Patents

Literature

70results about How to "Small transmission torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

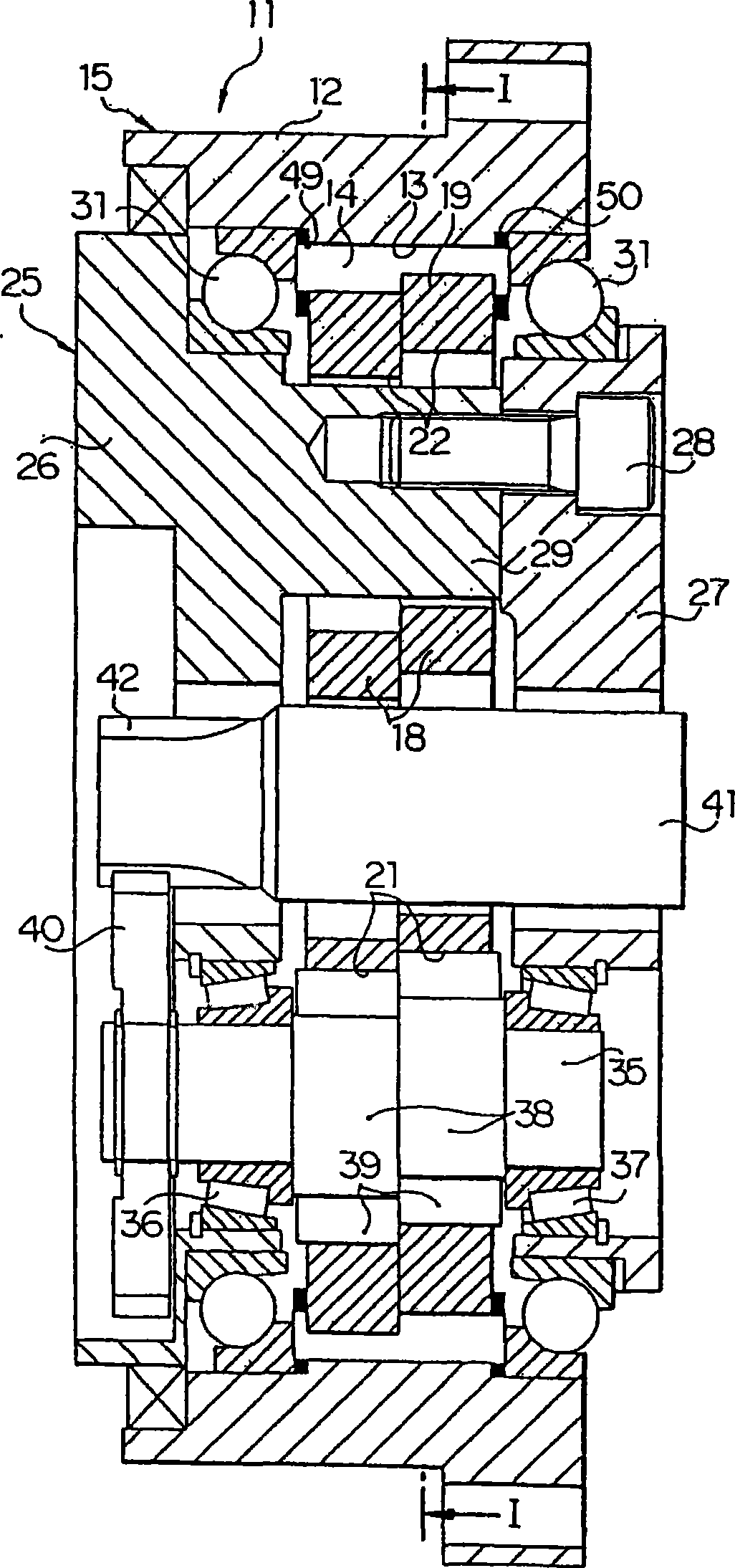

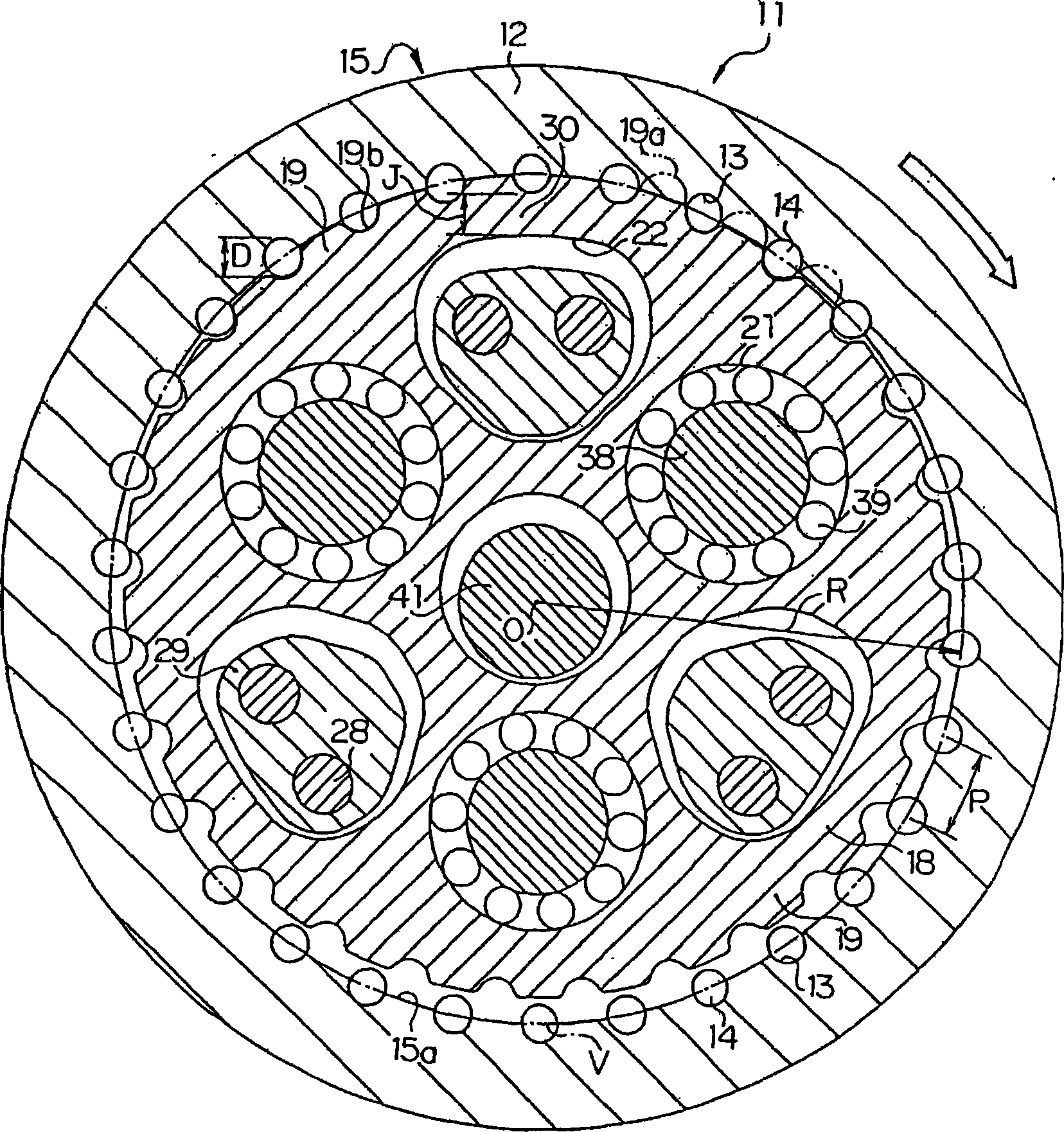

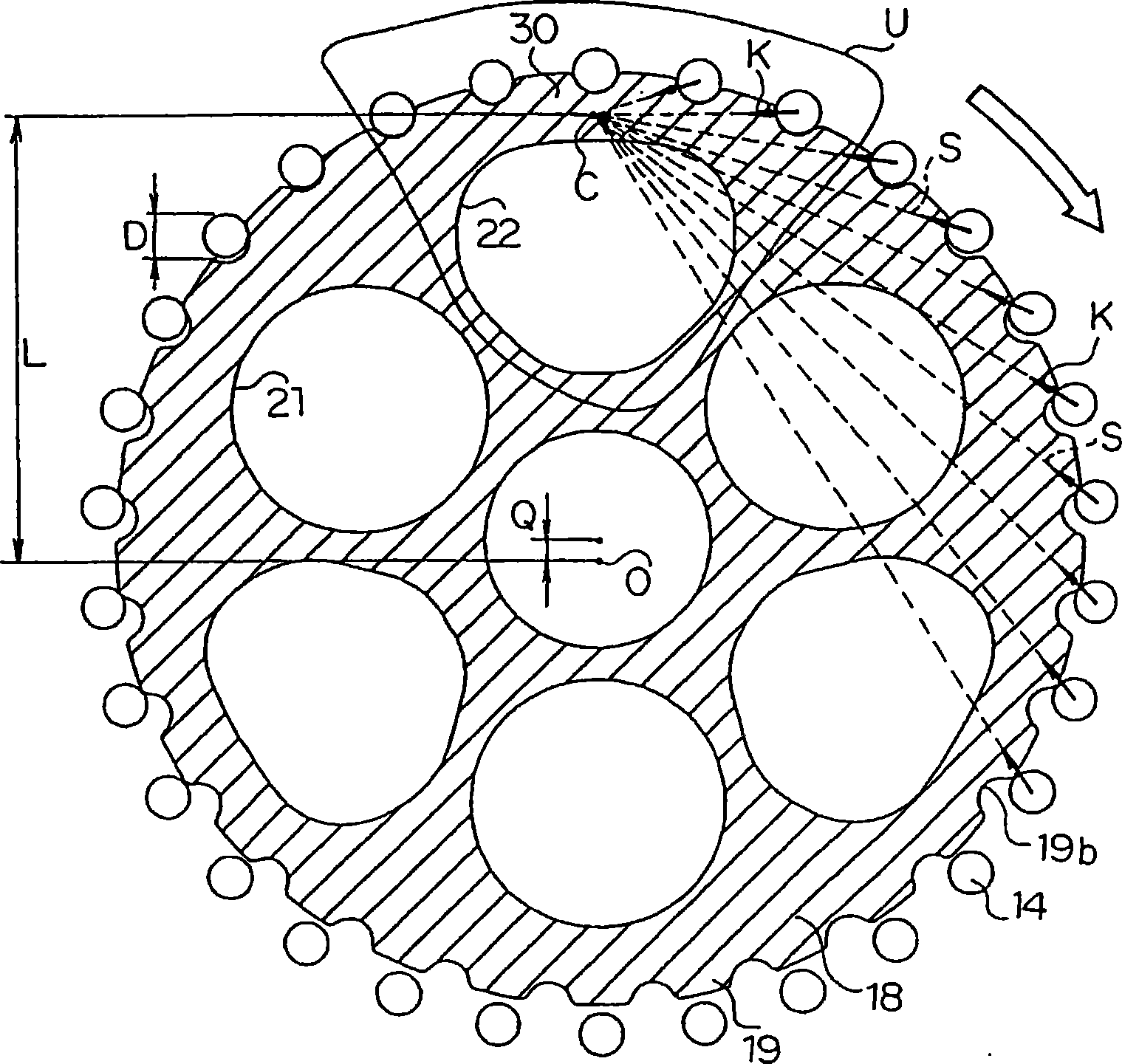

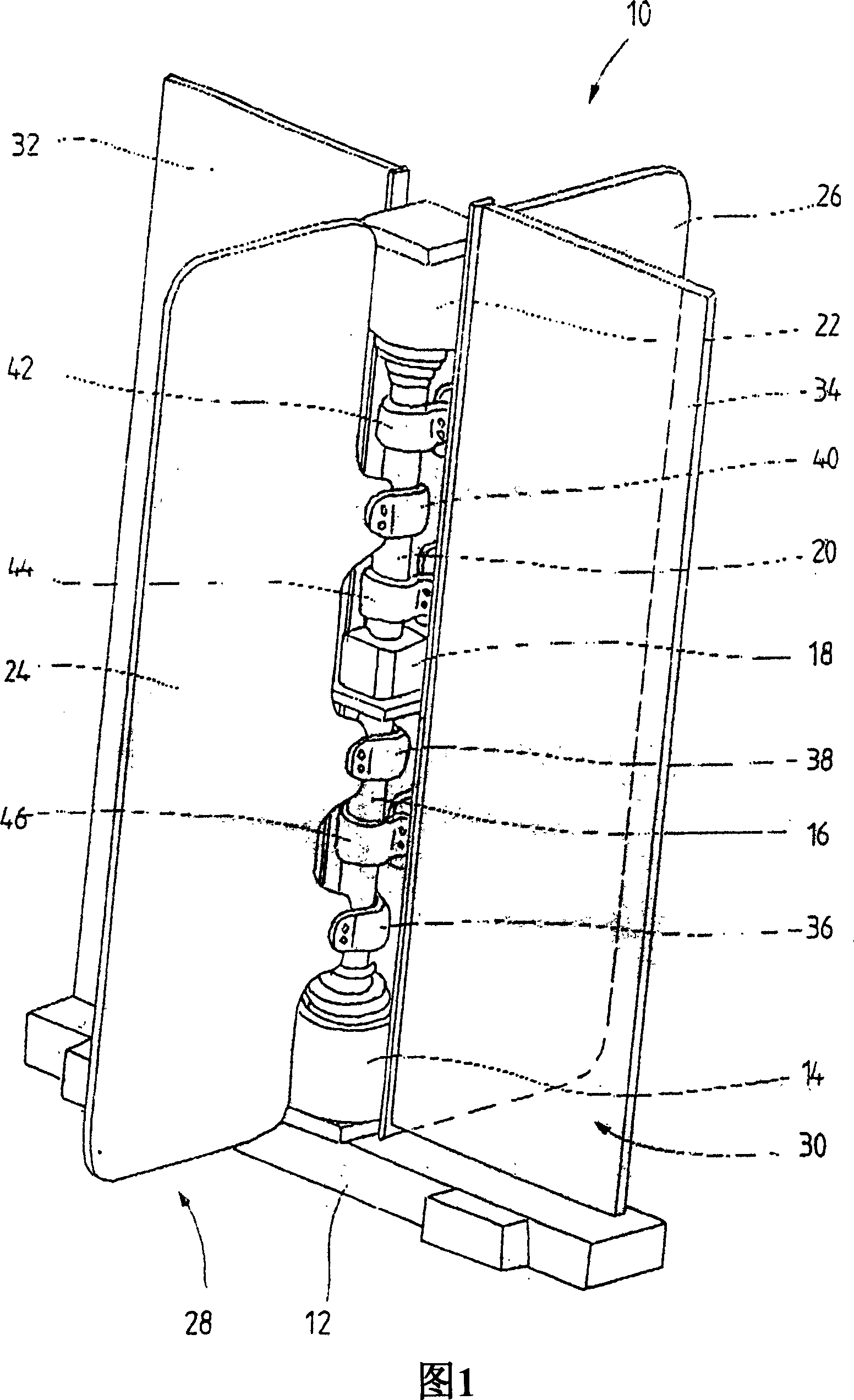

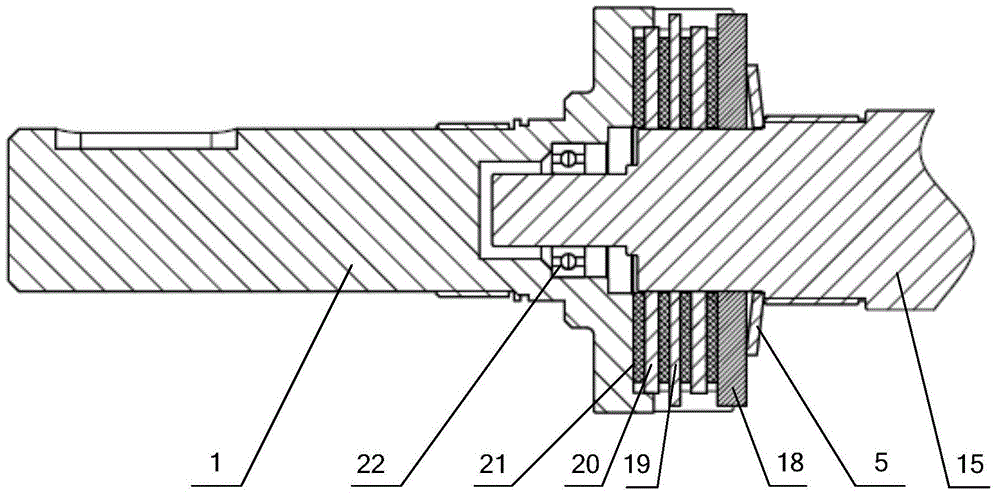

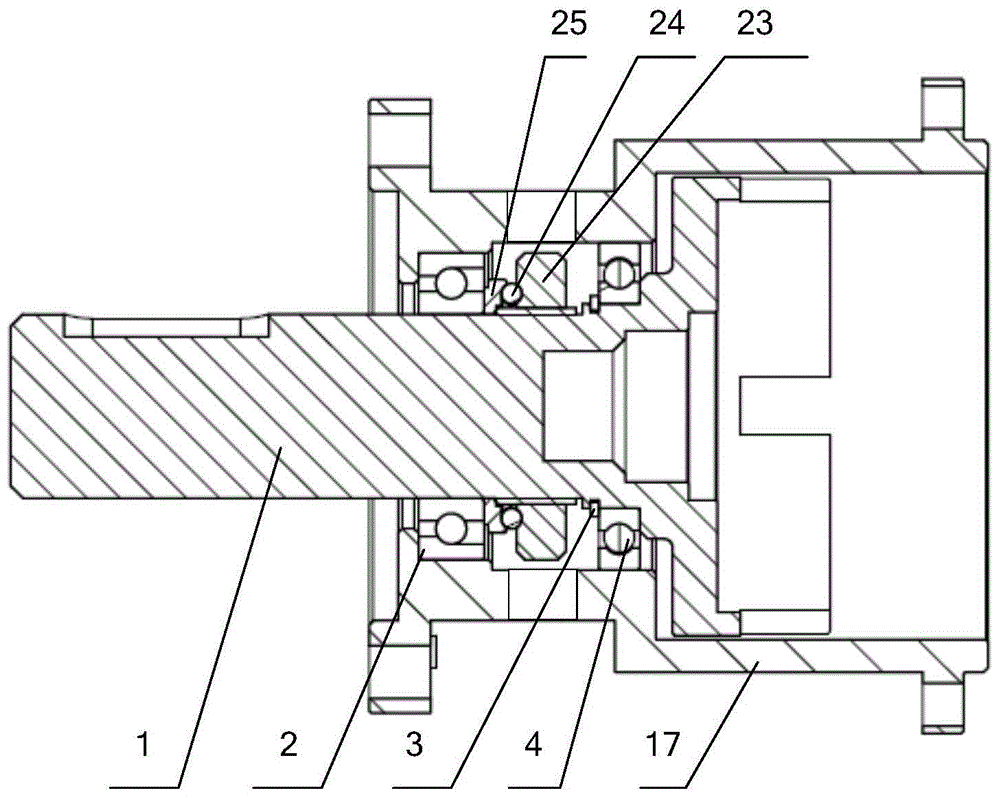

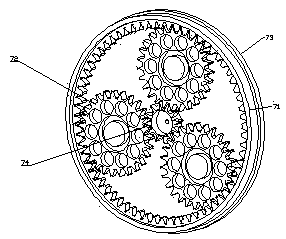

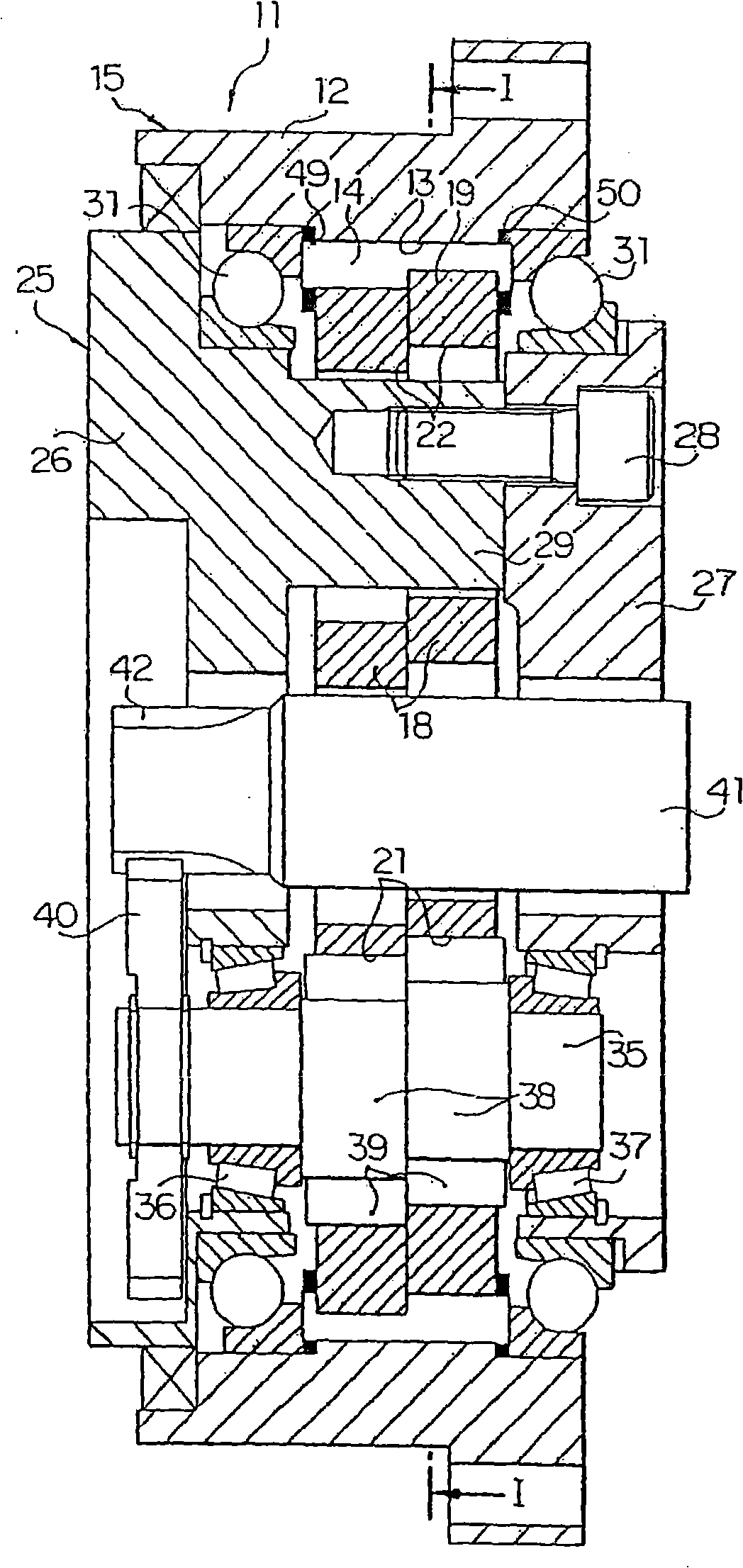

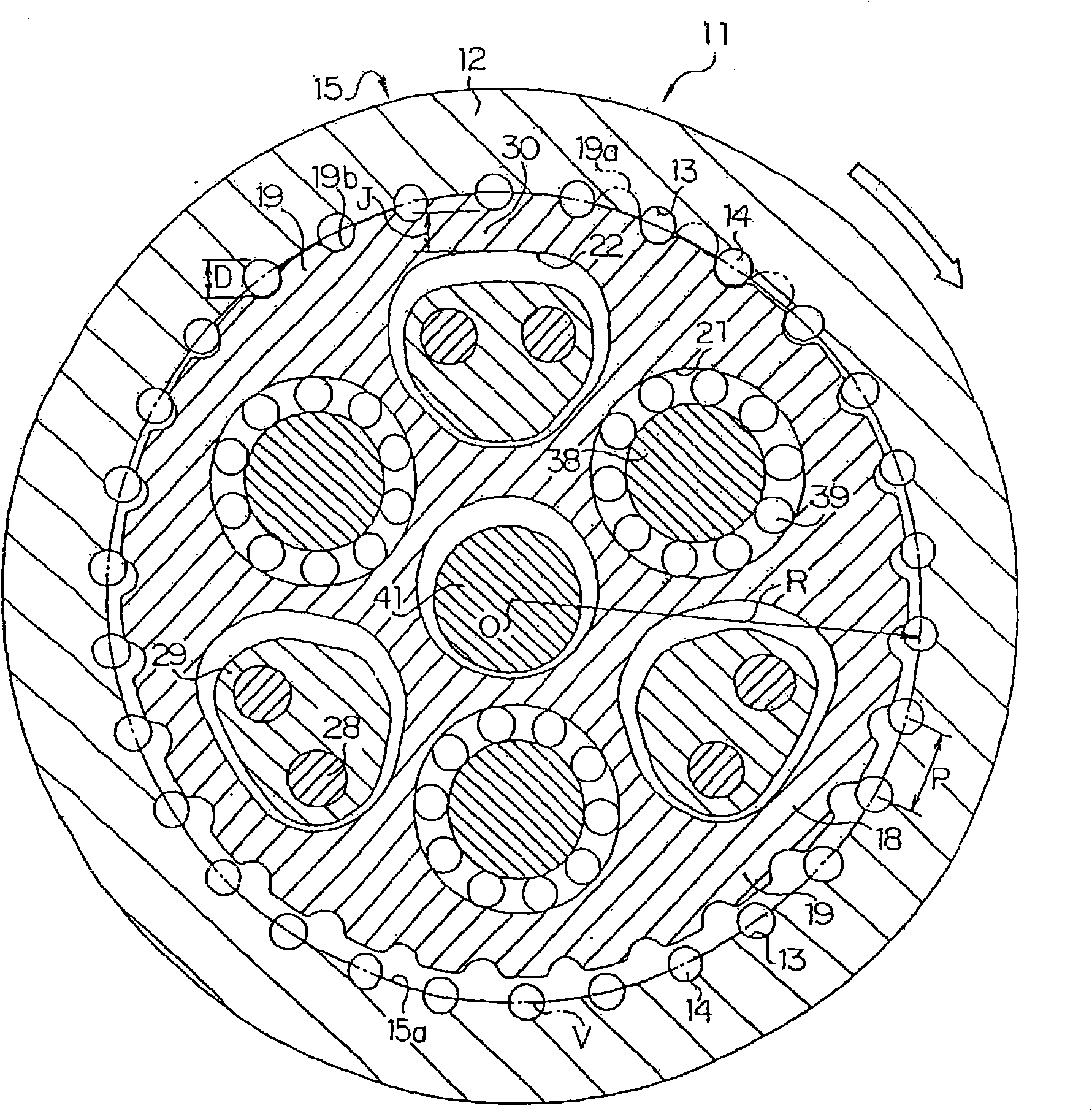

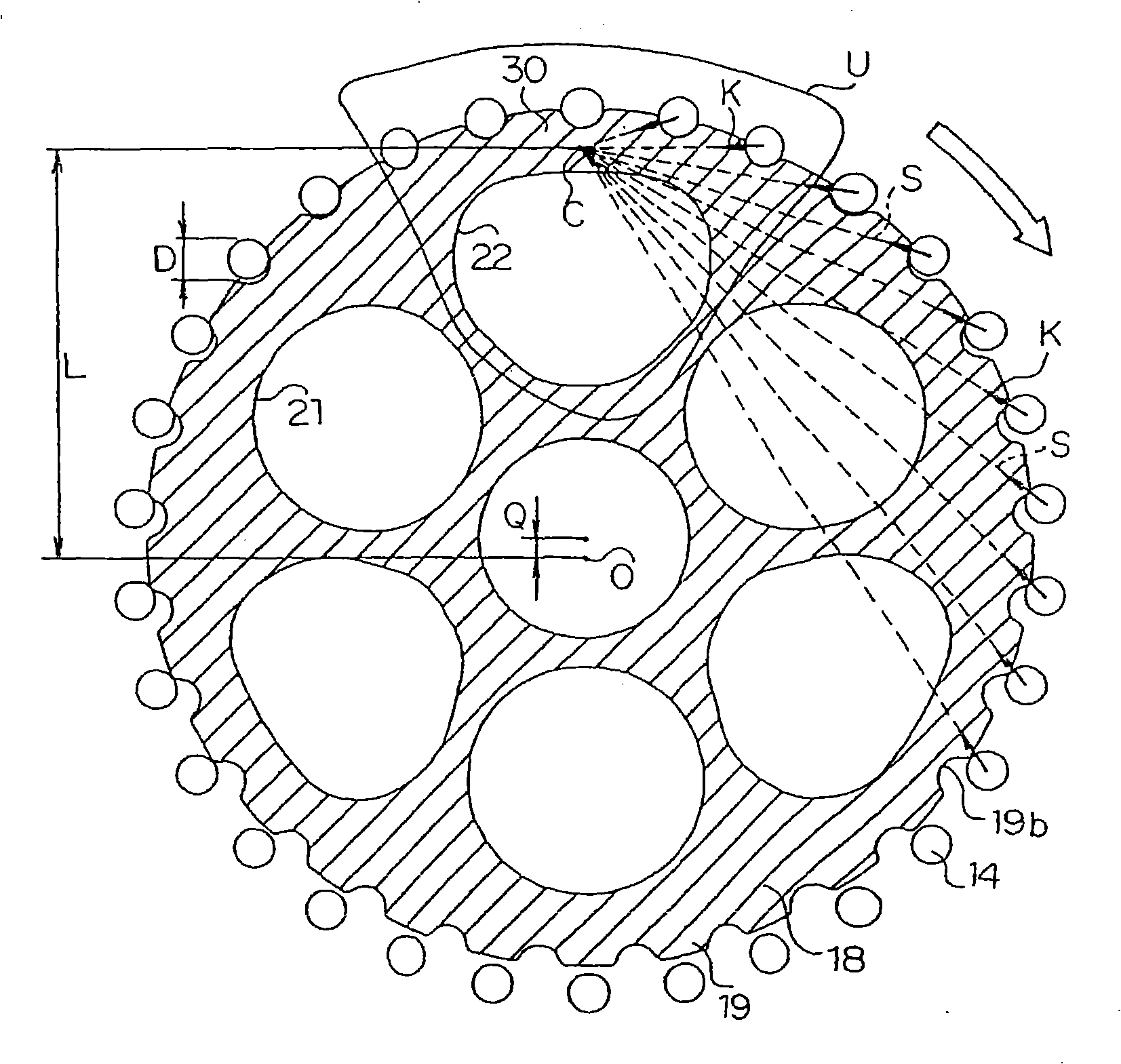

Eccentric swing type planetary gear device

ActiveCN1914438AExtend tooth surface lifeInhibition of elastic deformationToothed gearingsGear wheelEngineering

