Patents

Literature

94results about How to "Implement manual adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adaptive automobile seat system and seat adjustment method

InactiveCN102963274AImplement manual adjustmentAccurate adjustmentMovable seatsManufacturing technologySelf adaptive

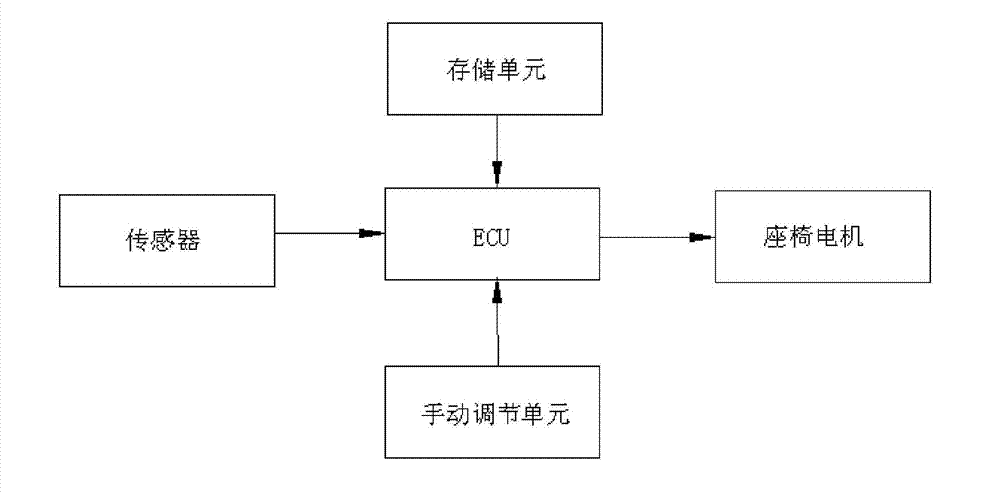

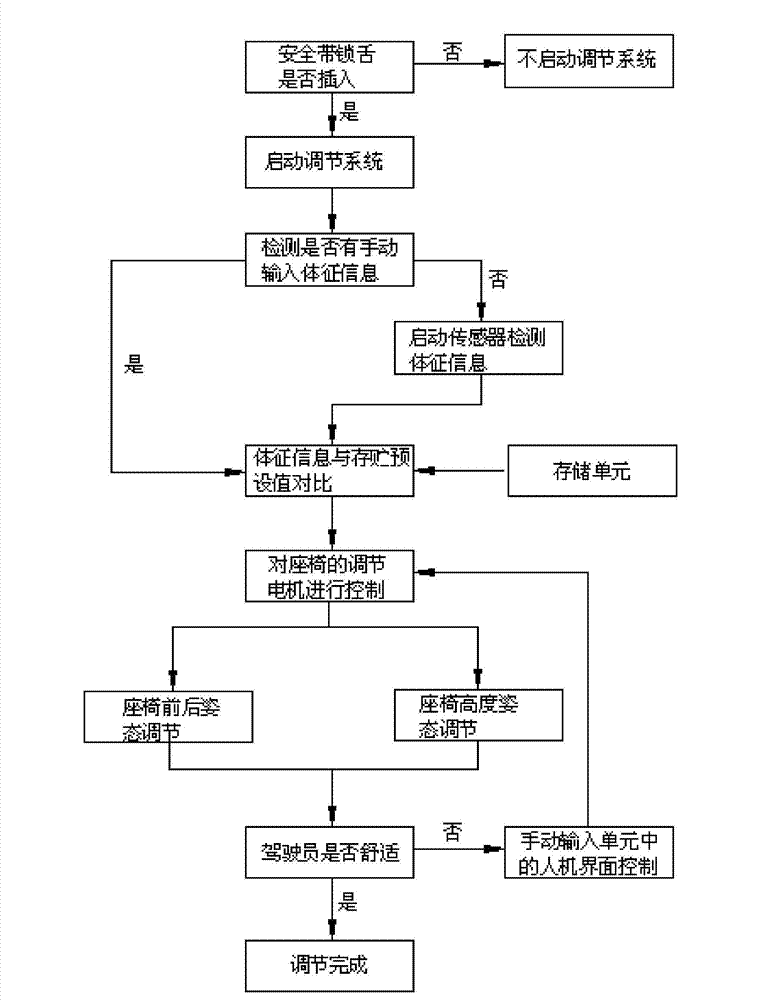

The invention discloses an adaptive automobile seat system and a seat adjustment method, and relates to the technical field of automobile manufacture. The system comprises seats, an adjustment motor for controlling the movement of the seats, a sensor, a storage unit and an electronic control unit. The seat adjustment method implemented by adopting the system comprises the following steps of: detecting and feeding back the weight and figure information of a driver; performing comparison to determine preset values related to physical characteristics of the driver; and controlling the adjustment motor for the seats according to seat coordinates corresponding to the preset values by using the electronic control unit. According to the system and the method, the adjustment of the seats is more accurate and humanized, the influence of individual differences of persons is more taken into account, and the system and the method can be used for persons with different figures, and are more widely applicable.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

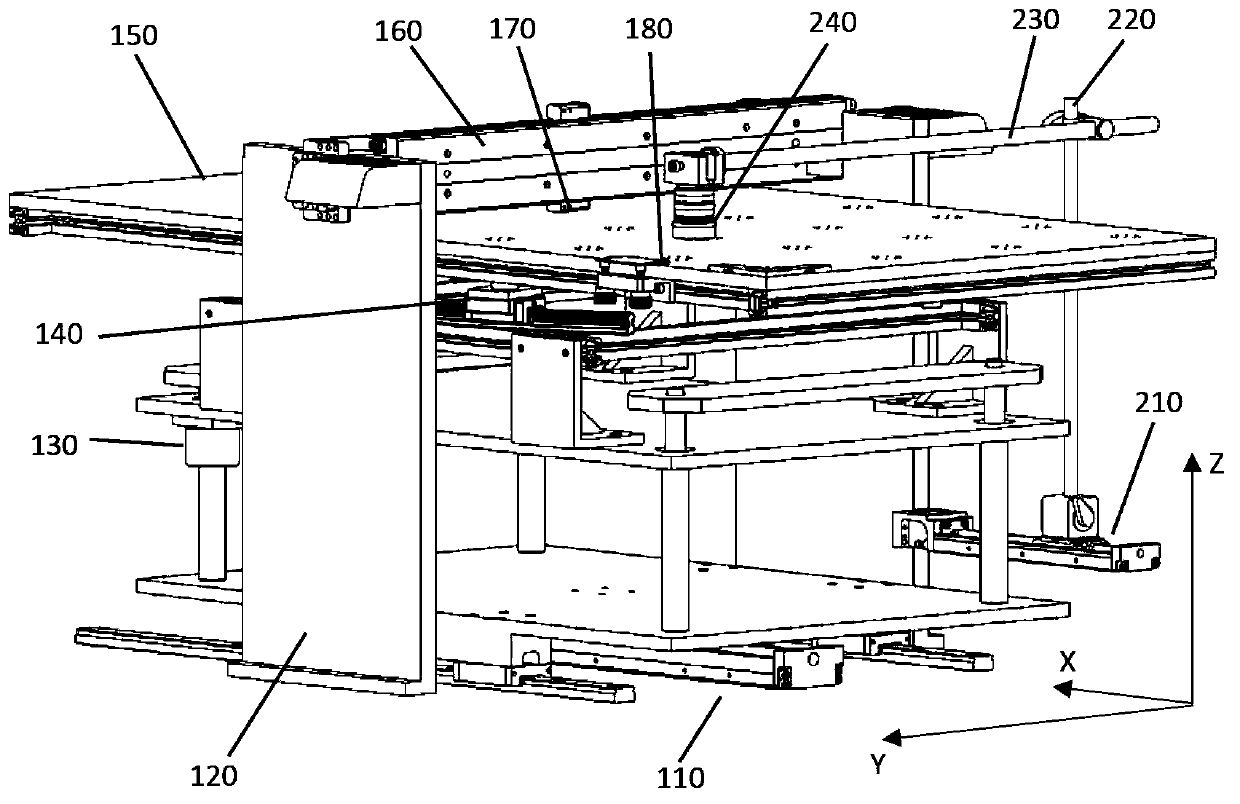

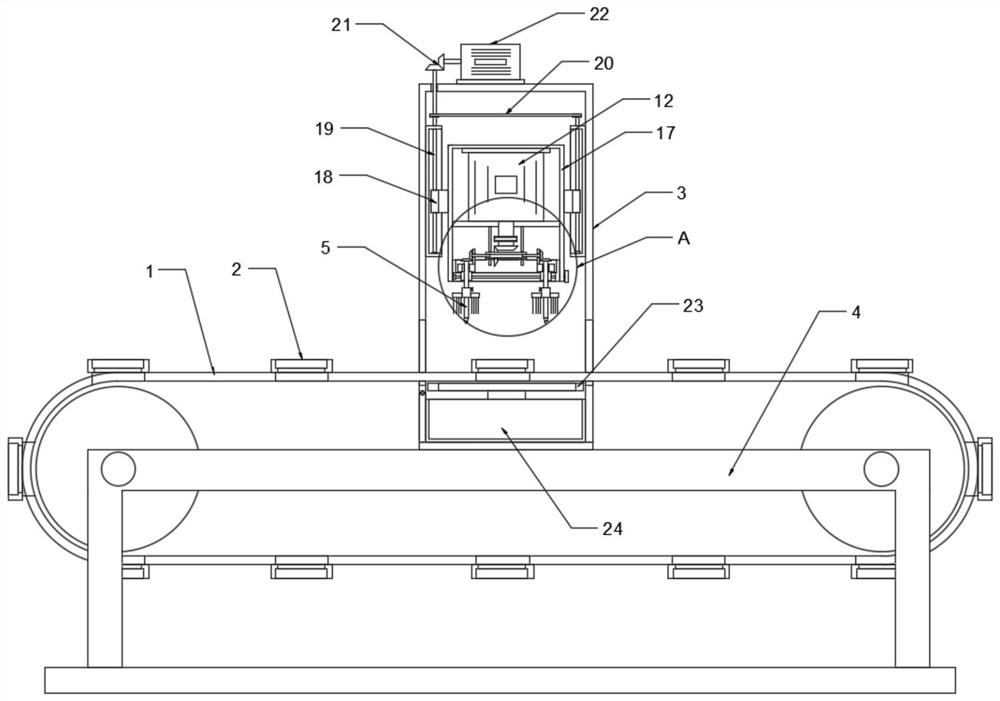

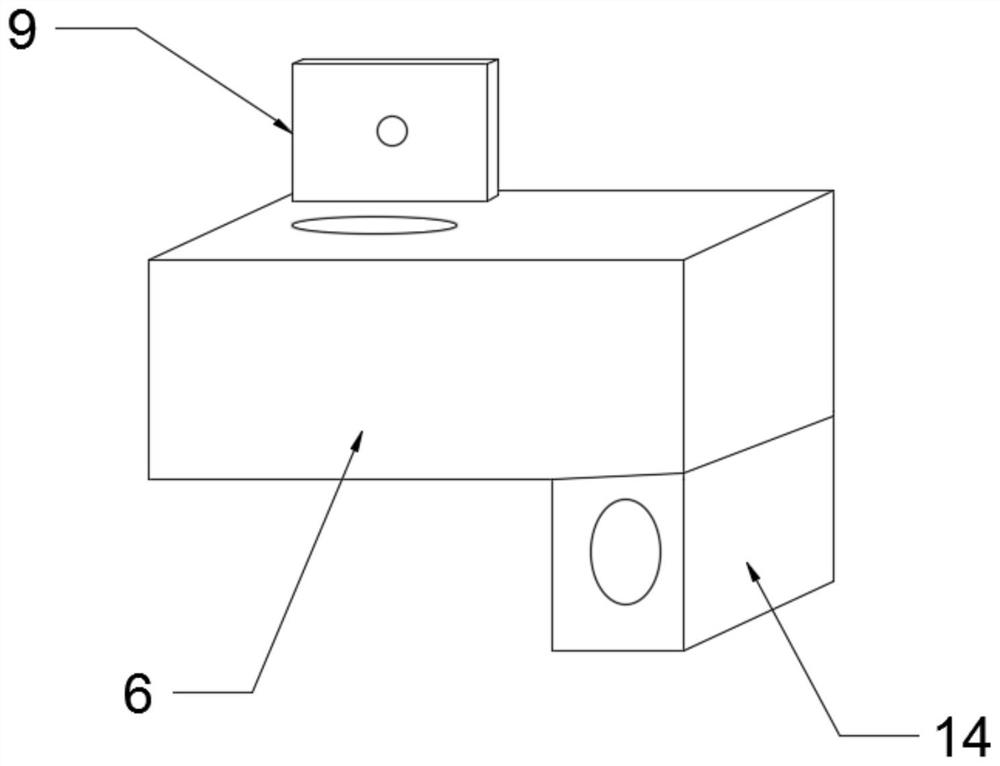

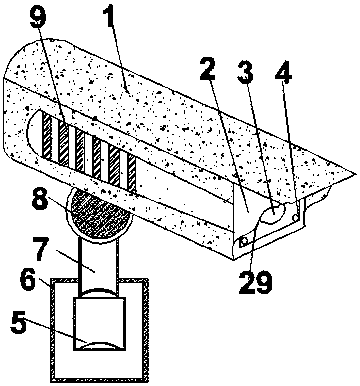

Machine-vision-based raster stereo image flat printer and method

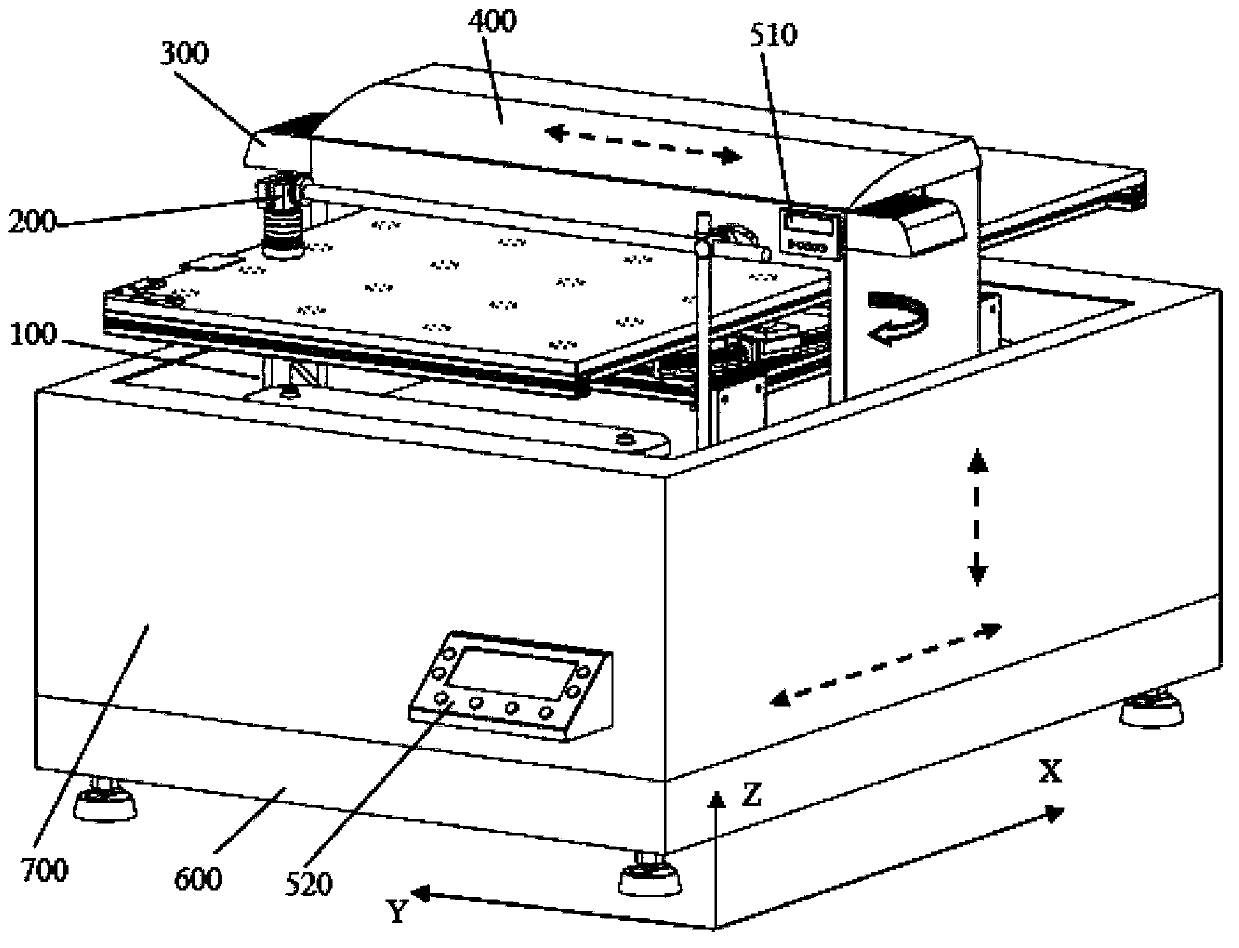

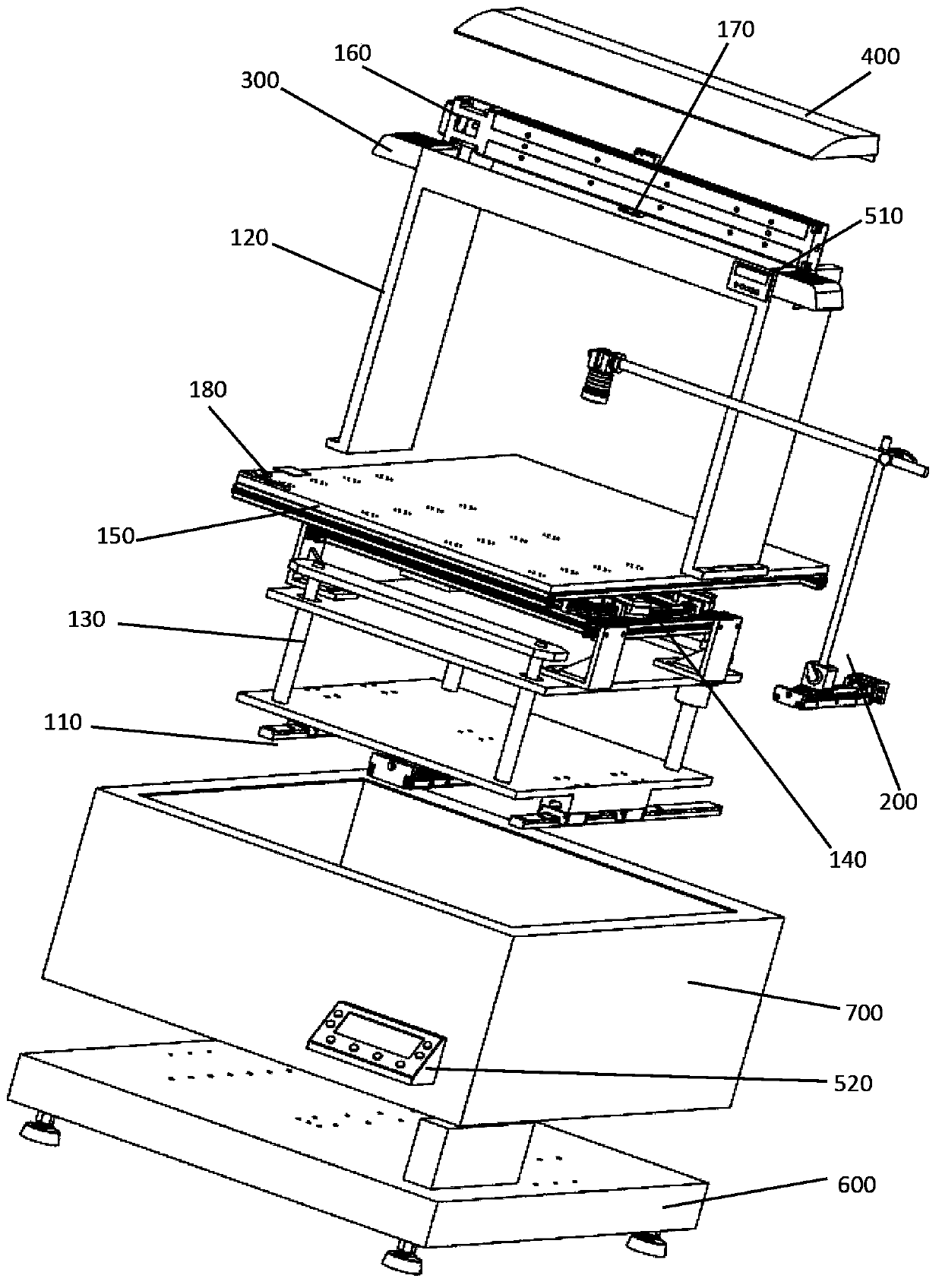

The invention discloses a machine-vision-based raster stereo image flat printer for realizing stereo printing on a raster plate matrix. The printer comprises a printing system, a visual sense measuring system and an error correction processing system, wherein the visual sense measuring system is used for obtaining the image of a raster plate on the printing system and detecting a position and an angle; the error correction processing system calculates the position deviation of the raster plate and the printed image according to the position and the angle and controls the printing system to perform corresponding position error correction according to the deviation so that a stereo image can be obtained by printing at an accurate position. By using the printer and the method provided by the invention, the problems of low printing precision, complicated operation, difficult automation realization and the like in a conventional raster stereo image printing process can be overcome, a method of machine visual sense measuring positioning and mechanical and visual sense auxiliary error correction is adopted so that the stereo image printing based on the raster plate can be realized, the material adaptability can be improved, the operation is convenient, and the printing precision is high.

Owner:HUAZHONG UNIV OF SCI & TECH

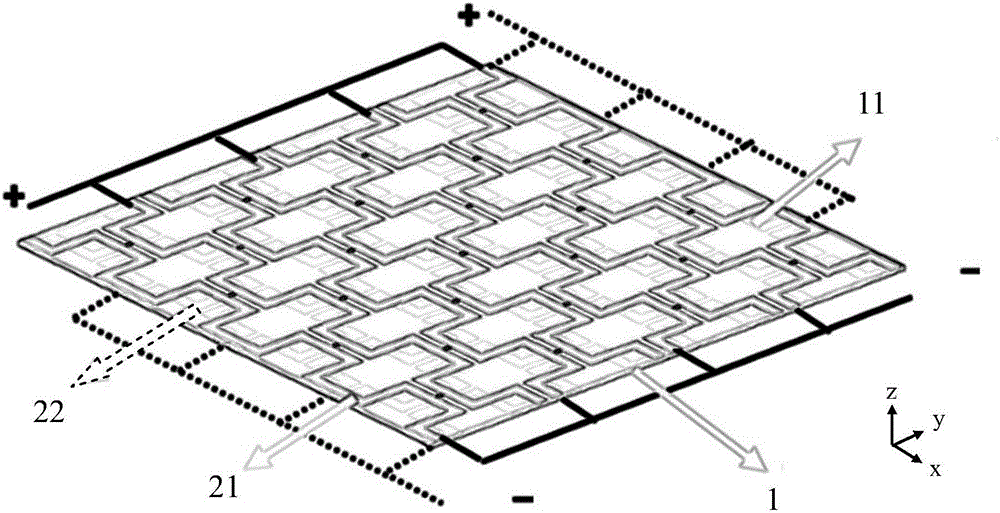

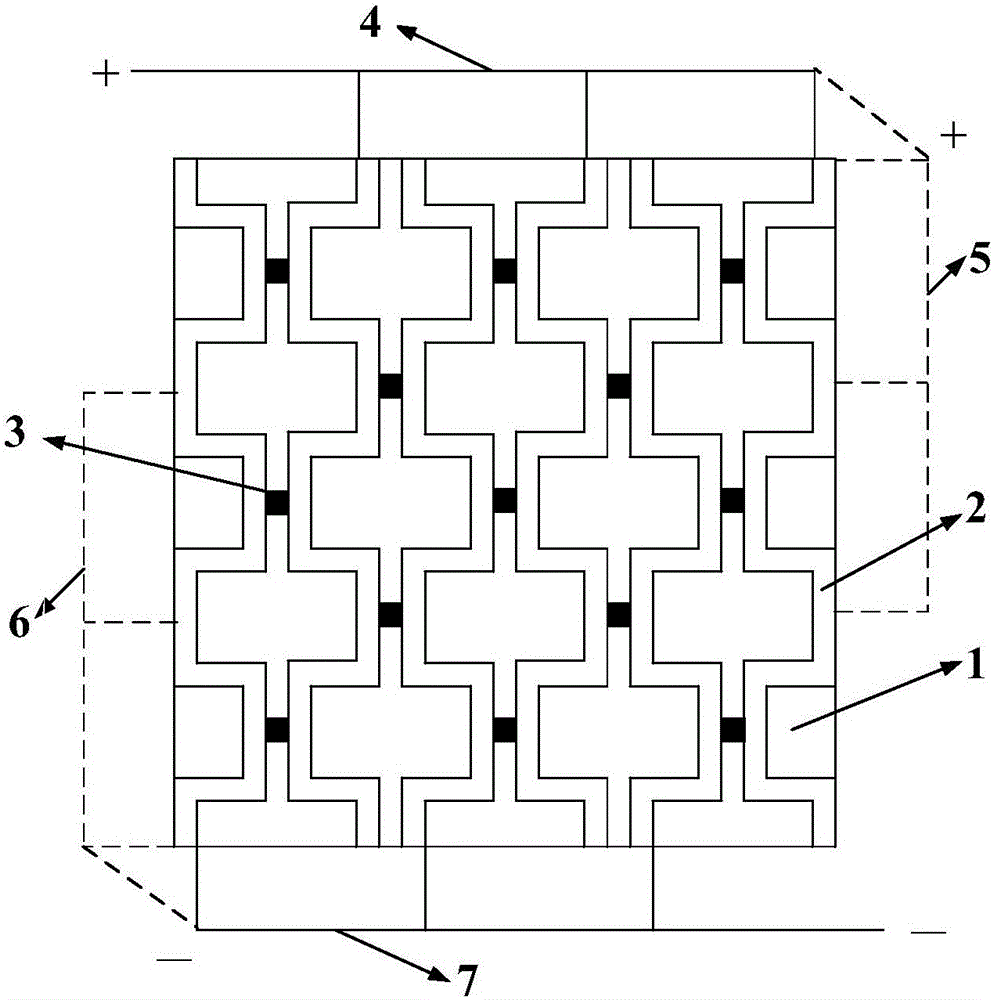

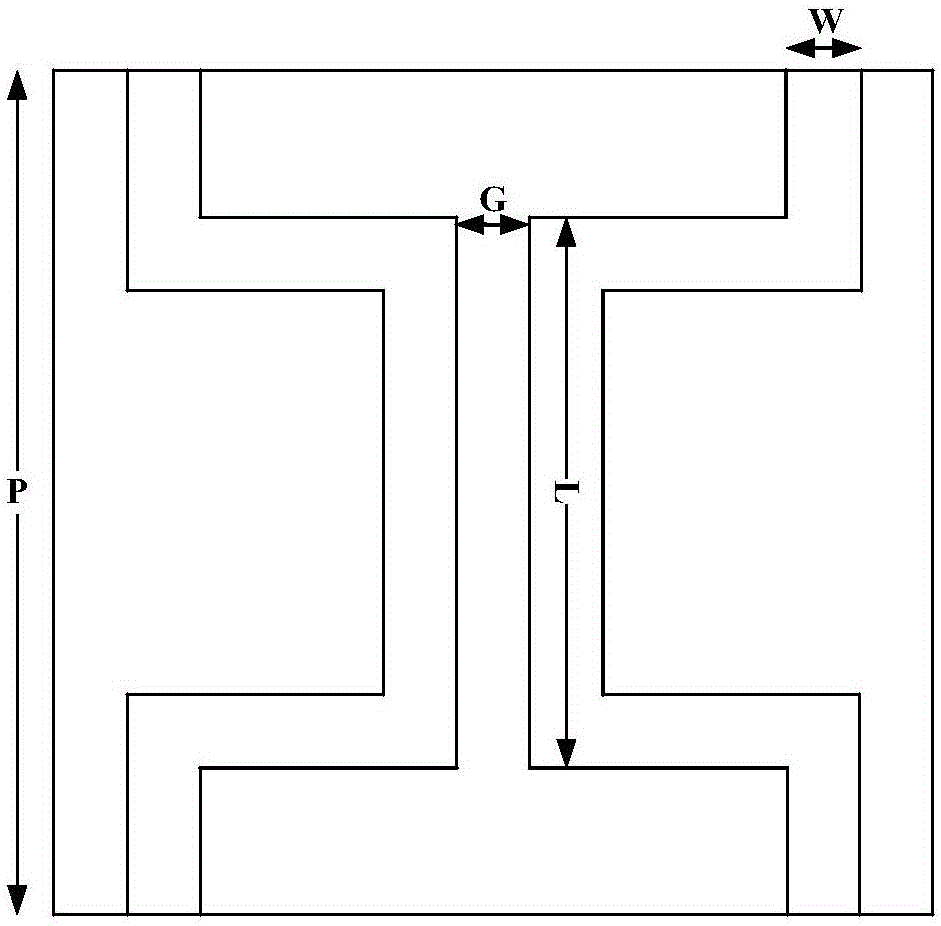

Active frequency selection surface structure

InactiveCN106571534AImplement manual adjustmentEasy to operateRadiating element housingsDielectric substrateEngineering

