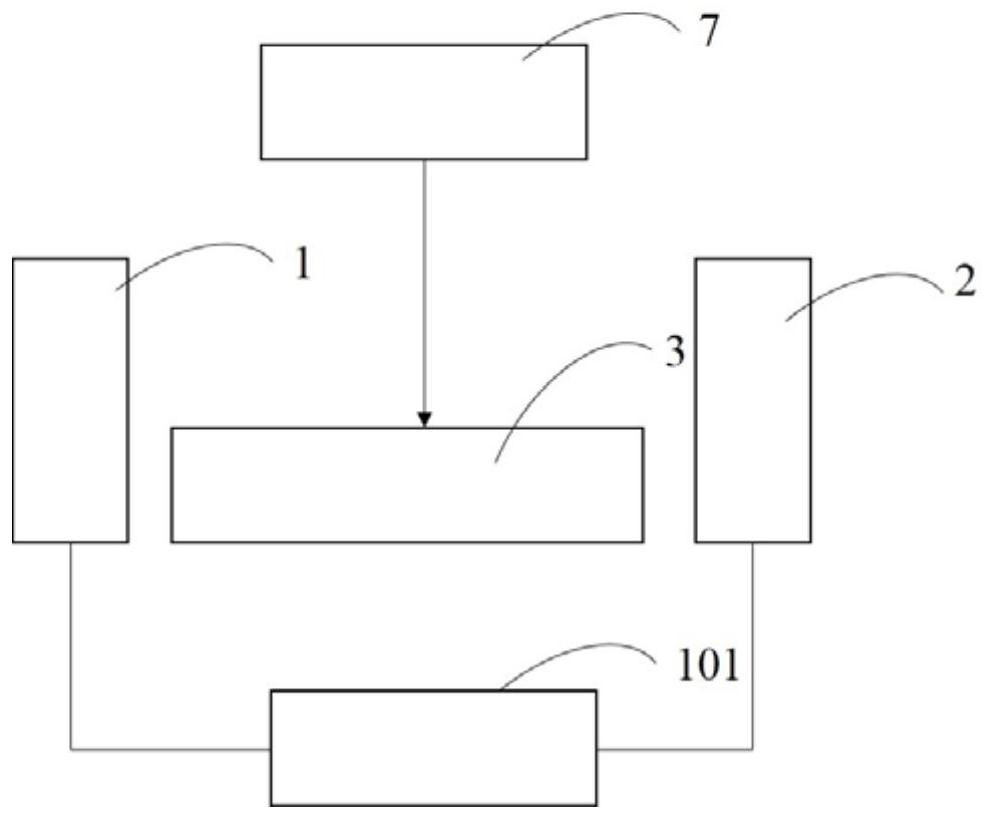

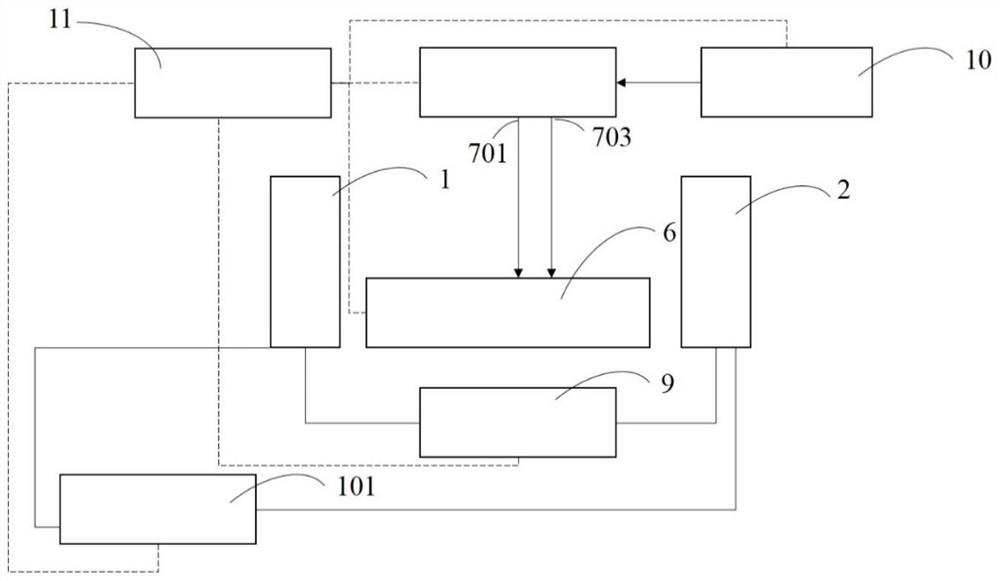

Electrostatic field assisted laser additive manufacturing device and method

An auxiliary laser and additive manufacturing technology, which is applied in the directions of additive processing, process efficiency improvement, and energy efficiency improvement, and can solve the problems of difficulty in adjusting the internal composition and performance of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] In this example, the DC power supply is used as the power supply for the field, the direction along which the molten pool is formed is the application direction of the electrostatic field, the fiber laser with a wavelength of 1064 nm is used as the light source for laser additive manufacturing, and the laser beam adopts a Gaussian beam. The specific process is as follows:

[0113] Step 1. Select 304 stainless steel as the substrate to be clad, with a size of 200mm×200mm×10mm, and the additional material (cladding powder) is stainless steel 316L metal powder, with a particle size of 75-150μm;

[0114] Step 2, the pretreatment of the substrate to be clad and the metal powder, the substrate to be melted is polished with sandpaper, then the oil stains are removed with anhydrous ethanol, dried, and the metal powder is dried;

