Microwave sterilizing device applied to food process and production line

A microwave sterilizing device and food processing technology, applied in food processing, application, food preservation, etc., can solve problems such as difficult to meet production requirements, long processing time, high energy consumption, etc., achieve remarkable energy saving effects, improve product quality, and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In this embodiment, a plurality of microwave units are arranged in series on the production line along the material conveying direction, and the power and time of each microwave unit are independently controllable.

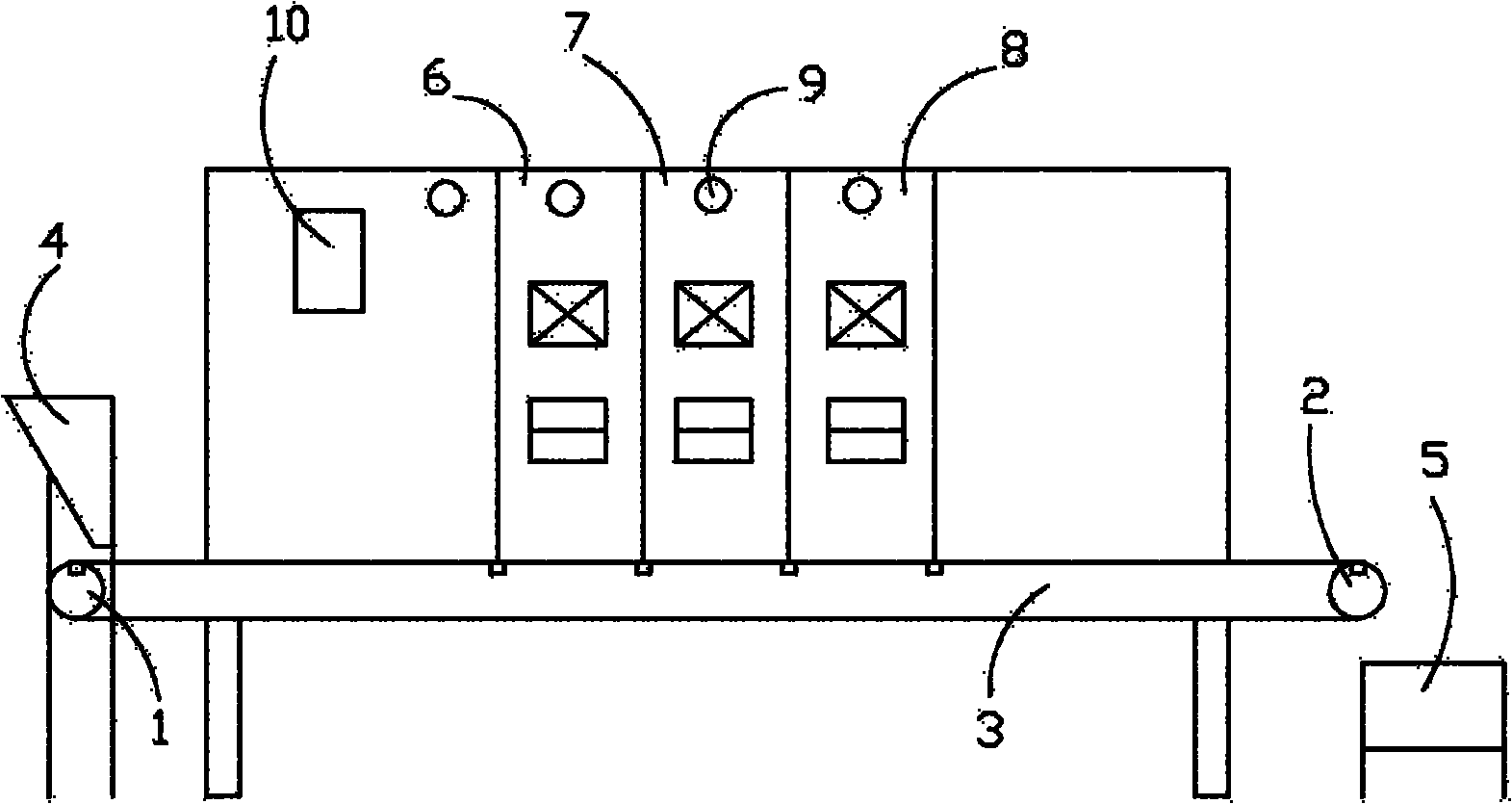

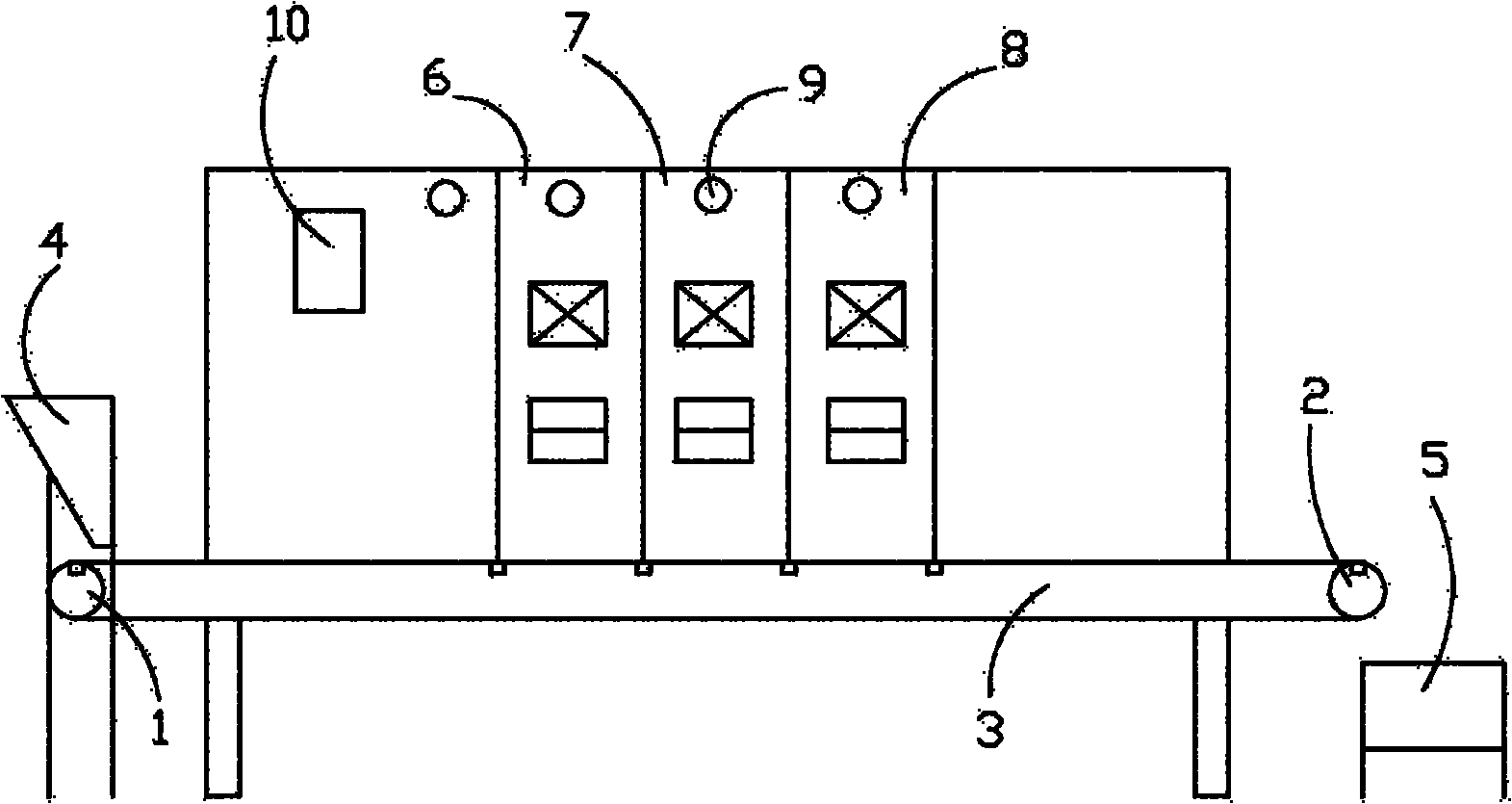

[0016] see figure 1 The specific implementation includes a material conveying system composed of a driving roller 1, a passive roller 2 and a conveyor belt 3, an upper hopper 4 is arranged at the feeding end of the conveyor belt 3, a lower hopper 5 is arranged at the discharging end of the conveyor belt 3, and the material conveying direction is respectively arranged For the first microwave unit 6 , the second microwave unit 7 and the third microwave unit 8 , the power and time of each microwave transmission unit are independently controllable.

[0017] In order to cooperate with the automatic control and adjustment on the production line, a detection device 9 can be respectively set in each microwave unit to detect the temperature of the material, etc., an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com