The invention relates to a polarized stable active frequency selection surface structure. The structure comprises a dielectric substrate, a first zigzag line structure, a second zigzag line structure, PIN diodes which are loaded in cycle units, and feed lines which provide bias on the edge around the surface for PIN tubes. A number of metal lines are etched on upper and lower surfaces of the dielectric substrate to form the zigzag line structures. The zigzag lines of the same surface are parallel to each other and are spaced by the length of the translation of one unit. The zigzag lines of upper and lower surfaces are orthogonal. The middle parts of the metal lines close to each other in each unit are connected by welding PIN tubes. Positive and negative voltage bias are added into corresponding edge feed lines of upper and lower surfaces, and the working status of the PIN tubes is controlled. According to the invention, the structure can be applied to a radome; the frequency selection characteristic of manually adjustable surface frequency selection is realized; the polarization of different incident waves is stable; and the simple structure has the advantage of simple feeding mode, and is suitable for a complex electromagnetic environment.

Owner:SHANGHAI RADIO EQUIP RES INST

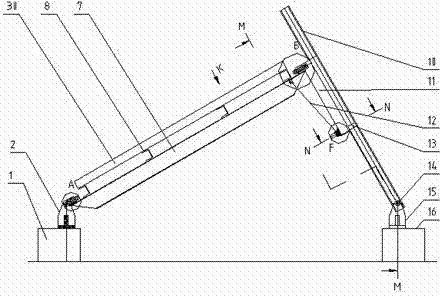

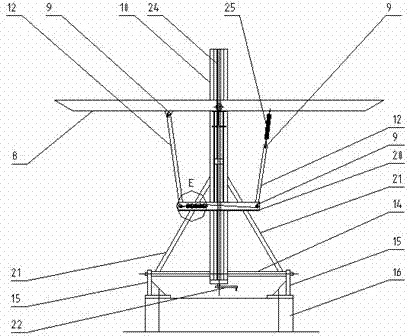

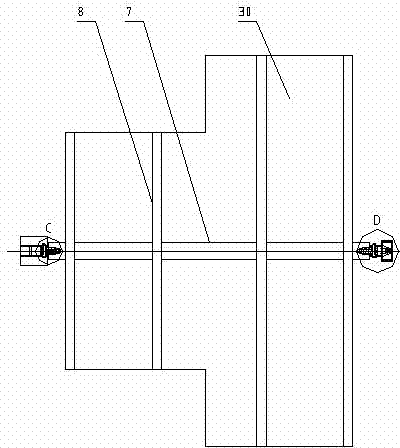

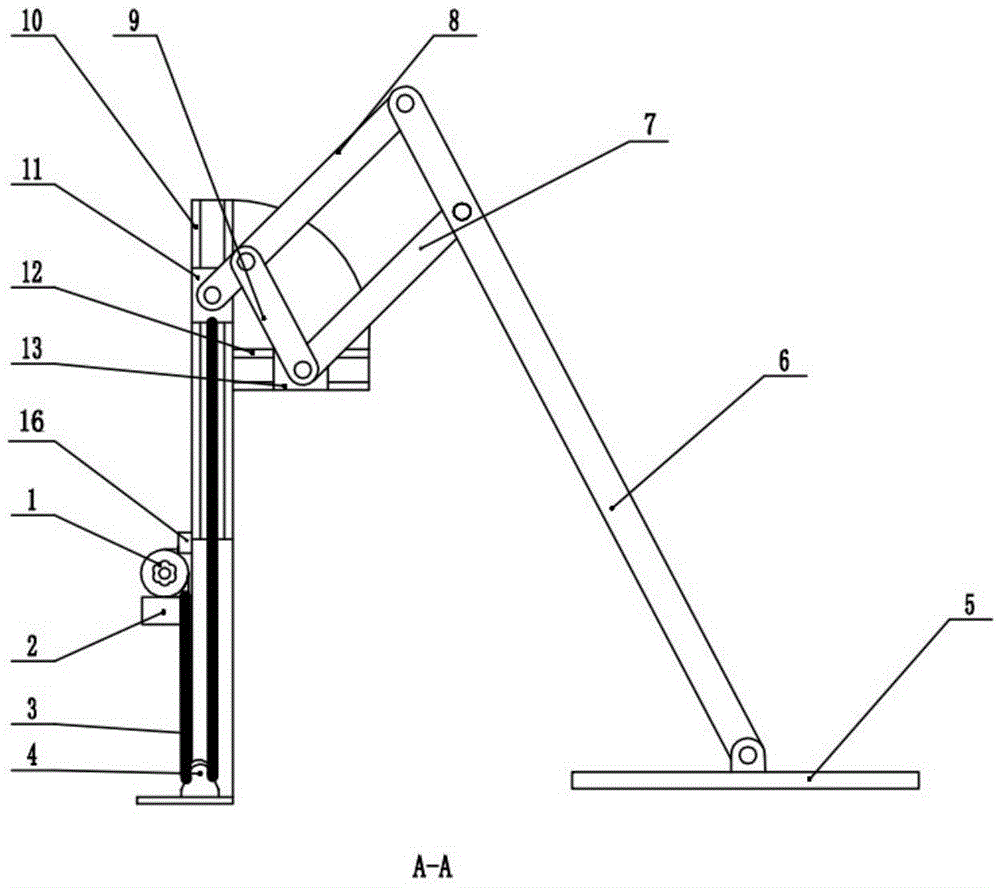

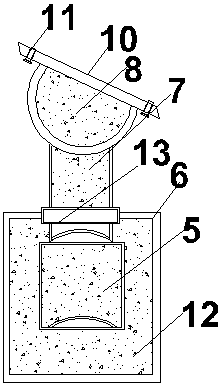

Solar energy tracking device

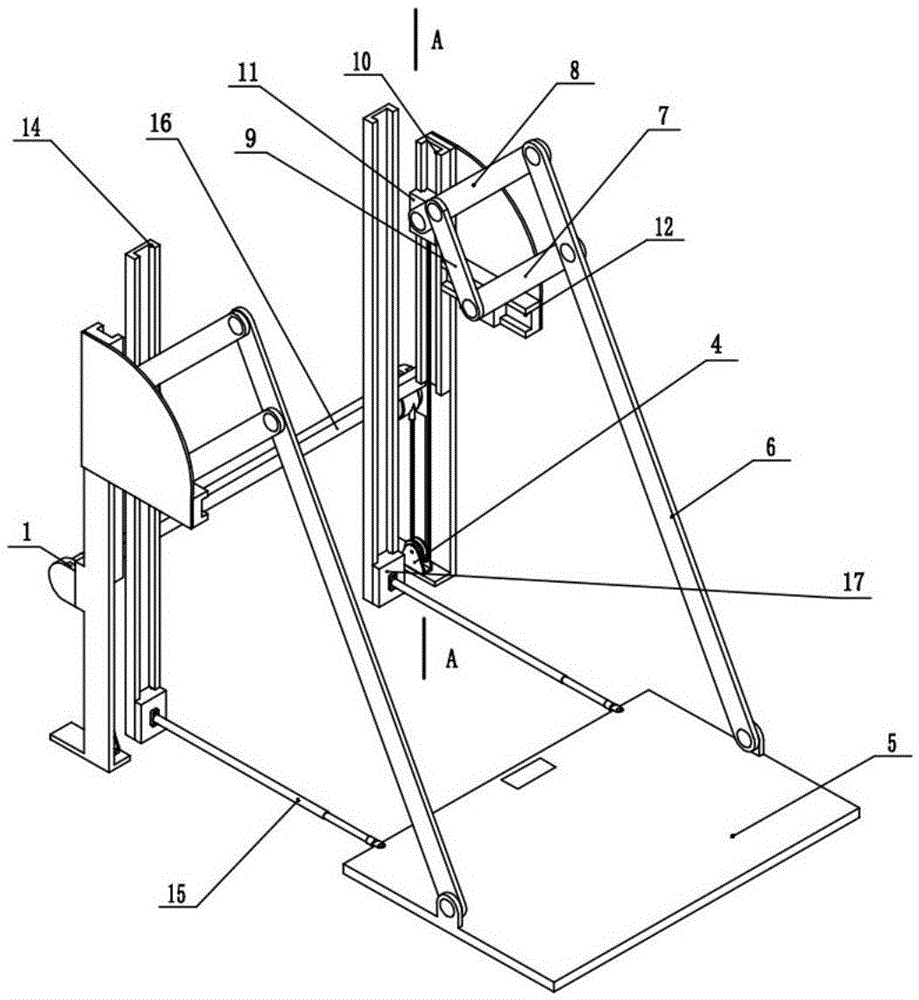

InactiveCN103246294AAchieve tension controlLow costControl using feedbackEngineeringMechanical engineering

The invention discloses a solar energy tracking device which is characterized by comprising a first base, a first hinged support, a primary beam , an secondary beam, a slide rail column, a second hinged support, a second base, inclined struts, a screw rod, a lead screw nut, a C-shaped slide block and a photovoltaic panel, wherein the secondary beam is welded on the primary beam; the photovoltaic panel is mounted on an upper plane of the secondary beam; the primary beam is hinged with the first hinged support and the C-shaped slide block through a T-shaped shaft; the C-shaped slide block in in clearance fit with an inner slideway of the slide rail column; the lead screw nut is fixed in the C-shaped slide block; the screw rod is screwed into the lead screw nut; two ends of the screw rod are mounted in the slide rail column through a slide bearing; a shaft and the inclined struts are welded at the lower part of the slide rail column; and the side rail column is hinged with the second hinged support through the shaft. According to the solar energy tracking device, the automatic tracking for solar azimuths and the manual tracking for slowly-changing solar azimuths are achieved at low cost.

Owner:MAANSHAN JUBAO NEW ENERGY EQUIP TECH

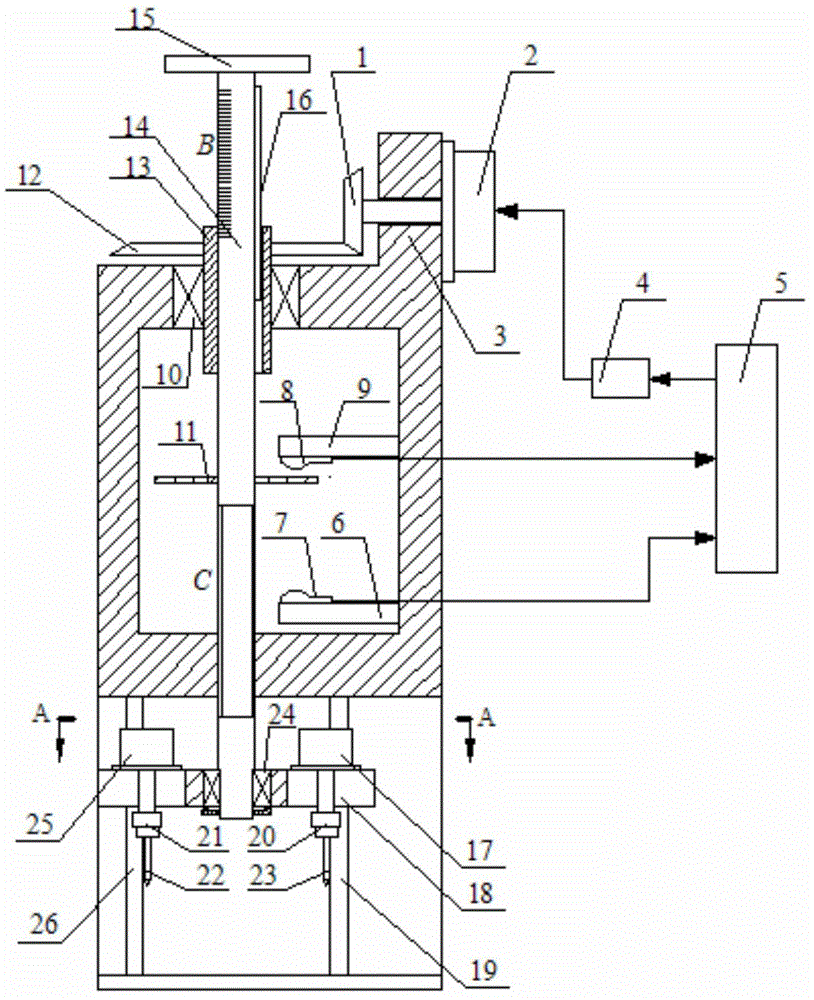

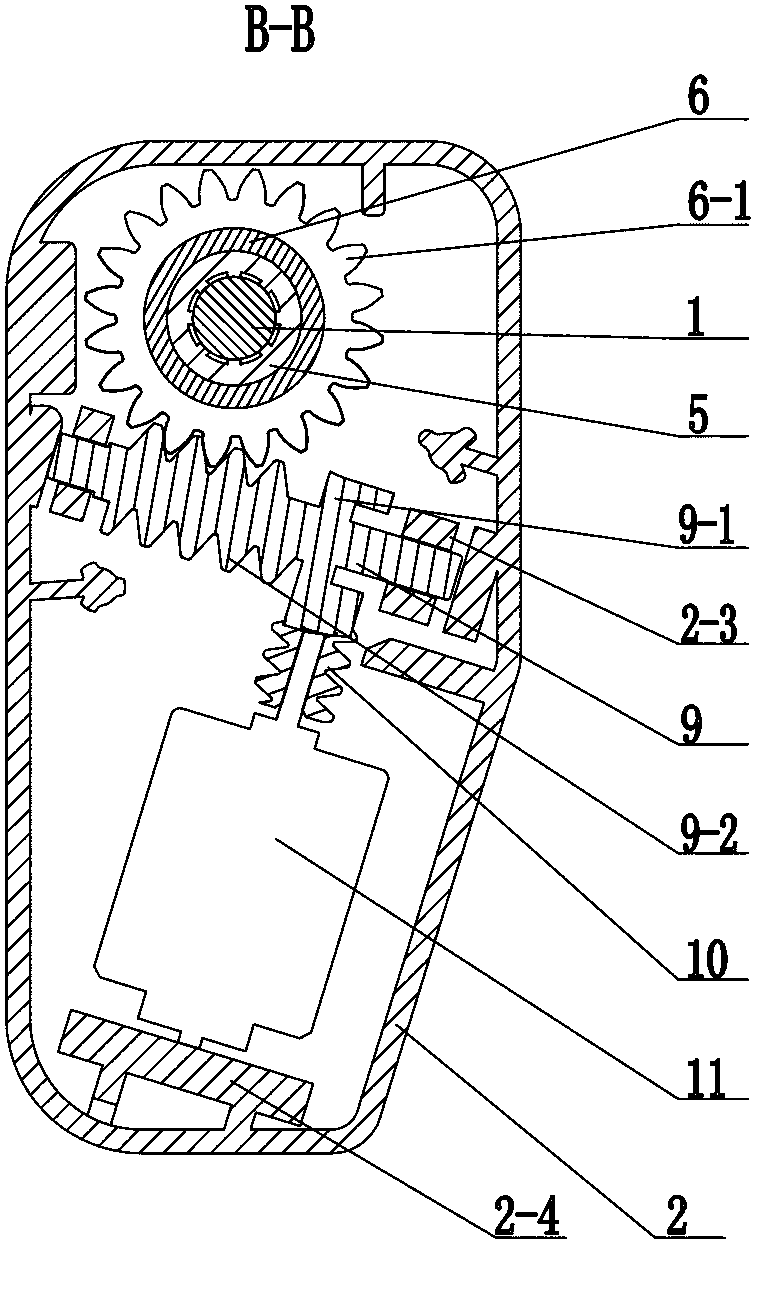

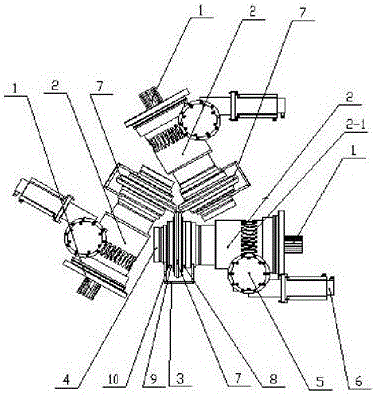

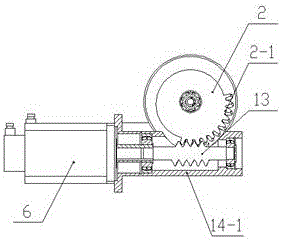

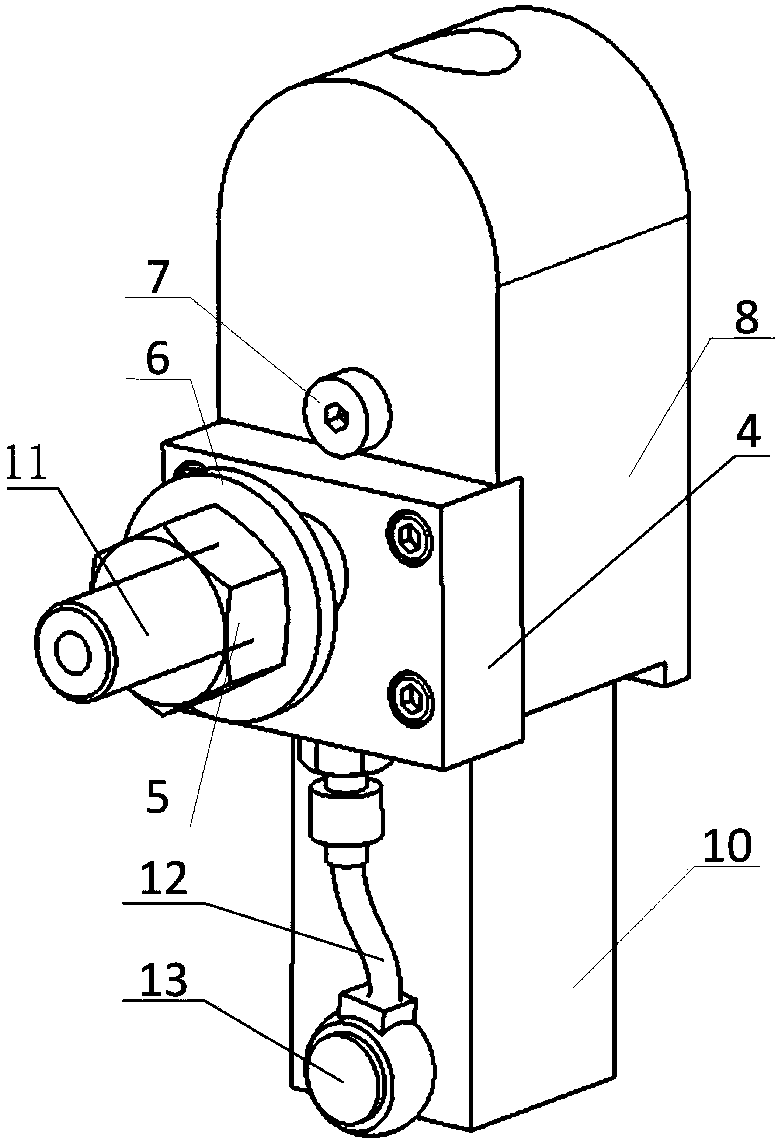

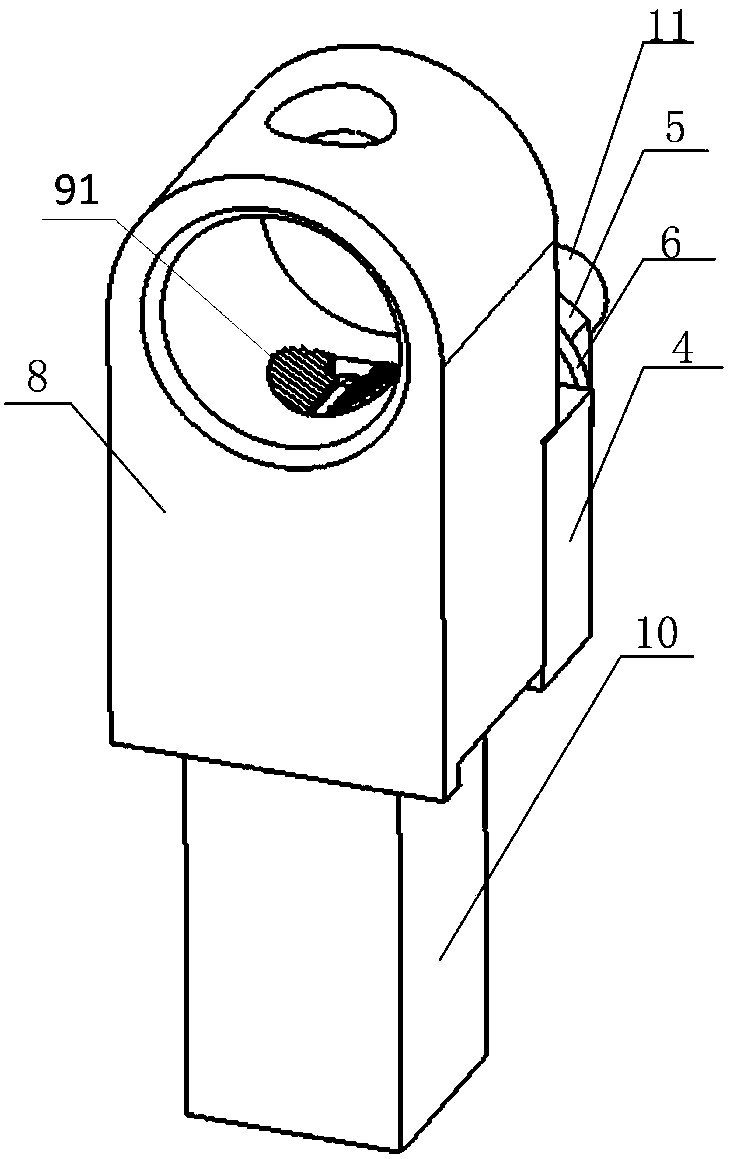

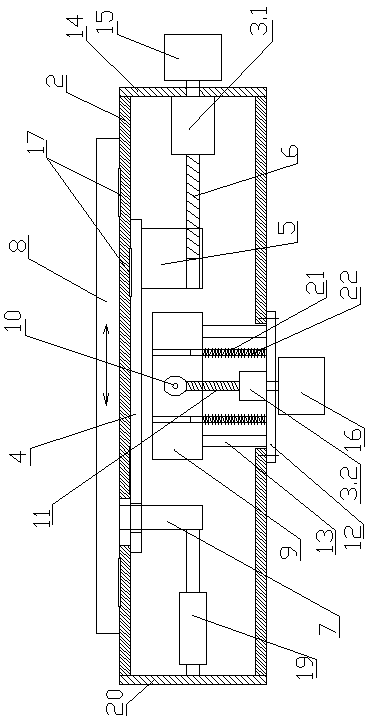

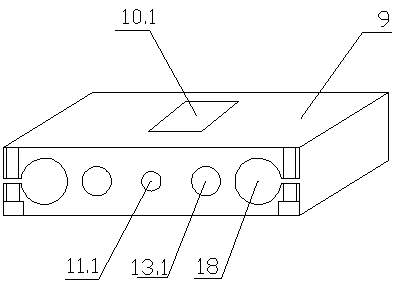

Manual operationandautomatic operation integrated drilling device

InactiveCN104400067AImplement manual adjustmentMeet diverse drilling needsStationary drilling machinesLarge fixed membersGear wheelEngineering

The invention discloses a manual operationand automatic operation integrated drilling device. The device comprises a bracket, a small bevel gear, a large bevel gear, a gear shaft, a stepper motor, a lead screw and a motor bracket, wherein the stepper motor is fixed on the bracket; the small bevel gear is fixed on an output shaft of the stepper motor; the gear shaft is connected with the bracket through a bearing; the large bevel gear is fixed on the gear shaft, and engages withthe small bevel gear; a flat key groove with a through shaft is formed in the gear shaft; a handle is mounted at the top end of the lead screw; a flat key is mounted on the lead screw, and is connected with the gear shaft; a scale is marked in a position B of the lead screw, and a thread is arranged in a position C; a through hole thread is arranged on the bracket, and is connected with a thread on the lead screw; the bottom end of the lead screw is connected with the motor bracket through a bearing; two guide rods are arranged at the lower end of the bracket, and are provided with guide slide blocks; the guide slide blocks are fixed on the motor bracket; through grooves are formed in the two sides of the motor bracket; and motors are mounted in the through grooves. The device not only can be adjusted manually, but also can be adjusted automatically.

