Patents

Literature

43results about How to "Improve softening resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

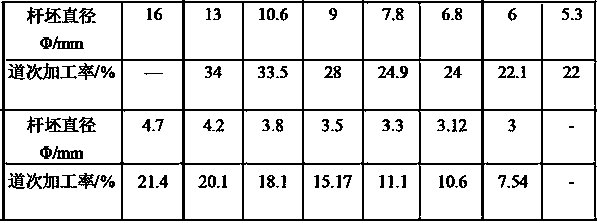

Rare earth copper alloy and its preparation method

The invention discloses a rare earth copper alloy and its preparation method, which comprises charging electrolytic copper by weight percentage, smelting 20-30 minutes, then charging 0.03-0.1% of zirconium, 0.02-0.16% of silver, 0.02-0.155 of rare-earth elements, smelting 1-3 minutes and casting, subjecting the cast alloy to heat preservation 1-4 hours at 800-850 deg C, forming bar stock through processing, the forging deformation amount is 50-80%, loading the bar stock into heat treatment furnace, thermally insulating 30-60 minutes at 800-950 deg C, then carrying out quenching treatment, subjecting the quenched alloy to 30-80% deformation treatment, cold drawing the alloy, thermally insulating 1-8 hours at 440-520 deg C, carrying out 50-70% deformation treatment to the alloy undergone ageing treatment. The invention can achieve high-strength and high conductivity.

Owner:HENAN UNIV OF SCI & TECH

Production method of high-strength, high-conductivity and heat-resistant copper alloy

ActiveCN108526422AGuaranteed lubrication effectImprove thermal conductivityCarbon compositesShielding gas

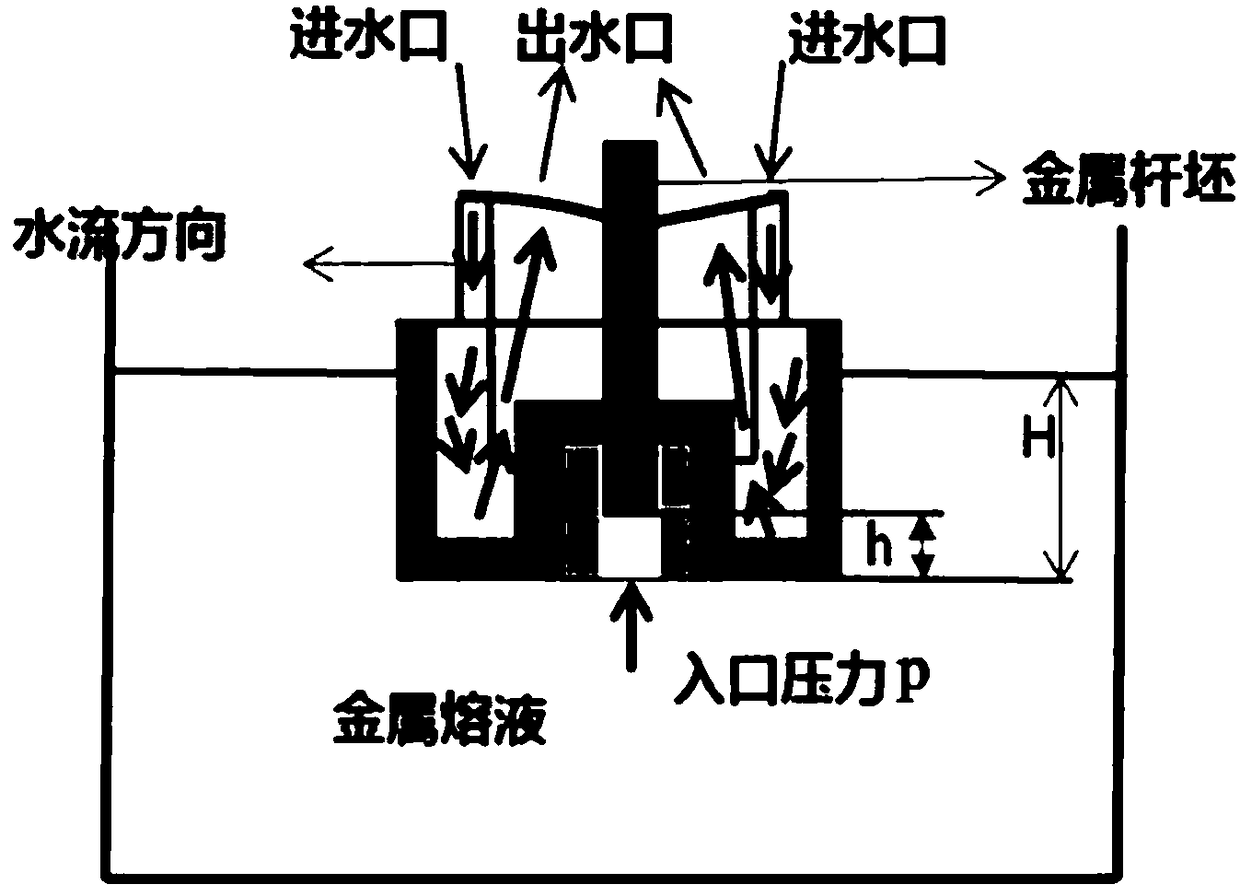

The invention discloses a production method of a high-strength, high-conductivity and heat-resistant copper alloy, and belongs to the technical field of copper alloy machining. Accoding to the production method of high-strength, high-conductivity and heat-resistant copper alloy, the inner liner of a crystallizer adopted in the upper-induced continuous casting process is a carbon-carbon composite material so as to ensure the lubrication, high heat conduction and high temperature resistance properties; the temperature of the upper-induced continuous casting is 1180-1230 DEG C, the casting temperature is low so that the problem that molten liquid in the crystallizer is difficult to solidify and the crystallizer inner liner is worn during casting can be effectively avoided; the pressure of protective gas nitrogen in the liquid surface of an upper-induced furnace is controlled to be 0.2-0.7 atmosphere, so that the phenomenon of solid-liquid interface separation in the crystallizer is avoided, and a copper-chromium alloy product with larger weight and length is produced; according to the production method of the high-strength, high-conductivity and heat-resistant copper alloy, the cheapelement (Mg) is used for replacing the rare noble metal, and the mechanical property and the softening resistance property of the copper-chromium alloy are improved; and the production method is a non-vacuum and short-process preparation technology, the cost is low, and the production method is suitable for large-scale industrial production and has important economic and social significances.

Owner:CENT SOUTH UNIV

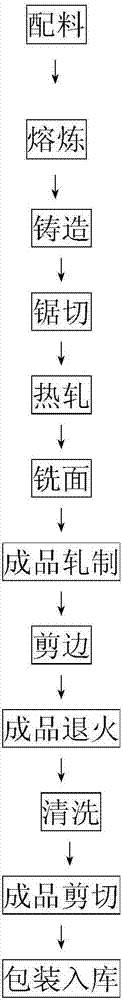

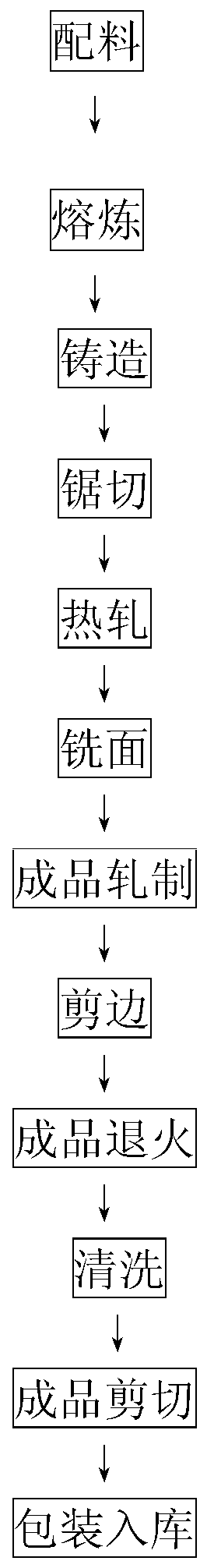

Preparation process of copper strip for framework material

ActiveCN107385270AIncreased strength and softening resistanceAvoid grain coarseningCorrosionScratching

Provided is a preparation process of a copper strip for a framework material. The preparation process comprises the technological steps of proportioning, smelting, casting, saw cutting, hot rolling, face milling, finished product milling, edge shearing, finished product annealing, washing, finished product shearing and packaging and putting into a storage. Compared with a special-shaped framework material manufactured by an original process, the copper strip produced by the preparation process has the remarkable advantages of high strength, good electrical conductivity, good subsequent machining performance and the like, chemical components of the material are stable, the surface is clean, smooth, free of oxidation discoloration, and free of defects like peeling, burrs, bubbles, cracks, layering, inclusion, holes, black points, folding, verdigris, scratching and corrosion, the copper strip can adapt to the more severe use environment, and the service life of a profiled bar is prolonged.