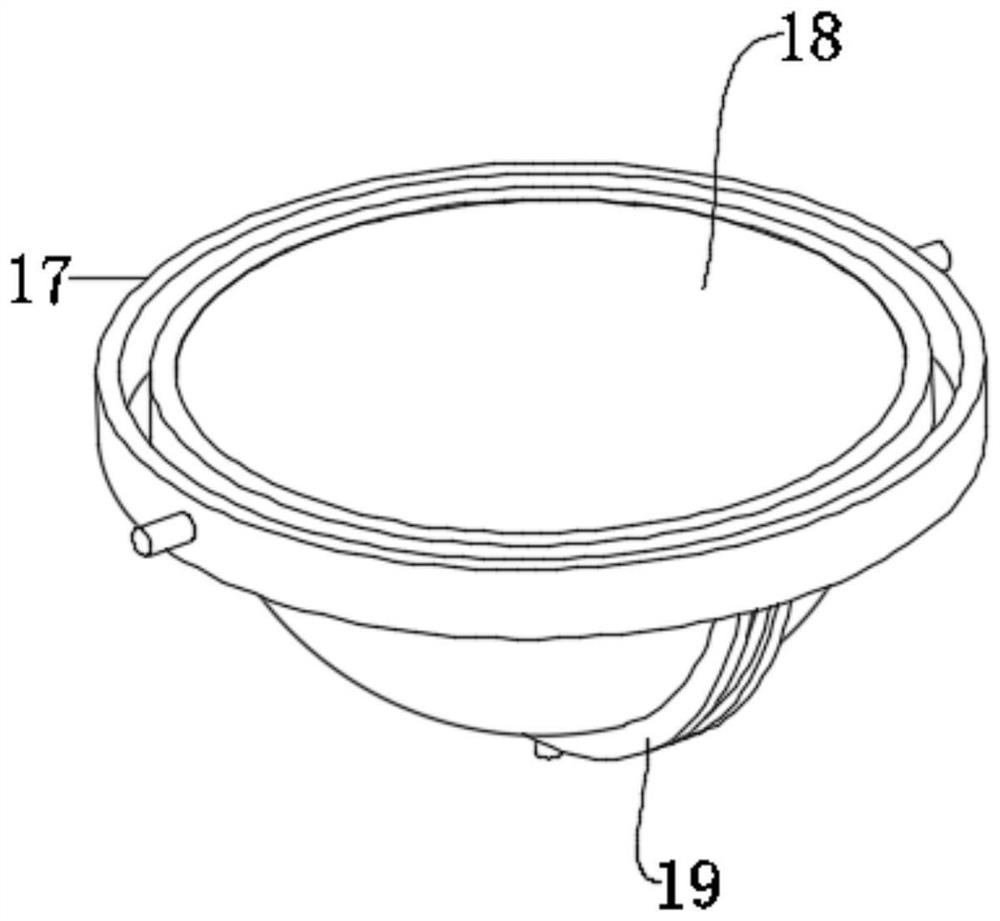

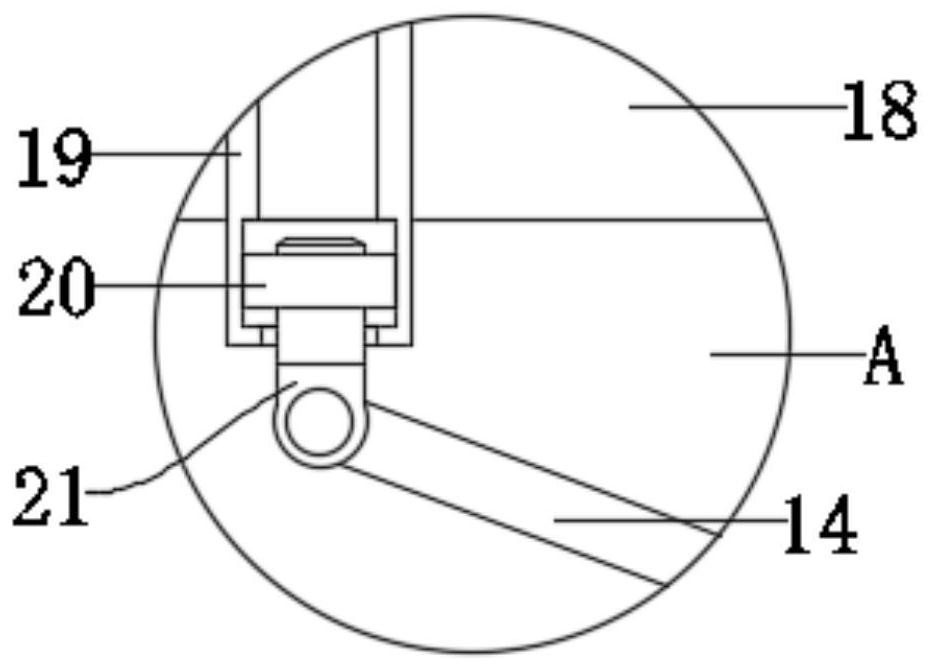

The invention provides eccentric swing type planetary gear device, deformation of bridge sections in an externally toothed gear and of outer teeth is suppressed, and this extends the life of tooth surfaces of external teeth (19), improves vibration characteristics, and drastically increases output torque while preventing a planetary gear device (11) from becoming large in size. To achieve the above, a ratio obtained by dividing the diameter (D) of pins constructing internal teeth (14) by the pitch (P) of the internal teeth (14) is made smaller to an extent where the tooth tops (19a) of the external teeth (19) are radially outside the inner periphery (15a) of an internally toothed gear (15), or alternatively, a meeting point (C) where the lines (S) of action of reaction forces (K) as drive force components meet is moved more radially outward than a conventional position so as to be positioned between a pin circle (P) passing the centers of all the internal teeth (pins) (14) and an outer end passing circle (G) passing radially outer ends of through-holes (22), or further alternatively, the amount (H) of eccentricity of an externally toothed gear (18) relative to an internally toothed gear is set not less than 0.5 times the radius (R) of the internal teeth (pins)(14).

Owner:NABLESCO CORP

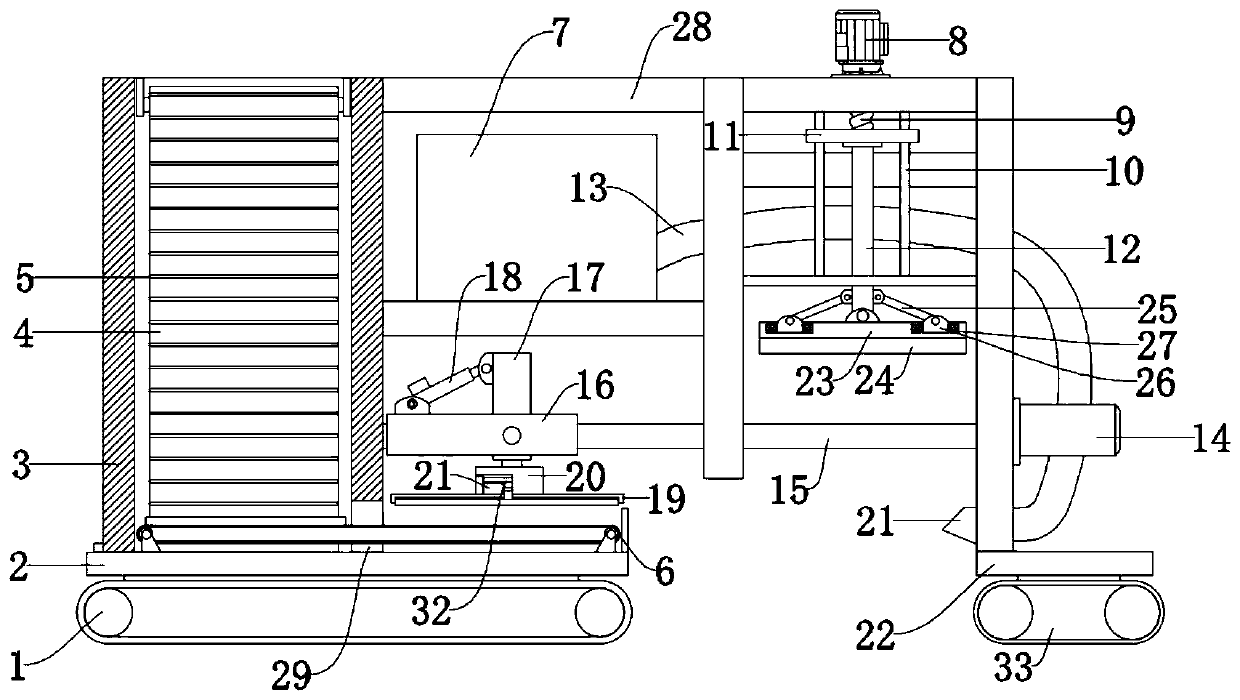

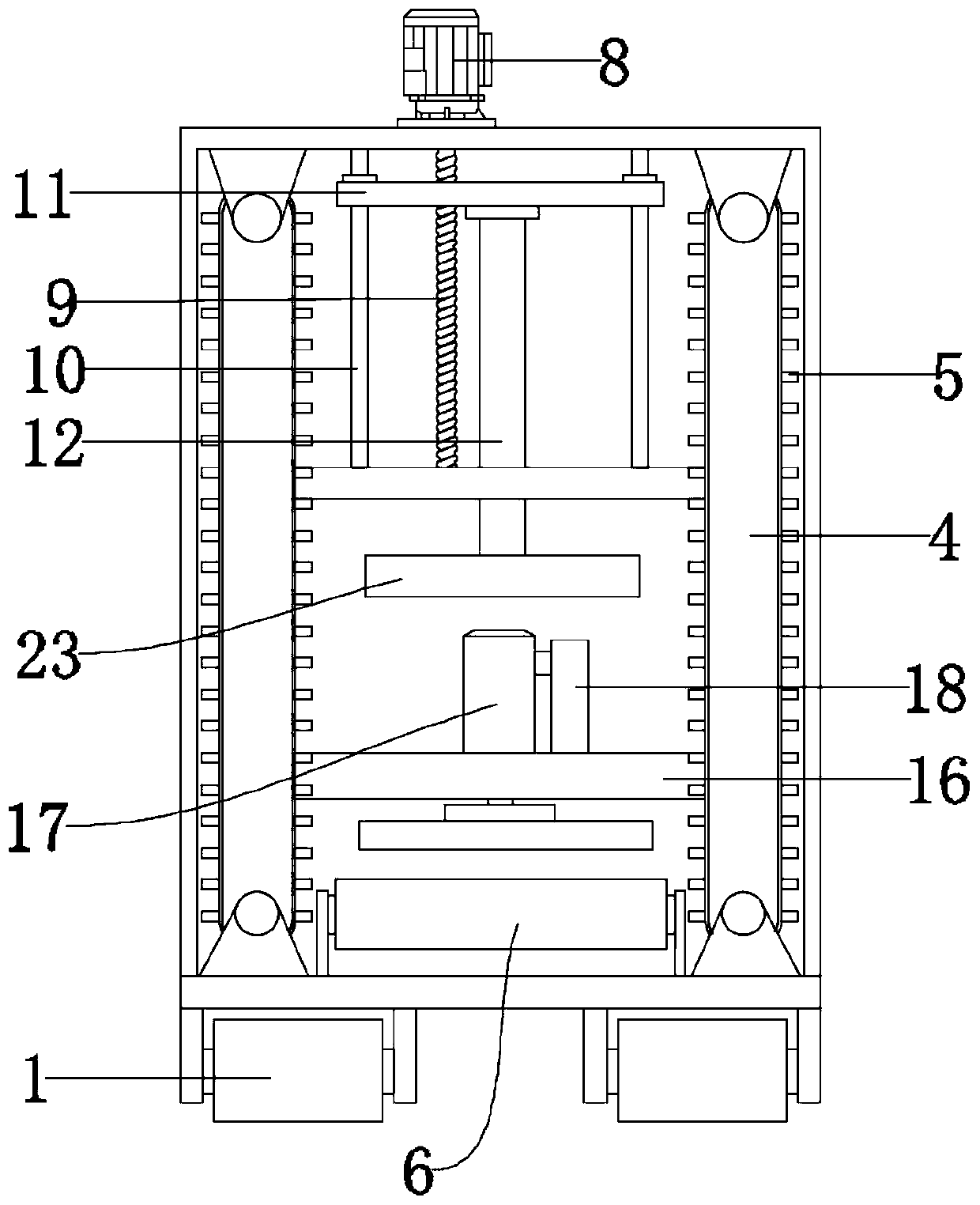

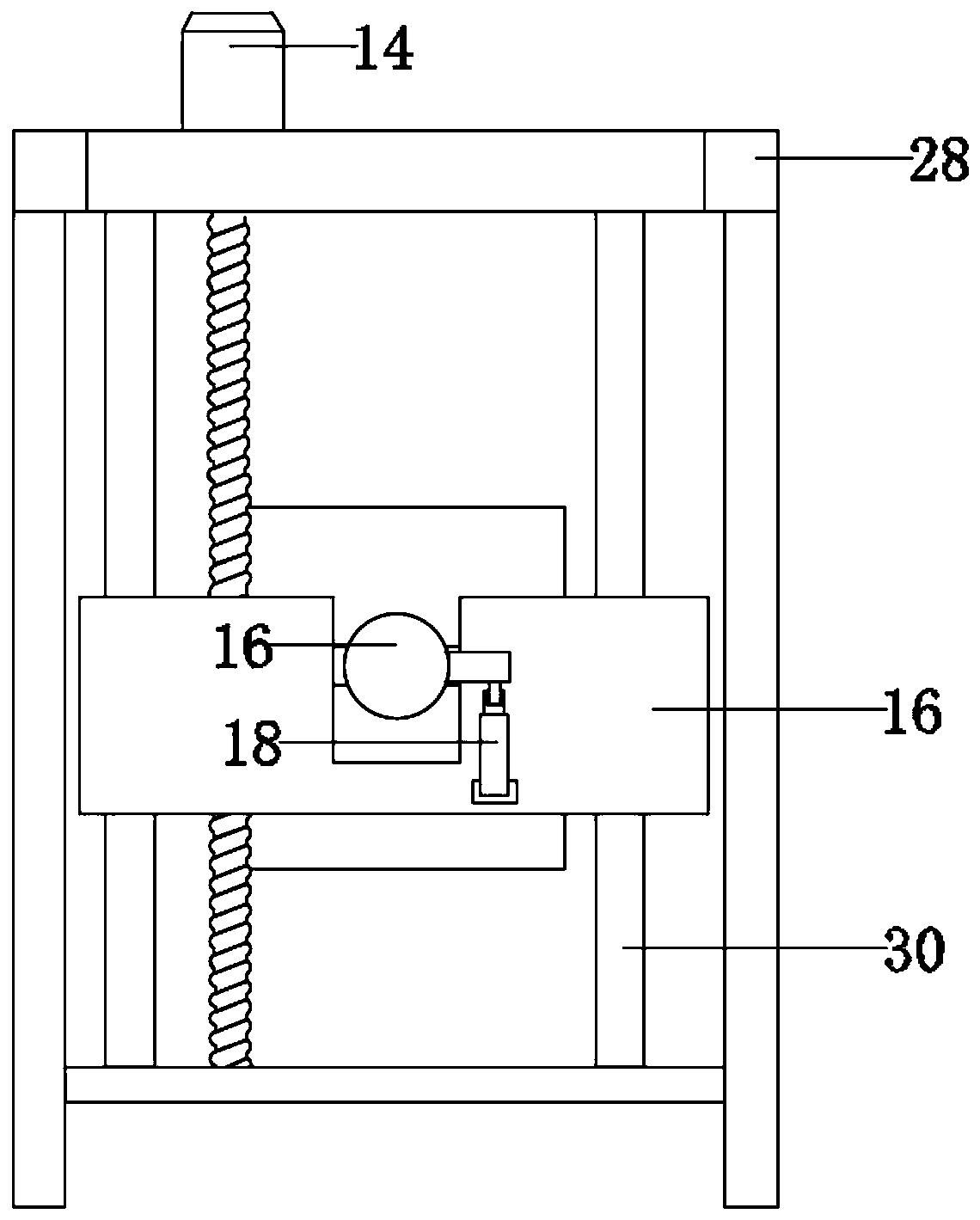

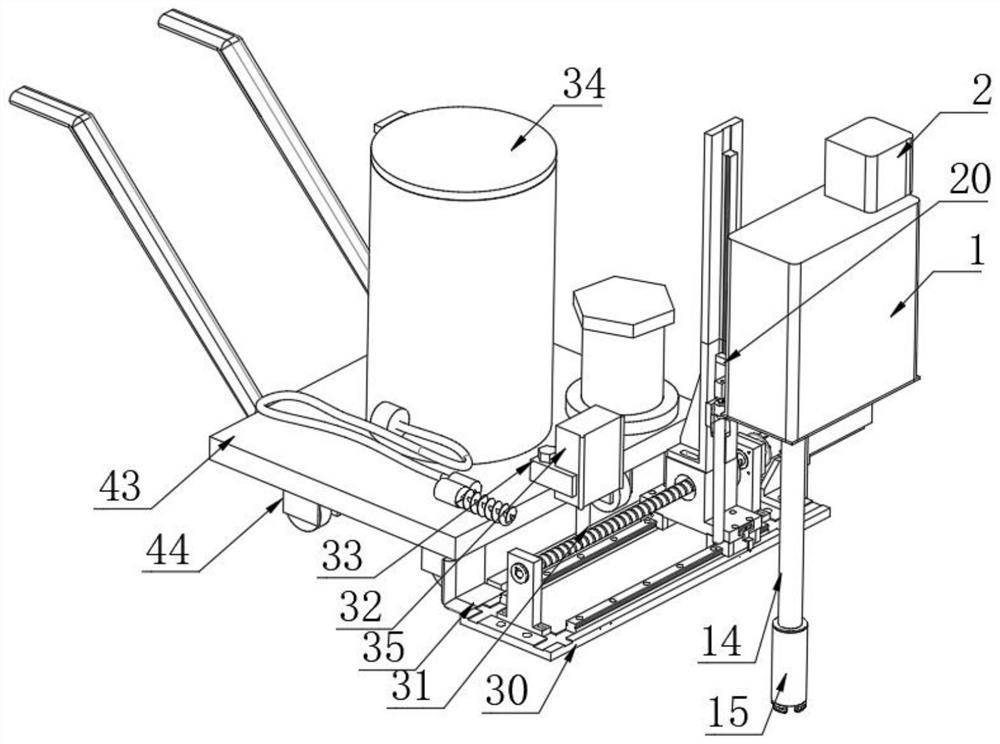

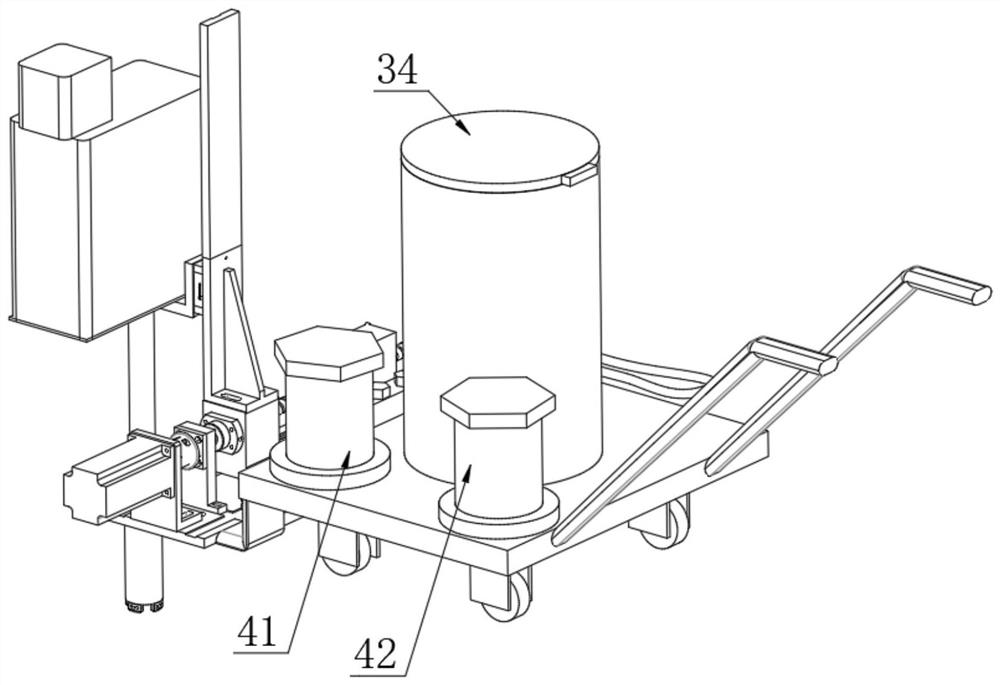

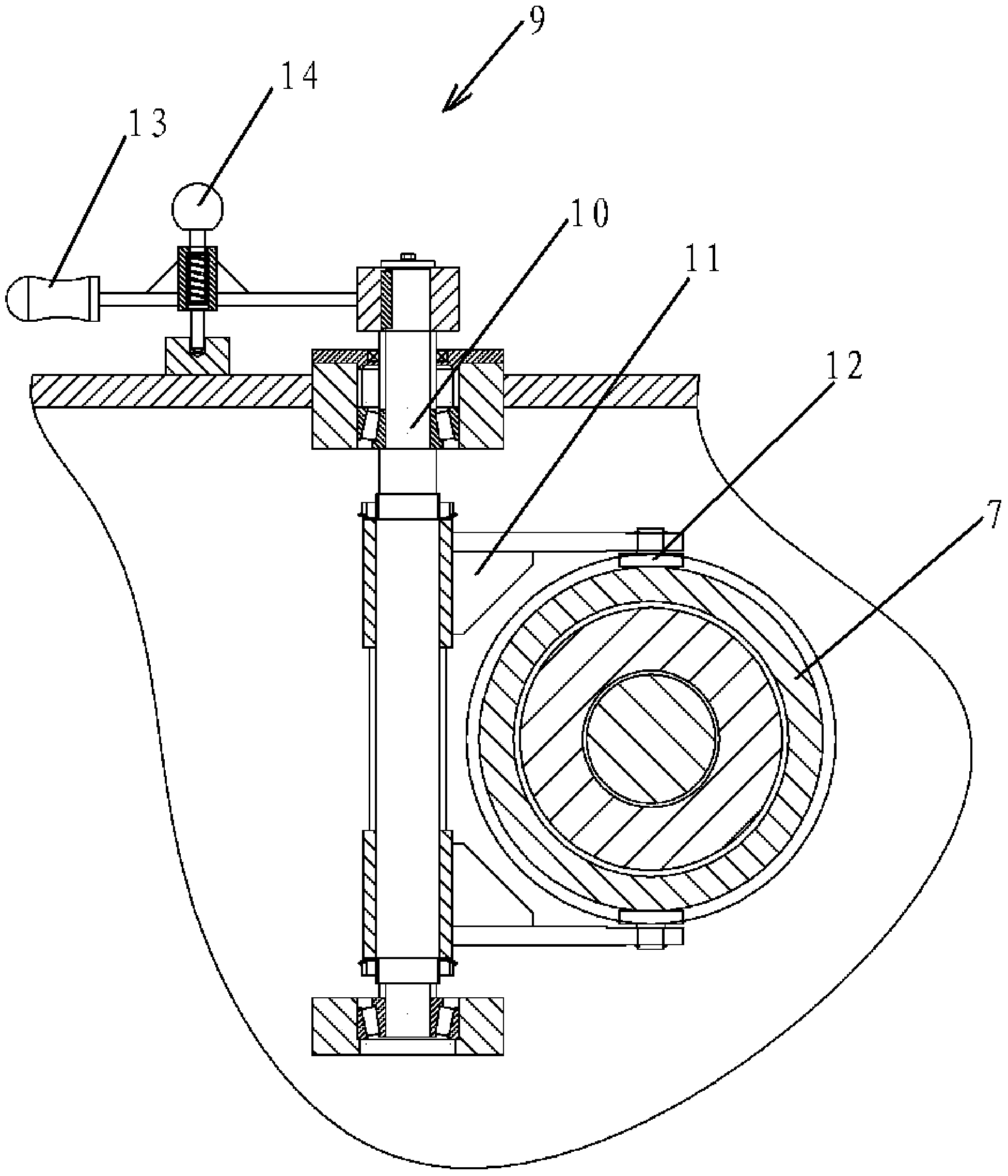

Floor tile laying device for building

ActiveCN111502212AReduce loadAchieve supportBuilding constructionsDrive wheelArchitectural engineering