Owner:NORTHEAST FORESTRY UNIVERSITY

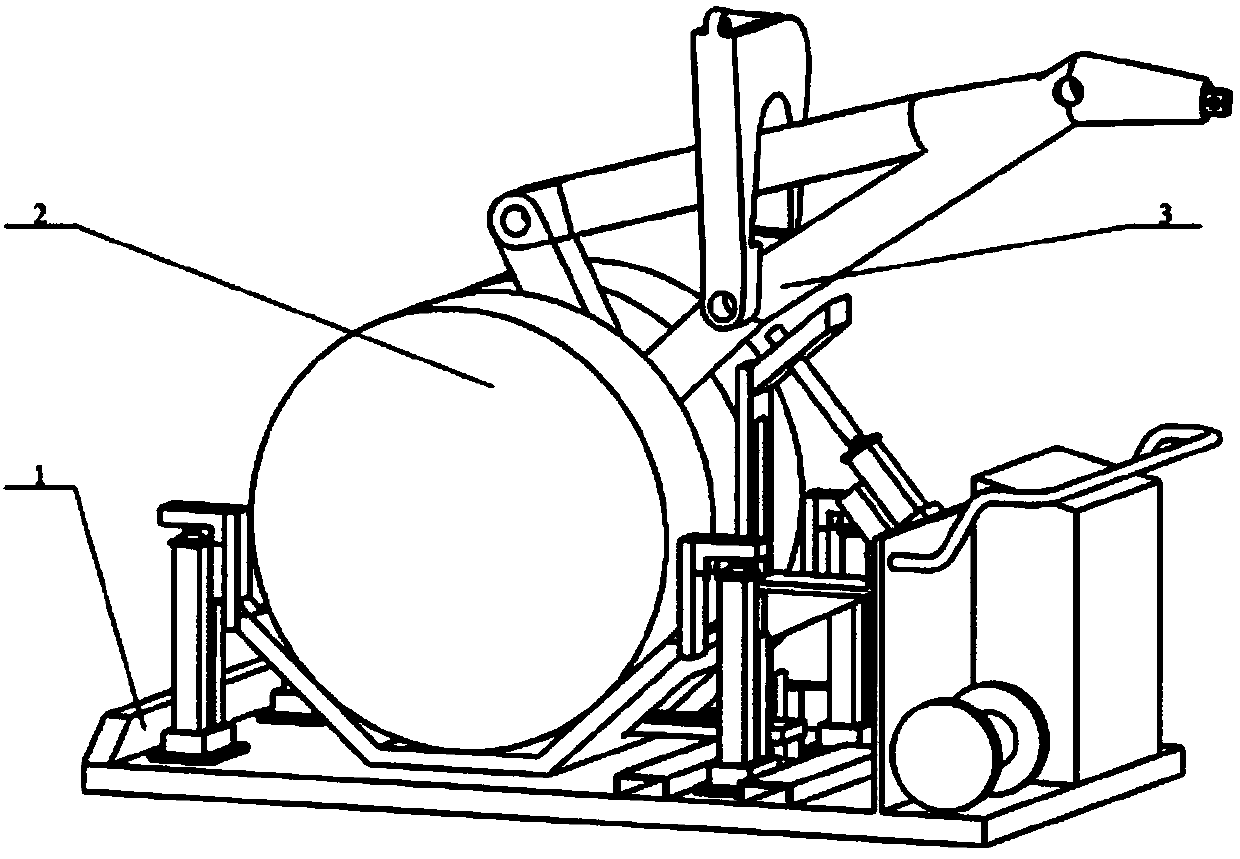

Assembly test vehicle of airplane main landing gear

InactiveCN103434654AIncrease freedomImprove assembly accuracyAircraft components testingJet aeroplaneAirplane

The invention discloses an assembly test vehicle of an airplane main landing gear, and an air floatation platform and five servo electric cylinders are used for achieving six-freedom-degree movement of the main landing gear and rotation of a strut of the nose landing gear along an axle. The movement amount, along an X axis and a Y axis, of the main landing gear and the rotation amount, along a Z axis, of the main landing gear can be adjusted manually, the movement amount, along the Z axis, of the main landing gear, the rotation amount, along the X axis and the Y axis, of the main landing gear and the rotation amount, along the axle, of the strut of the main landing gear can be adjusted quantitatively through the servo electric cylinders, and the six-freedom-degree movement is achieved through real-time quantitative control. The assembly test vehicle of the airplane main landing gear is high in freedom degree, easy to align in an assembly process and capable of achieving the quantitative control in the assembly process and flexible manual adjustment, and therefore assembly accuracy of the main landing gear is greatly improved.

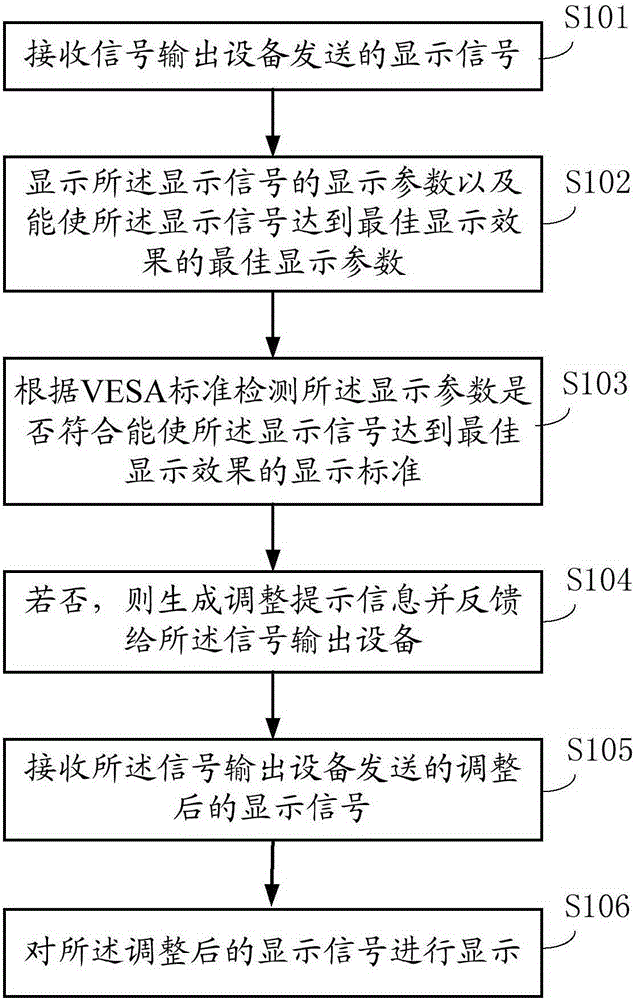

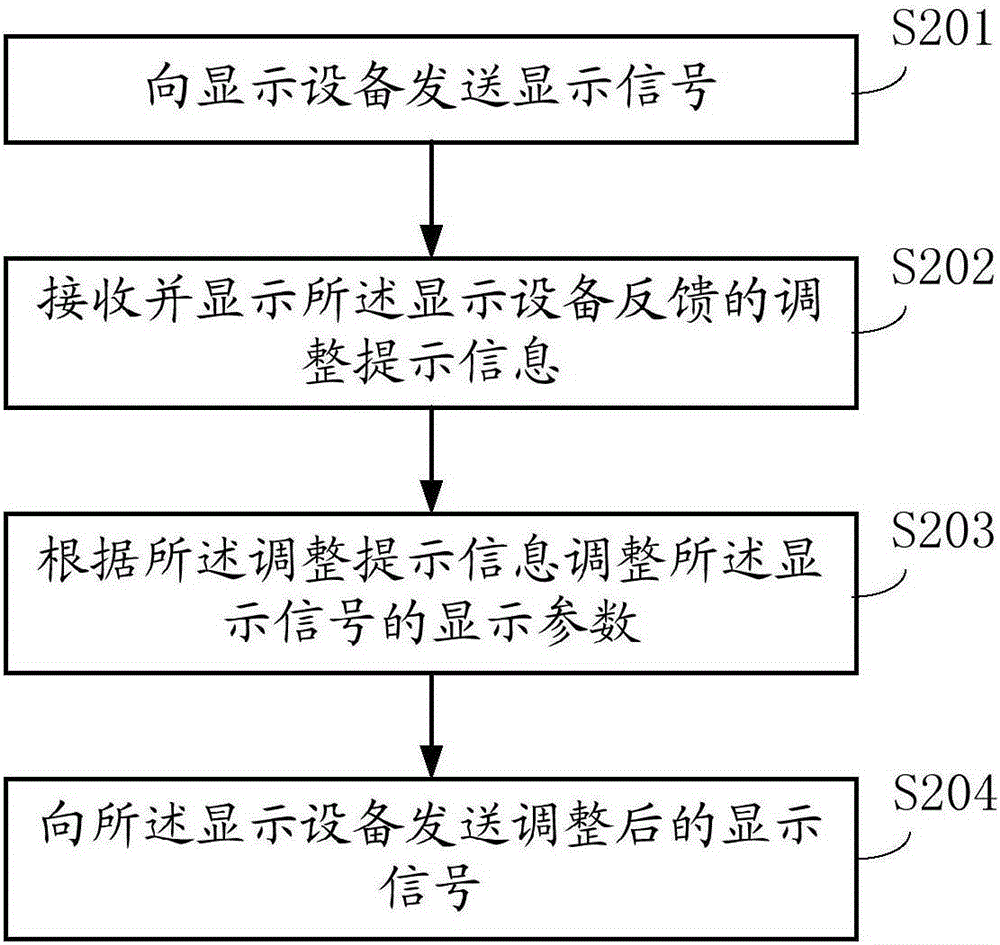

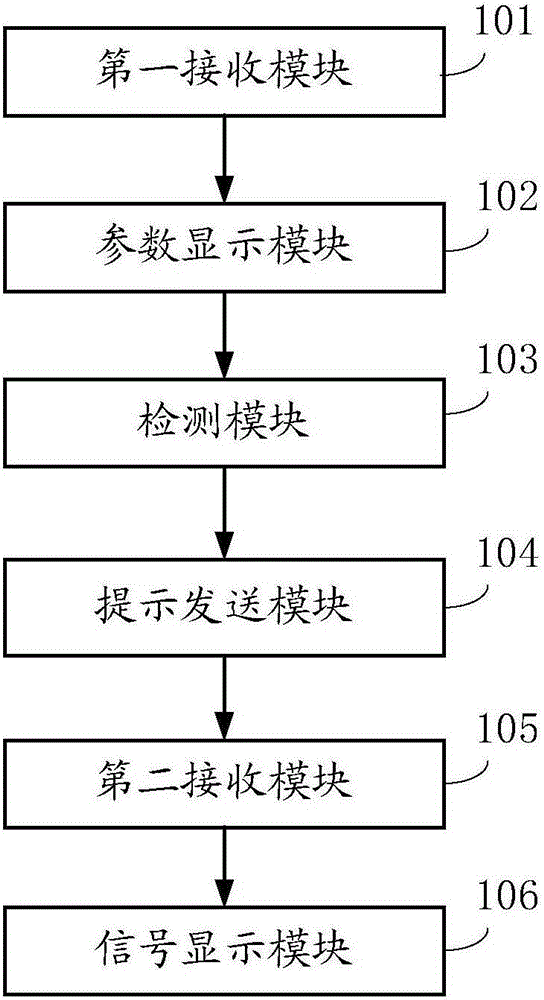

Method and system for adjusting display parameters of display signal

ActiveCN105225646ARealize automatic adjustmentImplement manual adjustmentStatic indicating devicesOutput deviceComputer engineering

The invention is applicable to the field of display and provides a method and system for adjusting display parameters of a display signal. The method comprises the following steps: receiving the display signal sent by a signal output device; displaying the display parameters of the display signal and an optimum display parameter enabling the display signal to reach an optimum display effect; detecting whether the display parameter meets a display standard enabling the display signal to reach the optimum display effect or not according to VESA standards; if not, generating adjusting prompt information and feeding the adjusting prompt information to the signal output device; receiving an adjusted display signal sent by the signal output device; and displaying the adjusted display signal. According to the invention, whether the display parameter of the display signal sent by the signal output device meets the standard or not is detected, and the adjusting prompt information is generated and sent to the signal output device if the display parameter of the display signal sent by the signal output device does not meet the standard, and the signal output device corrects the display signal, so that the functions of automatically identifying and adjusting the display signal to the optimum display effect are realized.

Owner:HKC CORP LTD

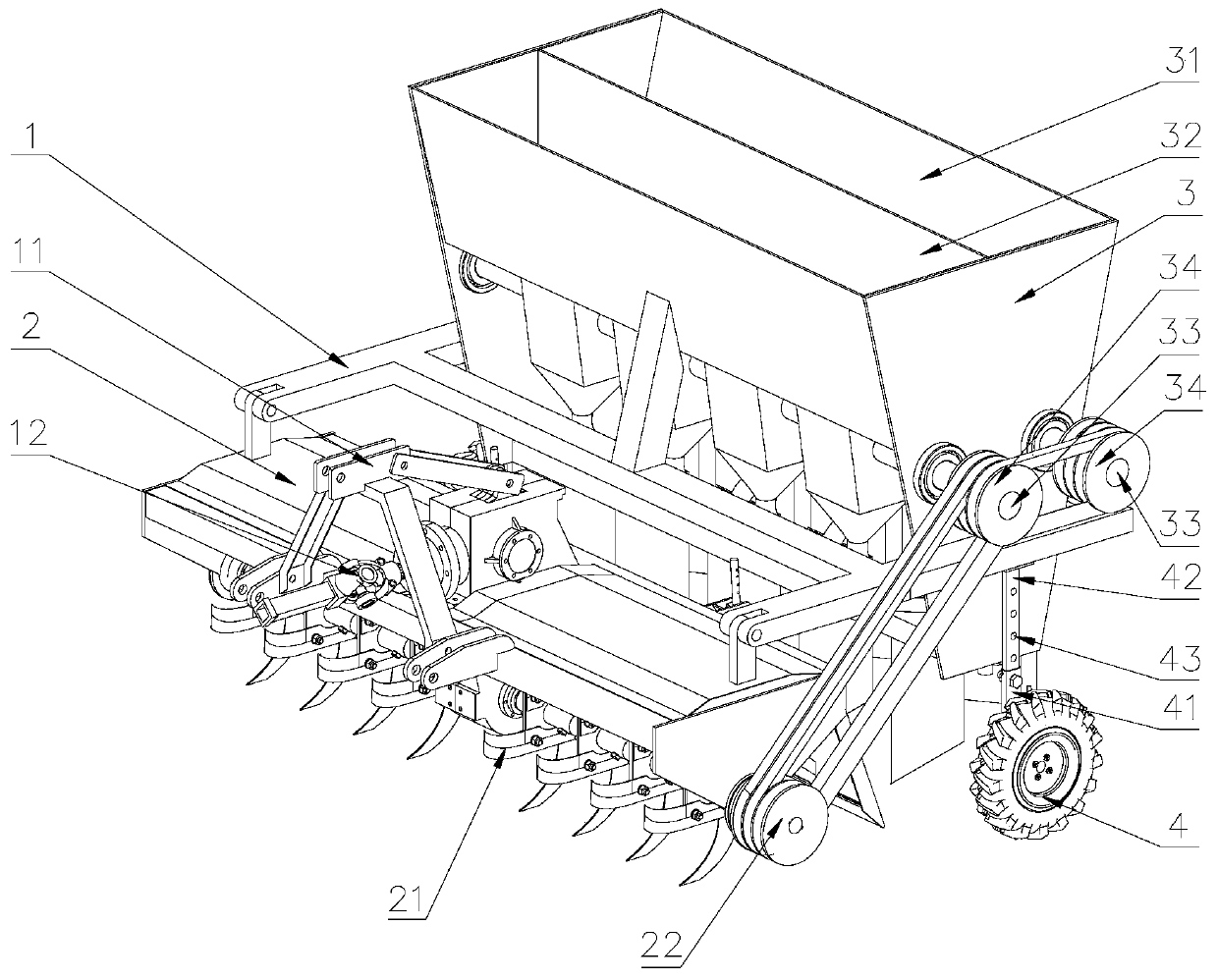

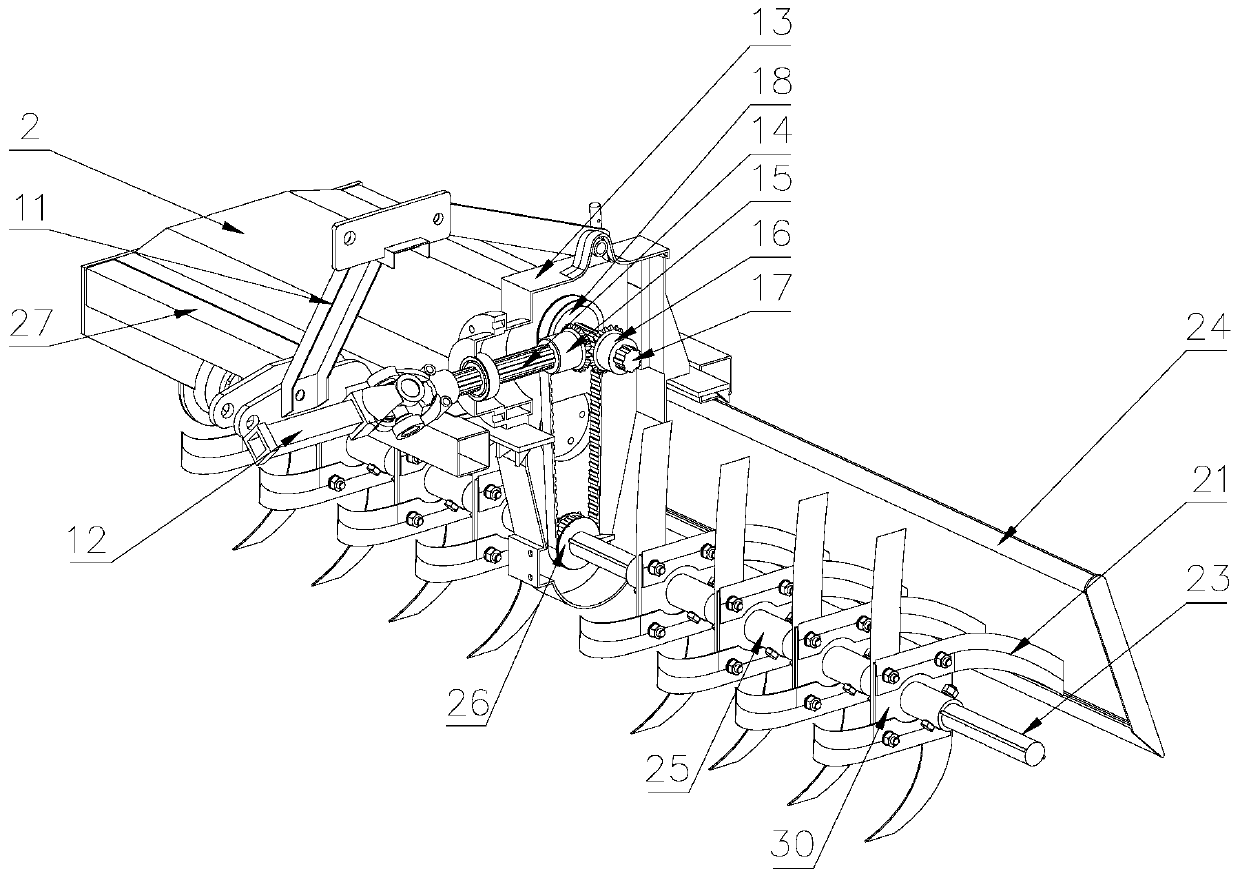

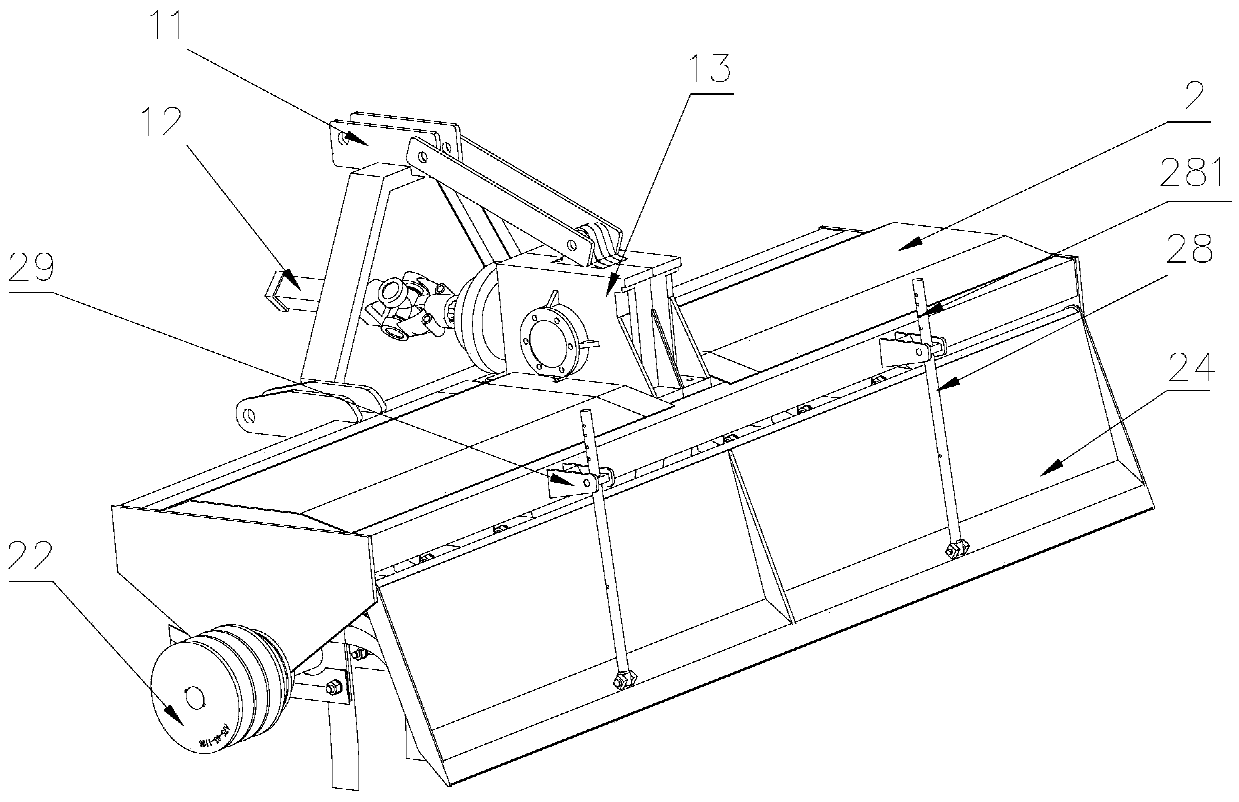

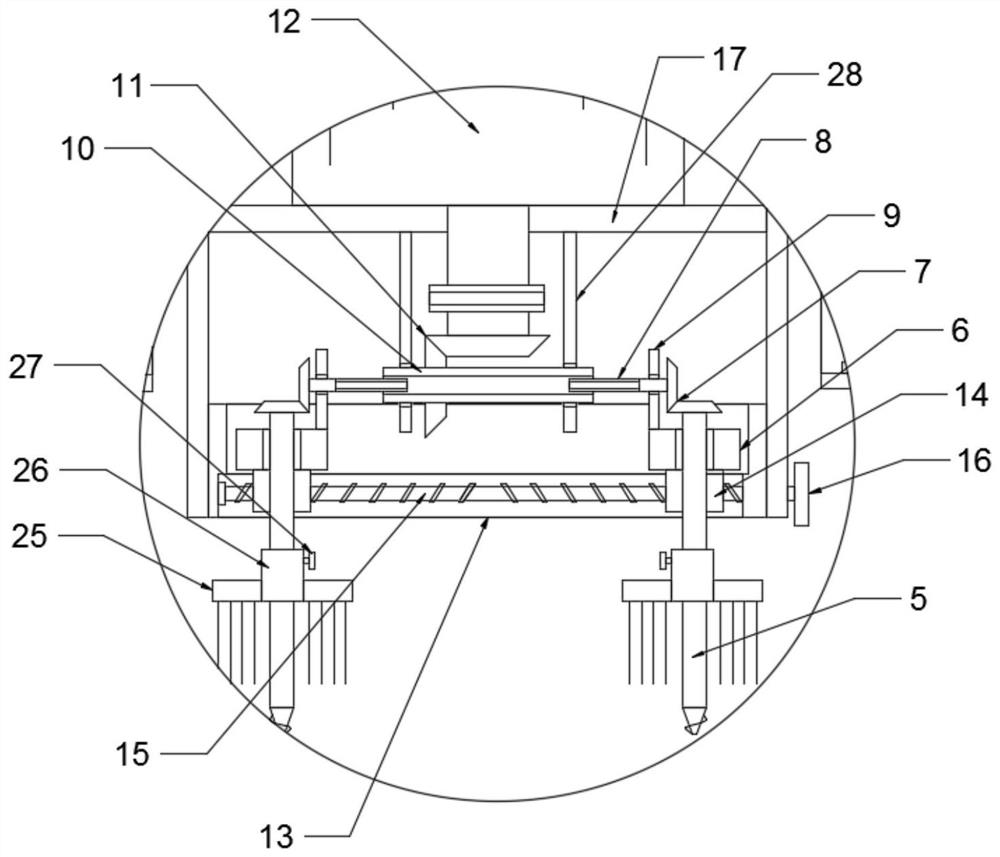

Soil loosening, sowing and fertilizing integrated device

InactiveCN111165105AImprove planting efficiencyGuarantee the effect of sowing and fertilizingSpadesPloughsAgricultural engineeringTillage

The invention discloses a soil loosening, sowing and fertilizing integrated device. A soil loosening device comprises a traction frame connected with a tractor, a coupler in transmission connection with an output shaft of the tractor, a shell and a transmission case arranged in the middle of the shell. A plurality of cutter heads are arranged on a third rotating shaft, and a plurality of rotary tillage blades are arranged on the cutter heads. A sowing and fertilizing device is connected with the soil loosening device through a fixing frame, a furrow opener is fixedly installed on a fixing plate, the lower end of a fixing rod is movably connected with a supporting wheel, and a plurality of second adjusting holes are formed in the fixing rod. The soil loosening device on one side of the fixing frame is connected with the output shaft of the tractor, the output shaft of the tractor rotates to drive the rotary tillage blades on the third rotating shaft to rotate to achieve soil loosening,seeds and fertilizer are poured into a storage bin of the sowing and fertilizing device on the other side of the fixing frame, sowing and fertilizing are achieved through the furrow opener, the soil loosening, sowing and fertilizing device is kept horizontal through the height-adjustable supporting wheel, and the sowing and fertilizing effect is guaranteed while the planting efficiency is improved.