Owner:中铝洛阳铜加工有限公司

Copper alloy having high strength and high softening resistance

InactiveCN101113499AAvoid crackingImprove softening resistanceSemiconductor/solid-state device detailsSolid-state devicesHigh intensityLead frame

Disclosed is a Cu-Fe-P alloy capable of enabling high strength, high electrical conductivity, and excellent softening resistance to coexist. The Cu-Fe-P alloy is suitable for use as a constituent material of a lead frame for a semiconductor device. With the Cu-Fe-P alloy with strength rendered higher by micronizing Fe-containing compounds, when enhancing softening resistance by increasing Sn content so as to exceed 0.5 mass%, at least one element selected from the group consisting of Ni, Mg, Ca, Al, Si, and Cr, in trace amounts, are caused to be additionally contained to thereby check cracking likely to occur at the time of forging and hot rolling in a process of producing the copper alloy, as a result of an increase in the Sn content.

Owner:KOBE STEEL LTD

Copper strip preparation process for high-end frame material

Provided is a copper strip preparation process for a high-end frame material. According to the weight percentage of components in a smelting furnace, the total content of standard electrical cathode copper and Cu in all alloys is 96.5% or above, iron Fe accounts for 2.1-2.6%, phosphor P accounts for 0.015-0.15%, zinc Zn accounts for 0.05-0.20%, stannum Sn accounts for 0.005-0.050%, magnesium Mg accounts for 0.008-0.05%, the sum of impurities does not exceed 0.1%, the sum of alloy elements and impurities is 0.15% or below, and the weight sum of the above components is 100%; then, the followingsteps of smelting, casting, saw cutting, hot rolling, face milling, cold rolling, edge cutting, annealing, rolling of finished products, cleaning, shearing of finished products and package and warehousing are carried out. The problem of high temperature softening and other aspects of an original TFe2.5 and other frame material copper strips is solved, the high-end frame material has the obvious advantages of high strength, excellent electrical conductivity, good subsequent processing performance and the like compared with frame materials prepared by adopting an original process, the chemical composition of the material is stable, and the surface is clean, smooth and free of oxidation and discoloration.

