Micro-vibration long-distance real time image detecting system based on image surface digital holography

A digital holography and micro-vibration technology, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inability to detect irregular vibrations in real time, low shooting speed of photoelectric imaging devices, complex demodulation calculation process, etc. problem, to achieve the effect of remote detection of surface vibration, real-time detection of vibration, and avoidance of diffraction calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

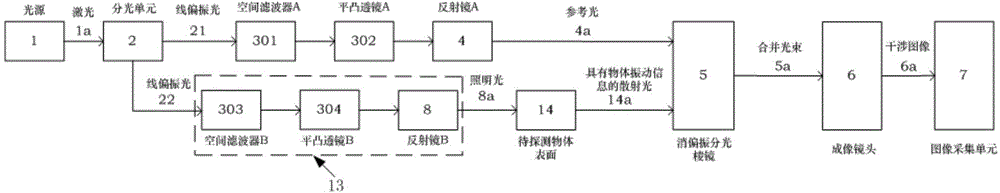

[0031] Such as figure 1 , figure 2 As shown, the present invention is a micro-vibration remote real-time surface detection system based on digital holography of the image surface. Reflecting mirror A4, reflecting mirror B8, depolarizing beam splitting prism 5, imaging lens 6 and image acquisition unit 7.

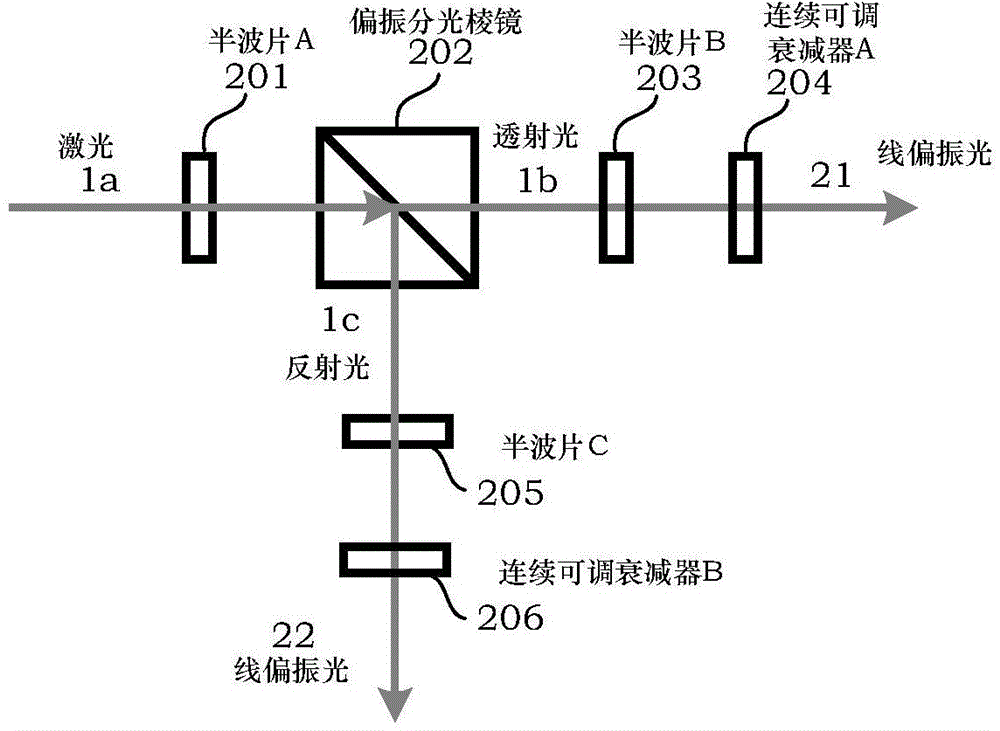

[0032]The light splitting unit 2 receives the laser light emitted by the light source 1, and outputs linearly polarized light A21 and linearly polarized light B22; the linearly polarized light A21 passes through the spatial filter A301, the plano-convex lens A302, and the mirror A4 in sequence, and then enters the depolarization beam splitter 5 The linearly polarized light B22 is incident on the depolarization beam splitter 5 after passing through the spatial filter B303, the plano-convex lens B304, the mirror B8, and the surface 14 of the object to be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com