Patents

Literature

198results about How to "Realize online adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

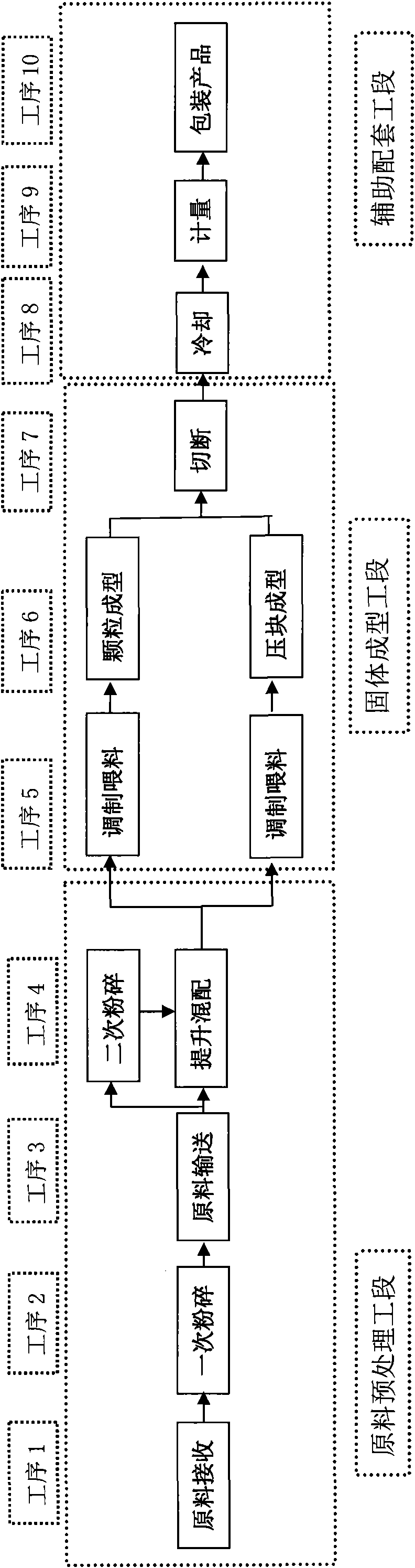

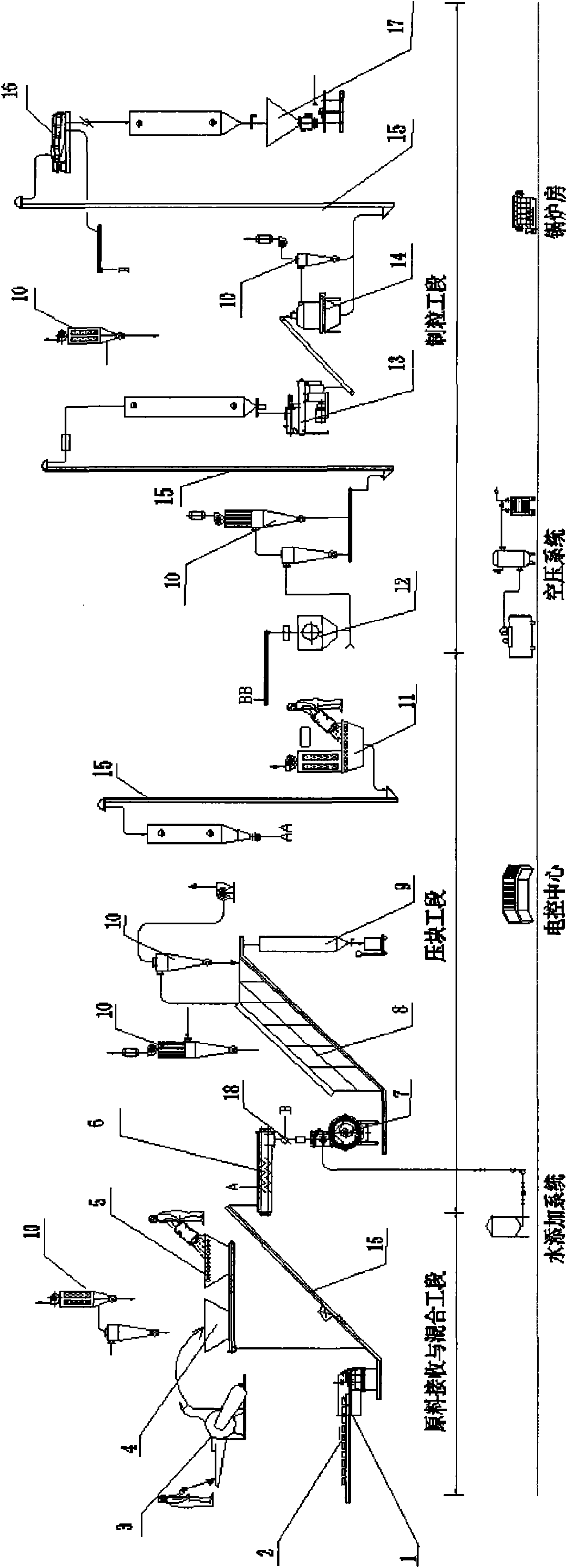

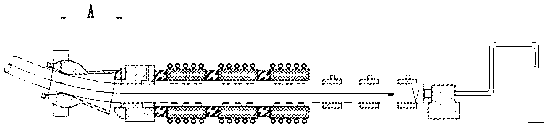

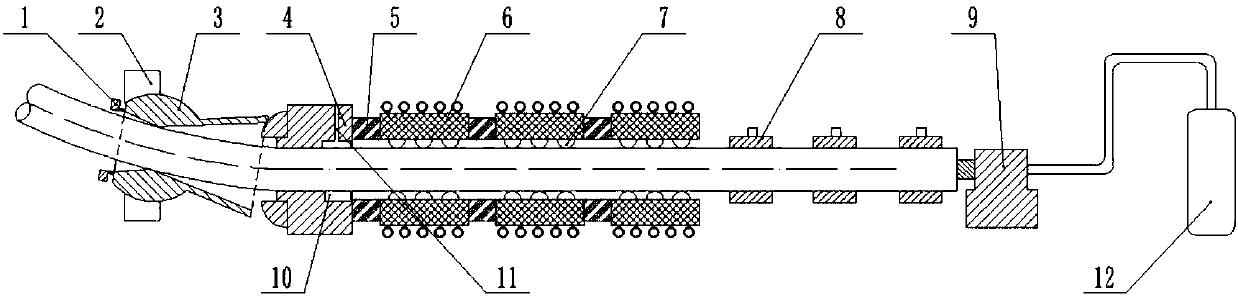

Processing method for biomass solid molding fuel

InactiveCN101555429AImprove processing capacityImprove market competitivenessBiofuelsSolid fuelsBiomassCrop

The invention discloses a processing method for biomass solid molding fuel, which pertains to the technical field of solid fuel and aims at solving problem of comprehensive use of energy and biomass energy in rural areas. The technical proposal is as follows: biomass energy such as crop straws, shrub forest, forestry residues and the like are used as raw materials, and the secondary crushing technique and the mixed technique combining continuous feeding with adjustable feeding are adopted, therefore, two types of solid fuels, namely, block-type and granular fuels, can be produced. The technical proposal comprises three stages namely, pre-treatment of raw materials, solid molding and auxiliary assorting, and the specific working procedures comprise raw material cracking, drying, conveying, mixing, feeding, molding, cutting, cooling and measuring and packaging and adding a compulsory ventilating dust-removing system during the whole process. The processing method for biomass solid molding fuel solves the problem of diversification of biomass raw materials, and the biomass solid fuel production line constructed by adopting the processing method realizes the industrial continuous and stable production, solves the problems of high energy consumption and low production efficiency in the existing small workshop-style production, and is also beneficial to solving the rural energy problem and improving the rural environment.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

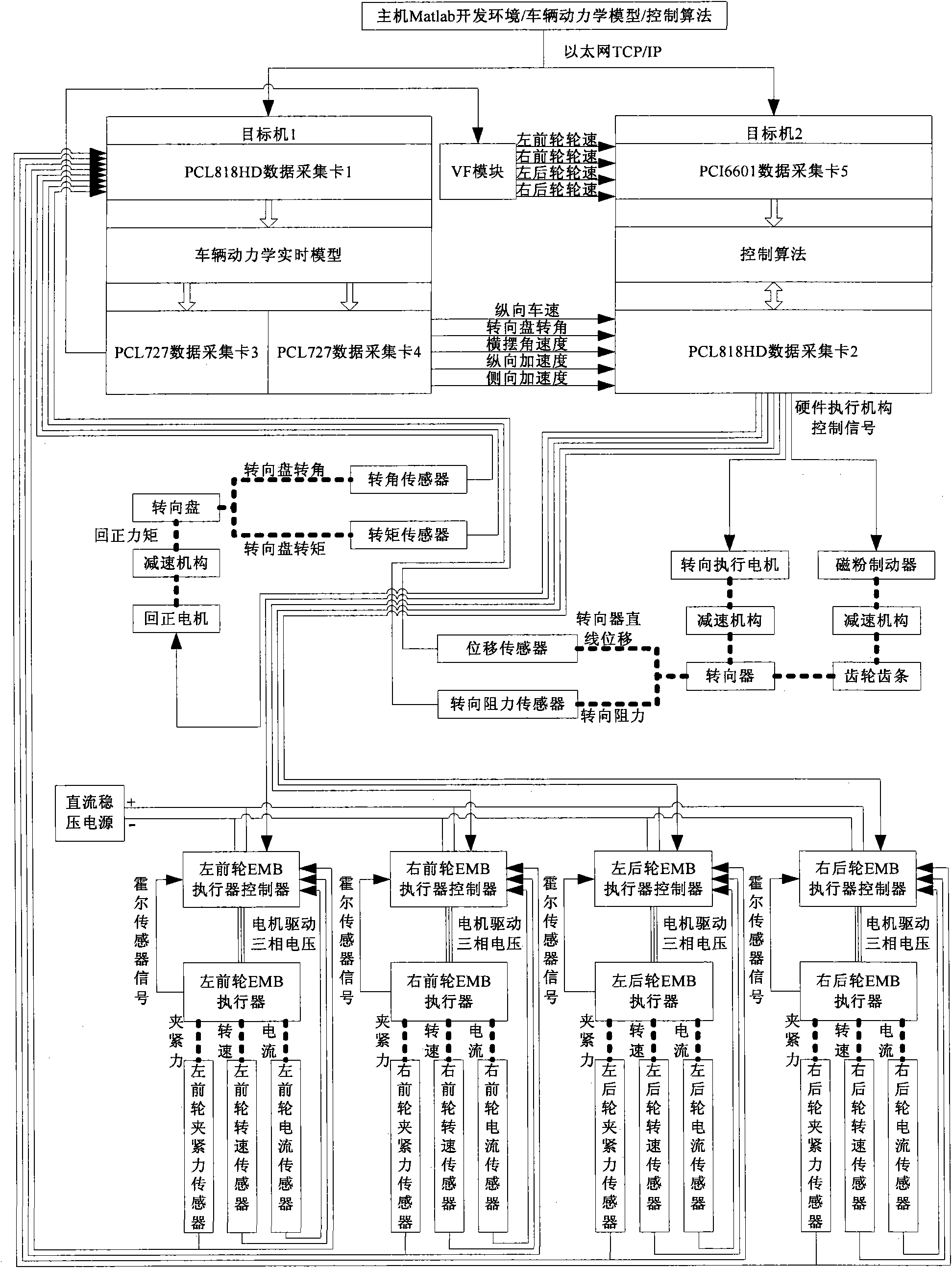

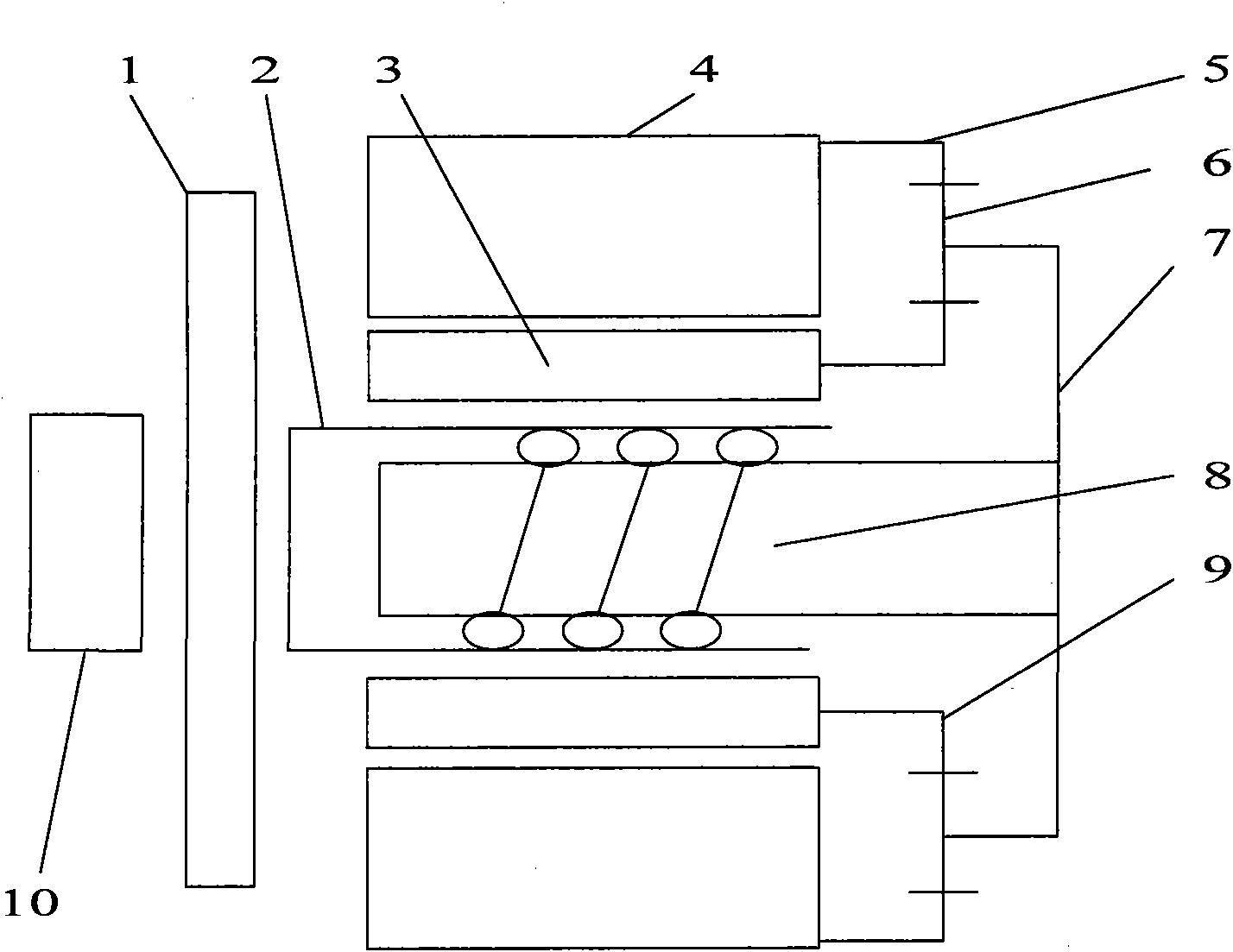

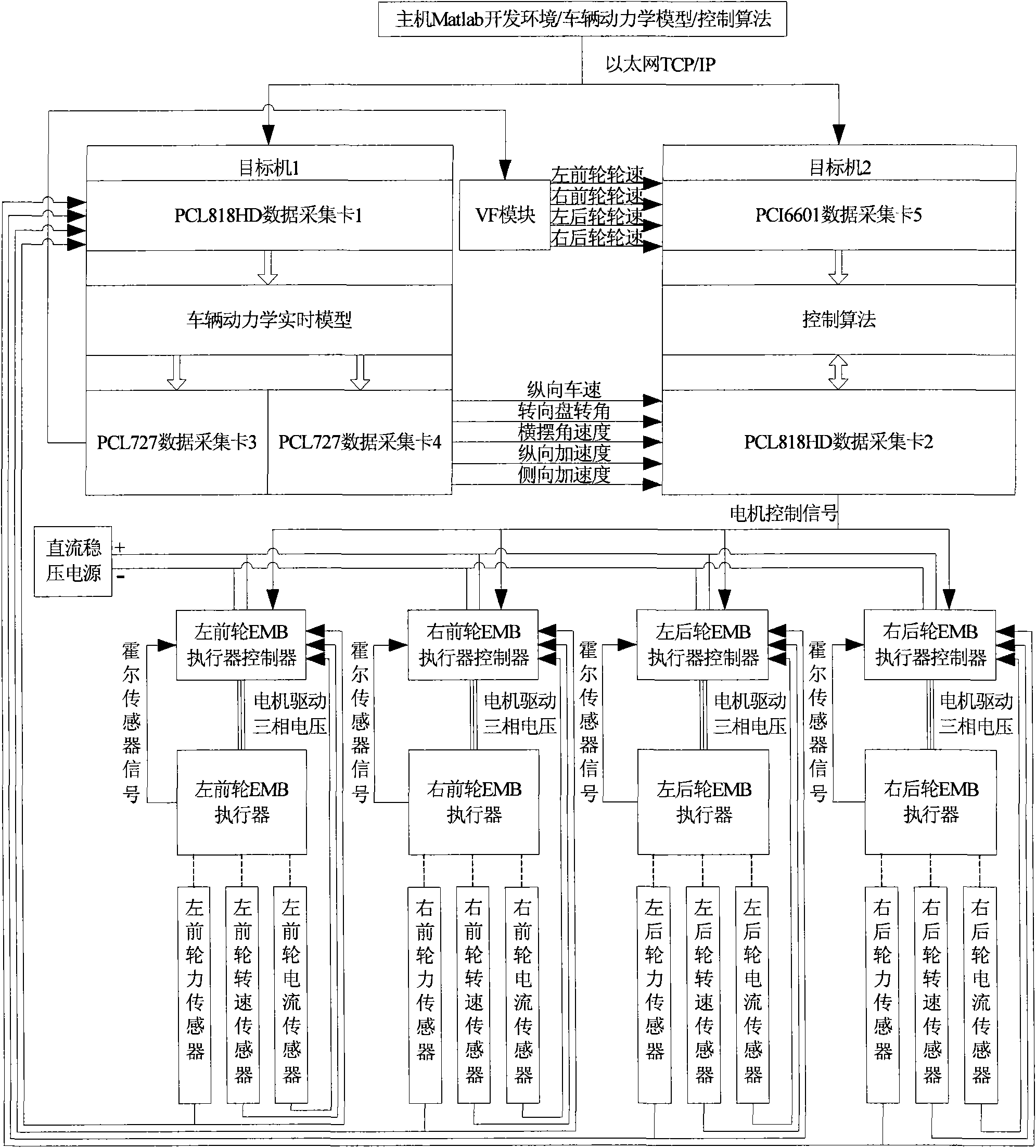

Brake-by-wire and steer-by-wire hardware-in-the-loop test bench for vehicle

InactiveCN101561353AThe simulation prediction results are accurate and reliableReduce development difficultyVehicle steering/rolling behaviourData acquisitionCurrent sensor

The invention discloses a brake-by-wire and steer-by-wire hardware-in-the-loop test bench for a vehicle. The test bench integrates a brake-by-wire system and a steer-by-wire system into a whole, and is divided into a software part, a real-time platform, a signal processing part and a hardware part, wherein the real-time platform consists of a host and target machines 1 and 2; the host and the target machines 1 and 2 are connected by a wireless network communication system; the signal processing part consists of first and second data acquisition cards with the model of PCL-818HD, third and fourth data acquisition cards with the model of PCL-727, a fifth data acquisition card with the model of PCI-6601 and a V / F conversion module; and the hardware part comprises a rotary angle sensor (12), a torque transducer (13), an opposite rotary motor (16), a steering resistance sensor (21), a steering actuating motor (18), an EMB actuator controller, and EMB actuator, a clamping force sensor, a revolution transmitter and a current sensor.

Owner:JILIN UNIV

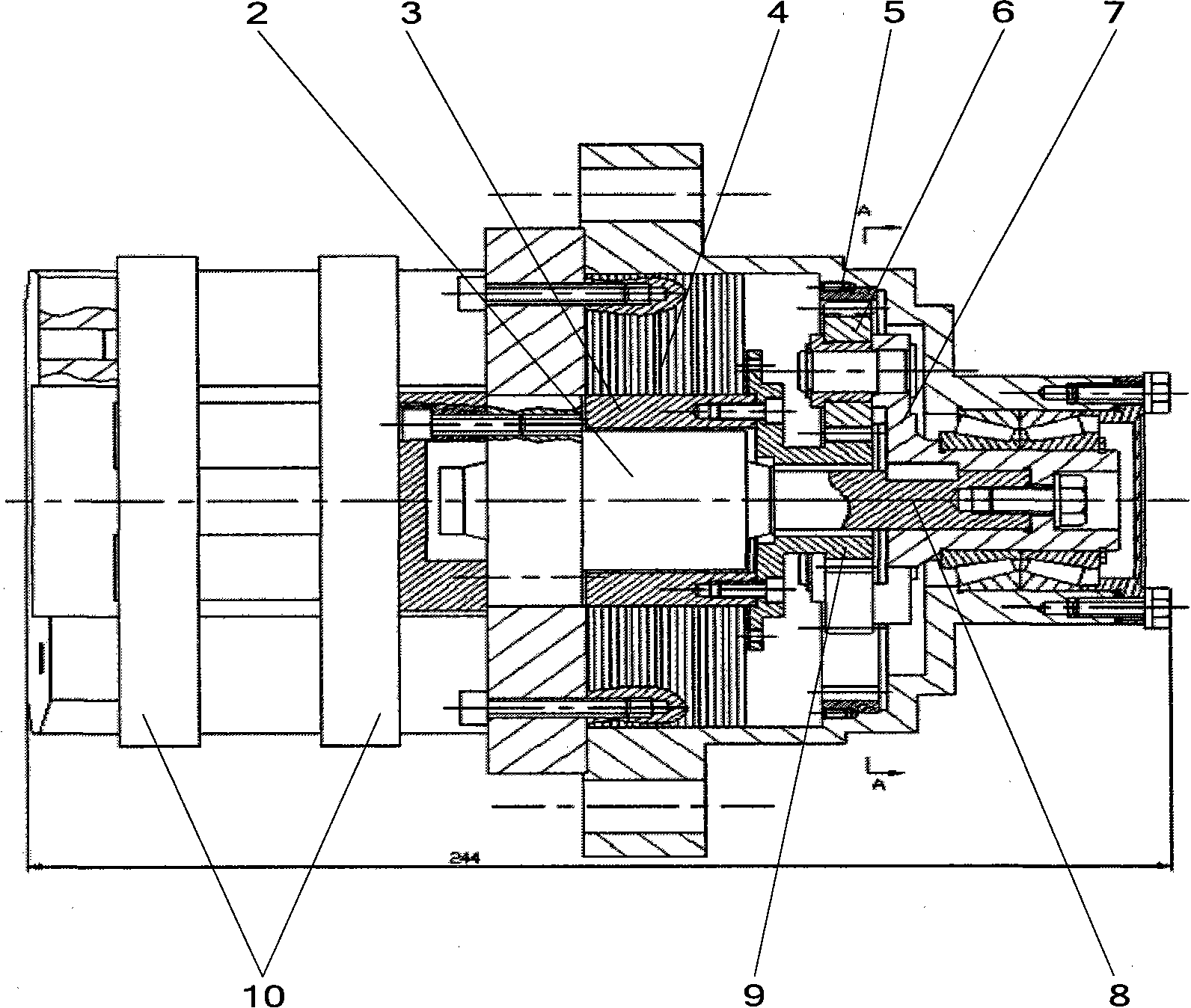

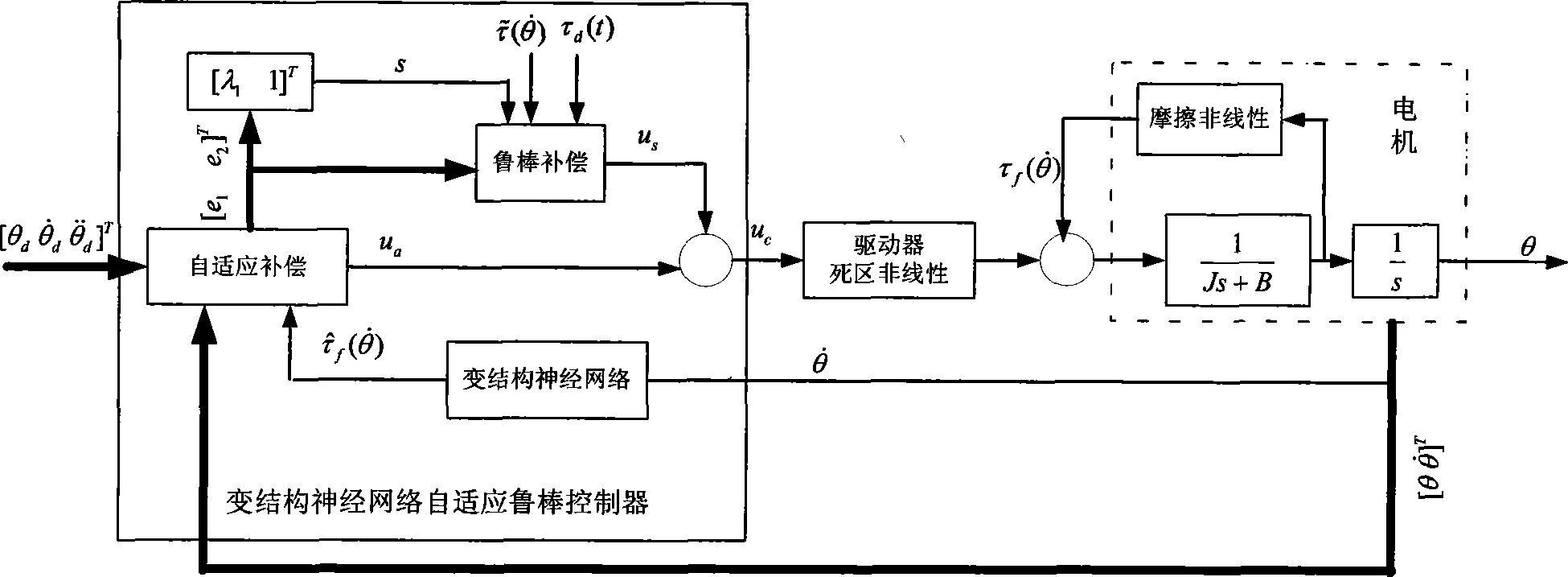

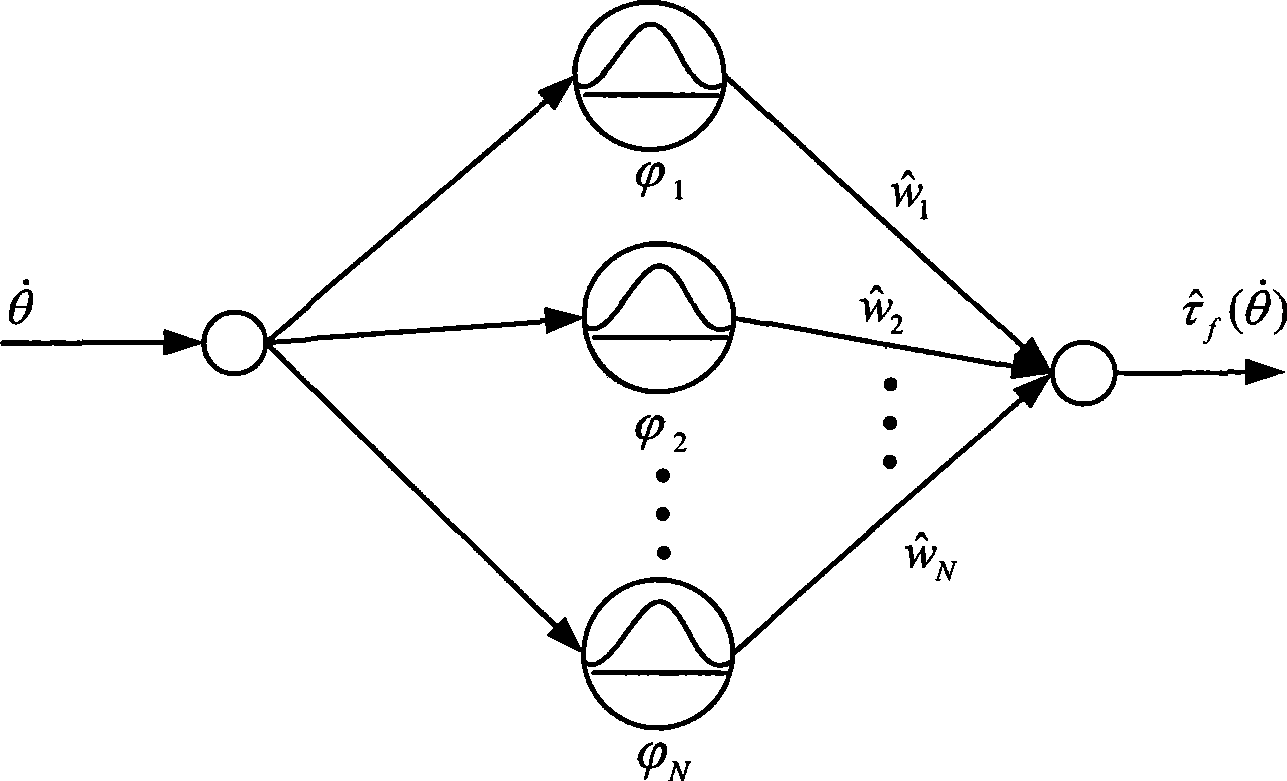

Essentially nonlinear compensation controller of servo system

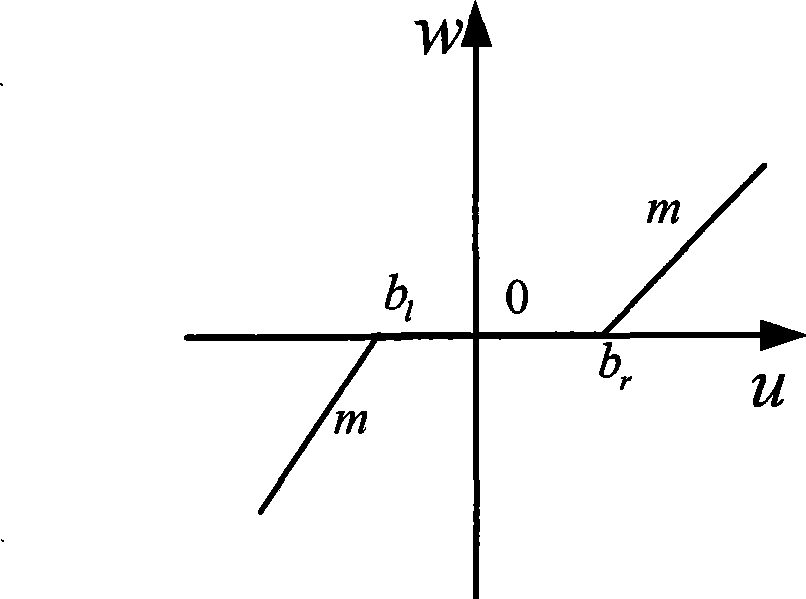

InactiveCN101488010AImprove practicalityAchieve friction compensationAdaptive controlNetwork sizeDead zone nonlinearity

