Zinc-copper-nickel alloy and preparation method and application thereof

A zinc-nickel alloy and alloy technology, applied in metal material coating process, coating, hot dip plating process, etc., can solve the problem of insufficient anti-oxidation and soldering performance, affect the appearance and reliability of shielding parts, and cannot meet the use of shielding cover materials. Demand and other issues, to achieve the effect of improving salt spray corrosion resistance, improving high temperature oxidation resistance, good fluidity and wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

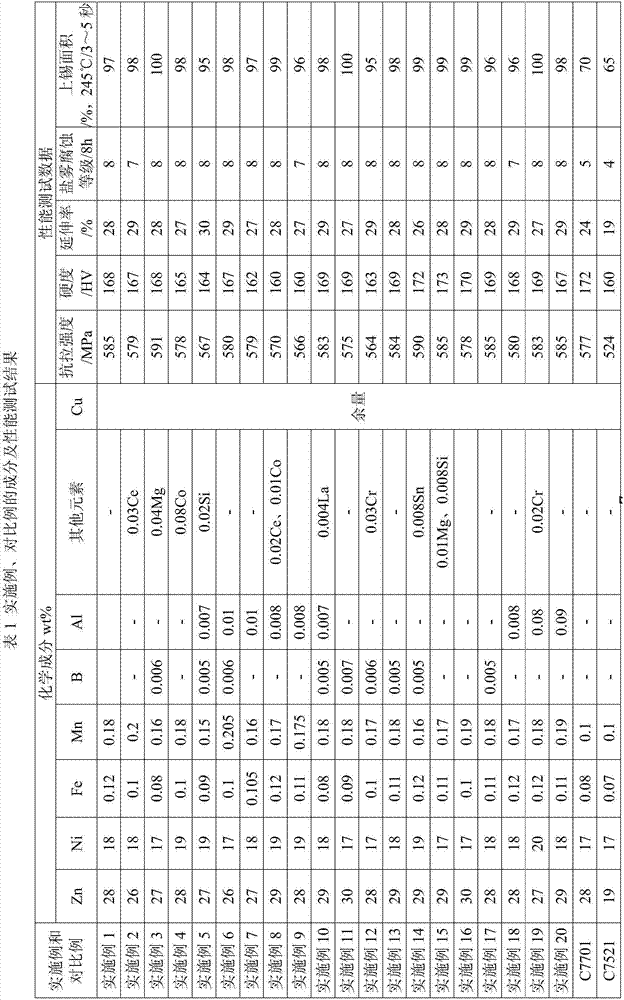

[0030] Below in conjunction with embodiment the present invention is described in further detail.

[0031] 20 example alloys and two comparison alloys (C7521, C7701) were selected and processed into strip products by the same preparation method. The preparation process is: batching→horizontal continuous casting→face milling→rough rolling→edge trimming→softening Annealing→cleaning→intermediate rolling→softening annealing→cleaning, grinding→finish rolling finished product→finished product cleaning, grinding→stretch bending straightening→shearing finished product, wherein the softening annealing is carried out in a protective atmosphere, the annealing temperature is 500~650℃, The holding time is 5-10 hours; the grinding is polishing and grinding with two sets of 600-3000-mesh non-woven abrasive brushes. The specific process is:

[0032] Batching → horizontal continuous casting → milling → rough rolling (14.5mm-10.5mm-8.5mm-7.0mm-6.0mm-5.0mm-3.9mm-3.1mm-2.4mm-1.9mm-1.5mm-1.2mm) →...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com