Vibrating and flattening device for impregnation production line of carbon fiber prepreg

A carbon fiber prepreg and flattening device technology, which is applied in the fields of final product manufacturing, textile material carrier processing, textile/flexible product manufacturing, etc., can solve problems such as unsatisfactory flattening effect, compressed air flow rate, and pressure stability. , to achieve the effect of simple and practical operation and enhanced applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

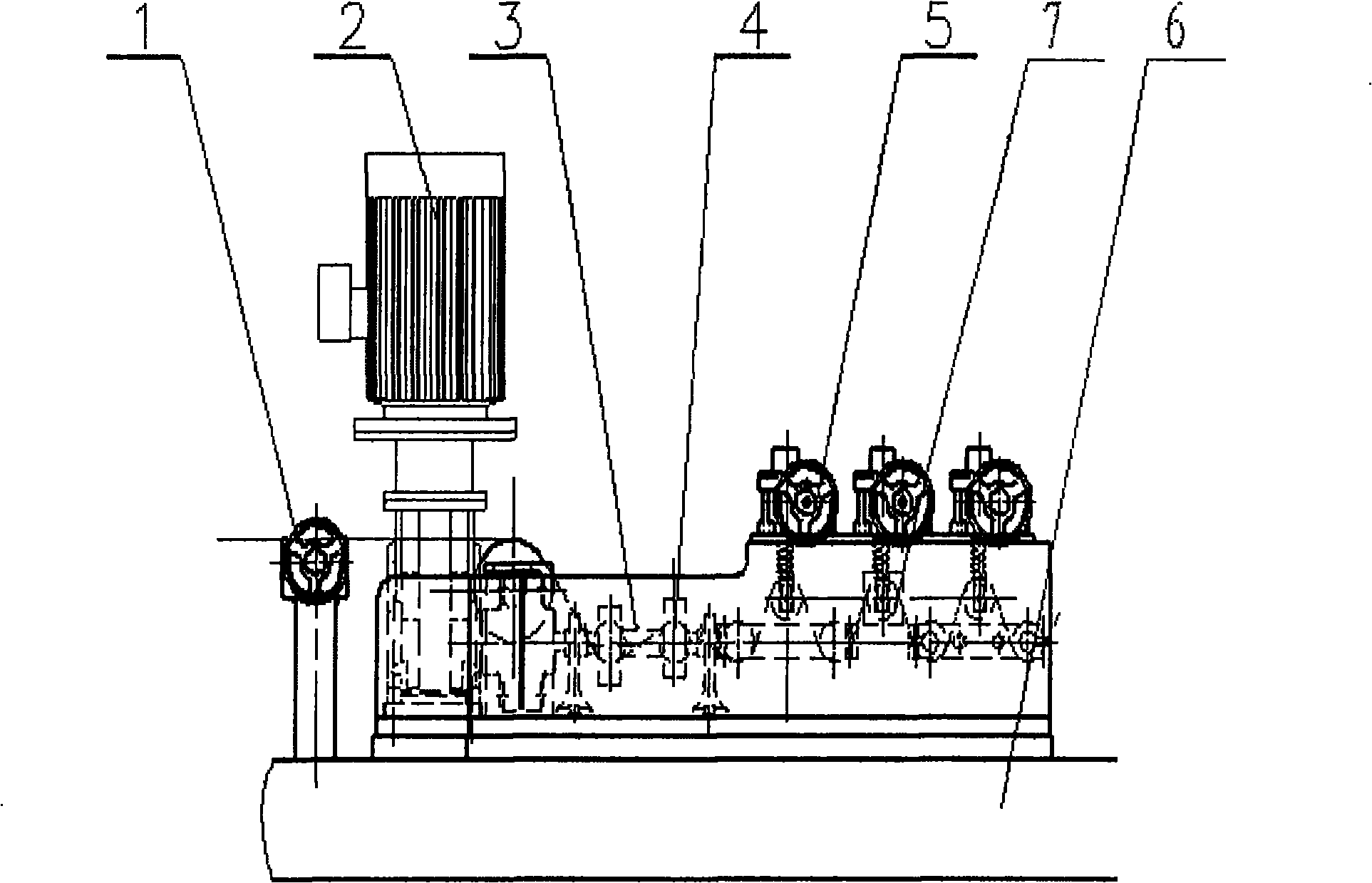

