Copper alloy with excellent hot rolling performance and manufacturing method thereof

A manufacturing method and copper alloy technology, applied in the field of copper alloy manufacturing, can solve problems such as ingot cracking and hot rolling interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

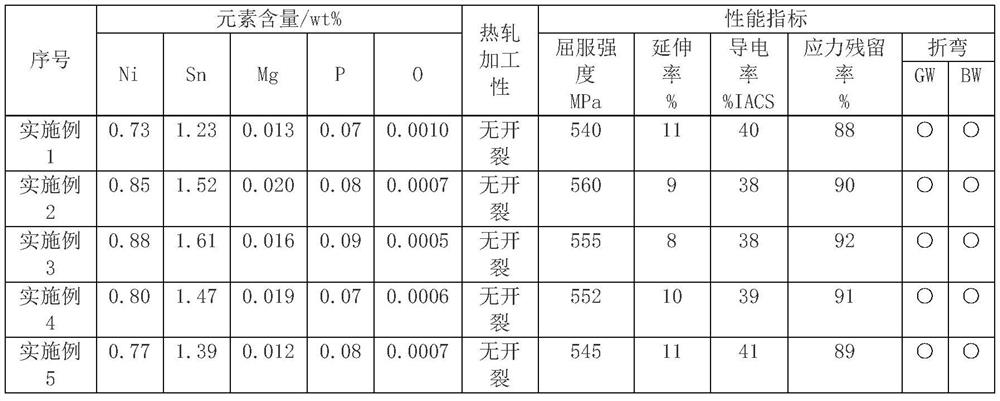

[0055] Embodiment: according to the copper alloy batching shown in each embodiment composition of table 1, adopt semi-continuous casting to carry out melting and casting under 1160 ℃~1220 ℃, the manufacturing specification is the ingot of 230mm*640mm. After the above ingot was kept at 960°C for 5 hours, it was hot rolled to a thickness of 14.5 mm. After milling 0.5mm on the upper and lower surfaces of the billet, the thickness of the strip reaches 13.5mm; after that, the strip is rolled to a thickness of 2mm by a rough rolling mill; then the strip is heated to 480°C, kept for 8 hours for aging treatment, and then rolled to a thickness of 2mm. 0.8mm, heat treatment for 30s in a continuous annealing furnace at a temperature of 600°C, then finish rolling to 0.25mm, and then annealed at a low temperature in a continuous annealing furnace at a temperature of 350°C to obtain a finished strip with a thickness of 0.25mm.

[0056] For the prepared strip samples of the alloys of the fiv...

Embodiment 2

[0062] This embodiment is roughly the same as the method provided in Example 1, the main difference is that the contents of Ni, Sn, Mg, P, O are different, wherein Ni: 0.85wt%, Sn: 1.52wt%, Mg: 0.020wt %, P: 0.08 wt%, O: 0.0007 wt%.

Embodiment 3

[0064] This embodiment is roughly the same as the method provided in Example 1, the main difference is that the contents of Ni, Sn, Mg, P, O are different, Ni: 0.88wt%, Sn: 1.61wt%, Mg: 0.016wt% , P: 0.09 wt%, O: 0.0005 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com