High-strength cementing agent suitable for marine sludge and preparation method of high-strength cementing agent

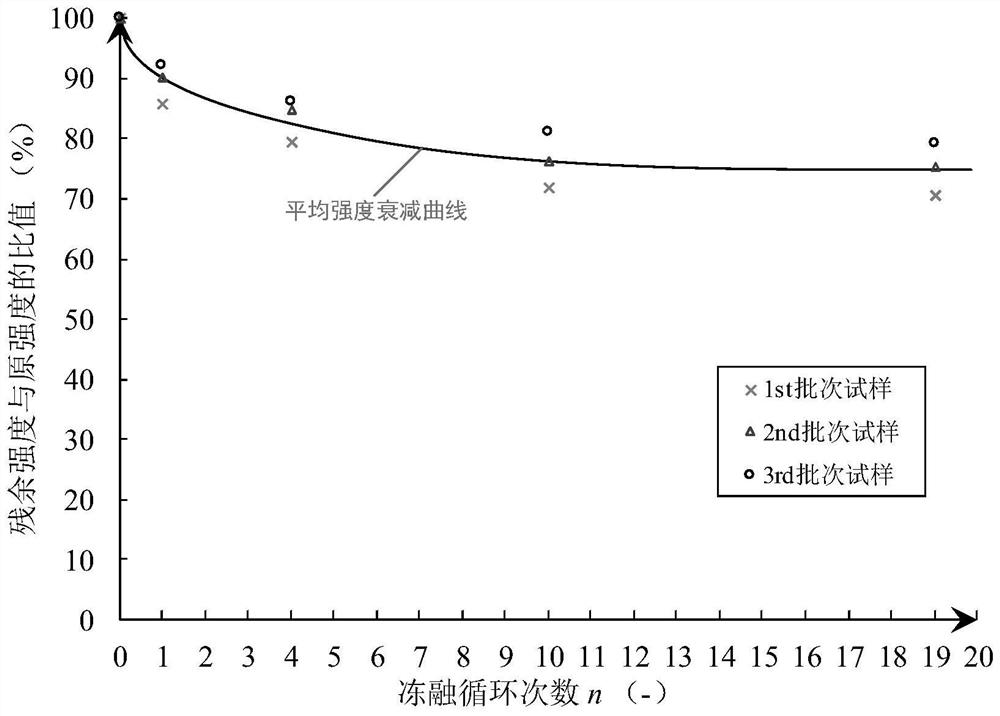

A cementing agent, high-strength technology, applied in the field of dredging product recycling, can solve the problems of low strength, high cost of solidifying marine sludge, weak anti-dispersion and anti-freezing, and achieves easy operation, low production cost, and high anti-freezing. Effects of sex and softening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

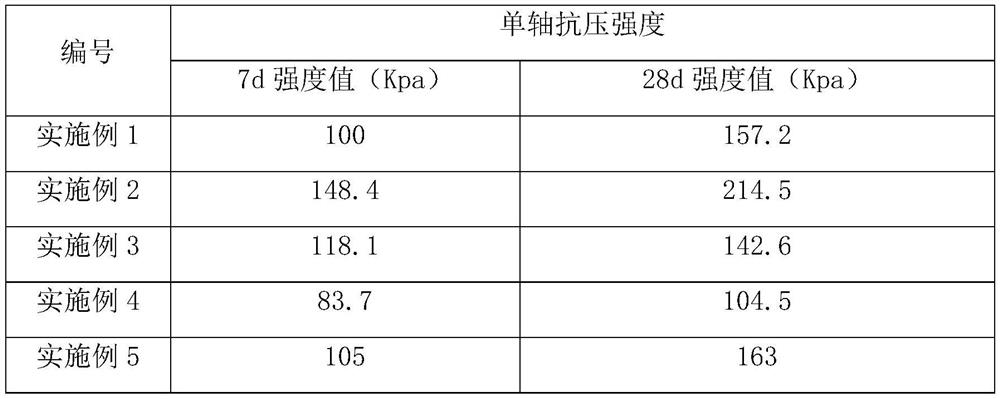

Embodiment 1

[0023] A high-strength cementing agent suitable for marine silt, its content (kg) is:

[0024] Clinker 50kg; fly ash 7.5kg; blast furnace slag powder 5kg; gypsum 2kg; activator 0.645kg.

Embodiment 2

[0026] A high-strength cementing agent suitable for marine silt, its content (kg) is:

[0027] Clinker 50kg; fly ash 2.5kg; blast furnace slag powder 10kg; gypsum 4kg; activator 0.665kg.

Embodiment 3

[0029] A high-strength cementing agent suitable for marine silt, its content (kg) is:

[0030] Clinker 50kg; fly ash 2.5kg; blast furnace slag powder 15kg; gypsum 6kg; activator 0.735kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com