Owner:新疆恒瑞建安工程建设有限公司

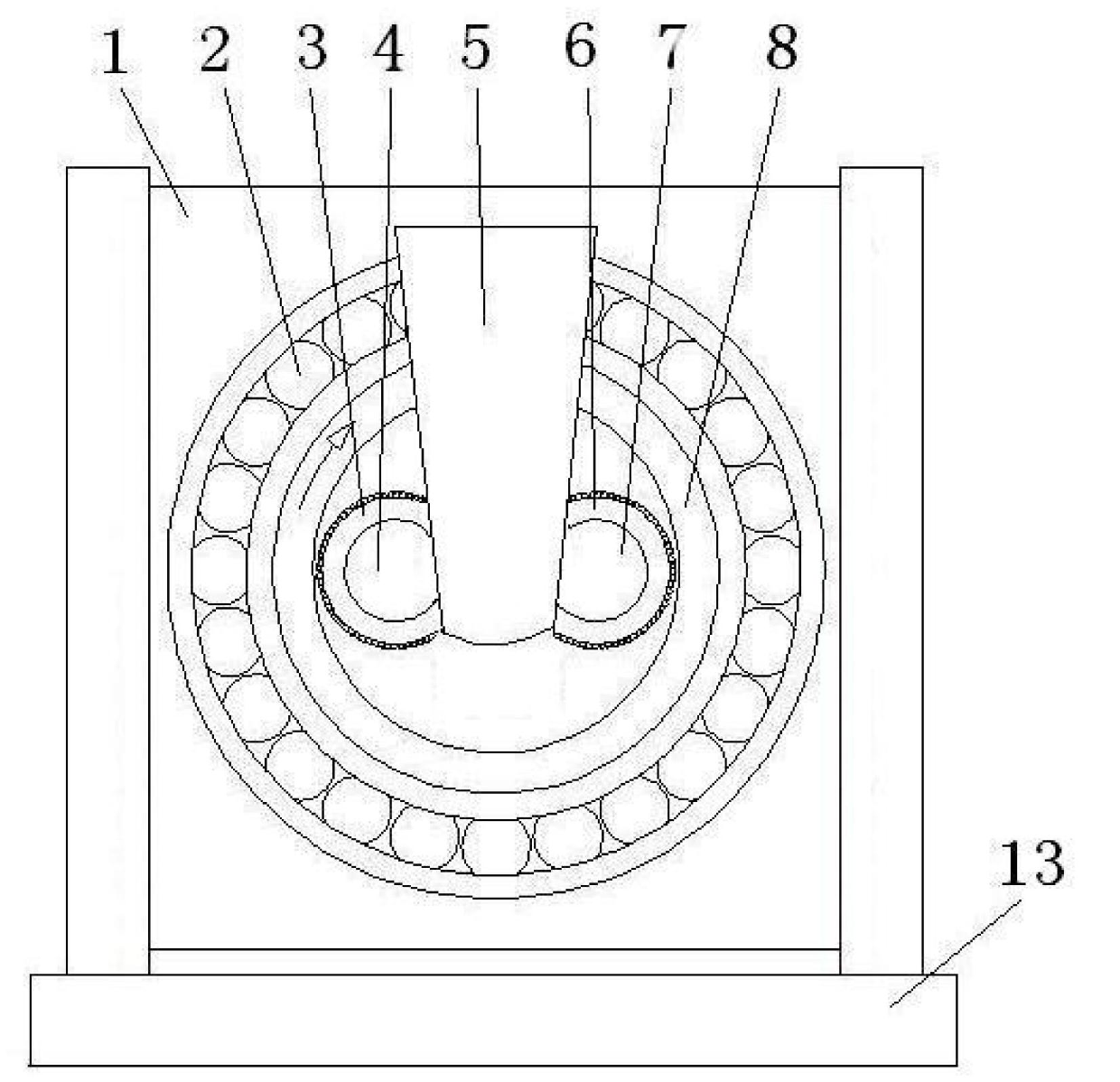

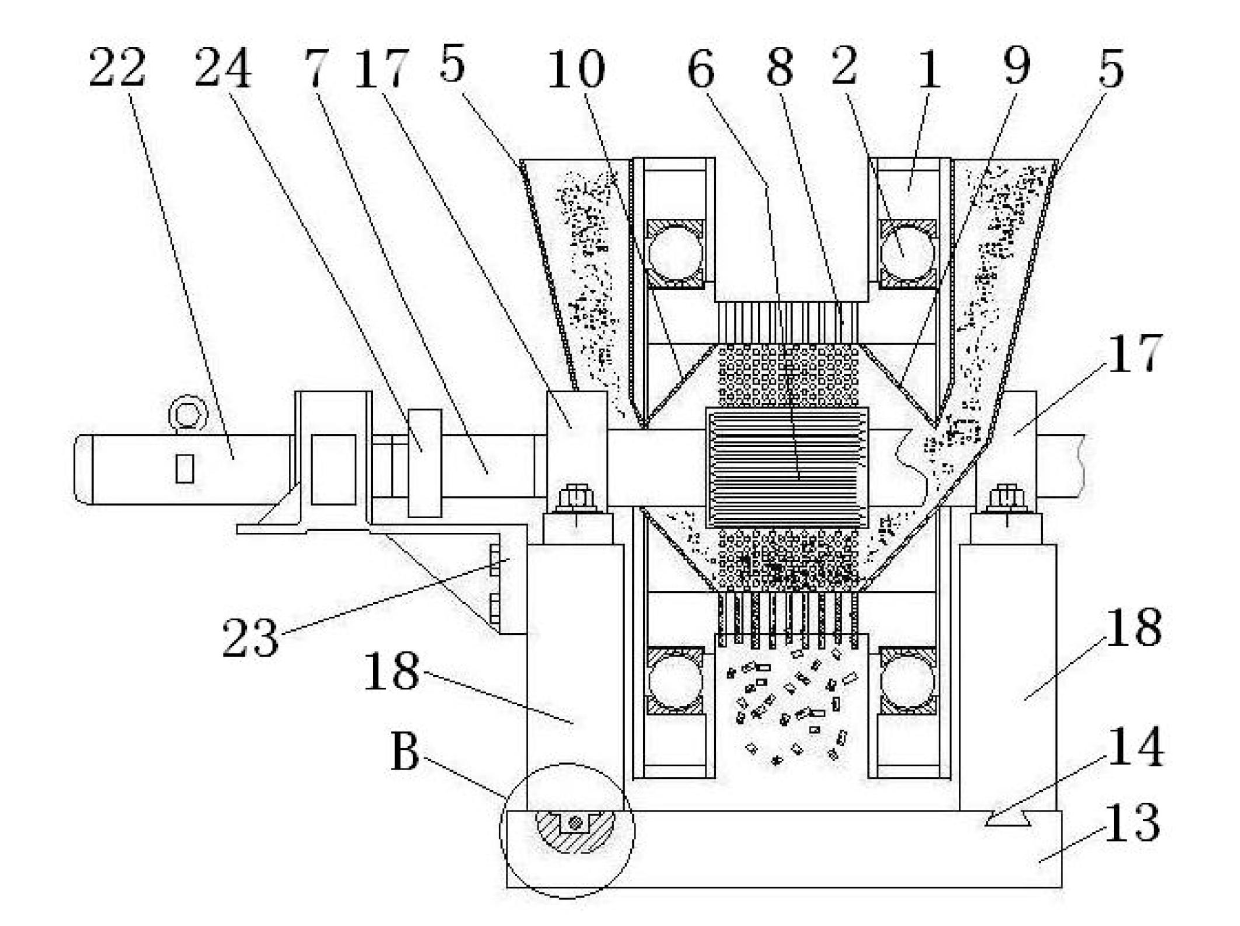

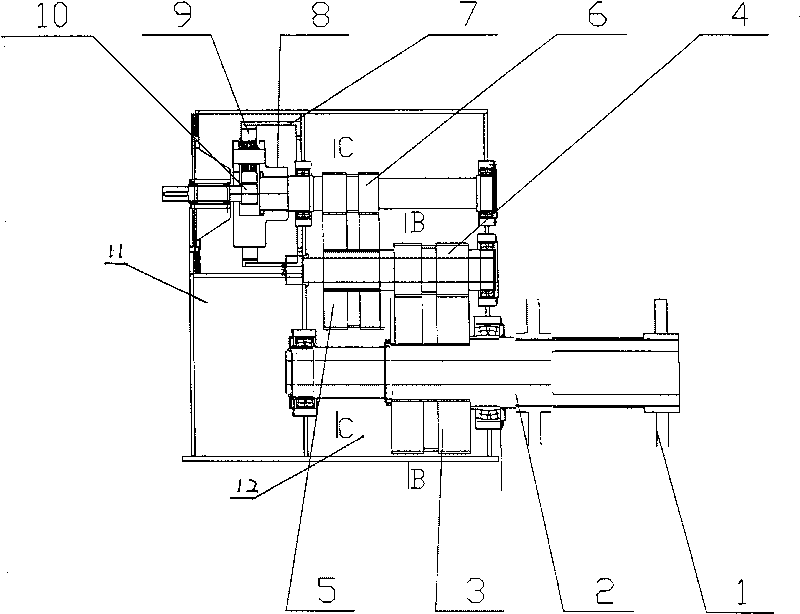

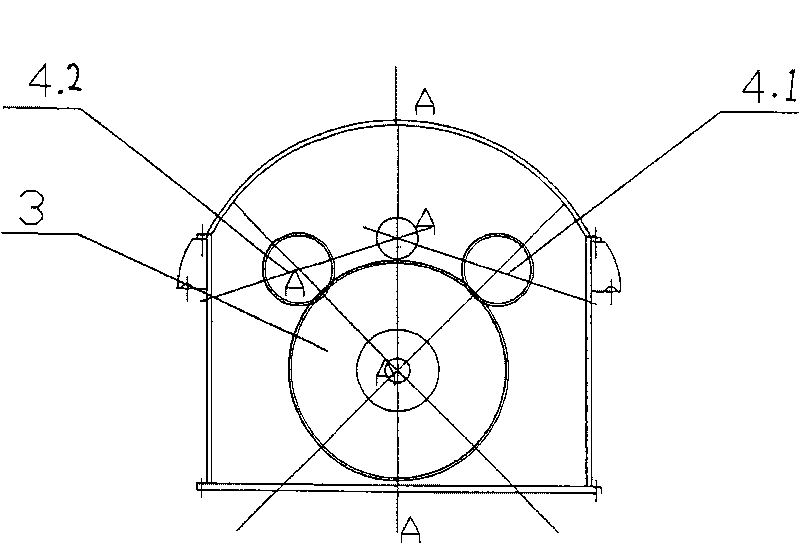

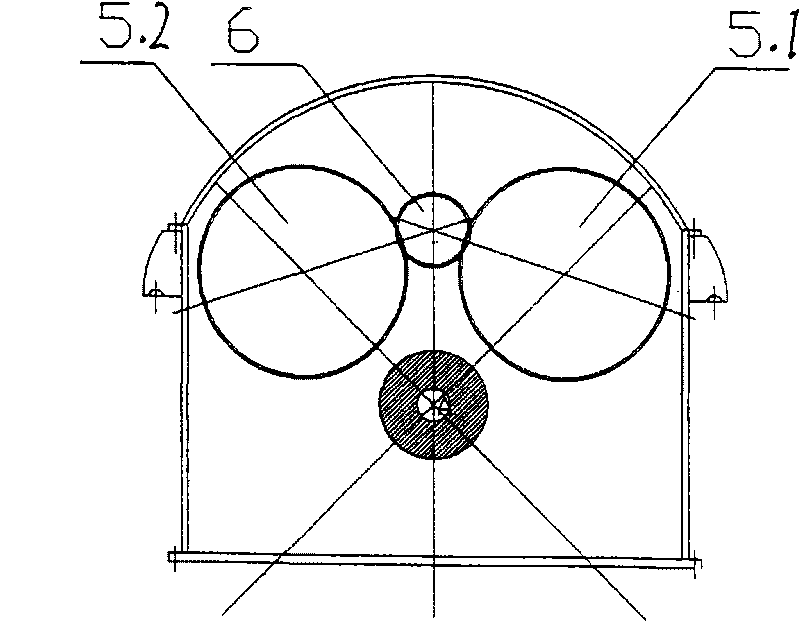

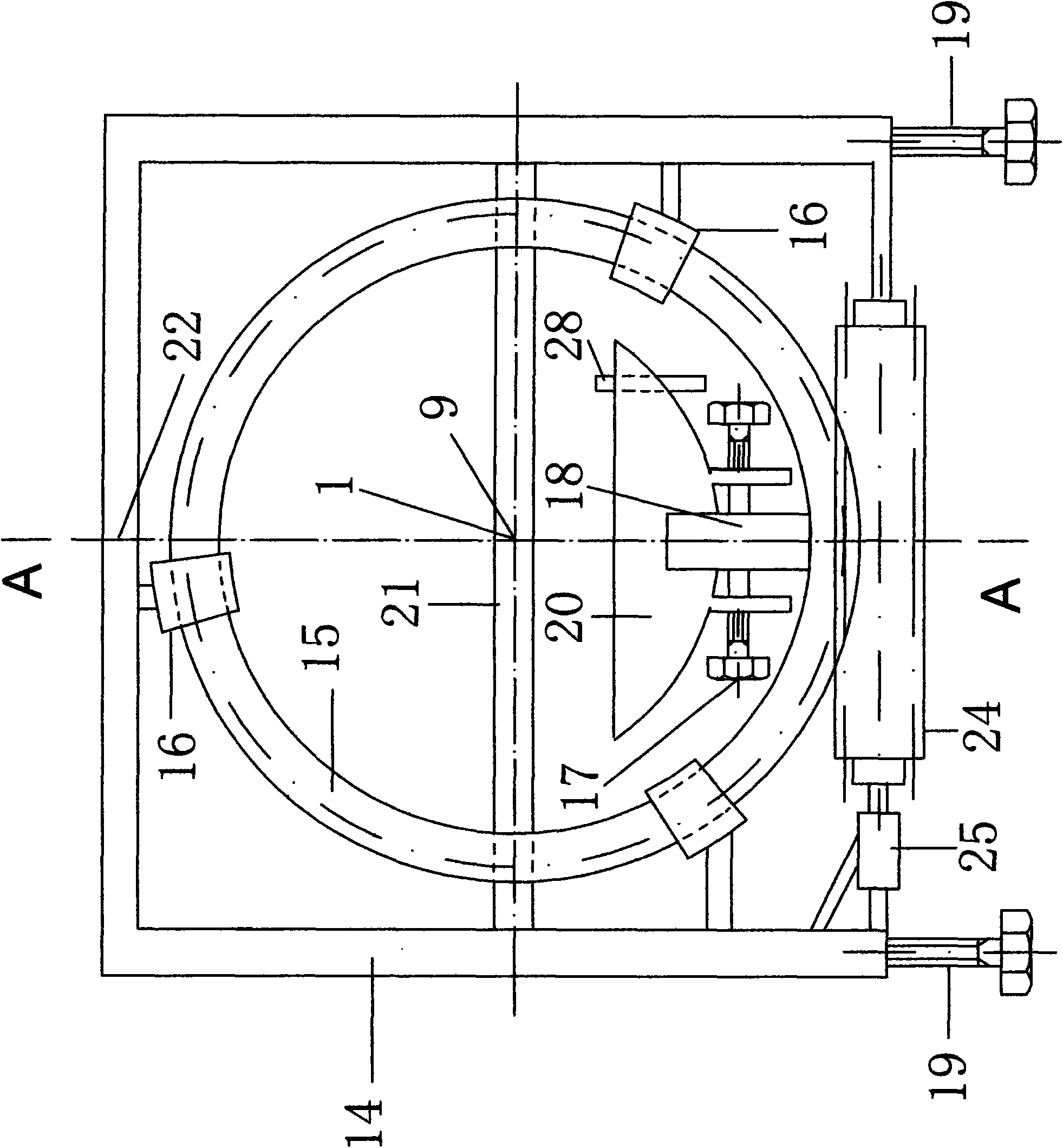

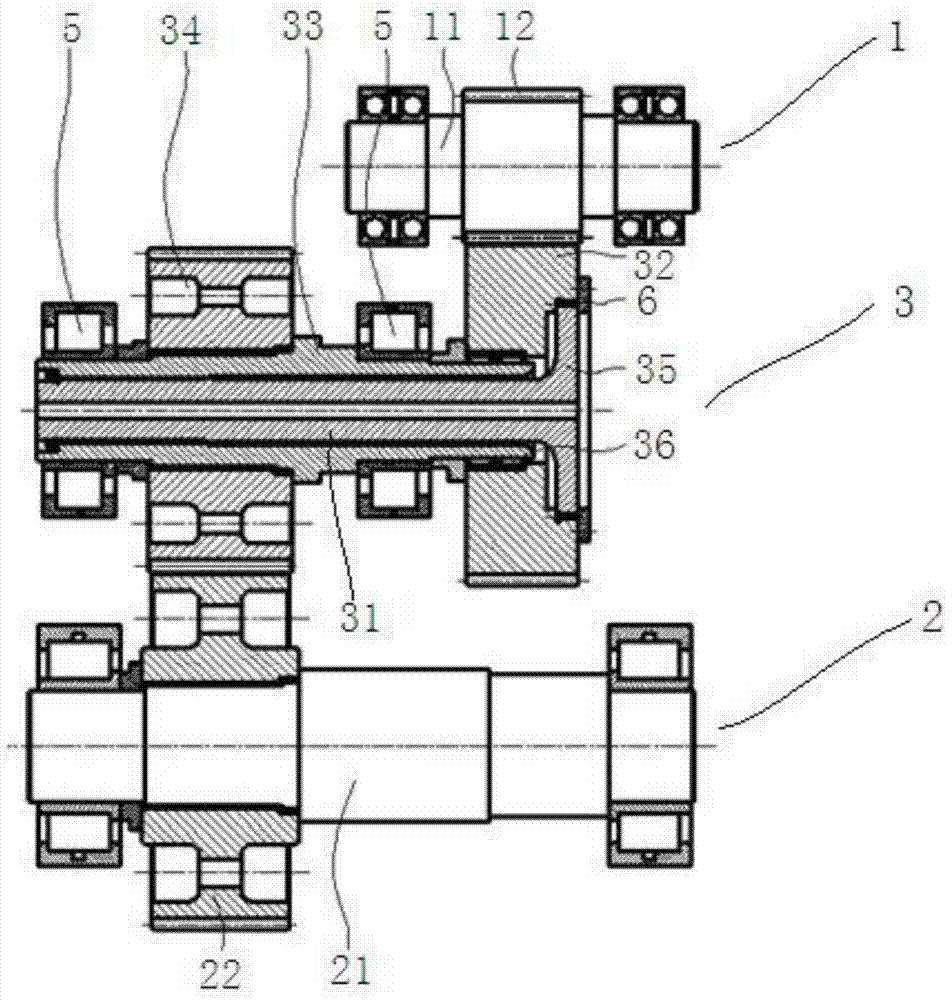

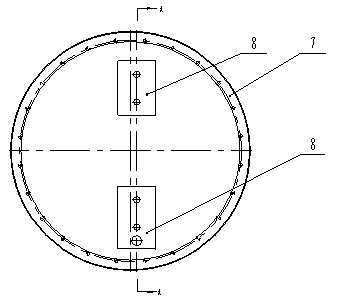

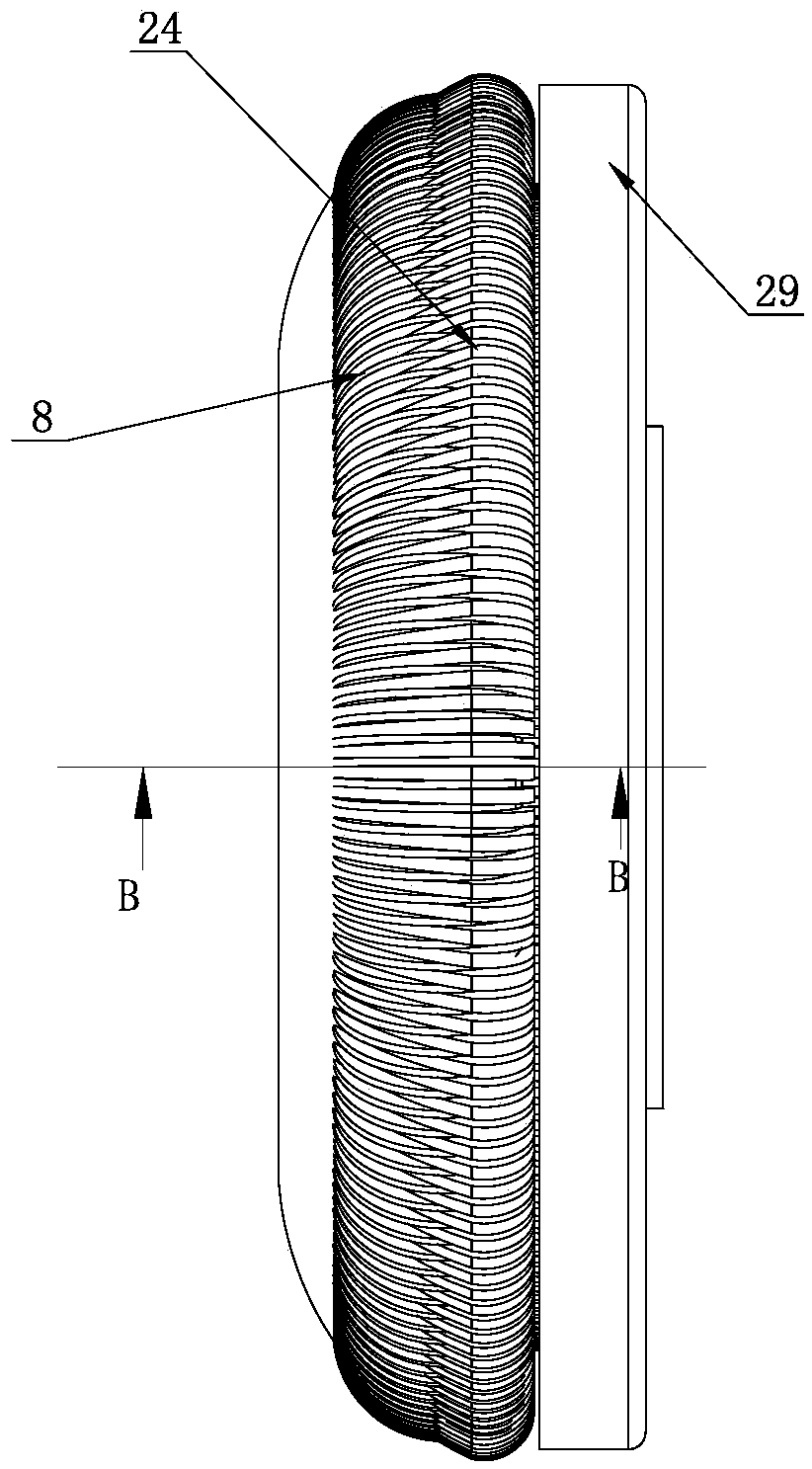

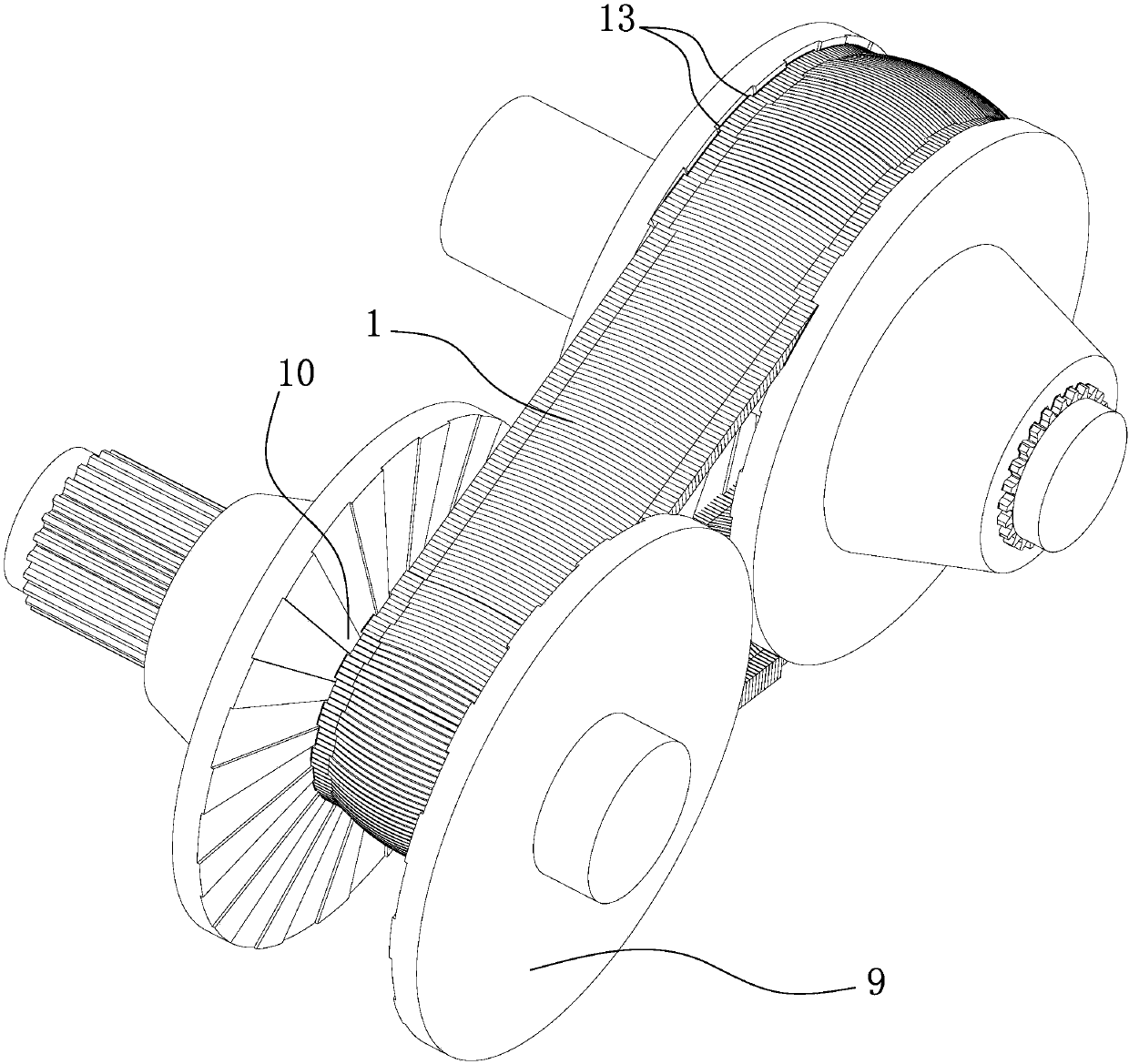

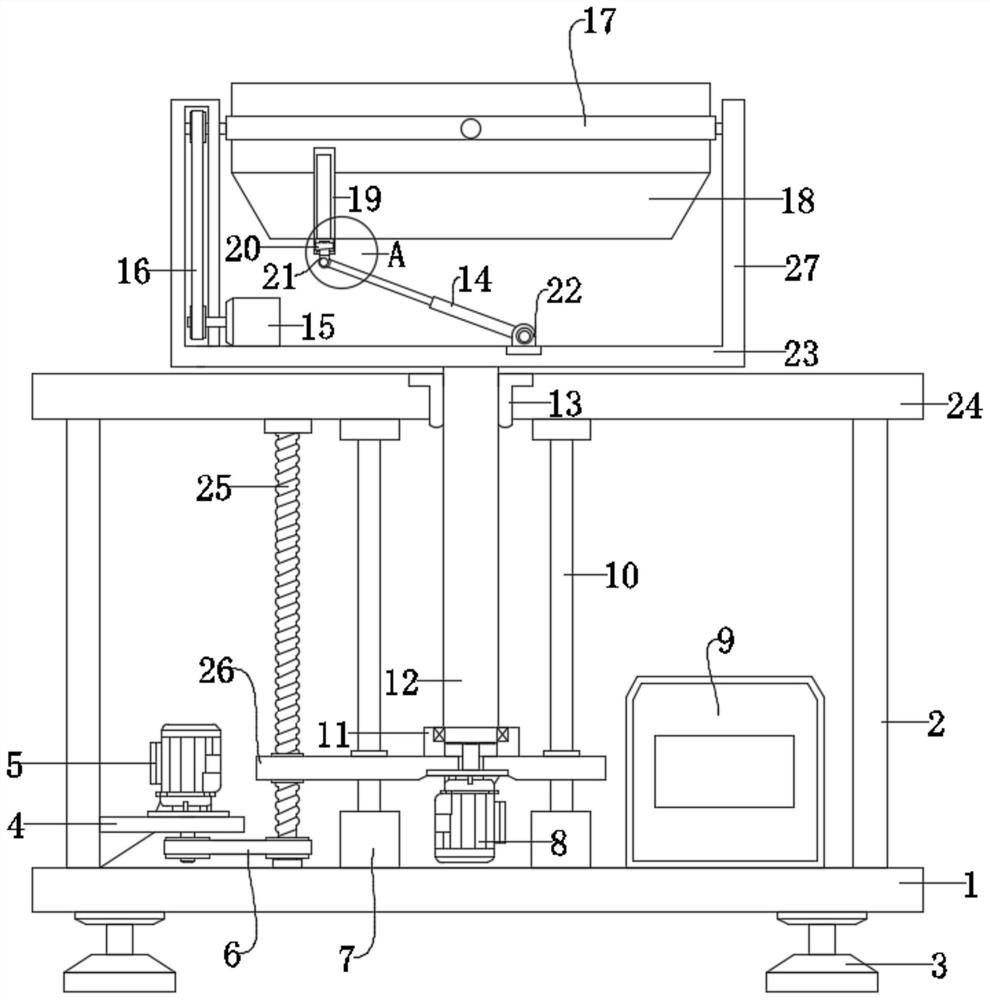

Moving roller-type circular mould granulator

InactiveCN102631866ASmall transmission torqueAvoid cross contaminationGranulation by pressingDrive motorEngineering

The invention belongs to the technical field of feed forming and processing, and relates to a moving roller-type circular mould granulator. The moving roller-type circular mould granulator mainly comprises a circular mould and a pair of parallel left compression roller and right compression roller horizontally arranged in the circular mould, wherein the left compression roller and the right compression roller are coaxially and fixedly connected with the middle parts of a left compression roller spindle and a right compression roller spindle; the left compression roller spindle and the right compression roller spindle are rotationally connected with a left compression roller support saddle and a right compression roller support saddle through bearings respectively; the compression roller spindle and the right compression roller spindle are independently driven by a left compression roller spindle drive motor and a right compression roller spindle drive motor respectively, and independently adjust a gap between the left compression roller and the right compression roller and the circular mould through compression roller sliding screw pairs respectively. The compression rollers disclosed by the invention are driving structures; the circular mould is a driven structure and the compression rollers and the circular mould are independently arranged on a base, thereby achieving adjustment of the gap between the circular mould and the compression rollers in a shutdown or non-shutdown state, avoiding cross contamination of the feed and butter, and being suitable for granulating of biomass raw materials such as the feed, sawdust, straw and the like.