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

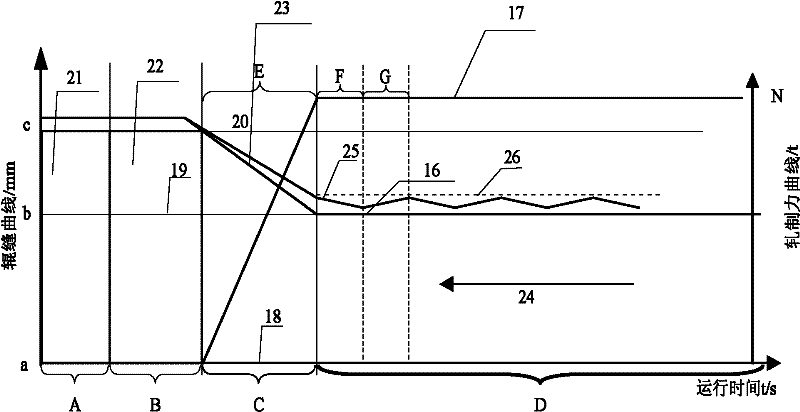

Method for rolling liquid core under heavy reduction rate by virtue of online thickness regulating roll by utilizing continuous casting machine

ActiveCN102189102AQuality improvementExempt from reheatingRoll force/gap control deviceMetal rolling arrangementsReduction rateLiquid core

The invention relates to a method for rolling a liquid core under heavy reduction rate by virtue of an online thickness regulating roll by utilizing a continuous casting machine. The method comprises the following steps of: when two rolling mills are loaded, setting a target thickness, feeding back the thickness value in real time and detecting oil pressure, carrying out conversion on a rolling force to judge whether the rolling force is higher than a limit value, if the rolling force is lower than the limit value, stabilizing rolling until the rolling is finished; if the rolling force is higher than the limit value, regulating and judging the rolling force again; if the target thickness is changed in the rolling process, calculating thickness variation by virtue of a rolling process computer, regulating roll gap of the two rolling mills to be the target thickness, and judging whether the rolling force is higher than the limit value again. In the method provided by the invention, a rolling signal can be changed to change the target thickness in the rolling process, and a wedge-shaped blank is rolled. By applying the method provided by the invention, the quality of a continuous casting can be better improved, the continuous casting and the wedge-shaped blank can be rolled, and the time of a process is reduced while the yield is improved; meanwhile, structure of equipment is simple, investment is less, control is simple, reliability is high, and energy can be greatly saved, thus the method has a good popularization and application prospect.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

Planning method of intelligent vehicle autonomous running dynamic trajectory and system of the same

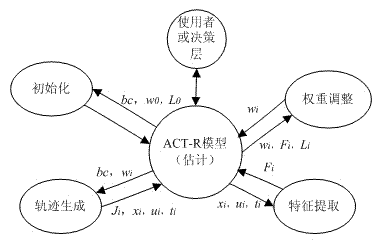

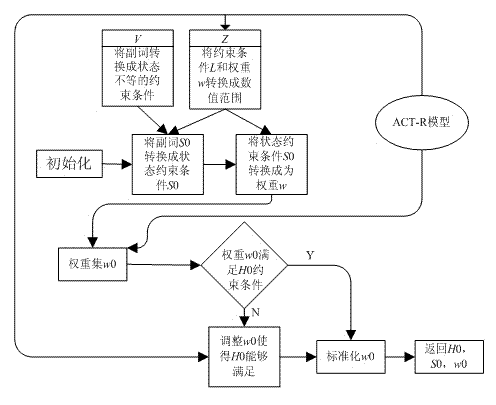

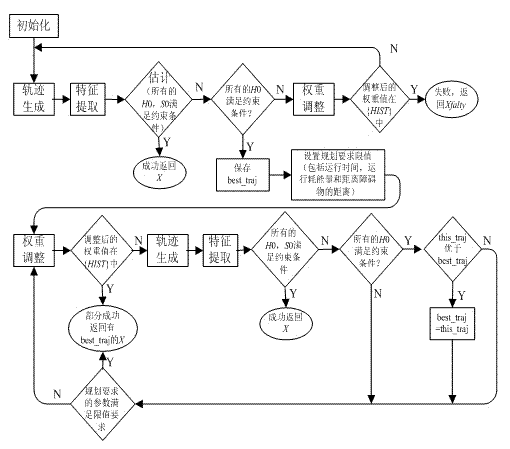

InactiveCN103035121AImprove learning abilityRealize online adjustmentRoad vehicles traffic controlSpecial data processing applicationsFeature extractionMathematical model

The invention discloses a planning method of an intelligent vehicle autonomous running dynamic trajectory and belongs to the technical field of intelligent transportation. The planning method of the intelligent vehicle autonomous running dynamic trajectory comprises (1) a step of generating a trajectory of an intelligent vehicle through searching for an optimum solution of a mathematical model by means of an optimum control method, (2) a step of extracting features of the trajectory generated in the first step, and (3) a step of judging whether the features meet presupposed constraint conditions or not; if the features meet the presupposed constraint conditions, regarding the trajectory as a final output trajectory; if the features do not meet the presupposed constraint conditions, adjusting weight W<1>, W<2>, and W<3> according to presupposed weight adjustment rules and then returning to the first step. The invention further discloses a planning system of the intelligent vehicle autonomous running dynamic trajectory. The planning system of the intelligent vehicle autonomous running dynamic trajectory comprises a trajectory generation module, a feature extraction module, an estimation module, and a weight adjustment module. Compared with the prior art, the planning method of the intelligent vehicle autonomous running dynamic trajectory and the system of the same have a stronger learning ability and a better adaptability to the unknown environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Hardware-in-the-loop test bench based on electromechanical braking system

InactiveCN101561354AThe result is accurateReduce testing costsVehicle testingCurrent sensorData acquisition

The invention discloses a hardware-in-the-loop test bench based on an electromechanical braking system, which is divided into a software part, a real-time platform, a signal processing part and a hardware part, wherein the real-time platform consists of a host and target machines 1 and 2; the host and the target machines 1 and 2 are connected by a wireless network; the signal processing part consists of first and second data acquisition cards with the model of PCL-818HD, third and fourth data acquisition cards with the model of PCL-727, a fifth data acquisition card with the model of PCI-6601 and a V / F conversion module; the first and second data acquisition cards with the model of PCL-818HD and the third and fourth data acquisition cards with the model of PCL-727 are connected with the target machines 1 and 2 by an ISA bus; the fifth data acquisition card with the model of PCI-6601 is connected with the target machine 2 by a PCI bus; and the hardware part comprises an EMB actuator controller, an EMB actuator, a force sensor, a revolution transmitter and a current sensor.

Owner:JILIN UNIV

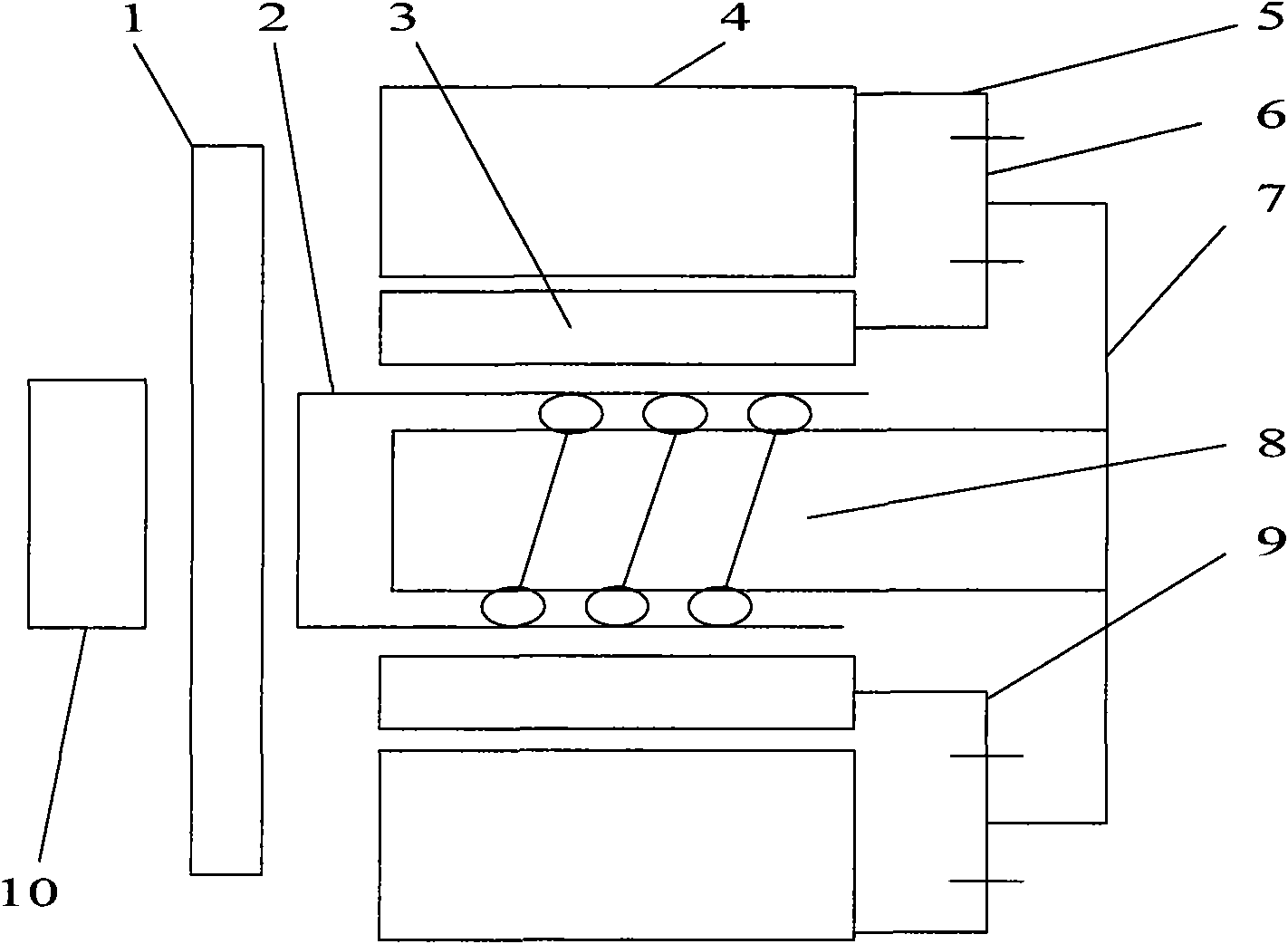

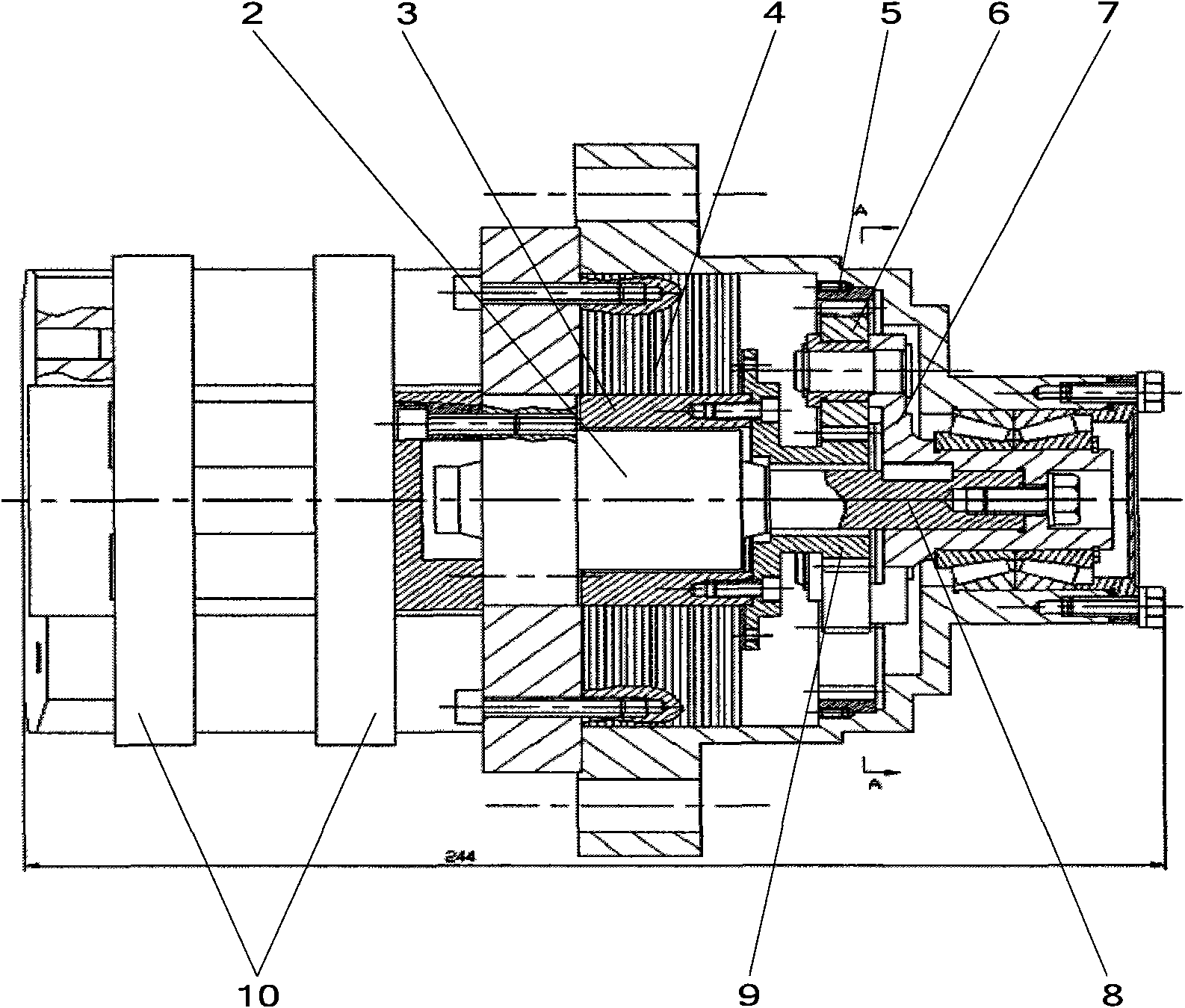

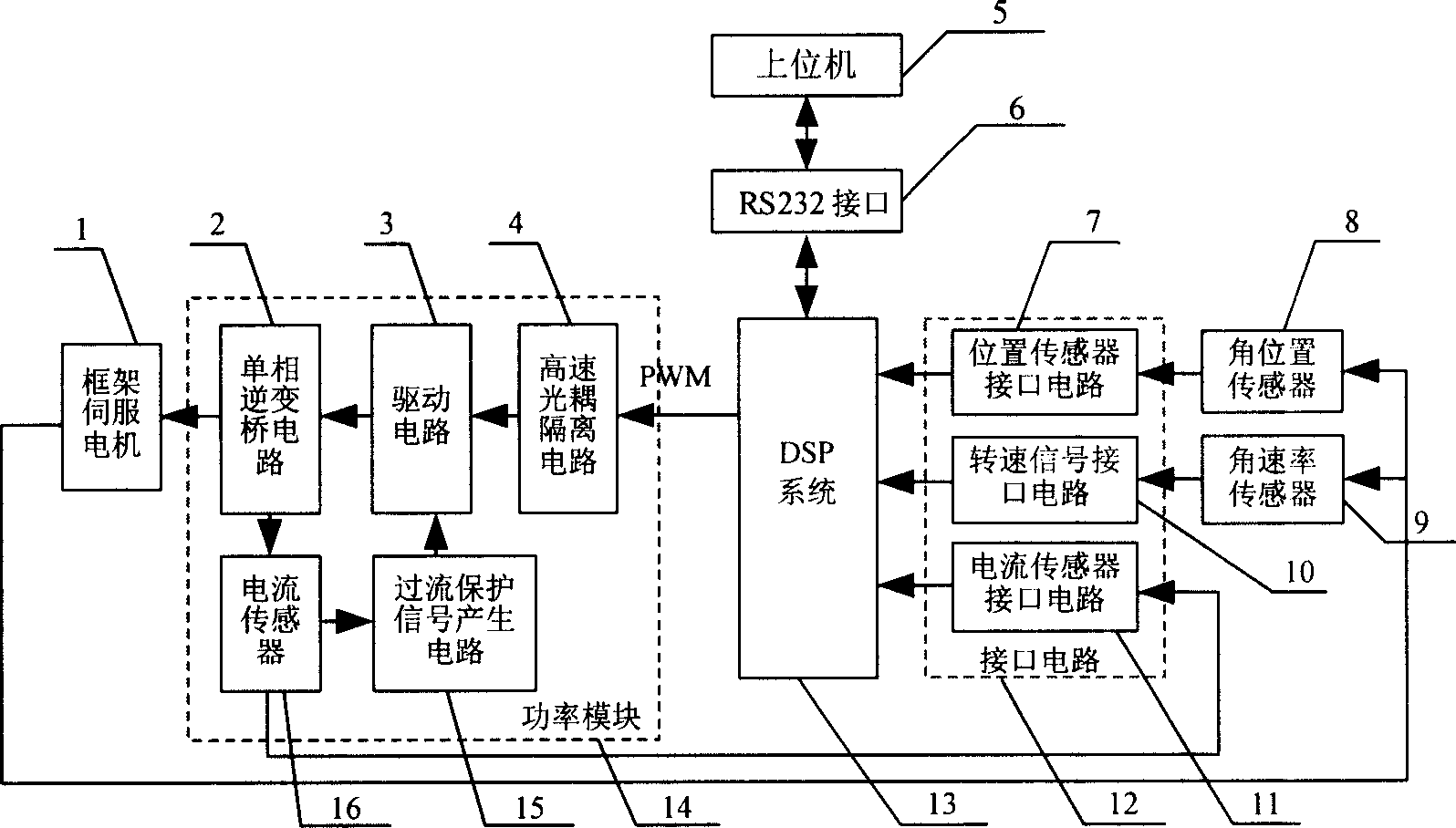

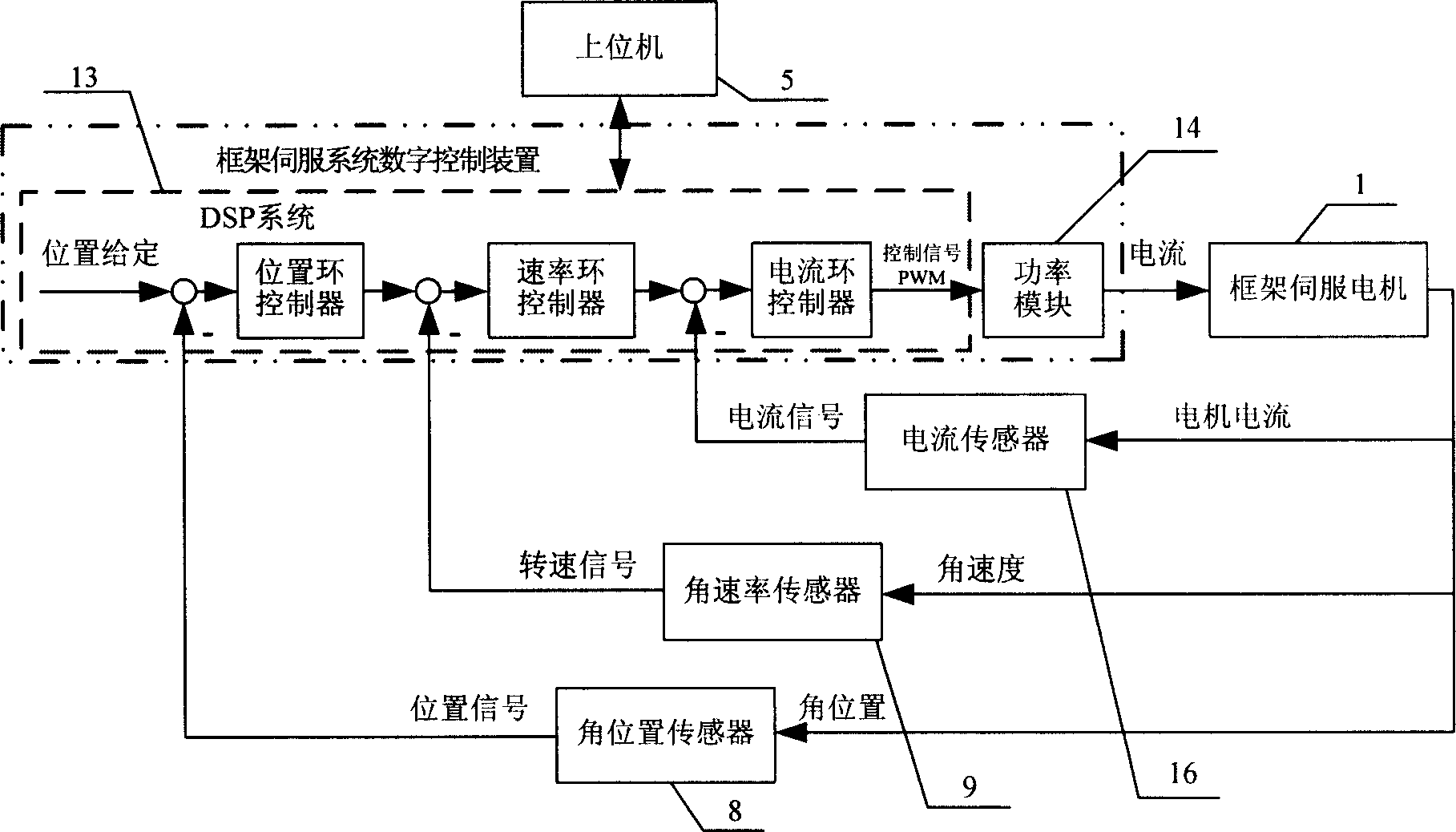

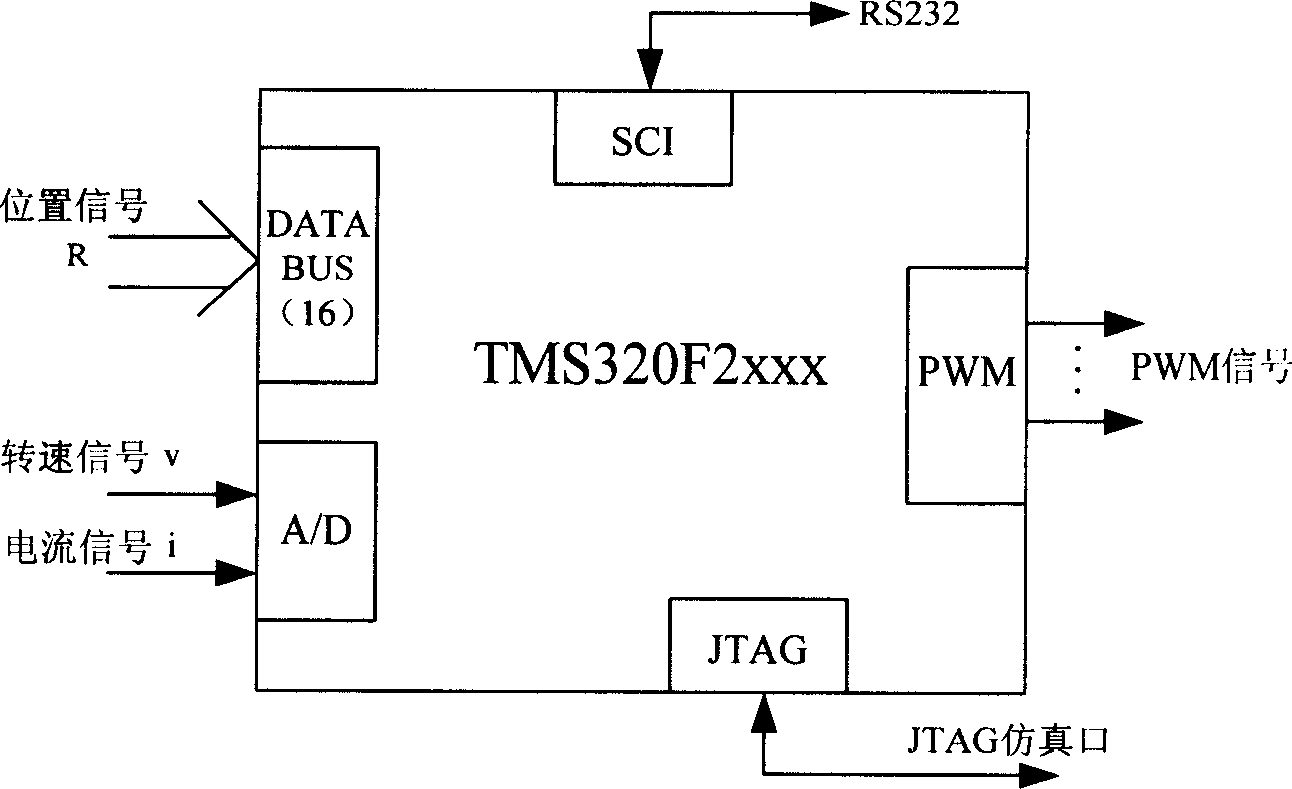

Integral high precision control moment gyro gimbal servo digital controller

InactiveCN1869846ASimple structureReduce volumeProgramme controlComputer controlEngineeringControl theory

A digital device for accurately controlling frame servo system of torque gyro is featured as obtaining current, rotary speed and position signal of frame servo motor by DSP system through interface circuit; carrying out operation as per certain control algorithm to generate out control amount to be PWM-modulated; transmitting modulated PWM signal to single-phase contra variant bridge circuit by driving circuit for generating control current required by frame servo motor so as to realize accurate control of frame servo system.