Owner:中铝洛阳铜加工有限公司

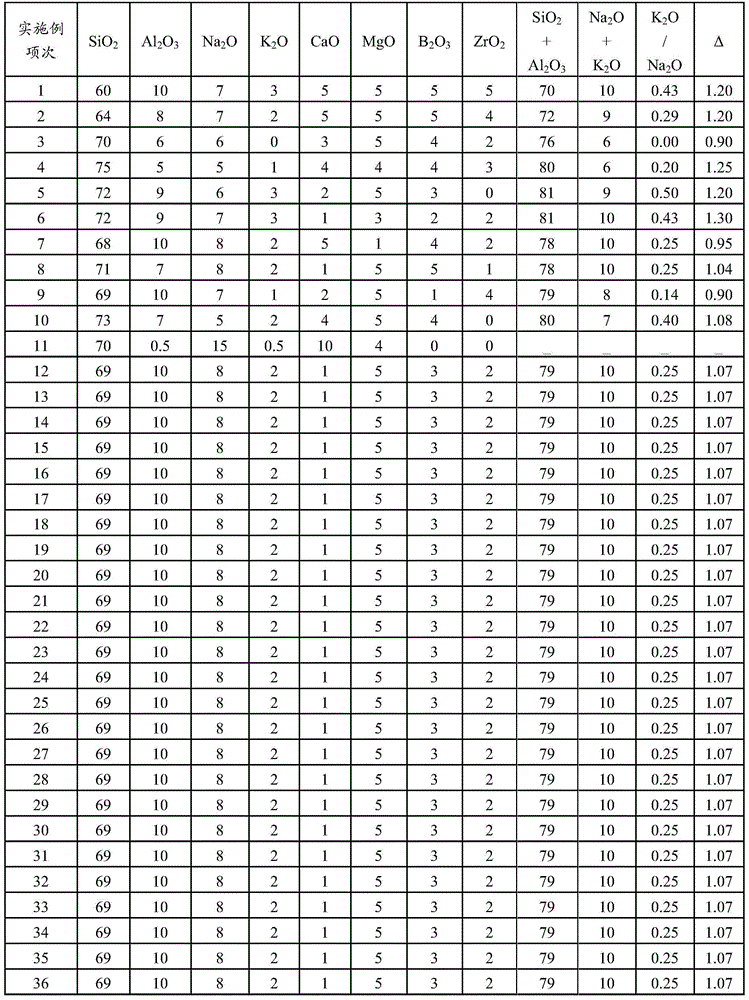

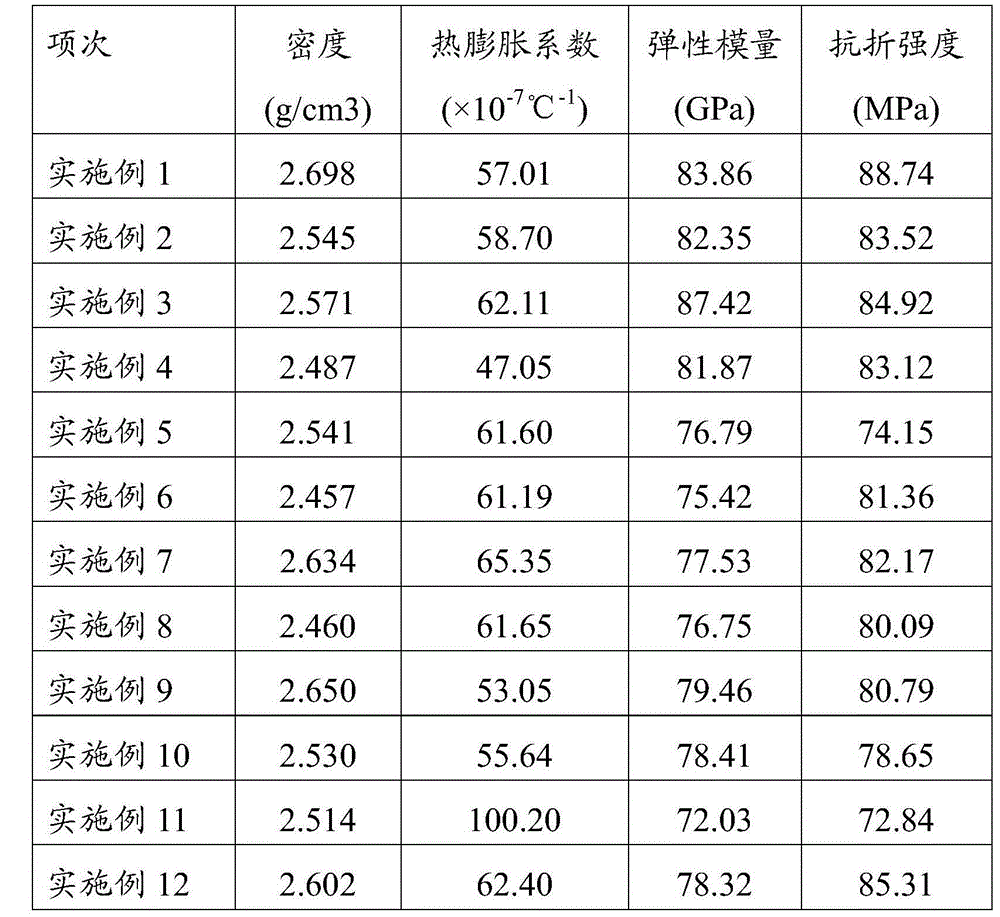

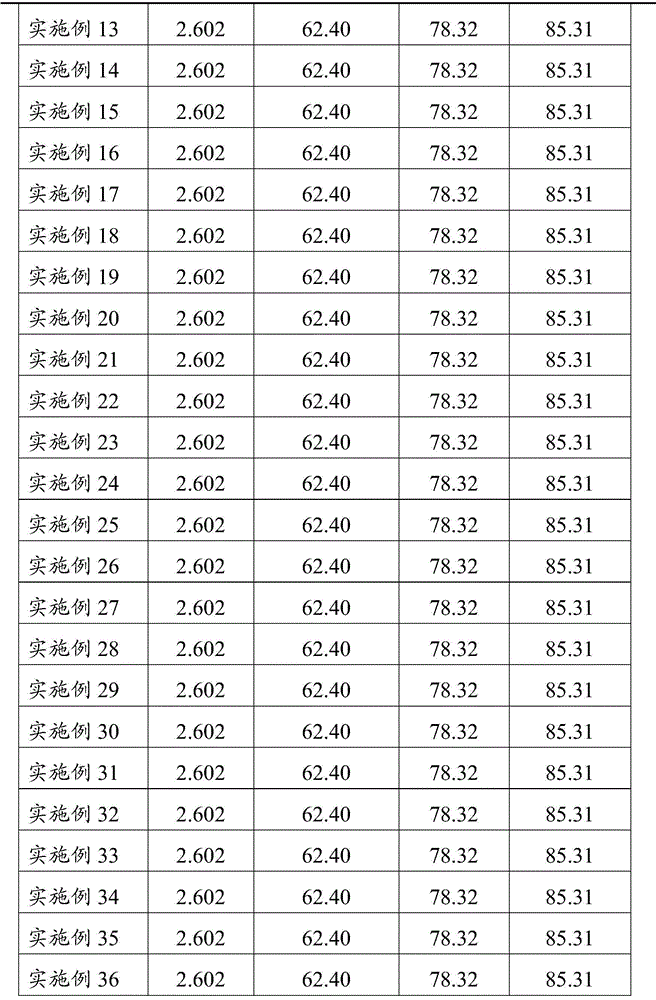

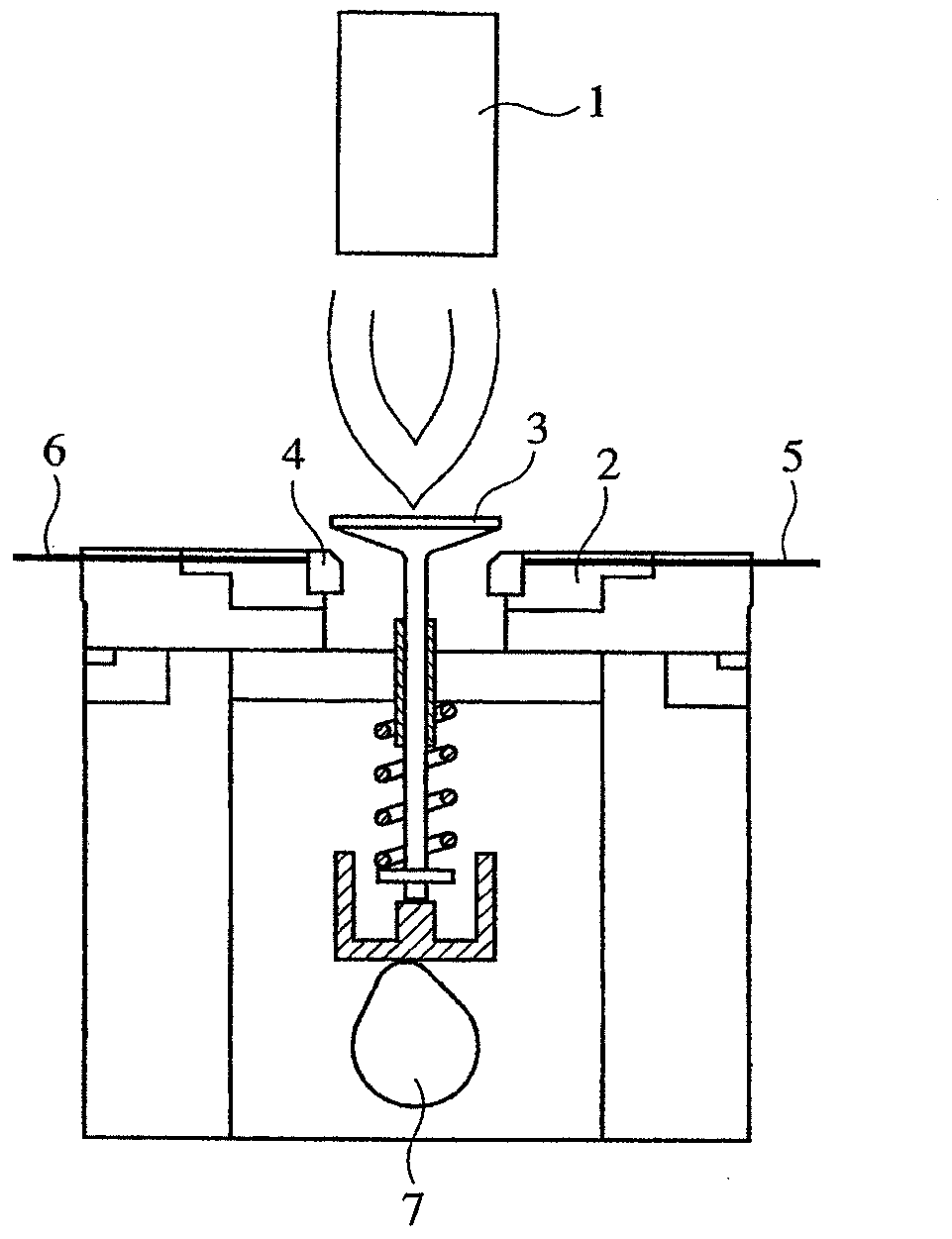

Alumina silicate glass and tempered glass

ActiveCN104556685AHigh strain pointGood chemical stabilityGlass tempering apparatusSilicate glassPotassium

The invention discloses alumina silicate glass. The alumina silicate glass comprises the following components in percentage by mole: 60-75% of silicon dioxide, 5-10% of aluminum oxide, 5-8% of sodium oxide, 0-3% of potassium oxide, 1-5% of calcium oxide, 1-5% of magnesium oxide, 2-5% of diboron trioxide and 0-4% of zirconium dioxide; the free oxygen coefficient delta of the alumina silicate glass is larger than or equal to 0.9 and smaller than or equal to 1.3, wherein delta is (Na2O+K2O+0.7CaO+0.3MgO-Al2O3) / B2O3; in the formula, each component represents the percentage by mole of the component. The alumina silicate glass can be used for improving the tempered strength. The invention also provides tempered glass prepared by tempering the alumina silicate glass.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD

Low-carbon high-chromium abrasion-resistant ball and preparation technique thereof

ActiveCN106319336AReduce contentImprove wear resistanceFurnace typesHeat treatment furnacesNiobiumManganese

The invention provides a low-carbon high-chromium abrasion-resistant ball and a preparation technique thereof. The low-carbon high-chromium abrasion-resistant ball is prepared from, by mass, 2.35%-2.46% of carbon, 0.85%-1.12% of silicon, 0.45%-0.6% of manganese, 18%-22% of chromium, 0.2%-0.25% of aluminum, 0.1%-0.18% of titanium, 0.05%-0.1% of tantalum, 0.1%-0.12% of boron, 0.02%-0.04% of niobium, 0.01%-0.03% of zirconium, 0.01%-0.025% of sulfur, 0.01%-0.025% of phosphorus, 0.2%-0.24% of nitrogen, and the balance ferrum and inevitable impurities. The low-carbon high-chromium abrasion-resistant ball is prepared through the steps of smelting, pouring, quenching, tempering and the like, the content of the carbon element is decreased, and nitrogen is introduced in the smelting process, so that the abrasion resistance of the ball is improved through formed metal nitride; and meanwhile, the situation that the hardenability is reduced due to excessive carbide is avoided. The quenched HRC of the low-carbon high-chromium abrasion-resistant ball is equal to or higher than 65, the impact fatigue life of the low-carbon high-chromium abrasion-resistant ball is equal to or longer than 19600 times, and the breakage rate of the low-carbon high-chromium abrasion-resistant ball is equal to or lower than 2.5%.

Owner:安徽中建材开源新材料科技有限公司

Copper alloy for turbine type generator rotor and processing technology of copper alloy

InactiveCN107385275AImprove high temperature stabilityImprove mechanical propertiesNiobiumCryogenic treatment

The invention discloses a copper alloy for a steam turbine generator rotor and its processing technology. The copper alloy is composed of copper, nickel, silicon, chromium, silver, magnesium, niobium, etc., and is smelted→continuously extruded→cold deformed→solid solution Quenching→second cold deformation→cryogenic treatment→aging and other processing processes; the technical solution provided by the invention has excellent material properties and fully meets the requirements of the turbine generator rotor.