Owner:CHINA AGRI UNIV

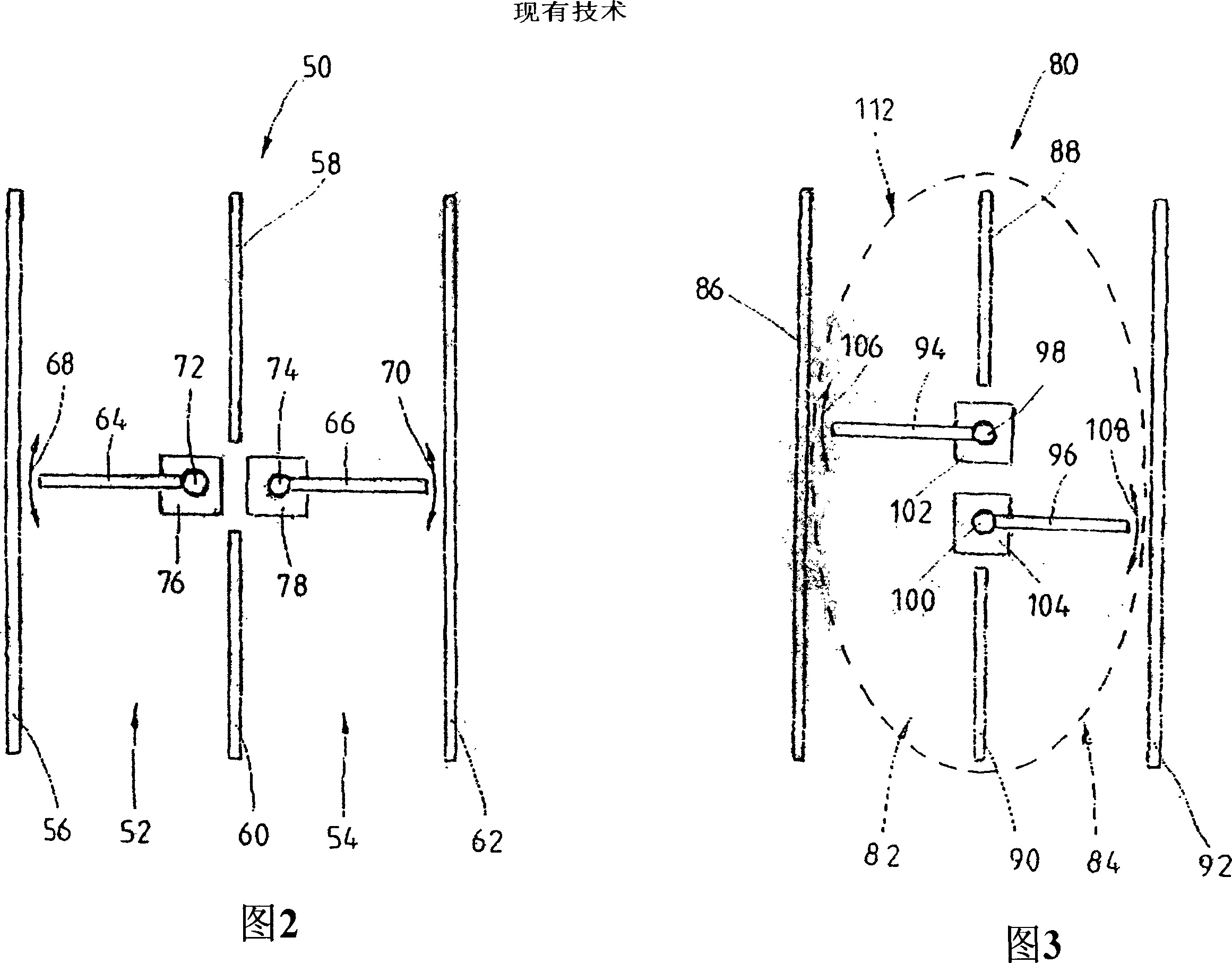

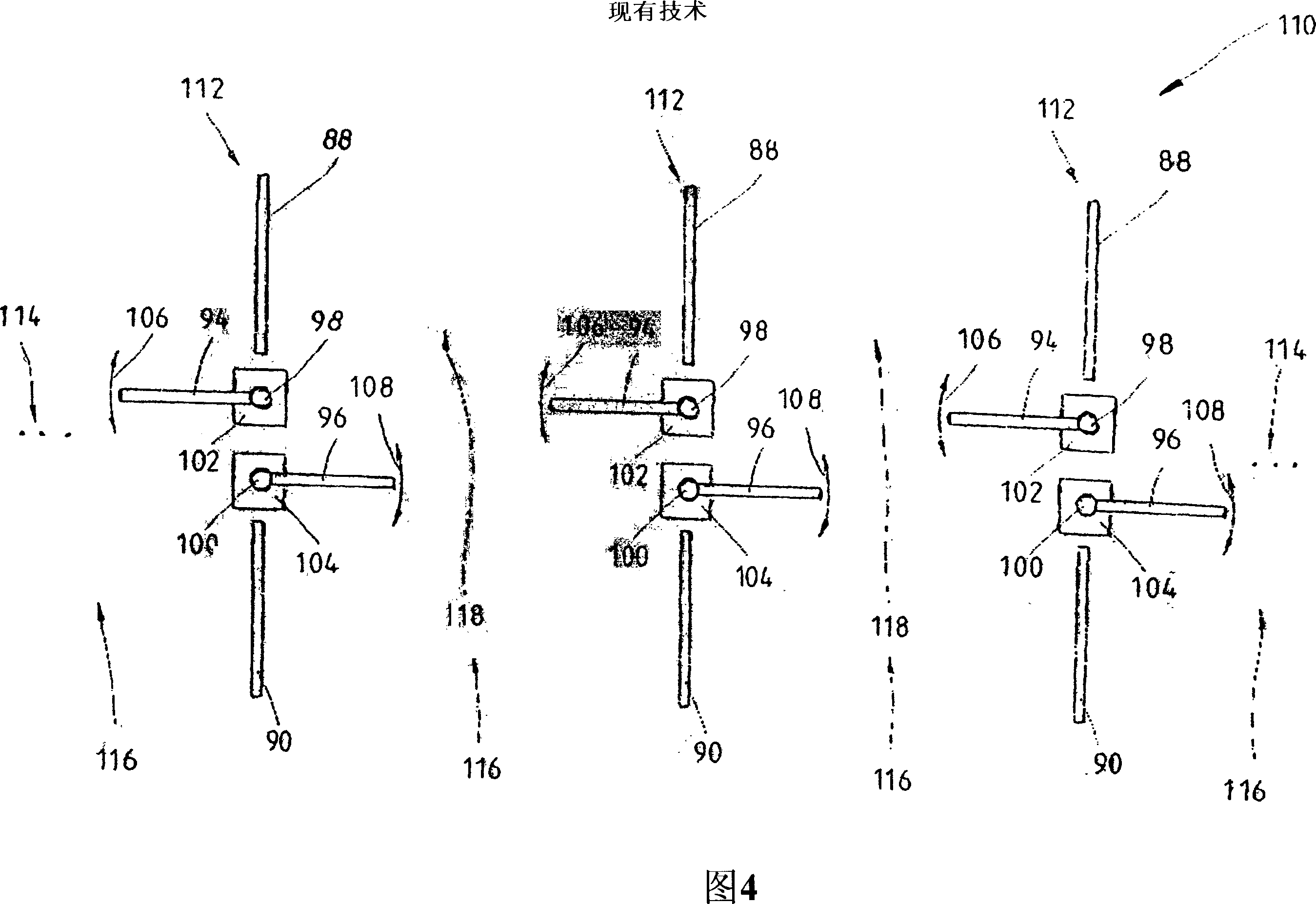

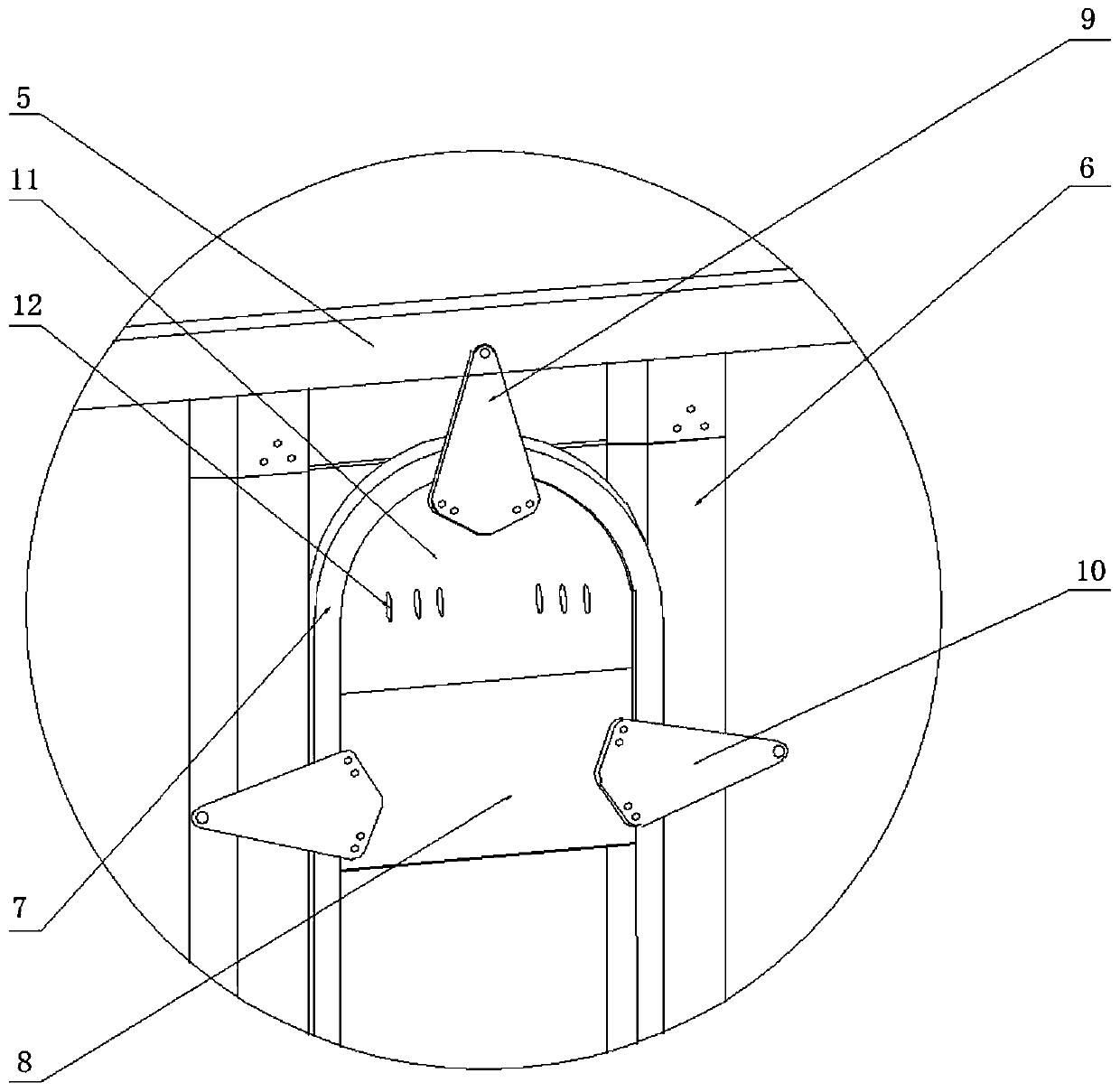

Passage barrier

InactiveCN101025068ASave construction spaceCompact structureRevolving doorsPower-operated mechanismEngineeringMechanical engineering

Owner:SCHEIDT BACHMANN GMBH

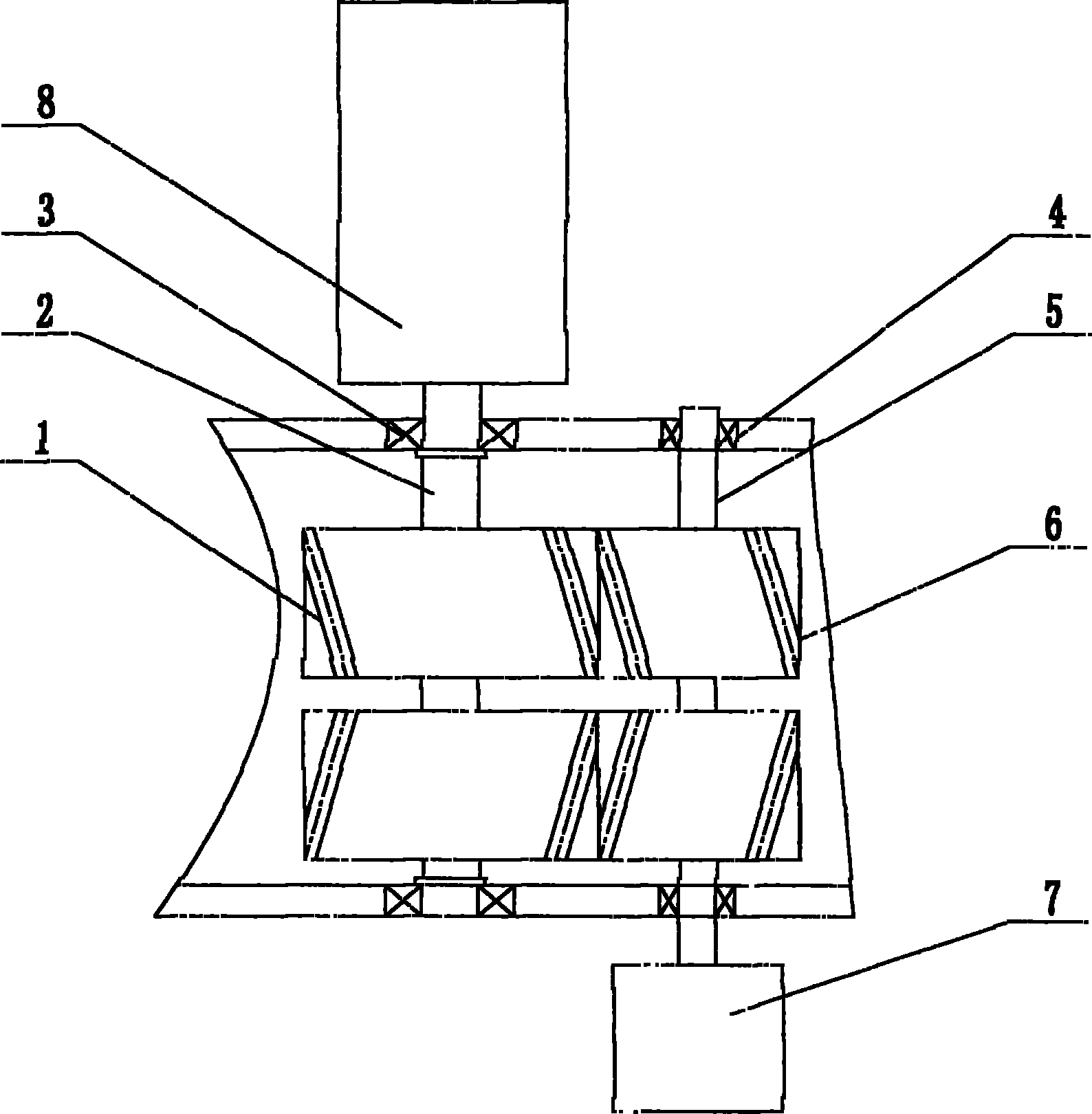

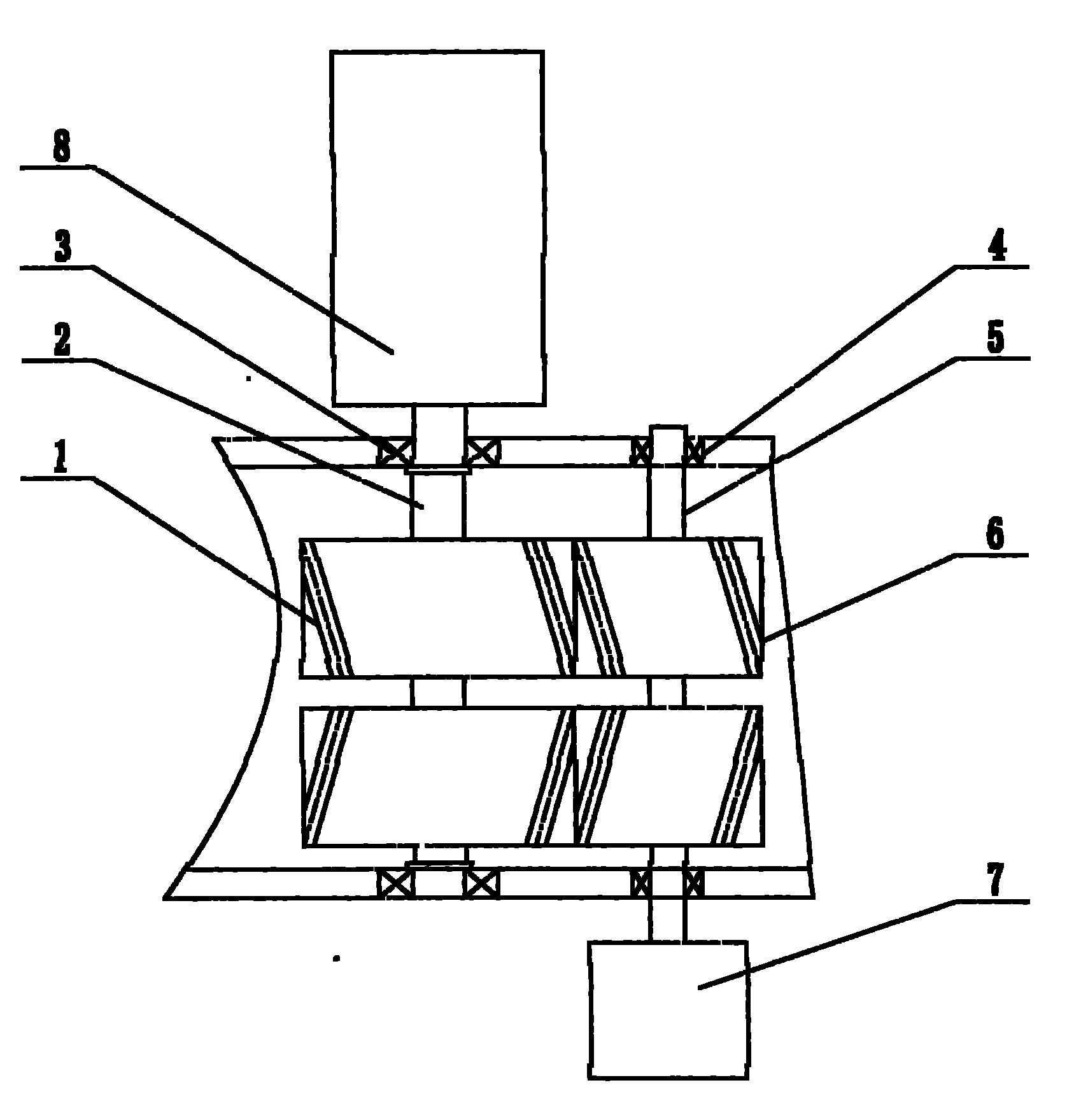

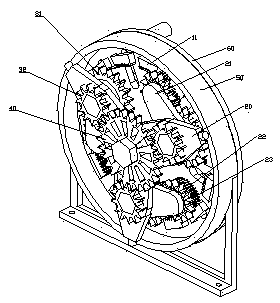

Speed-increasing gearbox of wind driven generator

InactiveCN101699065ASolution to short lifeImprove transmission efficiencyToothed gearingsMachines/enginesWind drivenLow speed

The invention relates to the improvement of a speed-increasing gearbox of a wind driven generator, which is characterized in that: a gear transmission has 3 to 4 stages, wherein the last stage is a planetary gear transmission; the former stages are all double-circular-arc cylinder herringbone spiral gear transmissions. Compared with the conventional generally-used speed-increasing gearbox which mainly uses the planetary gear transmission, because the low-speed stages (1 to 3 stages) adopt double-circular-arc cylinder herringbone spiral gears with high transmission efficiency and a subsequent stage adopts the planetary gear transmission, the advantages of the double-circular-arc cylinder herringbone spiral gear transmission and the planetary gear transmission are combined together, thus the effective one-off life is long, the transmission efficiency is high and the volume is small; and moreover, the double-circular-arc cylinder herringbone spiral gear is used for the speed-increasing gearbox of the wind driven generator for the first time.

Owner:YIXING HUATAI INT GRP IND

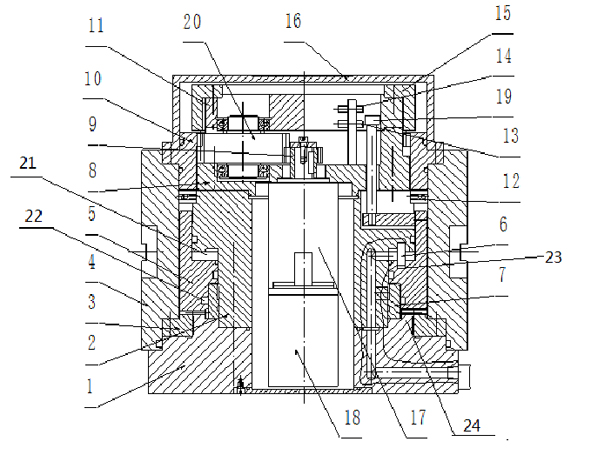

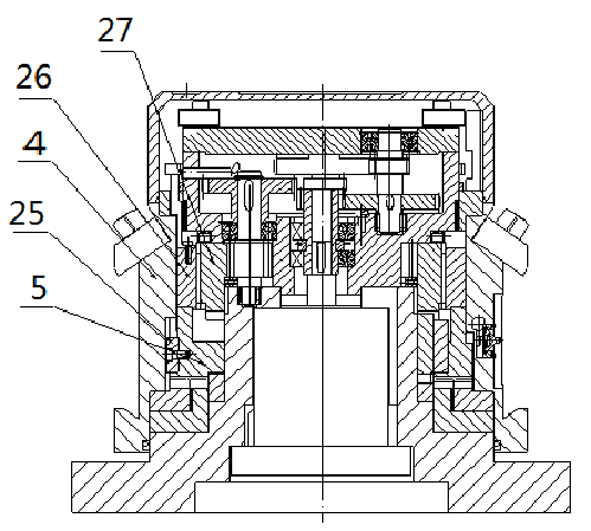

Vertical servo hydraulic tool rest

The invention discloses a vertical servo hydraulic tool rest, which comprises a base, cylindrical vertical shafts, a drive system, inner gear rings, tool stages and a braking and loosening component, wherein the inner sides of the lower ends of the tool stages are fixedly with a movable fluted disc respectively, while upper ends are fixedly connected with the inner gear rings; fixed fluted discs are arranged on the upper end face of the base between the movable fluted discs and the vertical shafts; meshing teeth are arranged on the upper end faces of the movable fluted discs and the fixed fluted discs; the inner gear rings and the tool stages are driven by the drive system to rotate; the drive system comprises a speed reducer, a servo motor, a drive gear and a transmission gear; the speed reducer and the servo motor are connected with each other and are arranged below a bearing block; the drive gear is arranged above the bearing block, and is connected with an output shaft of the speed reducer; and the transmission gear is arranged on the bearing block, is externally meshed with the drive gear and is internally meshed with the inner gear rings. The vertical servo hydraulic tool rest has the characteristics of small moment of inertia, stable rotation, large output torque and relatively larger braking torque.

Owner:烟台环球机床装备股份有限公司

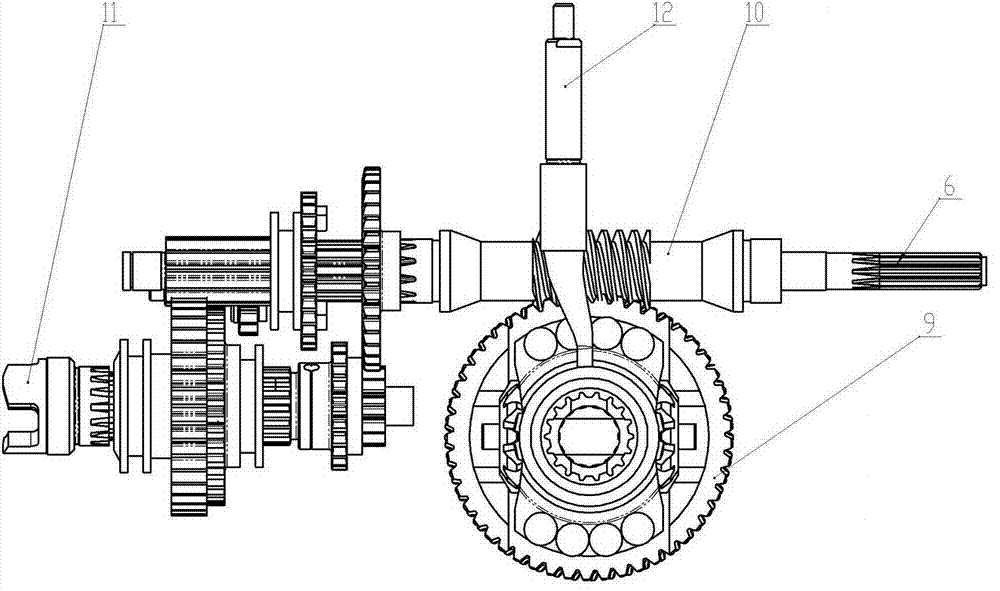

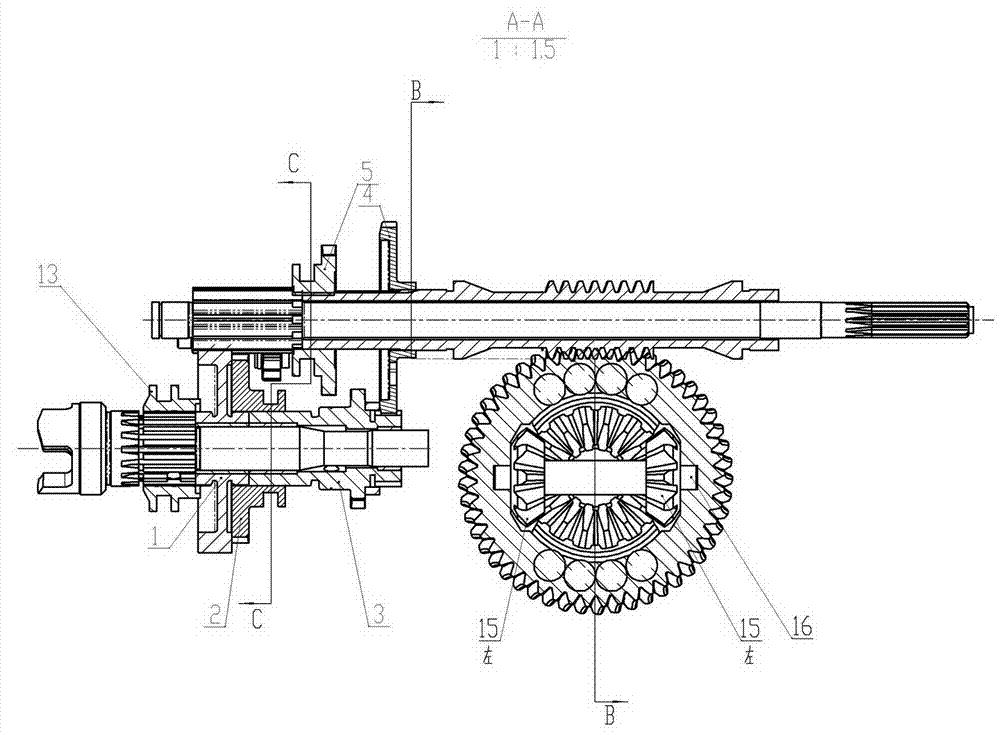

Horizontal gearbox for micro-cultivators

InactiveCN103032529AFlexible steeringImprove safety performanceAgricultural machinesToothed gearingsGravitationFruits and vegetables

The invention discloses a novel gearbox which is horizontal and characterized in that an operating power transmission case is separated from a travel steering device and has a differential lock function. The horizontal gearbox mainly consists of a gearbox housing, a gear wheel shaft, a hollow worm, a rotary cultivator power shaft, a steering mechanism, a travel box and a power output shaft. With the technical scheme of the invention, the micro-cultivator has a flexible steering function, and the safety is greatly improved; since the differential mechanism is only used for travel and steering operations, the transfer torque is reduced and thus the failure rate is extremely low; owing to the differential lock mechanism, the micro-cultivator can work in complicated working places and is not liable to skid during travel; and with the horizontal structure, the center of gravity of the machine is lowered, and the micro-cultivator can meet the requirements for working in a mountain area or in a narrow space of a fruit and vegetable greenhouse.

Owner:JIAOZUO KAIER TRACTOR MFG

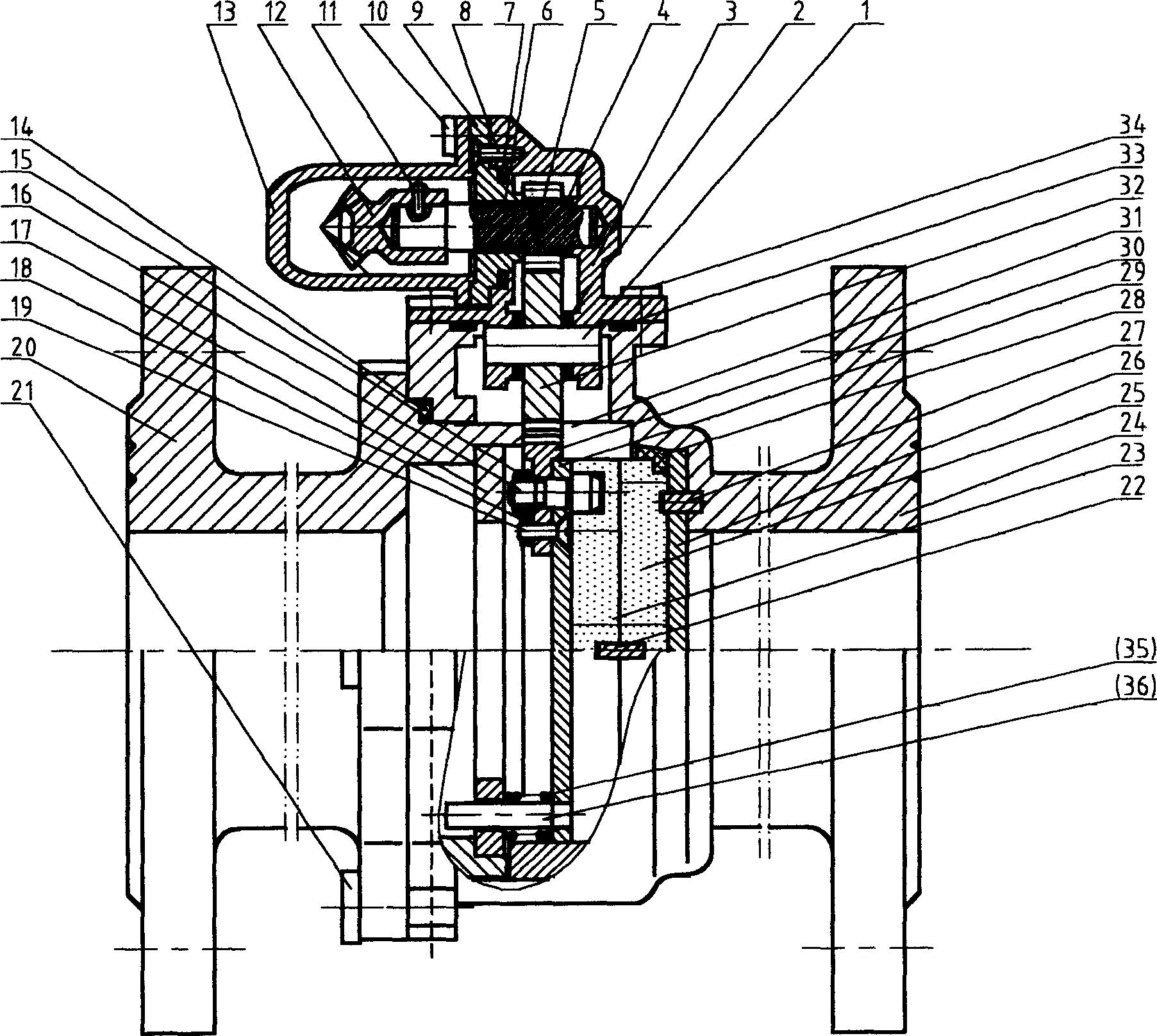

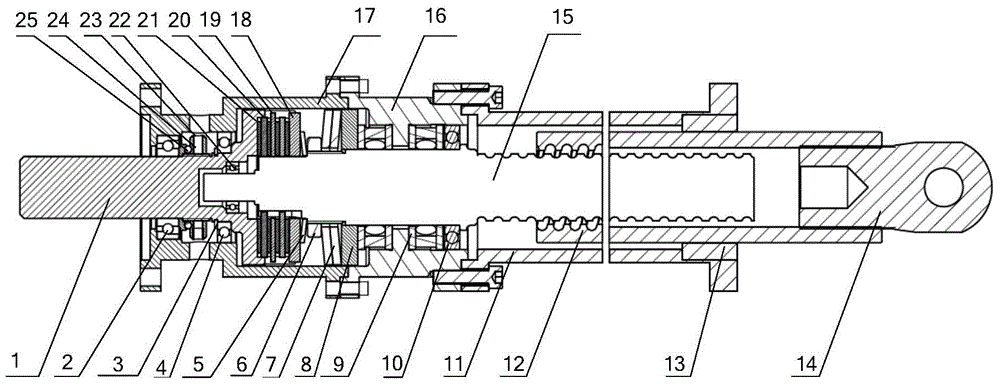

Spinning stop valve

InactiveCN1548794ASmall transmission torqueReduce power consumptionOperating means/releasing devices for valvesSlide valveWheel and axleBevel gear

The present invention discloses one kind of rotating pressure type cut-off valve technology, and aims at solving the technological problem of liquid leakage. The rotating pressure type cut-off valve consists of transmission shaft, bevel gears, driving gear shaft, driven gear shaft, segment gear, moving valve sheet and static valve sheet forming sealing, compression spring, protecting board, connecting board, valve body and other parts. The valve of the present invention is suitable for water, oil and other fluid medium with pressure of 0.01-3.7 MPa pressure and has good sealing performance.