Owner:BEIHANG UNIV

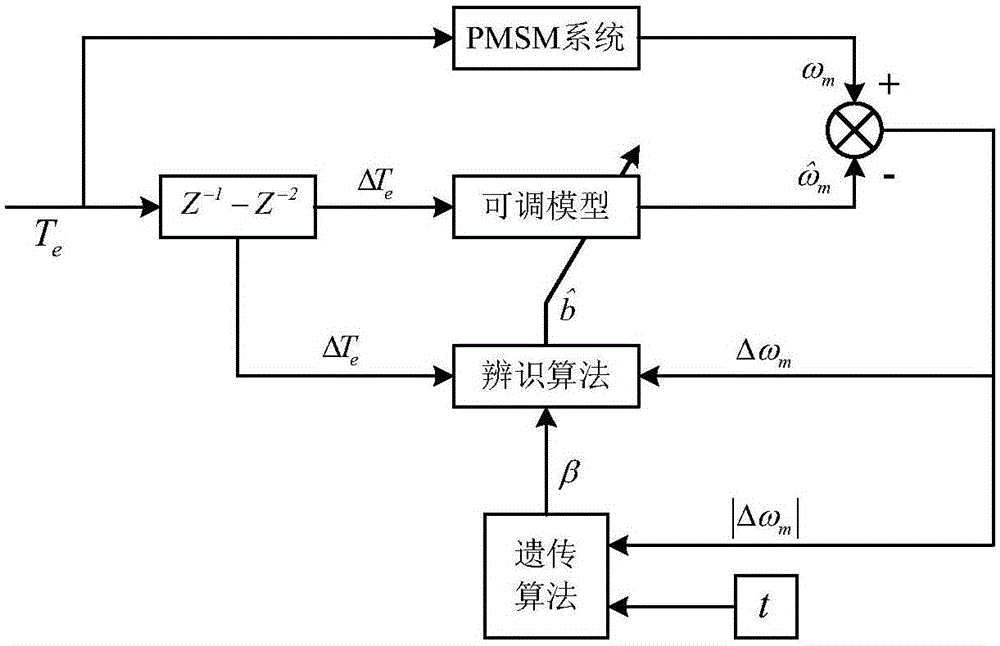

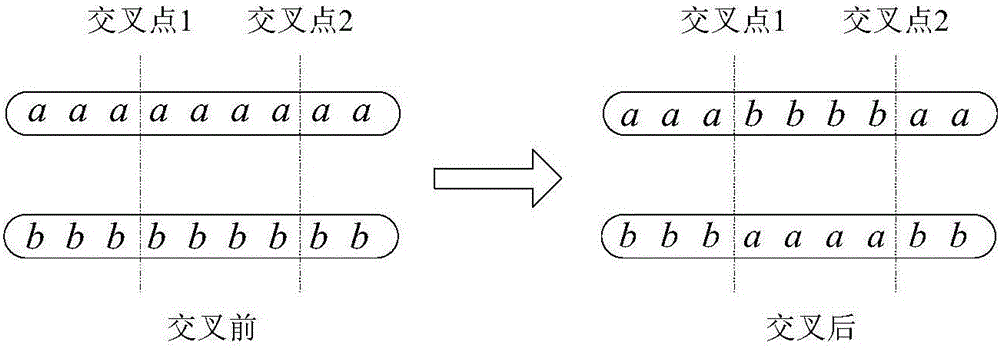

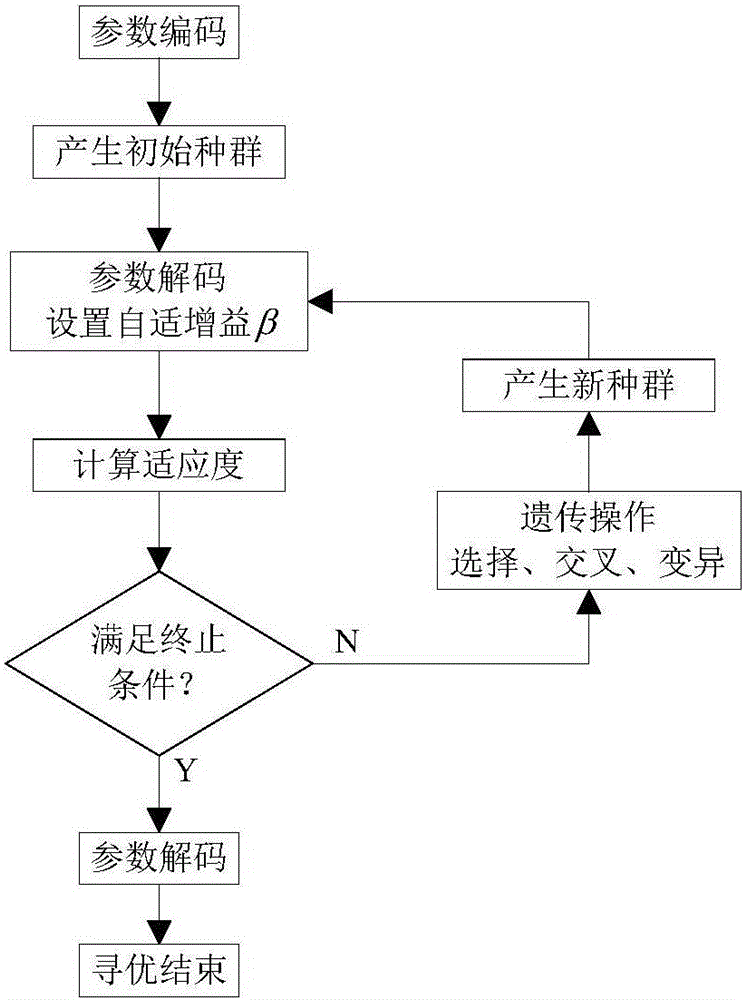

Servo system inertia identification method adopting genetic algorithm for optimization

ActiveCN105915121ARealize online adjustmentEasy to identifyElectronic commutation motor controlElectric motor controlRotary inertiaSelf adaptive

The invention discloses a servo system inertia identification method adopting a genetic algorithm for optimization. Based on a model reference self-adaption theory, the self-adaption rule of inertia identification is designed according to a Landau discrete time recursive algorithm. The global searching capability of the genetic algorithm is utilized, a model reference self-adaption system is used as a control object, an output difference between a motor practical angular speed and an estimated angular speed is used as a control error, the integration of the product of time and an error absolute value is used as an optimization target, the self-adaption gain [beta] in the inertia identification is dynamically adjusted, and the online optimization of control parameters is realized. According to the invention, both the higher convergence speed and the higher identification precision are realized in inertia identification, and the relatively high self-adaption capability to the change of rotary inertia is achieved.

Owner:无锡超通智能制造技术研究院有限公司

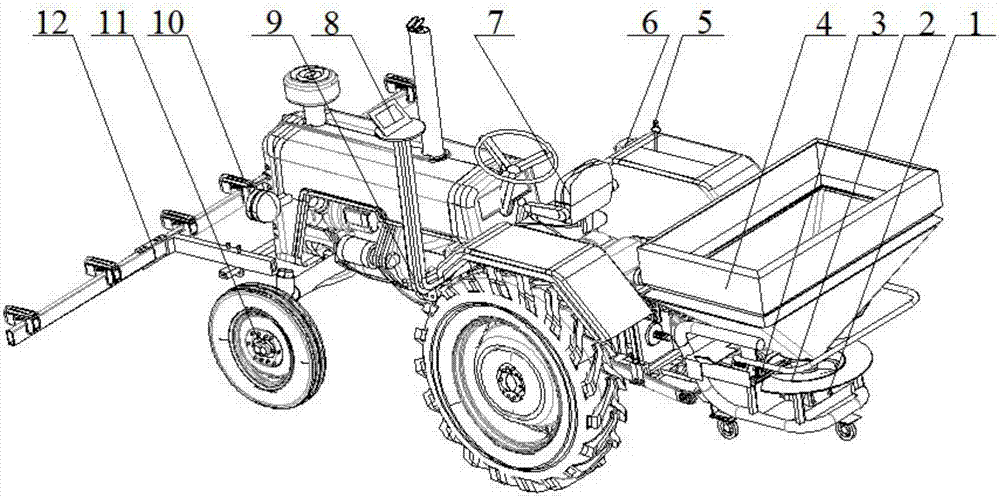

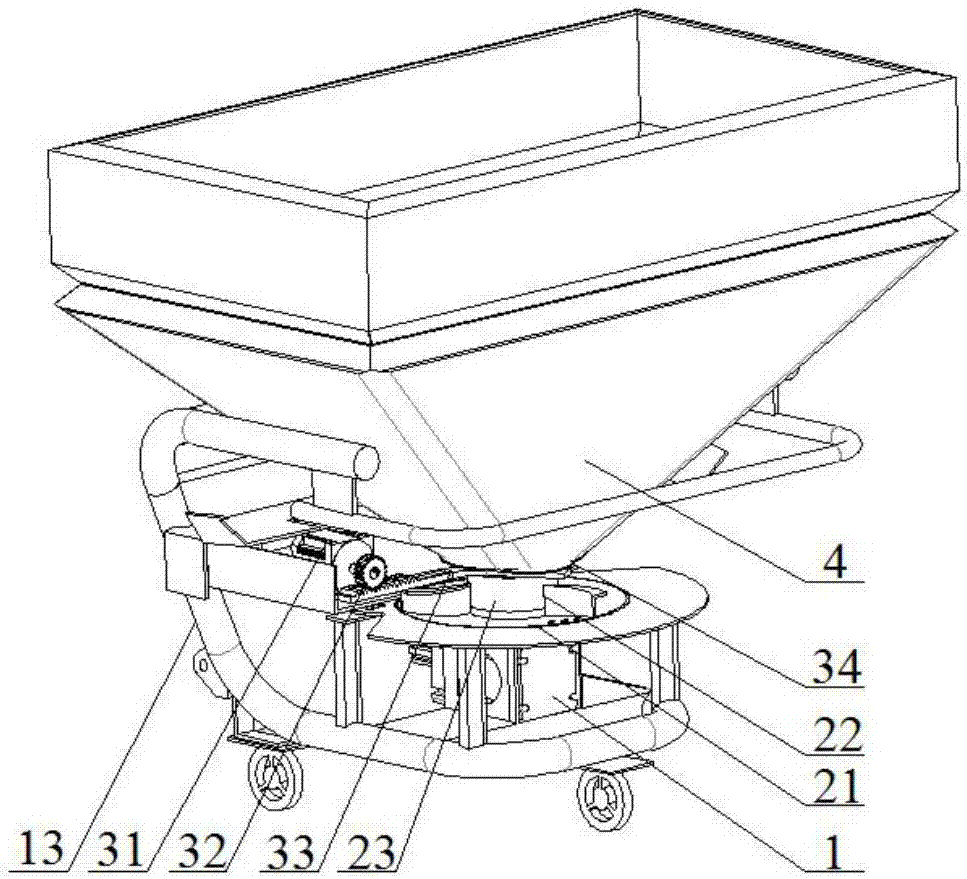

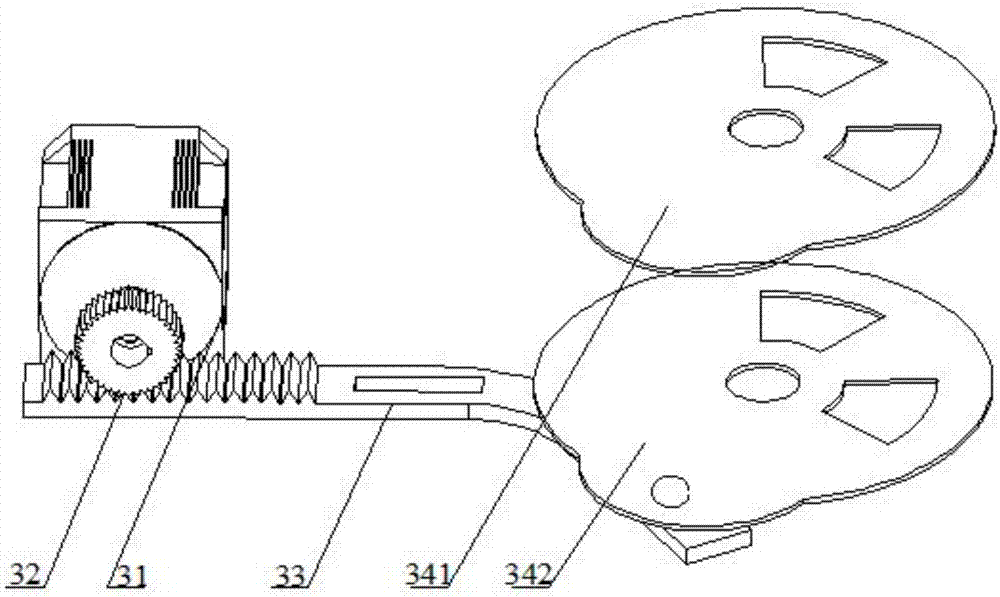

Real-time quantity variable fertilizer distributor based on crop growth information

InactiveCN106856763AControl not to be spilled and wastedRealize online adjustmentFertiliser distributersCircular discControl communications

The invention discloses a real-time quantity variable fertilizer distributor based on crop growth information and relates to the technical field of agricultural machinery. The real-time quantity variable fertilizer distributor comprises a crop growth information acquisition system, a walking system, a quantity variable fertilizer distribution system and a control communication system. The crop growth information acquisition system is arranged at the front end of the walking system through a bracket; canopy face-shaped information of crops is obtained in real time by a spectrum sensor; the information is transmitted to a vehicle-mounted control terminal arranged in the walking system through data exchanger ; a traveling speed and GPS (Global Positioning System) data information of the fertilizer distributor are monitored in real time by combining a speed sensor; a quantity variable fertilizer application decision-making system is operated through the control communication system and information is fed back to an intelligent quantity variable controller; the quantity variable fertilizer distribution system is executed and rotary speeds of a hydraulic motor and a stepping motor are regulated, and opening position and size of a fertilizer quantity regulation mechanism are controlled, so that online regulation of a fertilizer application amount is realized. According to the real-time quantity variable fertilizer distributor, a fertilizer distribution circular disc is of a shape with a warped concave spherical surface and the section of a fertilizer distribution blade is of a curve shape, so that the uniformity of fertilizer distribution is facilitated.

Owner:NANJING AGRICULTURAL UNIVERSITY

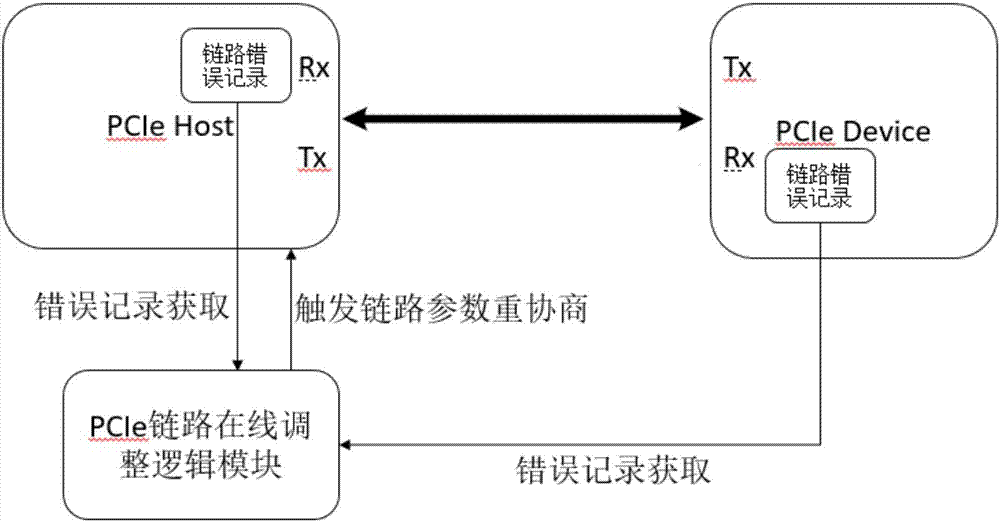

Method and device for online adjusting link parameter

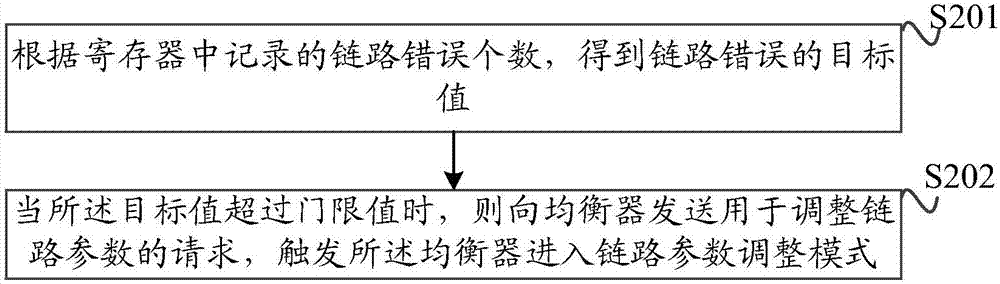

InactiveCN107066417AGuaranteed reliabilityRealize online adjustmentTransmitter/receiver shaping networksElectric digital data processingProcessor registerComputer module

An embodiment of the invention discloses a method and a device for online adjusting a link parameter. The method comprises the following steps that: for a data transmission link established between two PCIe chips, the number of link errors recorded in a register of two PCIe chips can be real-time monitored through a PCIe link online adjustment logic module; a target value of the link error is obtained according to the number of link errors recorded in the register; and when the target value exceeds a threshold value, which means that the link parameter is already not suitable for demand of a current link, a request for adjusting the link parameter is sent to an equalizer, so as to trigger the equalizer to enter a link parameter adjustment mode. It can be appreciated that according to the technical solution of the method and the device, the online adjustment of the link parameter can be implemented, therefore, reliability of the link under different conditions is ensured.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Solid-liquid composite cast rolling machine for dual-metal-layer composite pipe

The invention provides a solid-liquid composite cast rolling machine for a dual-metal-layer composite pipe. The machine comprises a machine frame, a pouring unit used for aluminum liquid pouring, a pressing-down and balance adjusting device and a cast roller unit, and further comprises an annular flow distribution device and a guide support. The annular flow distribution device is covered with a heating device used for keeping metal liquid in a molten state. The cast roller unit comprises a first cast roller and a second cast roller which jointly form a circular hole, and a pipe base material to be composited enters the circular hole. The solid-liquid cast rolling forming technology is adopted for producing the dual-metal-layer composite pipe, and metallurgical bonding of dual metal interfaces can be achieved by combining the rapid solidification technology with the rolling technology. Compared with the prior art, cladding metal is poured in a liquid state, the problem that the requirements of traditional solid-solid composite technologies such as drawing composite, expanded connection composite and spinning composite for blank size and shape precision are high is solved, and the solid-liquid composite cast rolling machine has the beneficial effects of remarkably saving energy, being high in efficiency and short in process, and the like.

Owner:YANSHAN UNIV

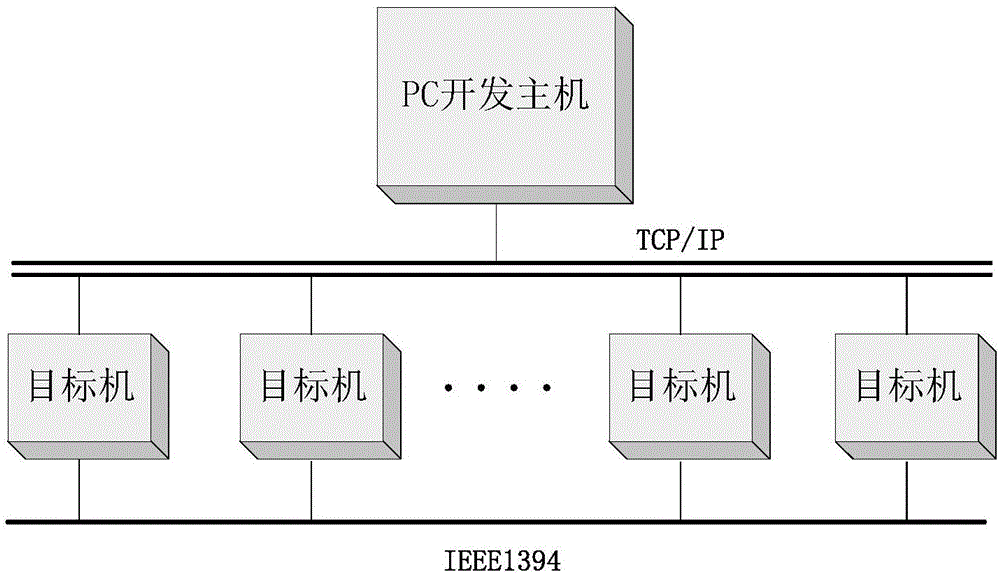

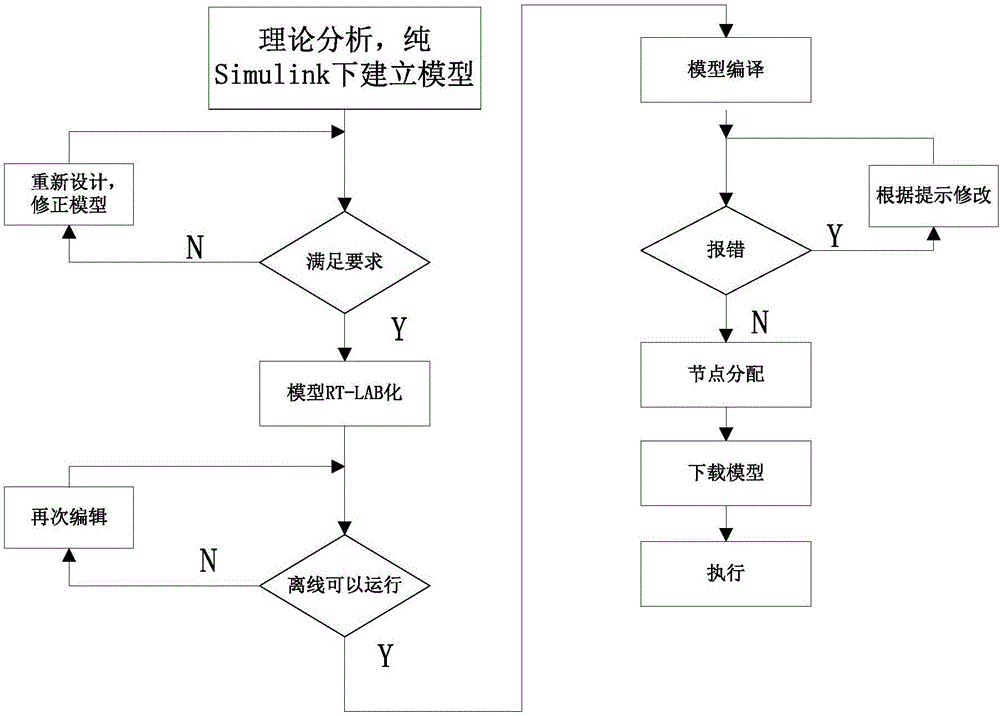

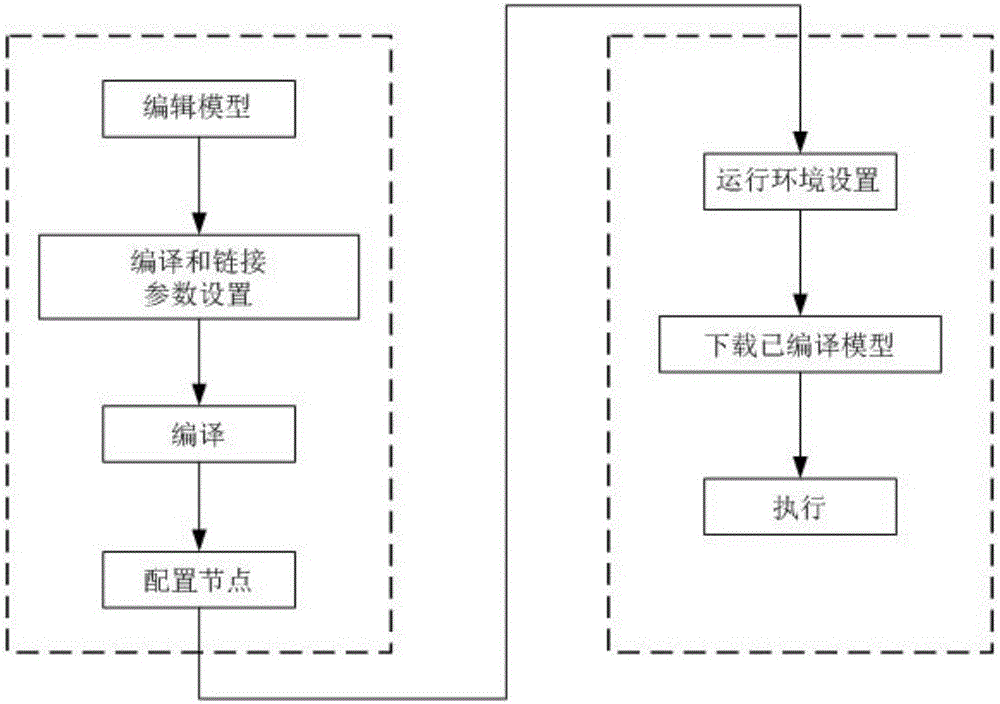

Flight control distributed type real-time simulation system

InactiveCN106372370ARealize online adjustmentDoes not require simulation to runGeometric CADSpecial data processing applicationsReal-time simulationPhysical system

The invention discloses a flight control distributed type real-time simulation system, relates to the field of flight control simulation, and solves the problems that a model cannot be installed with a large quantity of I / O (Input / Output) physical systems and real-time simulation cannot be realized in the prior art. The flight control distributed type real-time simulation system comprises one or two development host units and multiple target machines, wherein the development main units are system dynamics, navigation and control model development and simulation state monitoring platforms; the target machines are real-time simulation processors; each target machine can be regarded as a node in a real-time network and operates a QNX real-time operating system; the main units are connected with the target machines through a TCP / IP network; the target machines are connected with one another through an IEEE-1394 bus. By the adoption of multi-kernel and multi-model distributed type simulation, parallel simulation of multiple models is realized, and the simulation efficiency is obviously improved; synchronous real-time simulation of the simulation time and the actual physical time is realized; all the models are independent from one another but also cooperated with one another, so that the flexibility of module configuration is improved.