Owner:徐高杰

Asphalt mixture anti-rut agent and preparation method thereof

The invention discloses an asphalt mixture anti-rut agent. The anti-rut agent is characterized in that the anti-rut agent is obtained through mixing 30-50wt% of steel slag micro-powder, 10-25wt% of mineral slag micro-powder, and 25-45wt% of gangue incineration ash, carrying out stirring reacting on the resulting mixture and a sodium silicate solution which are mixed according to a weight ratio of(1.5-3):(1-2), carrying out curing maintenance, heating, carrying out thermal insulation, and grinding, wherein the steel slag micro-powder is obtained through mixing hot closed steel slag with lime,heating to 900-950DEG C, maintaining the temperature for 2.5-3h, quenching and ball-milling; and the gangue incineration ash is obtained after maintaining a temperature of 750-900DEG C for 2.5-3h. The invention also discloses a preparation method of the anti-rut agent. The anti-rut agent of the invention has the advantages of no appearance of rut traces, and full guarantee of the pavement planarization and the driving safety because of difficult softening of the asphalt mixture.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Preparation technology of copper alloy for short process slot wedge

The invention discloses a preparation process of a copper alloy for short-flow slot wedges, which adopts the preparation processes of upward continuous casting→continuous extrusion→solution quenching→cold deformation→cryogenic treatment→aging; the copper alloy is composed of copper, nickel, silicon , chromium, silver, magnesium and other components, the technical solution provided by the invention, the obtained material performance is excellent, fully meet the use requirements of the turbine generator rotor slot wedge.

Owner:徐高杰

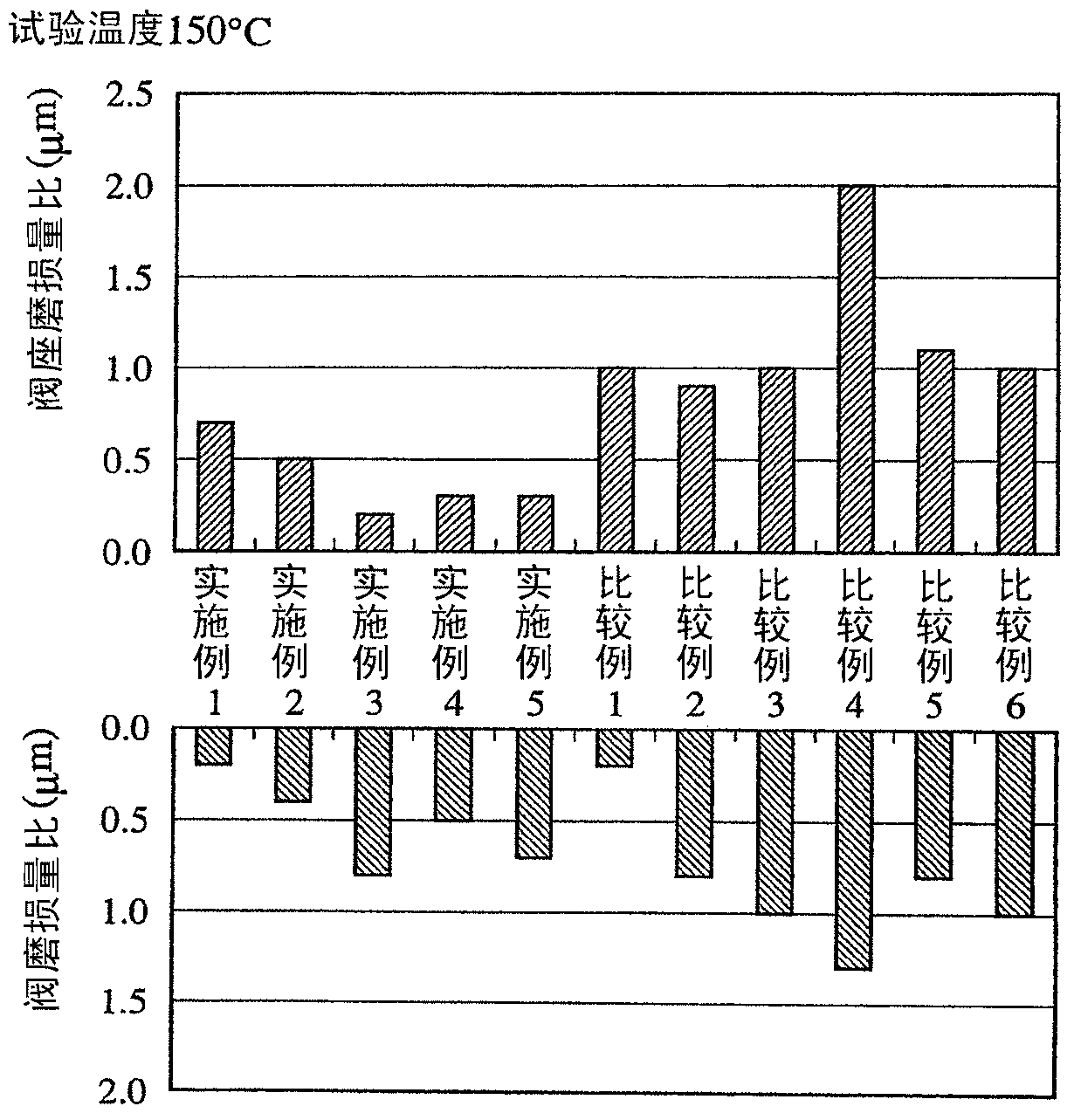

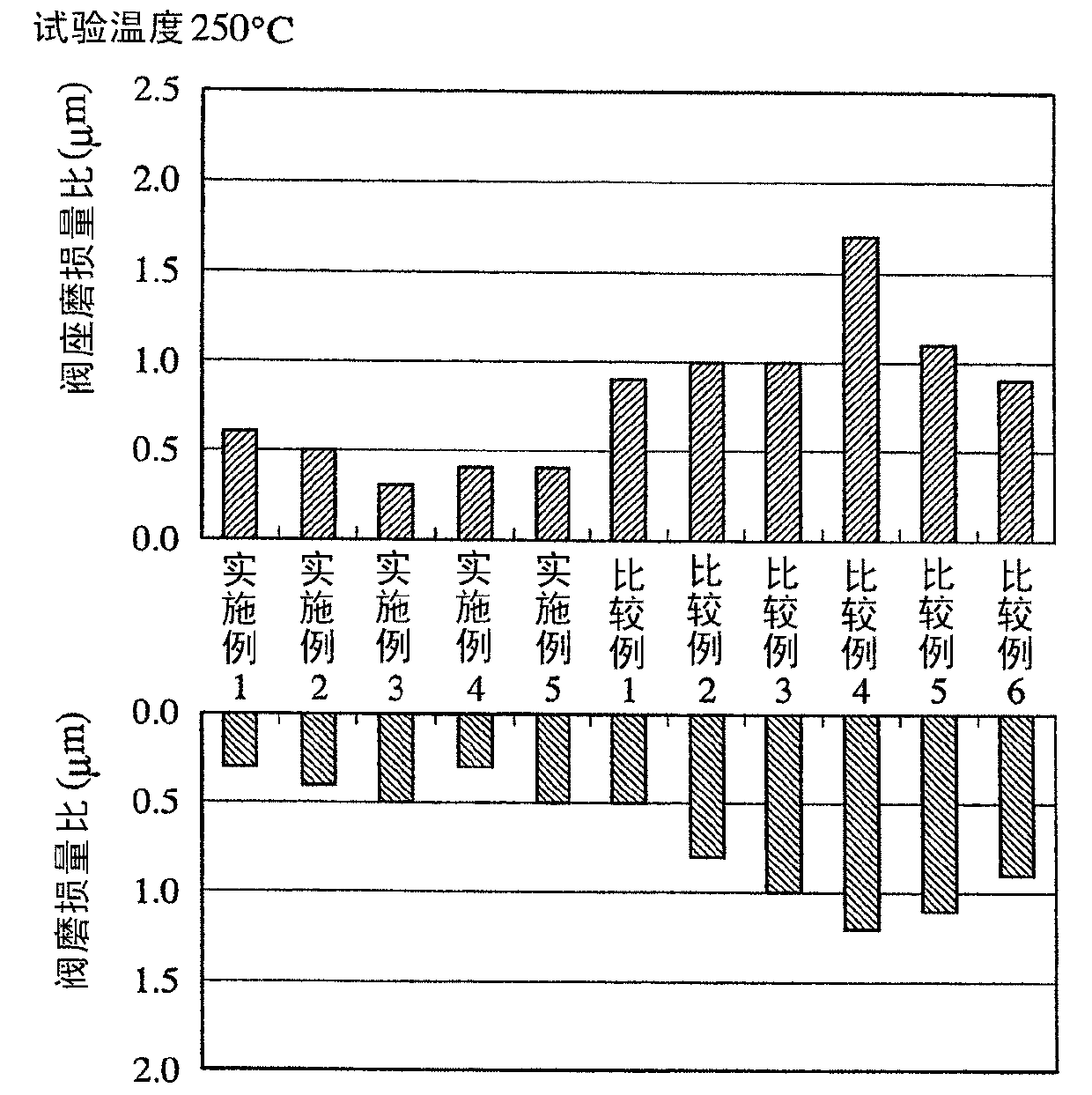

Iron-based sintered alloy valve seat

InactiveCN103328776AHigh strengthImprove the lubrication effectMachines/enginesLift valveWear resistantHigh intensity

