Primary spring load adjustment method in rail vehicle servicing state

A technology of a rail vehicle and an adjustment method, which is applied to railway auxiliary equipment, a device for lateral relative movement between an underframe and a bogie, etc., can solve the problems of narrow working space and difficulty in manually adjusting the wheel weight difference, and avoid connection operations. , The effect of good adjustment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

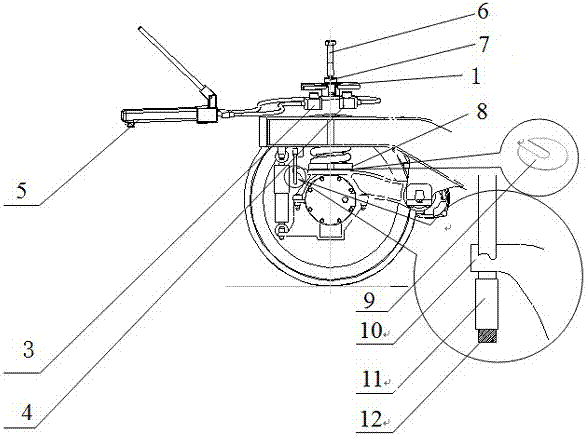

[0034] A method for adjusting the load of a series of springs in a state of maintenance of a rail vehicle, specifically using a set of hydraulic adjustment devices and a limit block 11 to realize the adjustment of the load of a series of steel springs in the state of maintenance.

[0035] The hydraulic adjustment device includes: a separate manual double-acting hydraulic jack, a high-strength tension bolt 6 and a bearing plate 1 .

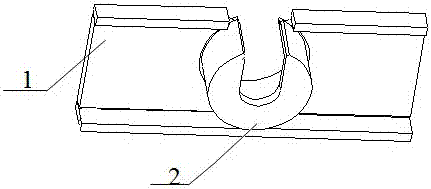

[0036] The bearing plate 1 is provided with an open U-shaped sleeve 2, and the jack includes a left jack 3 and a right jack 4.

[0037] The method for adjusting the load of the primary spring is specifically implemented through the following steps:

[0038] S1. Check the rail vehicle to keep the vehicle in a state of readiness, including complete assembly of the vehicle, full water tank, new wheels, and norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com