Composite fiber and preparation method thereof

A composite fiber and production method technology, which is applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of oil absorption characteristics, poor crack resistance and anti-aging performance, and improve low temperature crack resistance. Economical Considerable benefits and significant investment benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The composition of the composite fiber is lignocellulose and polymer fiber synthetic silk, and the weight ratios thereof are 67%-77% and 23%-33%, preferably 72% and 28%.

[0015] The lignocellulose has a pH value of 7.5 ± 1.0, a length of less than 6mm, an oil absorption rate greater than 5 times its own weight, an ash content of (18 ± 5)%, and a 0.150mm air sieve passing rate of (70 ± 10)%. The original wood fiber, or other wood fiber of the same standard; the polymer fiber synthetic filament is a kind of long 6 ± 1.5mm, diameter 0.01 ~ 0.025mm, tensile strength ≥ 500Mpa, elongation at break ≥ 15%, Heat-resistant 210°C polymer staple fiber with no change in volume for 2 hours.

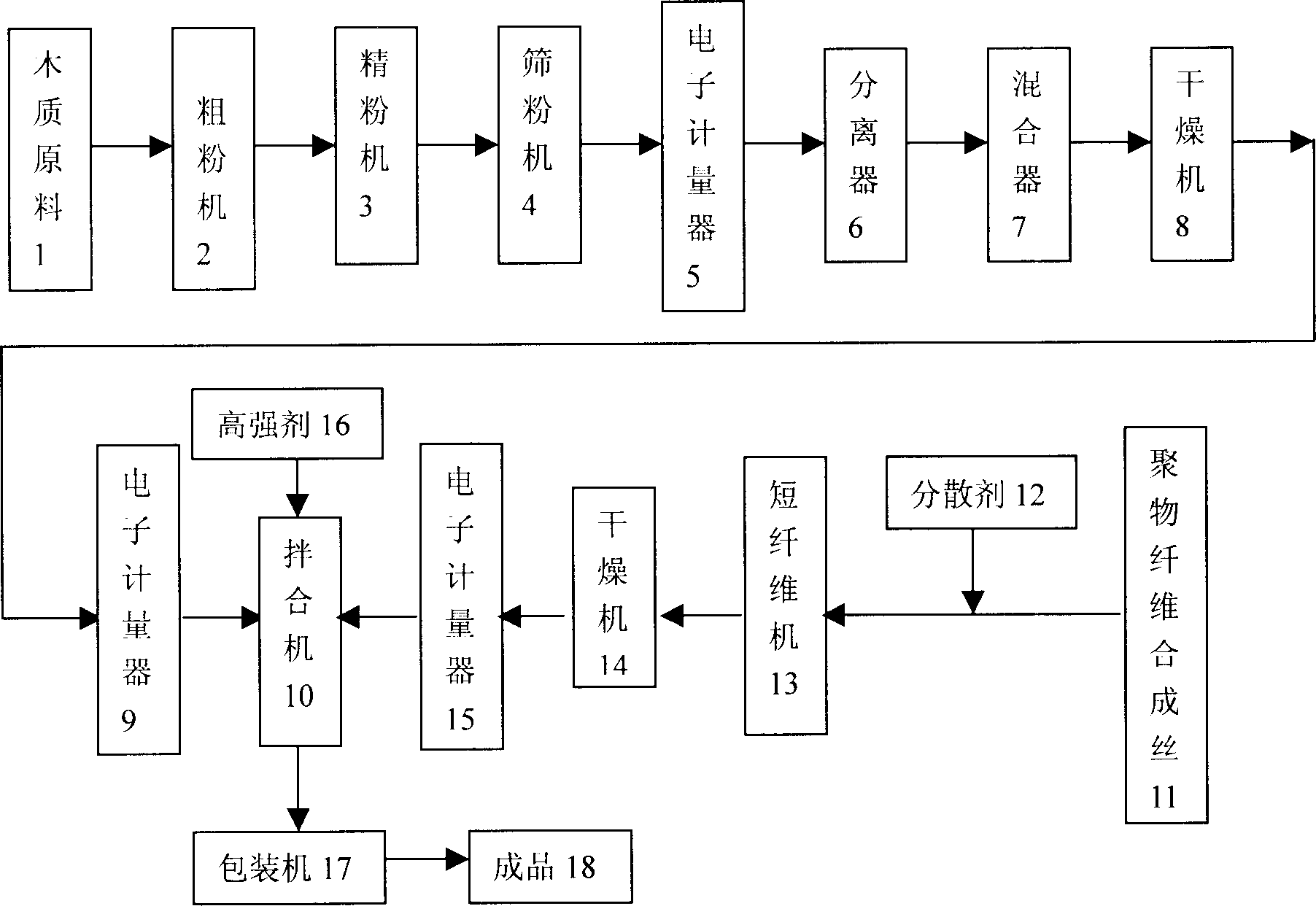

[0016] see figure 1 , the production method of the composite fiber of the present invention comprises the following process steps: the wooden raw material 1 is coarsely pulverized through the coarse pulverizer 2 [the degree of pulverization is: air-sieve 0.15mm sieve passing rate (55 ± 10)%], ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com