Owner:SHANDONG AGRI & ENG UNIV

Regulating type fire extinguishing device for fire control

InactiveCN108144232AMeet different height needsAchieve clamping and fixingFire rescueFire controlWater storage tank

The invention discloses a regulating type fire extinguishing device for fire control. The regulating type fire extinguishing device comprises a motor, a rod body, universal wheels, a base, a second non-slip mat, a first non-slip mat, a water storage tank, and a sprayer; a barrel body is driven to rotate by using the rotation of the motor to drive a rotating seat to rotate, so that regulation of the water injection direction of the sprayer is further realized, manual regulation is not required, and a lot of manpower is saved; by adjusting the rod body to expand in the barrel body, the regulation of the height of the rotating seat is realized, the regulation of the height of the sprayer is further realized, and different height requirements of users in different situations and heights are met; by arranging the universal wheels, the device is conveniently moved for the users, therefore the fast fire extinguishing of the users is further facilitated when the fire occurs; and by arranging the second non-slip mat, the friction between the inner wall of a fixed groove and the sprayer is increased, and the effect of fixing the sprayer is improved.

Owner:ZHONGHUI ELECTROMECHANICAL TECH

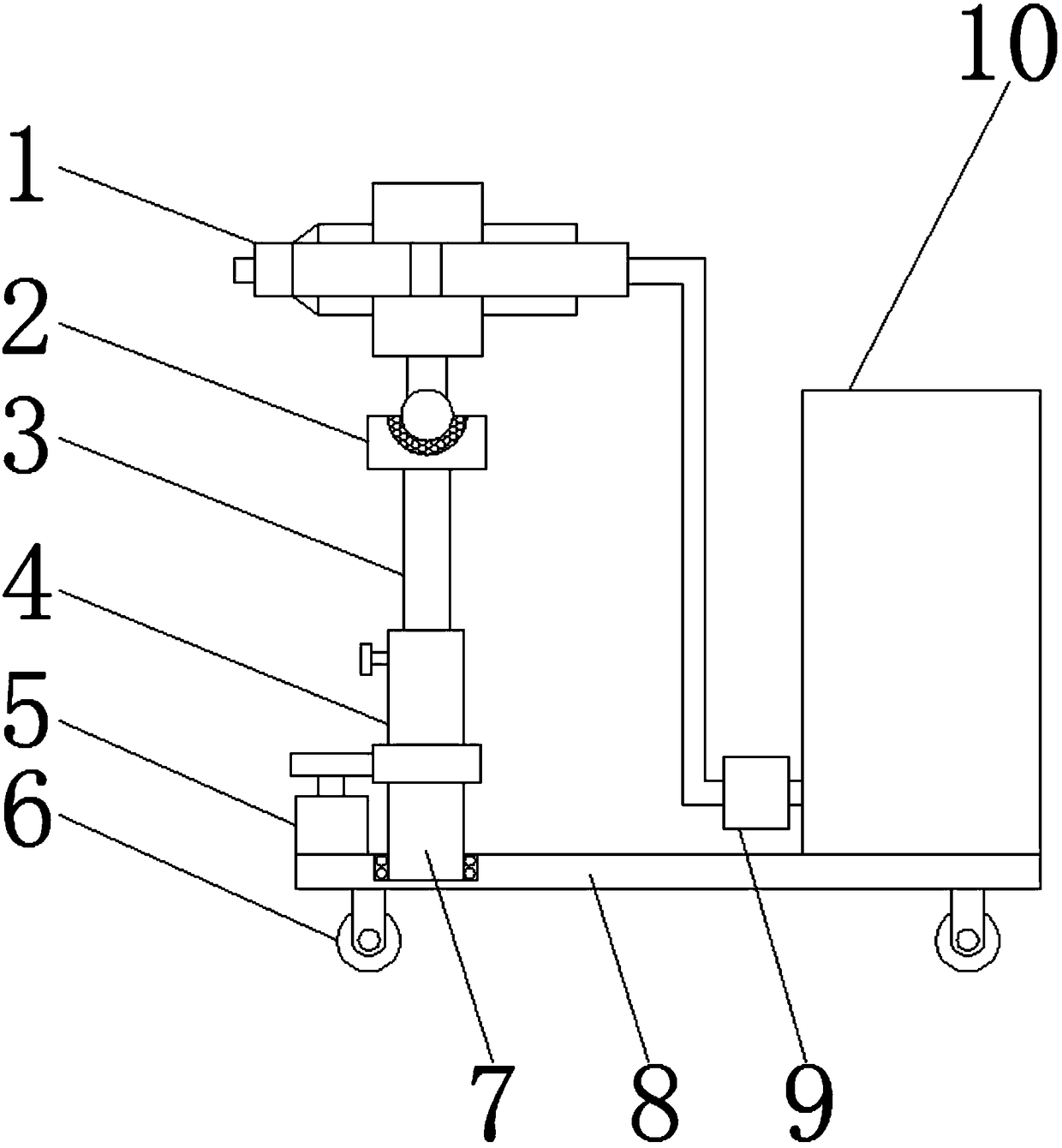

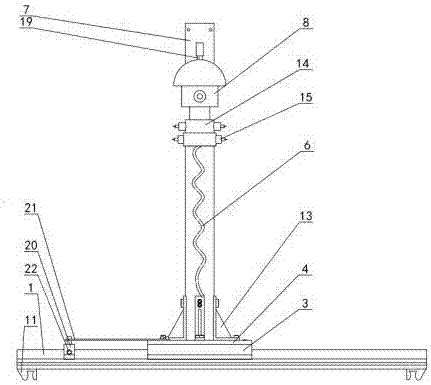

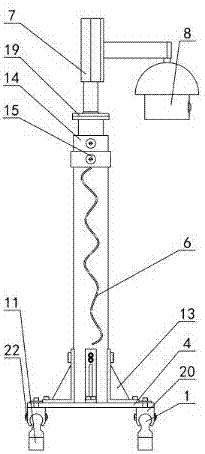

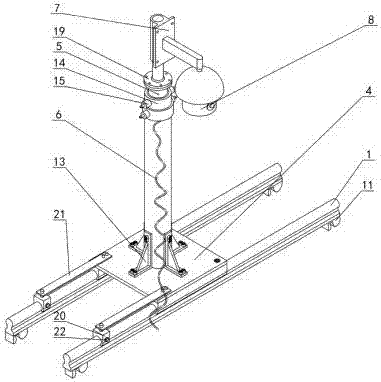

Vehicle-mounted lifting detecting device based on face recognition technology

InactiveCN106885113AImplement manual adjustmentRealize monitoringCharacter and pattern recognitionClosed circuit television systemsEngineeringCrowds

The invention discloses a vehicle-mounted lifting detecting device based on the face recognition technology. The vehicle-mounted lifting detecting device based on the face recognition technology comprises a sliding rail, a large sliding block matched with the sliding rail, a base fixed to the large sliding block and a manual lifting device fixed to the base. The two ends of the bottom of the sliding rail are fixedly provided with clamping devices. The portion, close to the base, of the sliding rail is provided with a fixing device used for fixing the base. A supporting plate is fixedly provided with a face recognition camera. A spiral cable is arranged in the manual lifting device. One end of the spiral cable is in circuit connection with the face recognition camera. The other end of the spiral cable is connected with a display processor. The vehicle-mounted lifting detecting device based on the face recognition technology has the beneficial effects that through the manual lifting device fixed to the base, the height of the monitoring device can be manually adjusted, the face recognition camera can achieve face monitoring and tracing in crowds, and the display processor processes and compares shooting data to find out a stated target.

Owner:ZHEJIANG UNIV OF TECH

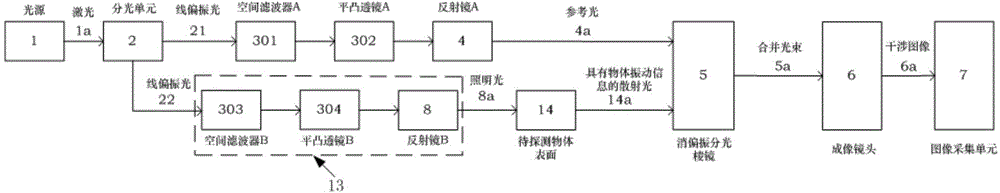

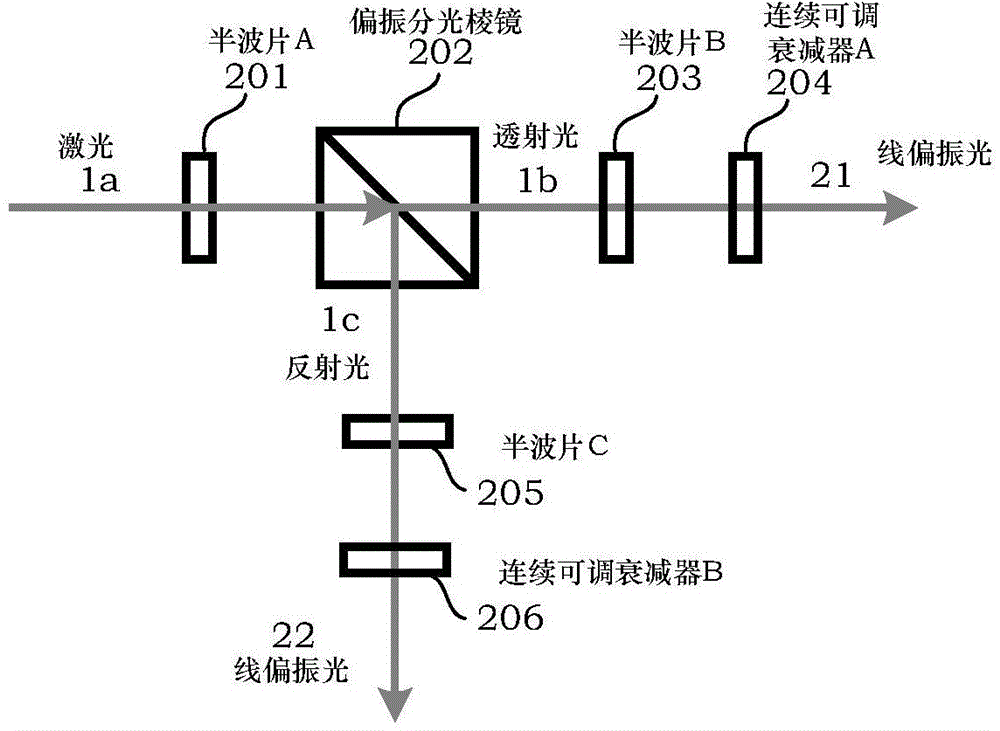

Micro-vibration long-distance real time image detecting system based on image surface digital holography

InactiveCN104535171AAvoid diffractionEasy to useSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansCamera lensOptoelectronics

The invention discloses a micro-vibration long-distance real time image detecting system based on image surface digital holography. Received laser is divided into two beams of linear polarized light by a light split unit, and then the two beams of the linear polarized light are input in two spatial filters; one beam of the linear polarized light sequentially passes through a planoconvex lens and a reflector, and then the beam of the linear polarized light is seemed as reference light passes into a dispolarization splitting prism; the other beam of the linear polarized light sequentially passes through a planoconvex lens and a reflector and turns into illumination light. The illumination light irradiates the outer surface of an object which is to be detected, passes into the dispolarization splitting prism after scattering, and is output into an image collecting device through an imaging lens. Using a high-speed CMOS camera, digital hologram can be continuously shot at a high-speed. The detection range of the vibration frequency of the device can be improved, and multi-position micro-vibration long-distance real time detection in a certain area of the outer surface of the object can be achieved.

Owner:BEIHANG UNIV

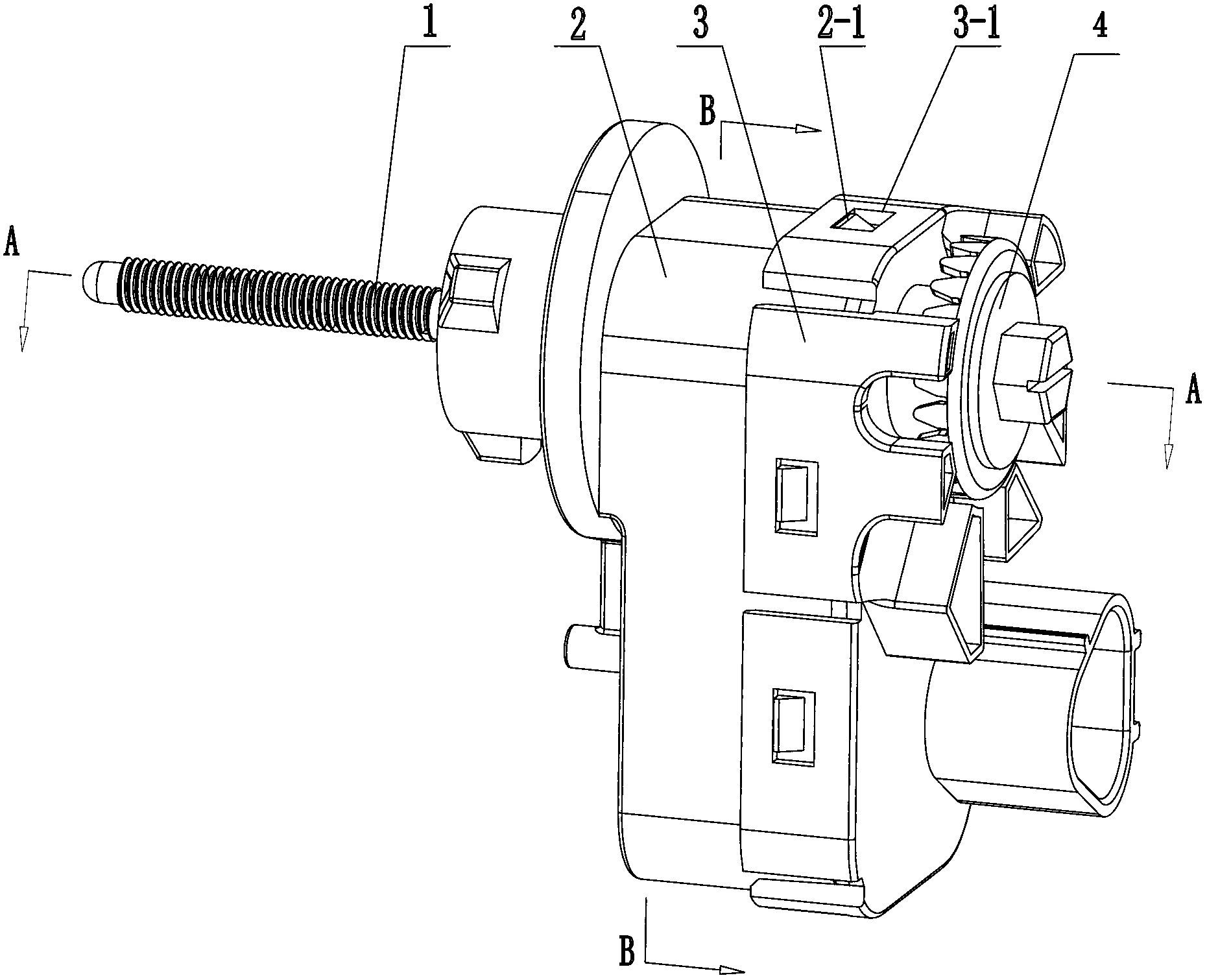

External dimming motor device for automotive headlamp

InactiveCN102700456AAchieve regulationImplement manual adjustmentOptical signallingMotor driveDrive shaft

The invention relates to an external dimming motor device for an automotive headlamp. A regulating mechanism comprises a dimming screw rod and a shaft sleeve connected with the dimming screw rod, wherein the shaft sleeve is supported in a bearing seat of a shell; a motor worm of a motor driving mechanism is arranged on an output shaft of a motor, two sides of a transmission shaft are respectively arranged on two shaft seats of the shell; a middle worm gear on the transmission shaft is meshed with the motor worm, a middle worm on the transmission shaft is meshed with a worm gear on a gear sleeve, and an inner hole of the gear sleeve is connected with the shaft sleeve through threads; and a circuit board arranged in the shell is electrically connected with the motor and is used for controlling the continuous operation of the motor, a rear cover is arranged at the rear part of the shell in a sealing mode, a manually regulating sleeve provided with bevel gears at the periphery or / and notches at the rear part is arranged on the rear cover in a sealing mode, and the manually regulating sleeve is connected with the rear part of the dimming screw rod. According to the device disclosed by the invention, dimming can be carried out by the motor or manually, the size and the weight of the whole device can bes reduced, and the cost is reduced.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

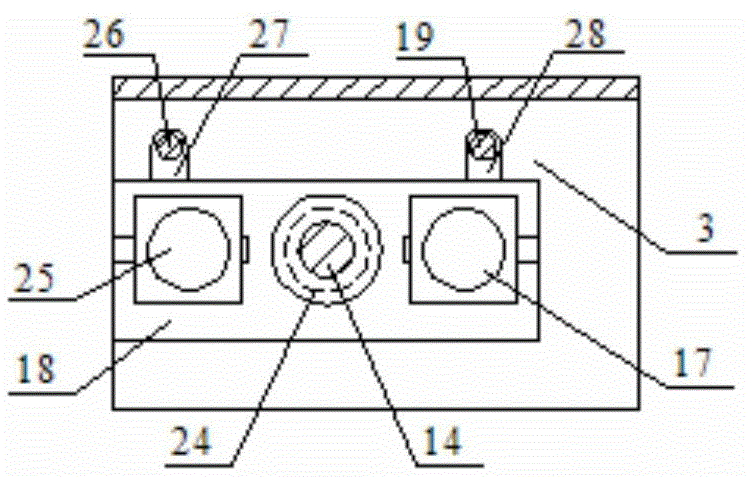

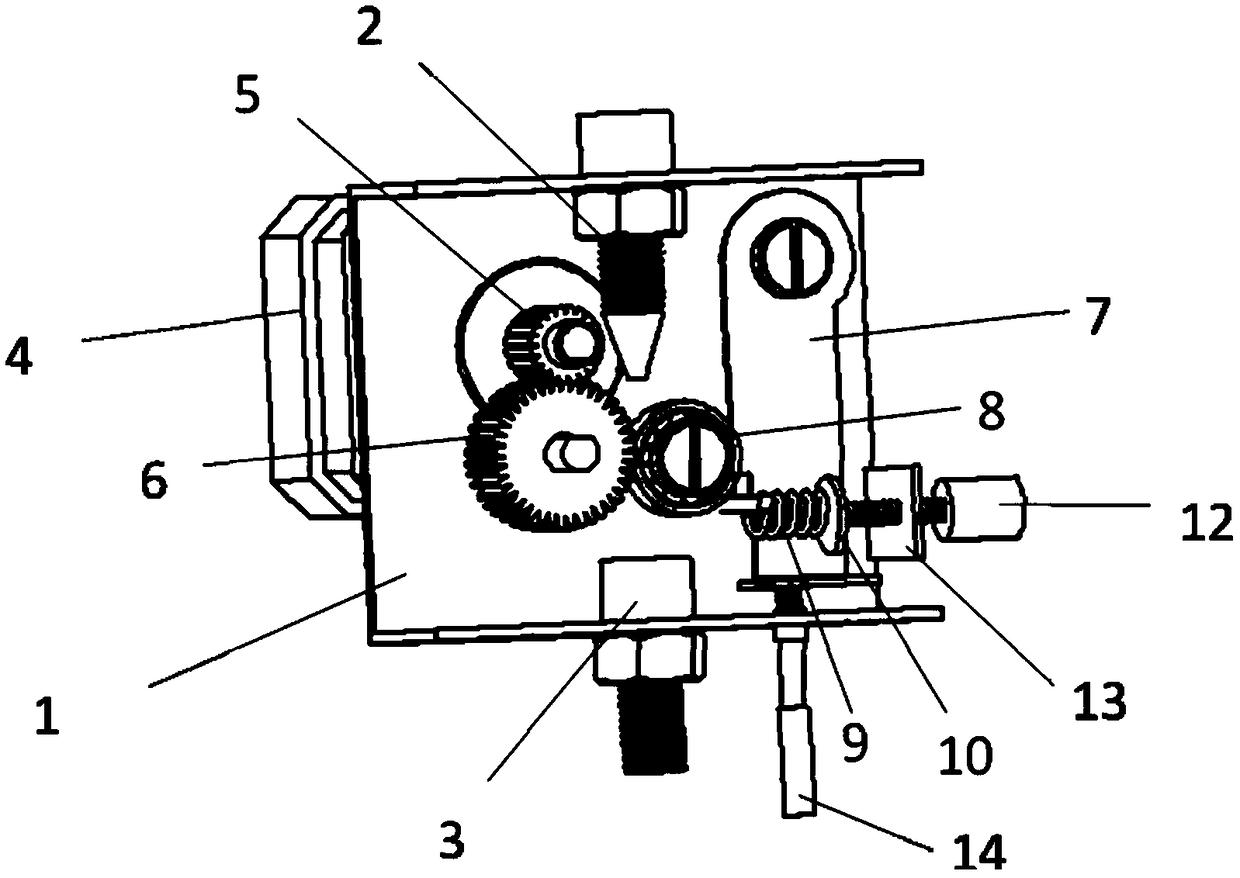

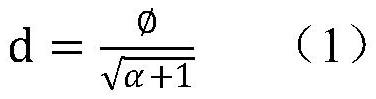

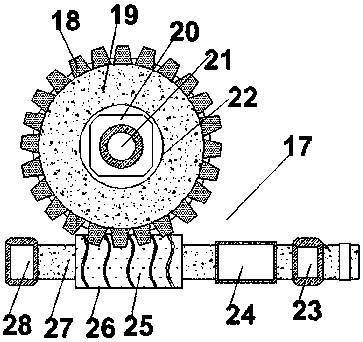

Precise and fine wire feeding machine

PendingCN108772617ARealize precise controlMeet different transmission ratio requirementsArc welding apparatusDrive wheelTooth number

The invention provides a precise and fine wire feeding machine which comprises a machine frame groove, a wire feeding guide tube, a wire discharging guide tube and a pressing mechanism. The wire feeding guide tube is arranged on one side wall of the machine frame groove, the wire discharging guide tube is arranged on the other side wall of the machine frame groove, and the wire feeding guide tubeand the wire discharging guide tube are located in the same straight line to form a wire feeding route. The pressing mechanism is mounted in the machine frame groove and located on one side of the wire feeding route. The precise and fine wire feeding machine further comprises a transmission mechanism arranged on the other side of the wire feeding route. The transmission mechanism comprises a motor, a driving wheel and a driven wheel. The motor is fixedly mounted on the machine rack groove, and an output shaft of the motor is provided with the driving wheel. The driven wheel is fixedly mountedin the machine frame groove and is engaged with the driving wheel. The driving wheel and the pressing mechanism are matched to achieve wire feeding. The driving wheel is engaged with the driving wheelwith different tooth number, the different transmission ratio requirements can be met, and different wire feeding speed is obtained.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