Owner:王洪生

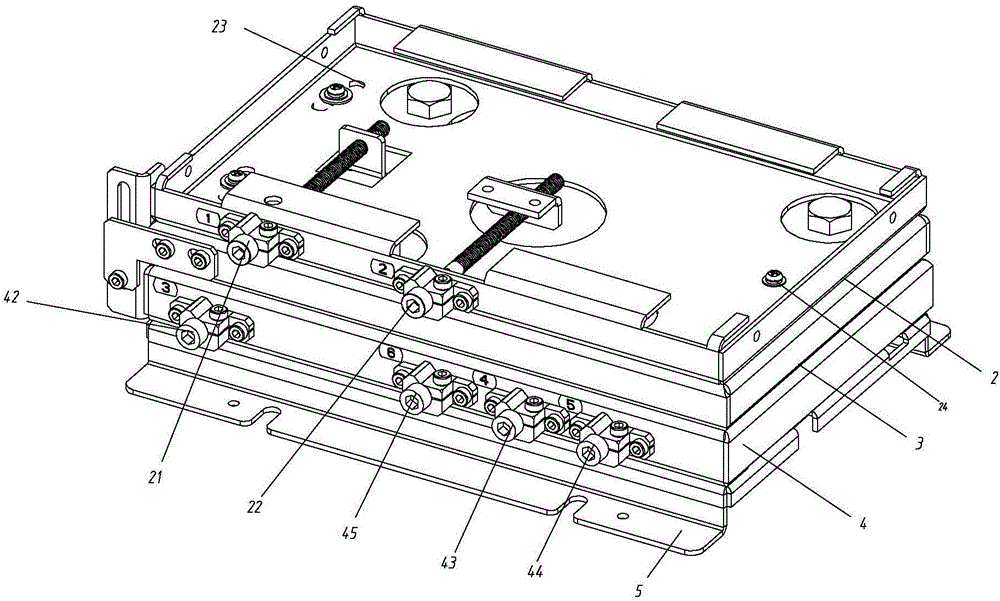

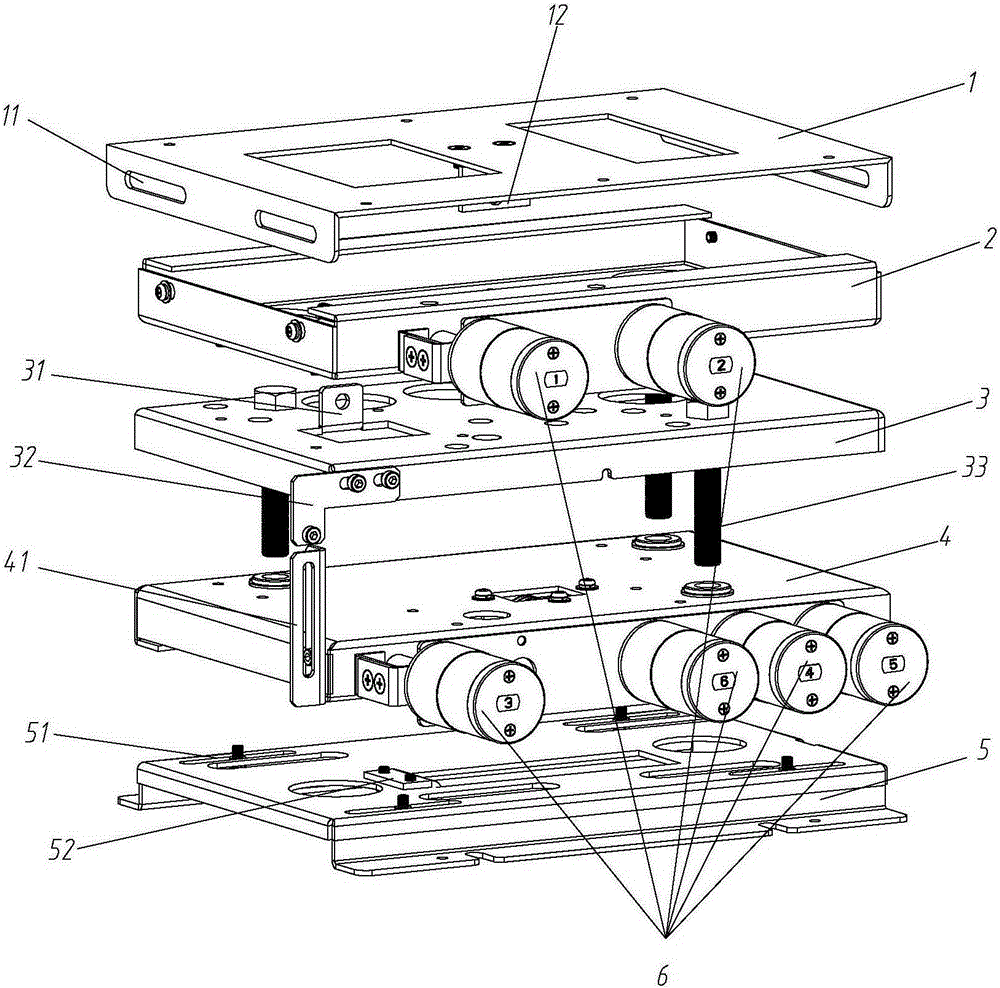

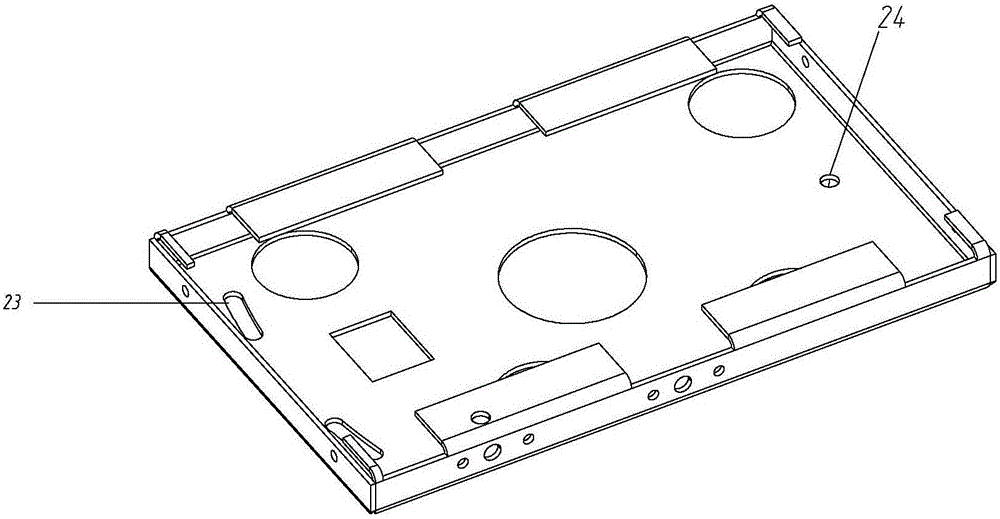

Wireless remote control electric six-shaft adjusting platform

ActiveCN105114773AImprove verticalityHigh precisionProjectorsStands/trestlesProduction scheduleRemote control

The invention relates to an adjusting device, in particular to a wireless remote control electric six-shaft adjusting platform applied to a DLP large-screen splicing system. The wireless remote control electric six-shaft adjusting platform comprises a supporting plate, a first adjusting plate, a fixing plate, a second adjusting plate and a bottom plate which are sequentially connected from top to bottom in the vertical direction, wherein the supporting plate is provided with an L-type support, the first adjusting plate is provided with two shafts in the horizontal transverse direction, a vertical support is arranged on the upper surface of the fixing plate, three vertical threaded rods are arranged on the lower surface of the fixing plate, the second adjusting plate is provided with four shafts in the horizontal transverse direction, and a horizontal longitudinal threaded rod is fixed to the bottom plate. One ends of the six shafts of the first adjusting plate and the second adjusting plate are connected with an output shaft of a wireless remote control motor. According to the adjusting device, a remote control unit is used for controlling the motor to adjust the six shafts to adjust the platform, adjusting is easy and convenient, and time and labor are saved; after adjusting is finished, by means of a locking device, displacement situations such as deflection, loosening and sinking are avoided permanently; the adjusting device is lighter, efficient and high in adjusting precision, and saves labor, and a noise-free adjusting mode is adopted; the adjusting efficiency is high, and the production schedule is shortened.

Owner:杭州矽晶科技有限公司

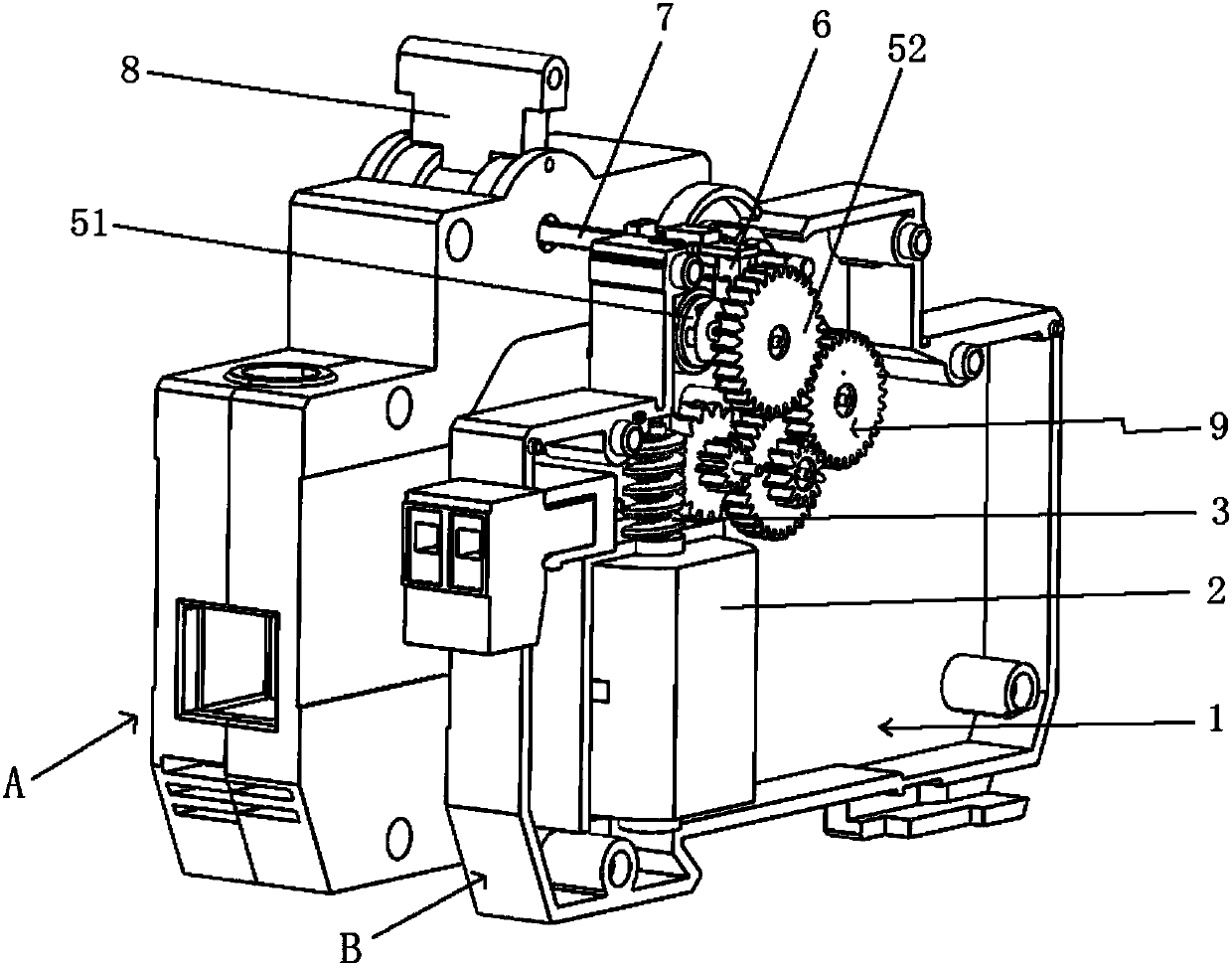

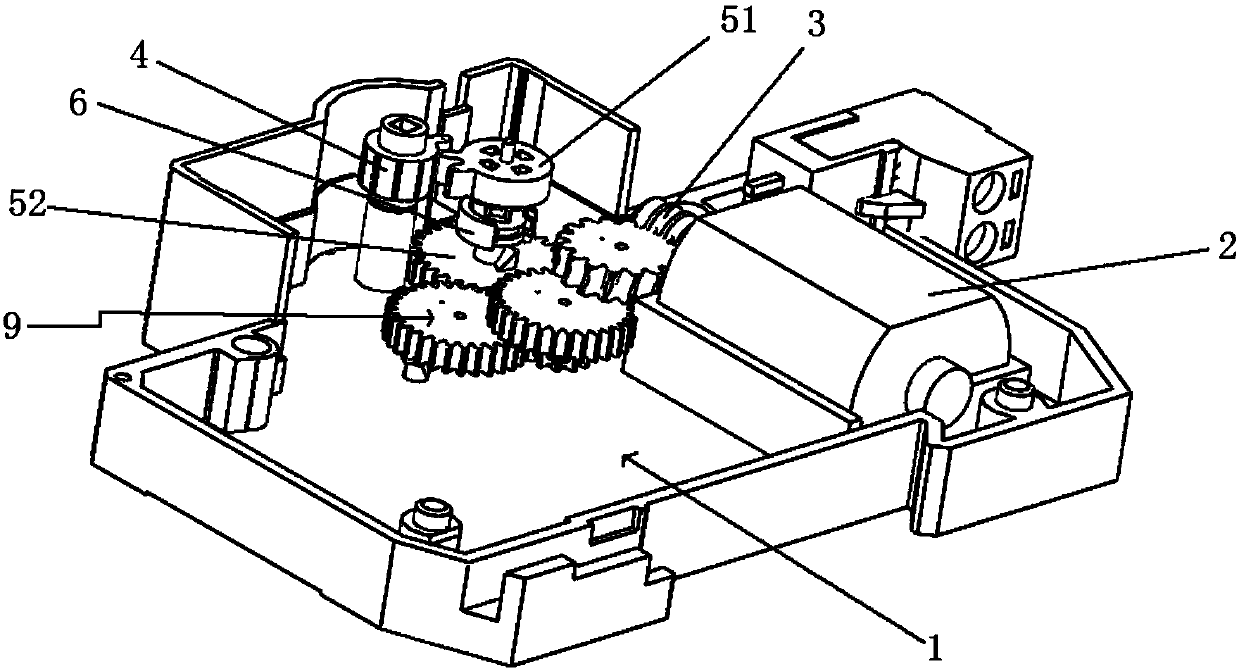

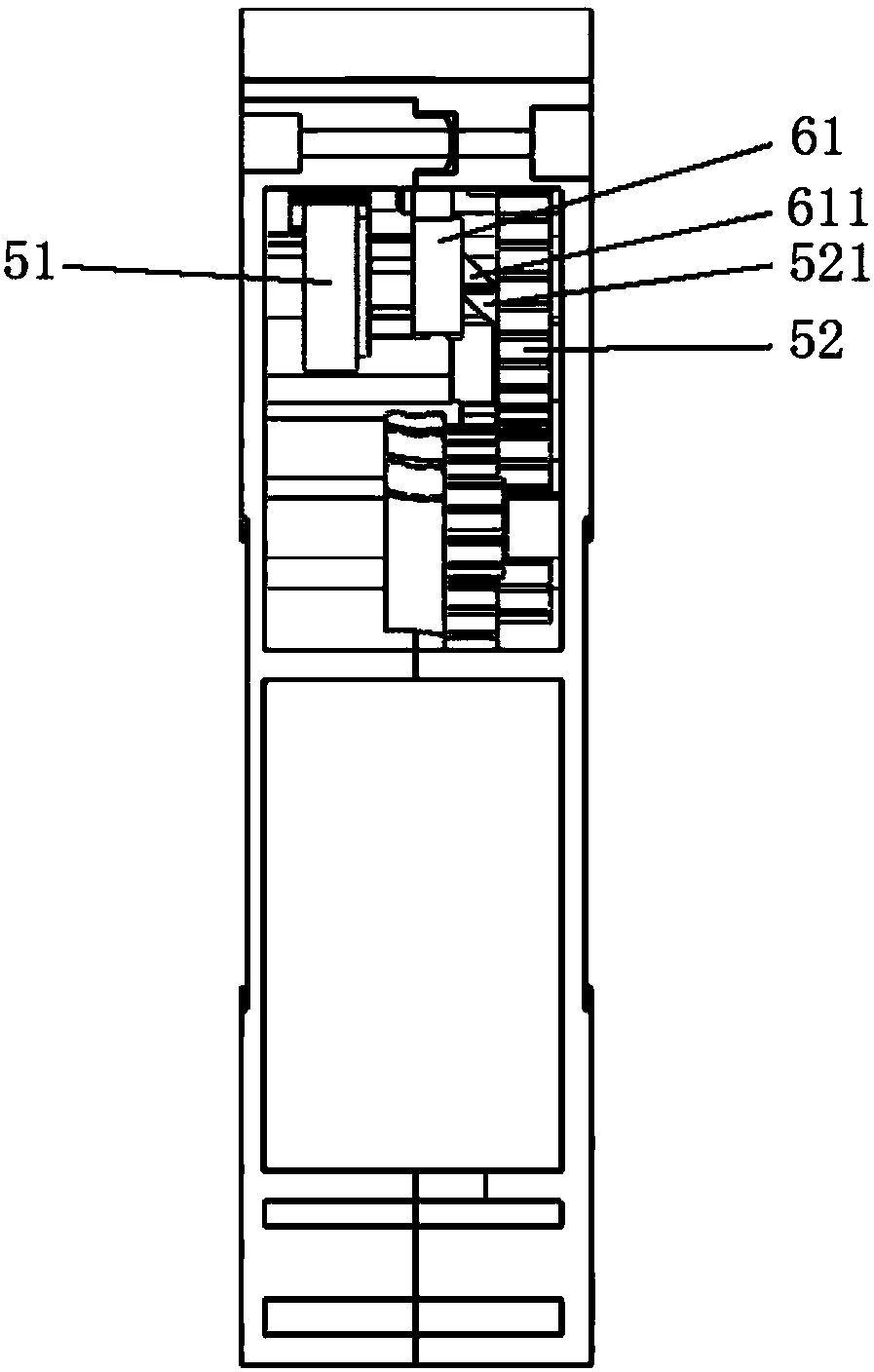

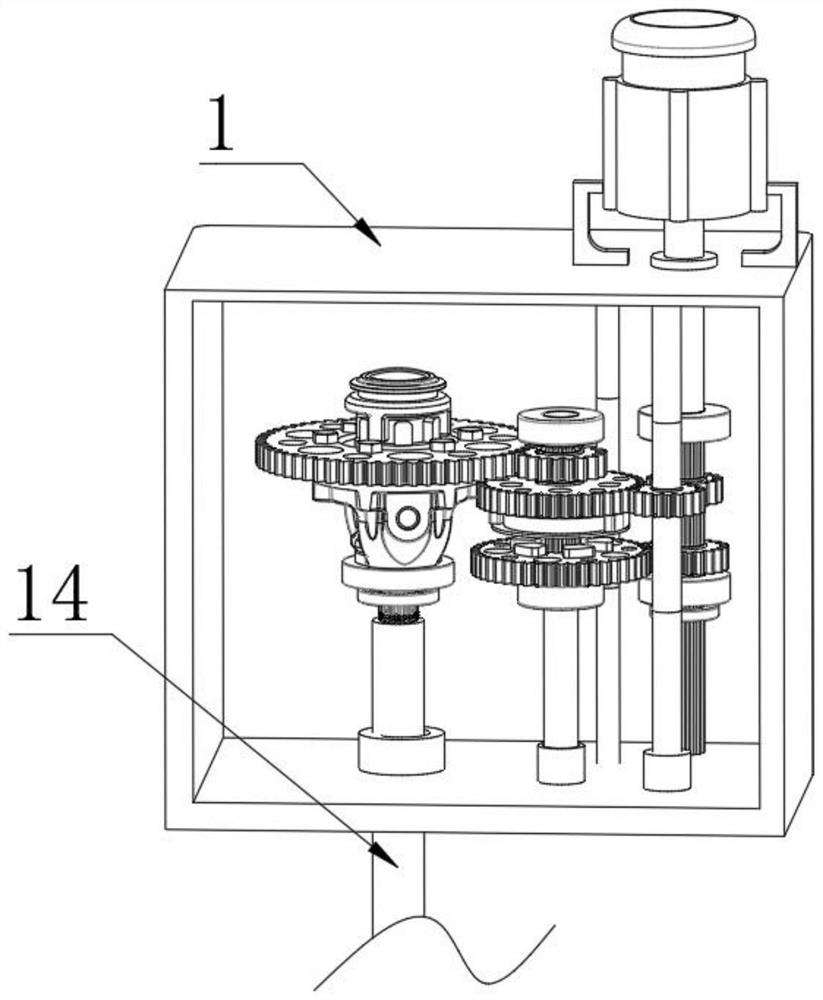

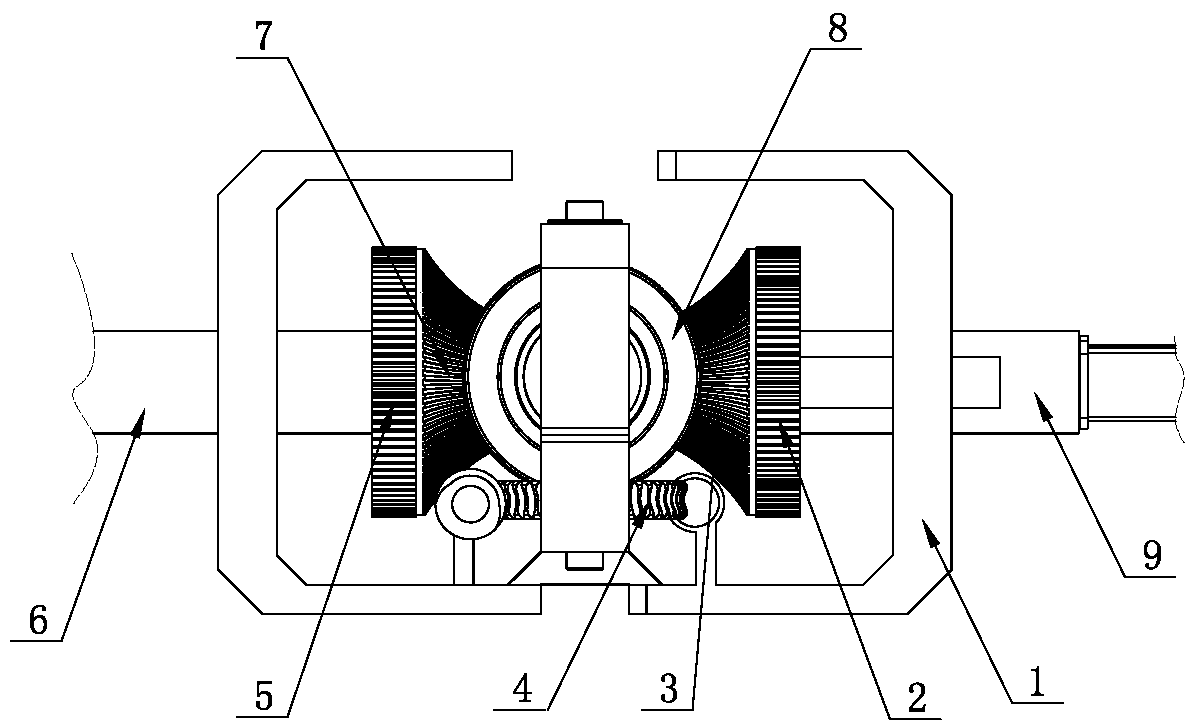

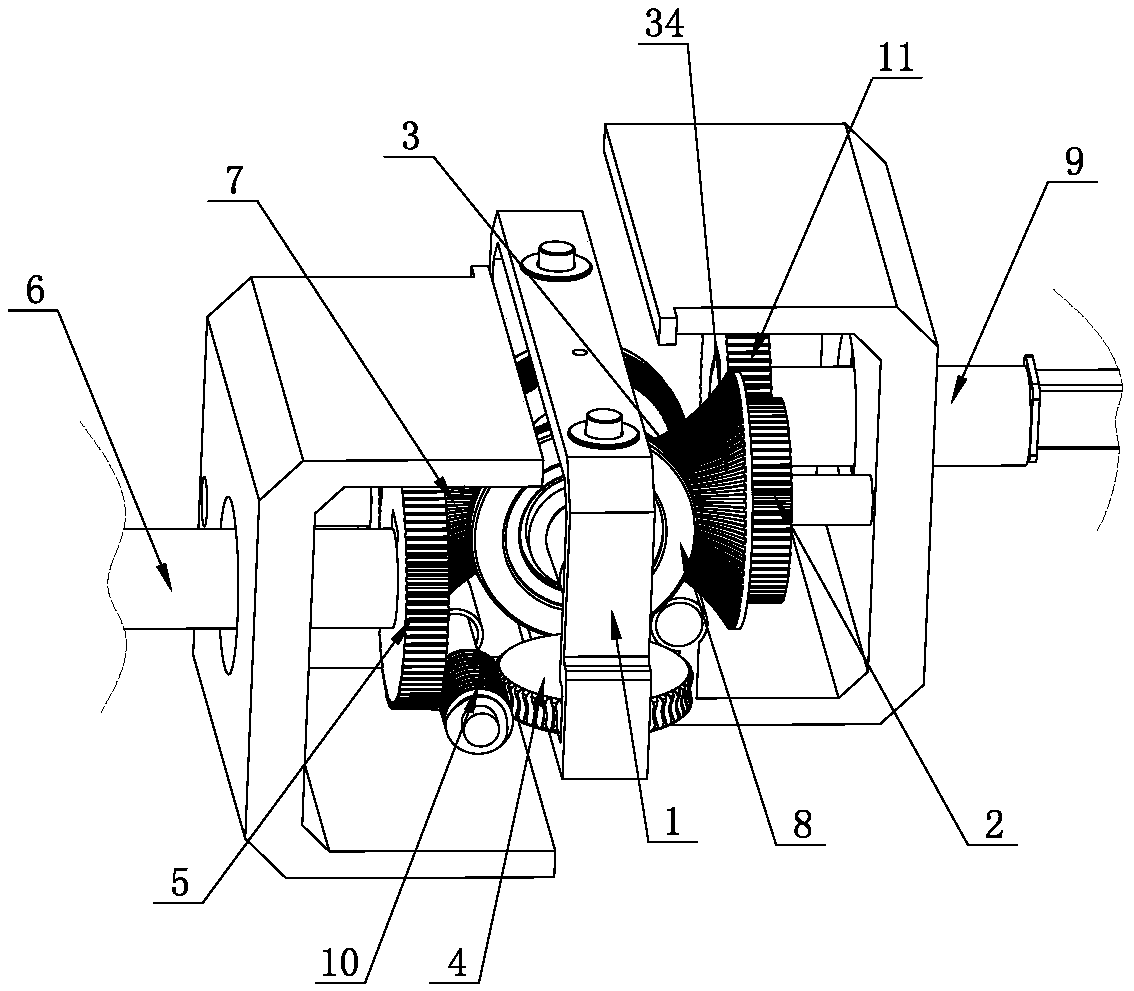

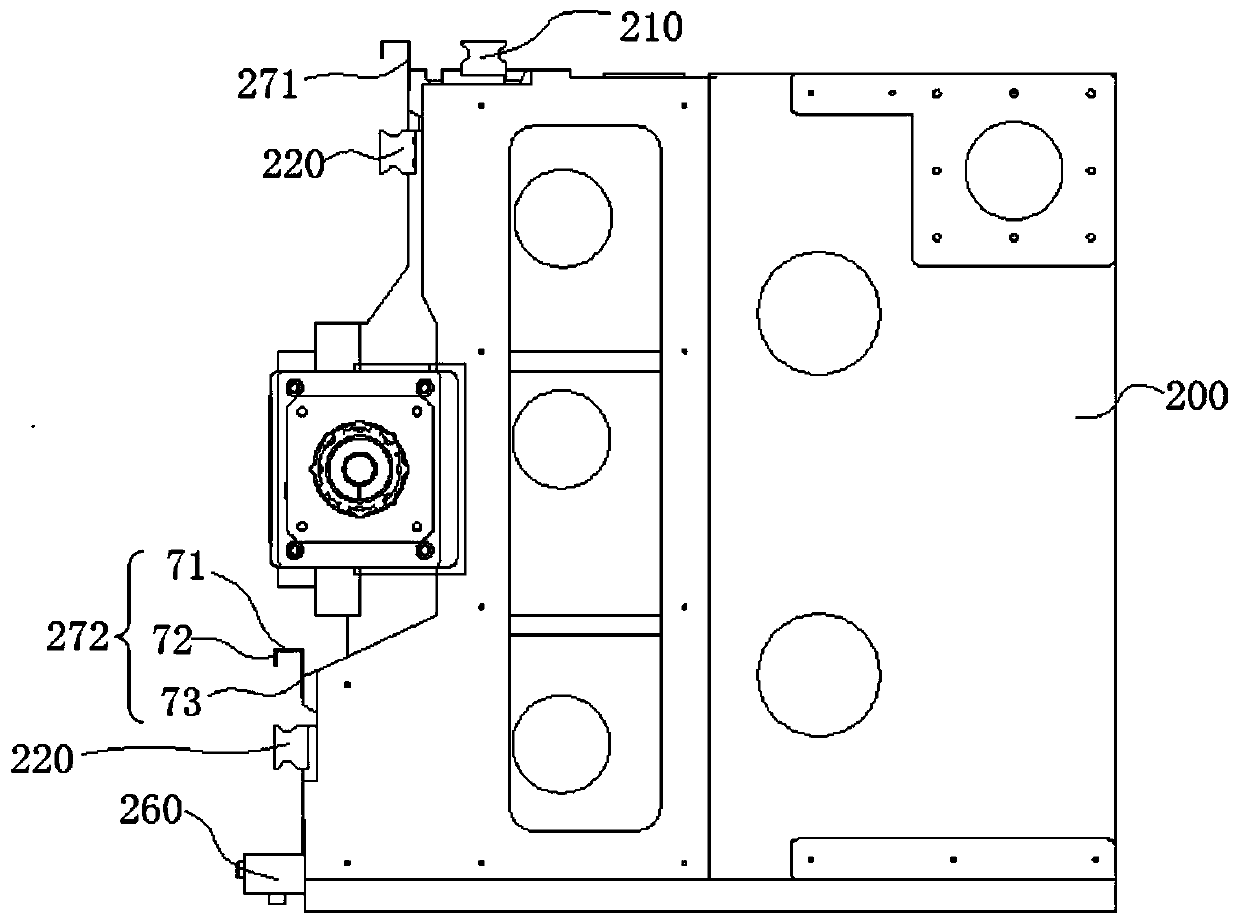

Opening and closing transmission device with clutch function, and breaker

InactiveCN107610986AOvercome the phenomenon of not being able to moveSmall transmission torqueContact mechanismsProtective switch operating/release mechanismsControl systemDrive motor

The invention discloses an opening and closing transmission device with a clutch function, and a breaker. The device includes a shell, and a driving motor, a breaker handle mechanism and a gear transmission mechanism that are arranged in the shell, and a shifting lever switching structure; the shifting lever switching structure comprises a shifting lever part and a linkage part, the linkage part can move between the first driven gear and the second driven gear in a cooperated reciprocating telescoping mode under the driving of the shifting lever part, and has a first position state enabling the first driven gear and the second driven gear to form a coaxial linkage fit, and a second position state enabling the first driven gear and the second driven gear to release the linkage relation. Theshifting switching structure can overcome the problem that the breaker handle cannot be shifted due to clamping and blocking, manual and automatic mode switching can be truly realized without being controlled by an external power supply, the control system is simplified, the manufacturing cost is saved, the use is convenient, and the usability of the product is improved.

Owner:温州市正松电气有限公司

Double-shaft jaw clutch

PendingCN106321681AReasonable designSimple and smart structureMagnetically actuated clutchesRack and pinionRotating disc

The invention discloses a double-shaft jaw clutch. The double-shaft jaw clutch comprises a casing provided with an excitation coil, a mounting seat connected with the casing, an input shaft and an output shaft, wherein the input shaft is arranged on the inner end surface of the mounting seat and provided with an input rotating disc; the output shaft is arranged on the inner end surface of the casing and provided with an output rotating disc; an armature is connected with one end, close to the output rotating disc, of the input rotating disc; a spring seat is arranged in the center of the casing; multiple grooves are uniformly distributed in the casing and located in the circumferential direction of the periphery of the spring seat; a spring hole opposite to the spring seat is formed in the end surface center, close to the armature, of the output rotating disc; two racks distributed at a 180-degree angle are arranged on the output rotating disc and located on the periphery of the spring seat; the racks are embedded into the two corresponding grooves in a matched manner; disengaging springs are mounted in the spring seat and the spring hole in a matched manner. The double-shaft jaw clutch is simple in structure, small in size, light in weight, reasonable in layout and good in reliability.

