Preparation method of foam concrete with adjustable pore characteristics

A foam concrete, adjustable technology, applied in the field of concrete, can solve the problems of foam concrete shrinkage and cracking, affecting the performance of foam concrete, hardened body mechanical properties and poor frost resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method for preparing foamed concrete with adjustable pore characteristics. The foamed concrete includes expansion-shrinkage material, cement and mixing water. The expansion-shrinkage material is selected from polyacrylate type superabsorbent resin, comprising the following steps:

[0073] S1, calculate the required cement mass m per cubic meter according to the mix ratio design method b , dry expansion and contraction material mass m q , The pre-absorbed water mass m′ required by the expansion and contraction material w and the mass of mixing water m w ;

[0074] S2, calculate and weigh the amount of each material in step S1 according to the pouring volume (including the quality of cement, the quality of dry expansion-shrinkage material, the quality of pre-absorbed water required by the expansion-shrinkage material and the quality of mixing water), and the weighing accuracy is ±0.5% ;

[0075] S3, perform pre-absorption treatment on the dry expansion-shrinkage mat...

Embodiment 2

[0080] A method for preparing foamed concrete with adjustable pore characteristics, as described in Example 1, the difference is that the method for designing the mix ratio in step S1 includes the following steps:

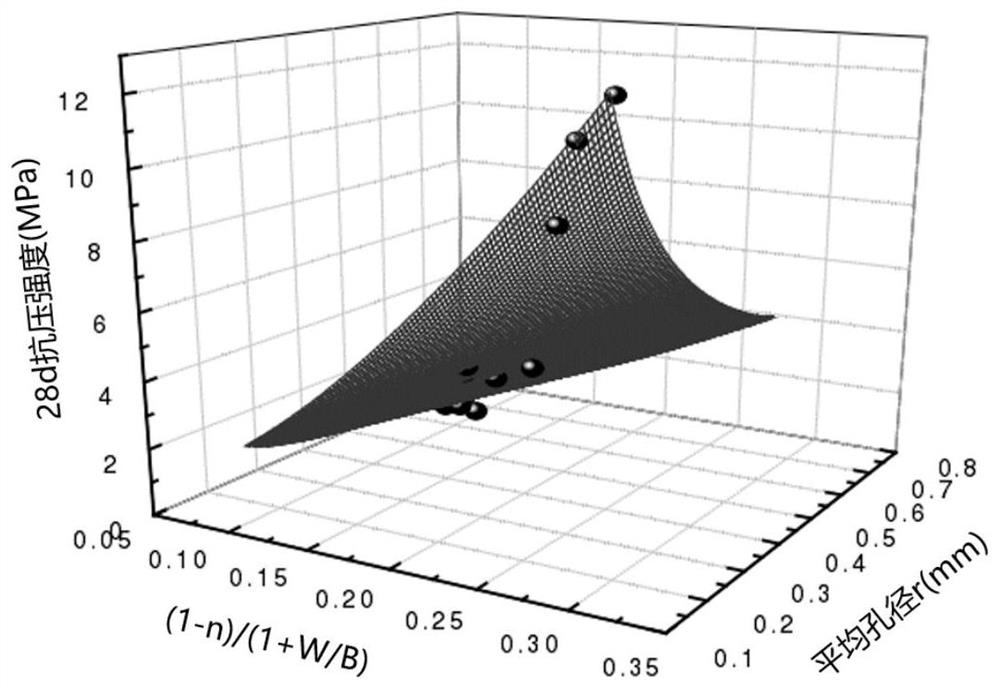

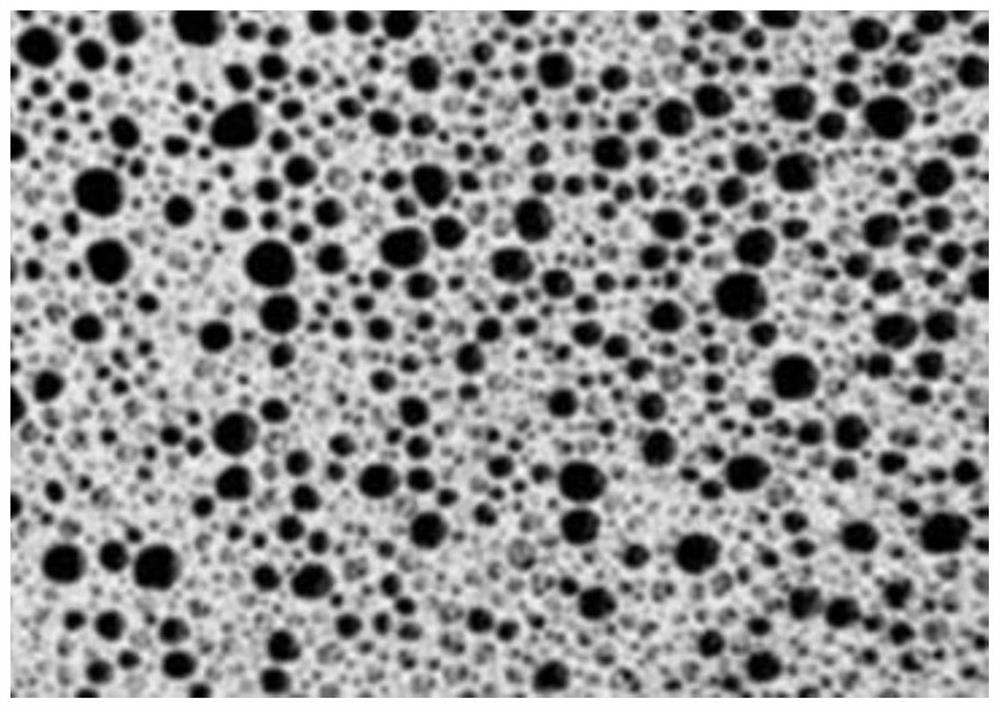

[0081] A. Design of pore characteristics: Calculate the particle size of the dry expansion-shrinkage material required according to the design pore size of the foam retarded concrete and the water absorption expansion coefficient of the expansion-shrinkage material, and the specific calculation is as follows:

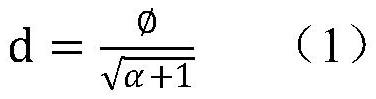

[0082]

[0083] In the formula (1), d is the particle size of the dry expansion and contraction material, mm;

[0084] is the design aperture of foam concrete, mm;

[0085] α is the water absorption volume expansion coefficient of the expansion-shrinkage material, that is, the ratio of the volume of the expansion-shrinkage material after absorbing water to the volume of the expansion-shrinkage material in a dry state;

[0086] B. Calculate the water-ce...

Embodiment 3

[0124] A method for preparing foamed concrete with adjustable pore characteristics, as described in Example 2, the difference is that the pre-absorption rate k, the density ρ of the expansion-shrinkage material after the pre-absorption treatment p , and the water absorption volume expansion coefficient α of the expansion-shrinkage material is determined by the following method:

[0125] Add a certain quality of dry expansion-shrinkage material into a certain amount of water for pre-absorption treatment for 10 minutes to obtain the expansion-shrinkage material after pre-absorption treatment, and then add the expansion-shrinkage material after pre-absorption treatment into the cement slurry, It is necessary to measure the flow value of the cement slurry before adding the shrinkage material. The flow value test method can refer to the regulations in the "Technical Regulations for Cast-in-place Foam Lightweight Soil" CECS: 2008. The expansion-shrinkage material after pre-absorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com