Preparation process of copper strip for framework material

A preparation process and frame material technology, which is applied in the field of preparation technology of copper strips for frame materials, can solve the problems of high temperature softening and hardness index failing to meet the use requirements, comprehensive performance failing to meet the use requirements, and difficulty meeting the use requirements, etc. Thermal processing performance, good follow-up processing performance, and the effect of reducing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

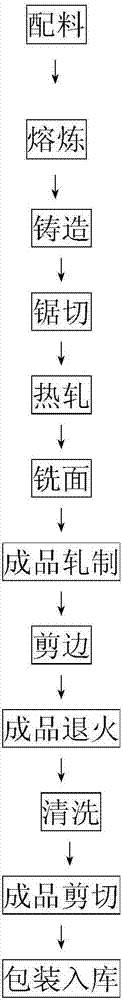

Image

Examples

Embodiment 1

[0044] It is used for special-shaped frame material products that require high temperature softening hardness in the subsequent processing process and ensure electrical conductivity. Its comprehensive performance is that the copper strip requires a soft state before forging, and the copper strip is required to be harder, with high conductivity and high conductivity after forging. High temperature softening hardness is high, and its technical requirements are:

[0045] Brand: LY80

[0046] Copper strip specification: 1.52×42mm

[0047] State: soft state (M)

[0048] Mechanical property requirements: tensile strength Rm195-300MPa, elongation A11.3≥35%, hardness HV70-80, hardness after forging HV105-125, high temperature softening hardness HV≥100

[0049] Tolerance requirements: thickness tolerance ±0.02mm, width tolerance ±0.20mm

[0050] Conductivity: ≥88%IACS, conductivity after forging ≥85%IACS

[0051] The processing technology is as follows:

[0052] The first step, batc...

Embodiment 2

[0077] It is used for special-shaped products that require high temperature softening hardness and high conductivity in the subsequent processing process. The comprehensive performance is that the copper strip requires a soft state before forging, and the copper strip is required to be hard, high conductivity and high temperature after forging. The softening hardness is high, and its technical requirements are:

[0078] Brand: LY80

[0079] Copper strip specification: 2.0×48mm

[0080] State: soft state (M)

[0081] Mechanical property requirements: tensile strength Rm195-300MPa, elongation A11.3≥35%, hardness HV70-80, hardness after forging HV105-125, high temperature softening hardness HV≥100

[0082] Tolerance requirements: thickness tolerance ±0.02mm, width tolerance ±0.20mm

[0083] Conductivity: ≥88%IACS, conductivity after forging ≥85%IACS

[0084] The processing technology is as follows:

[0085] The first step, batching: use the standard cathode electric copper a...

Embodiment 3

[0110] It is used for special-shaped products that require high temperature softening hardness and high conductivity in the subsequent processing process. The comprehensive performance is that the copper strip requires a soft state before forging, and the copper strip is required to be hard, high conductivity and high temperature after forging. The softening hardness is high, and its technical requirements are:

[0111] Brand: LY80

[0112] Copper strip specification: 2.4×59mm

[0113] State: soft state (M)

[0114] Mechanical property requirements: tensile strength Rm195-300MPa, elongation A11.3≥35%, hardness HV70-80, hardness after forging HV110-130, high temperature softening hardness HV≥100

[0115] Tolerance requirements: thickness tolerance ±0.02mm, width tolerance ±0.20mm

[0116] Conductivity: ≥88%IACS, conductivity after forging ≥85%IACS

[0117] The processing technology is as follows:

[0118] The first step, batching: use the standard cathode electric copper a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com