Owner:NAT UNIV OF DEFENSE TECH

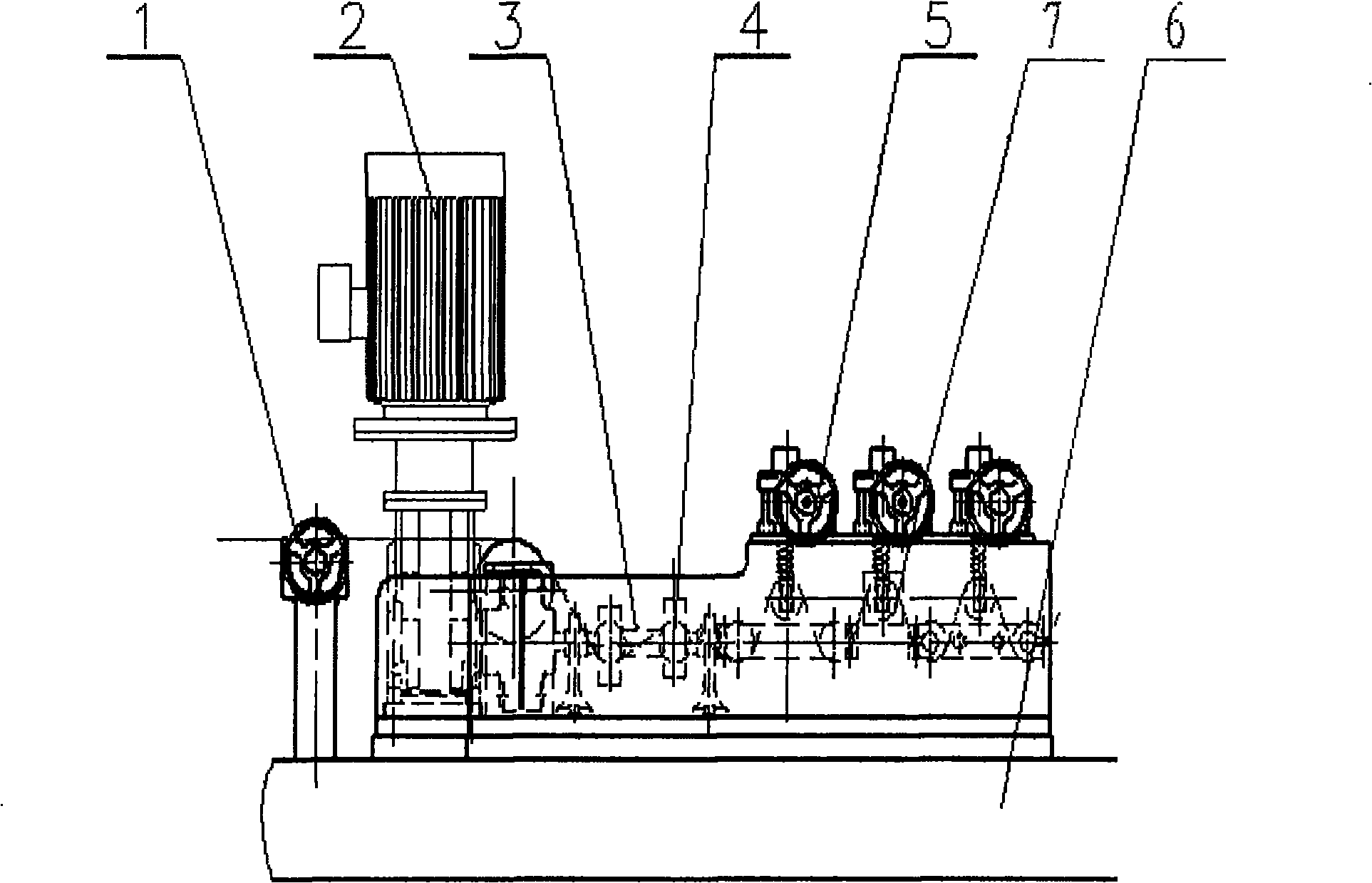

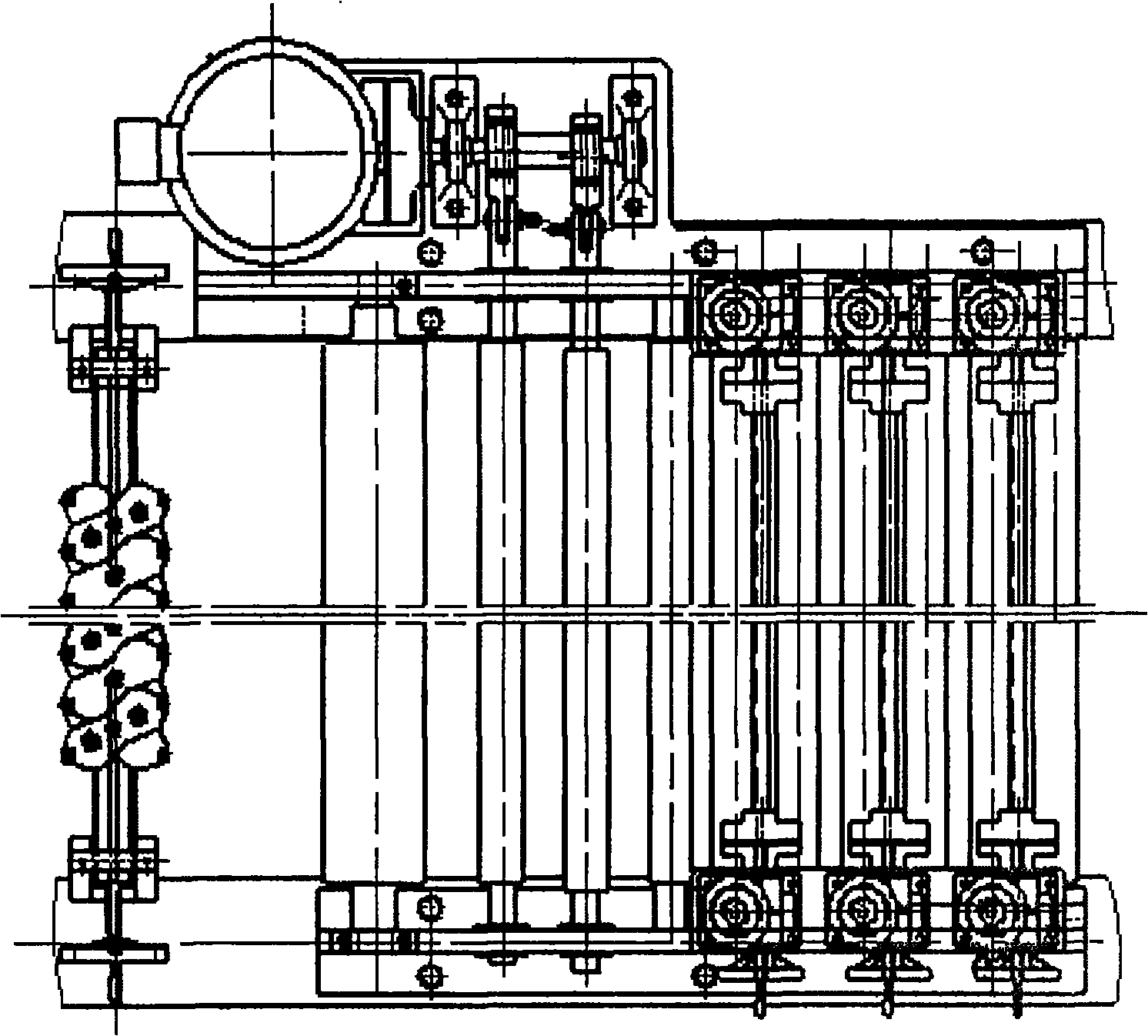

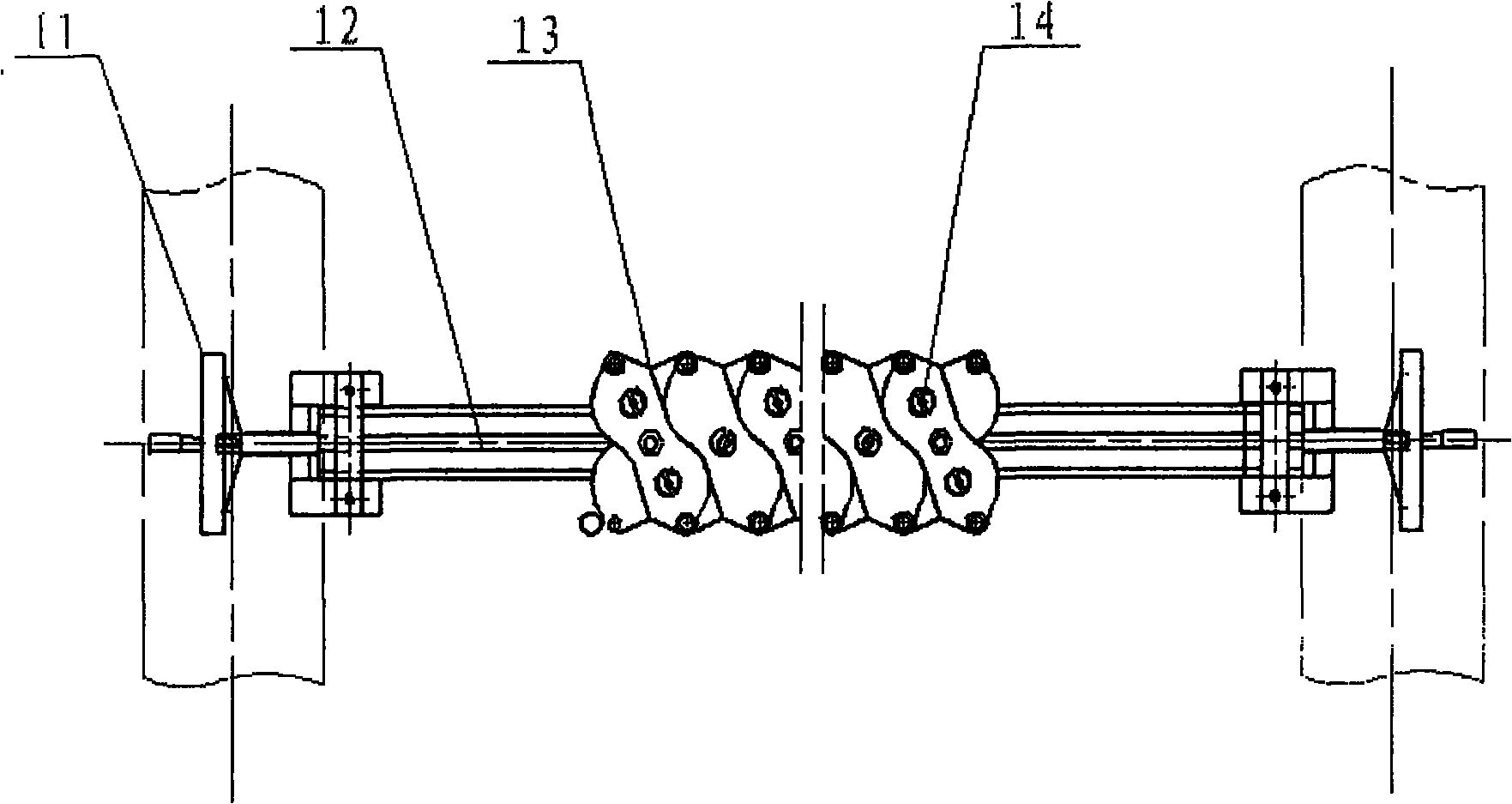

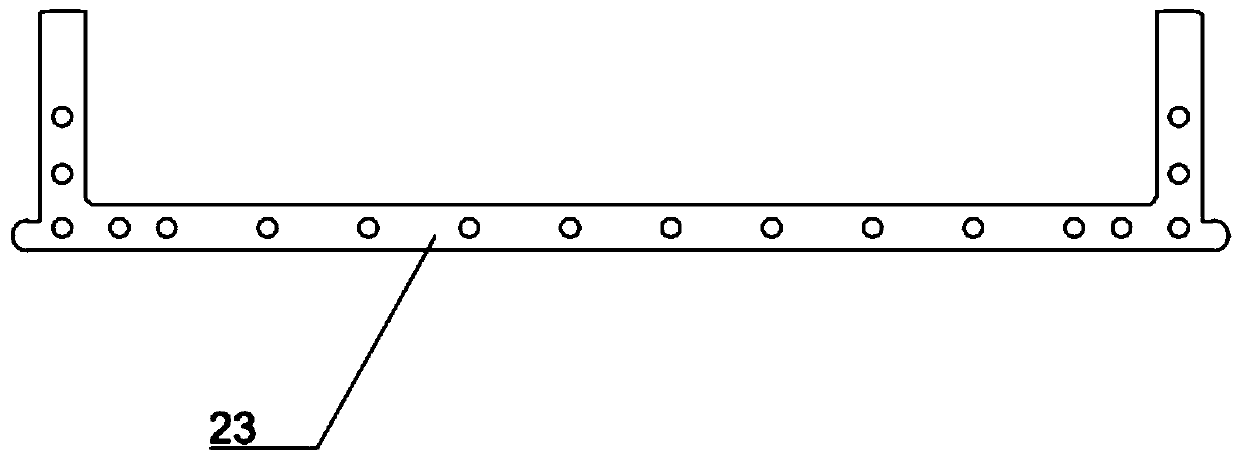

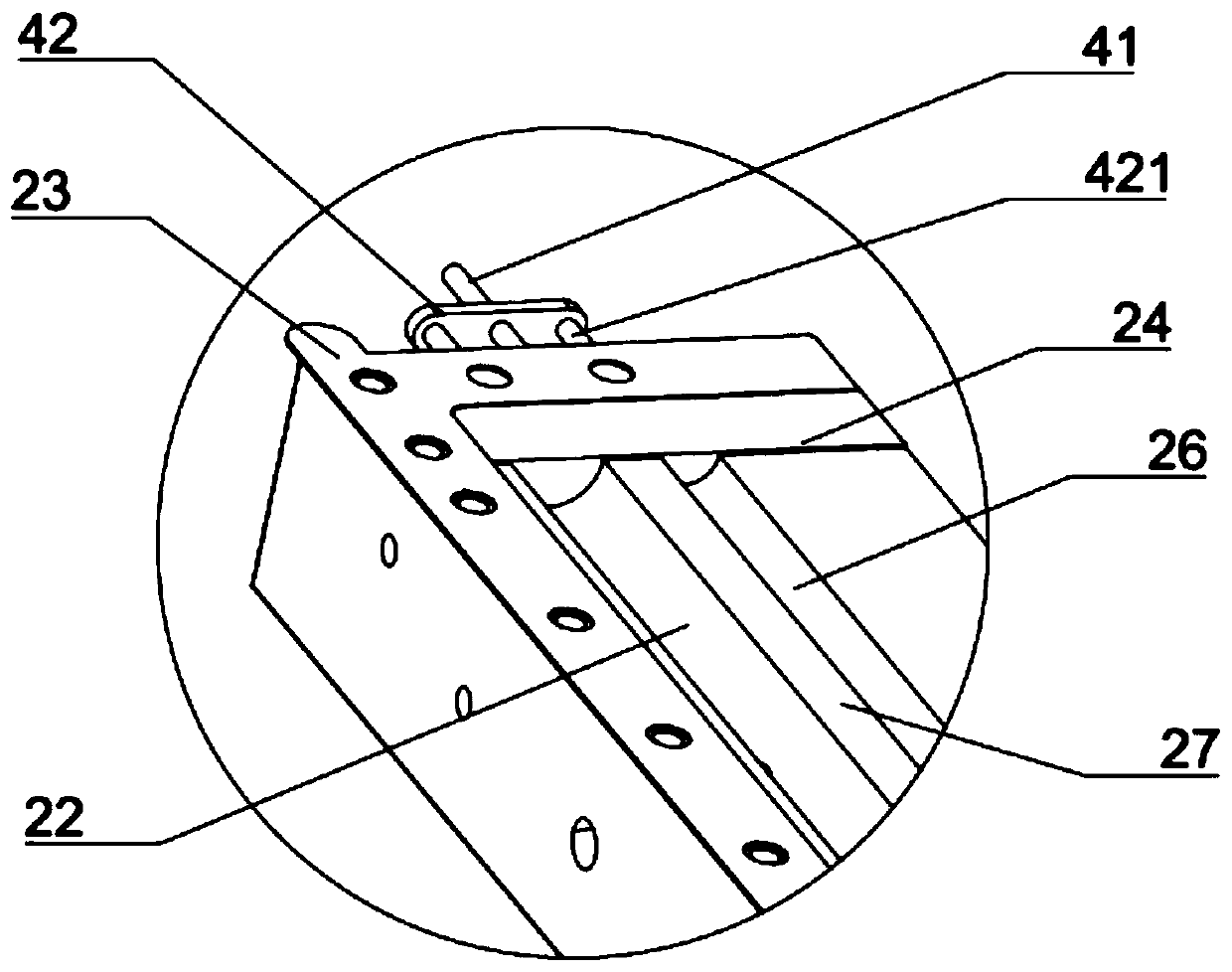

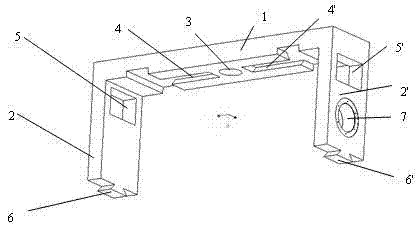

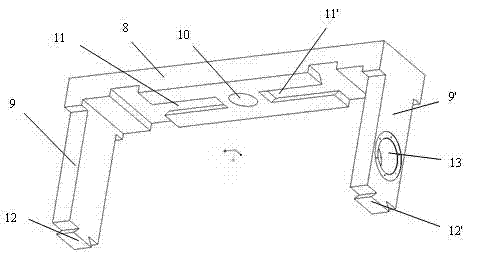

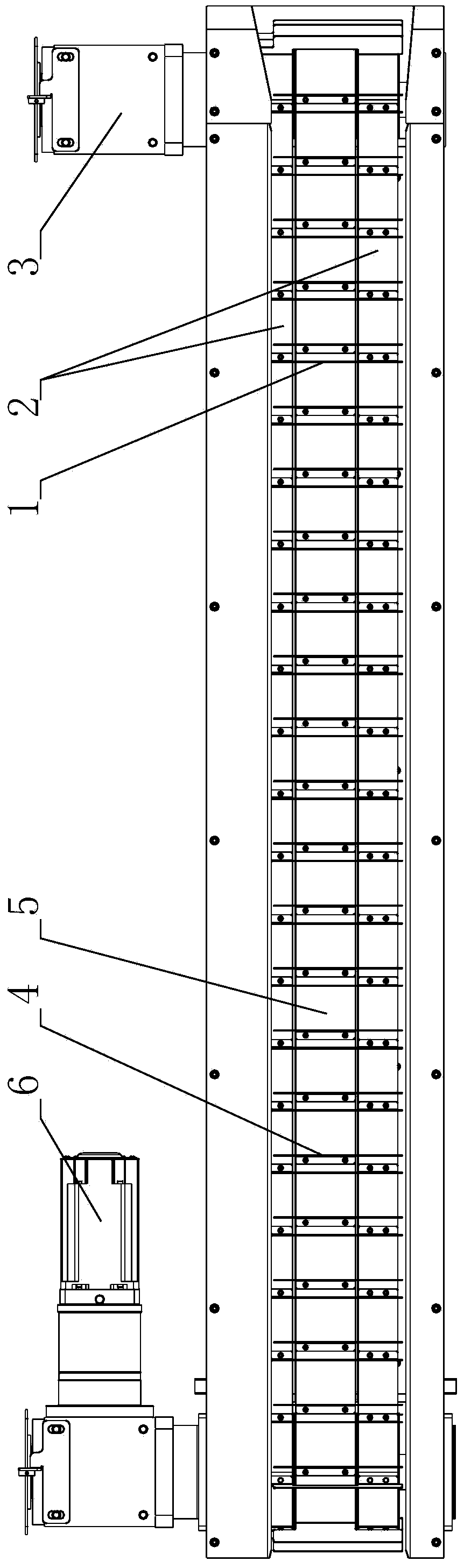

Vibrating and flattening device for impregnation production line of carbon fiber prepreg

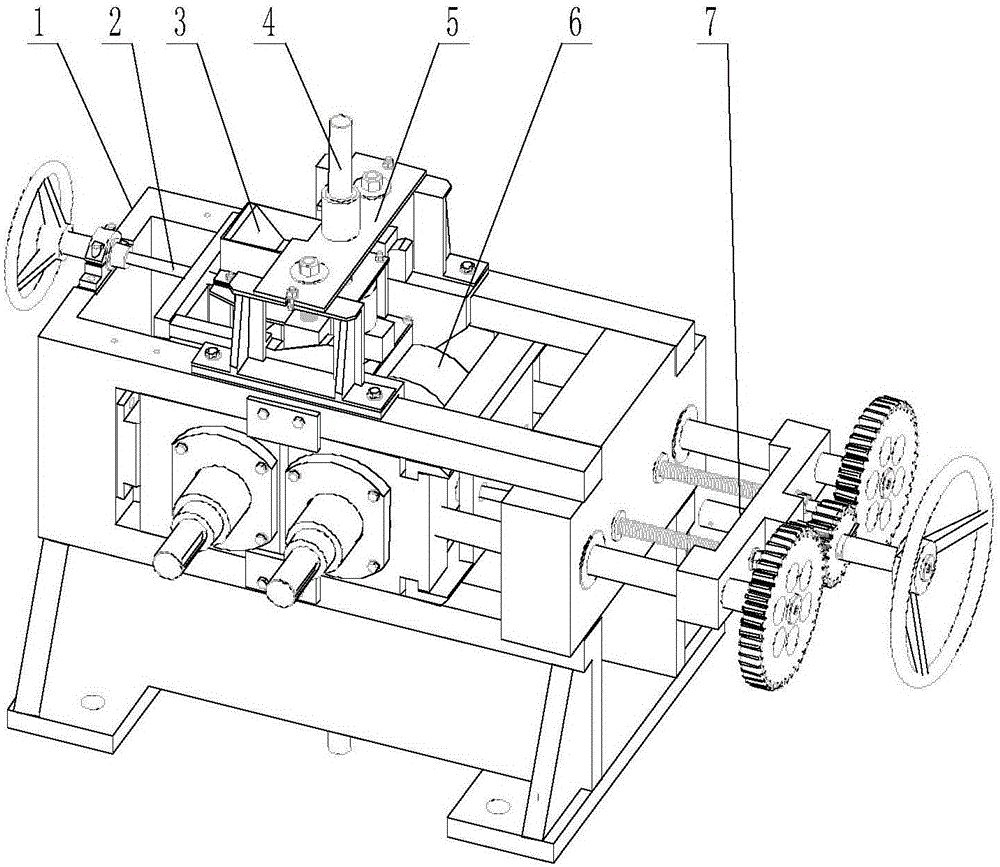

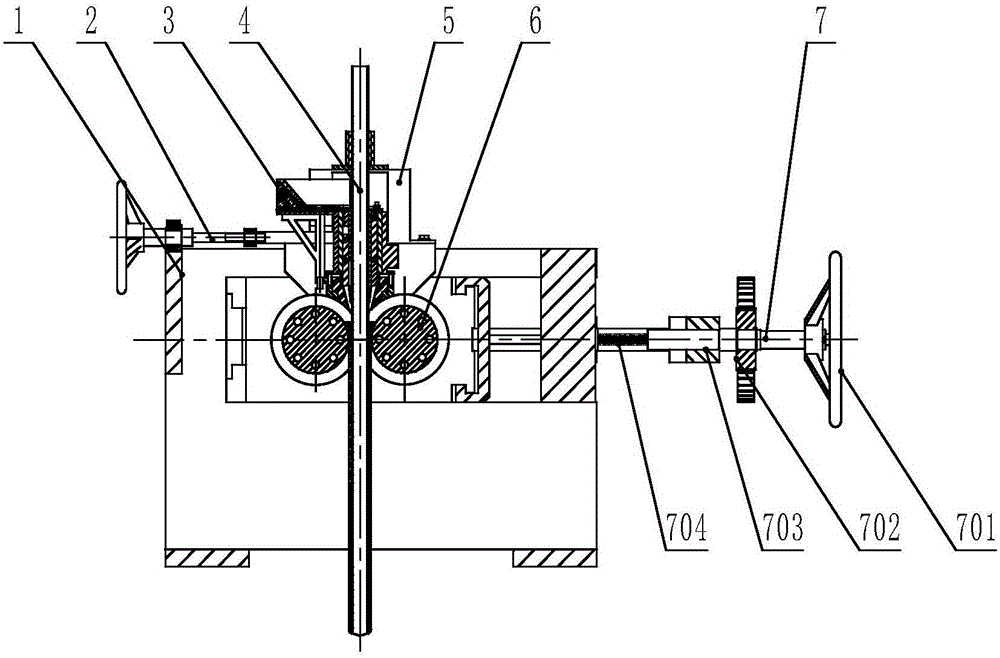

ActiveCN101818425ARealize online adjustmentStable flattening effectTextile/flexible product manufactureTextile treatment carriersFiberProduction line

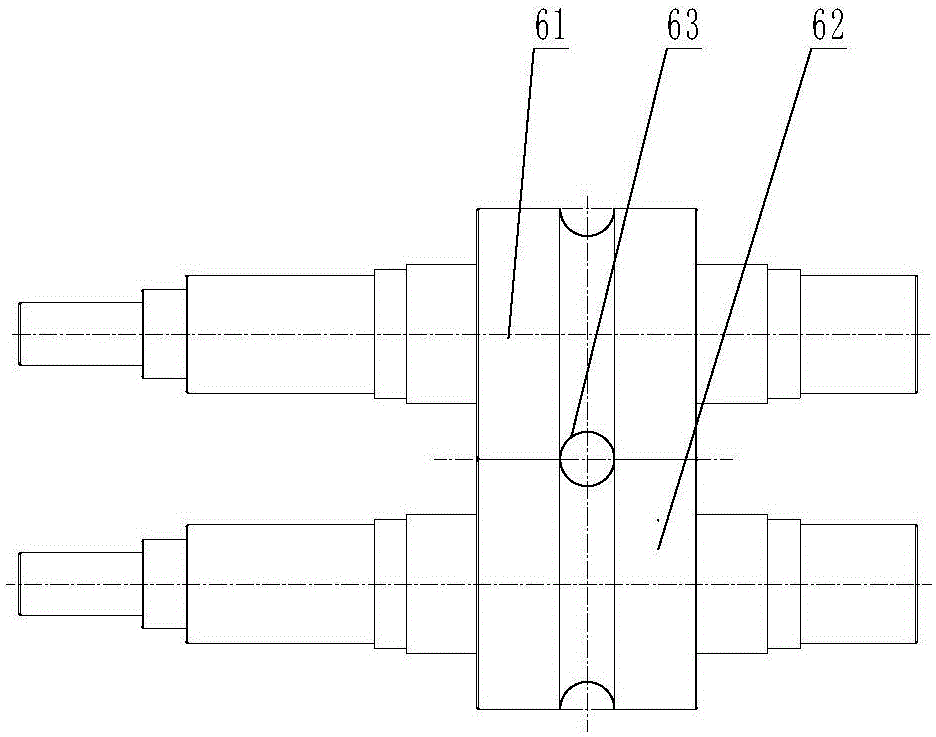

The invention discloses a vibrating and flattening device for an impregnation production line of a carbon fiber prepreg, comprising a splitting comb (1) with adjustable spacing, a variable frequency motor reduction gear (2), a cam shaft (3), two vibrating rollers (4), three groups of lifting rollers (5), a support (6) and a fixed roller (7). The splitting comb (1) with adjustable spacing, the reduction gear for the variable frequency motor (2), the cam shaft (3), two vibrating rollers (4), the lifting rollers (5) and the fixed roller (7) are jointly arranged on the support (6); the splitting comb (1) with adjustable spacing is arranged on the left side of the support (6), and the rear end of the splitting comb (1) with adjustable spacing is equipped with the variable frequency motor reduction gear (2); two vibrating rollers (4) are arranged on the rear end of the variable frequency motor reduction gear (2); the cam shaft (3) is arranged between two vibrating rollers (4); three groups of lifting rollers (5) are arranged behind two vibrating rollers (4); and the fixed roller (7) is arranged under three groups of lifting rollers (5).

Owner:大连橡胶塑料机械有限公司

Coating die head for single or multiple lithium battery pole pieces

PendingCN110302942ARealize online adjustmentAvoid cleaningLiquid surface applicatorsElectrode manufacturing processesSlurryEngineering

The invention discloses a coating die head for single or multiple lithium battery pole pieces. The coating die head comprises an upper die head and a lower die head. A feed inlet is formed in the upper die head or the lower die head, and a trough for accommodating coating slurry is formed in the lower die head, the feed inlet communicates to the trough, and the front sides of the upper die head and the lower die head are matched to form a die nozzle. The upper die head and the lower die head define a die cavity for accommodating the coating slurry, and the front side of the die cavity is isolated by the upper die head and the lower die head to form a silt of the die nozzle; the trough stretches along the length direction of the lower die head, a plurality of adjusting slide blocks are distributed vertical to the coating direction between the upper die head and the lower die head, the adjusting slide blocks slide along the surface of the lower die head, and the adjusting slide blocks are matched on the side of the die nozzle to form a discharge port with variable width for coating slurry. The dimension of the die cavity is adjusted by controlling the slide blocks, so that the coating width of the coating die is adjusted online. The die cavity is not opened in the adjusting process, so that the production efficiency is improved and consistent production of products is facilitated.

Owner:NINGBO VEKEN BATTERY

Martensite steel 3D free-bending forming device and method

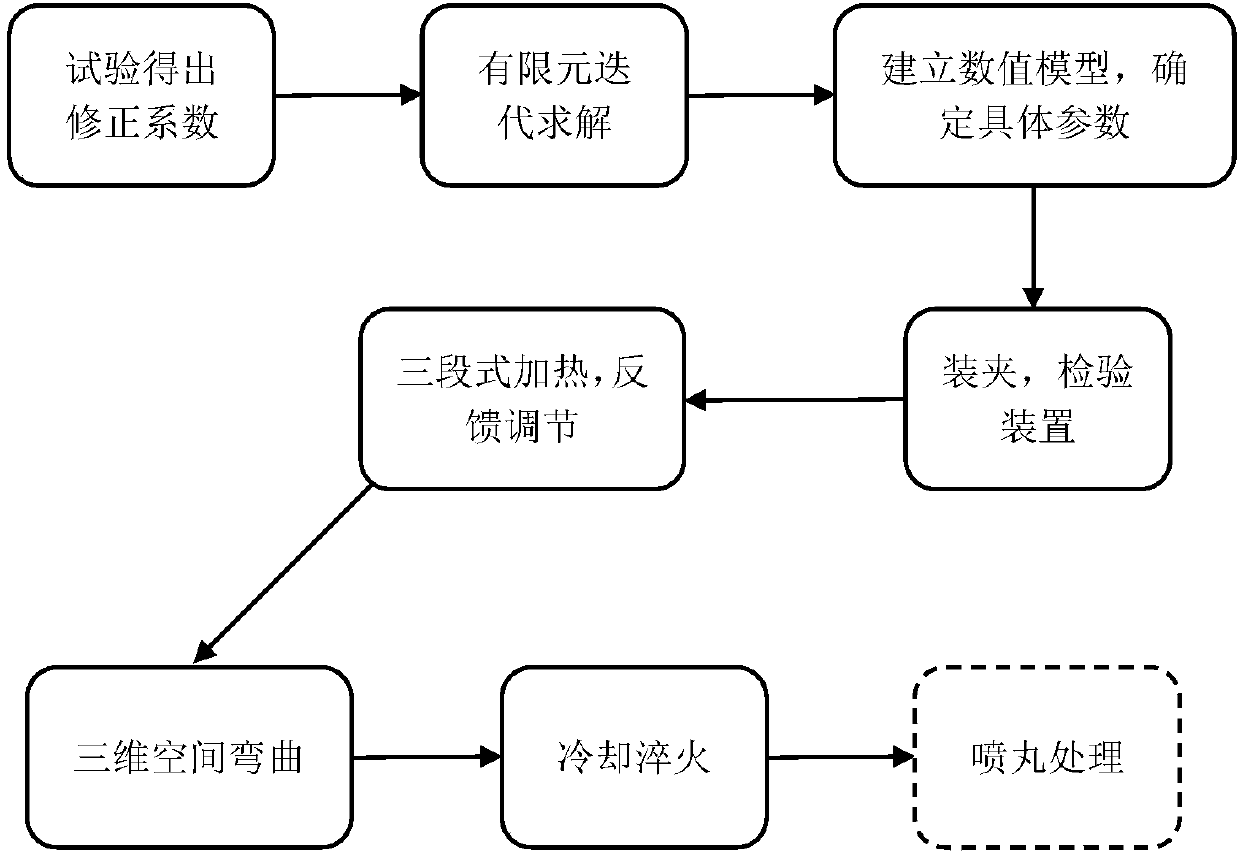

ActiveCN107755490AIncrease productivityRealization of free bending pipeShaping toolsMetal-working feeding devicesNuclear powerMartensite

The invention discloses a martensite steel 3D free-bending forming device and method and belongs to the technical field of advanced manufacturing and plastic forming. Firstly, based on relative parameters of the forming performance of a pipe material, a corresponding correction factor of the material is obtained through repeated iterative calculation, and an initial model is corrected; after the using situations of parts are tested and calibrated, a three-stage type induction heating device and sensors are matched to achieve precise temperature-control heating; the three-dimensional space of abending mould rotates to extrude the front end of the pipe material to enable the front end of the pipe material to be in a bent shape with the complicated space; and the quenching process is conducted through an annular water-cooling spraying head and accordingly is rapid and uniform. The martensite steel 3D free-bending forming technical problem is solved, and high-temperature free-bending forming under the three-dimensional space is achieved; by means of a rapid quenching system, the strength of 1400 MPa or above is obtained, formation coordinated control of an ultrahigh-strength steel 3Dfree-bending member is achieved; and thus the martensite steel 3D free-bending forming device and method have important engineering application value in the fields of aerospace, rail transportation, automobiles and nuclear power.