Owner:SHAOXING IND SCI DESIGN & RES INST CO LTD

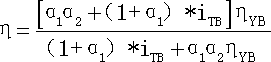

Engine and motor power coupling mechanism and automobile

InactiveCN111409442ASimple structureLow costHybrid vehiclesGas pressure propulsion mountingAutomatic transmissionGear wheel

The invention discloses an engine and motor power coupling mechanism and an automobile. The engine and motor power coupling mechanism comprises an engine, a motor, a one-way clutch, a brake, a lockupclutch and a planetary gear mechanism, wherein the planetary gear mechanism comprises a gear ring, a sun gear and a planet carrier; the engine is connected with the gear ring and the gear ring connecting shaft through an output shaft and the one-way clutch; one end of the brake is fixed to the shell, the other end of the brake is connected with the output shaft and the one-way clutch, and a rotorof the motor is connected with the sun gear and the lockup clutch into a whole through a sun gear connecting shaft; and the planetary gear mechanism is used for coupling power of the engine and the motor and is connected with an automatic transmission through the planet carrier and the input shaft. The mechanism has the advantages of being compact in structure and improving the power performance of the automobile at a low gear.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

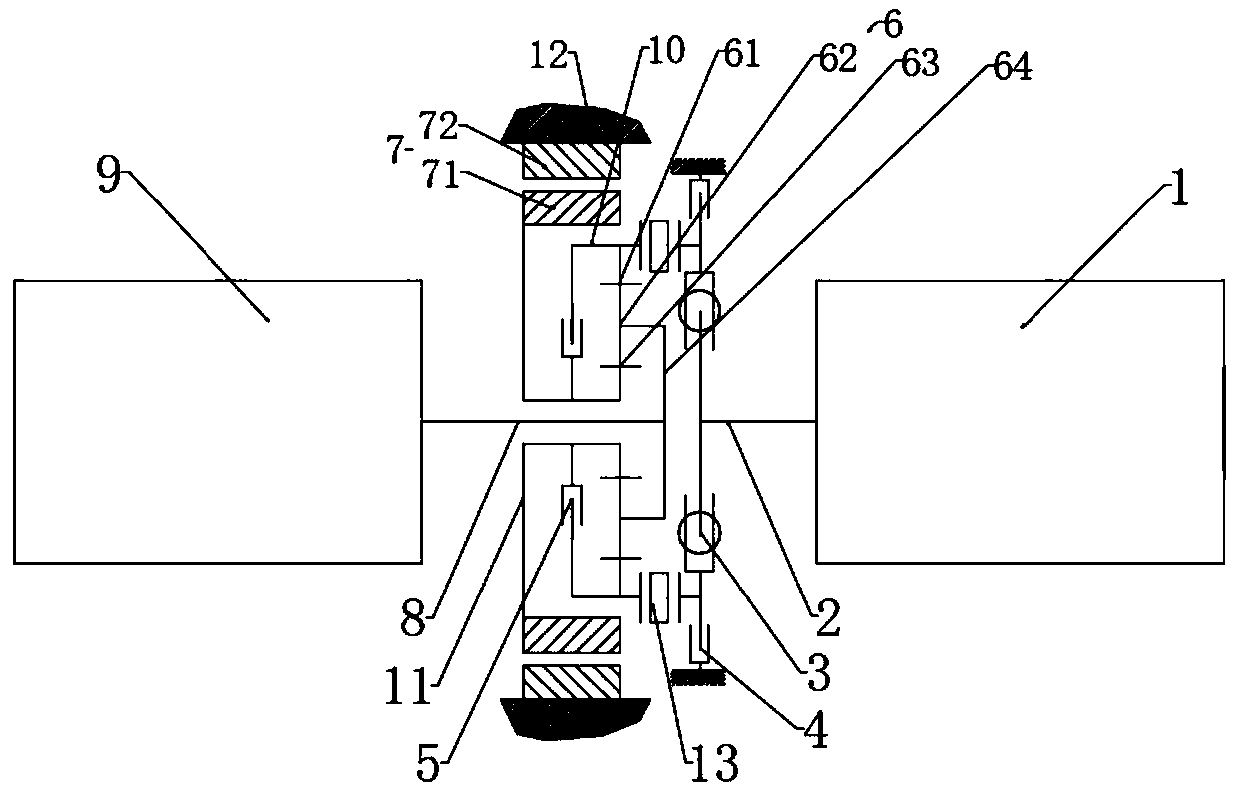

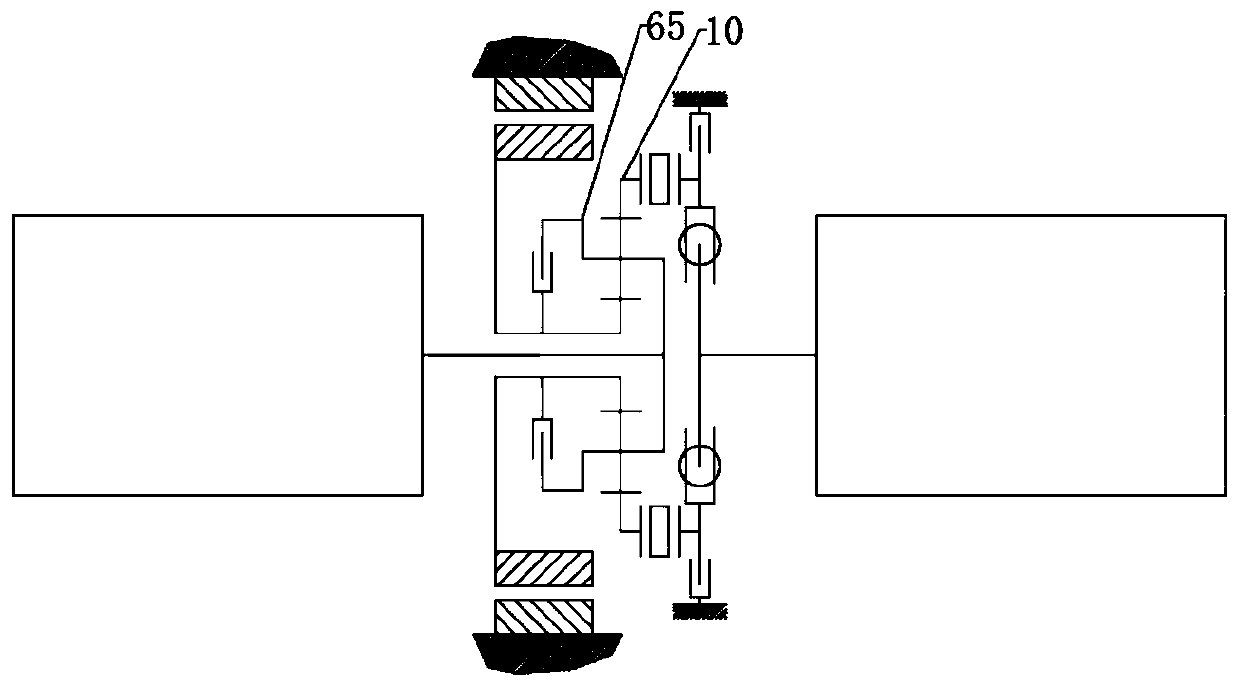

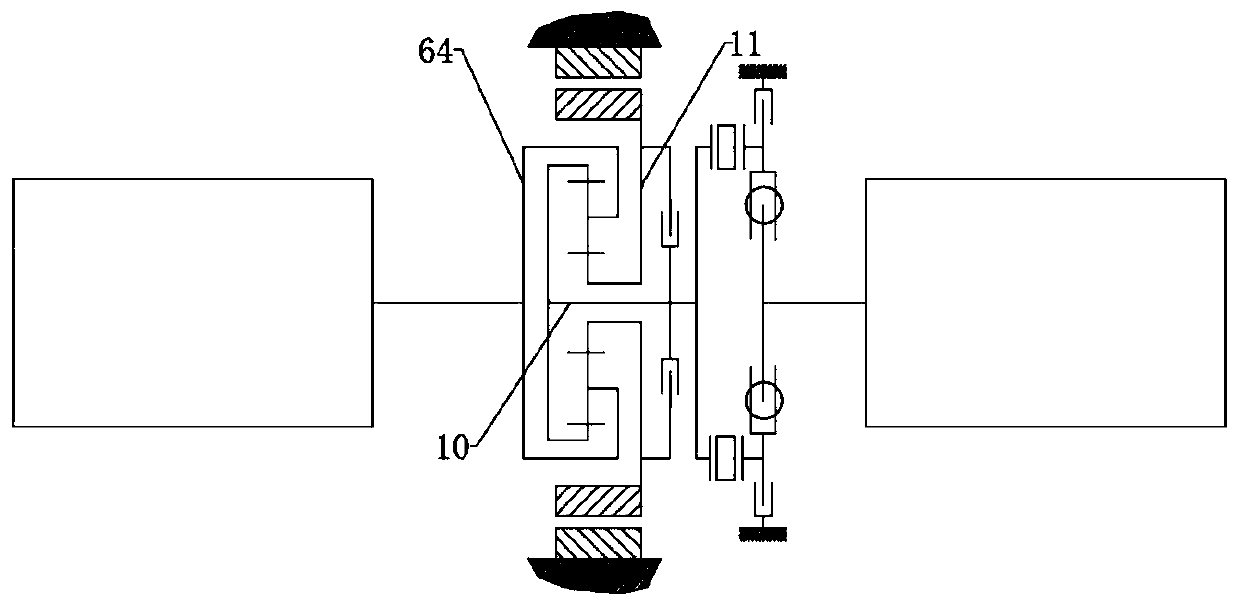

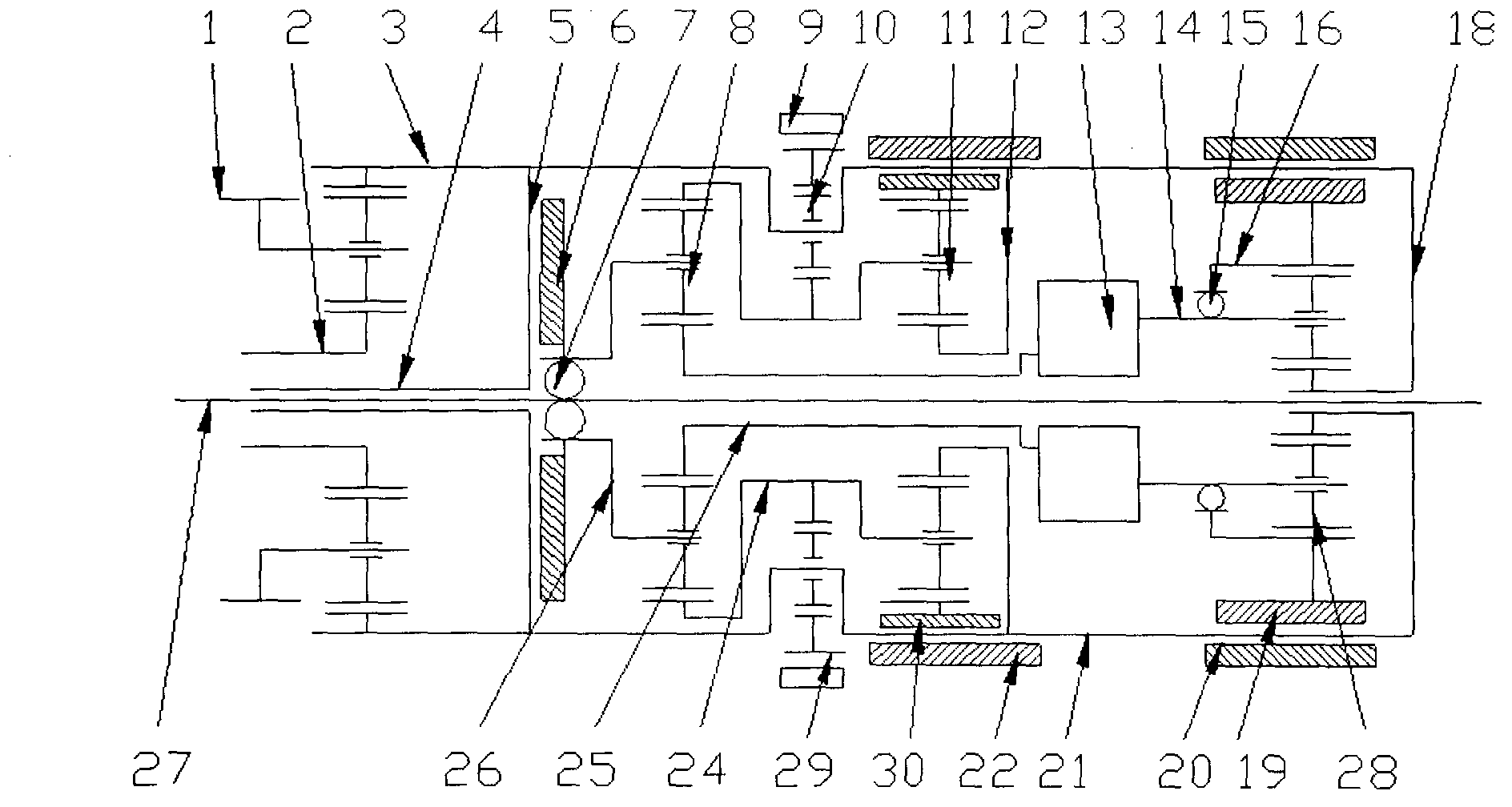

Drive control mechanism of permanent magnetic and gear compound drive continuously variable transmission

The invention relates to a drive control mechanism of a permanent magnetic and gear compound drive continuously variable transmission. A distribution planet row is arranged to divide the power required to be transferred into two ways, one way is that the power is fed back directly through gear drive, and the other way is that the power is fed back through a permanent magnetic slip frequency drive mechanism; a planetary gear system mechanism is designed in the two ways, and is used for transferring power between driving and driven mechanisms of the continuously variable transmission and acquiring different drive specific values according to working station exchange, so that the rotation speed difference of the driving and driven elements of the permanent magnetic slip frequency drive mechanism is less so as to acquire higher efficiency; and the torque of the continuously variable transmission varies continuously along with the drive ratio. The specific structure characteristics are that the drive control mechanism of the permanent magnetic and gear compound drive continuously variable transmission consists of the distribution planetary row 8, a low-speed planetary row 10, a speed-reduction planetary row 11, the permanent magnetic slip frequency drive mechanism 13, a coupling planetary row 28, two overrunning clutches 10 and two permanent magnetic flexible locking mechanisms, and is applied to the fields of vehicles, wind power generating systems, aircrafts, machine tools, industrial and mineral machinery, engineering machinery and the like.

Owner:NANJING INST OF TECH

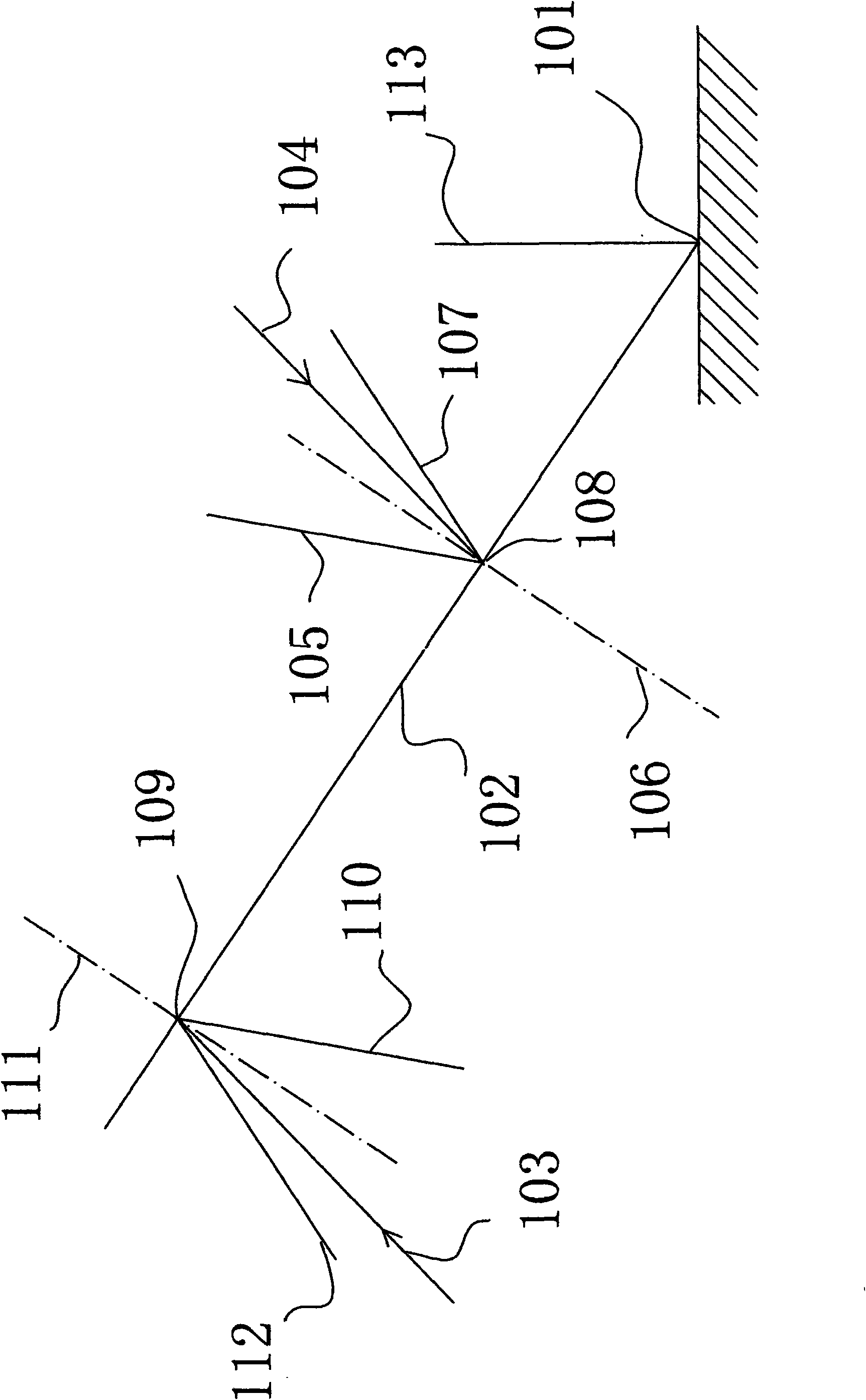

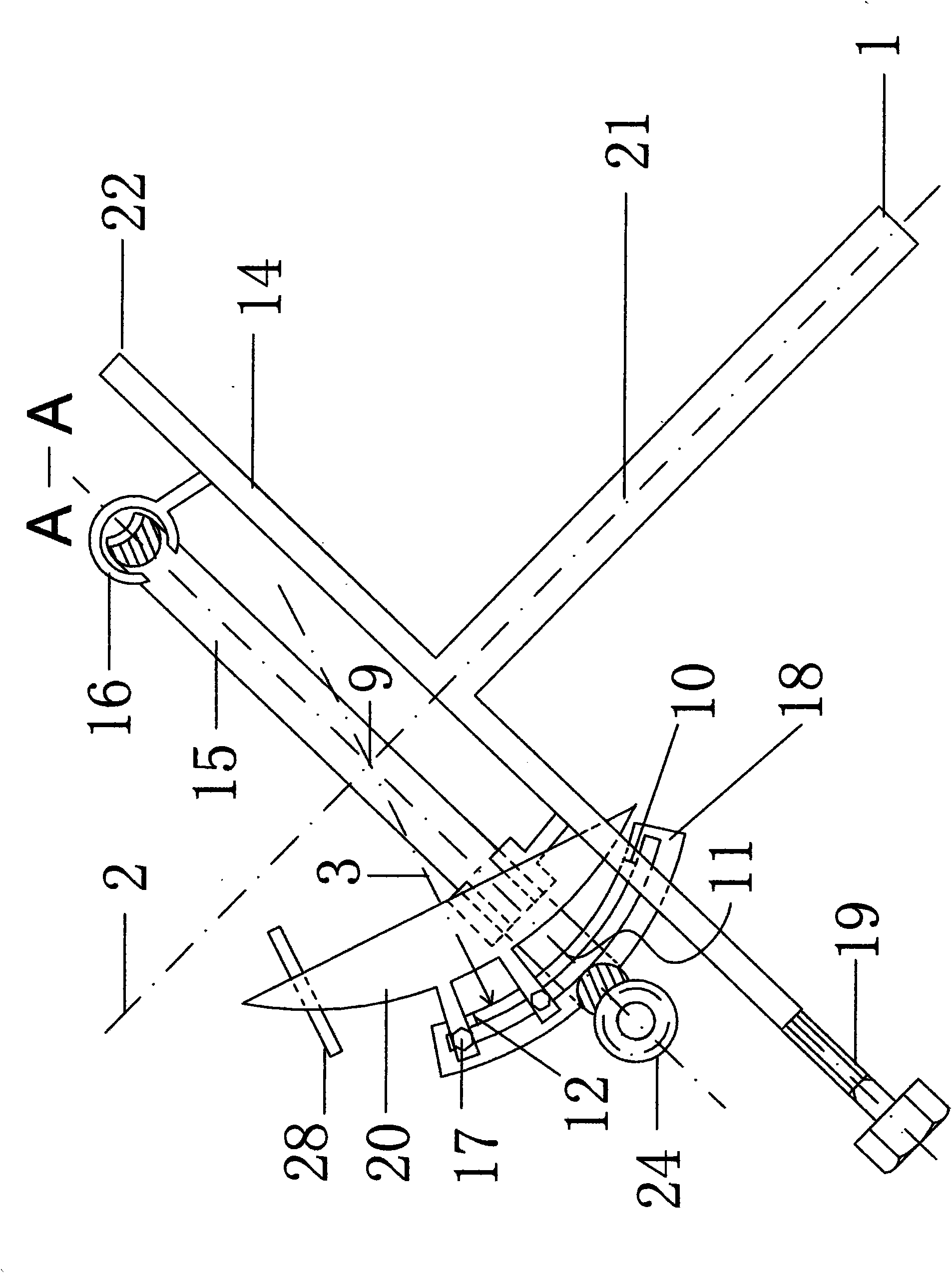

Tracking condenser lens

InactiveCN101551165AHigh practical significanceLow costSolar heating energySolar heat devicesElevation angleEngineering

The invention provides a tracking condenser lens, belonging to a solar applying field, and a medium and high temperature photothermal equipment capable of accurately tracking sunlight. The device can resolves problems that the prior concentration equipment uses electric-controlled facilities and has high cost. The parallel of earth axis is perpendicular to the center line of a rotating support body (15), a condenser lens (20) is fixed on the rotating support body (15), the rotating support body (15) is connected with a elevation angle adjustable frame equipment by a support body (16), the condenser lens rotates alone the sunlight when driving the rotating support body (15) by rotating one cycle as an apparent solar day, the focal point position is coincided with the center of the rotating support body (15) all along. The invention provides a non-electric-controlled and sunlight effective tracking solar heating equipment.

