Automatic stop charging control circuit of positive and negative combination pulse charge machine

A technology of controlling circuits and combining pulses, applied in battery circuit devices, electric vehicles, circuit devices, etc., can solve the problems of reducing battery capacity and service life, coarse grains of plates, overcharging, etc. The effect of saving electricity and avoiding water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

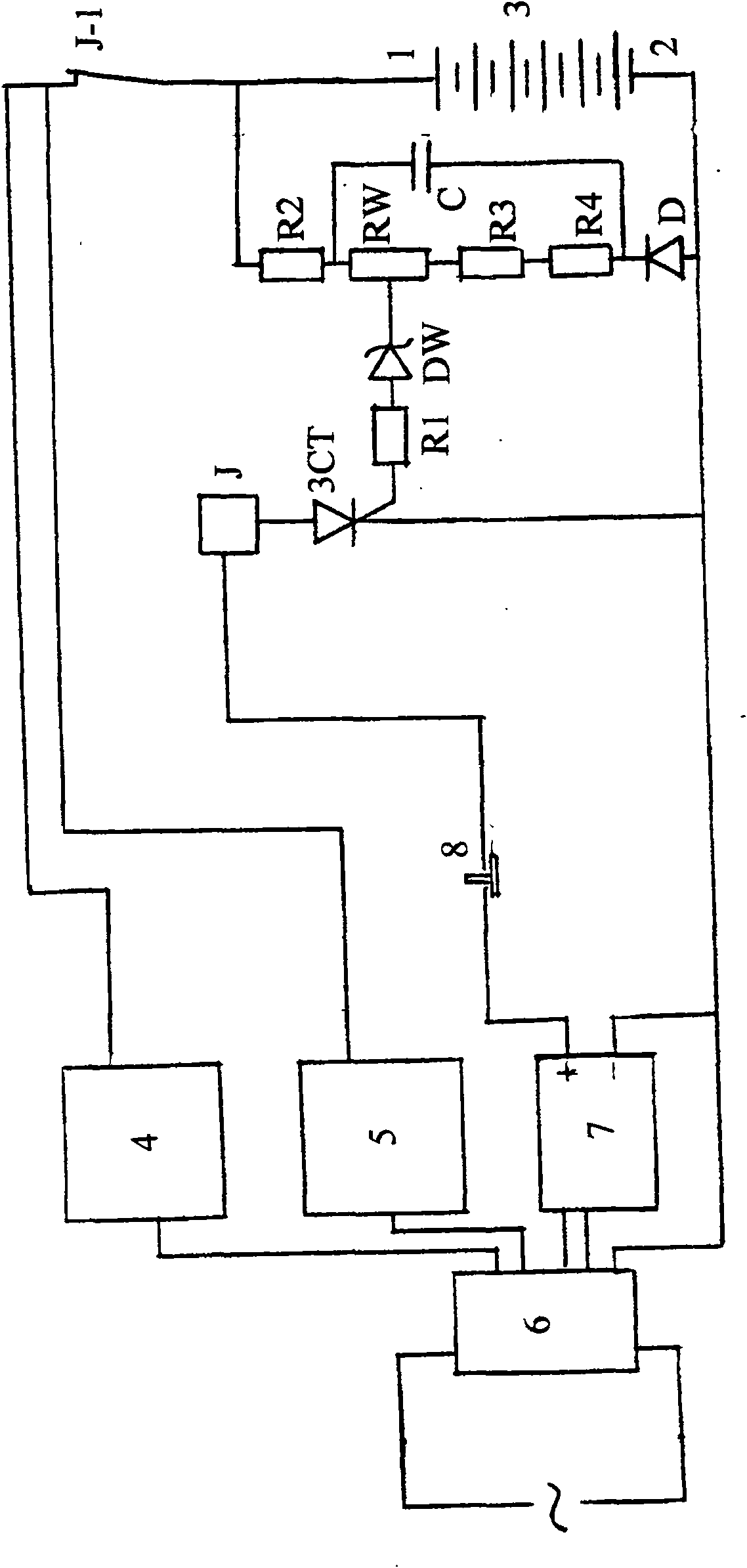

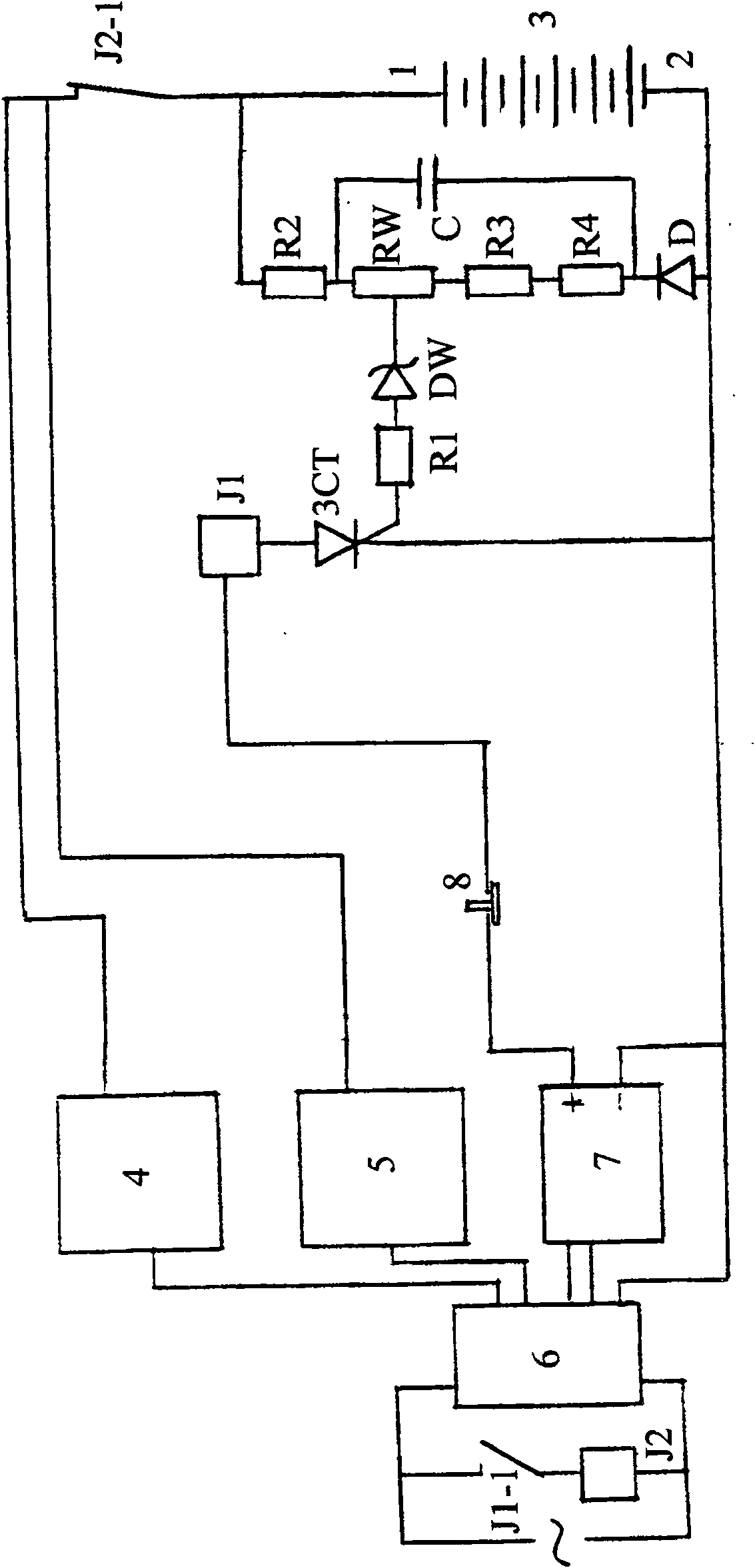

[0011] see figure 1 As shown, the automatic stop charging control circuit of the positive and negative combination pulse charger of the present invention is composed of first to fourth resistors R1 to R4, variable resistor RW, capacitor C, diode D, Zener diode DW, thyristor 3CT, Composed of relay J, wherein: the anode of the diode D is connected to the charging negative pole 2 of the charger; the second resistor R2, the variable resistor RW, the third resistor R3 and the fourth resistor R4 are sequentially connected in series between the charging positive pole 1 of the charger and the diode D Between the cathodes; one end of the relay J is connected to the positive pole of the regulated power supply 7 of the charger, and the other end is connected to the anode of the thyristor 3CT; the cathode of the thyristor 3CT is respectively connected to the negative pole of the regulated power supply 7 and the negative pole 2 of the charger, Its control pole is connected to the middle en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com