Owner:NANJING INST OF TECH +1

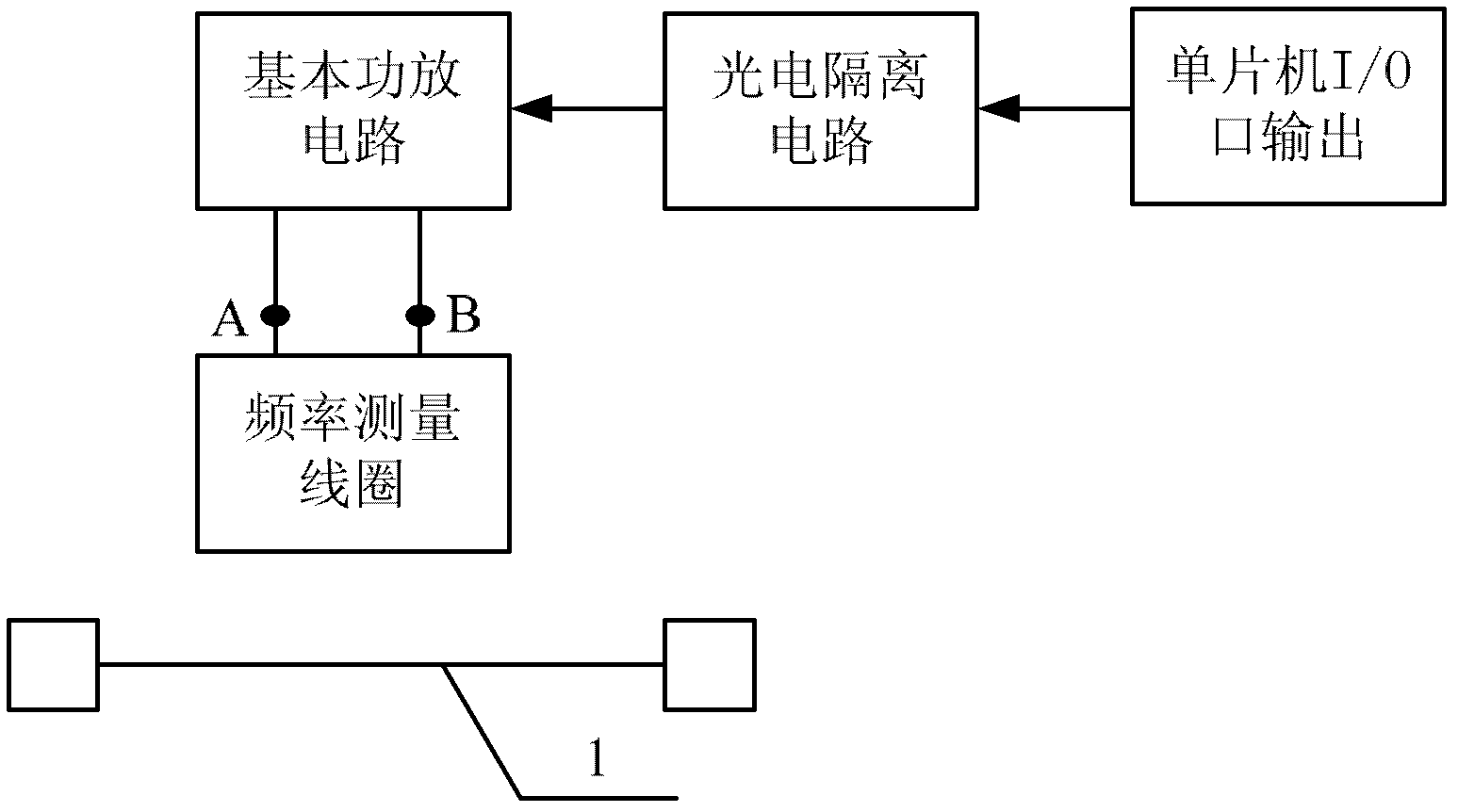

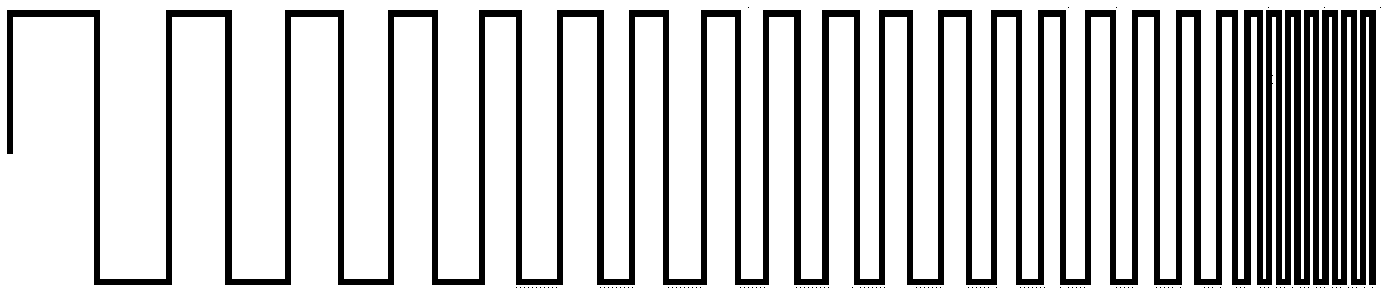

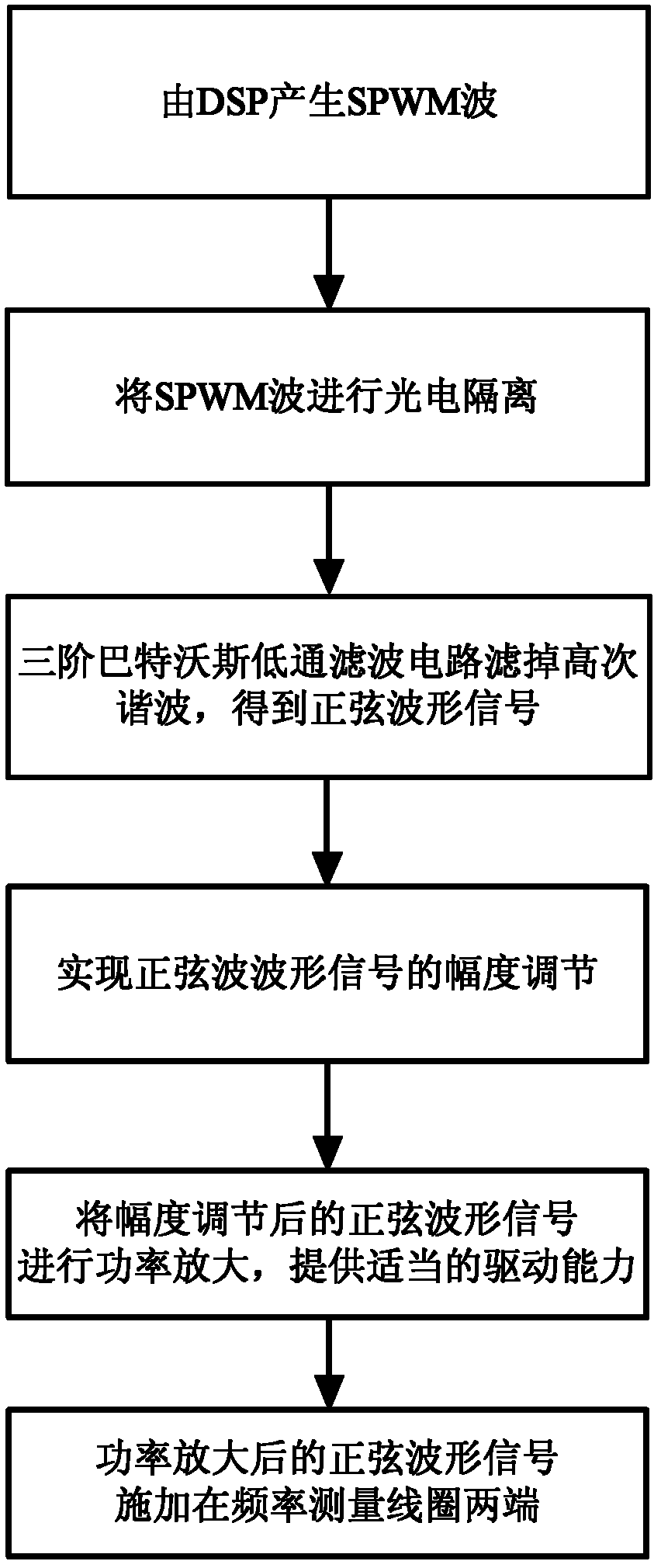

Vibration method and device for a vibrating wire instrument

InactiveCN102288279AAddress reliabilitySolve problems with clutterSubsonic/sonic/ultrasonic wave measurementUsing electrical meansControl signalResonance

The present invention relates to an excitation method and device of a vibrating wire instrument. The method generates a SPWM wave, and then filters the generated SPWM wave through a filter circuit to obtain a sinusoidal waveform signal, and then applies the sinusoidal waveform signal to the vibrating wire instrument. The two ends of the frequency measuring coil in the instrument generate alternating electromagnetic force under the action of the permanent magnet, which drives the steel string to generate resonance. The SPWM waveform excitation signal whose pulse width changes according to the sinusoidal waveform rule generated by the method improves the precise control ability of the excitation signal and solves various limitations caused by the traditional excitation method using a pulse square wave.

Owner:CHINA GEOKON INSTR

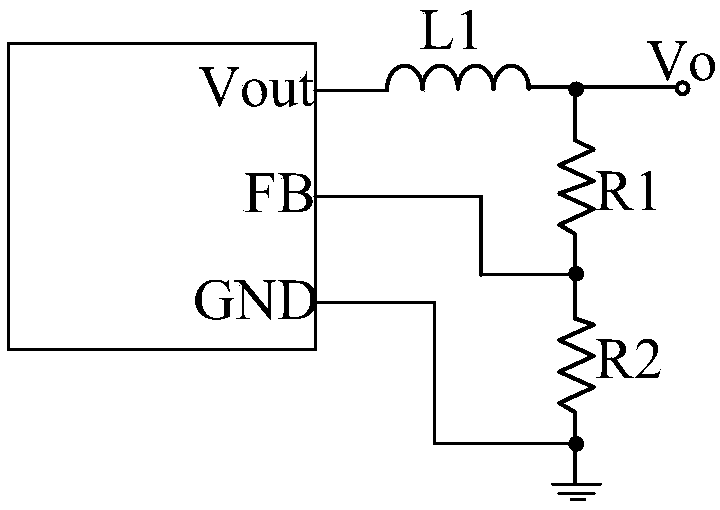

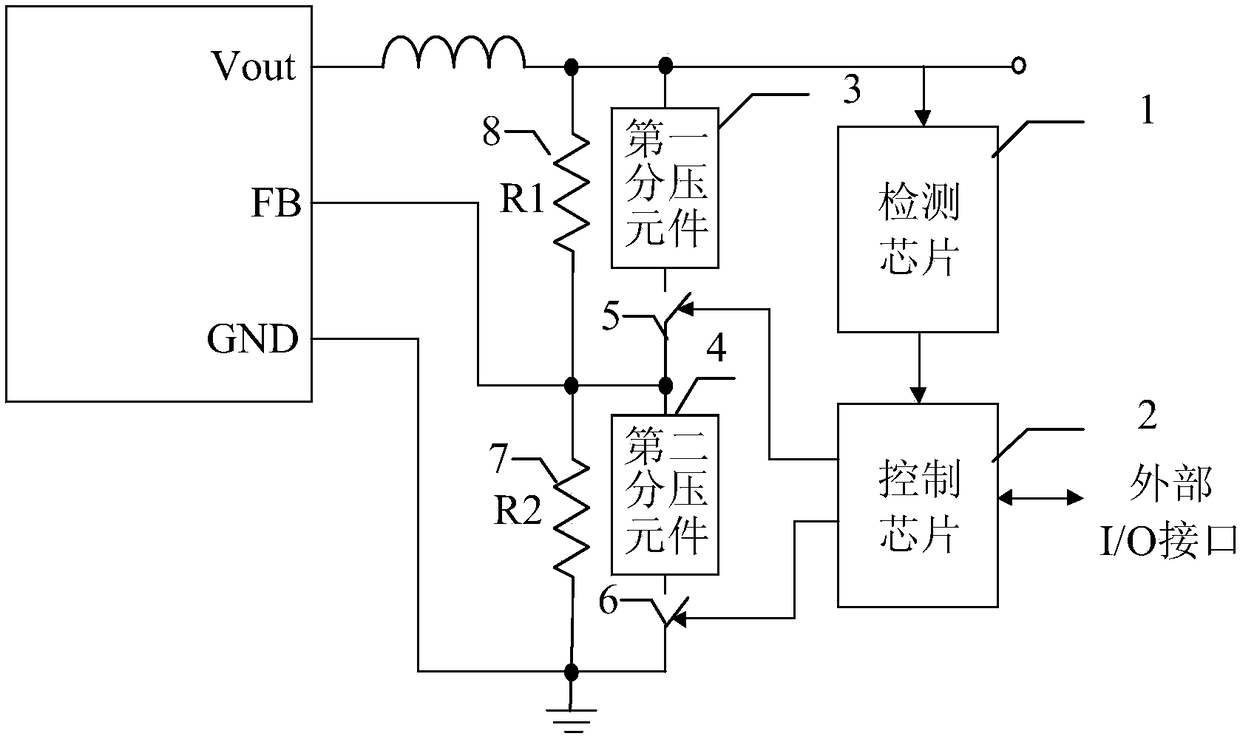

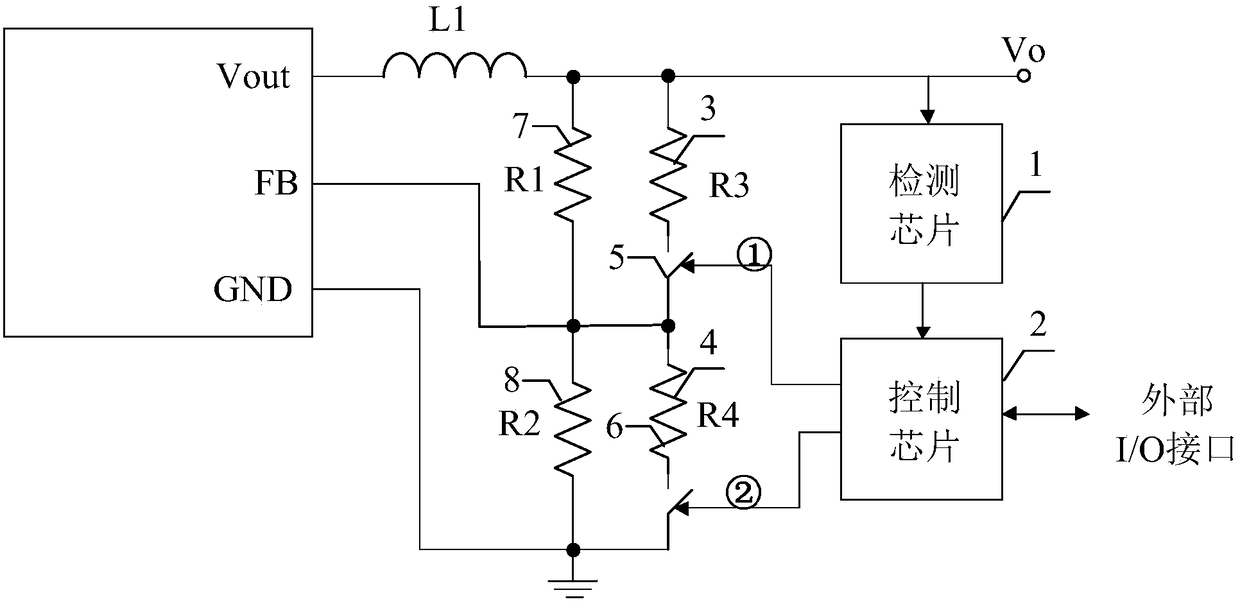

Single-board power supply voltage online adjusting circuit

InactiveCN108073213AReduce complexityRealize online adjustmentElectric variable regulationEngineeringElectrical and Electronics engineering

The invention provides a single-board power supply voltage online adjusting circuit. A first voltage division circuit is connected to a first bias resistor in parallel, a second voltage division circuit is connected to a second bias resistor in parallel, an initial output voltage of a single-board power supply is acquired through a detection chip, and finally a control chip controls the on-off state of a first switch on the first voltage division circuit and the on-off state of a second switch on the second voltage division circuit according to the initial output voltage and a preset voltage,so that the feedback value of a feedback pin of the single-board power supply changes, then the output voltage of the single-board power supply changes, and the output voltage of the single-board power supply is adjusted. In the adjusting process, the bias resistors do not need to be manually welded, and the on-off states of the first and second switches are automatically controlled through the control chip, so that the output voltage of the single-board power supply is changed changes and the complexity of adjustment of the output voltage of the single-board power supply is reduced.

Owner:CHENGDU HUAWEI TECH

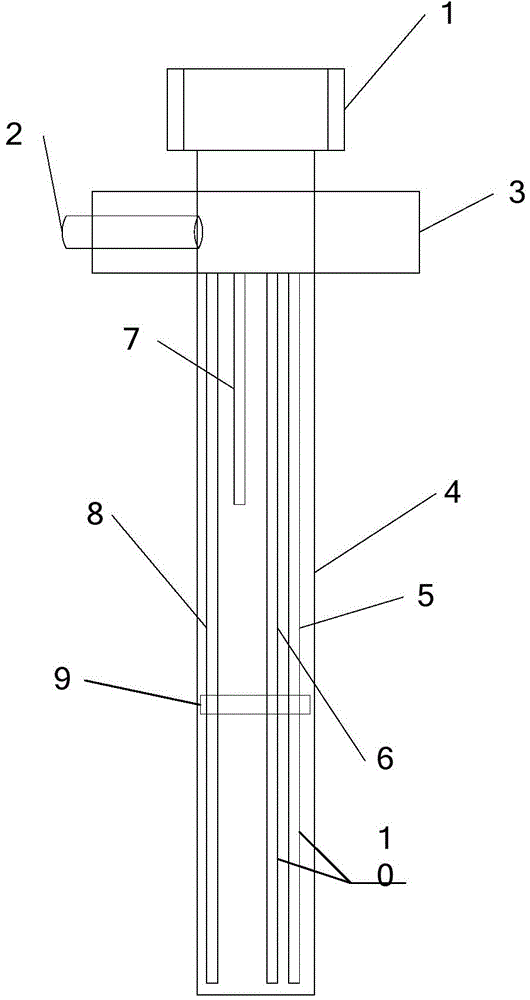

Spent fuel water tank liquid level and temperature measuring device

InactiveCN104575640AMeet monitoring requirementsAvoid surveillanceNuclear energy generationNuclear monitoringEngineeringLevel measurement

The invention belongs to the technical field of nuke industry measurement, and particularly relates to a spent fuel water tank liquid level and temperature measuring device. The device comprises a measuring barrel with an opening in the bottom, wherein a RTD continuous liquid level sensor, a differential thermocouple discrete liquid level sensor and a thermocouple temperature sensor, which are isolated with one another, are installed in the measuring barrel along the height direction; the liquid level measuring range of the RTD continuous liquid level sensor is from the top of a fuel grillage to the full water level of a water tank, and the thermocouple discrete liquid level sensor is arranged on a set standard height level of the water tank; the RTD continuous liquid level sensor, the differential thermocouple discrete liquid level sensor and the thermocouple temperature sensor are connected with respective transmitting processing units through respective cables. The continuous liquid level, the discrete point liquid level and the temperature in the water tank are measured by adopting the three sensor elements based on different measuring principles and independent from one another, and the problem for simultaneously monitoring the continuous liquid level, the discrete point liquid level and the temperature in the water tank, caused by the failure of a common mode, can be avoided.

Owner:CHINA NUCLEAR POWER ENG CO LTD

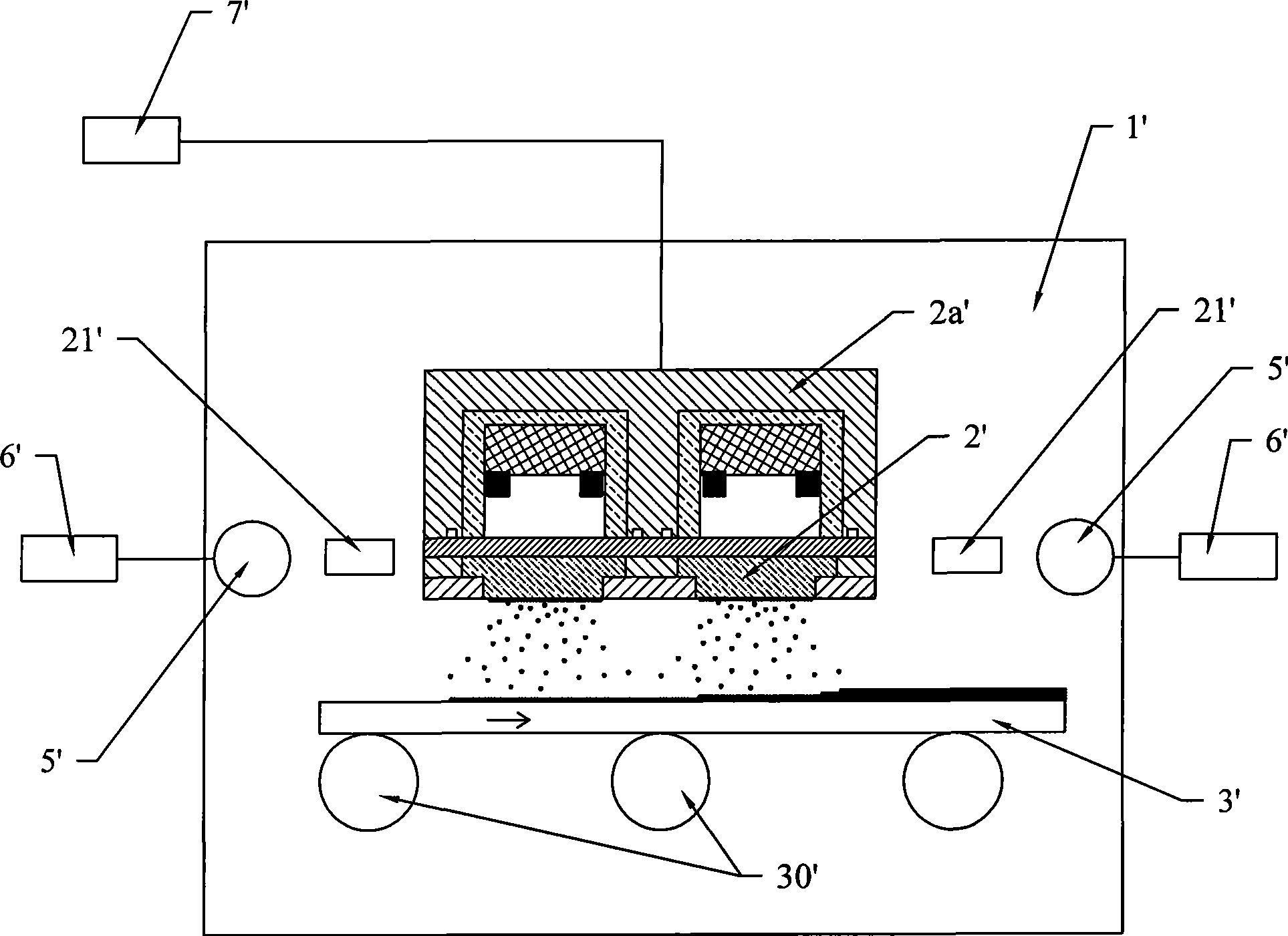

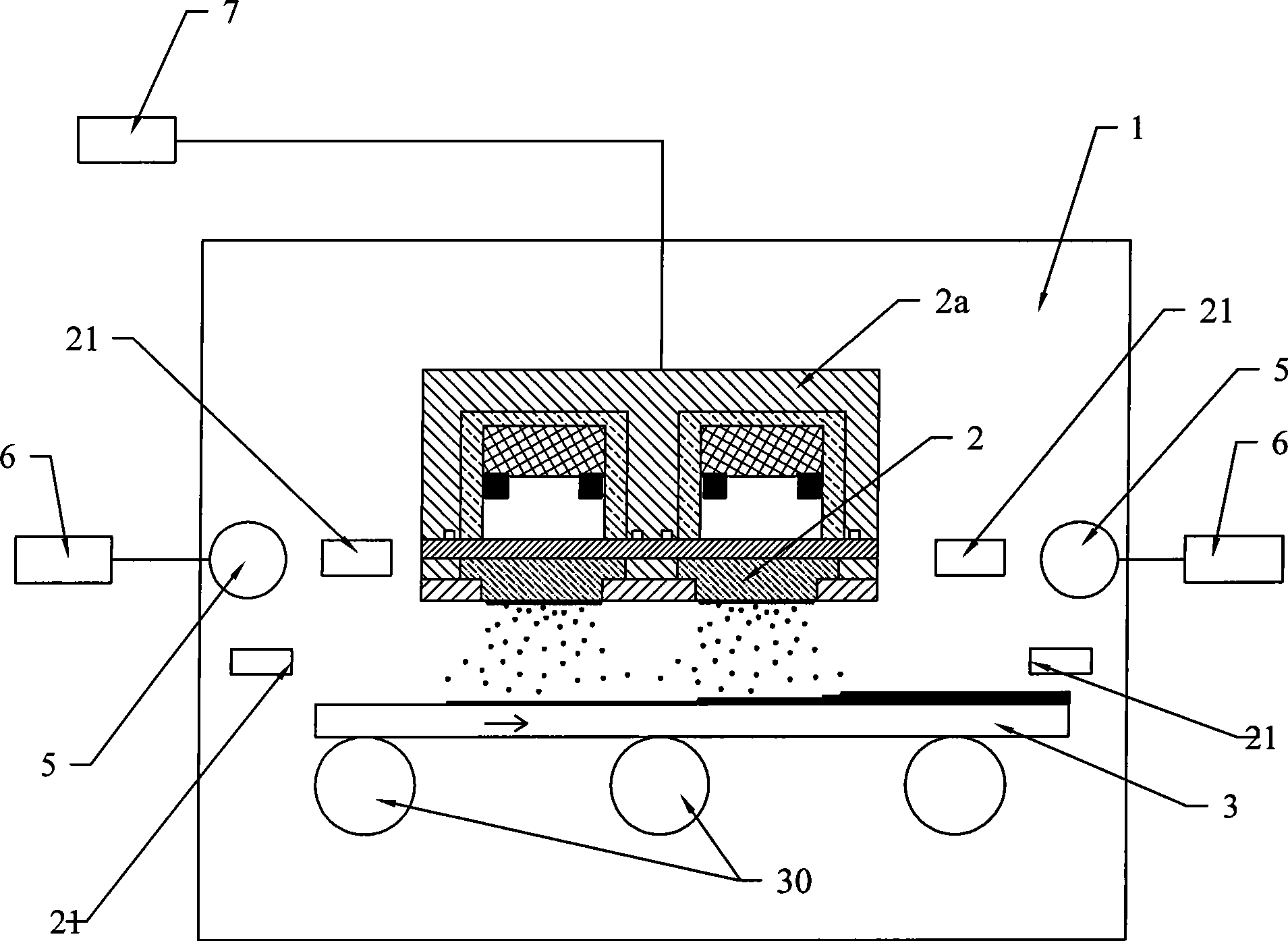

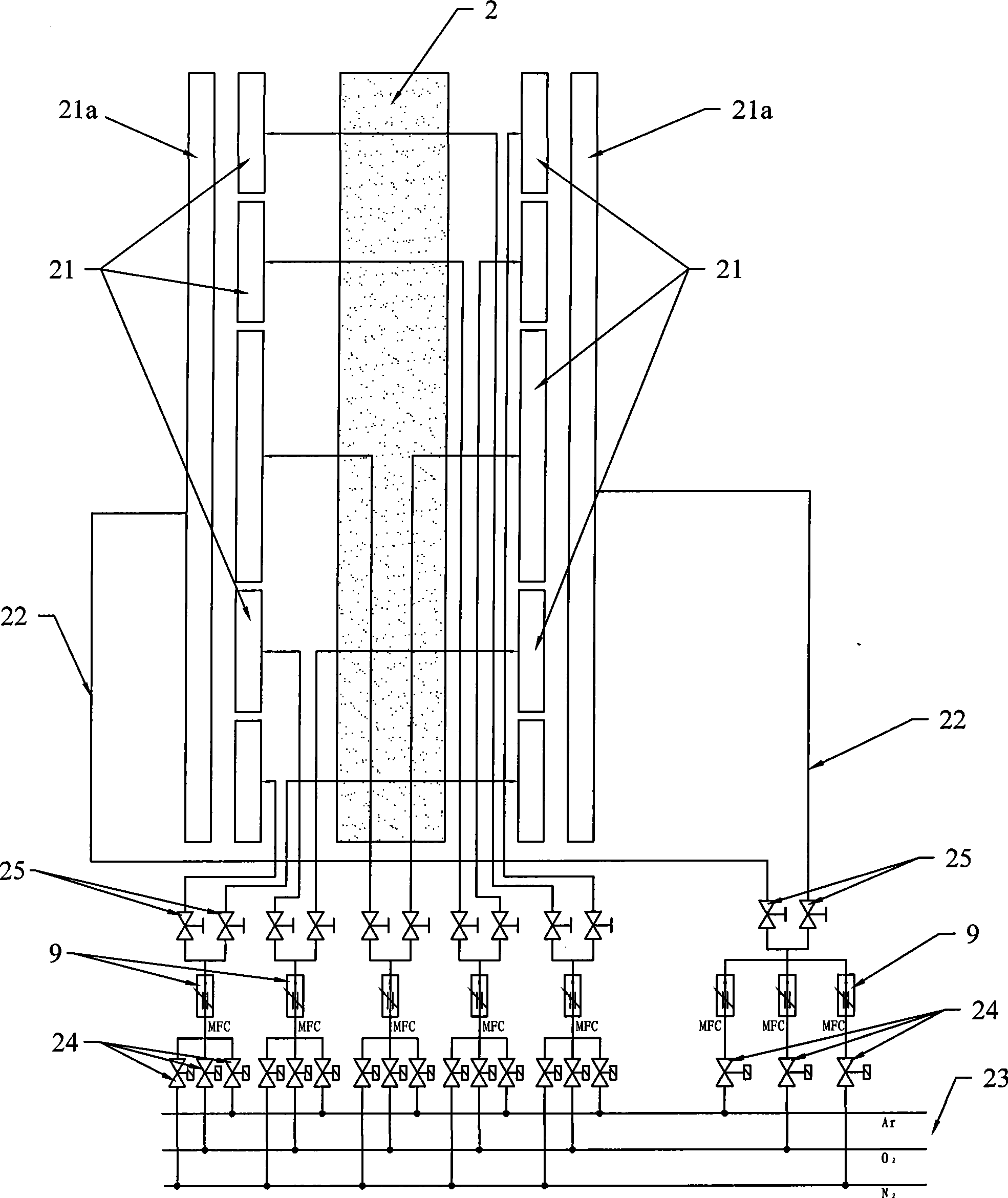

Sputtering film-plating apparatus

ActiveCN101497990AAchieve uniformityAchieve uniformity with online adjustmentsVacuum evaporation coatingSputtering coatingSputteringProcess engineering

The invention relates to a sputtering coating device which comprises a vacuum chamber, an anode target, a cathode target, a coating product and a gas supply system, wherein the anode target and the cathode target are arranged in the vacuum chamber, the gas supply system comprises gas inlets and gas supply channels for communicating an external gas source and the gas inlets, wherein the gas inlets are arranged into a plurality of sections on the length direction along the cathode target, and a gas-flow controller used for independently controlling the sorts and the flow rates of process gases of each gas inlet is arranged on the gas supply channel communicated with each gas inlet. As the gas inlets in the gas supply system are arranged into a plurality of sections which are distributed on the length direction along the cathode target, and the gas-flow controller is arranged on the gas supply channel corresponding to each gas inlet, the sorts and the flow rates of gases in all gas supply channels can be controlled, thereby further locally and dynamically adjusting the process gases near the cathode target in the vacuum chamber. During the production process of a coating, the on-line adjustment of the evenness of the thickness of the coating can be achieved by adjusting the distribution states of the process gases by adjusting all gas-flow controllers in time.

