A kind of highly conductive copper-silver-tin-chromium alloy plate strip and its preparation and processing method

A processing method and high-conductivity technology, applied in the field of copper-silver-tin-chromium alloy sheets and strips and their preparation and processing, can solve the problems of low strength, affecting the service life of the motor, poor softening resistance, etc., to improve the electrical conductivity and increase the heat dissipation. The effect, the performance is uniform and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

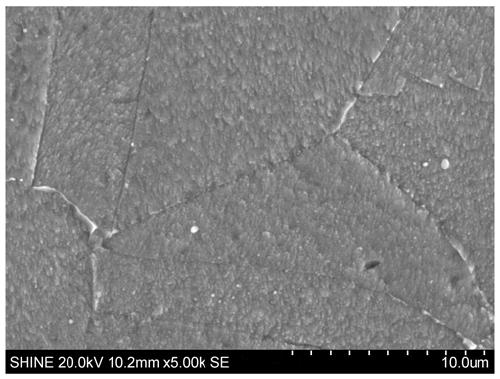

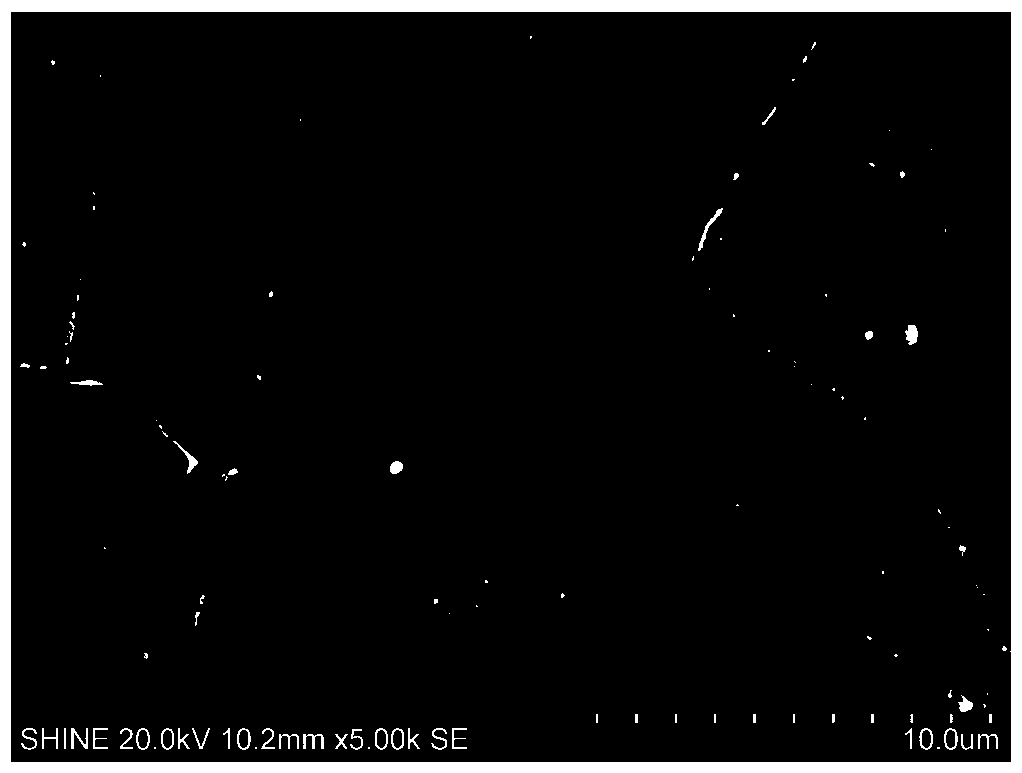

Image

Examples

Embodiment 1

[0029] The composition of the alloy is shown in Example 1 of Table 1.

[0030] 1. Melting: use non-vacuum induction furnace for melting. First add copper (Cu), after melting, then add pure silver (Ag), pure tin (Sn), pure zinc (Zn) at low temperature, and then add copper-chromium alloy (Cu-Cr), copper-boron alloy (Cu -B), then covered with calcined charcoal, the thickness of the covering layer was 30cm, and degassed with argon for 30min. The melting temperature is 1160°C, and the casting temperature is controlled at 1140°C.

[0031] 2 Hot-rolling: The hot-rolled slab is rolled out at a temperature of 905±10°C, rolled for 9 passes, and the total hot-rolled deformation is 90%.

[0032] 3. Face milling: face milling of the alloy (0.60mm milling on the upper and lower surfaces).

[0033] 4. Preliminary rolling: the alloy strip after face milling is subjected to 85% deformation treatment.

[0034] 5. Intermediate annealing: put the cold-rolled strip into a bell-type heat treatm...

Embodiment 2

[0042] The composition of the alloy is shown in Example 2 of Table 1.

[0043] 1. Melting: use non-vacuum induction furnace for melting. First add copper (Cu), after melting, then add pure silver (Ag), pure tin (Sn), pure zinc (Zn) at low temperature, and then add copper-chromium alloy (Cu-Cr), copper-boron alloy (Cu -B), then covered with calcined charcoal, the thickness of the covering layer was 30cm, and degassed with argon for 30min. The melting temperature is 1150°C, and the casting temperature is controlled at 1140°C.

[0044] 2 Hot rolling: the temperature of hot rolling of cast slab is 921±10°C, 9 passes of rolling, and the total deformation of hot rolling is 91%.

[0045] 3. Face milling: face milling of the alloy (0.60mm milling on the upper and lower surfaces).

[0046] 4. Preliminary rolling: the alloy strip after face milling is subjected to 78% deformation treatment.

[0047] 5. Intermediate annealing: put the cold-rolled strip into a bell-type heat treatment...

Embodiment 3

[0055] The composition of the alloy is shown in Example 3 of Table 1.

[0056] 1. Melting: use non-vacuum induction furnace for melting. First add copper (Cu), after melting, then add pure silver (Ag), pure tin (Sn), pure zinc (Zn) at low temperature, and then add copper-chromium alloy (Cu-Cr), copper-boron alloy (Cu -B), then covered with calcined charcoal, the thickness of the covering layer was 30cm, and degassed with argon for 30min. The melting temperature is 1170°C, and the casting temperature is controlled at 1150°C.

[0057] 2. Hot rolling: the temperature of casting slab hot rolling is 895±10℃, 9 passes of rolling, and the total deformation of hot rolling is 90%.

[0058] 3. Face milling: face milling of the alloy (0.60mm milling on the upper and lower surfaces).

[0059] 4. Preliminary rolling: 80% deformation treatment is carried out on the alloy strip after face milling.

[0060] 5. Intermediate annealing: put the cold-rolled strip into a bell-type heat treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com