A steel truss-concrete slab composite beam based on shear connection construction

A technology for concrete slabs and steel trusses, which is applied to truss bridges, bridges, bridge parts, etc., can solve the problems of a large number of connecting components of shear connectors, inconvenient construction, and low construction efficiency, and achieve high economic and social benefits. , The effect of convenient construction and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

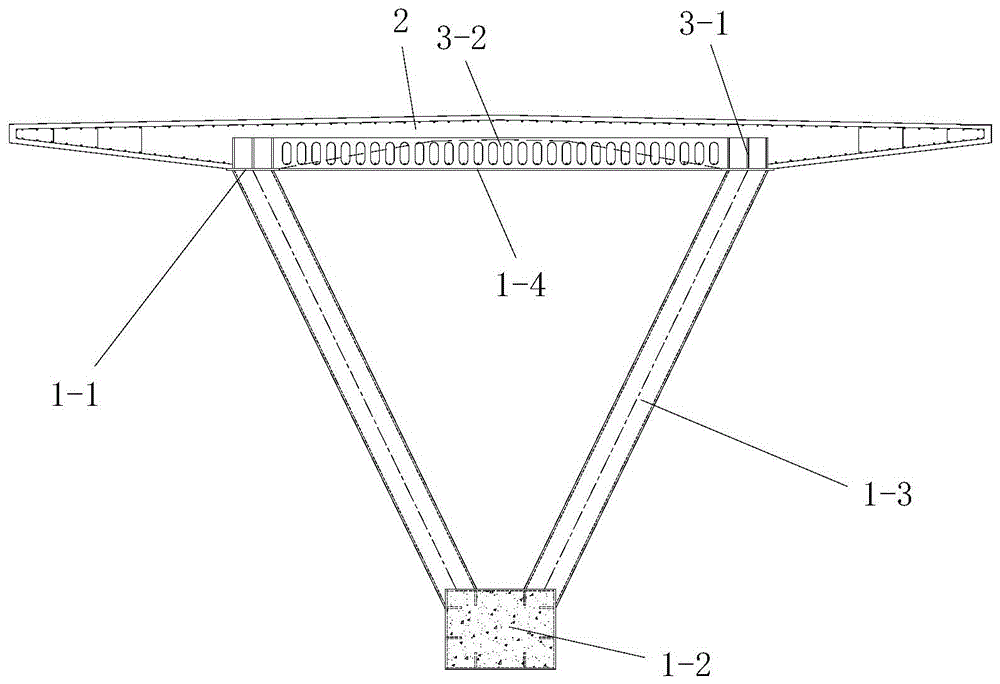

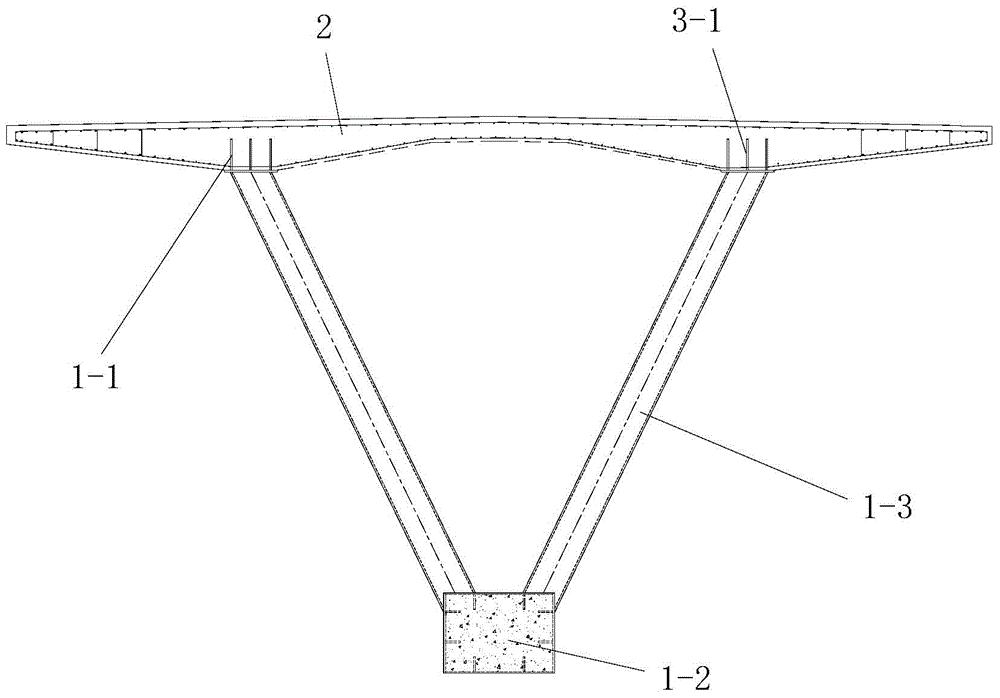

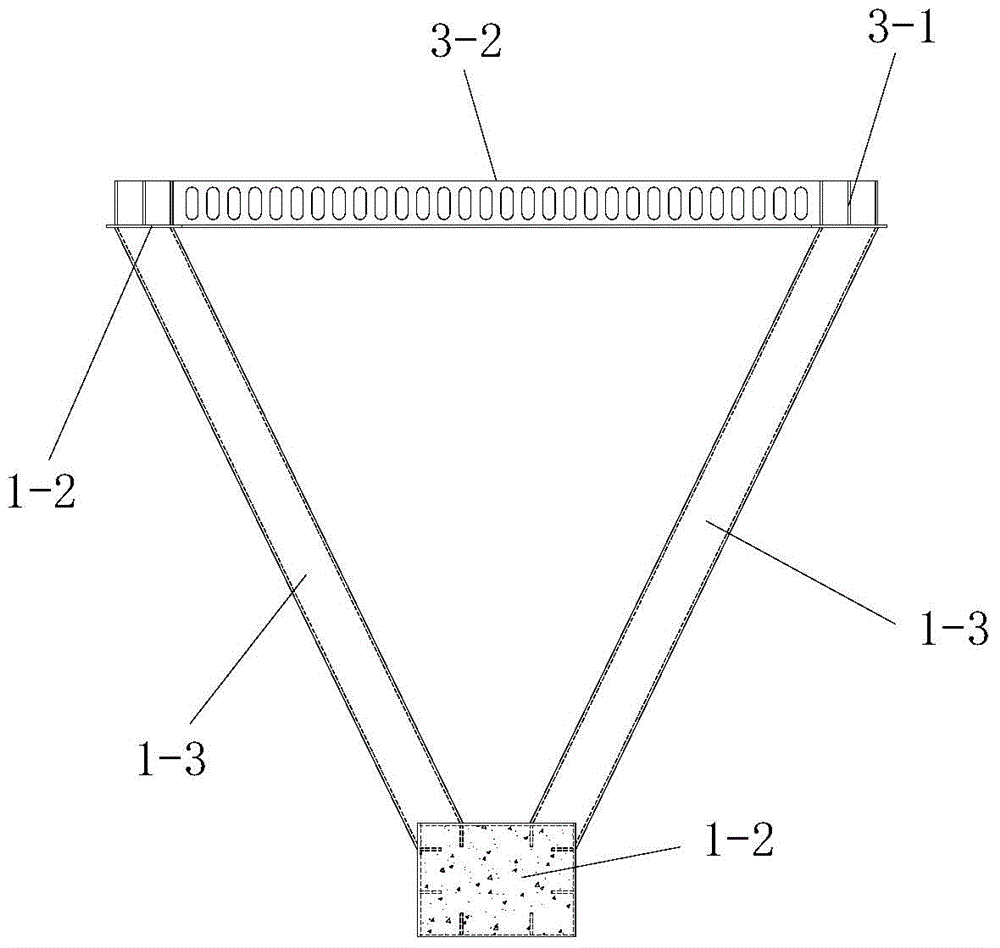

[0057] Such as figure 1 , figure 2 As shown, the present invention includes a steel truss arranged in a longitudinal bridge direction and a concrete slab 2 arranged directly above the steel truss, and the concrete slab 2 is arranged in a longitudinal bridge direction. The steel truss includes one or more steel truss units arranged in the longitudinal bridge direction, and a plurality of the steel truss units are arranged on the same plane from left to right along the transverse bridge direction, and the structures of the plurality of steel truss units and All have the same size and are tightly connected as one.

[0058] In this embodiment, the number of steel truss units included in the steel truss is one.

[0059] combine image 3 , Figure 3-1 and Figure 4 , the steel truss unit is a diagonal rod supported between the lower chord 1-2 and the two upper chords 1-1 by two upper chords 1-1, one lower chord 1-2 and two left and right rows An inverted triangular truss beam...

Embodiment 2

[0099] In this example, if Figure 12 As shown, the difference from Embodiment 1 is that the number of steel truss units included in the steel truss is multiple, and the upper chord 1 shared by the left and right adjacent steel truss units in the lattice type upper chord structure -1 is a shared type upper chord, and the upper chords 1-1 in the lattice type upper chord structure except the shared type upper chord are all ordinary type upper chords; The distance between the vertical perforated steel plates one 3-1 is greater than the distance between two adjacent vertical perforated steel plates one 3-1 in the common top chord.

[0100] In this embodiment, the lower chords 1-2 of the two adjacent steel truss units on the left and right are two adjacent lower chords 1-2 arranged on the same plane, and the lower chord transverse connection system 1-5 is adjacent to the left and right The two lower chords 1-2 are arranged on the same horizontal plane and include multiple lower ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com