Owner:曹宏海

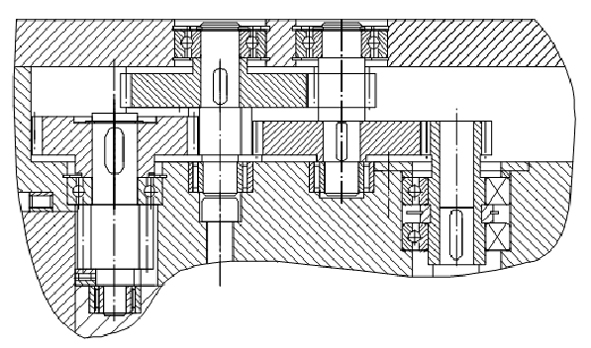

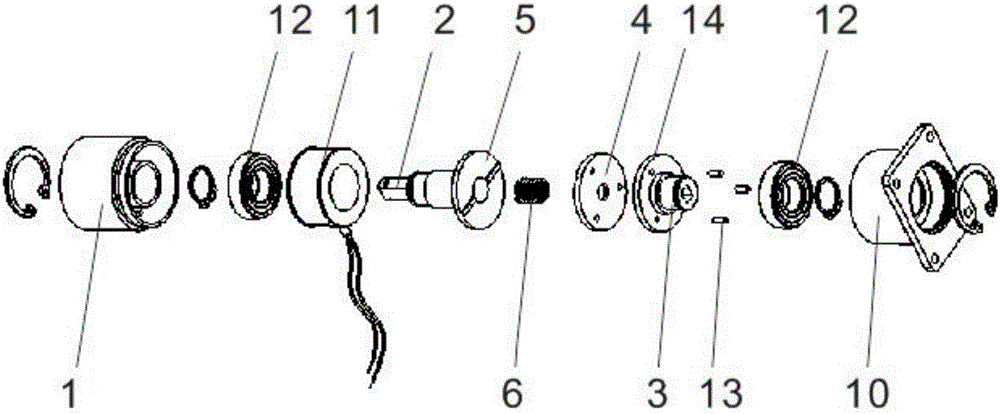

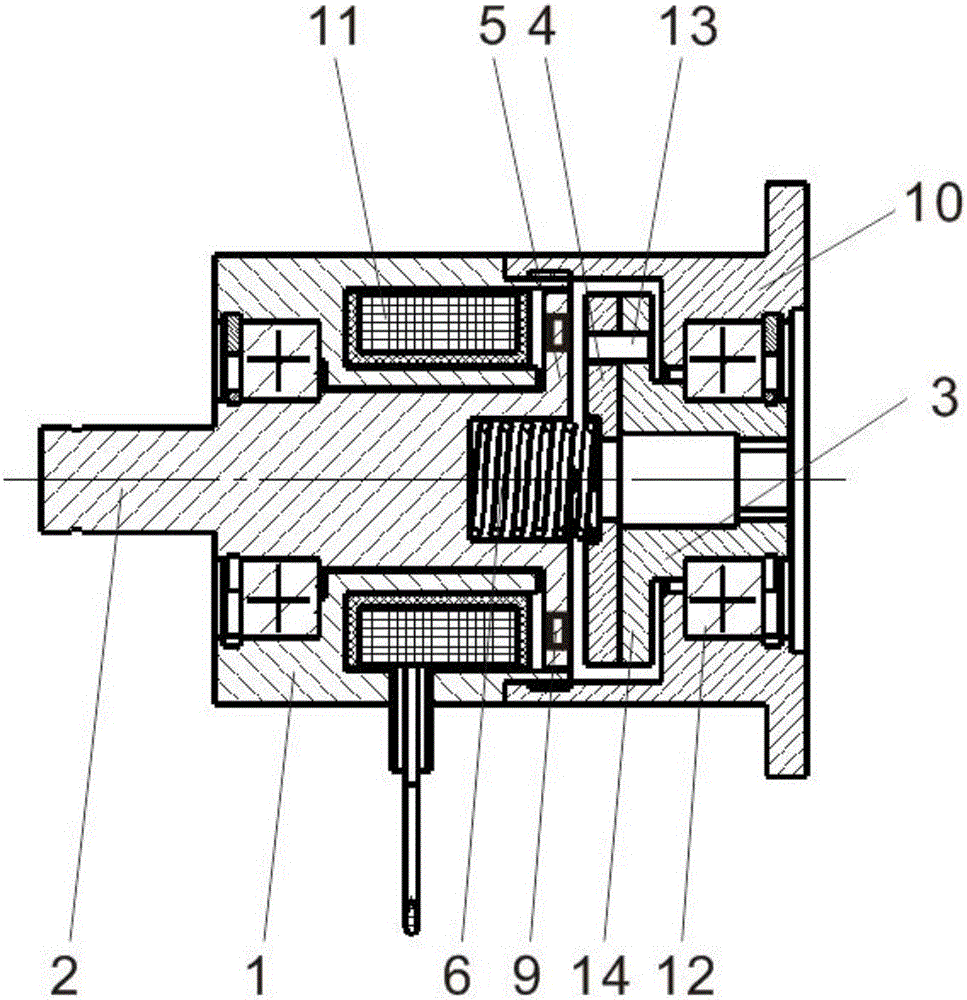

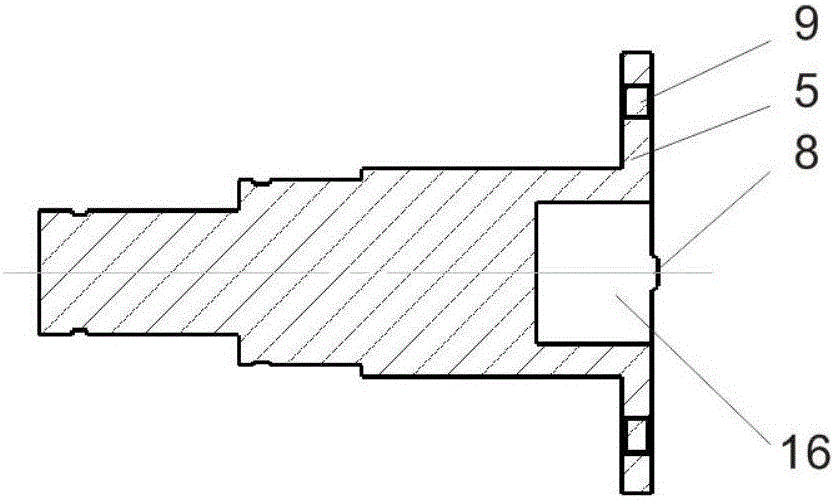

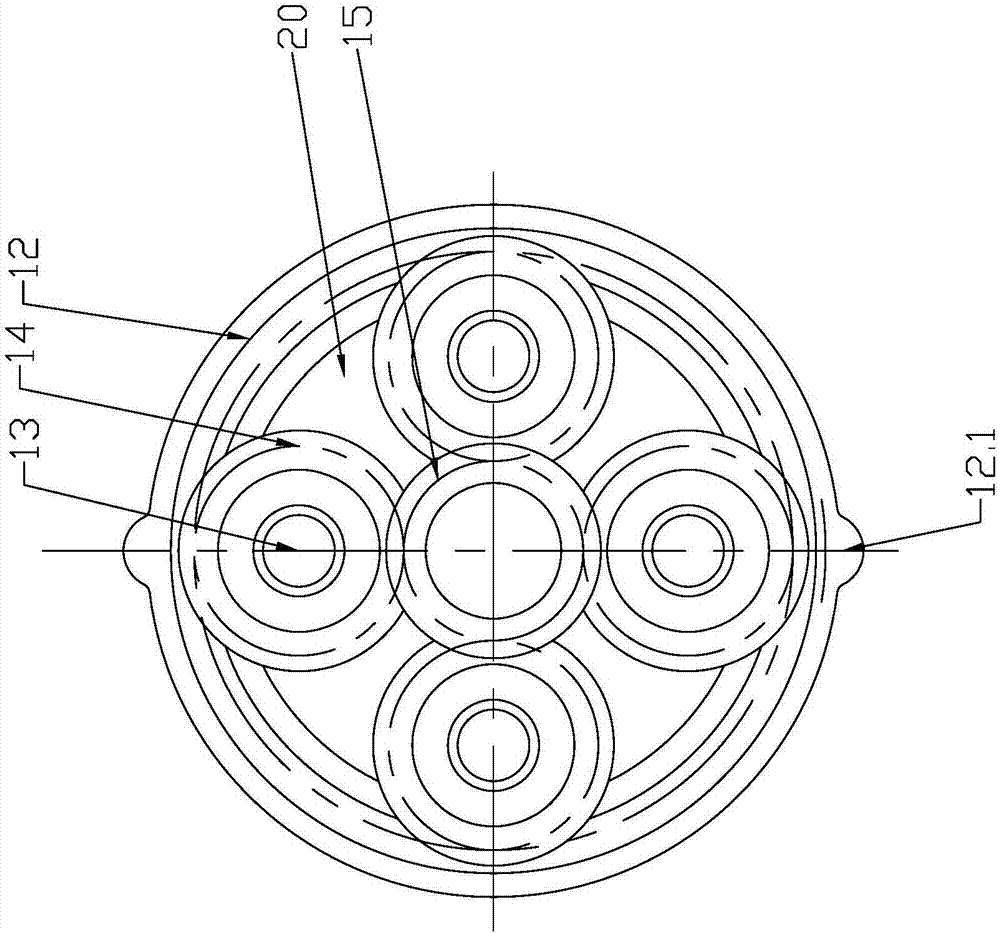

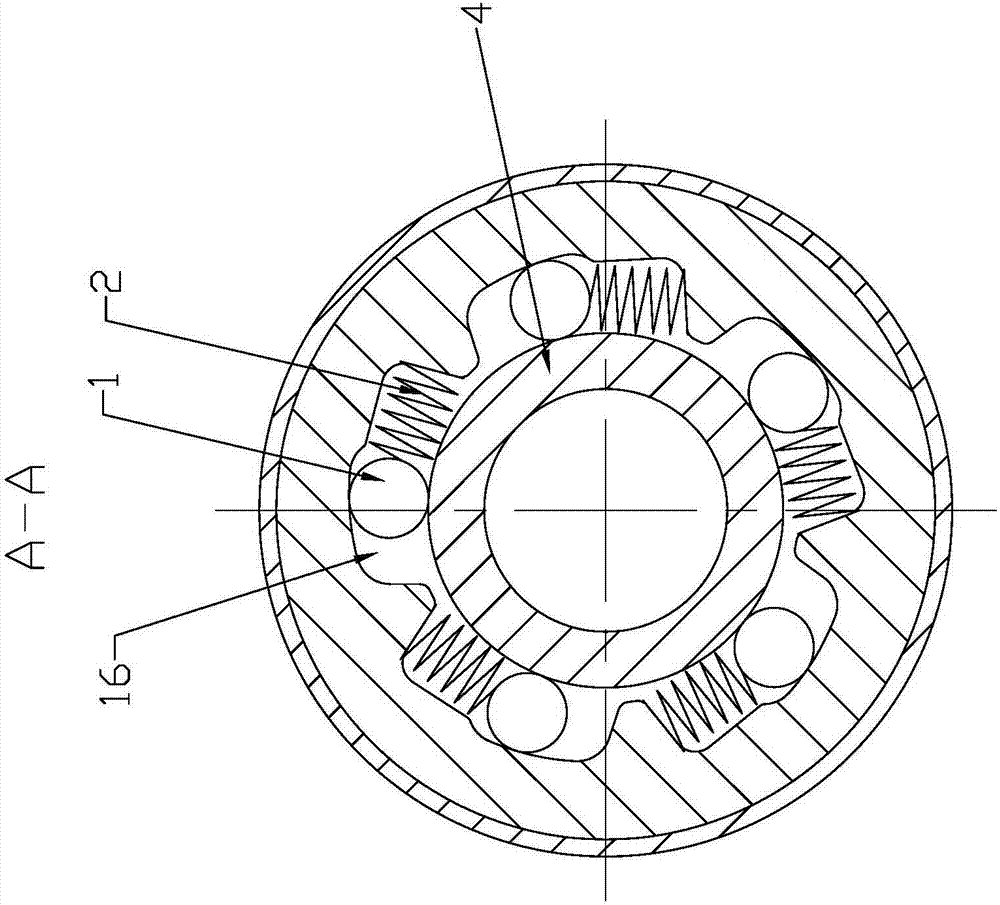

Cantilever-type planetary transmission one-way clutch

The invention relates to a cantilever-type planetary transmission one-way clutch, in particular to a one-way clutch with an internal combustion engine and a starter transferring power uniaxially and slipping reversely, and belongs to the technical field of clutches. The clutch comprises a one-way clutch mechanism, a planetary shaft, an annular gear, a planetary gear, and a input shaft. The left part of a hollow pipe is sequentially provided with a smooth part of a pipe and a spline part of a pipe. Inside a driving gear is sequentially provided with an inner bore part of a gear and an inner spline part of a gear, wherein the inner bore part of a gear of the driving gear is connected with the smooth part of a pipe of the hollow pipe in a sliding mode, and the inner spline part of a gear of the driving gear is connected with the spindle part of a pipe of the hollow pipe in a meshed mode; a splined sleeve is arranged on the right part of the hollow pipe in a sleeved mode, and the inner side faces of the spline sleeve face a plurality of wedge-shape rollaway nests on the end face of the spline sleeve. A pin roller and a spring is arranged inside each wedge-shape rollaway nest, and the springs tightly press the pin rollers in the circumferential direction. The clutch has the advantages of convenient and easy assembly, secure connections, stable quality, and stable and reliable engaging; the size of the clutch is compact and small, and the driver torque of the clutch is large.

Owner:无锡市神力齿轮冷挤有限公司

Vacuum extruder with herringbone gear

InactiveCN101774212AReduce stressImprove stress conditionCeramic extrusion diesGear driveStress conditions

The invention discloses a vacuum extruder with herringbone gears, comprising a motor, a transmission mechanism and an operating mechanism, wherein the output shaft of the motor is connected with the input shaft of the transmission mechanism, and the output shaft of the transmission mechanism is connected with the operating mechanism. The vacuum extruder is characterized in that at least one pair of transmission gears of the transmission mechanism is the herringbone gears. The above technical scheme has the following technical effects: helical gear transmission in the prior art is characterized by meshing by one pair of gears, but the herringbone gear is characterized meshing by two pairs of gears; under the condition that other technical parameters are constant, driving torque distributed to each pair of gears is lowered by half, thus greatly improving the stressing condition of each pair of gears, improving the service life and lowering the possibility of faults, such as snaggletooth and the like; gear contact ratio is doubled to ensure stable transmission and improve whole machine operation performance. In addition, because the axial dip angles of the herringbone gear on the transmission shaft are same but have different directions, axial force mutually offsets, therefore, the stressing condition of the transmission shaft is improved, and the service life of the bearing is prolonged.

Owner:张信聪

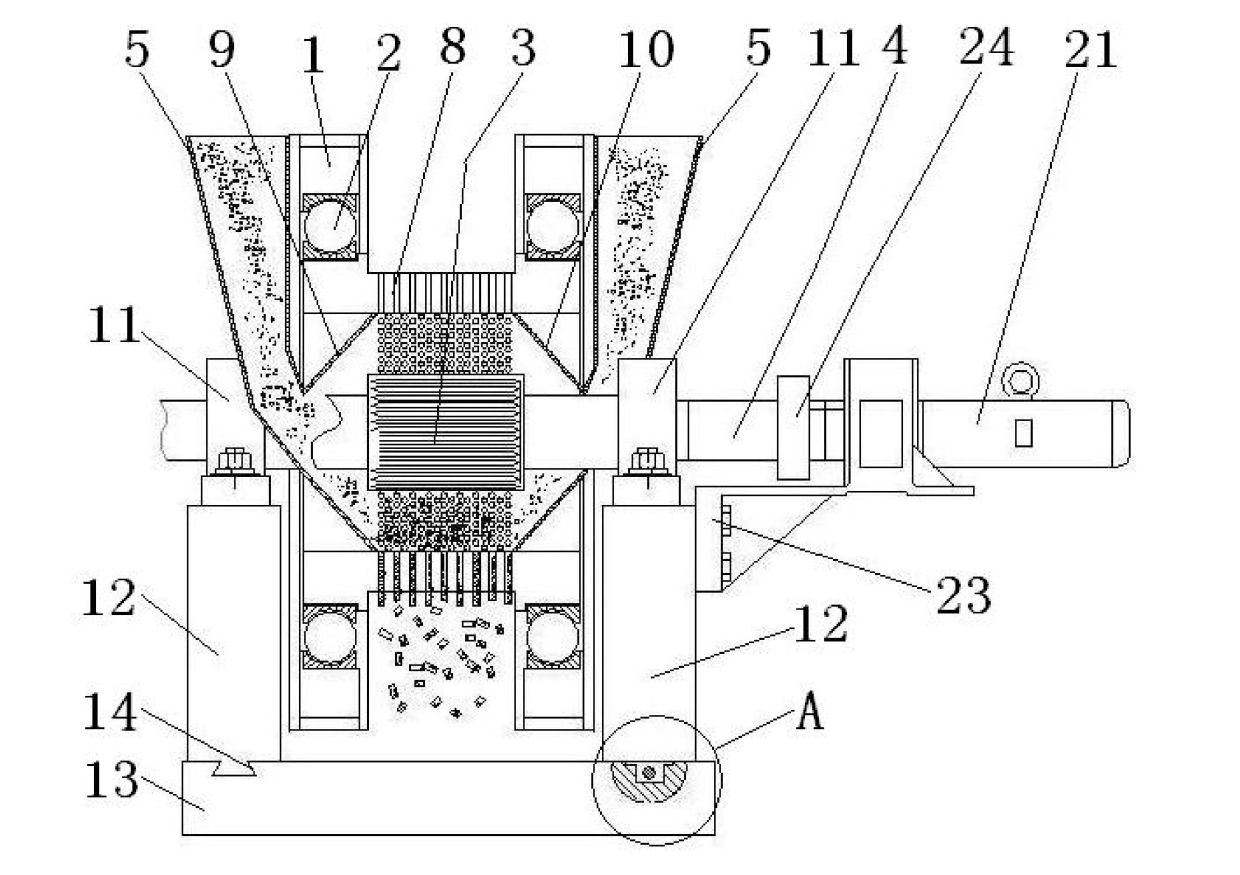

Road surface coring equipment with repairing function for road detection and method

PendingCN113865923ALarge transmission torqueGood transmission effectWithdrawing sample devicesElectric machineryAutomotive engineering

The invention discloses road surface coring equipment with a repairing function for road detection and a method, and particularly relates to the technical field of road detection coring. The road surface coring equipment comprises a transmission box, wherein a protective shell is arranged at the top end of the transmission box, a transmission mechanism is arranged in the transmission box, and an adjusting coring mechanism is arranged on one side of the transmission box; a filling mechanism is arranged on one side of the adjusting coring mechanism. A transmission mechanism is arranged, a transmission gear drives a connecting pinion to enable a supporting shaft rod to drive a linkage gear to rotate, a driving gear downwards presses a supporting rod to drive a coring barrel to rotate, an embedded blade can be rapidly embedded into a road surface during downward sampling; meanwhile, an embedded discharging piece and a coring blade rapidly rotate to discharge materials, so that the large rotating force can be achieved by driving only through a small motor, the transmission torque force is larger, the transmission effect is better, carrying is facilitated, and coring operation on a thick or hard road surface is facilitated.

Owner:安杰

Axial tension safe clutch for large load

InactiveCN104632933ADisengagement process safetyAct as overload protectionAutomatic clutchesClutchEngineering

The invention provides an axial tension safe clutch for large load. The axial tension safe clutch for the large load comprises a shell, an input shaft, a lead screw, a friction engaging and disengaging mechanism, a reset pre-tightening adjusting mechanism and a lead screw nut matched with the lead screw, wherein the input shaft and the lead screw penetrate through the shell to be arranged in a rotating mode, the friction engaging and disengaging mechanism is used for transmission between the input shaft and the lead screw, and the reset pre-tightening adjusting mechanism is arranged on the input shaft. The friction engaging and disengaging mechanism comprises an input friction disc axially fixed to the input shaft, an output friction disc axially fixed to the lead screw, and a reset spring arranged between the lead screw and the output friction disc. The reset pre-tightening adjusting mechanism comprises a reset locking nut fixed at the axial position and is arranged on the input shaft through threaded connection. When the driving tension load of the input shaft or the lead screw is smaller than the corresponding separation load, the input friction disc and the output friction disc rotate synchronously under the effect of the pre-tightening force. When the driving tension load of the input shaft or the lead screw is not smaller than the corresponding separation load, the input friction disc and the output friction disc slip.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

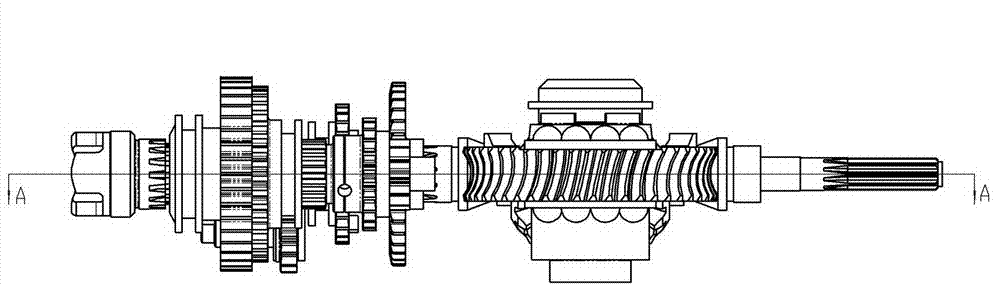

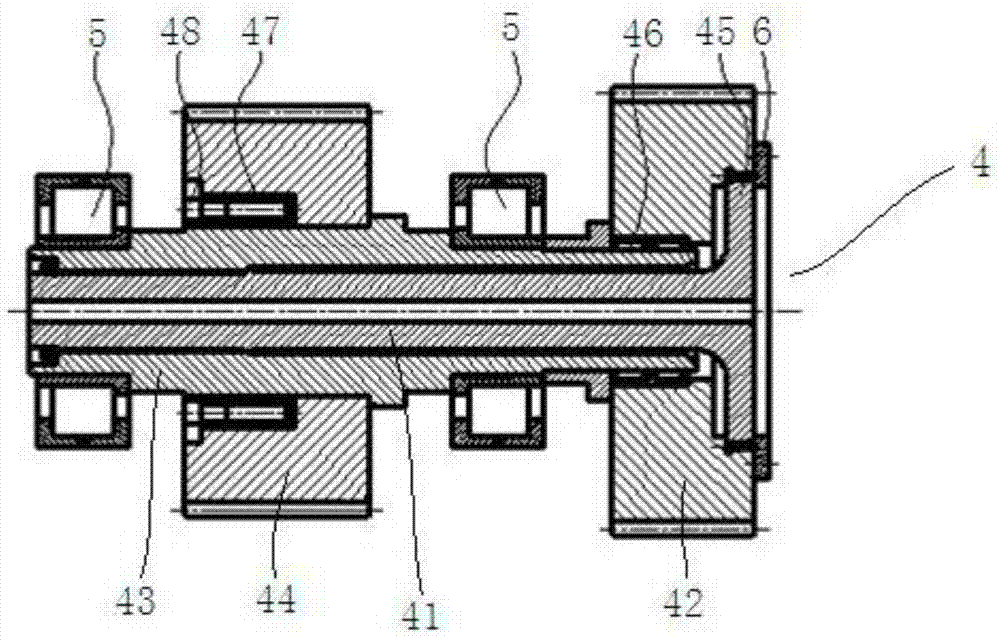

Branch torque transmission mechanism for speed reduction

InactiveCN104500707ALight in massLarge transmission ratioGearing detailsTorque transmissionOutput device

The invention discloses a branch torque transmission mechanism for speed reduction. The mechanism comprises an input device, an output device, a transmission system I and a transmission system II; the input device comprises a power input shaft and an input drive gear; the output device comprises a power output shaft and an output driven gear; the transmission system I comprises a flexible shaft I, an input driven gear I, a middle shaft sleeve I and an output drive gear I; the transmission system II comprises a flexible shaft II, an input driven gear II, a middle shaft sleeve II and an output drive gear II; the input driven gear I and the input driven gear II are arranged at intervals, and the output drive gear I and the output drive gear II are arranged at intervals. The branch torque transmission mechanism is light, large in transmission ratio, compact in structure, high in bearing capability and easy to machine; the transmission torques of gears of branches are reduced, the bearing capability of the gears are improved, the fatigue lives of the gears are prolonged, the average load performance of the mechanism is improved, and the assembling difficulty of the mechanism is lowered.

Owner:CHONGQING UNIV

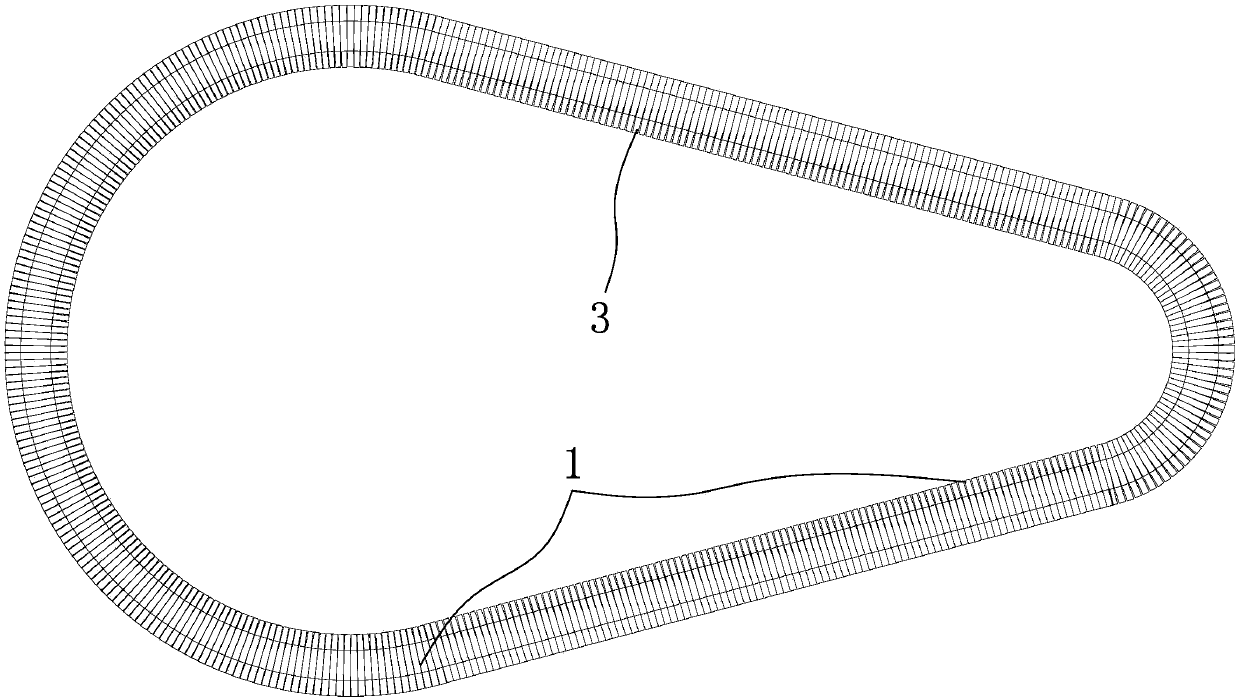

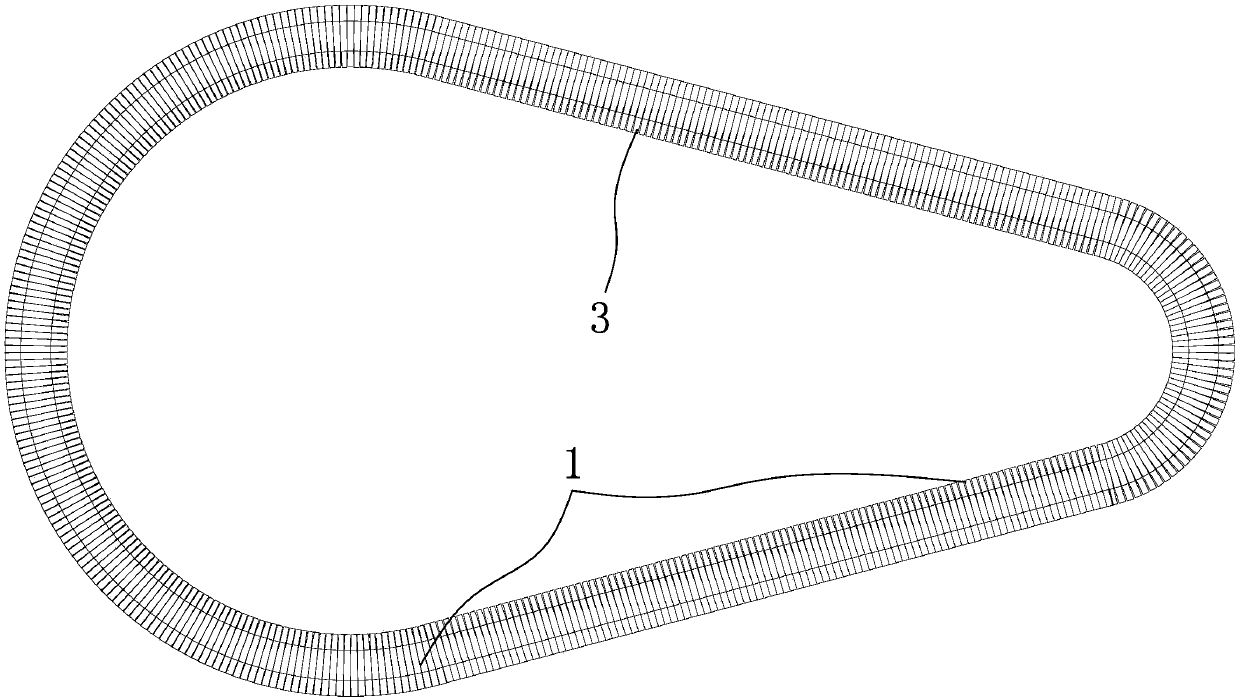

Movable piece continuously variable transmission

ActiveCN107630993ASmall transmission torqueReduced carrying capacityGearingPortable liftingVariatorAerospace engineering

A movable piece continuously variable transmission comprises an active cone disk assembly, a passive cone disk assembly and an annular transmission belt arranged on the active cone disk assembly and the passive cone disk assembly in a sleeving manner, and is characterized in that the transmission belt comprises an annular bearing body and transverse parts installed on the annular bearing body; andthe transverse parts are continuously arranged and installed on the annular bearing body, and can transversely move left and right on the axis of the annular bearing body, so that the surfaces of thetwo sides of the transmission belt can form a tooth profile in any shape and size. Transmission teeth are arranged on the cone face of a cone disk included by the active cone disk assembly and the passive cone disk assembly. The movable piece continuously variable transmission has the beneficial effects that the continuously variable transmission can achieve tooth engagement continuously variablespeed transmission, and the defects that a continuously variable transmission performing transmission by means of conventional friction force is small in transmitted torque, low in bearing capacity,poor in overload resistant and impacting resistant performance, large in sliding rate, low in mechanical efficiency, large in power loss, and limited in transmission power and application range are overcome.

Owner:陈学琴

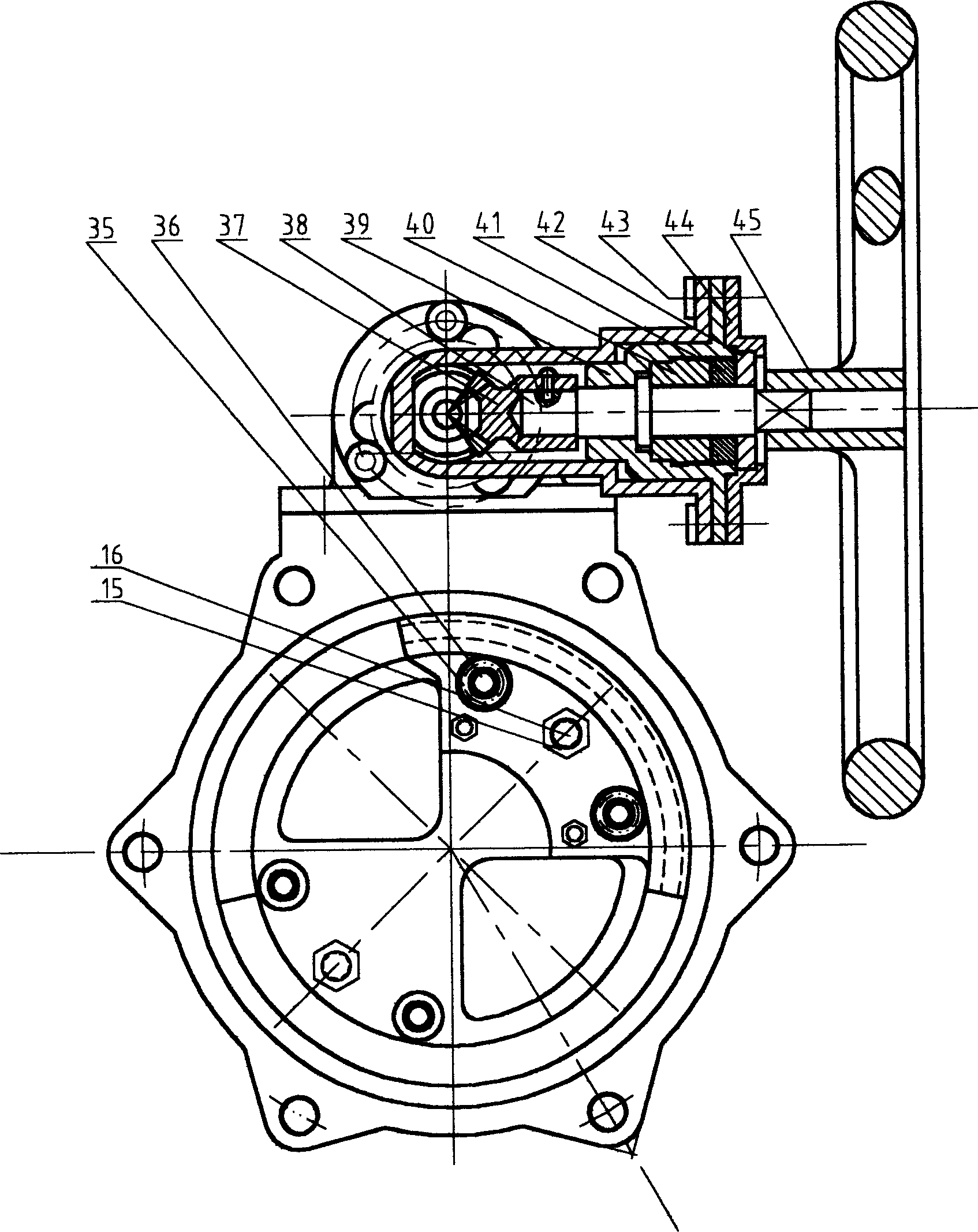

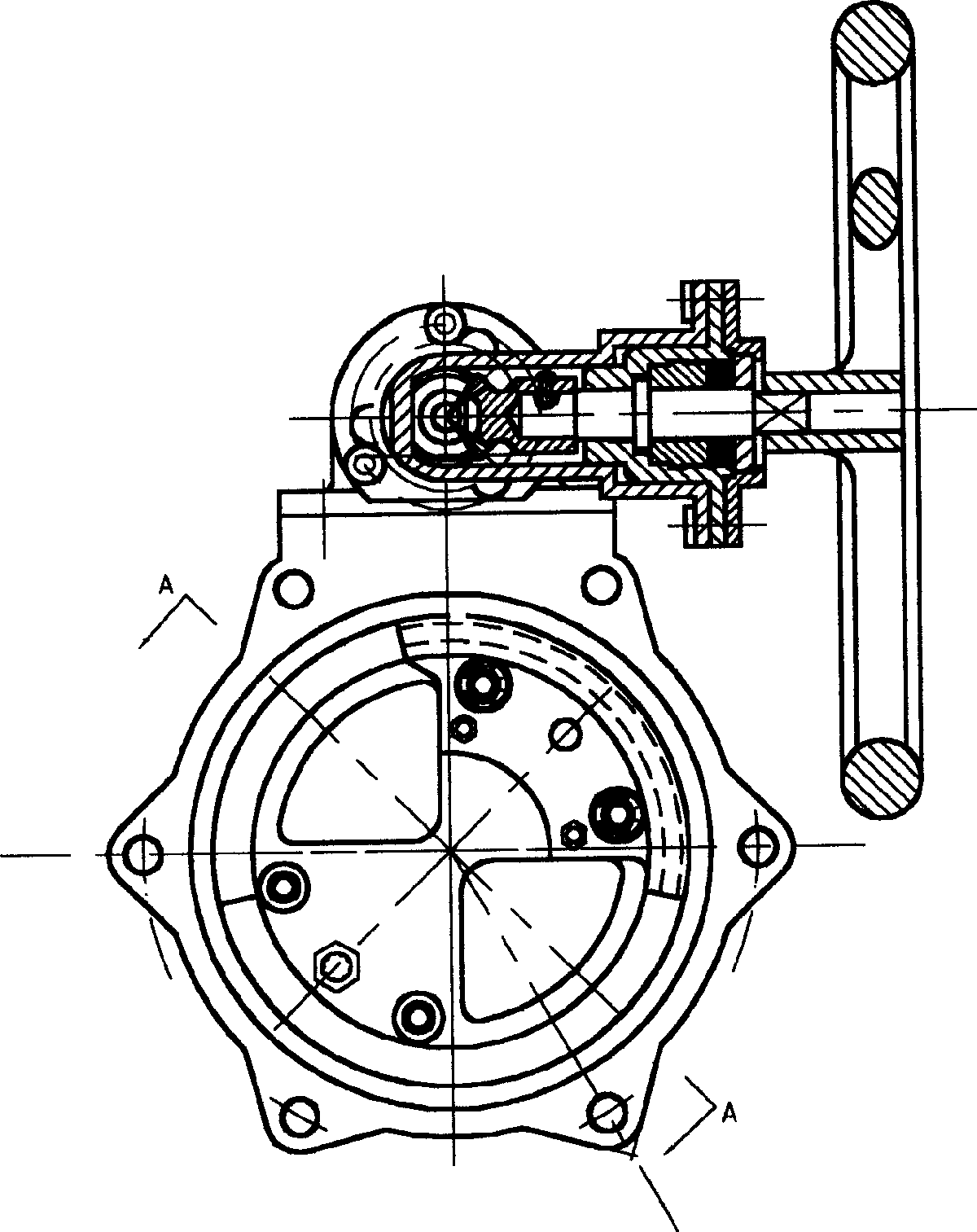

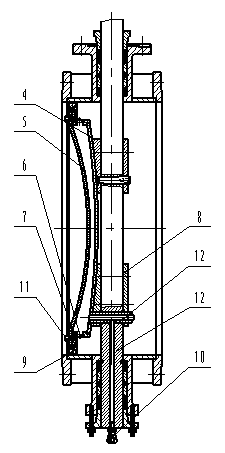

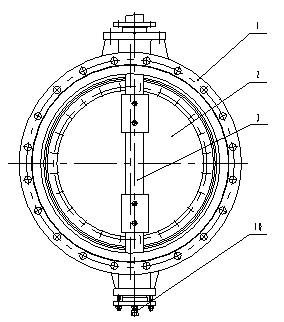

Butterfly valve with inflation seal valve plate

ActiveCN103075526AChange the traditional way of thinkingImprove sealing accuracyLift valveEngineeringButterfly valve

The invention discloses a butterfly valve with an inflation seal valve plate, belongs to the technical field of butterfly valves, and aims to provide a butterfly valve with a good seal effect and small sealing and opening resistance. According to a technical scheme, the valve plate of the butterfly valve consists of an upper ball panel, a lower ball panel, an elastic ring and a seal holder ring; radii of curvature of the upper and lower ball panels are positioned on the same side, and ball centers are opposite in the same line on the same side; the elastic ring and the seal holder ring are in parallel encircling connection between circumferences of the upper and lower ball panels; and an air source connector is communicated with a cavity formed among the upper ball panel, the lower ball panel, the elastic ring and the seal holder ring of the valve plate through air holes. A rigidity seal structure of the traditional butterfly valve is changed, an inflation hollow valve plate with a double-layer structure is adopted, and the whole working process of the valve is qualitatively changed. The seal accuracy of the butterfly valve can reach a high level. The butterfly valve is skillful in design and novel in style, is an innovation for the seal design of the butterfly valve, achieves unexpected good effect and deserves promotion and application.

