Steel-wood combined bridge structure with pored steel plate connecting piece

A combination technology of perforated steel plate and steel-wood, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of increasing the spanning capacity of wooden bridges, a large number of connecting components, and inconvenient construction, so as to improve driving comfort, The effect of simple structure and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

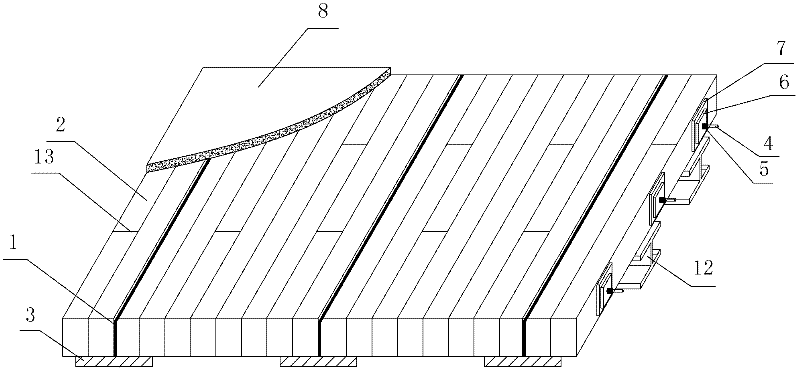

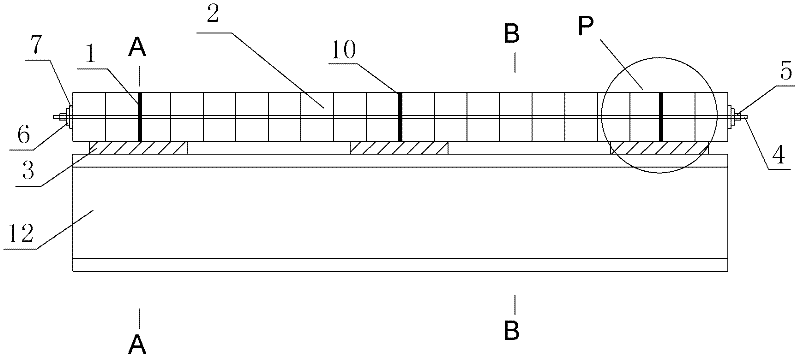

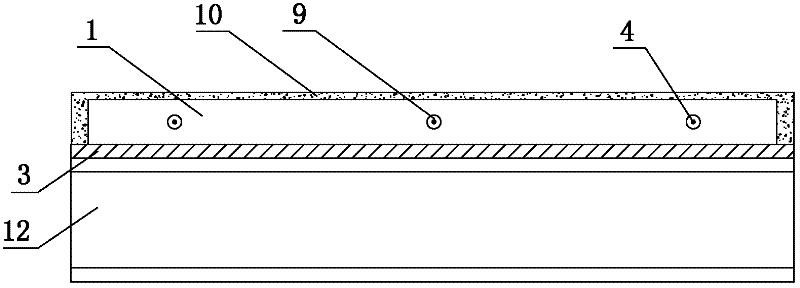

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, the present invention includes a bridge superstructure and a bridge substructure that integrally supports the bridge superstructure, and the bridge superstructure includes a wooden bridge deck composed of a plurality of rectangular planks 2 laid on the same plane and positioned at The bottom load-bearing structure directly below the wooden bridge deck, in which a plurality of perforated steel plates 1 arranged longitudinally are sandwiched. The bottom load-bearing structure includes a plurality of lower beams arranged on the same plane and a plurality of lower beams 12 arranged on the same plane, the plurality of lower beams are arranged in parallel, and the plurality of lower beams 12 are arranged in parallel. They are arranged in parallel, and the lower longitudinal beams and the lower cross beams 12 are arranged perpendicularly. The plurality of lower cross beams 12 are fixed...

Embodiment 2

[0056] Such as Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, in this embodiment, the difference from Embodiment 1 is that: the lower longitudinal beam is a longitudinal I-beam 14, the lower cross beam 12 is an I-beam, and the plurality of lower longitudinal beams and the plurality of The lower beams 12 are arranged on the same plane. In actual construction, a plurality of the lower longitudinal beams may also be arranged directly under the lower cross beam 12 . In this embodiment, the plurality of lower longitudinal beams and the plurality of lower cross beams 12 are assembled into one body through a plurality of connecting bolts 15, and the perforated steel plate 1 is vertically welded on the upper wing of the longitudinal I-beam 14 Middle of top edge. On the premise of adding load-bearing beams of the bridge, the bridge superstructure formed in this embodiment can be directly applied to bridges with relatively large spans.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com