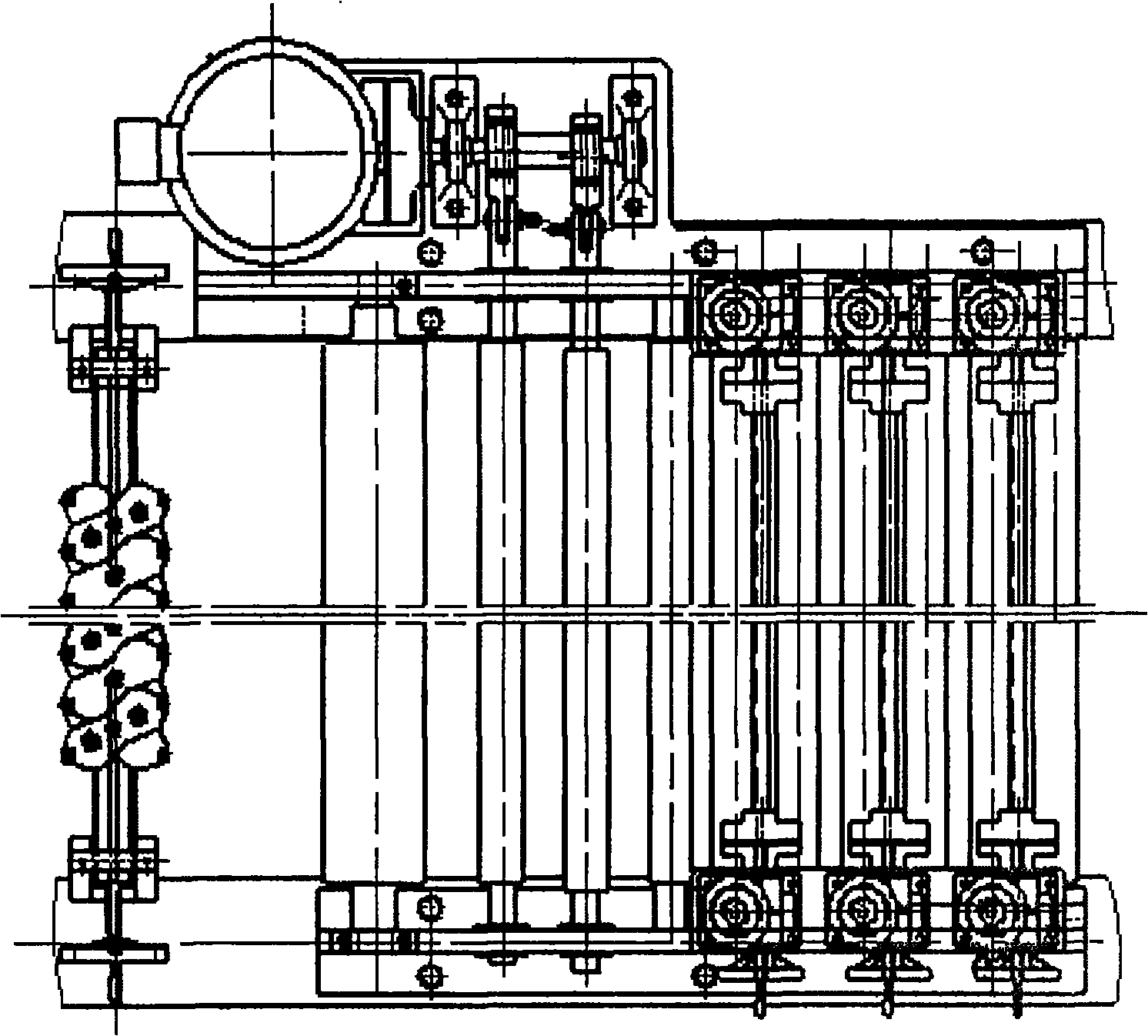

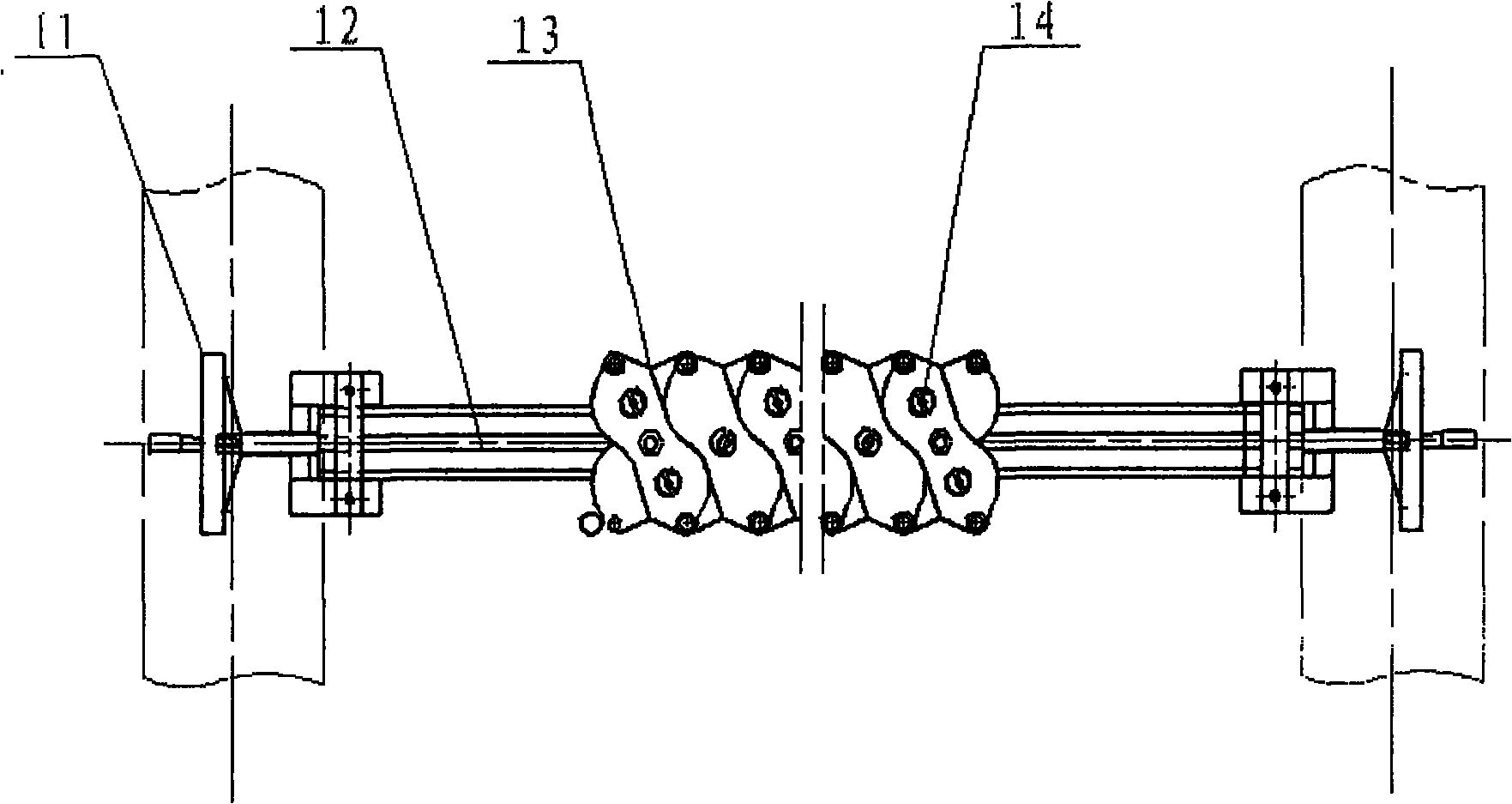

[0017] Such as figure 1 , figure 2 As shown, the vibration flattening device of the carbon fiber prepreg dipping production line of the present invention includes a splitter comb 1 with adjustable spacing, a frequency conversion motor reducer 2, a camshaft 3, two vibrating rollers 4, three groups of lifting rollers 5, a bracket 6 and Fixed roller 7, the splitting comb 1 with adjustable spacing, variable frequency motor reducer 2, camshaft 3, two vibrating rollers 4, lifting roller 5, and fixed roller 7 are jointly arranged on the support 6, and the adjustable spacing The splitter comb 1 is arranged at the left end of the bracket 6, the rear end of the adjustable-spacing splitter comb 1 is provided with a variable frequency motor reducer 2, the two vibrating rollers 4 are arranged at the rear end of the variable frequency motor reducer 2, and the camshaft 3 Located between two vibrating rollers 4, three sets of elevating rollers 5 are arranged behind the two vibrating rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com