The purpose of the present invention is to provide an iron-based sintered alloy valve seat that can be used in a DI-type internal combustion engine adapted for enhanced fuel economy, lower emissions, and higher output, the seat being highly wear-resistant across a wide temperature range. To achieve this purpose, the added amount of a solid lubricant dispersed in a base material for the iron-based sintered alloy valve seat is limited, and at least two types of hard particles of different hardness levels are dispersed in the base material, whereby high strength and self-lubricating properties are simultaneously obtained, and wear resistance is improved across a wide temperature range, even under no lubrication.

Owner:RIKEN CO LTD

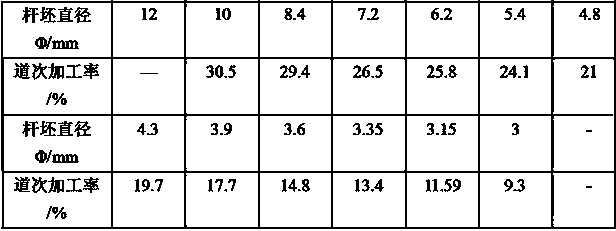

A kind of short-process preparation method of high-strength and high-conductivity cu-cr-ag alloy

ActiveCN108277378BThe degree of recrystallization is controllableComposition is stableStrength of materialsSolid solution strengthening

The invention provides a non-solid-solution treatment short-process preparing method for a high-performance Cu-Cr-Ag alloy. A Cu-Cr-Ag alloy rod billet is prepared and obtained through up-drawing continuous casting, and the up-drawing temperature is 1200-1250 DEG C; multi-pass drawing is conducted; aging is conducted; and final drawing is conducted. The supersaturated solute atomic concentration is obtained through the fast-cooling process of up-drawing continuous casting, solid solution treatment is not conducted, solute atoms are promoted to precipitate directly through matching of subsequent drawing and the aging technology, the recrystallization degree is controlled synchronously to retain a certain machining hardening effect, and through strengthening mechanisms of solid-solution strengthening, aging precipitation phase strengthening and cold work hardening, and the purpose of preparing the high-strength and high-conduction softening-resisting Cu-Cr-Ag alloy can be achieved without solid solution treatment. The tensile strength of materials can reach 500-755 MPa, the conductivity is 70-85% IACS, the elongation is 1-14%, and the softening temperature can reach 550-600 DEG C. The short-process preparing method has the characteristics of the short process, high efficiency and low energy consumption, and the prepared Cu-Cr-Ag alloy can meet the practical application demand ofthe fields such as semiconductors and rail traffic.

Owner:JIANGXI UNIV OF SCI & TECH

Microalloy copper foil and machining method thereof

The invention relates to a microalloy copper foil and a machining method thereof. The copper foil is Cu-Fe-Sn-P, and comprises, by weight, 0.010%-0.015% of Fe, 0.0080%-0.015% of Sn, 0.0035%-0.0085% of P and the balance Cu. According to the machining method of the microalloy copper foil, a horizontal continuous casting process is mainly adopted, then four times of cold rolling are conducted, and an annealing procedure is carried out between every two times of cold rolling. The microalloy copper foil is thin, the tensile strength and the softening resistance of the microalloy copper foil are improved, the electric conductivity and the hardness are high, the Fe alloying machining method is simple, and the microalloy cost is low. A radiator water tank made from the microalloy copper foil has the characteristics of small size, low weight, large radiating area, high radiating efficiency and the like, and the microalloy copper foil has practical application and popularization value.

Owner:HUBEI JINGYI HIGH PRECISION COPPER PLASTICS & STRIPS CO LTD

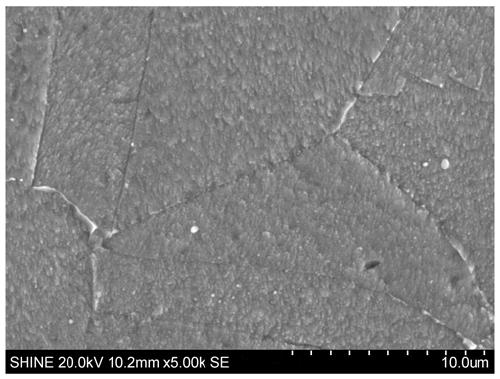

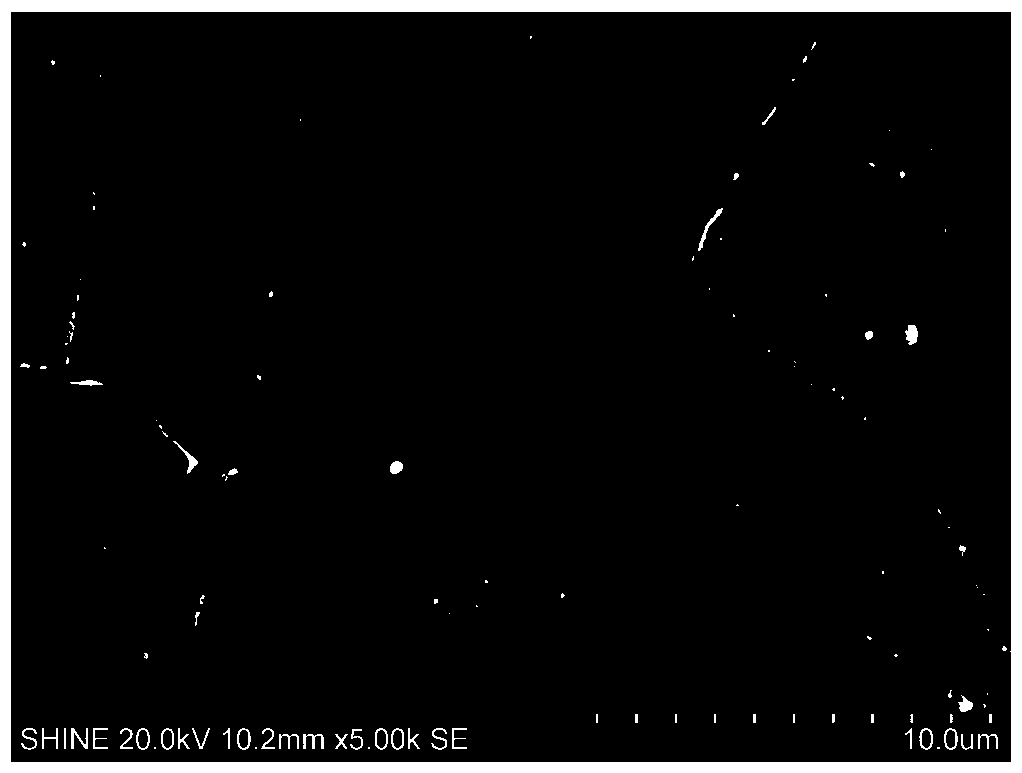

High-chromium-copper alloy material and preparation method thereof

The invention discloses a high-chromium-copper alloy material and a preparation method thereof and belongs to the technical field of metal alloy materials. The high-chromium-copper material alloy comprises, by mass, 20%-50% of Cr, 0.1%-1.0% of CeO2 and the balance Cu and inevitable impurities. The high-chromium-copper alloy material has high strength and high conductivity and meanwhile has high fusion welding resistance and arc erosion resistance. According to the performance indexes of the material, the hardness HV is 155-175, the conductivity is 30%-65% IACS, the softening temperature is 550-575 DEG C, the oxygen content is 450-550 ppm, the fusion welding force is smaller than or equal to 1.7*10-2 MPa under the direct-current load experiment conditions of 40V and 40A, and the contact resistance per unit area is smaller than or equal to 38.2 omega / m<2>. The requirements for high strength, fusion welding resistance and electric erosion resistance of a contact material in the vacuum switching industry can be met. Besides, the preparation process is simple, production efficiency is high, and cost is low.