Owner:CSG HOLDING

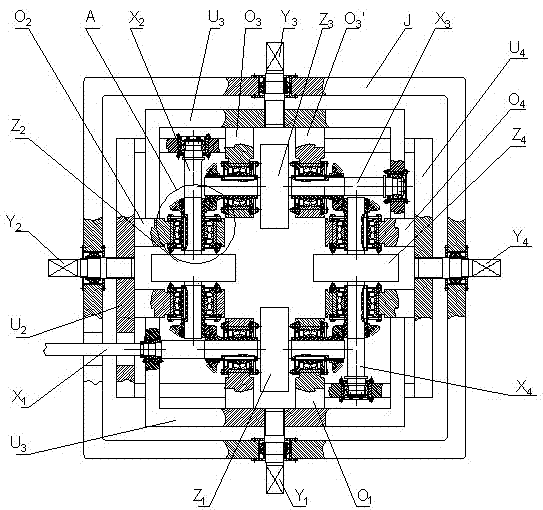

Roller radial adjusting mechanism of cross beam type four-roller profile rolling mill

InactiveCN102764769AAchieve radial adjustmentEasy to adjustMetal rolling stand detailsMetal rolling arrangementsScrew threadBevel gear

The invention discloses a roller radial adjusting mechanism of a cross beam type four-roller profile rolling mill, and belongs to the technical field of four-roller profile rolling mills. The mechanism comprises a frame, housing screws, a bevel gear transmission mechanism, rollers and bearing seats. The mechanism is characterized in that the housing screws are respectively arranged in the middle of four rims of the frame and connected with cross beams through threads; the four cross beams are 'U'-shaped, a transverse beam is positioned on the upper part, left and right side legs are positioned on two sides, a threaded hole is formed in the middle of the transverse beam, a dovetail block is made at the lower end of each of the two side legs, the lower part of one side leg is provided with a core shaft hole, and only the left and right side legs of the narrow leg type cross beams are narrow, so that the narrow leg type cross beams can be inserted into holes in the wide leg type cross beams; the upper and lower side legs of the narrow leg type cross beams are inserted into the holes in the two side legs of the wide leg type cross beams; and four rollers are respectively arranged on four core shafts, one end of each core shaft is supported in the core shaft hole of each side leg, a transmission bevel gear is arranged at the other end of each core shaft, and the bearing seats for installing the core shafts are matched with dovetail grooves in the cross beams through the dovetail blocks at the lower ends. The mechanism can realize radial adjustment of the rollers.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

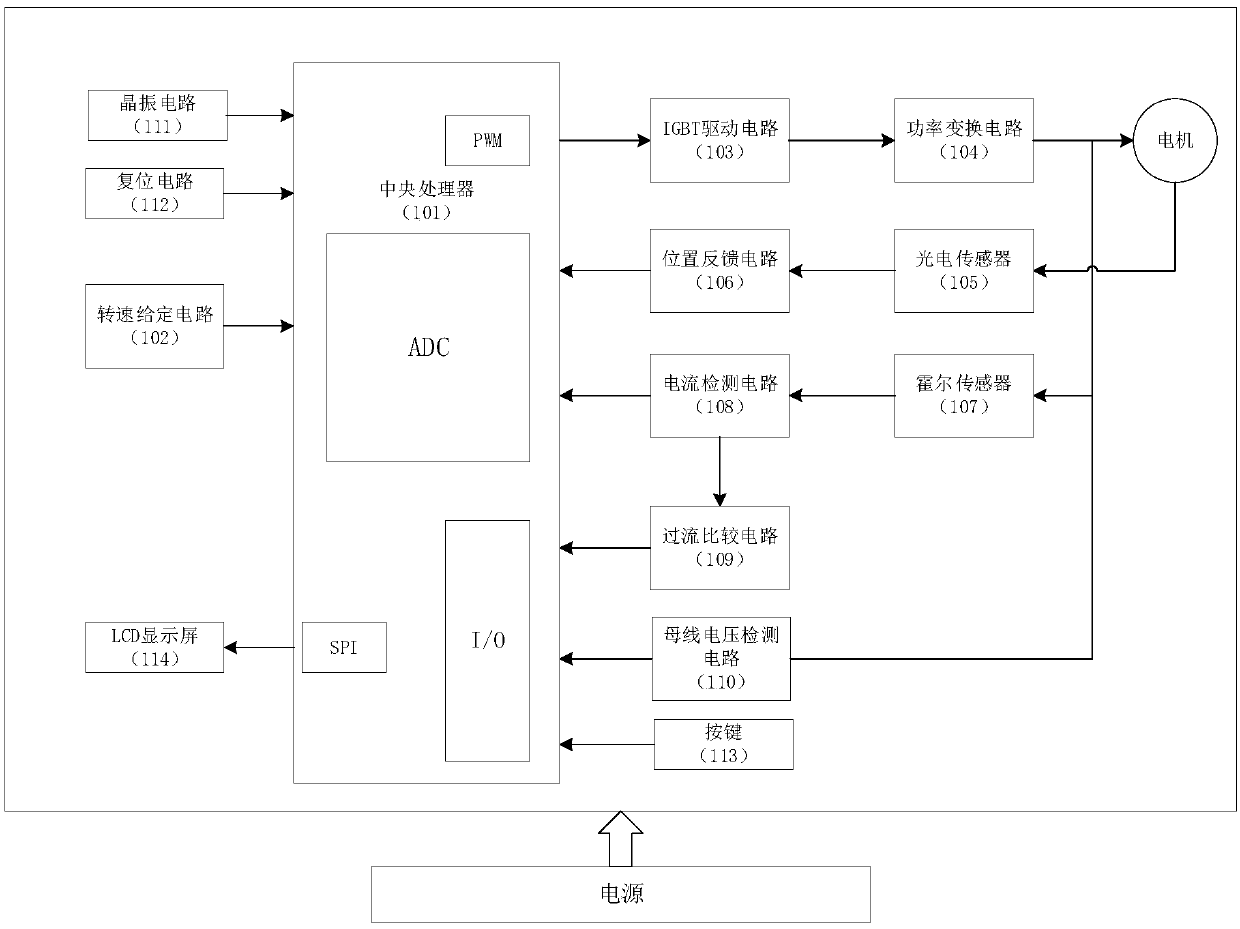

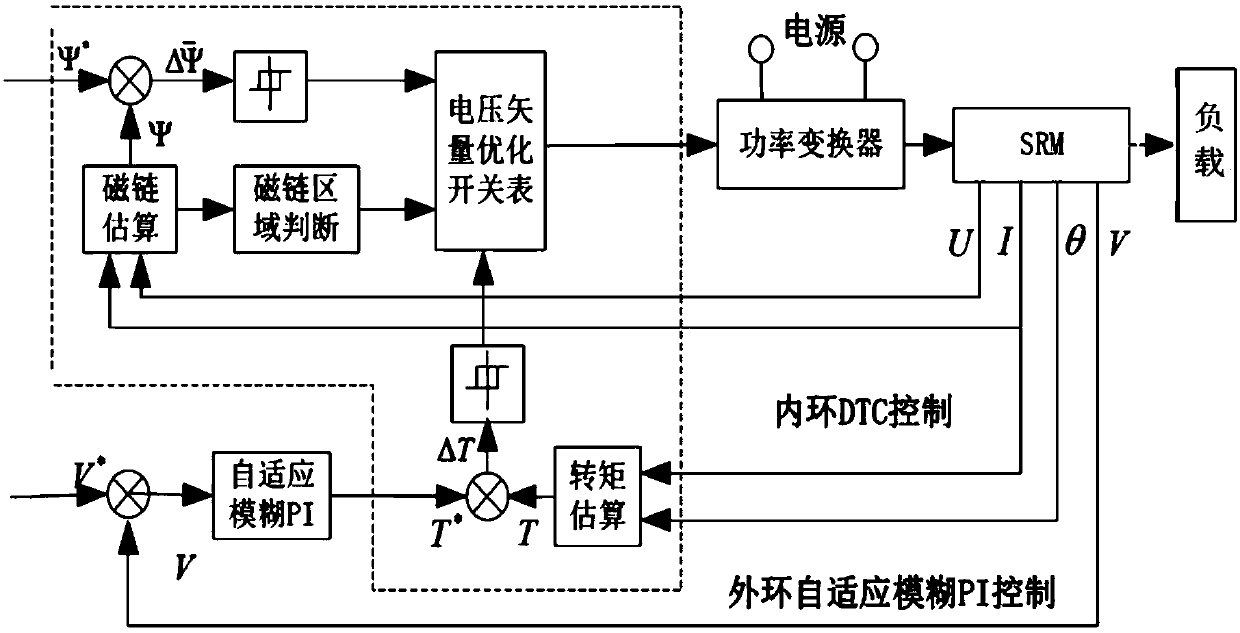

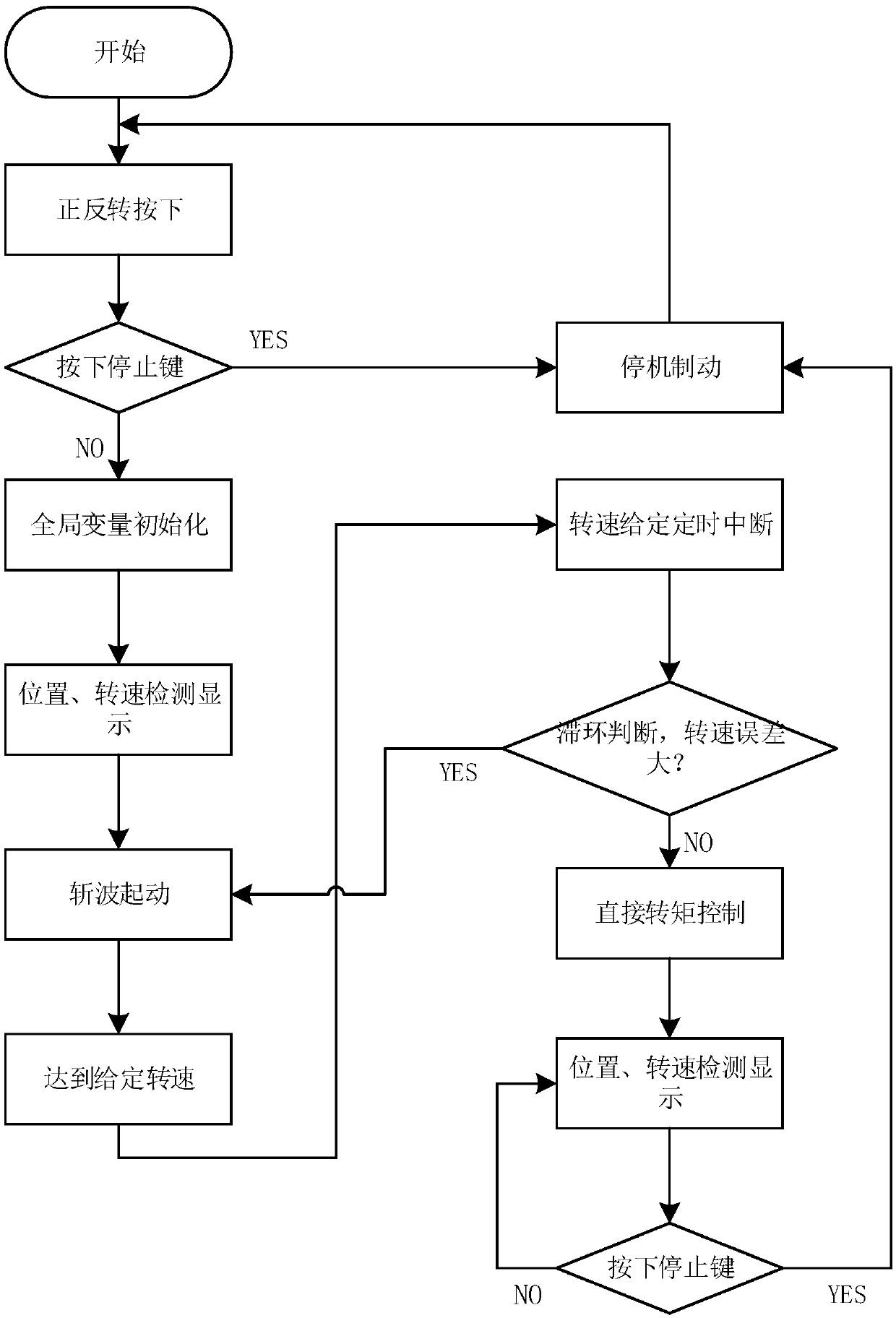

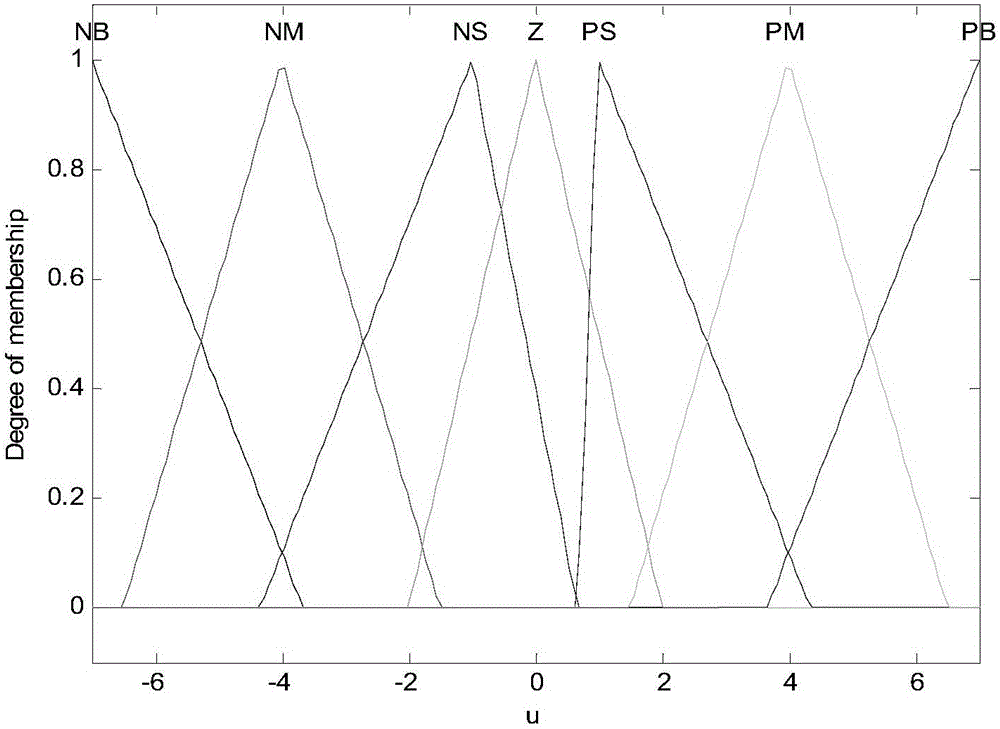

A switched reluctance motor speed regulating device and method based on compound fuzzy control

PendingCN109067278ASolve the problem of large torque rippleReduce torque rippleElectronic commutation motor controlAC motor controlClosed loopFeedback circuits

The invention belongs to the field of motor control, in particular to a switched reluctance motor speed regulating device and method based on compound fuzzy control. The device is composed of a CPU, aspeed setting circuit, an IGBT driving circuit, a power conversion circuit, a photoelectric sensor, a position feedback circuit, a Hall sensor, a current detecting circuit, an overcurrent comparing circuit, a bus voltage detecting circuit, a crystal oscillator circuit, a reset circuit, a key and an LCD display screen. By designing appropriate control strategies, the problems of noise and torque ripple of SRM and precise control in complex environment can be solved, and the application range of SRM can be expanded. The invention adopts direct torque control, realizes the closed loop control ofstator flux linkage and motor torque according to the reference flux linkage, the difference between torque and actual output flux linkage and torque, solves the problem of large motor torque ripple,can effectively reduce SRM torque ripple, and improves the robustness of SRD system.

Owner:ANHUI ELECTRICAL ENG PROFESSIONAL PROFESSIONAL TECHN COLLEGE +5

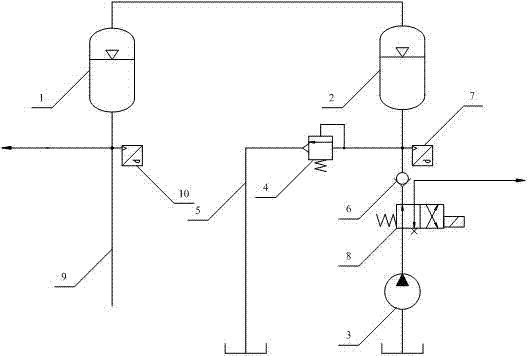

Energy accumulator system and water pump system

The invention discloses an energy accumulator system and a water pump system. The energy accumulator system comprises a working energy accumulator (1), a pressure-adjusting energy accumulator (2) and a hydraulic adjustment device, wherein a working port of the working energy accumulator (1) is connected with a working system with pulse flow; the pressure-adjusting energy accumulator (2) is communicated with an inflation port of the working energy accumulator (1) and used for adjusting the pre-inflation pressure of the working energy accumulator (1); and the hydraulic adjustment device is communicated with a liquid filling cavity of the pressure-adjusting energy accumulator (2) and used for adjusting the pressure of the pressure-adjusting energy accumulator (2) so as to adjust the pre-inflation pressure of the working energy accumulator (1) to be matched with the working pressure of the working system. Through the invention, online adjustment of the working pressure of the energy accumulator can be realized.

Owner:BEIJING SANY HEAVY MASCH CO LTD

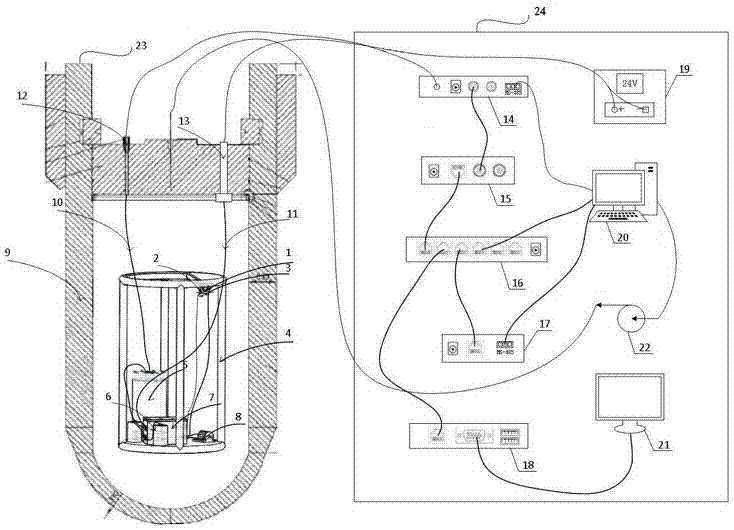

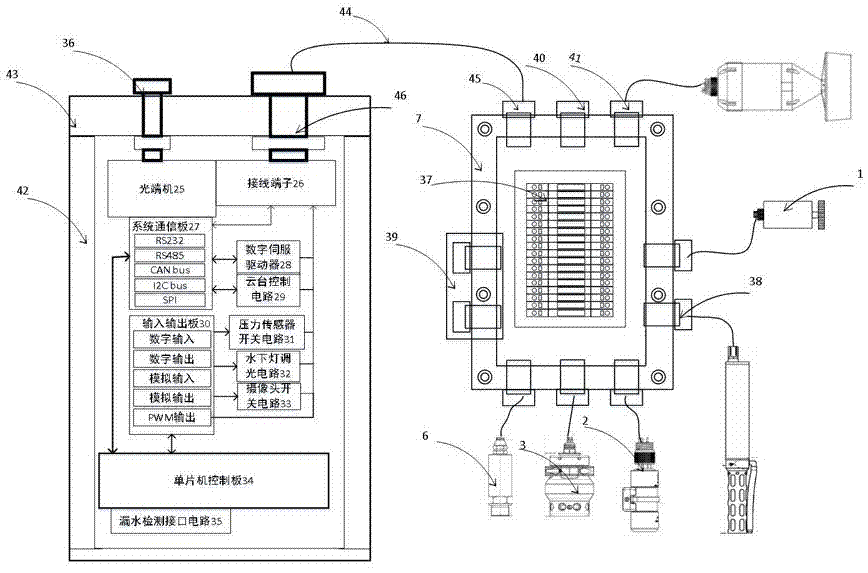

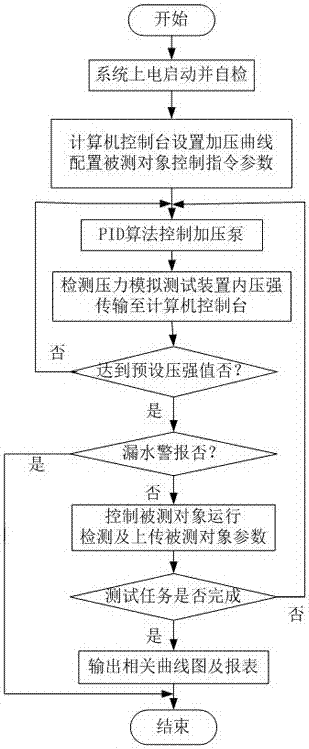

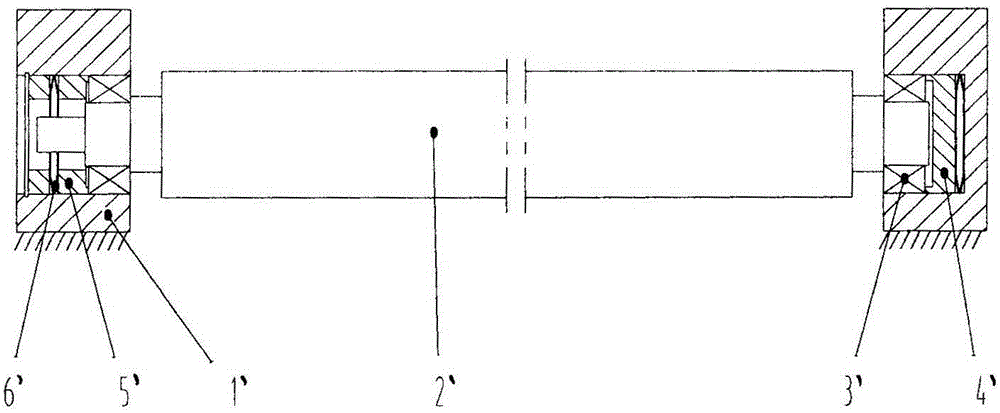

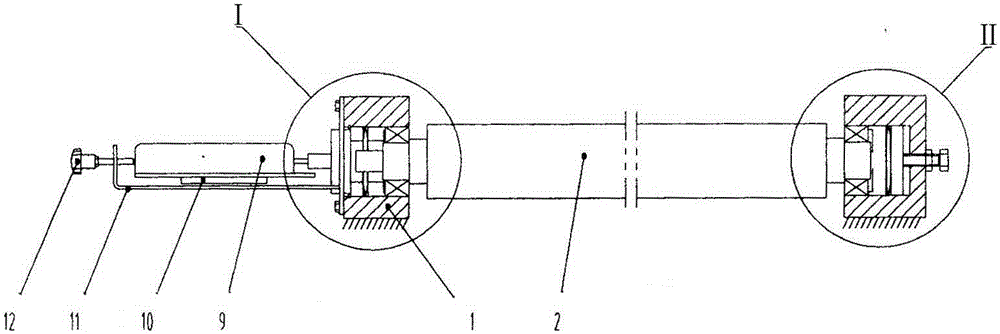

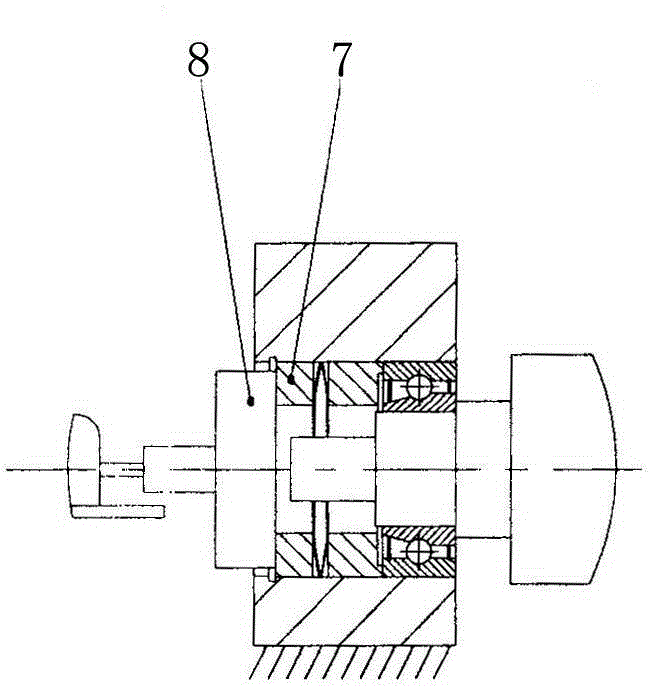

Real-time monitoring system and monitoring method for full deep sea pressure simulation test device

ActiveCN107294605ARealize real-time monitoringRealize visualizationTelevision system detailsNuclear energy generationVideo monitoringData information

The invention discloses a real-time monitoring system and monitoring method for a full deep sea pressure simulation test device. The system comprises a pressure simulation device and a monitoring system; the pressure simulation device comprises a control unit electronic cabin, an oil charging junction box, an underwater lamp, an underwater camera, a holder, a pressure sensor and a tested object which are arranged on a support; the support is arranged inside the pressure simulation device, the postures of the underwater lamp and the underwater camera can be adjusted via the holder, and relevant test data information acquired by the underwater camera can be transmitted to the monitoring system via a fiber. The pressure simulation test device is optimized and upgraded on function without being damaged, and the test process of 'blind pressure of a black box' is changed into 'visual pressure of a white box', so that the system has the functions of monitoring the pressure inside the pressure simulation test device, monitoring videos, monitoring and acquiring the state of the tested object and relevant parameters and the like.