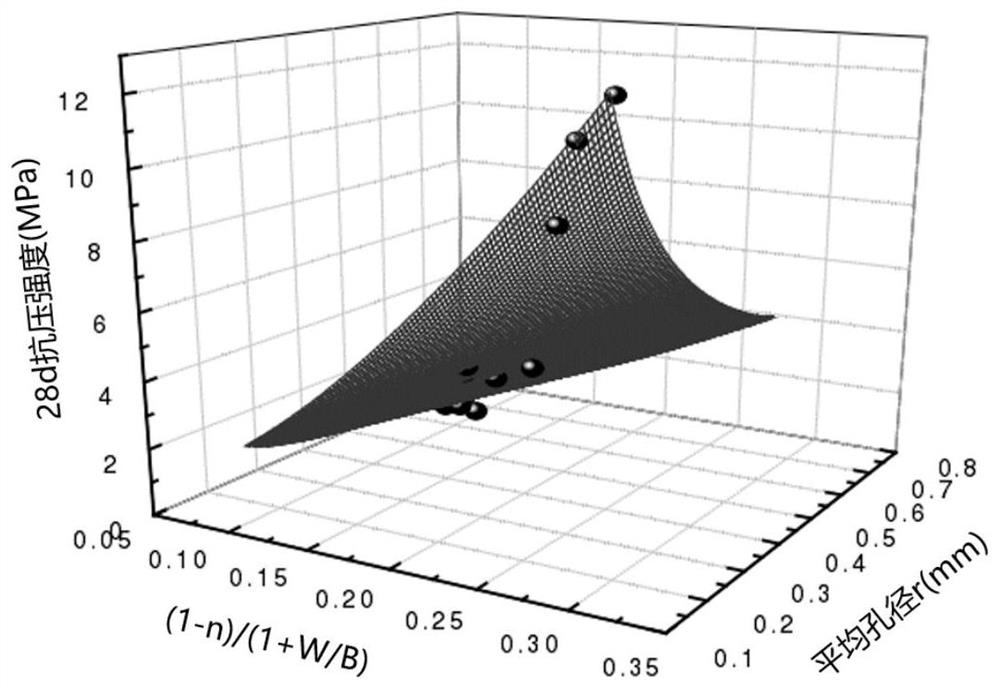

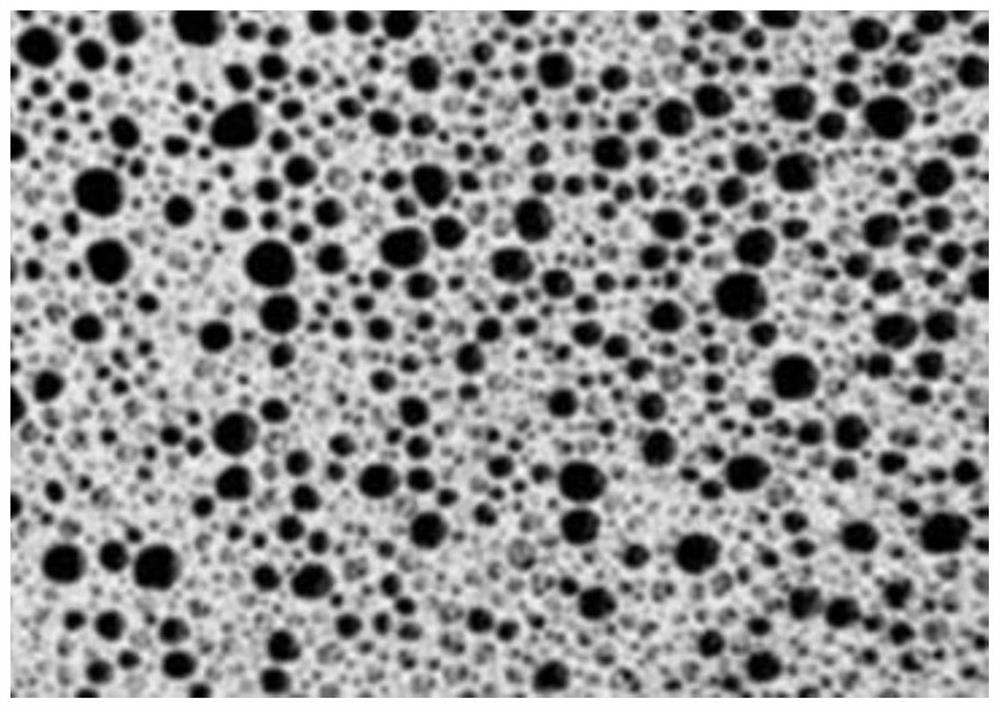

Preparation method of foam concrete with adjustable pore characteristics

ActiveCN111863155AImplement manual adjustmentAdjust apertureComputational materials scienceInstrumentsFoam concreteShrinkage cracking

The invention relates to a preparation method of foam concrete with adjustable pore characteristics, and belongs to the technical field of concrete. The foam concrete comprises an expansion and shrinkage material, cement and mixing water. The preparation method comprises the following steps: designing a mixing ratio, calculating and weighing the mass of each required material, carrying out pre-water-absorption treatment on the dry expansion and shrinkage material, stirring cement slurry, and uniformly stirring the expansion and shrinkage material subjected to the pre-water-absorption treatmentand the cement slurry to obtain the foam concrete. According to the invention, the problems of defoaming, pore structure, shrinkage cracking and foaming agent in the existing foam concrete preparation method can be effectively solved; during blending ratio design, the dry density, the designed pore diameter and the designed strength are taken as design indexes, the pore characteristics can be adjusted, the defect that the strength grade of the foam concrete cannot be controlled due to the fact that only the dry density is taken as the design index in an existing foam concrete mix proportion design method is overcome, and the produced foam concrete can meet the requirements for the dry density and the strength at the same time.

Owner:SHANDONG UNIV +1

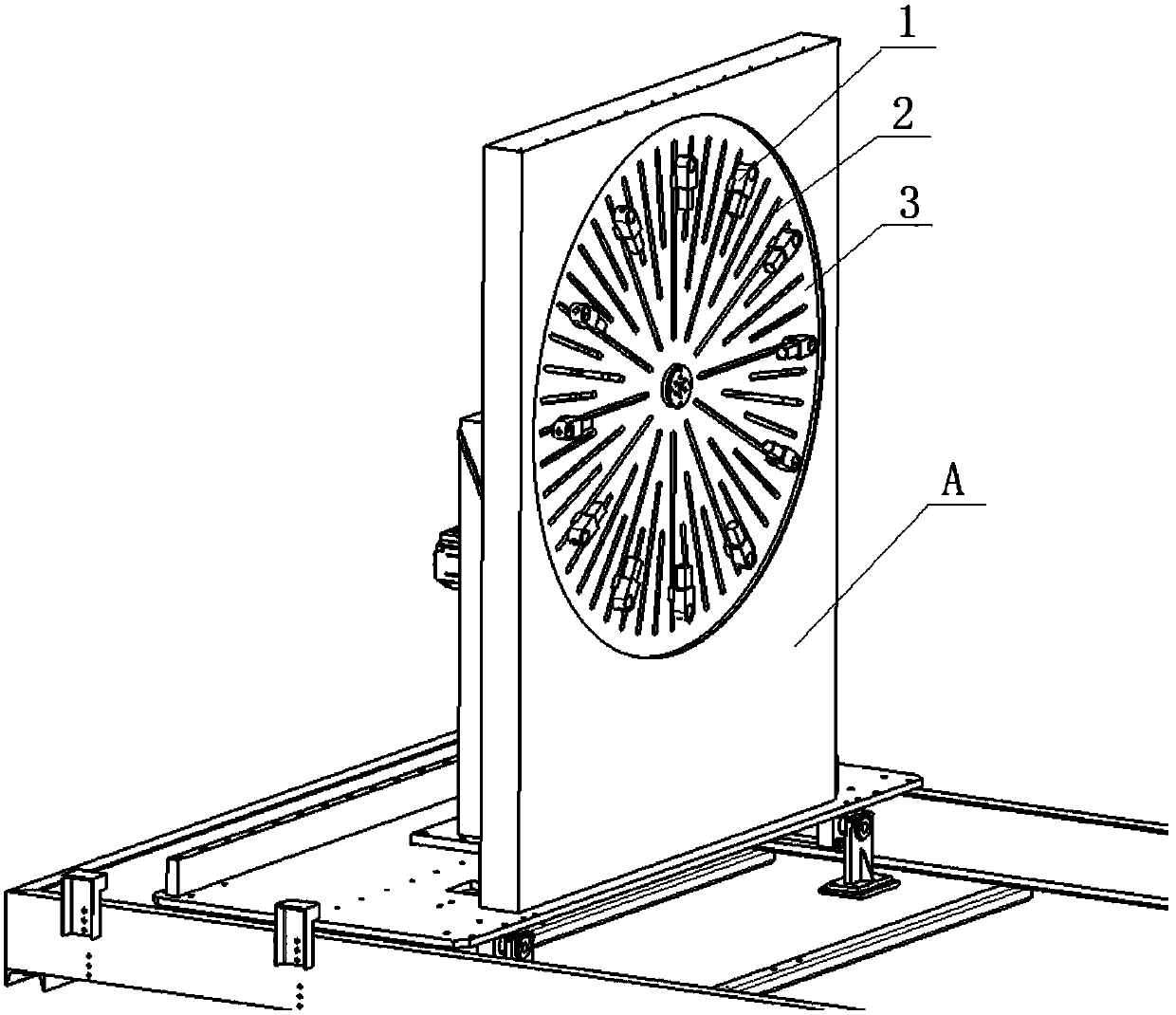

Radial adjusting mechanism of Y-shaped rolling mill

ActiveCN105728471ARealize online adjustmentAccurate transmission adjustment positionMetal rolling stand detailsMetal rolling arrangementsRadial positionEngineering

The invention discloses a radial adjusting mechanism of a Y-shaped rolling mill and aims to overcome the problems that some of the Y-shaped rolling mills have no radial adjusting devices, the rolling reduction is non-adjustable, or the radial adjustment is achieved under unreasonable transmission structures, the adjustment amount is extremely small and difficultly meets the basic requirement of steady transmission, the service life of the rolling mill is seriously influenced, or the structure is complex, the processing and manufacturing difficulty is high, the cost is high, and the rolling mill is unsuitable for rolling special-shaped products. The radial adjusting mechanism of the Y-shaped rolling mill is characterized in that a main eccentric sleeve and a secondary eccentric sleeve are mounted on each main shaft; a worm mechanism sleeves each main eccentric sleeve; the worm mechanism drives the eccentric sleeves to rotate and accurately adjust the radial position of the roller. The radial adjusting mechanism of the Y-shaped rolling mill has the beneficial effects that on-line adjustment can be implemented; the requirements of the manufacturing accuracy and the assembly accuracy are relatively low; the adjusted radial position accuracy is high; the worms are located on front and back surfaces or the sides of the rolling mill; the servo control motor is conveniently mounted; the radial position can be rapidly and accurately adjusted on line.

Owner:沈阳重机重矿机械设备制造有限公司 +1

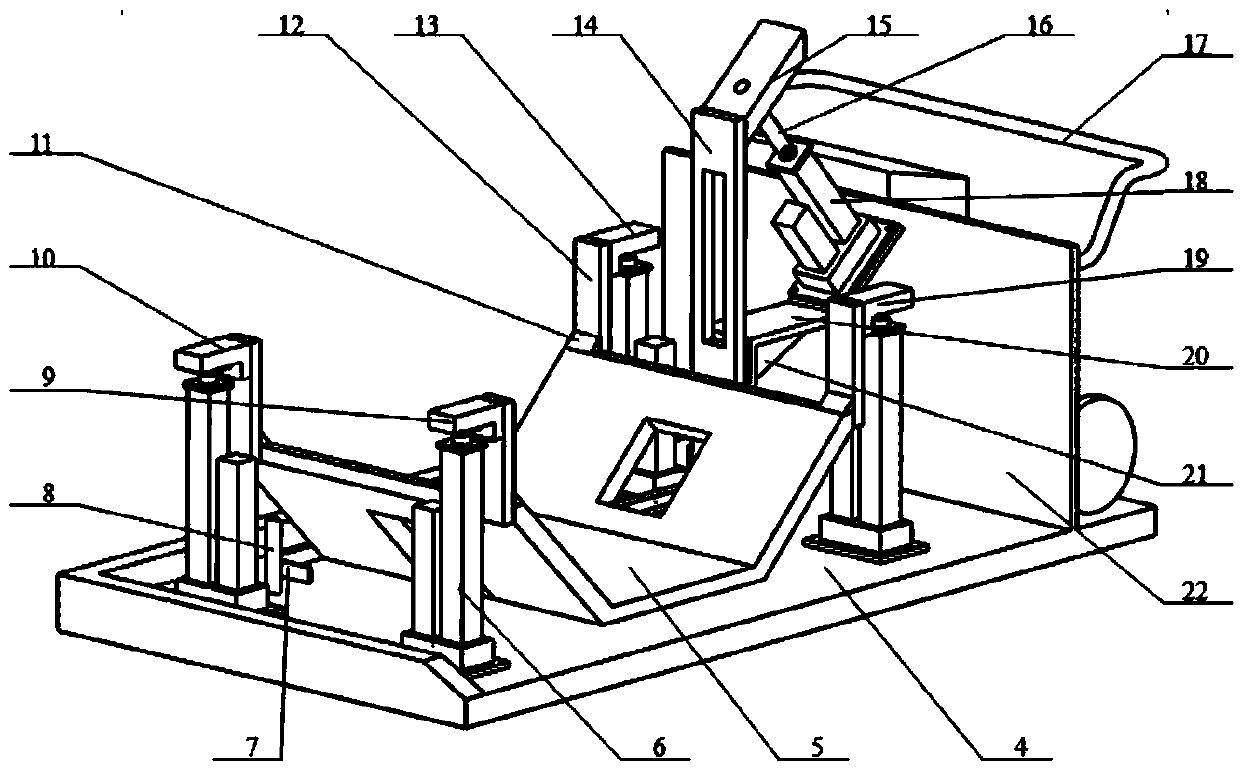

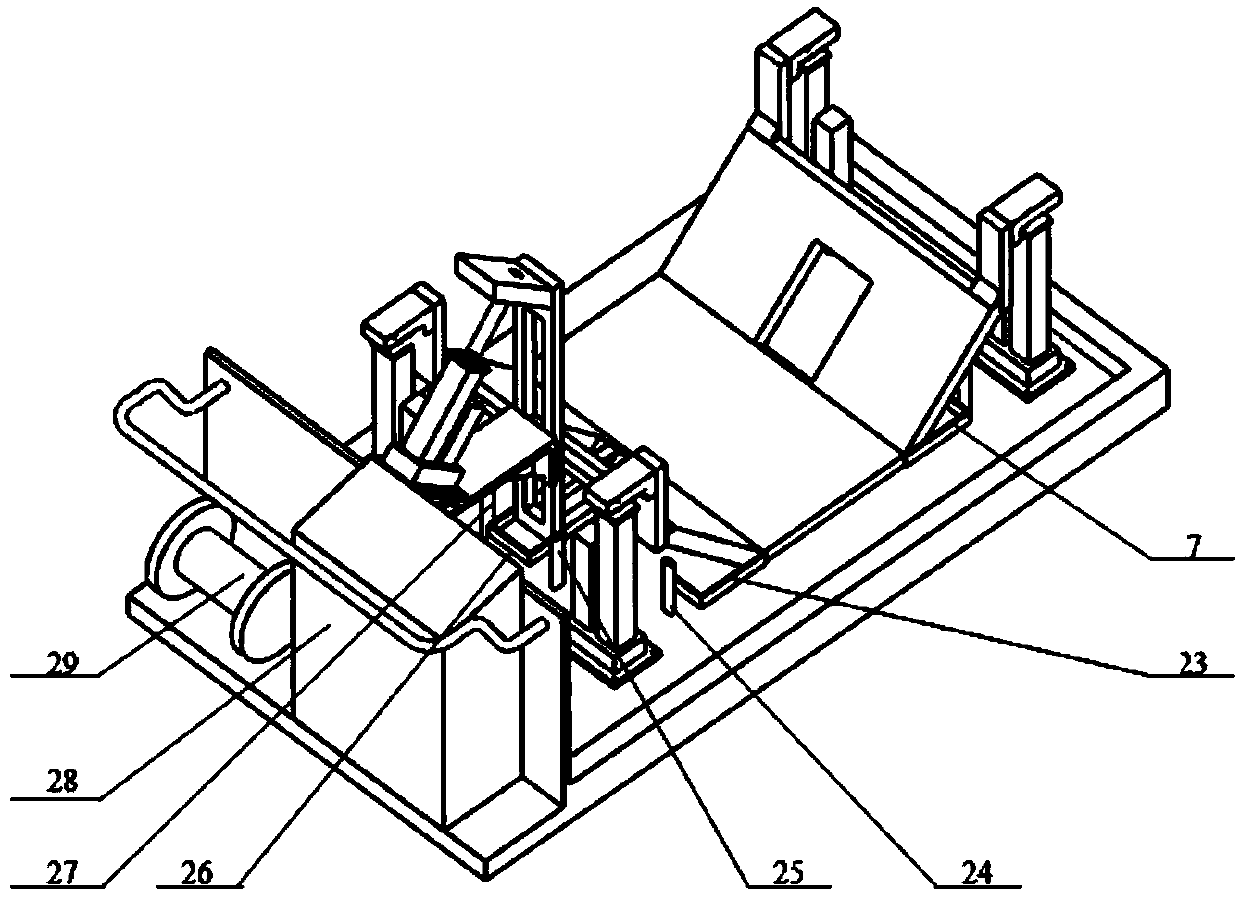

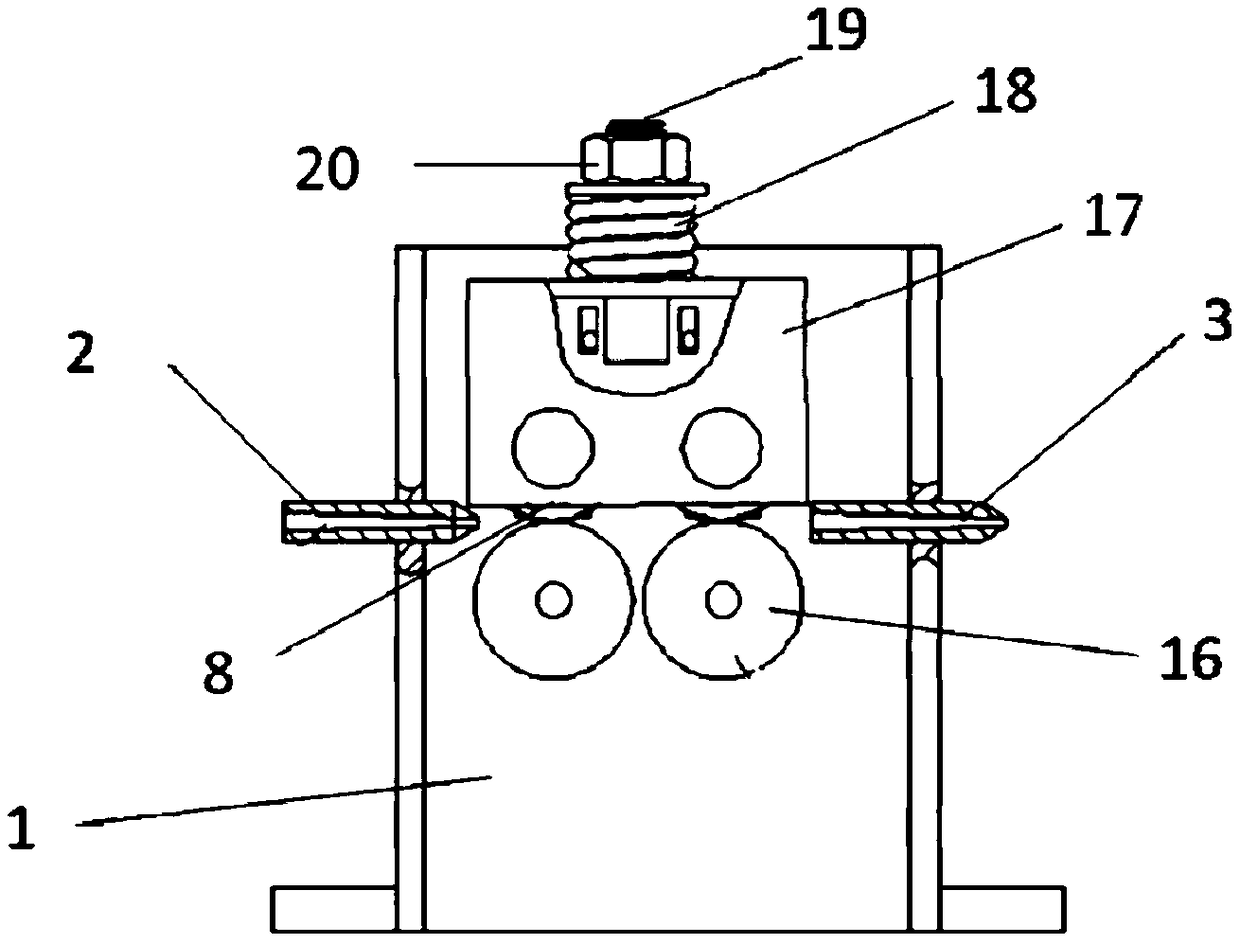

Movable hydraulic automatic reinforcement cage main reinforcement clamping device

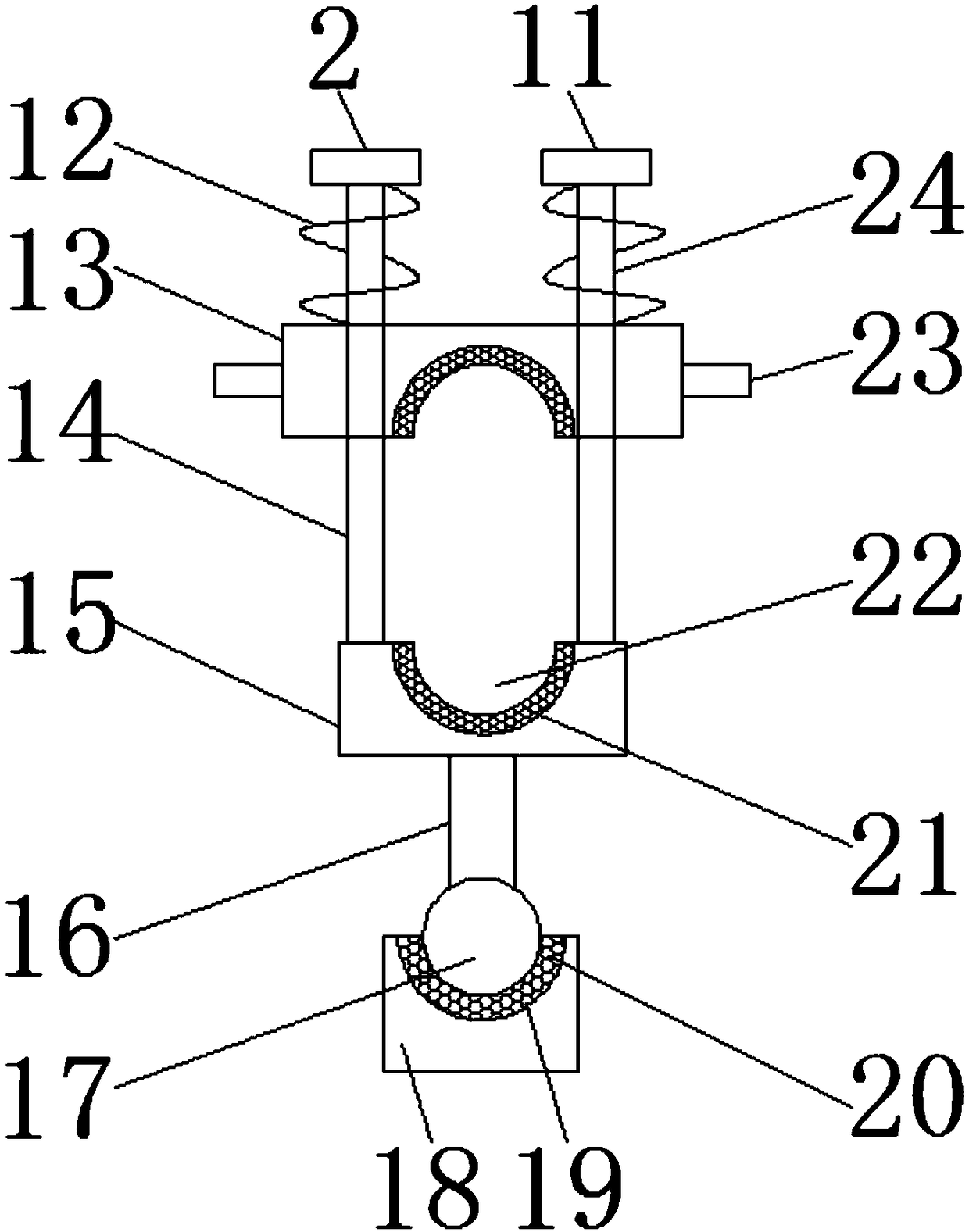

ActiveCN107717291ASimple structureLarge clamping forceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention discloses a movable hydraulic automatic reinforcement cage main reinforcement clamping device and relates to the field of reinforcement cage automatic production equipment. The problemsthat existing reinforcement cage seam welder main reinforcement clamping devices are insufficient in clamping force, high in workload and low in efficiency are solved. The movable hydraulic automaticreinforcement cage main reinforcement clamping device comprises a clamping body, a hydraulic cylinder of which the outer side of the upper end is fixedly connected with the outer side of the lower endof the clamping body, a pretightening rod which is arranged in the clamping body and fixedly connected with a piston rod of the hydraulic cylinder, a rotation brake screw inserted into the clamping body and fixed to the side face of the upper end of the pretightening rod, a right-angle oil circuit block fixed to the side face of the outer portion of the clamping body, a rotary shaft which extendsinto the right-angle oil circuit block and is fixedly connected with the right-angle oil circuit block, and a hydraulic oil pipeline of which the upper end extends into the right-angle oil circuit block and the rotary shaft, wherein the upper end of the pretightening rod makes contact with a reinforcement cage main reinforcement; the hydraulic cylinder drives the pretightening rod through the piston rod so that the reinforcement cage main reinforcement can be clamped in the clamping body; a hydraulic oil pump is connected with the upper end of the hydraulic oil pipeline; and the lower end ofthe hydraulic oil pipeline communicates with the interior of the hydraulic cylinder through a valve. The movable hydraulic automatic reinforcement cage main reinforcement clamping device is large in clamping force, low in workload and high in efficiency.