Owner:HENAN UNIV OF SCI & TECH

Slot wedge material for steam turbine generator rotor and machining technology of slot wedge material

The invention discloses a slot wedge material for a steam turbine generator rotor and its processing technology. The copper alloy is composed of copper, nickel, silicon, chromium, zirconium, silver, magnesium, niobium, etc., and is vacuum smelted → water-sealed extrusion → Cold deformation→aging→solution quenching→second cold deformation→cryogenic treatment→second aging and other processing processes; the technical solution provided by the invention, the obtained material has excellent performance and fully meets the use requirements of the turbine generator rotor .

Owner:徐高杰

Mixed polymerization additive for lead storage battery and preparation method of mixed polymerization additive

InactiveCN107579286AImprove electrochemical performanceImprove softening resistanceLead-acid accumulatorsPolymer scienceSilicon rubber

The invention provides a mixed polymerization additive for a lead storage battery and a preparation method of the mixed polymerization additive. Based on 100 volume parts, the mixed polymerization additive is prepared from the following components: 1 to 7 volume parts of organic siloxane of which a main-chain framework is of a (-C-Si-O) structure and the side group contains one or more unsaturatedhydrophilic active groups, 1 to 7 volume parts of organic silicon rubber, 70.5 to 95.95 volume parts of industrial pure water, 2 to 15 volume parts of fumed silica and 0.05 to 0.5 volume part of an emulsifier. The mixed polymerization additive is prepared according to the technique disclosed by the invention; mixed conventional sulfuric acid is added into the lead storage battery, so that the anti-softening capacity of a positive electrode active substance can be improved; the mixed polymerization additive has the effect of promoting re-hardening of the softened positive electrode active substance, and has the advantages of small adding amount and high cost-performance ratio.

Owner:东莞恒量新能源科技有限公司 +1

Mixed polymeric additive used for lead storage battery electrolyte and preparation method of additive

InactiveCN107611489AImprove electrochemical performanceImprove softening resistanceLead-acid accumulatorsSilicon rubberFumed silica

The invention provides a mixed polymeric additive of a lead storage battery electrolyte and a preparation method of the additive. The mixed polymeric additive comprises the following components and contents based on 100 parts of volume: 1-7 parts of organic siloxane which takes a (-C-Si-O-)-structured main chain framework and comprises more than one kind of unsaturated hydrophilic active group inthe side base, 1-7 parts of organic silicon rubber, 68.5-95.75 parts of industrial pure water, 2-15 parts of fumed silica, 0.2-2 parts of lauryl sodium sulfate and 0.05-0.5 parts of emulsifier; the mixed polymeric additive is prepared by the technological method disclosed in the invention; and a mixed conventional sulfuric acid solution is added to the lead storage battery, so that the softening resistance of the positive electrode active material can be reinforced, and an effect of assisting the softened positive electrode active material to be re-hardened can be realized, and the advantagesof low addition amount and high cost performance can be achieved.

Owner:东莞恒量新能源科技有限公司 +1

Copper alloy band used on auto radiator

InactiveCN103421982ASolve conductivity problemsSolve temperature problemsMachines/enginesStationary conduit assembliesIndiumPerformance index

The invention relates to a copper alloy band used on an auto radiator. The copper alloy band comprises the following chemical constituents by weight: more than or equal to 99.7% of copper, 0.05 to 0.20% of tin; 0.005 to 0.05% of antimony, 0.005 to 0.05% of indium; o to 0.0005% of oxygen, wherein the total content of copper, tin, antimony and indium is more than or equal to 99.99%; the total content of other impurities is smaller than 0.01%. The copper alloy band has the advantages that the components are reasonably optimized, the performance index is excellent, the electrical conductivity is larger than 85% IACS, the anti-softening temperature is higher than 390 DEG C, the tensile strength is 380-450 MPa, and the Vickers hardness is larger than 120. Therefore, the copper alloy band can completely meet the performance indexes required by the auto radiator.

Owner:徐高磊

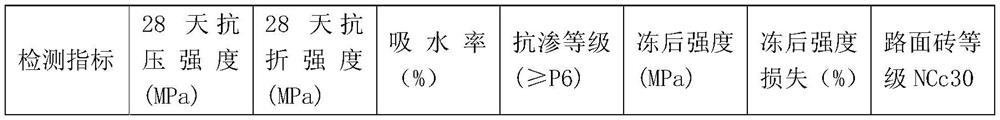

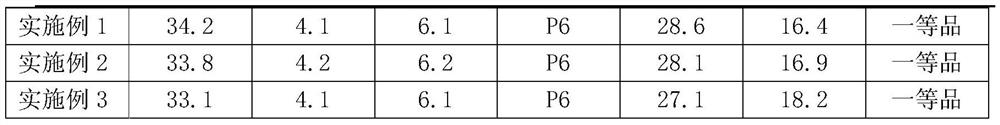

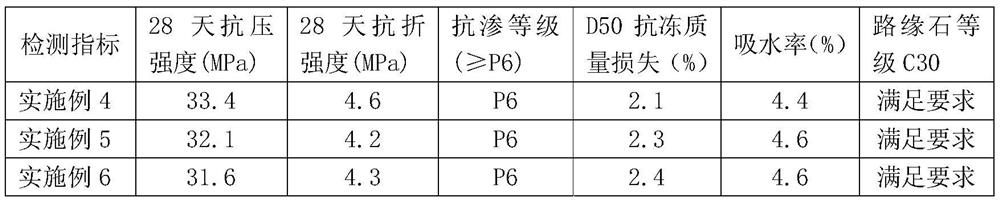

High-temperature anhydrous gypsum pavement brick and kerb and preparation method thereof

The invention discloses a high-temperature anhydrous gypsum pavement brick and kerb and a preparation method thereof, belongs to the technical field of road engineering, and aims to break through theshackle that gypsum products cannot be applied in an outdoor humid environment so as to increase the consumption way of industrial byproduct gypsum. Positive protection and absorption promotion effects can be achieved on natural environment protection, natural resource and hazardous waste recycling, civil cost reduction and the like. The high-temperature anhydrous gypsum pavement brick and kerb, provided by the invention, comprise high-temperature anhydrous gypsum, an admixture, an initiator, water, fibers and an additive. The preparation method of the high-temperature anhydrous gypsum pavement brick and kerb comprises the following steps: uniformly stirring the high-temperature gypsum, the admixture and the fibers at a low speed, adding the water, the additive and the initiator solution for high-speed stirring, finally pouring, molding, demolding and laminating for moisturizing maintenance, and finally obtaining the pavement brick and kerb made of the high-temperature anhydrous gypsummaterial with various indexes such as durability, strength, water resistance, wear resistance, softening resistance and the like reaching the national standard.

Owner:四川涅钰绿色新材料科技有限公司

A preparation process of copper strip for frame material

Provided is a preparation process of a copper strip for a framework material. The preparation process comprises the technological steps of proportioning, smelting, casting, saw cutting, hot rolling, face milling, finished product milling, edge shearing, finished product annealing, washing, finished product shearing and packaging and putting into a storage. Compared with a special-shaped framework material manufactured by an original process, the copper strip produced by the preparation process has the remarkable advantages of high strength, good electrical conductivity, good subsequent machining performance and the like, chemical components of the material are stable, the surface is clean, smooth, free of oxidation discoloration, and free of defects like peeling, burrs, bubbles, cracks, layering, inclusion, holes, black points, folding, verdigris, scratching and corrosion, the copper strip can adapt to the more severe use environment, and the service life of a profiled bar is prolonged.

Owner:中铝洛阳铜加工有限公司

Crucible for pulling monocrystalline silicon and preparation method therefor

InactiveCN105297132AHigh strengthSmall coefficient of thermal expansionBy pulling from meltElectric arcMonocrystalline silicon

The invention relates to a crucible for pulling monocrystalline silicon and a preparation method therefor. The crucible consists of a C / SiC crucible blank and various coatings, wherein the C / SiC crucible blank is prepared by manufacturing a green body by methods such as an SMC and then carrying out heat treatment; and the various coatings are prepared by an electric arc method. The crucible prepared by the method is comprehensively better than a quartz crucible prepared by the electric arc method.

