Graphene electroconductive macromolecular composite material and preparation method thereof, and electrothermal film obtained by graphene electroconductive macromolecular composite material

A conductive polymer and composite material technology, applied in the field of graphene, can solve the problems of long-term high-power ultrasound, low concentration of graphene, cumbersome preparation methods, etc., and achieve the effect of good strength, simple equipment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

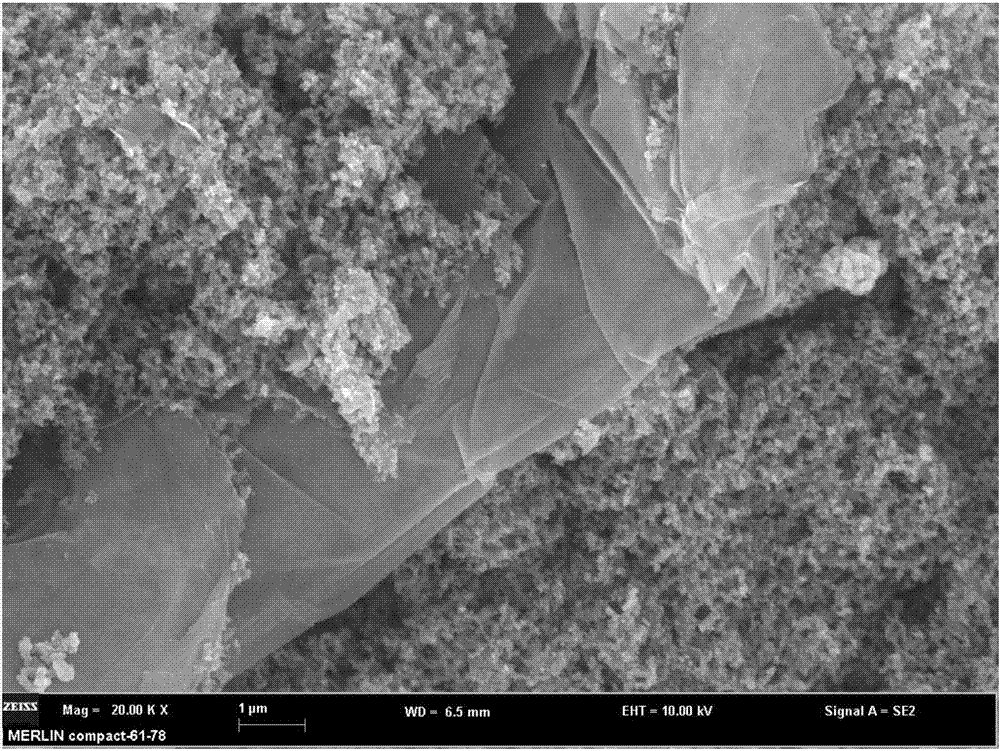

Image

Examples

preparation example Construction

[0042] Another aspect of the embodiments of the present invention provides a method for preparing a graphene conductive polymer composite material as described in any one of the above embodiments, comprising the following steps:

[0043] Dispersing the graphene prepared by the physical method in an aqueous solution, adding a water-based dispersant, and fully stirring to obtain a viscous slurry;

[0044] Adding a conductive polymer water-based dispersion to the viscous slurry, adding resin and / or resin and initiator under ultrasonic or stirring conditions, and fully stirring to obtain a stable slurry;

[0045] Adding carbon black, carbon nanotubes and graphite to the stable slurry, fully stirring to obtain a conductive slurry;

[0046] Adding a stabilizer, an infrared radiation agent, a defoamer, a leveling agent and a surfactant to the conductive paste, fully stirring, to obtain a graphene conductive polymer paste;

[0047] The graphene conductive polymer slurry is physically...

Embodiment 1

[0054] In 100 parts of viscous slurry (graphene solid content 5%) prepared by high-speed shearing method, add 0.5 part of polyvinylpyrrolidone dispersant, fully stir 10 minutes, form viscous slurry; Add 50 parts of polythiophene (PEDOT : PSS) conductive polymer aqueous dispersion (solid content 10%), under mechanical stirring condition (200RPM, 30 minutes), and add 20 parts of acrylic resins and an amount of initiator; Add 40 parts of carbon black and carbon nanotube mixture ( 1:1), adding an appropriate amount of additives such as stabilizer, defoamer, leveling agent, initiator and surfactant, under mechanical stirring conditions (200RPM, 30 minutes), to obtain graphene conductive polymer slurry. Add the above-mentioned graphene conductive polymer slurry into a sand mill, put in 2000 parts by weight of zirconia grinding balls (1mm: 2mm: 5mm weight ratio is 2:1:1), and grind for 6 hours at 300RPM at normal temperature and pressure , until the graphene conductive polymer slurry...

Embodiment 2

[0056] Put 1 part of graphene powder prepared by wet ball milling into 99 parts of an aqueous solution in which 0.3 part of sodium dodecylbenzenesulfonate has been added, and stir fully for 10 minutes to obtain a uniform black solution; add 30 parts of polypyrrole with high conductivity Molecular aqueous dispersion (solid content 10%), under the condition of high-speed mechanical stirring (500RPM, 30 minutes), add 40 parts of polyurethane resins and appropriate initiator; Then add the mixed powder of 20 parts of conductive carbon black and carbon nanotube ( Weight ratio 2:1), and an appropriate amount of defoamer and leveling agent, continue to stir for 30 minutes to obtain graphene conductive polymer slurry. The above-mentioned graphene conductive polymer slurry is put into the trough of a high-speed shear machine, and sheared and stirred for 2 hours at a speed of more than 3000 RPM to obtain a graphene conductive polymer composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com