Owner:CHANGCHUN UNIV OF SCI & TECH

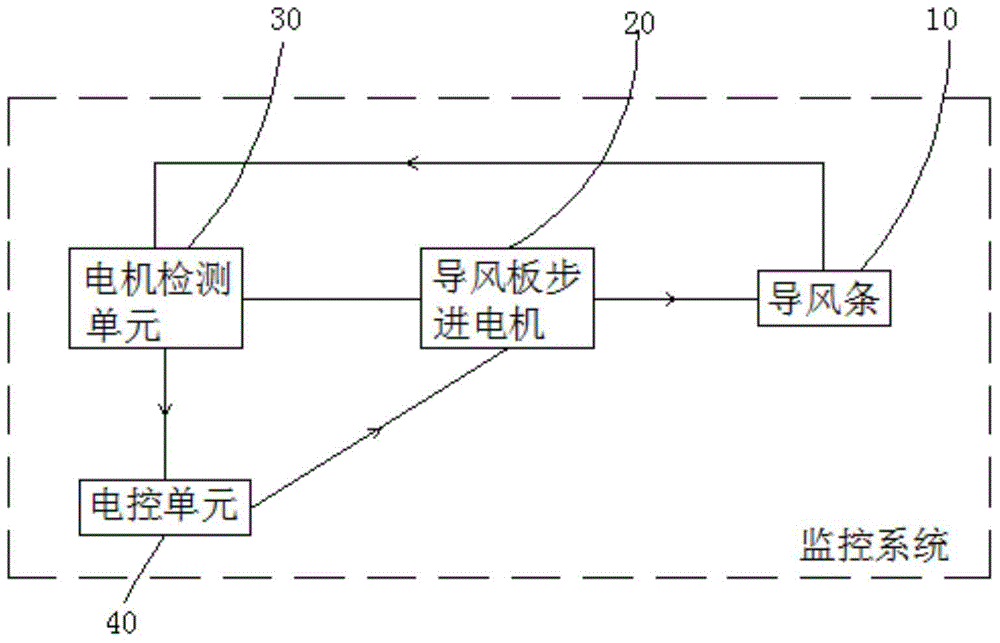

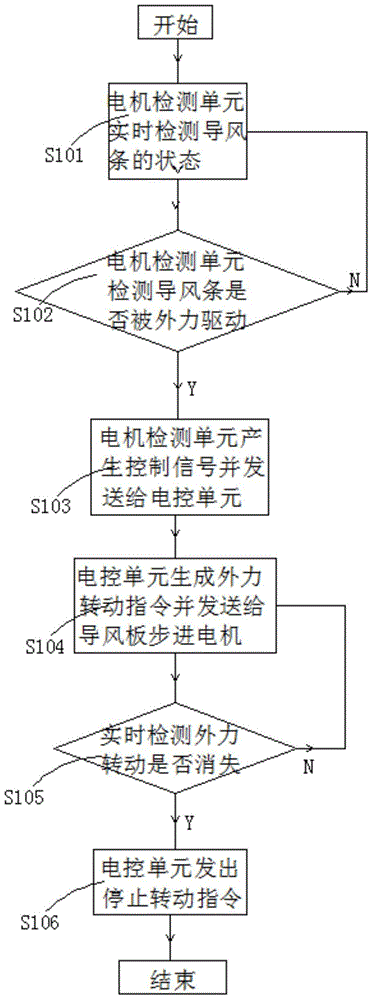

Air guidance monitoring method and system of air conditioner

ActiveCN104930649AImplement manual adjustmentMeet needsMechanical apparatusSpace heating and ventilation safety systemsControl signalElectric machine

The invention relates to the field of household air conditioners, in particular to an air guidance monitoring method and a system of an air conditioner. The air guidance monitoring method of the air conditioner comprises the following steps: (S101) a motor detecting unit detects the state of an air guide strip in real time; (S102) the motor detecting unit detects if the air guide strip is rotated by external force to change an air guide direction; if so, a step (S103) is performed; otherwise, the step (S101) is returned to; (S103) the motor detecting unit generates a control signal, and sends to an electric control unit; and (S104) after the electric control unit receives the control signal of the motor detecting unit, an external force rotating instruction is generated according to the control signal and sent to an air guide plate stepper motor; and the air guide plate stepper motor rotates in the external force direction to drive the air guide strip to rotate.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Primary spring load adjustment method in rail vehicle servicing state

ActiveCN107235051AAvoid join jobsIncrease productivityBogie-underframe connectionsRailway auxillary equipmentBogieLoad distribution

The invention discloses a primary spring load adjustment method in the rail vehicle servicing state. By means of a hydraulic adjusting device and a limiting cushion block, adjustment on a primary bearing steel spring in the vehicle servicing state is achieved, the hydraulic adjustment device comprises a separating manual double acting hydraulic jack, a high strength draw-in bolt and a bearing plate. The high strength draw-in bolt is connected with a bogie spring base, the acting force of the hydraulic jack is transmitted in the servicing state to press a primary spring to make a primary spring base separated from an axle box to form a gap, and an adjusting gasket is additionally arranged between a bogie swiveling jib and the primary spring base; primary spring load distribution is changed. According to the primary spring load adjustment method in the rail vehicle servicing state, compared with other adjustment methods in the prior art, operation of separating connection of a bogie and a vehicle body is avoided, the production efficiency is improved, and the manufacturing efficiency is greatly improved. Accordingly, operation is conducted conveniently, applied equipment is simple, the adjustment effect is good, and very high practicability and applicability are achieved.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

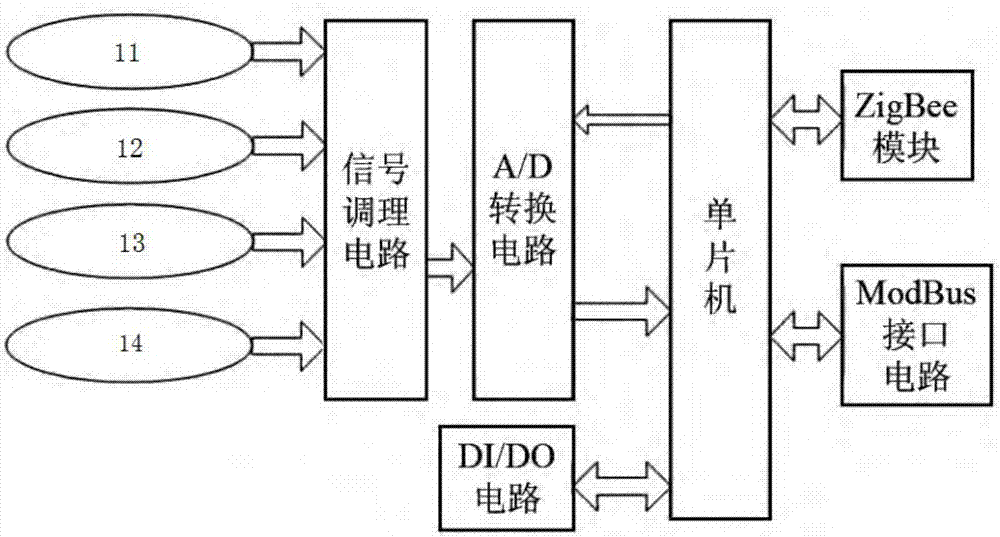

CMOS sensor-based embedded correction system and correction method thereof

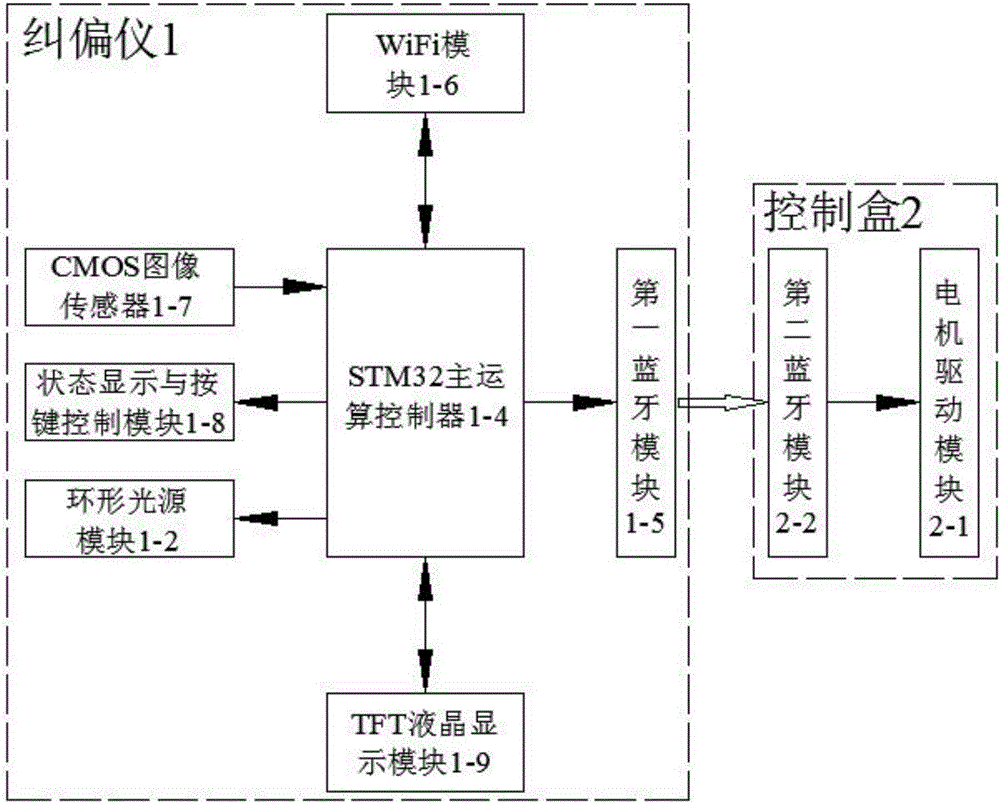

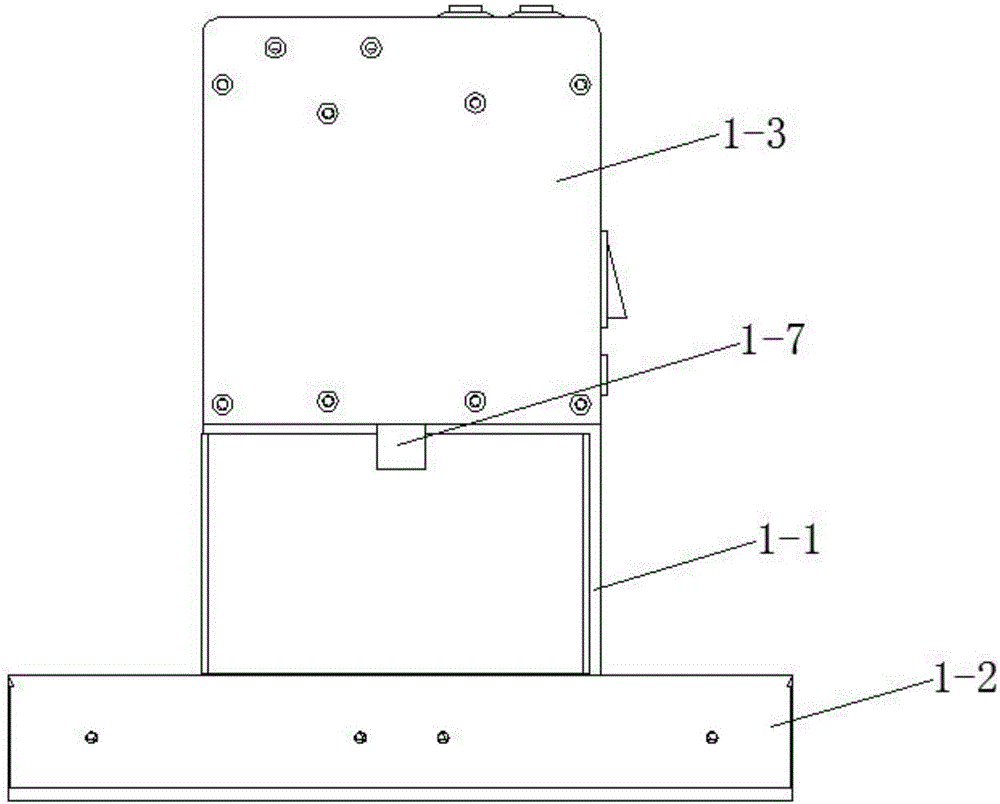

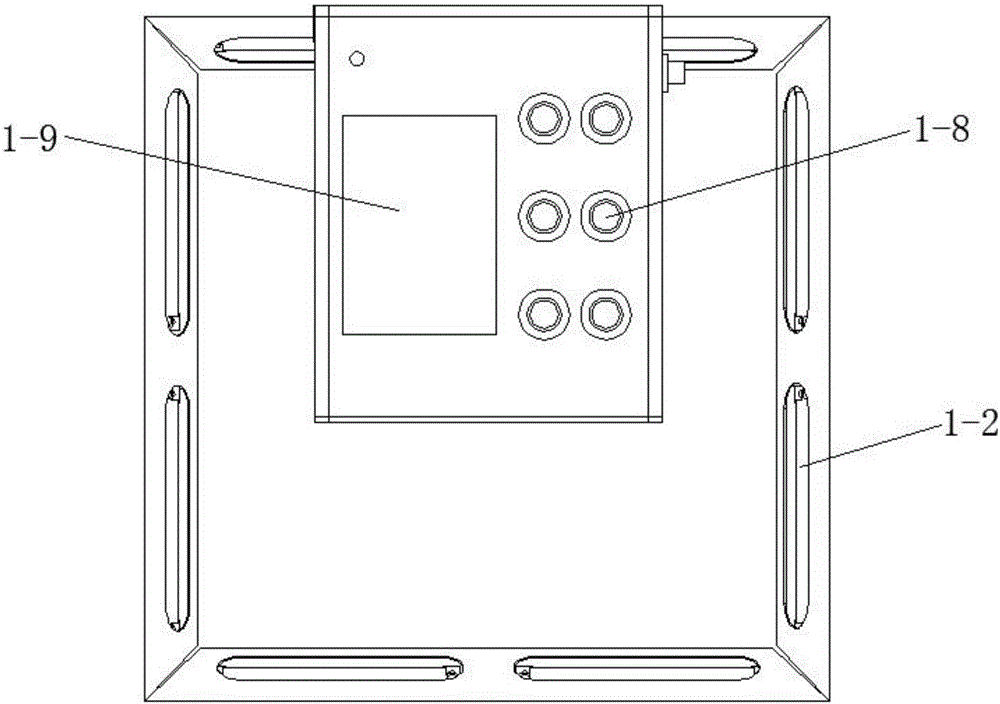

PendingCN106773991APrevent error correctionImprove accuracy and reliabilityProgramme controlComputer controlEmbedded systemCMOS sensor

The invention discloses a CMOS sensor-based embedded correction system and a correction method thereof. The CMOS sensor-based embedded correction system comprises a correction instrument and a control box, wherein the correction instrument comprises a bracket, an annular light source module, a shell, an STM32 main operation controller, a first Bluetooth module, a WiFi module, a CMOS image sensor, a state display and key control module and a TFT liquid crystal display module, wherein the annular light source module is fixed at the bottom of the bracket; the shell is fixed at the upper part of the bracket and located at the upper part of the annular light source module; the STM32 main operation controller, the first Bluetooth module and the WiFi module are arranged in the shell; the CMOS image sensor is arranged on the lower end surface of the shell; the state display and key control module is arranged on the upper end surface of the shell; and a motor drive module and a second Bluetooth module electrically connected with the motor drive module are arranged in the control box. Defect detection can be carried out on the edge of a strip before correction, so that the phenomenon of miscorrection is effectively prevented, the correction accuracy and reliability are improved and the CMOS sensor-based embedded correction system can adapt to comprehensive requirements of actual strip production.

Owner:CHANGZHOU INST OF OPTOELECTRONICS TECH

Loading and unloading assisting device

ActiveCN105540288AImplement manual adjustmentRealize the automatic perception of gravityLoading/unloadingManual conveyance devicesGas springEngineering

The invention provides a loading and unloading assisting device and relates to the technical field of loading and unloading machinery. A rack adopts an H-shaped structure, ground columns are arranged at left and right ends of a cross beam of the rack, vertical sliding chutes I matched with first sliding blocks are formed at upper half parts, pulleys are arranged at lower ends, horizontal sliding chutes are formed in side surfaces of the middles of the vertical chutes I, and horizontal second sliding blocks matched with the horizontal sliding chutes are arranged in the horizontal sliding chutes; a pair of columns with vertical sliding chutes II is arranged on the inner side of the cross beam, and third sliding blocks matched with the vertical sliding chutes II are fixedly connected with pneumatic springs; one end of each connecting rod III is hinged to the corresponding vertical first sliding block, and the other end is hinged to the upper end of a corresponding connecting rod I; one end of each connecting rod IV is hinged to the middle of the corresponding connecting rod III, the hinged end of the other end of the connecting rod IV and a corresponding connecting rod II is hinged to the corresponding horizontal second sliding block, and the other end of each connecting rod II is hinged to the corresponding correcting rod I; the lower end of each connecting rod I is hinged to the middle of the side surface of a flat plate; one end of each wire cable is fixedly connected with a balancer, and the other end winds around the corresponding pulley to be fixedly connected with the corresponding vertical first sliding block. The loading and unloading assisting device is mainly used for loading and unloading assistance.

Owner:SHANDONG WANGCHAOTIANRUN MACHINERY MFG CO LTD

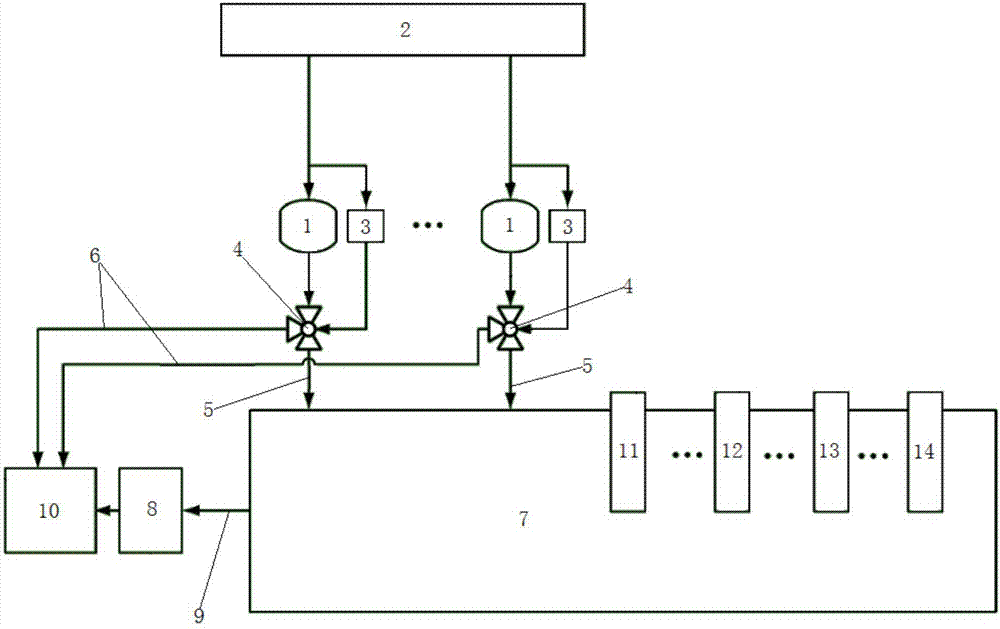

Sampling tank water quality acquisition device

PendingCN106980002AEnsure safetySave human resourcesWithdrawing sample devicesTemperature measurement of flowing materialsAquatic productWater quality

The invention discloses a sampling tank water quality acquisition device. The sampling tank water quality acquisition device comprises at least one water pump, wherein two pipelines of the water pump are connected to a sampling tank and a used water recycling pipeline respectively; the sampling tank is connected with the used water recycling pipeline through a drain valve; a water quality sensor used for collecting a water body from the sampling tank is arranged in the sampling tank; the sampling tank and the drain valve are connected through a drain pipeline; the water pump and the drain valve are connected with a water pump drain valve controller respectively; the water quality sensor is connected with a water quality parameter acquisition unit, and is used for transmitting data to a remote monitoring server. The system has the advantages of stable running, convenience in operation, low cost and the like, and can be applied to breeding production activities of aquatic products.

Owner:YULIN UNIV

Hinge streamlined drilling production equipment

InactiveCN111872441APrevent debris from flyingReduce processing noiseCleaning using toolsFeeding apparatusElectric machineryDrive motor

The invention discloses hinge streamline drilling production equipment which comprises a conveying belt and a drilling mechanism. The drilling mechanism comprises two sets of symmetrically-arranged drill rods, the upper portions of the drill rods are provided with sliding blocks in a penetrating manner, and are rotationally connected with the sliding blocks through bearings, prism shafts are connected to the upper ends of the drill rods through first transmission gear sets in a meshed manner, and a rotary drum is connected with an output shaft of a driving motor through a second transmission gear set. By arranging a bearing box provided with a rectangular through groove and a machining box, streamlined production of hinges is achieved, meanwhile, chippings are prevented from splashing, andmachining noise is lowered; through the arrangement of a sliding block, a transverse moving block, a transverse lead screw, an adjusting wheel, the rotary drum and the prism shafts, manual adjustmentof the drilling distance is conveniently achieved, and good adaptability is achieved; and through arrangement of an abutting frame, a slag crushing box, a brush plate and a sleeve, chippings in the bearing box are centrifugally swept, and the chipping collecting effect is improved.

Owner:黄展雄

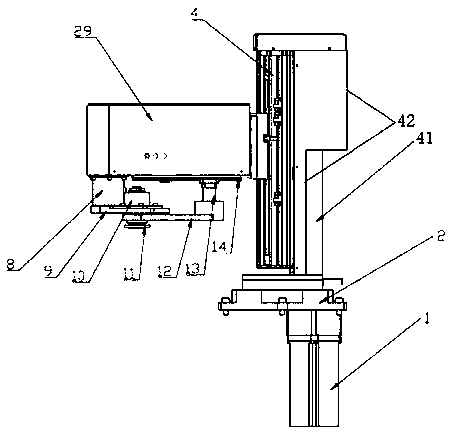

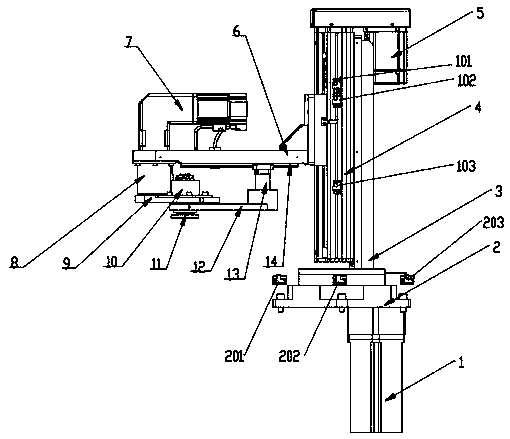

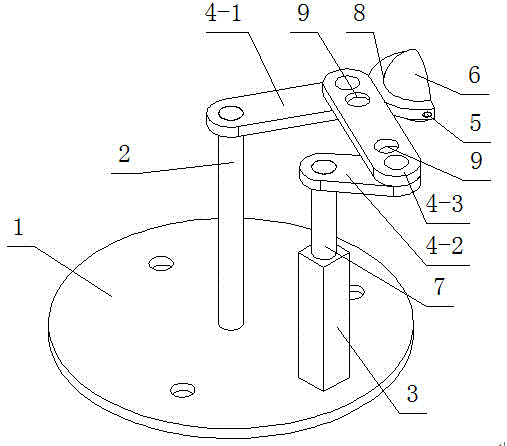

Mechanical arm and position adjusting method thereof

PendingCN111390878ASolve the problem that the degree of freedom is not enough to limit its application scenariosAchieve regulationProgramme-controlled manipulatorArmsMotor speedBall bearing

The invention discloses a mechanical arm and a position adjusting method thereof. The mechanical arm comprises an equipment base, a rotating device arranged on the equipment base, a lifting device arranged on the rotating device and a tail end rotating device arranged on the lifting device, wherein the lifting device comprises a linear guide rail I, a sliding block is arranged on the linear guiderail I, the tail end rotating device comprises a lifting arm fixedly connected with the sliding block, a servo motor speed reducer is arranged on the upper end face of the lifting arm, an output shaftof the servo motor speed reducer penetrates through the lifting arm and is arranged perpendicular to the lifting arm, a carrying platform is arranged on the output shaft, the mechanical arm further comprises a connecting part, the connecting part comprises bearing sleeves and connecting plates integrated with the bearing sleeves, movable holes are formed in the connecting plates, the bearing sleeves are arranged on two deep groove ball bearings in a sleeve mode, and the connecting plates are provided with the movable holes which are movably connected with the carrying platform. According to the mechanical arm and the position adjusting method thereof, the problem that the degree of freedom of an existing mechanical arm is not enough to limit the application scene of the existing mechanical arm is solved, position adjustment can be achieved at four displacement degrees of freedom, and the technical effects of being high in precision, good in rigidity and multiple in mechanical arm application scene are achieved.