Owner:罗万前

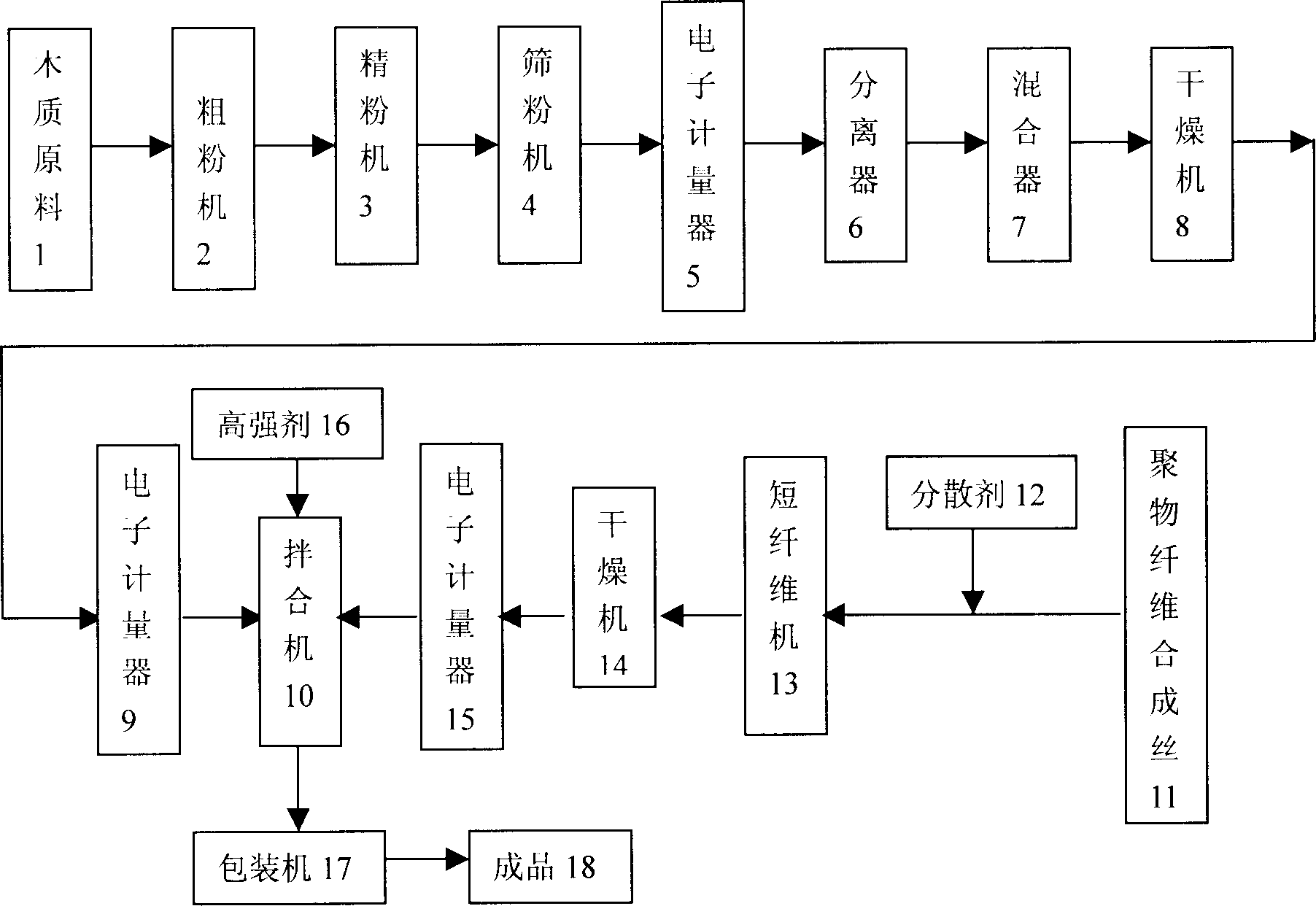

Composite fiber and preparation method thereof

ActiveCN1908256AImprove high temperature resistanceImprove softening resistanceFilament/thread formingFiberCellulose

The invention relates to a composite fiber formed by wooden cellulose and polymer composite fiber, wherein the pH value of wooden cellulose is 7.5+-1.0, while its length is less than 6mm, the oil adsorption is higher than 5 times of itself weight, the ash component is (18+-50%, and the air screen penetration is (70+-10%); the polymer composite fiber has 6+-1.5mm length and 0.01-0.025mm diameter, while its anti-tension strength is higher than 500MPa, the breakage extension rate is higher than 15%, and its volume will not change when being heated from 2 hours at 210Deg. C. The production of said composite fiber comprises: breaking, screening, separating, mixing, drying and weighting the wooden material; adding disperser into polymer composite fiber to be sheared and dried; then adding strengthener into said raw material to be mixed.

Owner:天成垦特莱赞皇科技有限公司

High-strength waterproof composite light partition board and preparation method thereof

The invention discloses a high-strength waterproof composite light partition board. The high-strength waterproof composite light partition board comprises the following materials by weight: 95-70 Kg of high-temperature gypsum, 5-30 Kg of a modified material, 1-2 Kg of a water reducing agent, 30-40 Kg of water, 0.1-0.3 Kg of fibers and 0.1-0.3 Kg of a retarder. The high-temperature gypsum is anhydrous gypsum prepared by heating dihydrate gypsum at high temperature to lose water; the modified material comprises cement, ground slag powder, silicon powder and ground steel slag; the water reducing agent is a water reducing agent for concrete; the fibers comprise artificial fibers and natural fibers; the retarder comprises citric acid, borax and melamine; and the water meets the standard requirements of concrete mixing water. With the high-strength waterproof composite light partition board and the preparation method thereof of the invention adopted, the defects of low strength, poor water resistance, small single nail hanging force and poor single nail bond stress of gypsum composite light partition boards can be solved; the consumption ways of industrial byproduct gypsum are increased. The high-strength waterproof composite light partition board and the preparation method play a positive role in protecting the natural environment, natural resources, recycling hazardous wastes, reducing the livelihood cost and the like and promoting absorption.

Owner:四川涅钰绿色新材料科技有限公司

Semitransparent straw paper for manufacturing semitransparent straws, and preparation method thereof

InactiveCN109653023AImprove softening resistanceHigh transparencyNatural cellulose pulp/paperWater-repelling agents additionUV curingPlastic materials

The invention discloses a semitransparent straw paper for manufacturing semitransparent straws, and a preparation method thereof. The straw paper comprises a base paper and an oil-proof coating, the base paper is a semitransparent base paper or a transparent base paper, and the surface of the base paper is glued or is coated with composite resin having a solid content of 0.1-25%, and then undergoes drying and UV curing to obtain the semitransparent straw paper. The semitransparent straw paper has good transparency and changes the current state that semitransparent straws can only be made of plastic materials. The surface of the straw paper is coated with the UV resin to form a good UV resin layer on the surface of the base paper, and the UV resin layer seals gaps in the surface of the basepaper, and has a good anti-penetration effect on water and other liquids, so the liquid penetration resistance of the straw paper is improved; and the UV resin applied to the surface can greatly improve the stiffness and hardness of the paper, so the strength of the paper straws in the liquids is increased, and the softening resistance of the straws is improved.

Owner:MINFENG SPECIAL PAPER

A kind of highly conductive copper-silver-tin-chromium alloy plate strip and its preparation and processing method

The invention relates to a high-conductivity copper sliver tin chrome alloy plate strip and a preparation and processing method thereof, and belongs to the field of nonferrous metal processing. The high-conductivity copper sliver tin chrome alloy plate strip comprises, by weight, 0.02-0.03% of Ag, 0.005-0.01% of Sn, 0.005-0.01% of Cr, 0.002-0.005% of Zn, 0.0005-0.001% of B, and the balance Cu. Thehigh-conductivity cooper sliver tin chrome alloy plate strip is obtained through the processing technologies of melting, casting, hot rolling, milling, blooming, intermediate annealing, pickling, intermediate rolling, on-line solid solution, finish rolling, on-line aging, stretch bending correction and the like. According to the copper sliver tin chrome alloy plate strip, the tensile strength ofthe copper alloy is 390-470 MPa, the Vickers hardness is 115-150 HV, the elongation rate is 6-11%, the conductivity is greater than or equal to 96.8% IACS, the softening temperature is greater than orequal to 360 DEG C, the corrosion resistance rate is 0.062-0.096 g.m<-2>.h<-1>, and the corrosive medium is artificial sea water.

