Preparation method of high-precision metal fiber felt for high-temperature gas dust removal

A technology of metal fiber felt and high-temperature gas, applied in the field of non-woven fabrics, can solve the problems of fiber mechanical properties, decreased folding resistance, poor bonding force of the felt layer, and difficult formation, etc., to achieve good mechanical properties and folding resistance, Not easy to break and short heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

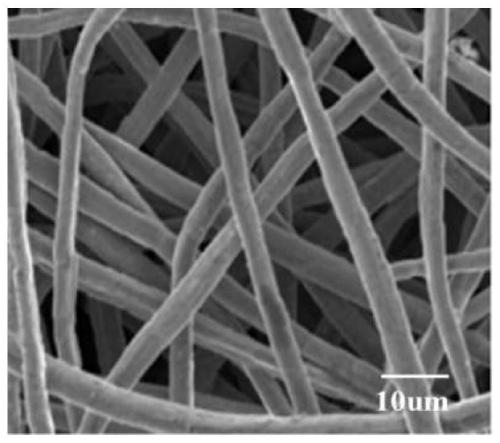

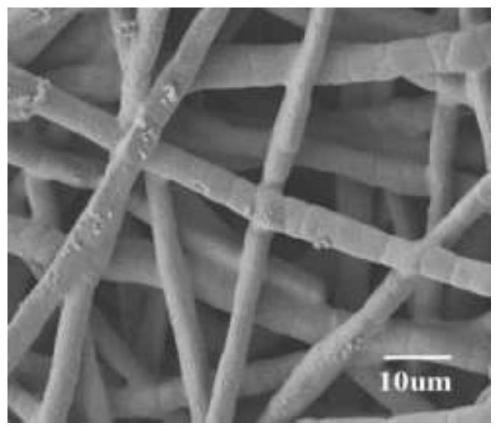

Image

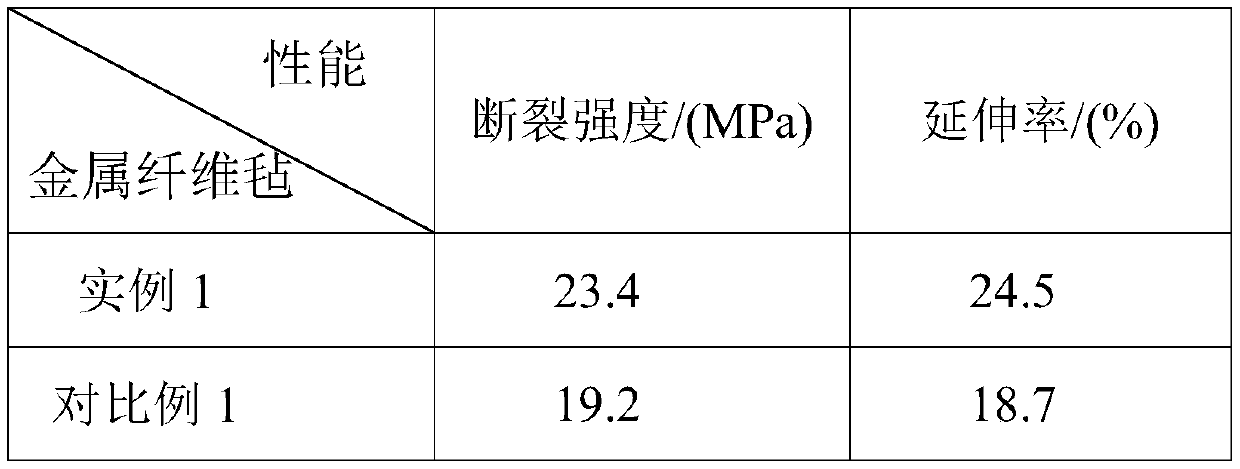

Examples

Embodiment 1

[0037] The preparation method of the high-precision metal fiber felt for high-temperature gas dedusting of the present invention is specifically implemented according to the following steps:

[0038] Step 1. Use felting equipment to pave the crude fiber into a coarse fiber mat, then check the uniformity of the coarse fiber mat at the light inspection station, take out the uniform coarse fiber mat, and set aside;

[0039] Among them, the diameter of the thick fiber is 22μm, and the unit weight is 600g / m 2 .

[0040] Step 2, using a high-temperature vacuum furnace to carry out vacuum high-temperature sintering treatment on the crude fiber felt blank, and obtain a coarse fiber sintered felt after cooling down, and set aside;

[0041] Among them, the temperature of vacuum high-temperature sintering treatment is 1100°C, the holding time is 120min, and the vacuum degree is 7.0×10 - 2 Pa, the gas quenching temperature is 750°C, and the high temperature vacuum furnace is filled wit...

Embodiment 2

[0049] The preparation method of the high-precision metal fiber felt for high-temperature gas dedusting of the present invention is specifically implemented according to the following steps:

[0050] Step 1. Use felting equipment to pave the crude fiber into a coarse fiber mat, then check the uniformity of the coarse fiber mat at the light inspection station, take out the uniform coarse fiber mat, and set aside;

[0051] Among them, the diameter of the thick fiber is 30μm, and the unit weight is 1200g / m 2 .

[0052] Step 2, using a high-temperature vacuum furnace to carry out vacuum high-temperature sintering treatment on the crude fiber felt blank, and obtain a coarse fiber sintered felt after cooling down, and set aside;

[0053] Among them, the temperature of vacuum high-temperature sintering treatment is 1200°C, the holding time is 150min, and the vacuum degree is 7.0×10 - 2 Pa, the gas quenching temperature is 800°C, and the high temperature vacuum furnace is filled wi...

Embodiment 3

[0061] The preparation method of the high-precision metal fiber felt for high-temperature gas dedusting of the present invention is specifically implemented according to the following steps:

[0062] Step 1. Use felting equipment to pave the crude fiber into a coarse fiber mat, then check the uniformity of the coarse fiber mat at the light inspection station, take out the uniform coarse fiber mat, and set aside;

[0063] Among them, the diameter of the thick fiber is 35μm, and the unit weight is 1500g / m 2 .

[0064] Step 2, using a high-temperature vacuum furnace to carry out vacuum high-temperature sintering treatment on the crude fiber felt blank, and obtain a coarse fiber sintered felt after cooling down, and set aside;

[0065] Among them, the temperature of vacuum high-temperature sintering treatment is 1300°C, the holding time is 180min, and the vacuum degree is 7.0×10 - 2 Pa, the gas quenching temperature is 700°C, and the high temperature vacuum furnace is filled wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com