Owner:陕西晟思智能测控有限公司

Swinging blade limiting structure and air conditioner indoor unit

InactiveCN109323438AImplement manual adjustmentFlexible adjustmentLighting and heating apparatusAir conditioning systemsEngineeringElastic component

The invention discloses a swinging blade limiting structure and an air conditioner indoor unit, and belongs to the technical field of air conditioners. The swinging blade limiting structure comprisesan elastic component, a sleeve and a limiting component; the elastic component is arranged on a volute bolt strip of the air conditioner indoor unit; the sleeve is arranged on the volute bolt strip; the limiting component is connected to the elastic component; the limiting component can sequentially penetrate through the sleeve and a through hole in the volute bolt strip to be matched with a clamping structure on a swinging blade; and the limiting component can do telescopic motion in the sleeve under the effect of the elastic component, so that the swinging blade can rotate for different angles. In the technical scheme, the limiting component can do telescopic motion under the effect of the elastic component, so that the swinging blade can rotate for different angles; further manual adjusting of the swinging blade is realized, so that the defect that the swinging blade is in direct contact with a framework is overcome; the problem that the swinging blade is prone to being abraded whenbeing adjusted manually is solved; and the swinging blade can be adjusted flexibly.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

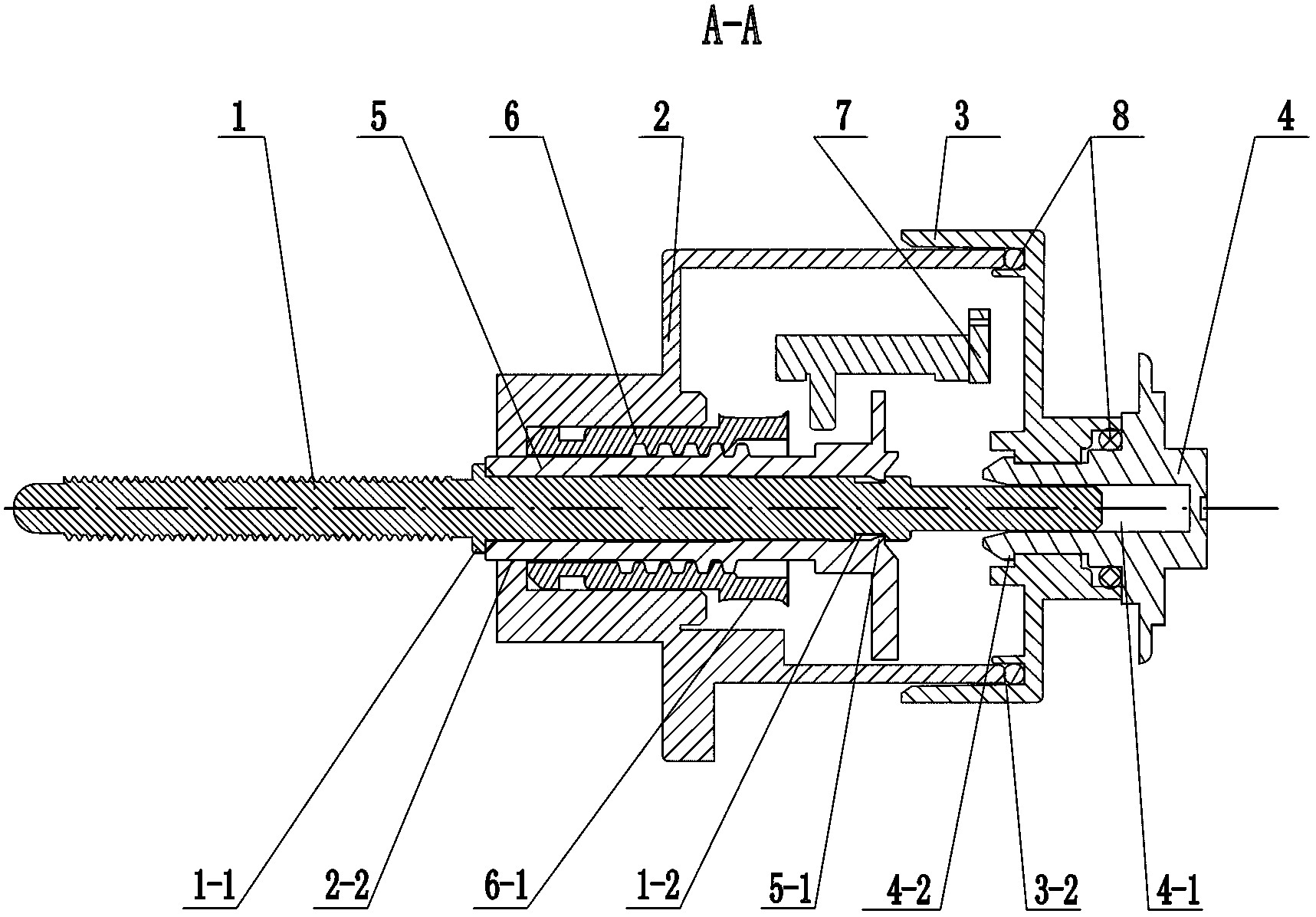

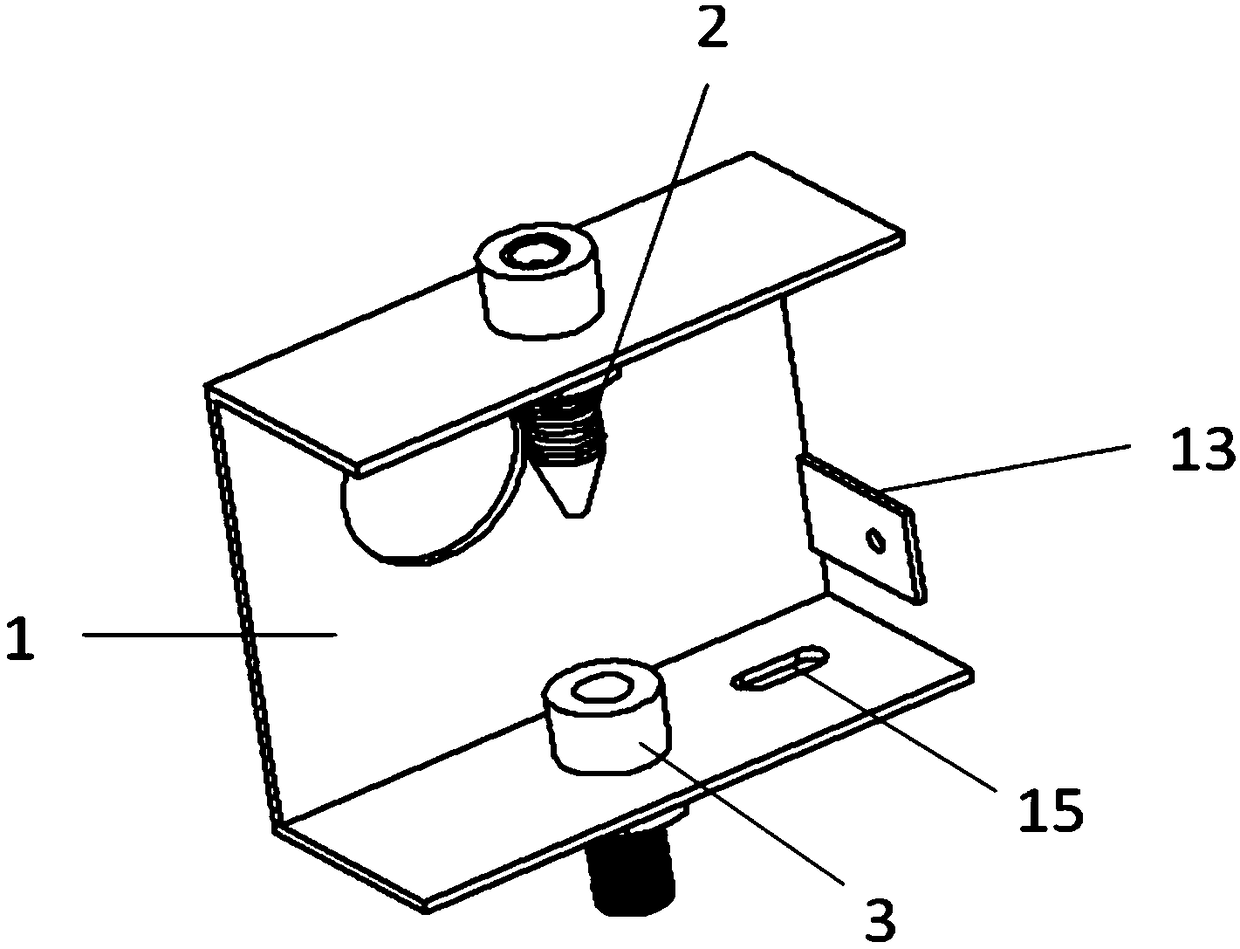

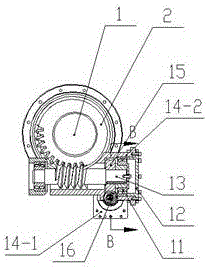

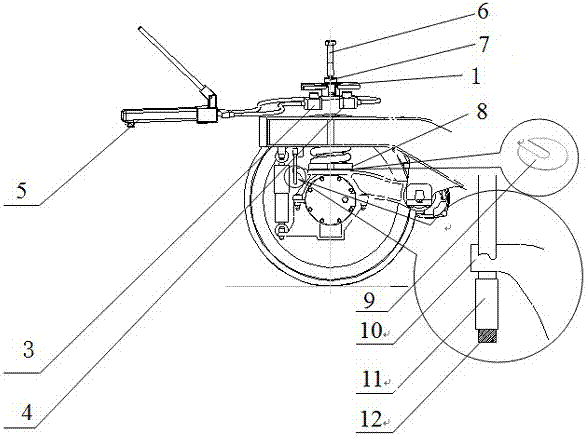

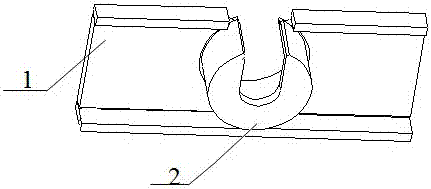

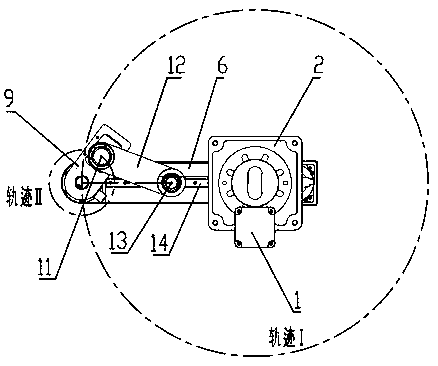

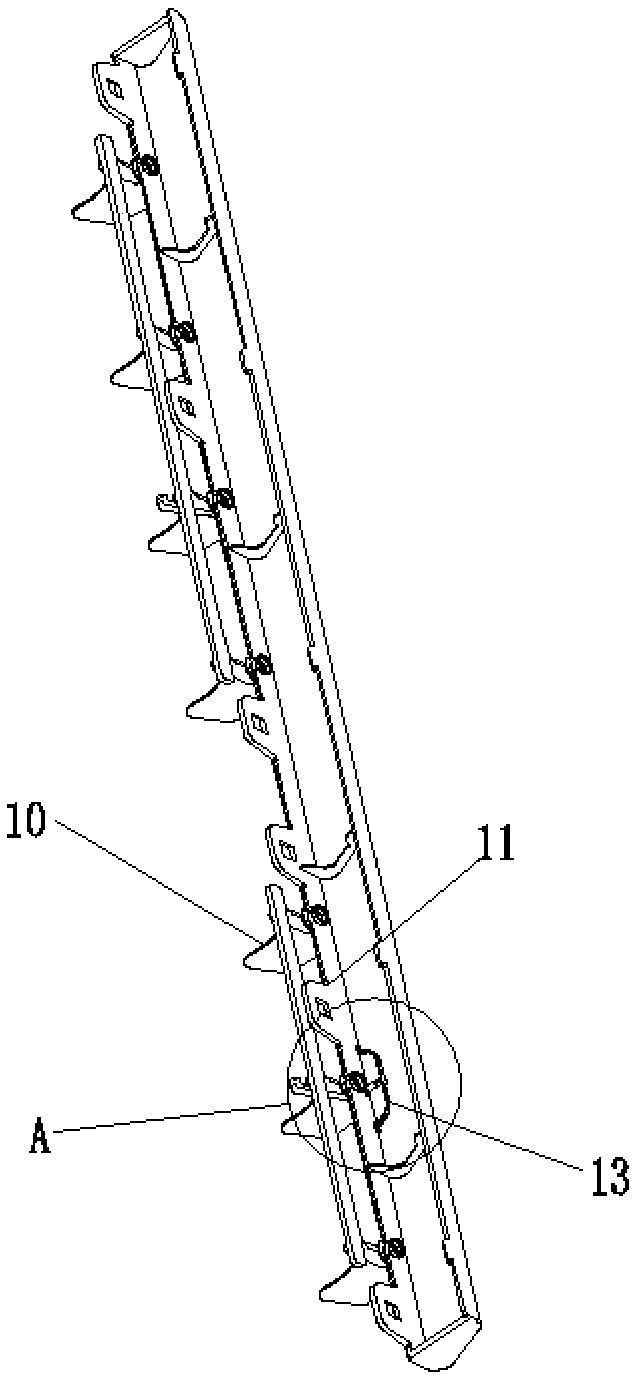

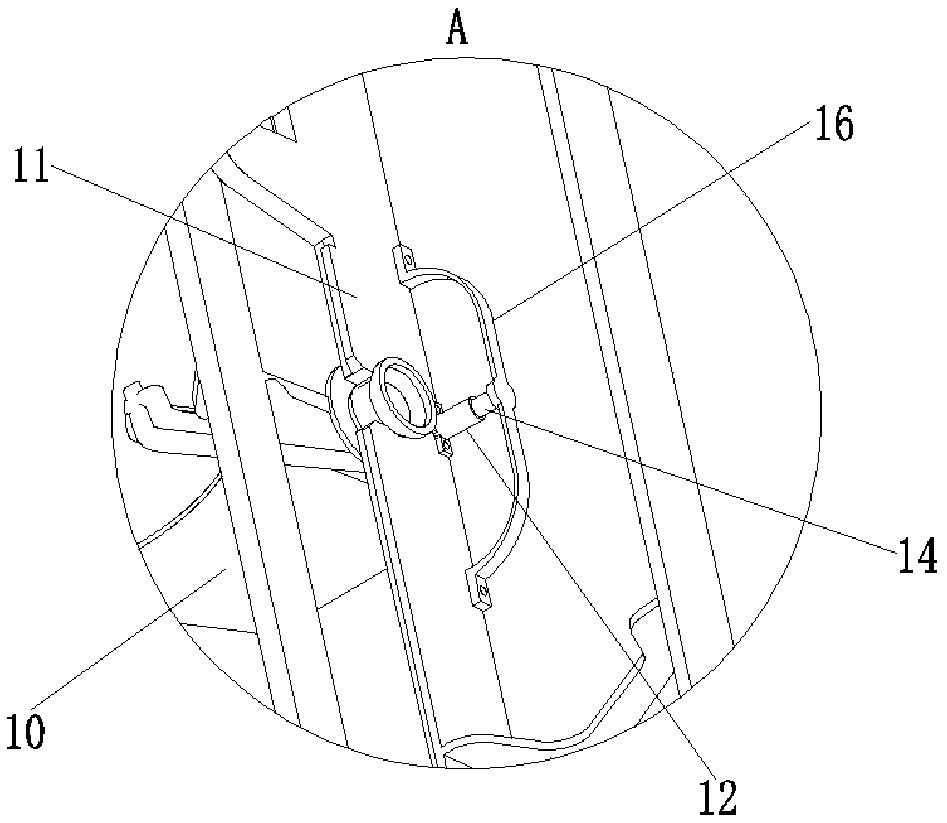

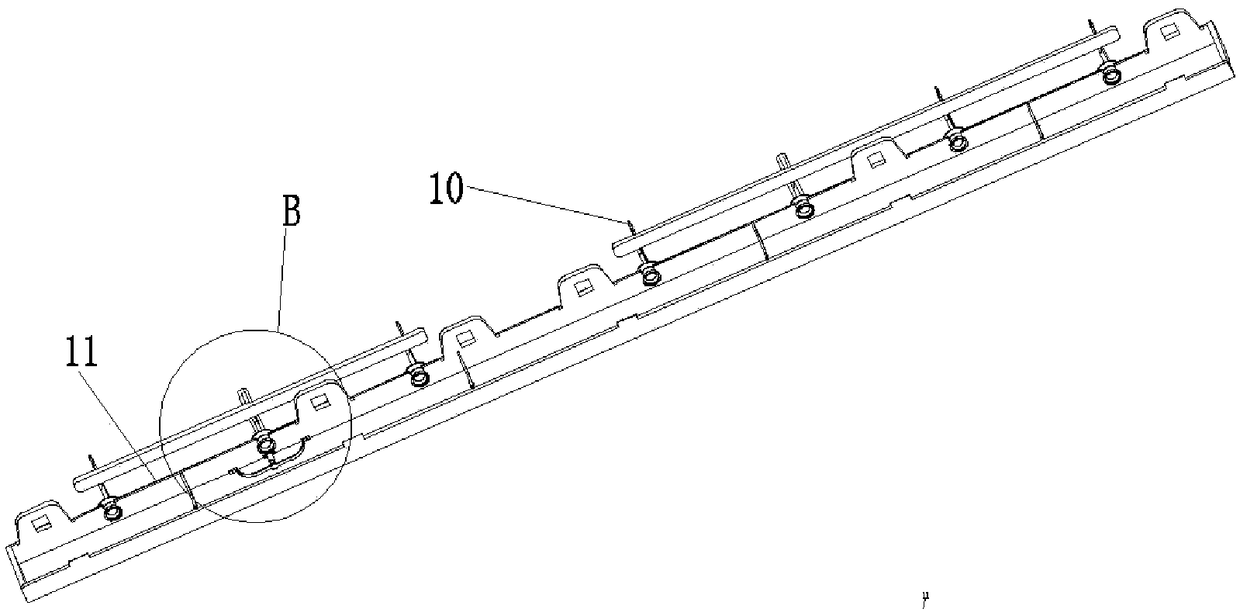

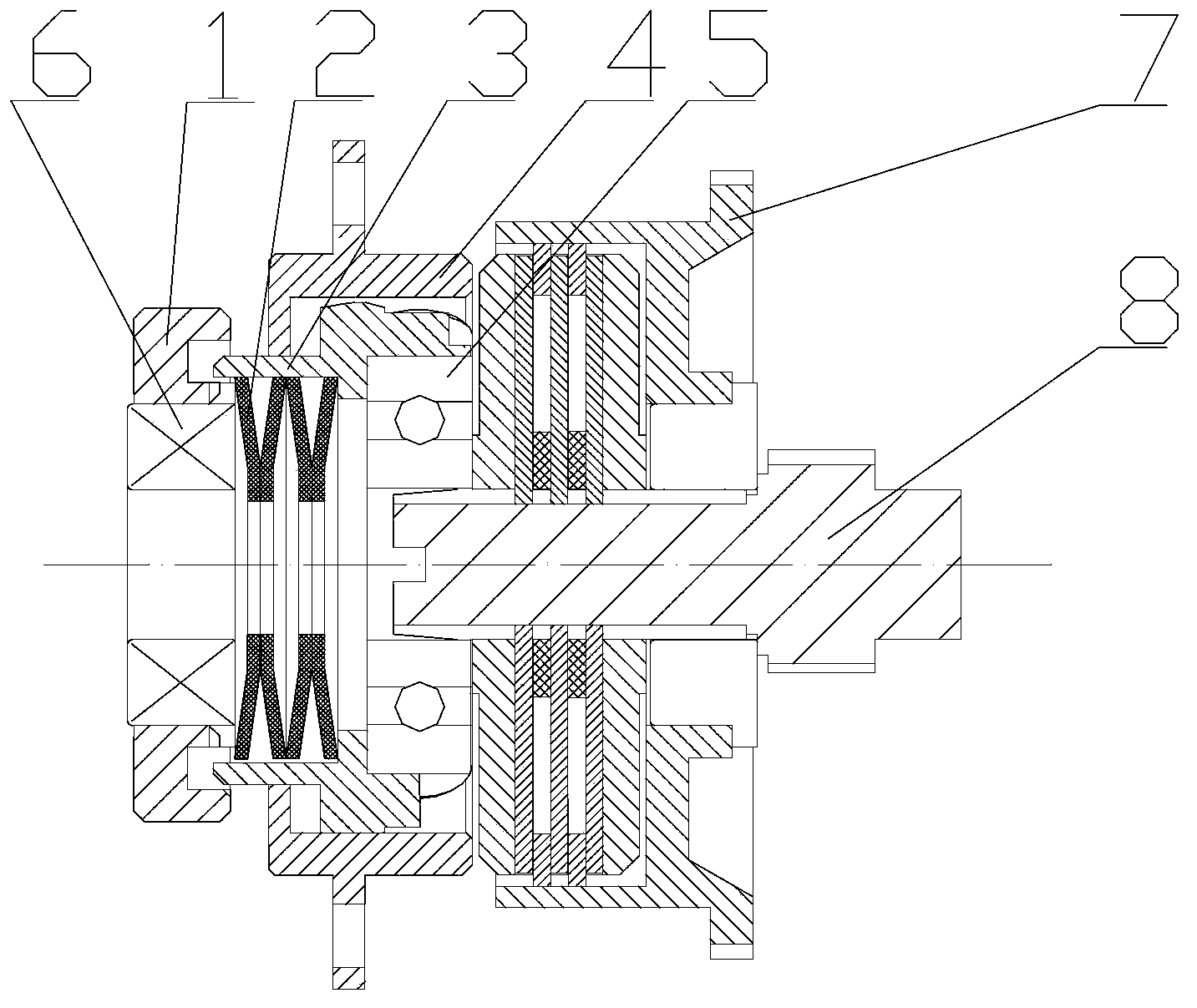

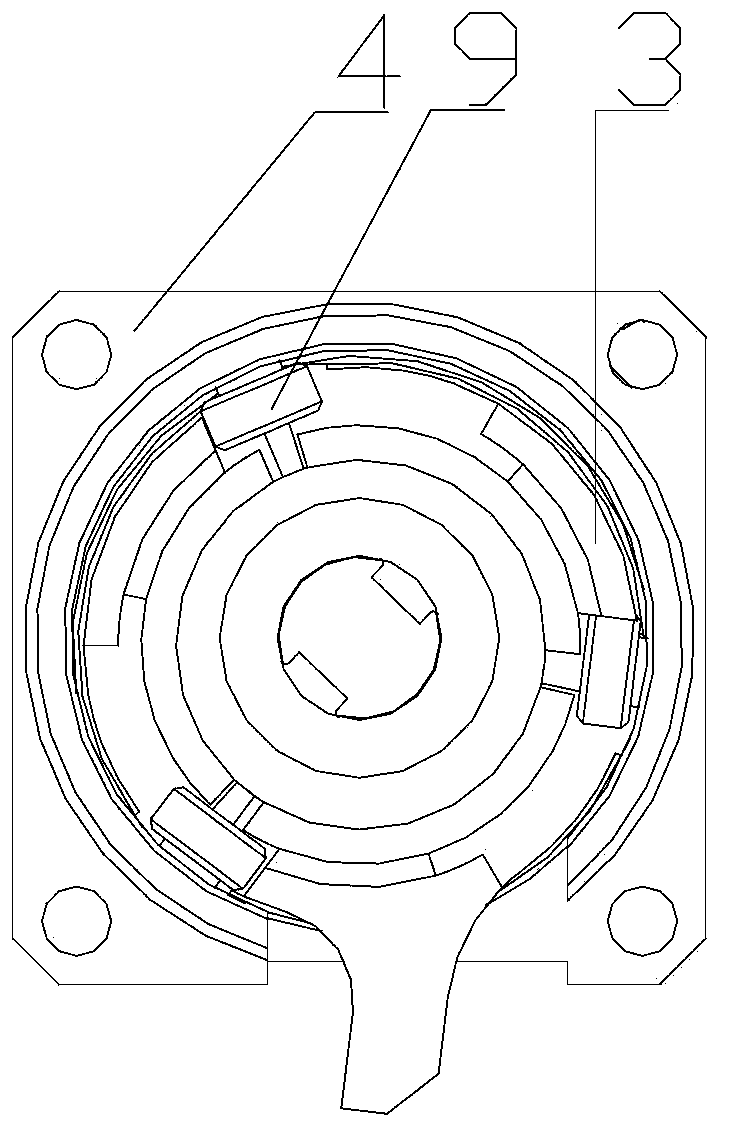

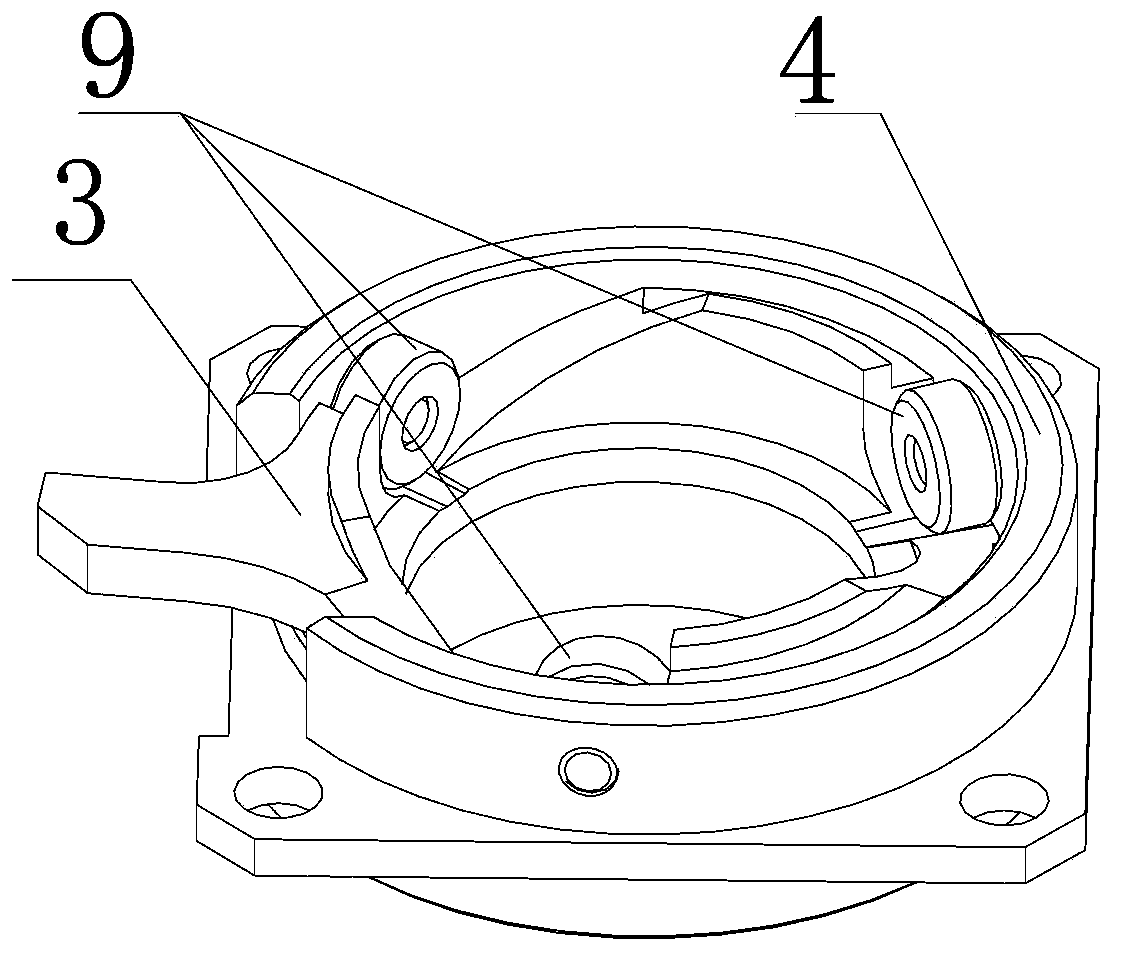

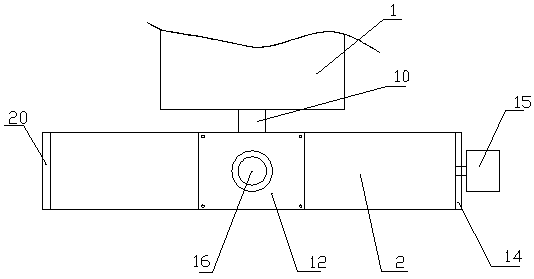

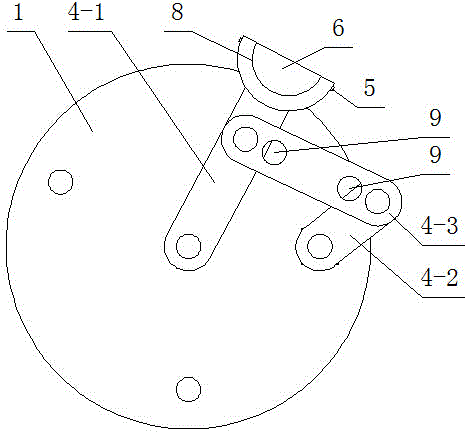

Automatic and manual integrated clutch

The invention relates to an automatic and manual integrated clutch. A bearing base 1 and a shell 4 of the automatic and manual integrated clutch are fixed on an electric mechanism; a shifting fork 3 is positioned inside the clutch shell 4; a spring piece set bearing 6 is arranged between a butterfly spring piece set 2 and the bearing base 1; a roller 9 is fixedly installed inside the clutch shell 4; the roller 9 contacts a bevel on the shifting fork 3; a friction piece set comprises a plurality of friction pieces 16; a friction ring 17 and a disc spring 14 are arranged between every two friction pieces 16; friction plates 13 are arranged on the two sides of each friction piece 16; the friction plates 13 contact a friction piece set bearing 5 and a transmission gear 7 respectively. Through the arrangement of the shifting fork, automatic and manual operations are integrated, an aero seat is regulated to adapt to various environments, and the safety of an aircraft and a pilot is ensured; the automatic and manual integrated clutch is reliable to work and significant in effect.

Owner:HARBIN DONGAN ENGINE GRP

Automatic register adjusting device of printing machine

The invention provides an automatic register adjusting device of a printing machine. The automatic register adjusting device comprises a screen frame fixing adjusting assembly located on a printing machine head and used for fixing a printing plate screen frame, the screen frame fixing adjusting assembly comprises an adjusting frame used for holding and fixing the screen frame, an electric motor isarranged in the adjusting frame, and positive and negative rotation of the electric motor is used for achieving transverse or / and longitudinal moving of the screen frame relative to the machine headposition. The electric motor is arranged on a traditional adjusting screw rod, a spindle of the electric motor is connected with a thread rod for register adjusting, positive and negative rotation ofthe electric motor is used for driving the thread rod to positively and negatively rotate, positive and negative rotation of the electric motor can achieve external manual control over positive and negative rotation, through an industrial computer, positive and negative rotation can be controlled, rapid register can be achieved, in addition, a traditional outer adjusting nut is still kept, manualadjusting is achieved, and three adjusting functions are integrated.

Owner:吴克生

Anti-theft monitoring camera device

InactiveCN108259854AEffective protectionPrevent deceptionTelevision system detailsColor television detailsDrive wheelEngineering