Owner:NINGBO XINGYE SHENGTAI GROUP

High chromium copper alloy material and preparation method thereof

The invention discloses a high-chromium copper alloy material and a preparation method thereof, belonging to the technical field of metal alloy materials. The high chromium copper alloy material is composed of the following components in mass percentage: 20-50% of Cr, 20.1-1.0% of CeO, and the balance is Cu and unavoidable impurities. The high-chromium copper alloy material in the present invention has high strength and high electrical conductivity, and also has relatively high welding resistance and arc corrosion resistance. Its performance indicators are: hardness HV155-175, electrical conductivity 30-65% IACS, softening Temperature 550~575℃, oxygen content 450~550ppm, welding force ≤1.7×10-2MPa under 40V and 40A DC load experimental conditions, contact resistance per unit area ≤38.2Ω / m2, which can meet the requirements of the vacuum switch industry for contact materials High-strength anti-welding and electric corrosion resistance requirements, and the preparation process is simple, high production efficiency, low cost.

Owner:HENAN UNIV OF SCI & TECH

A low-carbon high-chromium wear-resistant ball and its preparation process

ActiveCN106319336BReduce contentImprove wear resistanceFurnace typesHeat treatment furnacesNiobiumManganese

Owner:安徽中建材开源新材料科技有限公司

High-strength cementing agent suitable for marine sludge and preparation method of high-strength cementing agent

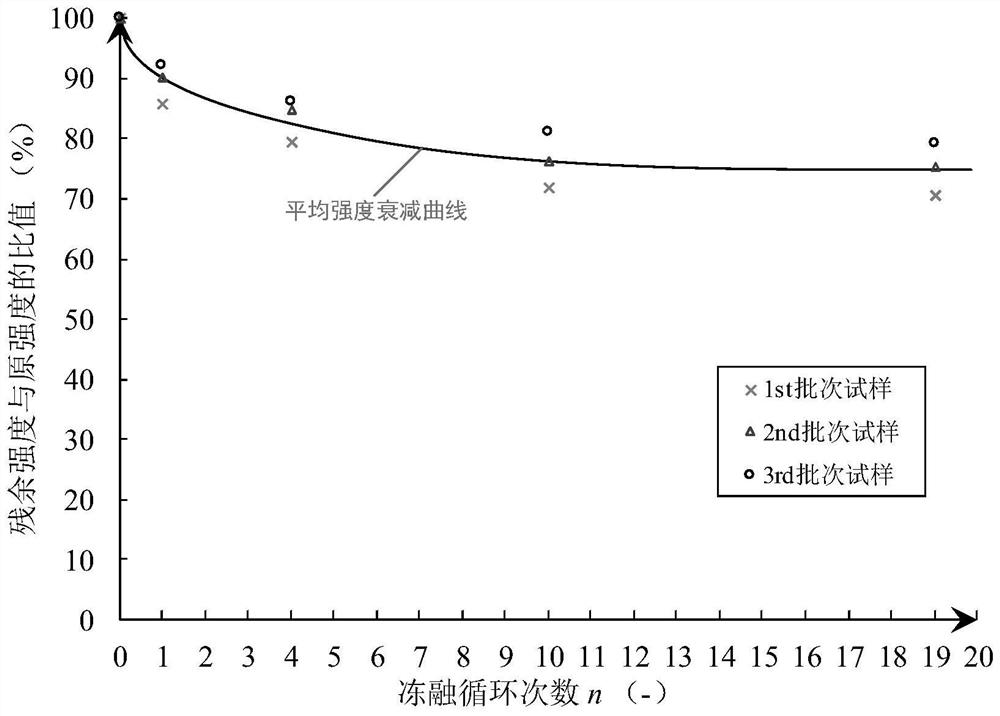

The invention relates to a high-strength cementing agent suitable for marine sludge and a preparation method thereof, the cementing agent is composed of a curing agent and an exciting agent, the curing agent comprises clinker, blast furnace slag powder, fly ash and gypsum, and based on the mass of the clinker, the addition amount of the other raw materials is as follows: 10-40% of blast furnace slag powder, 5-35% of fly ash and 4-16% of gypsum; and the adding amount of the exciting agent is 0.5-4.5% of the mass of the curing agent, the main material of the exciting agent is calcium silicate, and the content of the calcium silicate is greater than or equal to 98%. The preparation method comprises the following steps: mixing the clinker, blast furnace slag powder, fly ash and gypsum in proportion to obtain a curing agent mixture, and grinding the curing agent mixture through a ball mill to obtain curing agent powder; and adding the exciting agent into the curing agent powder, and uniformly stirring to obtain the cementing agent. The strength of the solidified sludge can be enhanced, high freezing resistance and softening resistance are achieved, the preparation method is easy and convenient to operate, and production is easy.

Owner:CCCC TIANJIN DREDGING

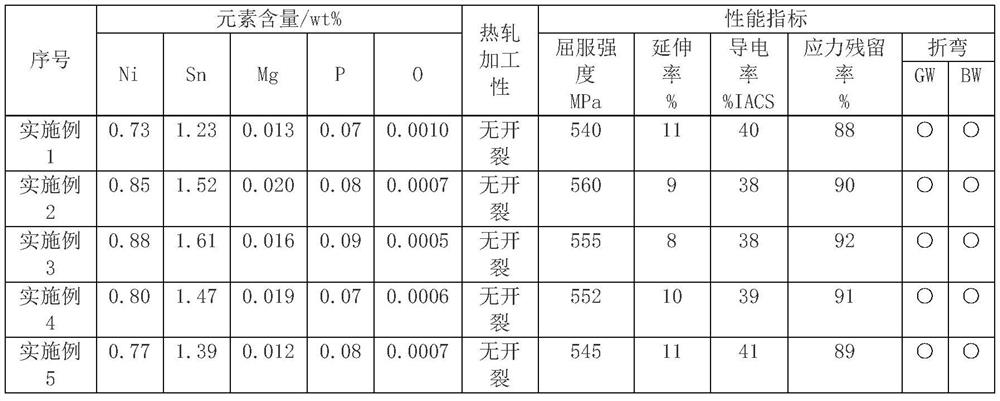

Copper alloy with excellent hot rolling performance and manufacturing method thereof

InactiveCN113981265AReduce performanceGuaranteed performanceConductive materialProcess efficiency improvementIngotHot working

The invention discloses a copper alloy with excellent hot rolling performance and a manufacturing method thereof, the copper alloy comprises the following components in percentage by weight: 0.6-1.0 wt% of Ni, 1.0-2.0 wt% of Sn, 0.01-0.03 wt% of Mg, 0.06-0.10 wt% of P, less than or equal to 0.0010 wt% of O, and the balance of Cu, and inevitable impurity alloy, oxygen-free copper is used as a matrix, the oxygen content is controlled to be less than or equal to 0.0010 wt%, the trace element Mg is added, the alloy has excellent hot workability, in the process of melting casting and hot rolling, the ingot has no cracking phenomenon and has excellent hot workability, the yield strength Rp of the alloy is larger than or equal to 520 Mpa, the ductility A11.3 is larger than or equal to 6%, the electric conductivity is larger than or equal to 38% IACS, the bending machining performance (GW and BW directions) R / t is smaller than or equal to 1, the stress residual rate is larger than or equal to 85% after heat preservation is conducted for 1000 hours at the temperature of 150 DEG C, and a plate strip processed by the alloy is widely applied to connectors, terminals or switch parts of electrical, automobile and communication devices and the like.

Owner:TONGLING NON FERROUS METAL GROUP CORP

A kind of special curing agent for curing gold mine tailings mud and application method

The invention relates to a special curing agent for curing gold mine tailings mud. The raw materials include 3%-7% of calcium silicate, 5%-8% of limestone, 10%-15% of gypsum and 0-1% of silicon oxide according to the mass ratio. , alumina 0-2%, coking desulfurization and denitrification ash 5%-10%, slag powder 57%-77%. The application method of the special solidifying agent for solidifying gold mine tailings mud is to mix the special solidifying agent and the gold mine tailing mud according to the ratio of 1:8-10 and then solidify. The curing agent component undergoes a series of inorganic macromolecular chemical reactions with mineral alkali metal ions, alkaline earth metal ions and water to form a large number of crystalline hydrates with plastic strength, bonding strength and great chemical inertness, slight expansion, and significant drainage. The colloid component acts as the cement of the particles and the pore filler, thereby greatly improving the structural strength of the mud drainage sediment. The gold mine tailings slurry using special curing agent can be backfilled or solidified by dry heap, and the 28-day compressive strength can reach more than 1.7MPa.

Owner:鞍钢绿色资源科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com