Enhancement ablation thermal protection composite material and preparation method thereof

A composite material, heat-proof technology, applied in flat products, other household appliances, textiles, etc., can solve the problems of large ablation, large thermal diffusivity, etc., and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

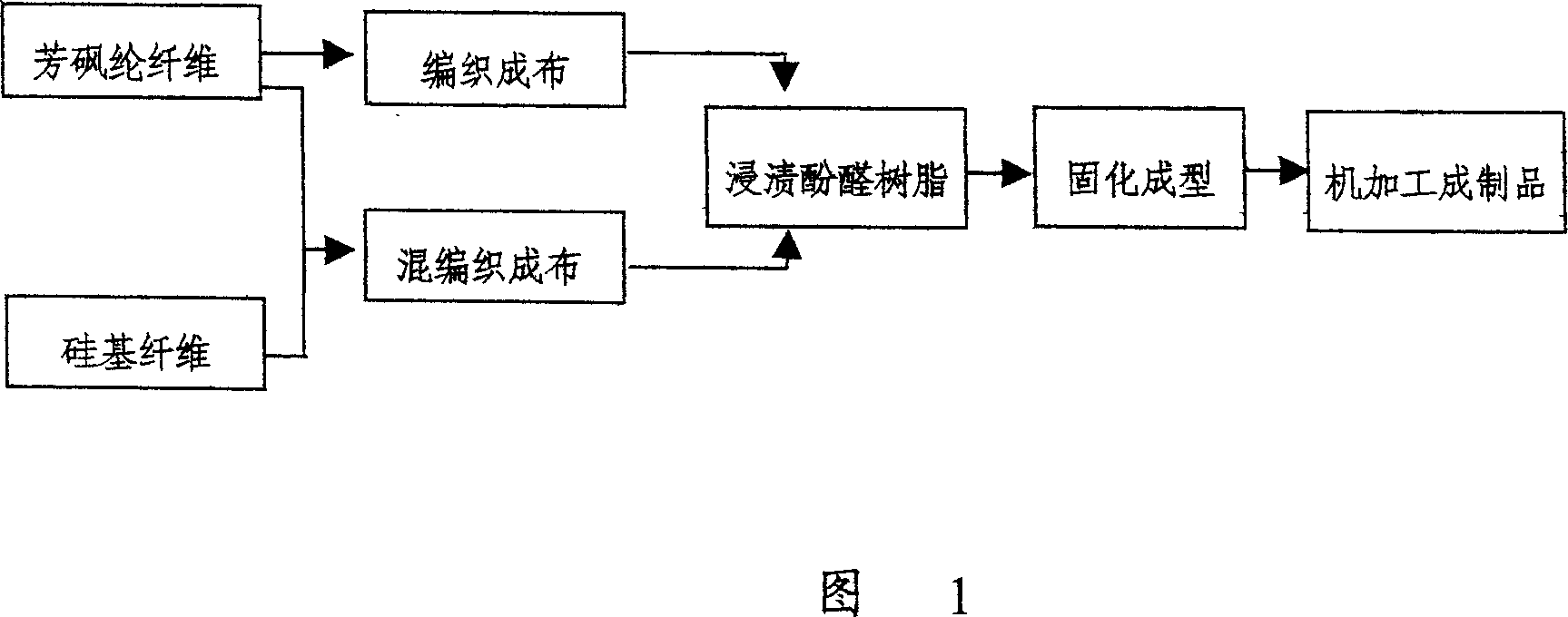

Method used

Image

Examples

Embodiment 1

[0043] Product name: high temperature heat insulation board

[0044] Dimensions: 500×500×10

[0045] The implementation steps are as follows:

[0046] (1) Use pure sulfonamide fiber yarn to weave the fabric, the yarn linear density is 75tex, the twist is 200 twists / m, the fabric structure is plain weave, the cloth thickness is 0.25mm, and the width is 1.0m.

[0047] (2) impregnating the thermosetting barium phenolic resin solution, the resin content of the tape is controlled to be 49±4%, and the volatile matter is controlled to be 4-8%.

[0048] (3) Cut out 40 sheets of 500×500 tape, align the edges of each sheet and stack them together, lay a layer of release cloth on the top and bottom, and put them into a hot press.

[0049] (4) After the contact pressure is applied, the temperature of the press is raised, and the heating rate is controlled at 30°C / h, and the temperature is kept at 95°C for 45 minutes, and then pressurized at 8 MPa, and then the temperature is raised to 1...

Embodiment 2

[0053] Product name: Cylinder heat insulation sleeve

[0054]Dimensions: inner diameter Φ600, thickness 5mm, length 1000mm.

[0055] The implementation steps are as follows:

[0056] (1) Select the mixed fabric of sulfonamide fiber and glass fiber. The linear density of sulfonamide yarn is 75tex, the twist is 200 twist / m; the linear density of glass fiber is 72tex, the twist is 55 twist / m. mm, the width is 1.0m.

[0057] (2) impregnated with thermosetting barium phenolic resin solution, the resin content of the tape is controlled to be 41±4%, and the volatile matter is controlled to be 4-8%. Cut the tape into a 50mm wide tape along the warp direction, and pour it into a disk.

[0058] (3) Use a cloth tape winding machine to wind in parallel on the Φ600 mold tire. Control the winding tension at 10-20kgf, the temperature at 60-130°C, the trolley moves forward 10mm every time the main shaft rotates, and the winding is repeated 5 times.

[0059] (4) Cover the surface of the ...

Embodiment 3

[0063] Product Name: Ablation-proof and heat-insulating taper sleeve

[0064] Dimensions: The inner diameter of the small end is Φ260, the inner diameter of the large end is Φ600, the thickness is 12mm, and the length is 1200mm.

[0065] The implementation steps are as follows:

[0066] (1) Select the mixed fabric of sulfonamide fiber and quartz fiber. The linear density of sulfonamide yarn is 75tex, the twist is 200 twist / m; the linear density of quartz fiber is 85tex, the twist is 50 twist / m. mm, the width is 1.1m.

[0067] (2) Immerse the thermosetting aminophenol-formaldehyde resin solution, the resin content of the tape is controlled to be 45±4%, and the volatile matter is controlled to be 4-8%. Cut the adhesive tape obliquely at 45° to the warp direction into strips with a width of 70 mm, stitch and overlap to form a continuous long adhesive tape, and then pour it into a disk.

[0068] (3) Use a cloth tape winding machine to wind and form the tapered tire obliquely, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com