Continuous rapid annealing process for brass-coated pure copper stranded wire high-speed rail through ground wire

A technology of through ground wire and rapid annealing, which is applied in the direction of improving process efficiency, manufacturing tools, improving energy efficiency, etc., can solve problems affecting processing and performance, coarsening of core material grains, etc. The effect of short time and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0033] Experiment example 1: hardness experiment

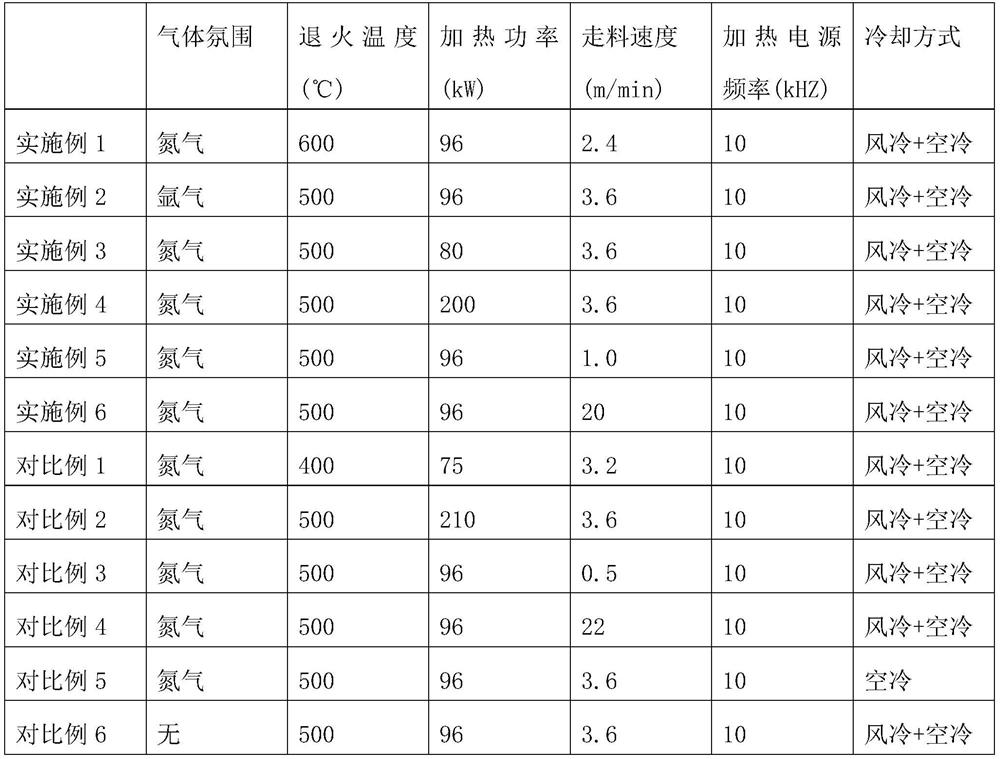

[0034] The hardness of each embodiment and the brass and pure copper before and after proportional annealing was detected, and each group was tested in three parallel tests, the results were expressed as an average, and the hardness detection method was determined by using a microhardness tester, and the results were shown in Table 2.

[0035] Table 2

[0036]

[0037] From the data of Table 2, it can be seen that before annealing, the hardness of brass and pure copper is 239HV and 134HV, respectively, the annealing temperature, heating power and feeding speed of the embodiment of the present invention are reasonable, brass and pure copper are basically completely recrystallized, the hardness is significantly reduced, the gap between brass and pure copper hardness is reduced, which is conducive to the subsequent coordinated deformation of the two materials. In the opposite proportion 1, the annealing temperature, heating power a...

experiment example 2

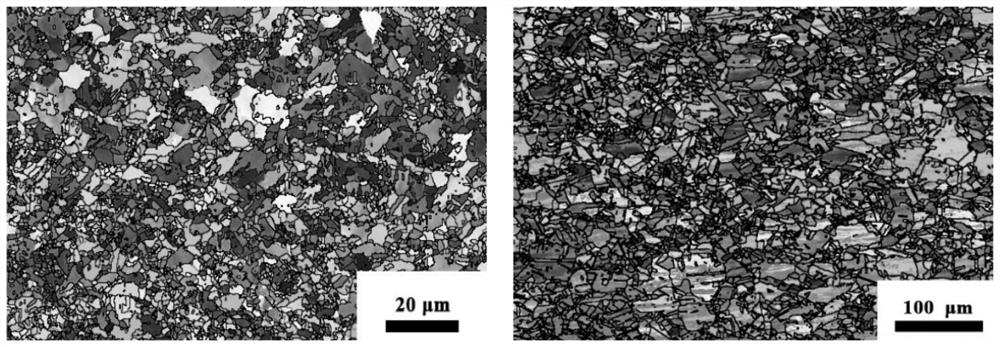

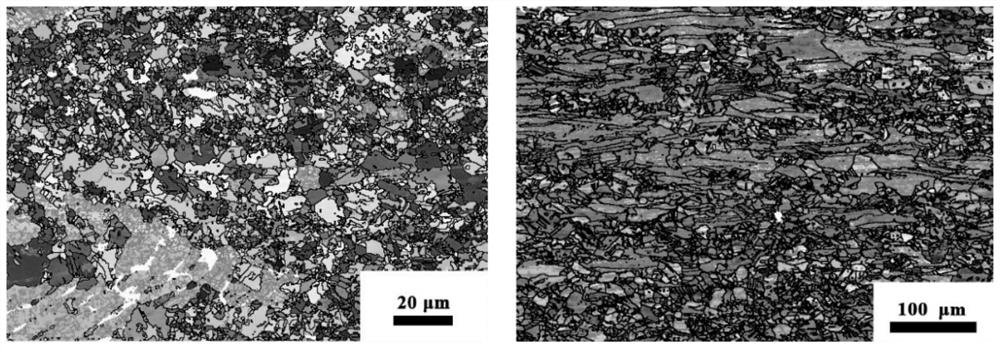

[0038] Experiment example 2: Microstructure

[0039] Microstructure experiments were performed on brass and pure copper after annealing in Example 1 and proportion 1, the results were as follows Figure 1 、 Figure 2 as shown. thereinto Figure 1 For the microstructure after annealing of Example 1, the left side is brass, the right side is pure copper; Figure 2 It is a microstructure after annealing in proportion 1, with brass on the left and pure copper on the right. Figure 1 In the middle, brass and pure copper are basically completely recrystallized, and the tissue is uniform, in the proportion 1, after annealing, brass and pure copper only partial recrystallization occurs, the organization is uneven, there are a large number of small angle grain boundaries, the hardness drop is not obvious, and the annealing effect is poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com