Owner:SHANGHAI OCEAN UNIV

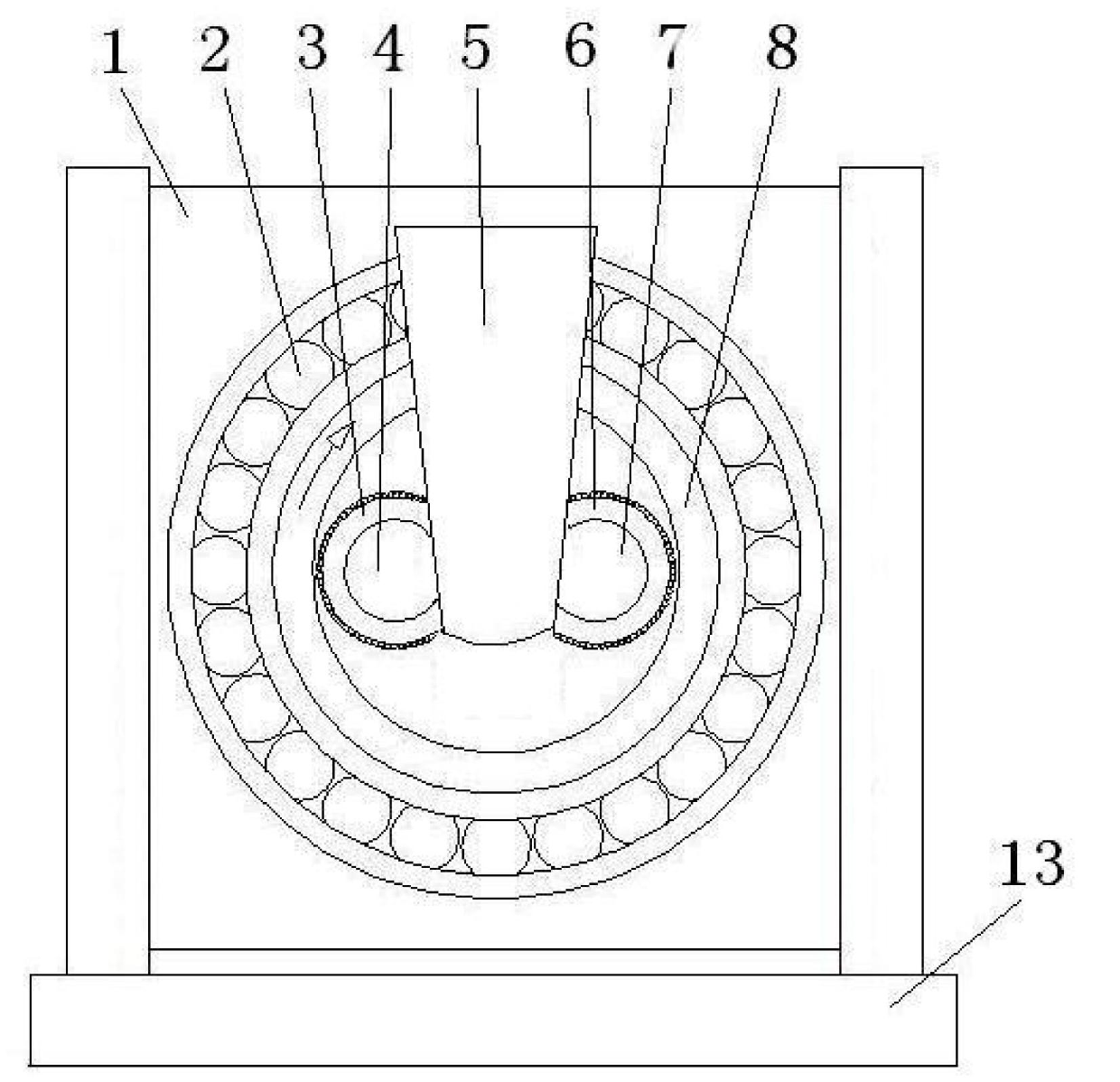

Detection apparatus of pre-tightening force of angular contact bearing and detection method thereof

InactiveCN105181211AExtended service lifeLow processing and manufacturing costsMeasurement of torque/twisting force while tighteningEngineeringPressure range

The invention discloses a detection apparatus of a pre-tightening force of an angular contact bearing and a detection method thereof. According to the apparatus, an axial dimension is adjusted to cooperate with a special-purpose measuring gauge for localization; a precise measuring tool is used for reading a pre-tightening spring to obtain a pressure value; and the compression value of the spring is adjusted to enable the pre-tightening force to reach a pressure range formulated by a bearing. During the assembling process, with the apparatus, the processing manufacturing cost and assembling adjusting cost of the equipment can be substantially reduced and quantitative detection and on-line adjustment of the pre-tightening force of the angular contact bearing can be realized, thereby substantially improving consistency and reliability of the equipment assembling and prolonging the service life of the bearing. The detection apparatus with low cost can be operated simply and conveniently and is easy to realize.

Owner:CHTC HEAVY IND +1

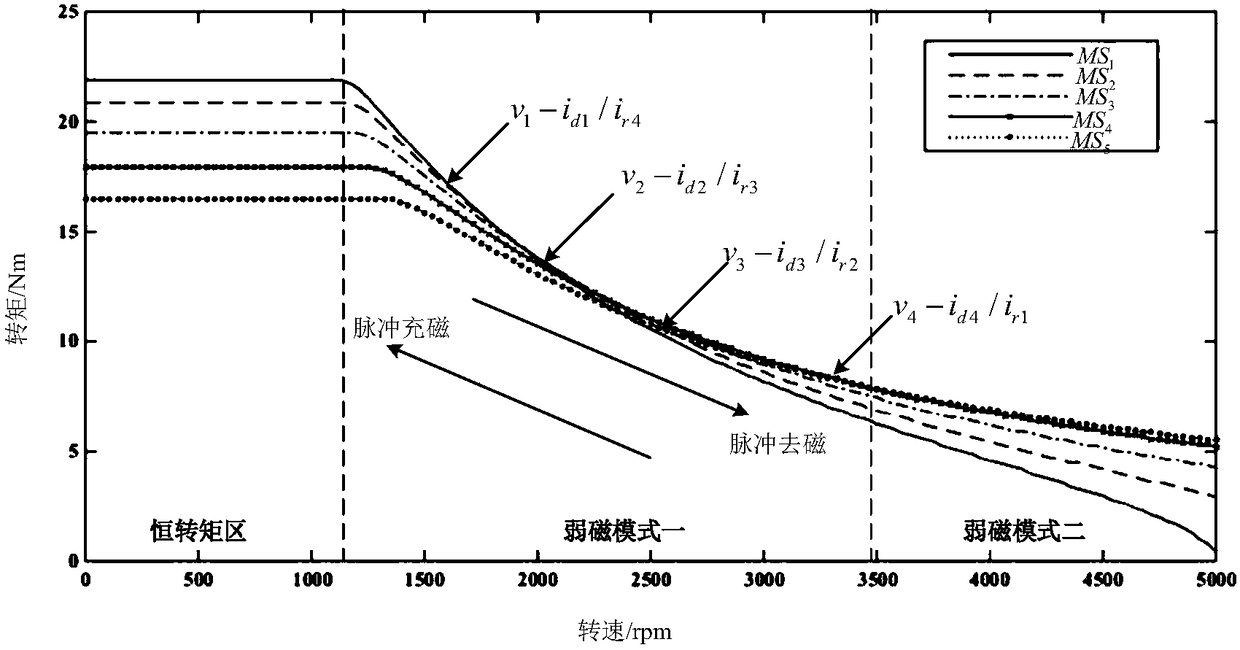

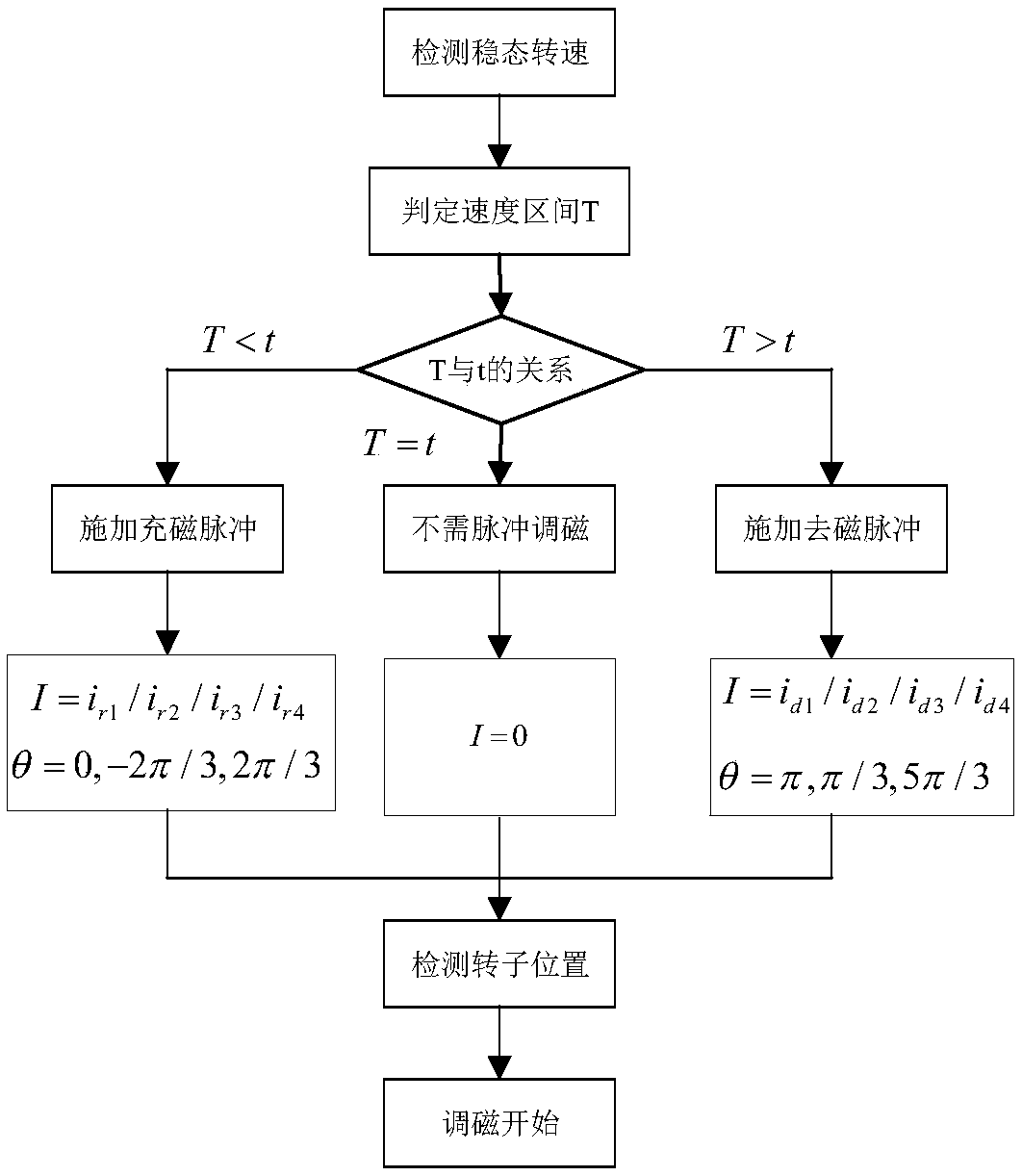

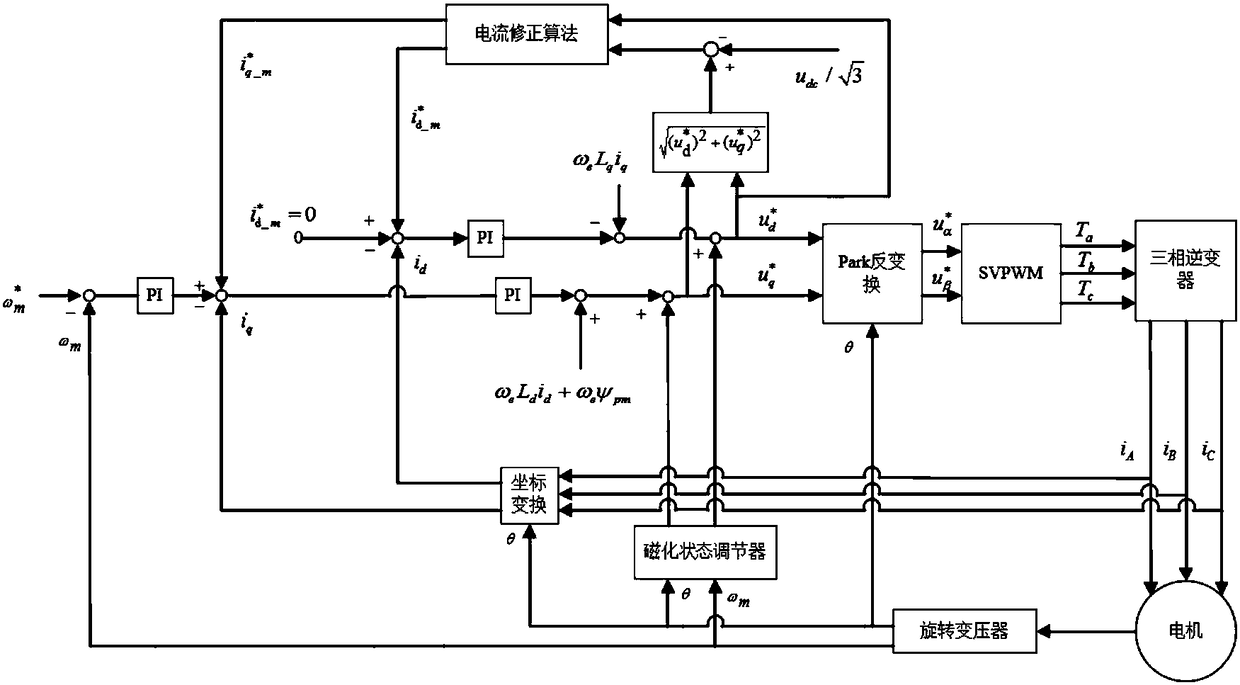

Segmented magnetic control method of AC magnetic control memory motor

ActiveCN108288933AWidened power speed rangeGood weak magnetic performanceAC motor controlElectric motor controlControl systemElectric machine

The invention discloses a segmented magnetic control method of an AC magnetic control memory motor. The segmented magnetic control method comprises the following steps of adding a magnetic control pulse module to a control system so as to achieve on-line regulation of motor flux linkage; selecting n target magnetic states during the running process of the motor, determining intersection points ofa corresponding T-N curve and a motor rotational speed corresponding to each intersection point; and determining the lowest magnetic level during the magnetic control process of the motor according toa relation between Psi<pm> / Ld and i<smax>, and only performing traditional armature current weak magnetism, wherein a permanent-magnet field is not weakened by magnetic control pulse any longer. In order to achieve optimal magnetic control effect, the rotor position at magnetic control initial moment and magnetic control pulse phase are reasonably allocated. Compared with a traditional weak magnetism expansion method, the segmented magnetic control method has the advantages that the direct-axis current component during the running process of the motor can be greatly reduced, the stator copperconsumption of the motor at a high-speed running zone is reduced, frequent on-line magnetic control of the permanent magnet is prevented, and the running efficiency of the motor and the practicability of the control system are improved.

Owner:SOUTHEAST UNIV

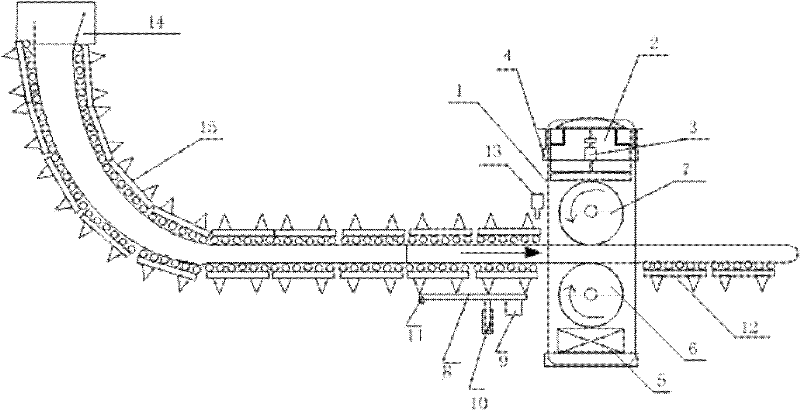

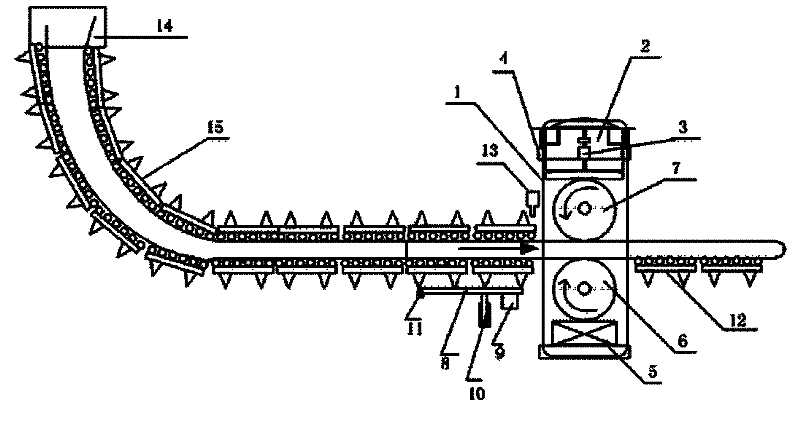

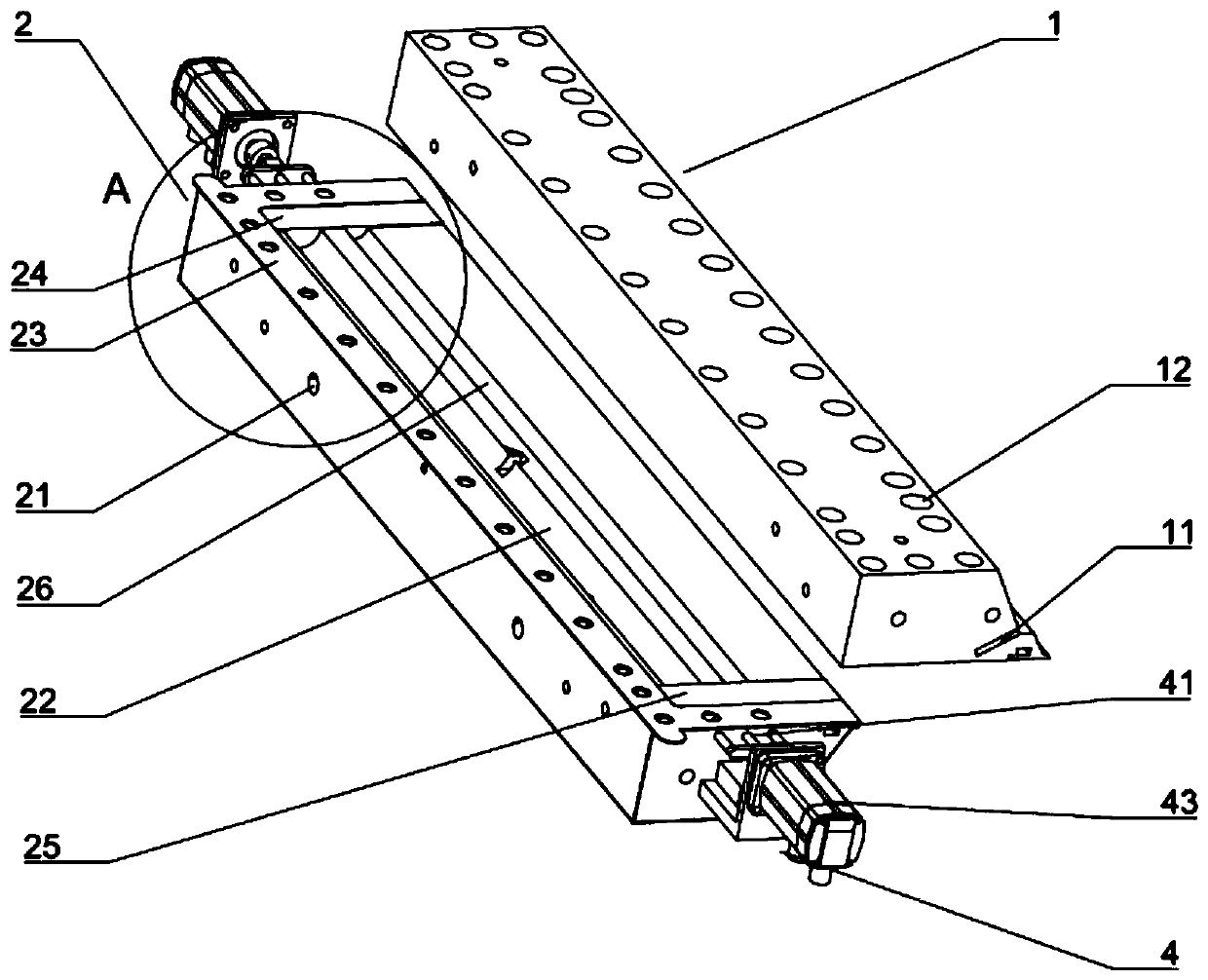

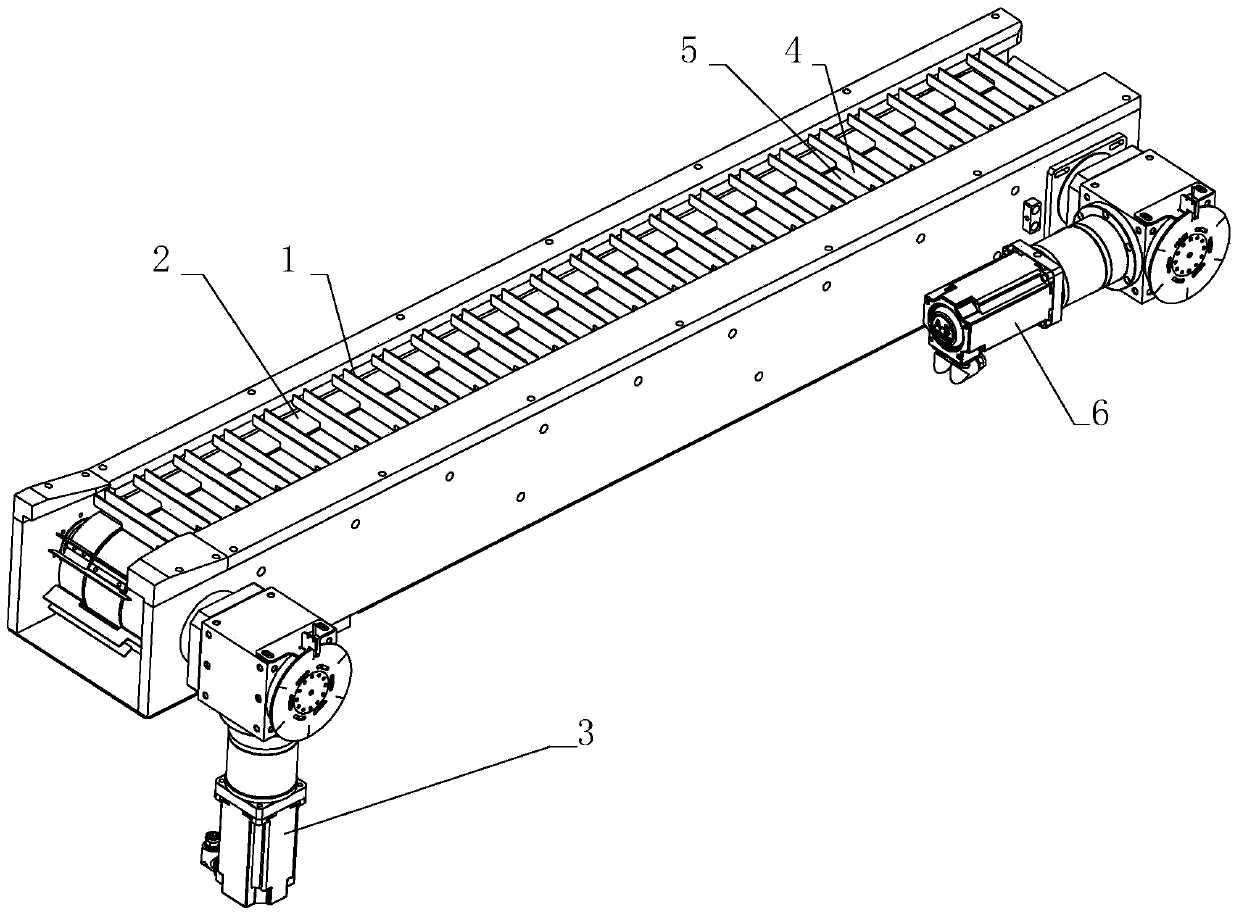

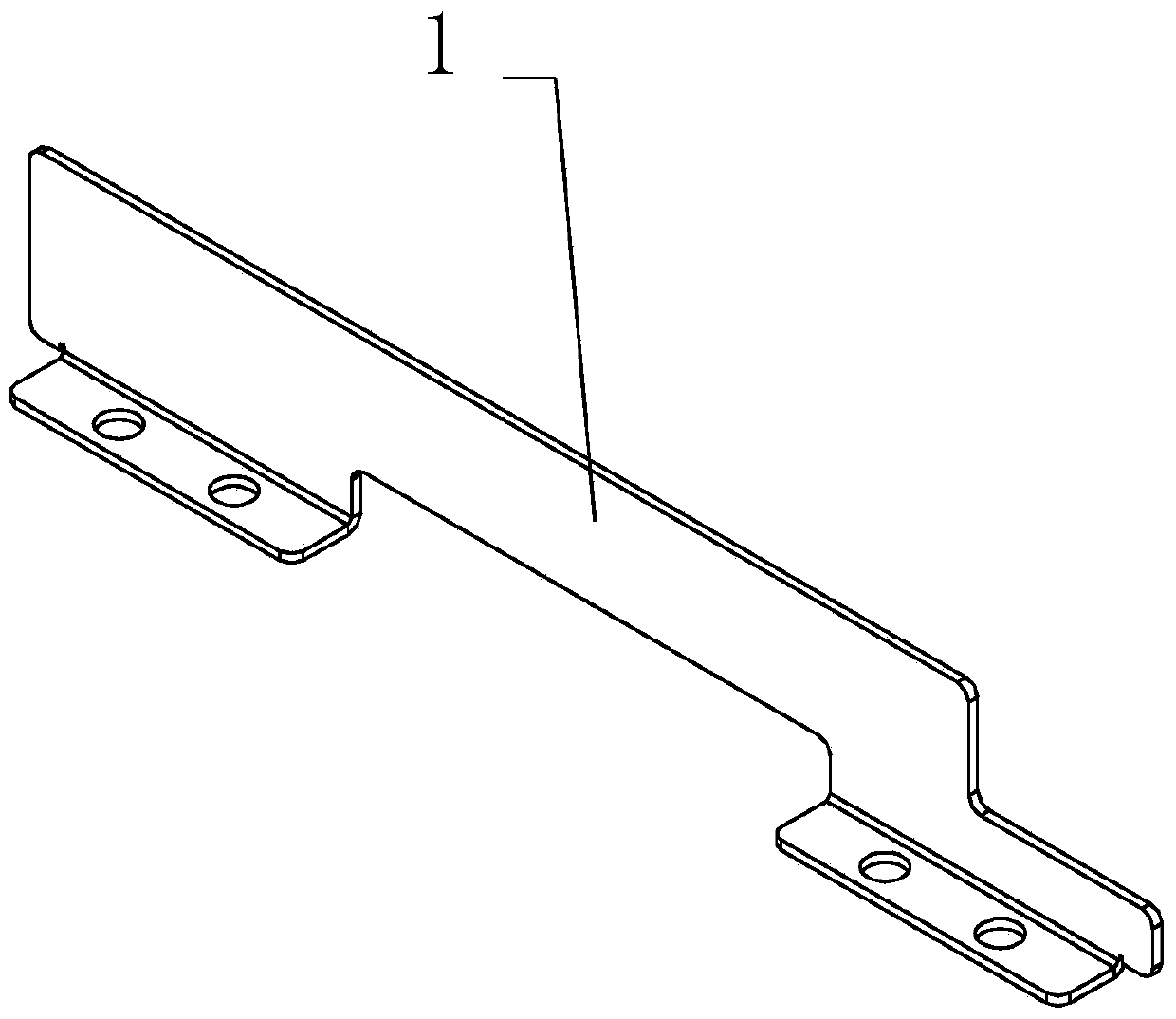

Conveying device

ActiveCN103466260ARealize online adjustmentAvoid disassembling equipmentConveyorsPackaging under special atmospheric conditionsManufacturing line

The invention discloses a conveying device. The conveying device comprises a first conveying mechanism and a second conveying mechanism. The first conveying mechanism circularly moves along a first working route, and the second conveying mechanism circularly moves along a second working route. The first working route and the second working route are at least partially overlapped; the first conveying mechanism is provided with first baffles which are distributed at equal intervals, the second conveying mechanism is provided with second baffles which are distributed at equal intervals, and the distance between the neighboring first baffles is equal to the distance between the neighboring second baffles; the first baffles and the second baffles are arranged at intervals at the overlapping position of the first working route and the second working route. The storing spaces on the conveying device are obtained through the baffles on the two synchronous belts which work independently, so that the widths of the storage spaces can be adjusted by adjusting the distances among the baffles, and the storage space width adjusting operation can be performed on-line when the conveying device is mounted on a product on a production line.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

