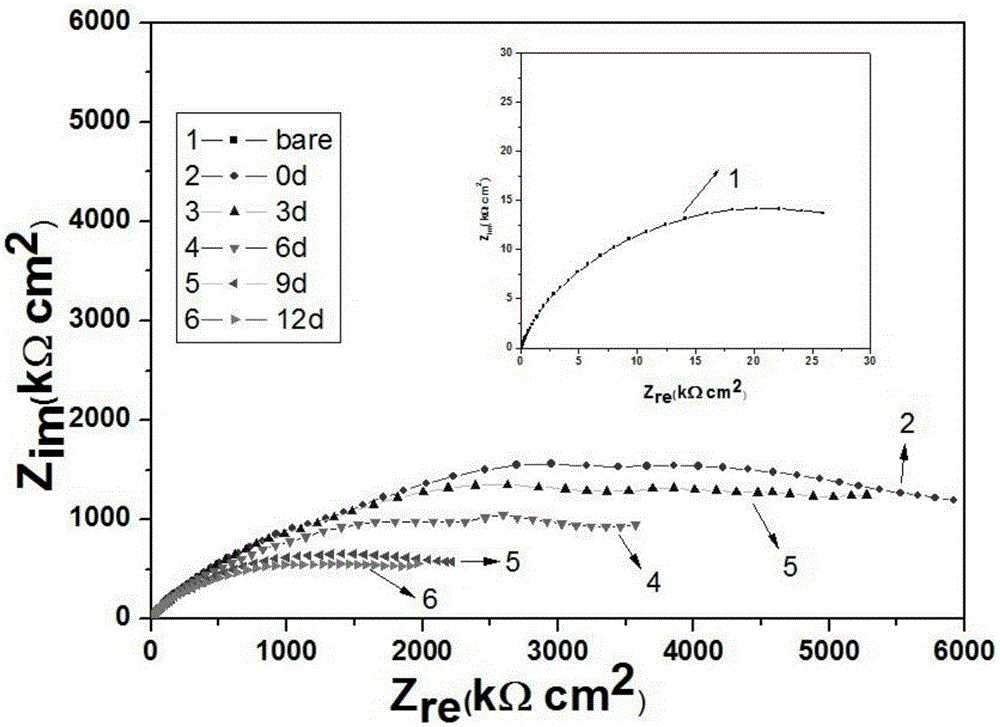

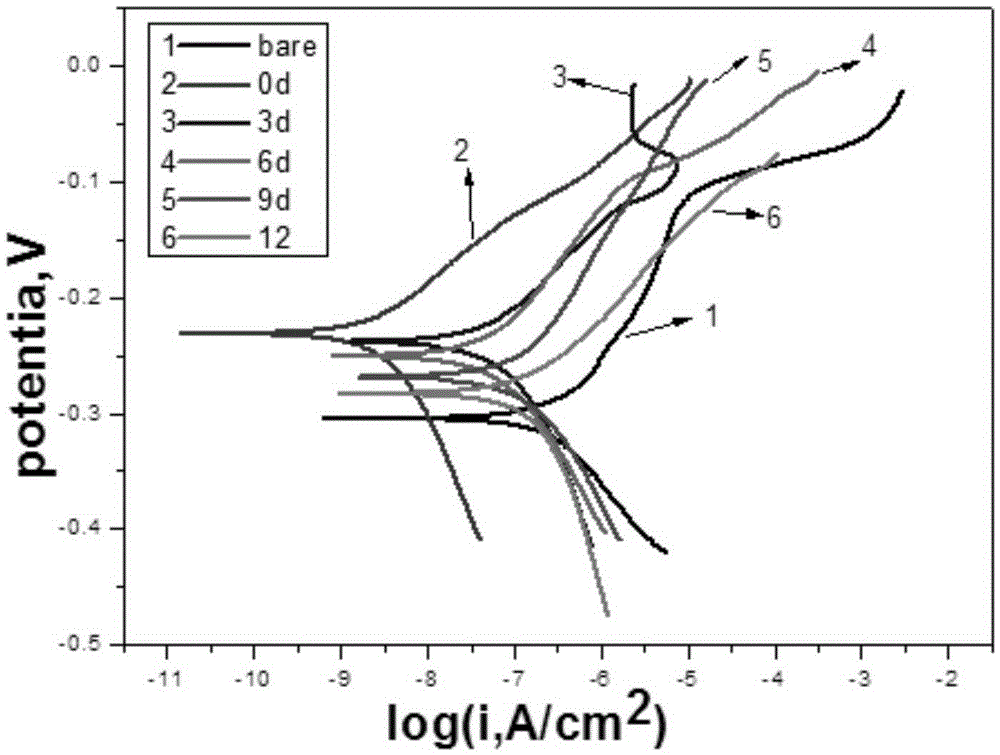

Cupronickel B30 having super-hydrophobic surface and preparation method thereof

InactiveCN103074629AImprove anti-corrosion performanceImprove corrosion resistanceLiquid surface applicatorsCoatingsCupronickelCorrosion prevention

The invention discloses cupronickel B30 having the super-hydrophobic surface and a preparation method thereof. The surface of cupronickel B30 is chemically etched by an HCl-H2O2 solution having a concentration of 5wt% and through a self-assembly technology, a stearic acid film is formed on the treated surface of the cupronickel B30. The preparation method comprises the four steps of etching liquid preparation, cupronickel B30 pretreatment, rough surface preparation by chemical etching, and self-assembling of stearic acid on the rough surface of cupronickel B30. The cupronickel B30 having the super-hydrophobic surface has high corrosion resistance. A contact angle of water and the surface of the cupronickel B30 having the super-hydrophobic surface is 152.8 degrees. The cupronickel B30 having the super-hydrophobic surface has good anticorrosion effects in a NaCl aqueous solution having a concentration of 3.5wt% and has corrosion inhibition efficiency eta of 96.7%. The preparation method has the advantages of simple processes, low production cost and easy process control.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Nickel silver band for piezoelectric crystal oscillator housing and method for producing same