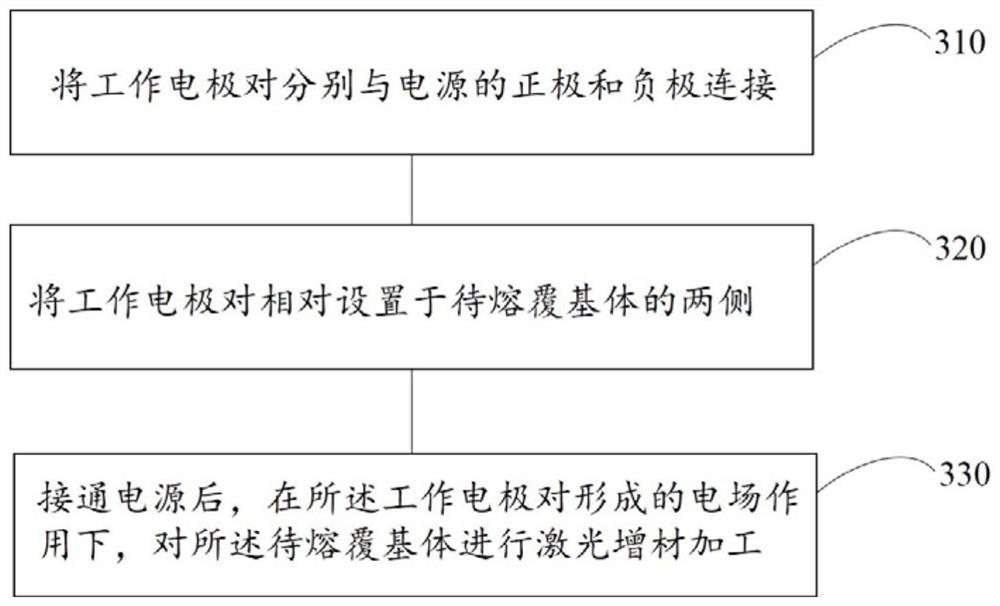

[0115] Step 3. The working electrode pairs are relatively arranged on both sides of the horizontal plane of the substrate to be clad vertically, and i...

Embodiment 2

[0120] In Example 2, the raw materials and process parameters for laser additive manufacturing are the same as those in Example 1, except that there is no electrostatic field assistance.

[0121]The samples of the clad substrates in Example 1 and Example 2 were cut along the scanning direction, and observed and characterized after grinding and polishing. Figure 10-11 The scanning electron microscope image and the metallographic image of the cross section of the cladding layer without the assistance of the electrostatic field in Example 2 are respectively shown, Figure 12-13 The scanning electron microscope image and the metallographic image of the cross section of the cladding layer with the assistance of the electrostatic field in Example 1 are shown. Compared Figure 10 and Figure 12 It can be seen that with the assistance of the electrostatic field (the strength of the electrostatic field is 133V / cm), the number of pores in the section of the cladding layer is signific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com