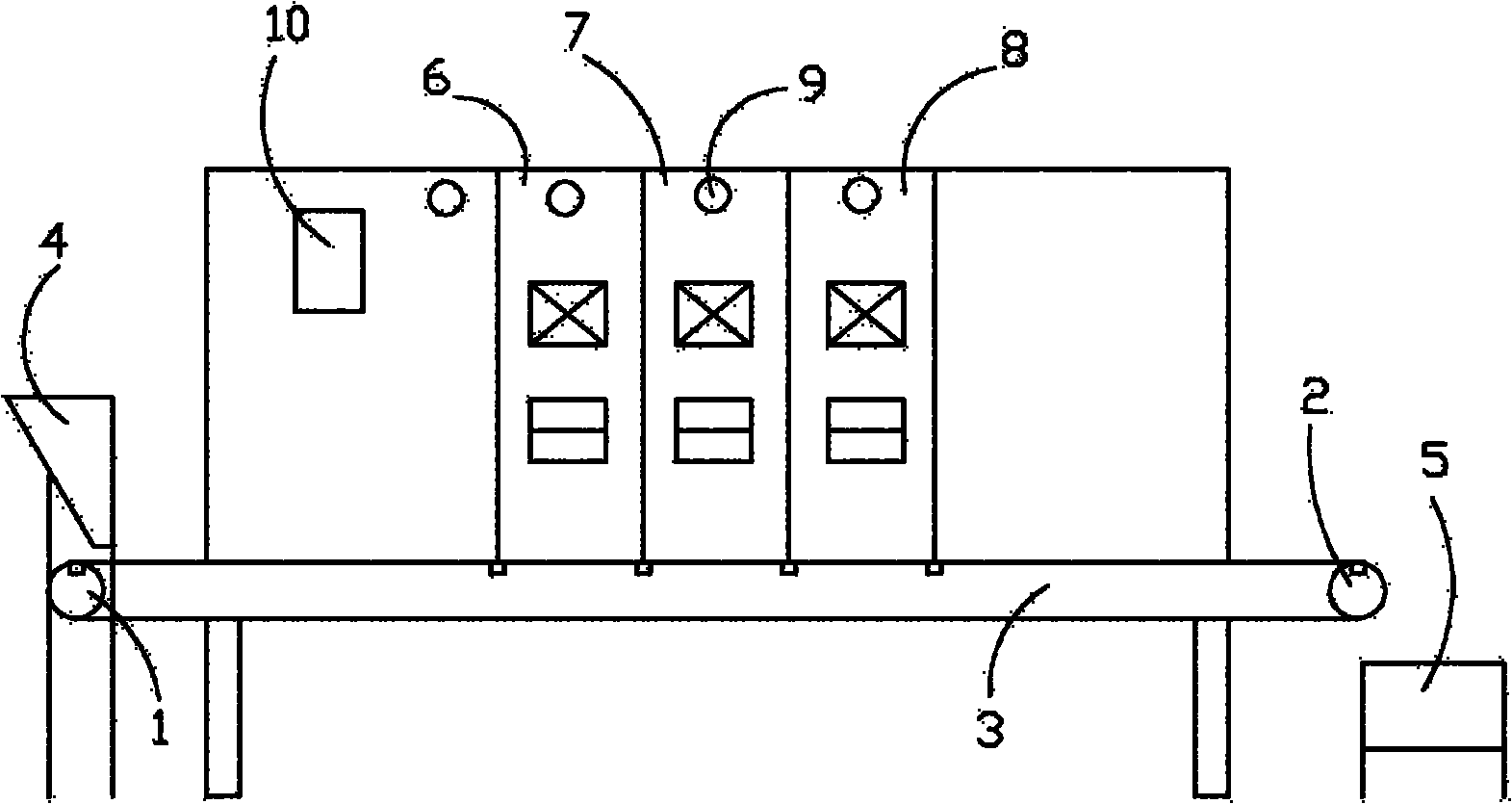

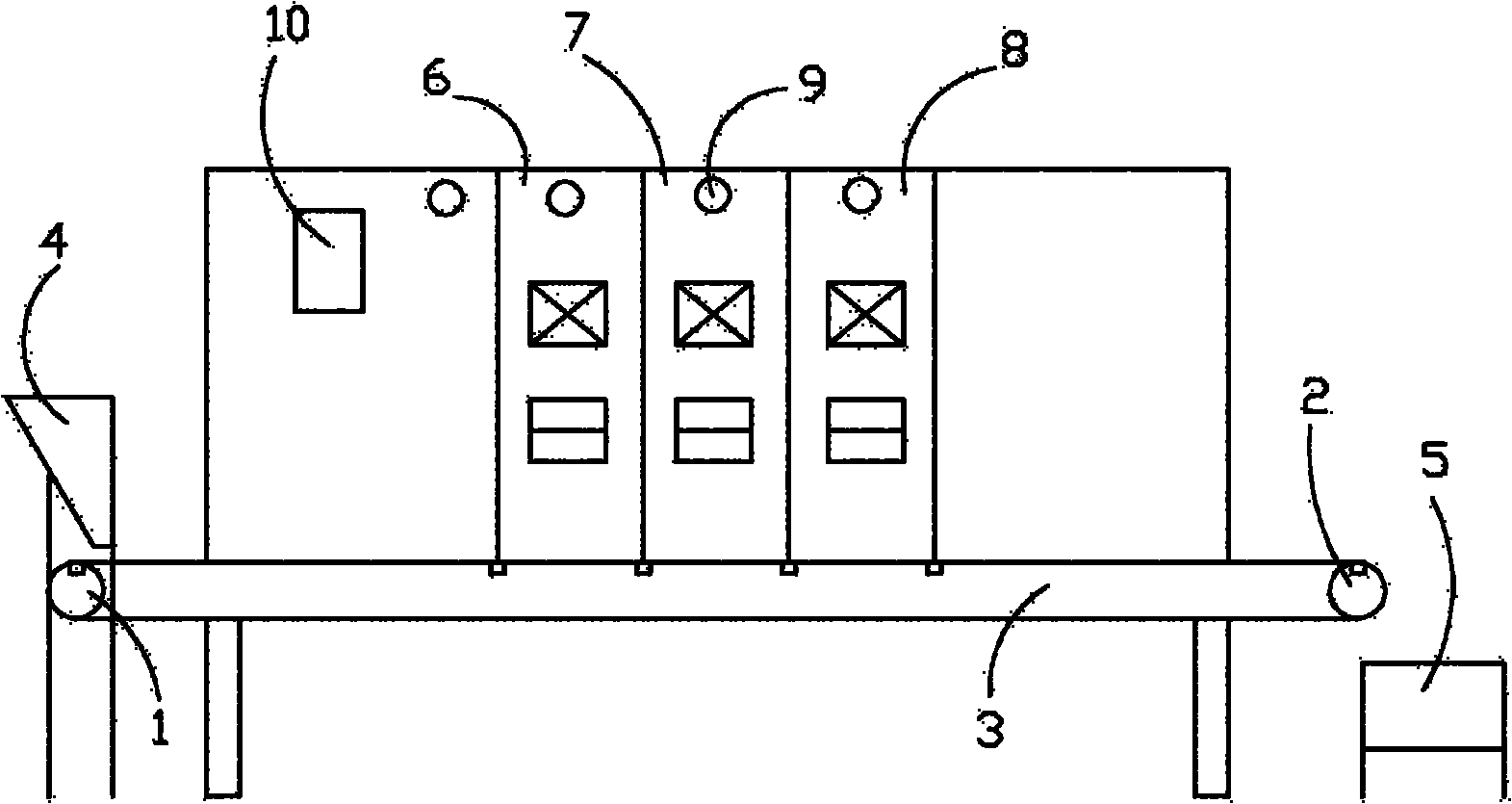

Microwave sterilizing device applied to food process and production line

InactiveCN102106586AEasy to adjustLarge adjustment rangeFood processingFood preservationProduction lineMicrowave

The invention discloses a microwave sterilizing device applied to a food process and production line. The microwave sterilizing device is characterized in that a plurality of microwave units are arranged on the production line along a material transfer direction in series, and the power and time of each microwave can be controlled independently. The microwave sterilizing device facilitates the adjustment of different requirements of different types and batches of products for the microwave sterilizing power and time, has large adjustable range and obvious energy-saving effect, and can meet different production requirements.

Owner:ANHUI YANZHIFANG FOOD

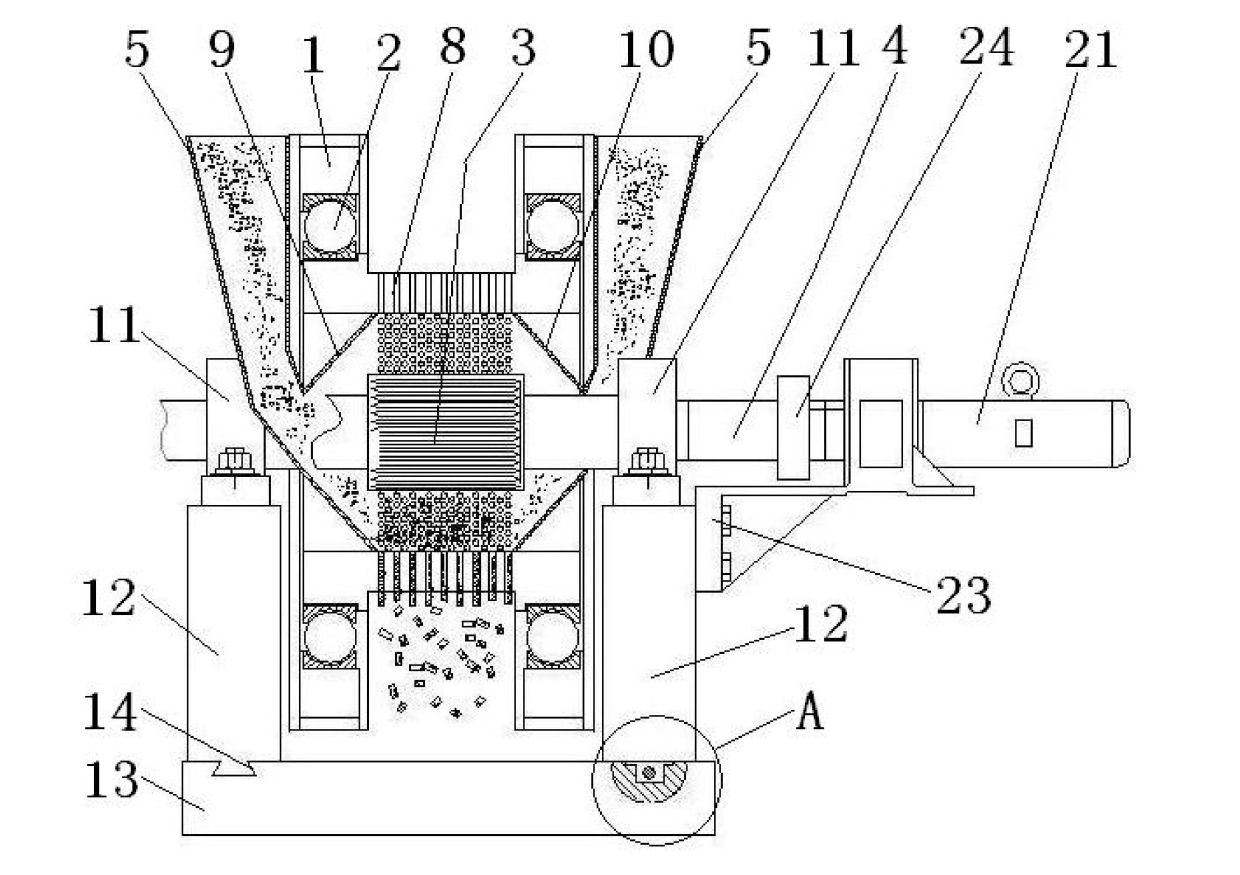

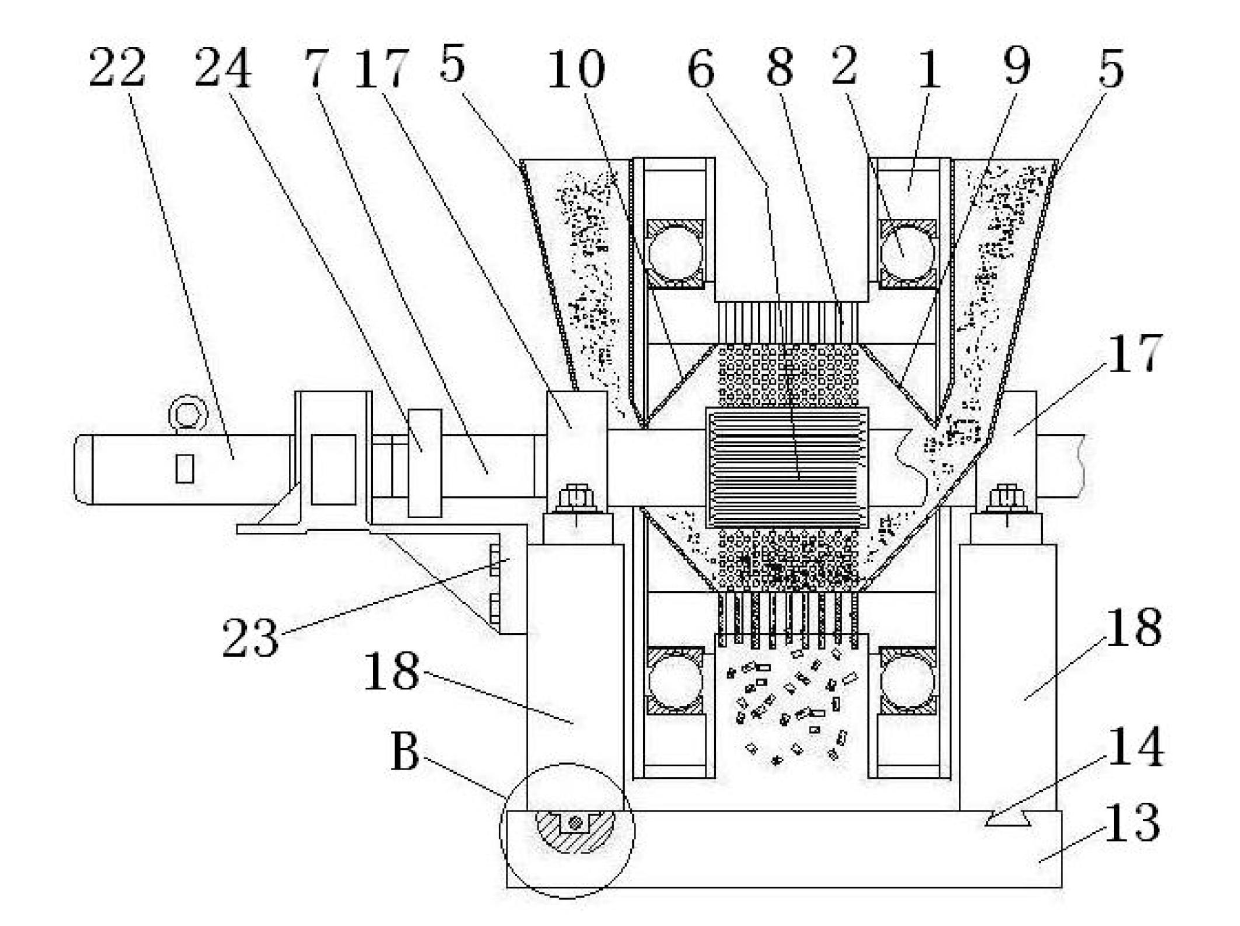

Moving roller-type circular mould granulator

InactiveCN102631866ASmall transmission torqueAvoid cross contaminationGranulation by pressingDrive motorEngineering

The invention belongs to the technical field of feed forming and processing, and relates to a moving roller-type circular mould granulator. The moving roller-type circular mould granulator mainly comprises a circular mould and a pair of parallel left compression roller and right compression roller horizontally arranged in the circular mould, wherein the left compression roller and the right compression roller are coaxially and fixedly connected with the middle parts of a left compression roller spindle and a right compression roller spindle; the left compression roller spindle and the right compression roller spindle are rotationally connected with a left compression roller support saddle and a right compression roller support saddle through bearings respectively; the compression roller spindle and the right compression roller spindle are independently driven by a left compression roller spindle drive motor and a right compression roller spindle drive motor respectively, and independently adjust a gap between the left compression roller and the right compression roller and the circular mould through compression roller sliding screw pairs respectively. The compression rollers disclosed by the invention are driving structures; the circular mould is a driven structure and the compression rollers and the circular mould are independently arranged on a base, thereby achieving adjustment of the gap between the circular mould and the compression rollers in a shutdown or non-shutdown state, avoiding cross contamination of the feed and butter, and being suitable for granulating of biomass raw materials such as the feed, sawdust, straw and the like.

Owner:CHINA AGRI UNIV

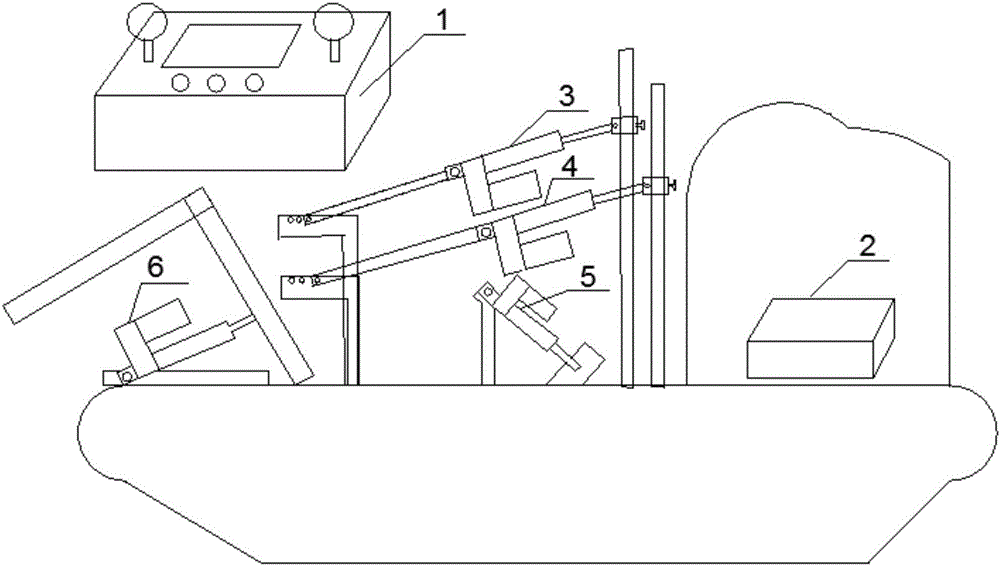

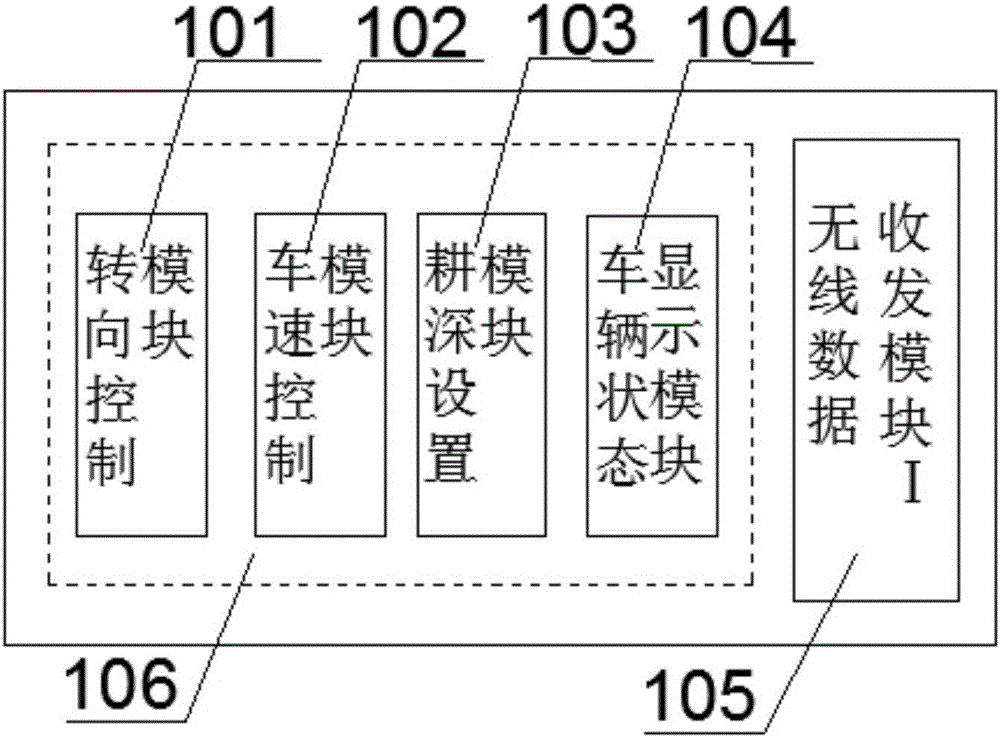

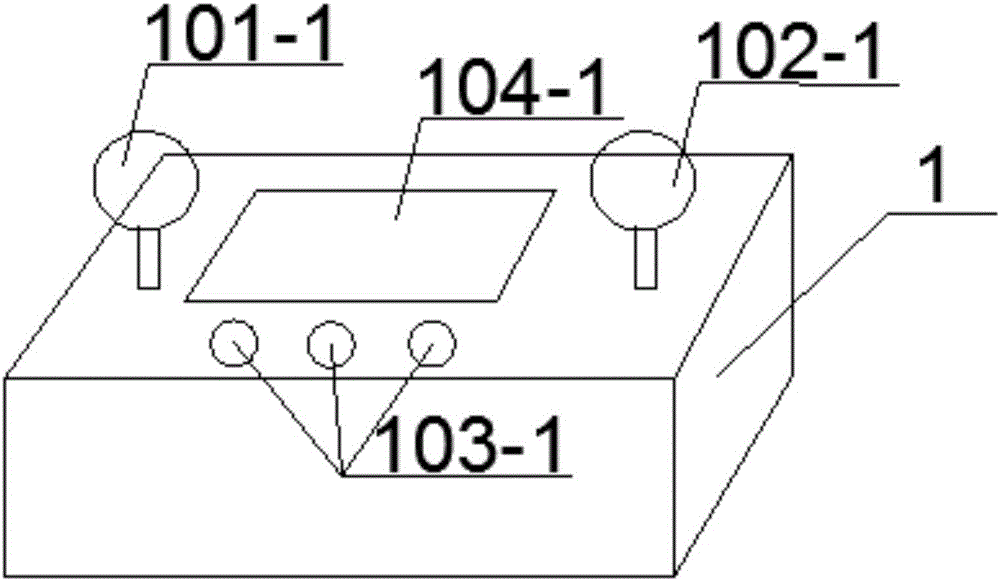

Remote control device and control method for pure electric crawler tractor

InactiveCN106205086AEasy to operateFriendly man-machine interfaceTransmission systemsEndless track vehiclesState parameterSelf locking

The invention relates to a remote control device and a control method for a pure electric crawler tractor belonging to the field of agricultural machinery. The remote control device comprises a remote controller, a controller, a left brake push rod, a right brake push rod, an accelerator push rod and a suspension push rod. The remote controller can send the control instruction to the controller and can receive the vehicle state parameter signal transmitted by the controller and display through a display screen; the controller and the vehicle CAN network are connected for receiving the complete vehicle state parameter signal transmitted by the vehicle controller and transferring to the remote controller as well as the control instruction transmitted from the remote controller to control the stretching and retracting of each push rod, therefore the tractor can be controlled to stop, advance, retreat, turn, and mount the farm tools. The remote control device adopts an electric push rod, which can keep the electric push rod to a fixed elongation length without the need of energy, by using the self-locking characteristic of the electric push rod. Compared with the prior patent and the product technology, the remote control device reduces the whole vehicle energy consumption significantly, while improving the control accuracy.

Owner:JIANGSU UNIV

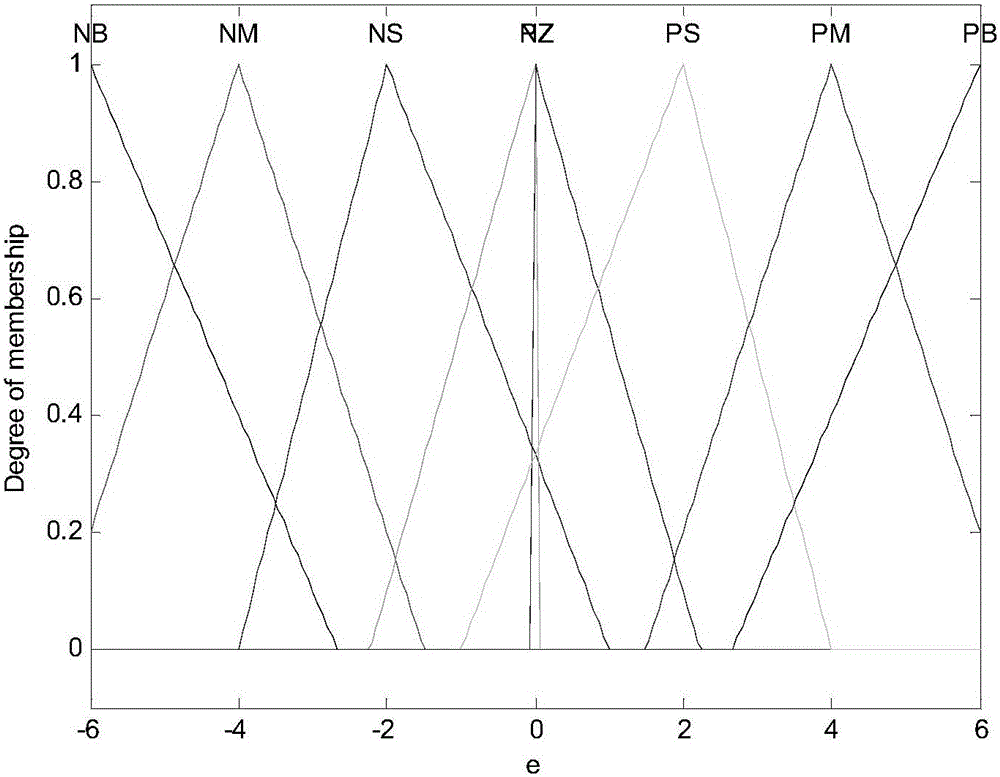

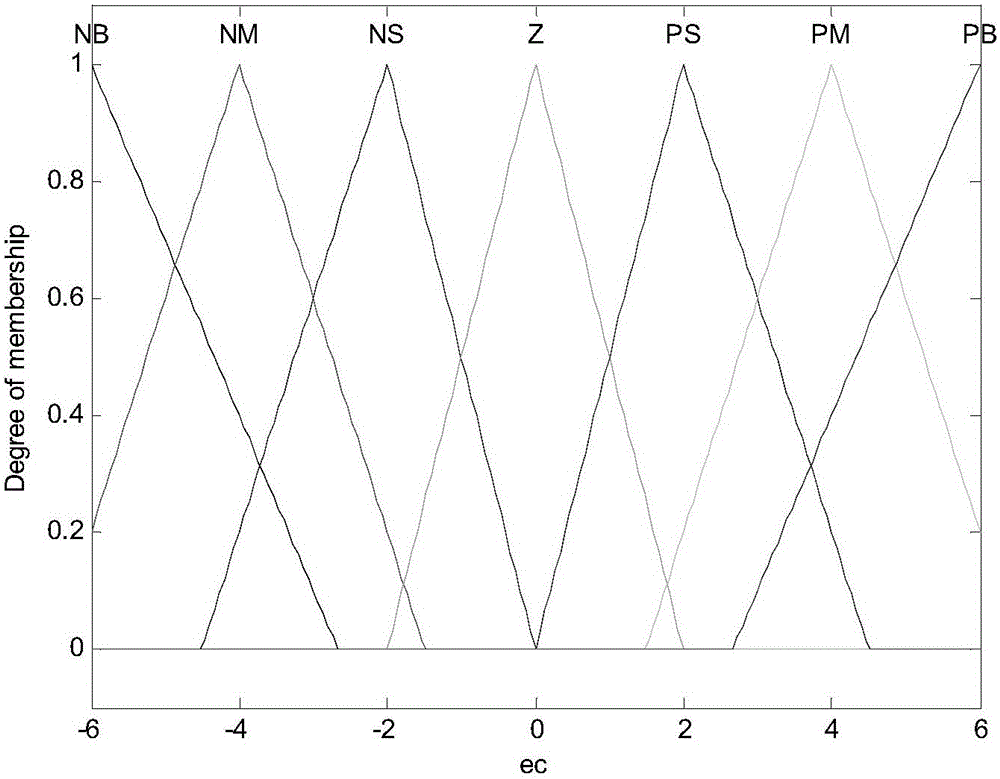

Fuzzy control method used for exoskeleton system

InactiveCN105955015AImprove robustnessAnd self-organizingControllers with particular characteristicsAdaptive controlRobustificationAutomatic control

The invention belongs to the technical field of automatic control, and relates to a fuzzy control method for an exoskeleton system. The main idea of the present invention is to solve the problem that traditional exoskeleton prototypes adopt PID position servo control. Although engineering can basically meet the control requirements, once the external environment or system parameters change, the mathematical model of the system will change. Changes ensue, which makes the system poorly controlled. The present invention designs the control law algorithm on the basis of the mathematical model of the hydraulic servo system. After the control model changes, the fuzzy adaptive control can track the expected curve better than the PID, and has the advantages of real-time performance, stability and robustness. There are clear advantages in terms of sex.

Owner:成都奥特为科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com