Application of amorphous alloy to preparation of razor blade and razor

An amorphous alloy, iron-based amorphous alloy technology, applied in metal processing and other directions, can solve the problems of poor strength, hardness, elastic limit corrosion resistance, etc., and achieve the effects of excellent strength, low production cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

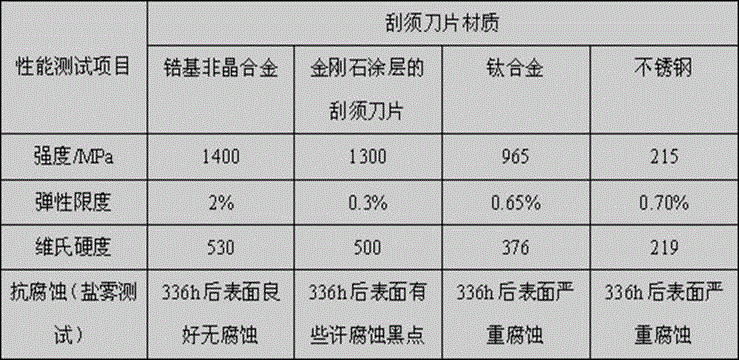

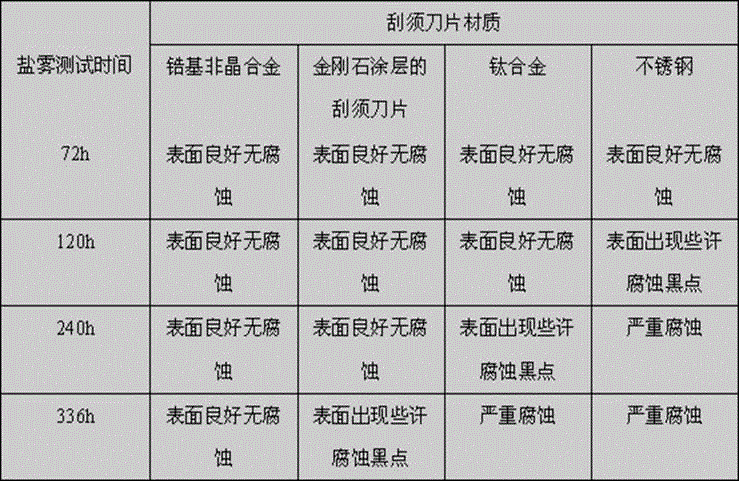

[0033] The application of the amorphous alloy of the present embodiment in the preparation of a scraper blade, specifically, the use of a zirconium-based amorphous alloy to prepare a scraper blade by a vacuum suction casting method, the strength of the prepared scraper blade is 1400 MPa, and the elasticity limit is 2% , Vickers hardness is 530, and the surface of the shaving blade is still good without corrosion after 336 hours of salt spray test. In this embodiment, the thickness of the prepared shaving blade is 1 mm. In this embodiment, the prepared shaving blade is subjected to mirror polishing surface treatment.

[0034] Compared with the blades coated or deposited with coating materials, and the blades directly cast from titanium alloy or stainless steel, the scraper blade prepared in Example 1 has excellent strength, elastic limit, Vickers hardness and corrosion resistance. Moreover, the use of zirconium-based amorphous alloy to prepare the scraper blade has the advantages...

Embodiment 2

[0036] The application of the amorphous alloy of the present embodiment in the preparation of a squeegee blade, specifically, the use of a copper-based amorphous alloy to prepare a squeegee blade by a ribbon spinning method, the strength of the prepared squeegee blade is 1500 MPa, and the elasticity limit is 2.2%, The Vickers hardness is 550. After 380 hours of salt spray test, the surface of the shaving blade is still good without corrosion. In this embodiment, the thickness of the prepared shaving blade is 0.1 mm. In this embodiment, the prepared shaving blade is subjected to mirror polishing surface treatment.

[0037] Compared with the blades coated or deposited with coating materials, and the blades directly cast from titanium alloy or stainless steel, the scraper blade prepared in Example 2 has excellent strength, elastic limit, Vickers hardness and corrosion resistance. Moreover, the use of copper-based amorphous alloy to prepare the scraper blade has the advantages of si...

Embodiment 3

[0039] The application of the amorphous alloy of the present embodiment in the preparation of a squeegee blade, specifically, the use of a nickel-based amorphous alloy to prepare a squeegee blade by a rapid discharge forming method, the strength of the prepared squeegee blade is 1600 MPa, and the elasticity limit is 2.5% , Vickers hardness is 600, after 480 hours of salt spray test, the surface of the shaving blade is still good without corrosion. In this embodiment, the thickness of the prepared shaving blade is 5 mm. In this embodiment, the prepared shaving blade is subjected to mirror polishing surface treatment.

[0040] Compared with the blades coated or deposited with coating materials, as well as the blades directly cast from titanium alloy or stainless steel, the scraper blade prepared in Example 3 has excellent strength, elastic limit, Vickers hardness and corrosion resistance. Moreover, the use of nickel-based amorphous alloy to prepare the scraper blade has the advant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com