ActiveCN1690236AOscillations generatorsPiezoelectric/electrostrictive/magnetostrictive devicesSurface finishManufacturing technology

A packfong belt applying to the shell of piezoelectric crystal oscillator, the material of the copper alloy is prepared by adding nickel and zinc element, and the main chemical constituent is as following: Cu: 62.0 to 66.0 percent; Ni: 16.5 to 19.5 percent; Zn: residual. The workflow is: material checking and accepting - batching - melting - sampling and analyzing (adjusting constituent) - rolling in holding furnace - sampling and analyzing (adjusting constituent) - horizontal continuous casting - batching on - milling - cool cogging rolling - end shearing - intermediate annealing - cold rolling - intermediate annealing - fine rolling - end item annealing - cutting - end item quality inspection - packaging and warehouse-in. The invention settles many technical problems, such as the low tensile strength, the high dimensional tolerance and the poor surface finish quality of the present packfong belt, and it also improves the the shielding property and corrosion resistance.

Owner:中铜(上海)铜业有限公司

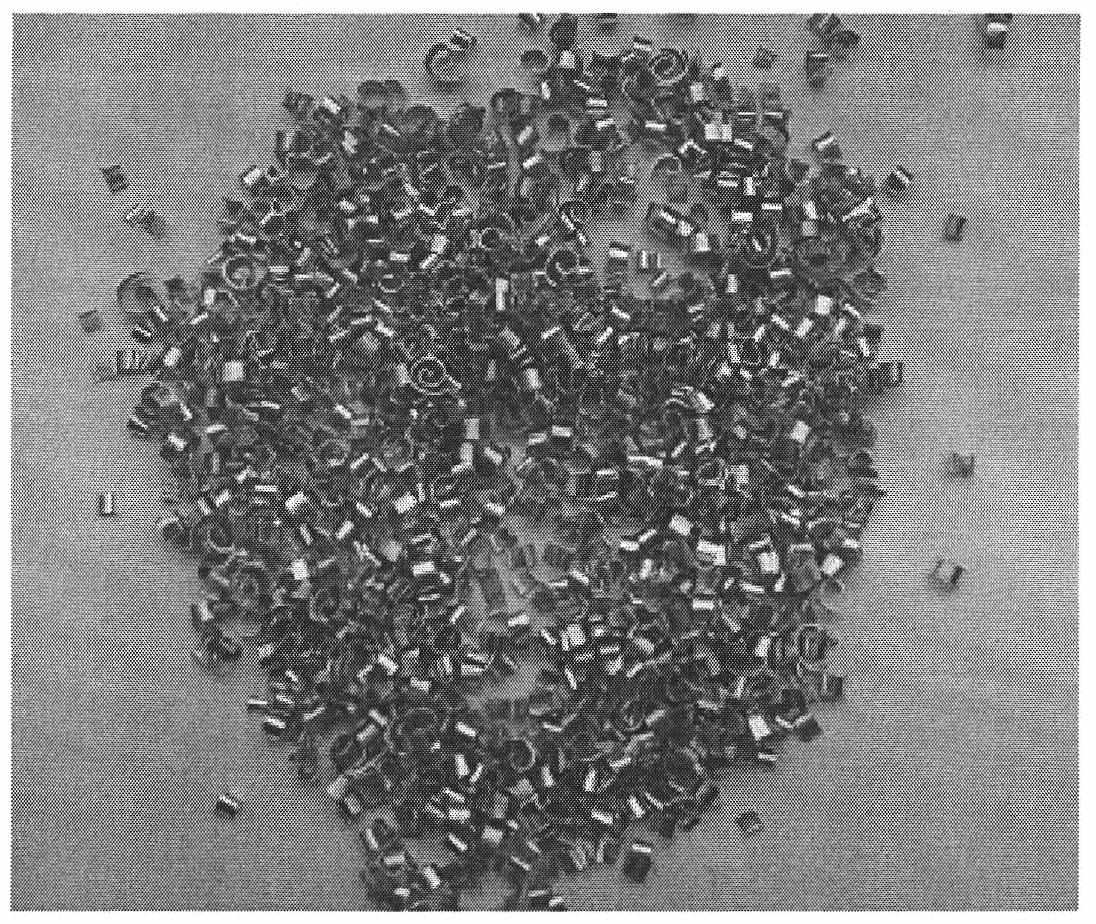

Production method of large-coil-weight white copper alloy coil pipe

The invention provides a production method capable of producing a large-coil-weight white copper alloy coil pipe with the weight being more than 300kg and high rate of finished products, and the method comprises the following steps of (1) smelting a white copper alloy material, and adopting a horizontal continuous casting technology of a composite electromagnetic stirring technology to produce a white copper alloy hollow casting blank; (2) rolling the white copper alloy hollow casting blank which is face milled, and utilizing a duplex pulling device to stretch a rolled pipe; (3) washing the inner wall and the outer wall of the white copper duplex stretched coil pipe, and adopting a passing-type sensing annealing device to continuously anneal the white copper duplex stretched coil pipe; (4) stretching the annealed duplex stretched coil pipe; (5) conducting eddy current test on the white copper stretched coil pipe, and simultaneously horizontally winding the copper pipe to form the large-coil-weight white copper alloy coil pipe; and (6) annealing the large-coil-weight white copper alloy coil pipe needing to be annealed. Due to the adoption of the production method of the large-coil-weight white copper alloy coil pipe, the large-coil-weight white copper alloy coil pipe with single coil weight being more than 300kg can be produced.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com