The invention discloses an anti-theft monitoring camera device comprising a shell, an adjustment rotation shaft, an installation box and a rotation device; through the arrangement of a camera, a videorecording function is achieved for recording a stealing process of a criminal offender; through the arrangement of a heat sink, heat dissipation of the device is effectively facilitated, so that theservice life of the device is longer; through the arrangement of a protective mirror, the camera can be effectively protected; through the arrangement of a dust cover, the protective mirror can be protected and prevented from being covered with dust; a motor is started via an external power source to drive a motor shaft, so that a rotation rod rotates, and then a main gear is driven to rotate, a main rack on a drive wheel rotates to drive the rack on the gear to rotate, furthermore, a rotary shaft drives a rotation shaft to rotate, and thus the whole device can be adjusted to a proper positionaccording to needs, and is simple and reasonable in structural design, convenient and rapid to operated when in use, extremely high in practicability, free of artificial adjustment, and capable of adjusting in real time.

Owner:FOSHAN YIYONGCHUANG NETWORK TECH CO LTD

Wide-angle automatic rotation lighting device

ActiveCN104566017AReduce in quantityReduce wasteLight fasteningsFixed installationElectric machineRemote control

The invention discloses a wide-angle automatic rotation lighting device, relating to the warehouse night lighting field. The lighting device comprises a lighting lamp, wherein the lighting lamp comprises a pedestal which is provided with a motor and a supporting pole. The upper end of the supporting pole is articulated with a rocking pole. The external end of the rocking pole is articulated with the lighting lamp. The output shaft of the motor is connected with a crank for driving the rocking pole to swing from left to right through a key. A connecting pole for connecting the crank and the rocking pole is articulated at the external ends of the crank and the rocking pole. The pedestal is further provided with a remote control device for controlling the motor. According to the wide-angle automatic rotation lighting device, the number of the lighting device is saved; the waste of the electric energy is decreased; the structure is simple; the control is convenient; the lighting device is applicable to popularize in a large range.

Owner:STATE GRID CORP OF CHINA +2

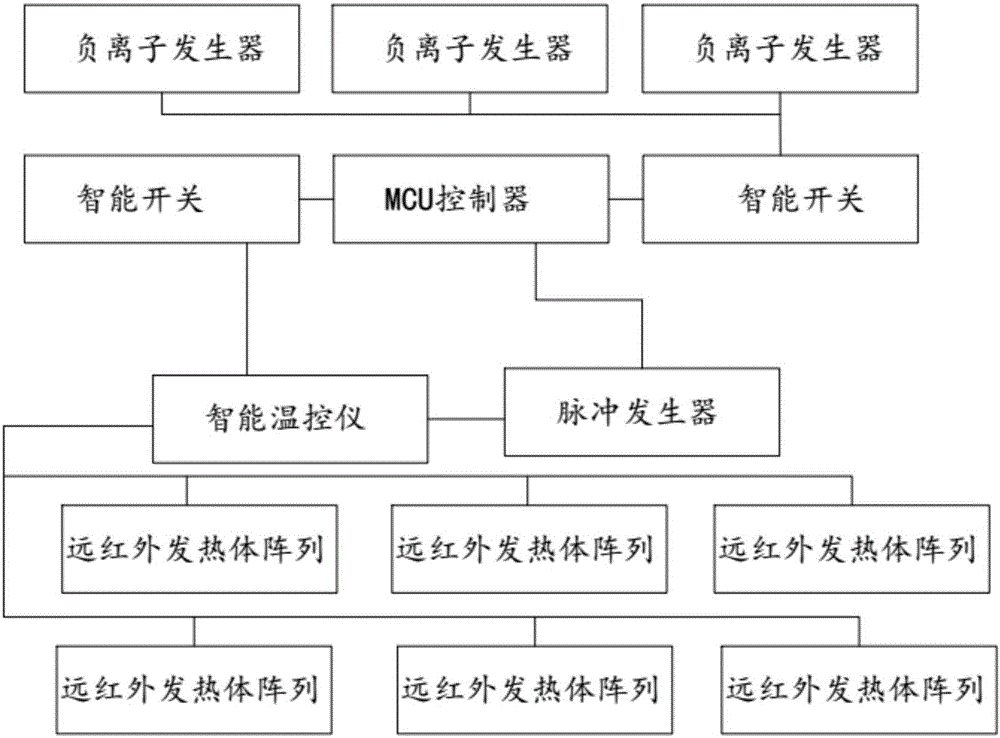

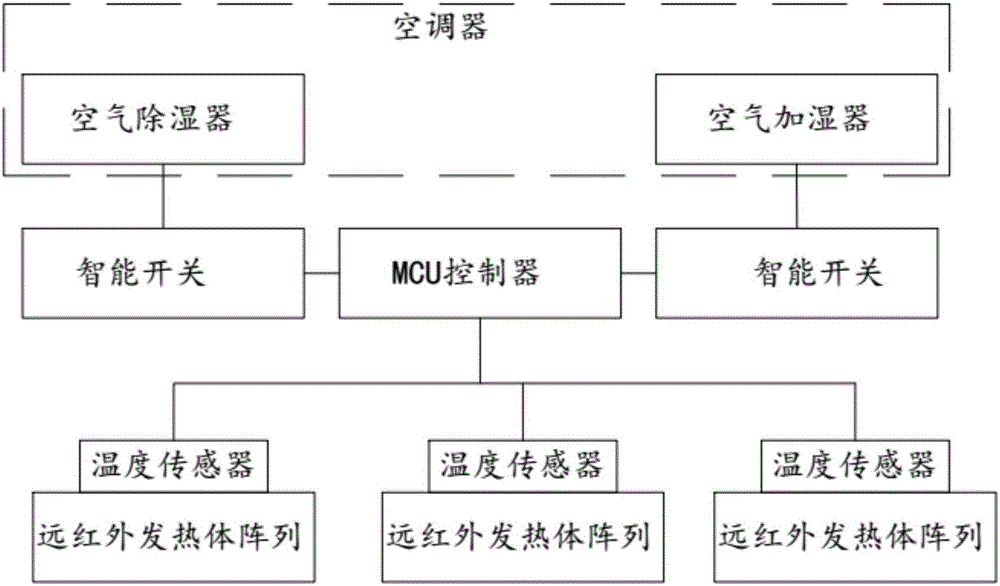

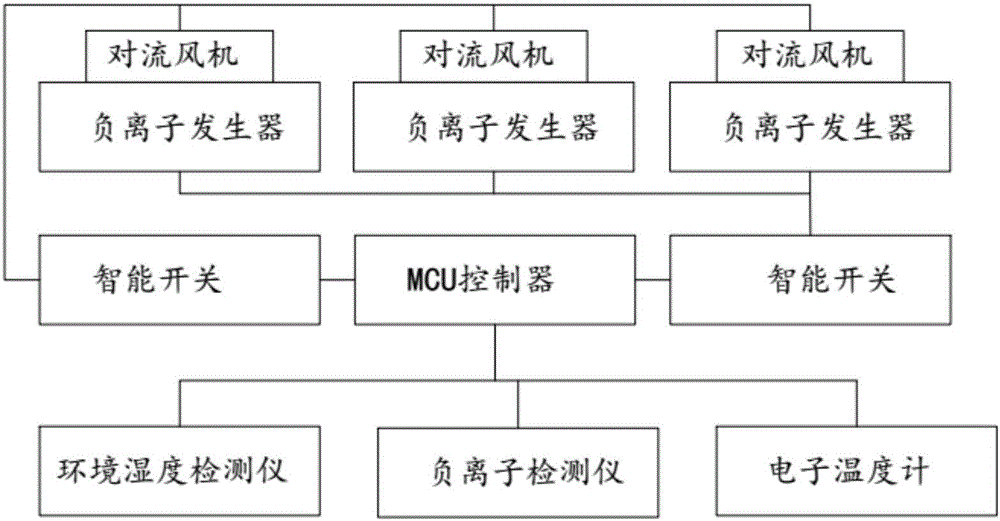

Indoor environment regulating method and system based on optical moxibustion healthcare

PendingCN106730397AQuick access to health indexImplement manual adjustmentDiagnostic recording/measuringSensorsSmart switchOxygen ions

The invention discloses an indoor environment regulating method and system based on optical moxibustion healthcare. The method comprises the steps as follows: a far infrared heating element array is arranged on at least one inner wall of an indoor space, so that far infrared rays with the wavelength being 8-14 mu m are densely distributed in the indoor space; a pulse generator controls drive current of far infrared heating elements to enable the far infrared heating elements to emit pulse optical waves of far infrared rays with the wavelength of 8-14 mu m; a plurality of negative ion generators are arranged in the indoor space, and thus the content of negative oxygen ions per cubic centimeter in the indoor air ranges from 1,000 to 300,000; the system comprises an MCU (microprogrammed control unit), an intelligent switch, an intelligent temperature controller, the pulse generator, the negative ion generators and the far infrared heating elements. The optical moxibustion technology is integrated in the indoor space, environments beneficial to human health are constructed in main human activity places such as residences, offices and the like, and the system has an optical moxibustion healthcare function.

Owner:深圳金田弘科技开发有限公司

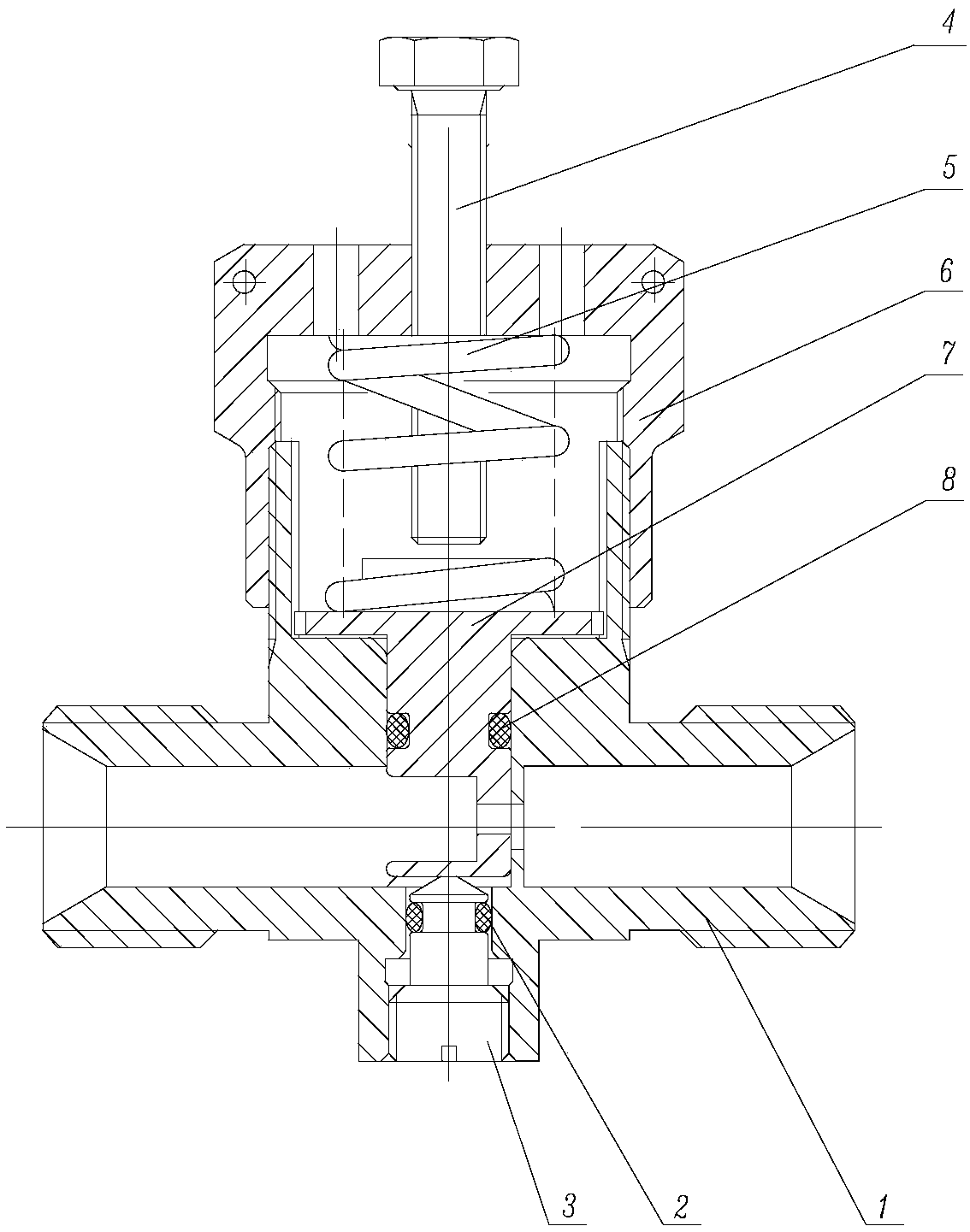

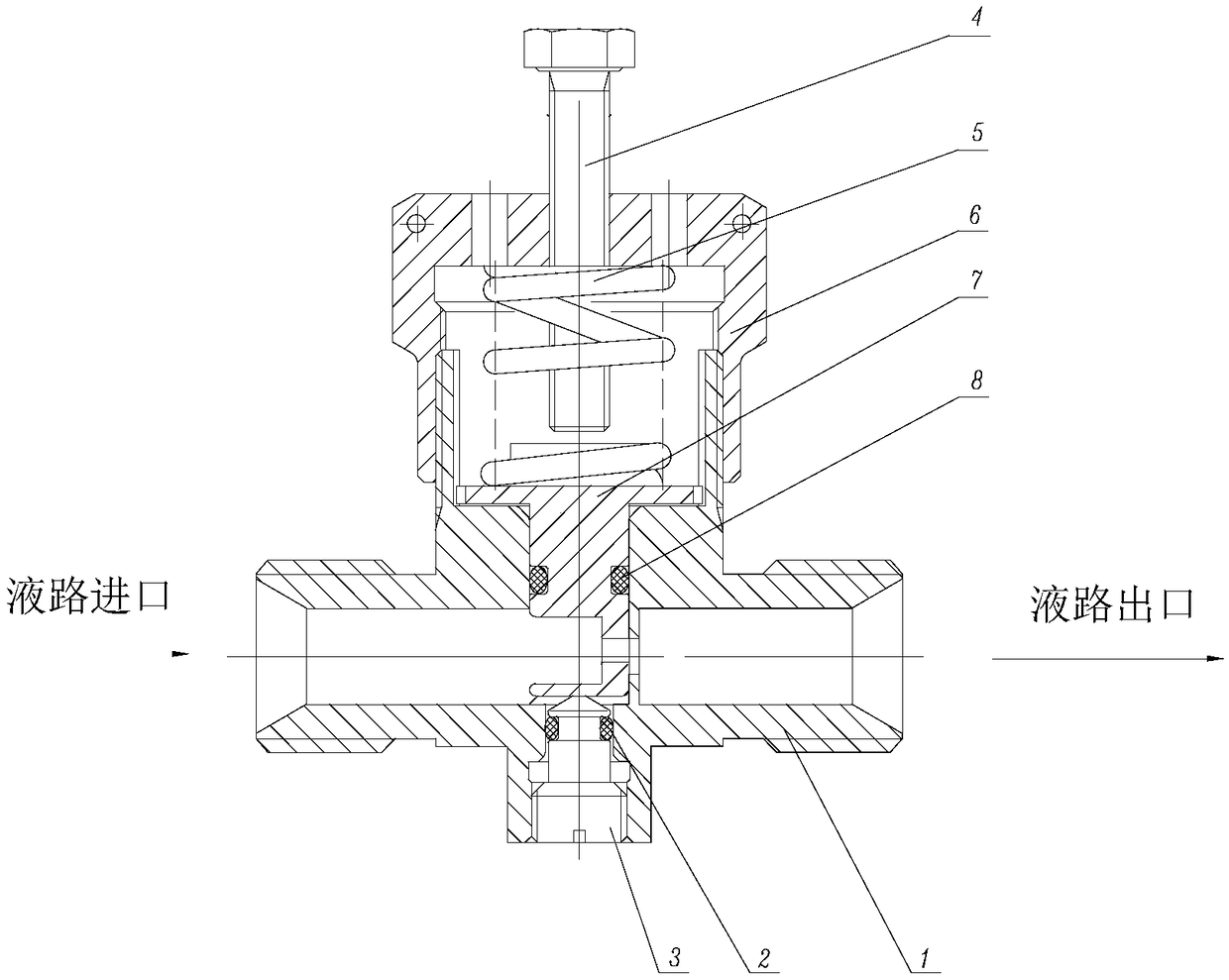

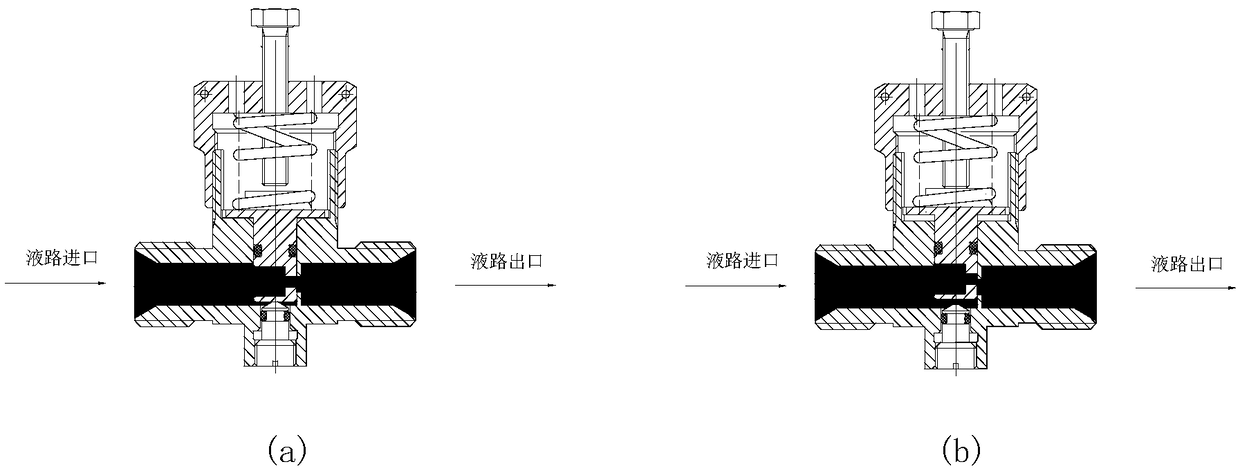

Liquid throttling pressure-stabilizing device

InactiveCN109282064ASimple structureImprove reliabilityEqualizing valvesSafety valvesSystem safetyEngineering

The invention provides a throttling pressure-stabilizing device. The throttling pressure-stabilizing device comprises a valve core, a shell, a stop nut, a spring, an adjusting nut and a limit bolt. The throttling pressure-stabilizing device achieves the purposes of adjusting the pressure stability of a liquid outlet through the mutual cooperation between a square hole in the valve core and a waist-shaped hole in the shell and realizing the automatic adjustment of the pressure, has simple structure and high reliability; the cooperation of two throttling orifices is realized by adopting an annular pin on the valve core and an annular groove on the shell; and the stop nut and the stop bolt are used to ensure that the valve core is fixed in two directions, the manual adjustment in the pressureadjustment range is achieved, and the dual guarantee of automatic operation and manual operation is achieved. In addition, the structure solves the problem of valve failure caused by water hammer andimproves the system safety. Therefore, the throttling pressure-stabilizing device realizes the double guarantee of automatic adjustment and manual adjustment of throttling and pressure stabilizationof liquid, and has the advantages of small volume, and simple and reliable structure.

Owner:SHANGHAI INST OF SPACE PROPULSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com