Owner:HEBEI CHANGHONG VALVE CO LTD

Speed-adjustable sheet-type engaged gear infinitely variable transmission

InactiveCN108895136ASolve technical problems with high wear and tearNot easy to wearGearingGear wheelEngineering

The invention discloses a speed-adjustable sheet-type engaged gear infinitely variable transmission in the technical field of mechanical transmission. The infinitely variable transmission comprises asupporting frame, a driving arc-shaped wheel and a driven arc-shaped wheel are rotatably connected on the supporting frame, an output end of a first external transmission device is in transmission connection with a driving gear, the driving gear is engaged with a driven gear, the driving arc-shaped wheel faces the driven arc-shaped wheel, a plurality of driving inserting grooves are formed in thedriving arc-shaped wheel, a plurality of driven inserting grooves are formed in the driven arc-shaped wheel, a plurality of connecting grooves are formed in a first roller and a second roller, the first roller and the second roller are connected with first elastic sheets and second elastic sheets through the connecting grooves, the first elastic sheets and the second elastic sheets have the same structures, the driving arc-shaped wheel is positioned between the first roller and the second roller, at least one elastic sheet on the first roller and at least one elastic sheet on the second rollerare inserted into the driving inserting grooves and the driven inserting grooves, and corresponding arc-shaped buses of the peripheries of the driving arc-shaped wheel and the driven arc-shaped wheelare positioned on the same circle. A transmission part of the device is safe and reliable and not easy to abrade.

Owner:YANGZHOU UNIV

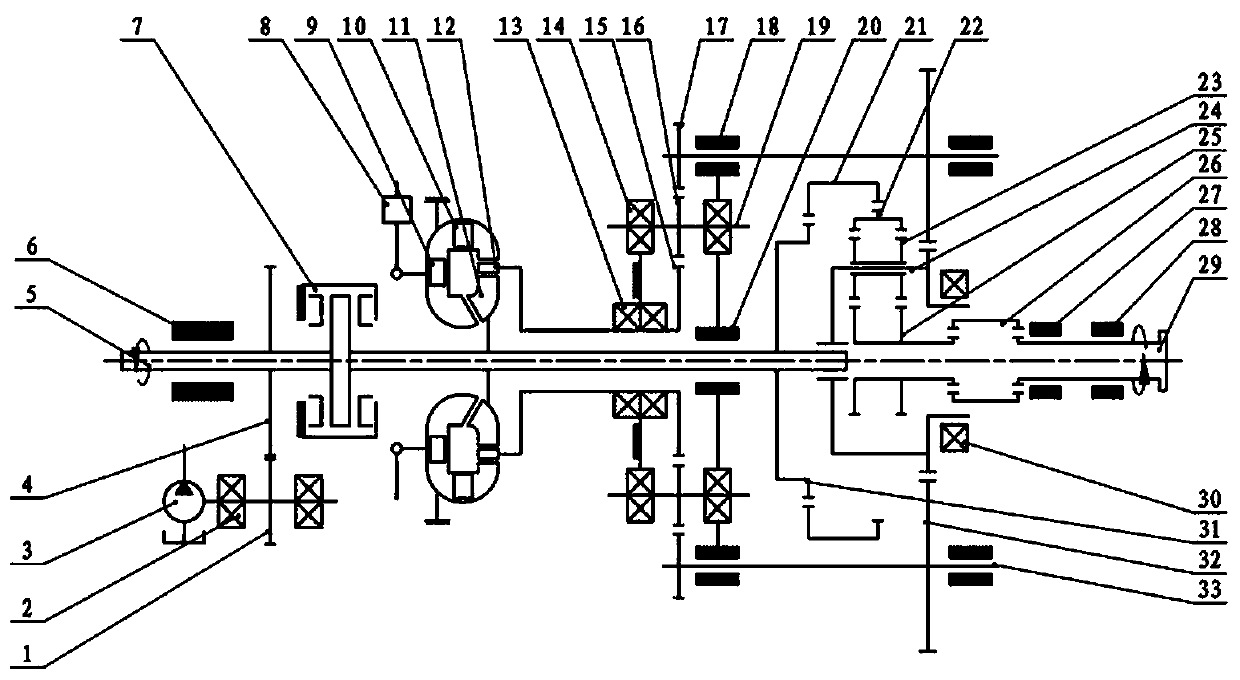

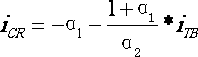

Novel hydraulic planetary speed regulating mechanism

The invention discloses a novel hydraulic planetary speed regulating mechanism, and relates to the technical field of transmission devices. The novel hydraulic planetary speed regulating mechanism is mainly composed of a gear power dividing system, a hydraulic torque converter system, a planet gear system, a lubricating oil system and the like. A guide vane adjustable-type hydraulic torque converter is adopted in the hydraulic torque converter system. The hydraulic torque converter system is composed of a pump impeller, a turbine, a fixed guide wheel, an adjustable guide wheel, an executing mechanism and the like. The planet gear system belongs to a differential gear train and further consists of an inner gear ring, a planet carrier, a planet wheel and a sun gear. The novel stepless speed regulating transmission device operates according to the principle of 'power dividing'. Although the hydraulic torque converter of the power multi-branch hydraulic planetary transmission device is low in efficiency, the divided power is small, and therefore the efficiency of the complete device is high and the rated condition can reach about 95%.

Owner:中国船舶重工集团公司第七0三研究所

Transmission chain coupling mechanism with adjustable phase

InactiveCN104358830AImprove carrying capacityExtended service lifeControlled membersMechanical actuated clutchesCouplingHigh transmission

The invention discloses a transmission chain coupling mechanism with adjustable phase. The mechanism comprises a first gear, a second gear, a bearing, an inner spline, an outer spline and an outer gear sleeve, wherein the first gear sleeves and is fixed to the first high-speed shaft; the second gear is sleeved by and fixed to the outer ring of the bearing; the first gear and the second gear are meshed with each other; a second high-speed shaft is sleeved by the inner ring of the bearing; the inner and outer splines sleeve and are fixed to the second high-speed shaft; the outer gear sleeve is respectively and detachably connected with the second gear and the inner and outer splines through splines; when the outer gear sleeve is connected with the second gear and the inner and outer splines through splines, the first high-speed shaft and the second high-speed shaft are operated synchronously, at the same rotate speeds and in opposite directions; when the outer gear sleeve is disconnected with the second gear and / or the inner and outer splines, the first high-speed shaft and the second high-speed shaft are operated independently. The technical scheme has the advantages of high bearing capacity, compact structure, convenient adjustment and maintenance, high transmission efficiency, high reliability and long service life, and brings great convenience for transmission chain phase adjustment, coupling and disconnection.

Owner:宁波东力股份有限公司

Variable-diameter gear continuously variable transmission

PendingCN110259895AReduce volumeReduce weightToothed gearingsPortable liftingEngineeringAmplification factor

The invention provides a variable-diameter gear continuously variable transmission. The transmission is composed of a variable-speed stage and an amplifying stage, wherein the variable-speed stage is a variable-diameter inner gear ring composed of a variable-diameter inner gear ring composed of a plurality of gear lobes, three variable-diameter planetary gear sets and an output sun gear; the amplification stage is a standard fixed transmission ratio planetary gear transmission, and a continuously varying variable ratio of the variable-speed stage is amplified by an appropriate amplification factor as required, an arbitrary speed regulation range can be combined not only through different amplification factors of the amplifying stage but also can be combined through different input rotational speeds, for example, according to the principled sample machine manufactured by a company, the variable ratio of the amplification stage is 5.5 times, an input rotational speed is 3000 revolutions / minute, and therefore the output rotational speed of an output shaft varies continuously from reverse 1600 revolutions / minute to forward 5200 revolutions / minute; due to the fact that the output rotational speed can approach to zero, so that the torque can approach to infinitely great, the significance of the characteristic is very important, and the revolutionary change of a whole industry can be brought.

Owner:大连嘉宏至伟新技术开发有限公司

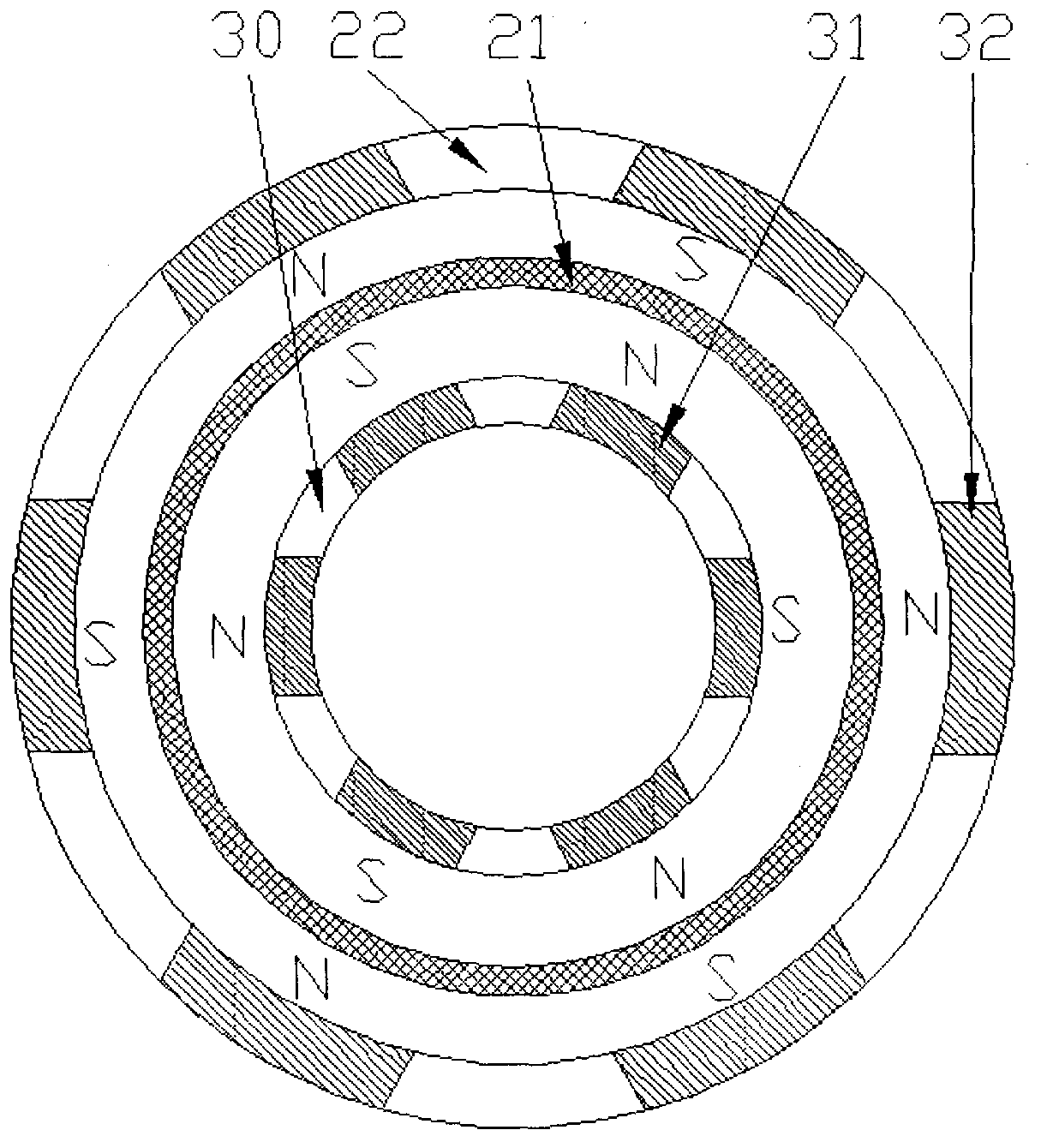

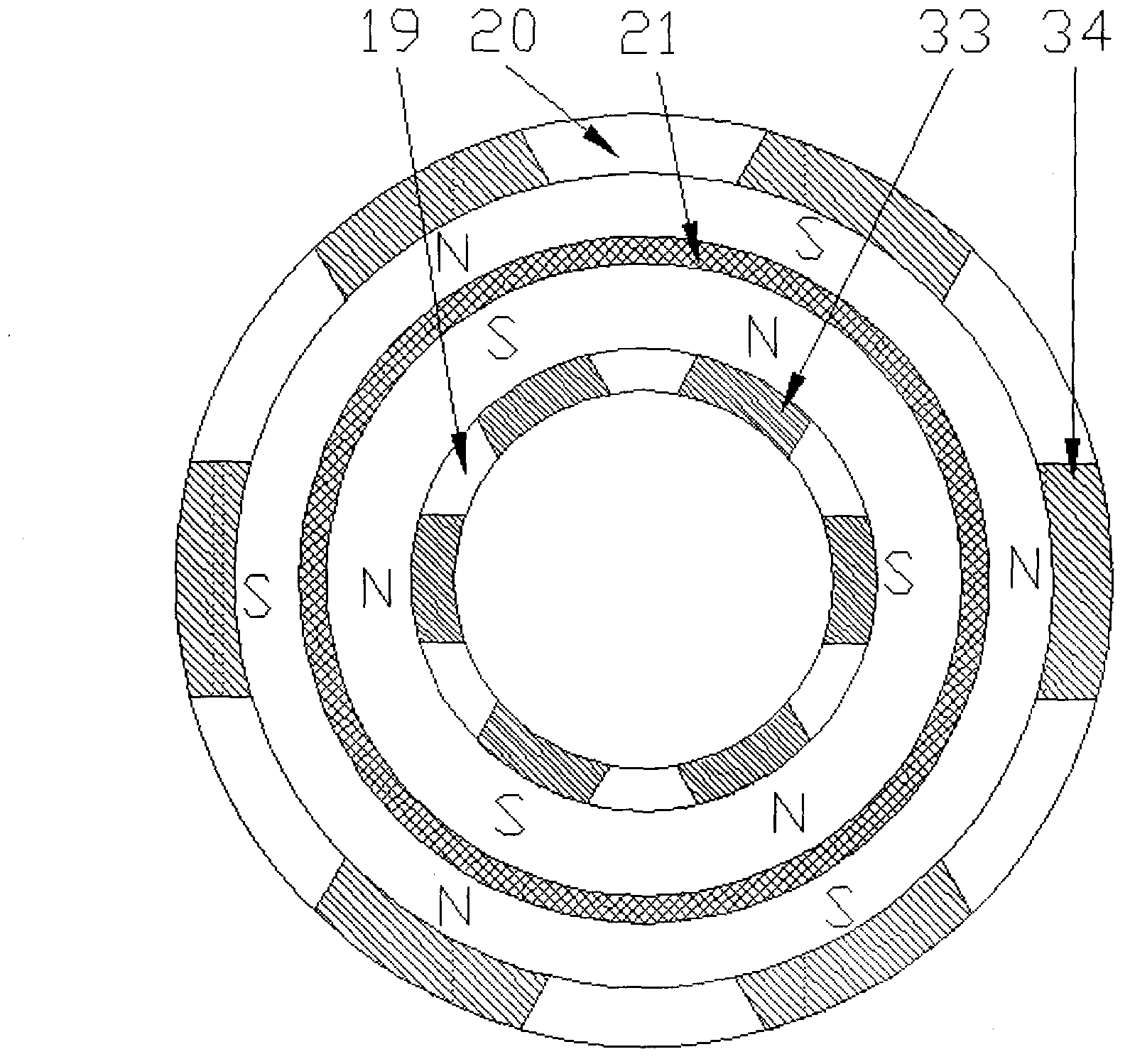

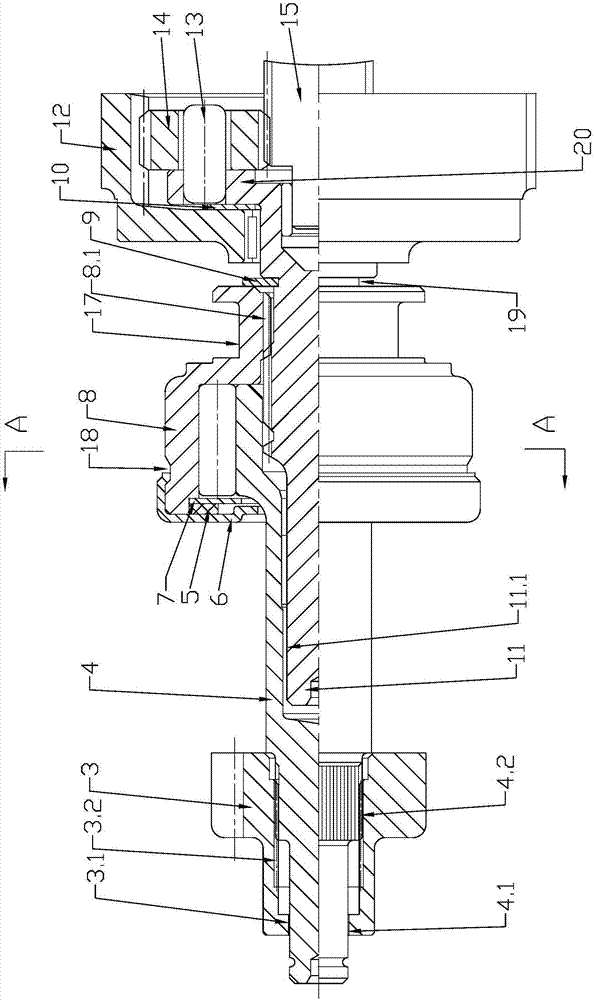

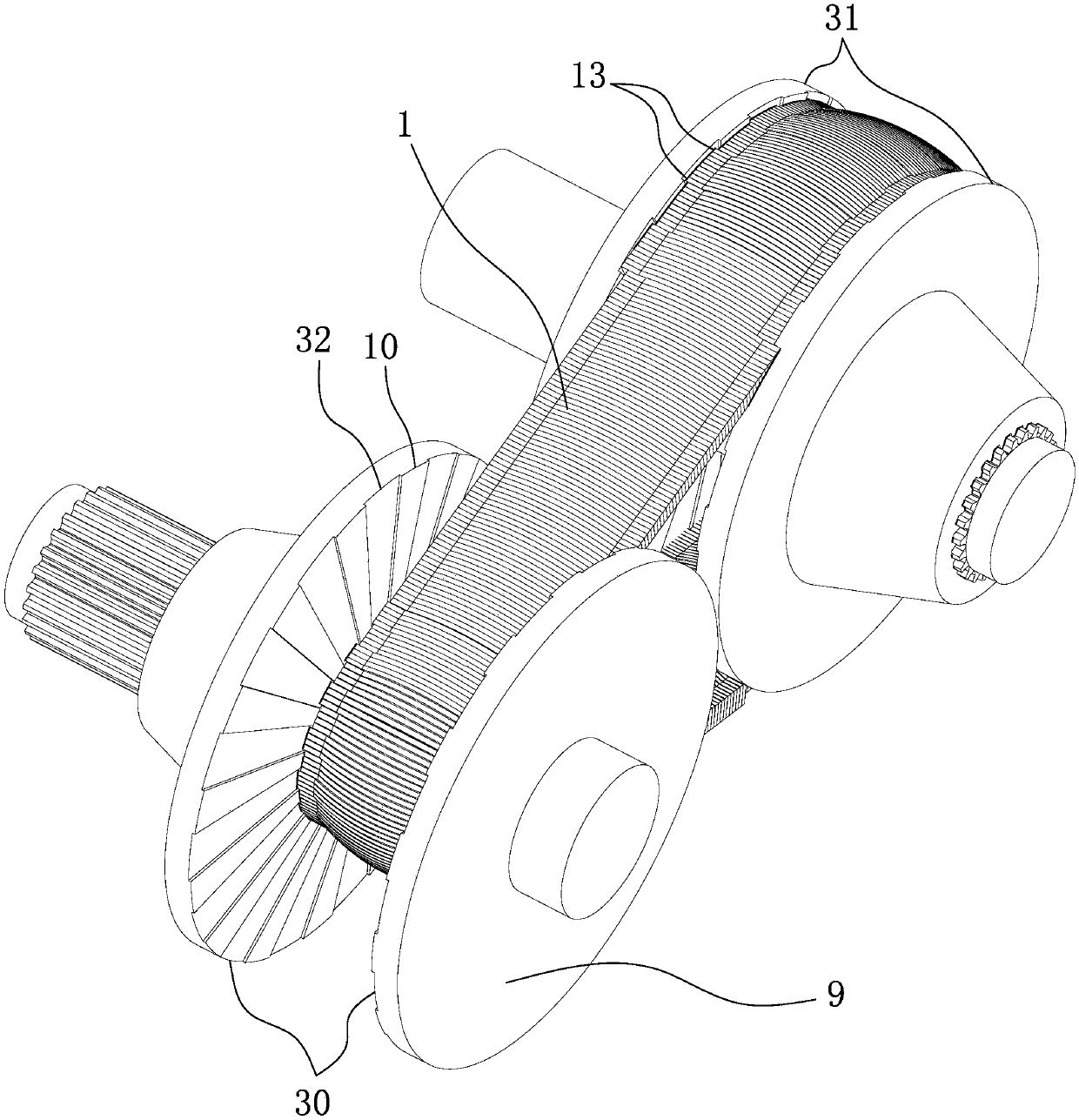

Eccentric oscillating-type planetary gear device

ActiveCN101328953AExtend tooth surface lifeInhibition of elastic deformationToothed gearingsFriction gearingsGear wheelControl theory

Deformation of bridge sections in an externally toothed gear and of outer teeth is suppressed, and this extends the life of tooth surfaces of external teeth (19), improves vibration characteristics, and drastically increases output torque while preventing a planetary gear device (11) from becoming large in size. To achieve the above, a ratio obtained by dividing the diameter (D) of pins constructing internal teeth (14) by the pitch (P) of the internal teeth (14) is made smaller to an extent where the tooth tops (19a) of the external teeth (19) are radially outside the inner periphery (15a) of an internally toothed gear (15), or alternatively, a meeting point (C) where the lines (S) of action of reaction forces (K) as drive force components meet is moved more radially outward than a conventional position so as to be positioned between a pin circle (P) passing the centers of all the internal teeth (pins) (14) and an outer end passing circle (G) passing radially outer ends of through-holes (22), or further alternatively, the amount (H) of eccentricity of an externally toothed gear (18) relative to an internally toothed gear is set not less than 0.5 times the radius (R) of the internal teeth (pins)(14).

Owner:NABLESCO CORP

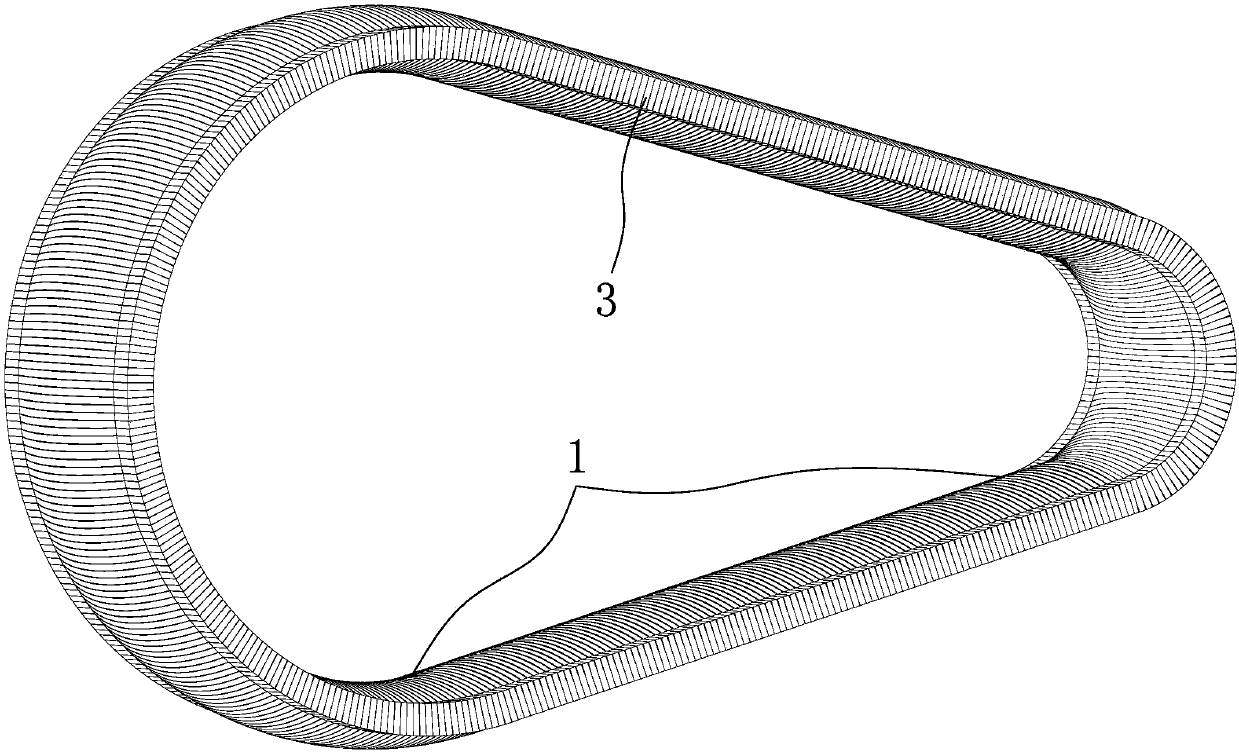

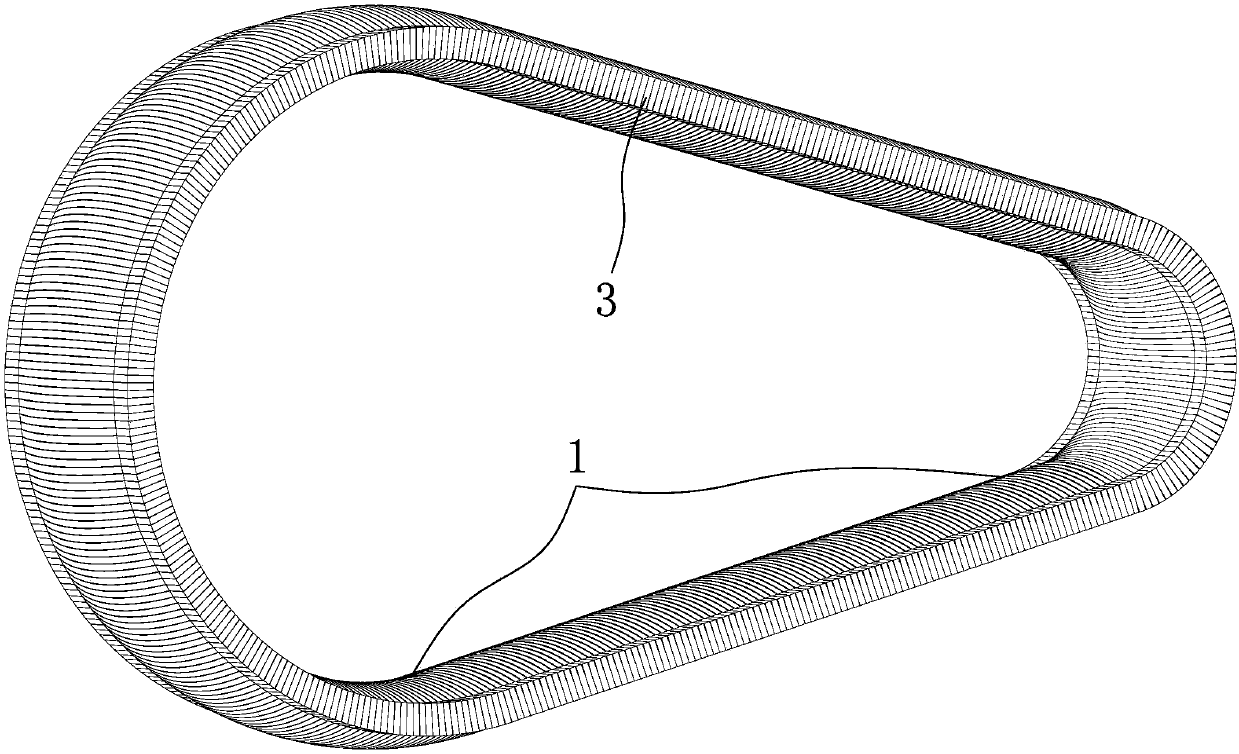

Continuously variable transmission driving belt with sliding vanes

ActiveCN107816509ASmall transmission torqueReduced carrying capacityDriving beltsTransmitted powerEngineering

A continuously variable transmission driving belt with sliding vanes comprises annular bearing bodies and transverse parts installed on the annular bearing bodies and is characterized in that the transverse parts are continuously arranged and mounted on the annular bearing bodies and can move transversely leftwards and rightwards on the axes of the annular bearing bodies so that tooth profiles with the arbitrary shapes and sizes can be formed on the surfaces of the two sides of the driving belt. The continuously variable transmission driving belt with the sliding vanes has the beneficial effects that tooth engagement and continuously variable driving can be achieved, and the defects that a common continuously variable transmission driving belt driven by frictional force is small in transmitted torque, low in bearing capacity, poor in overload resistant and impact resistant performance and large in sliding rate, the mechanical efficiency is low, the power loss is large, transmitted power is limited, and the application range is limited are overcome.

Owner:陈学琴

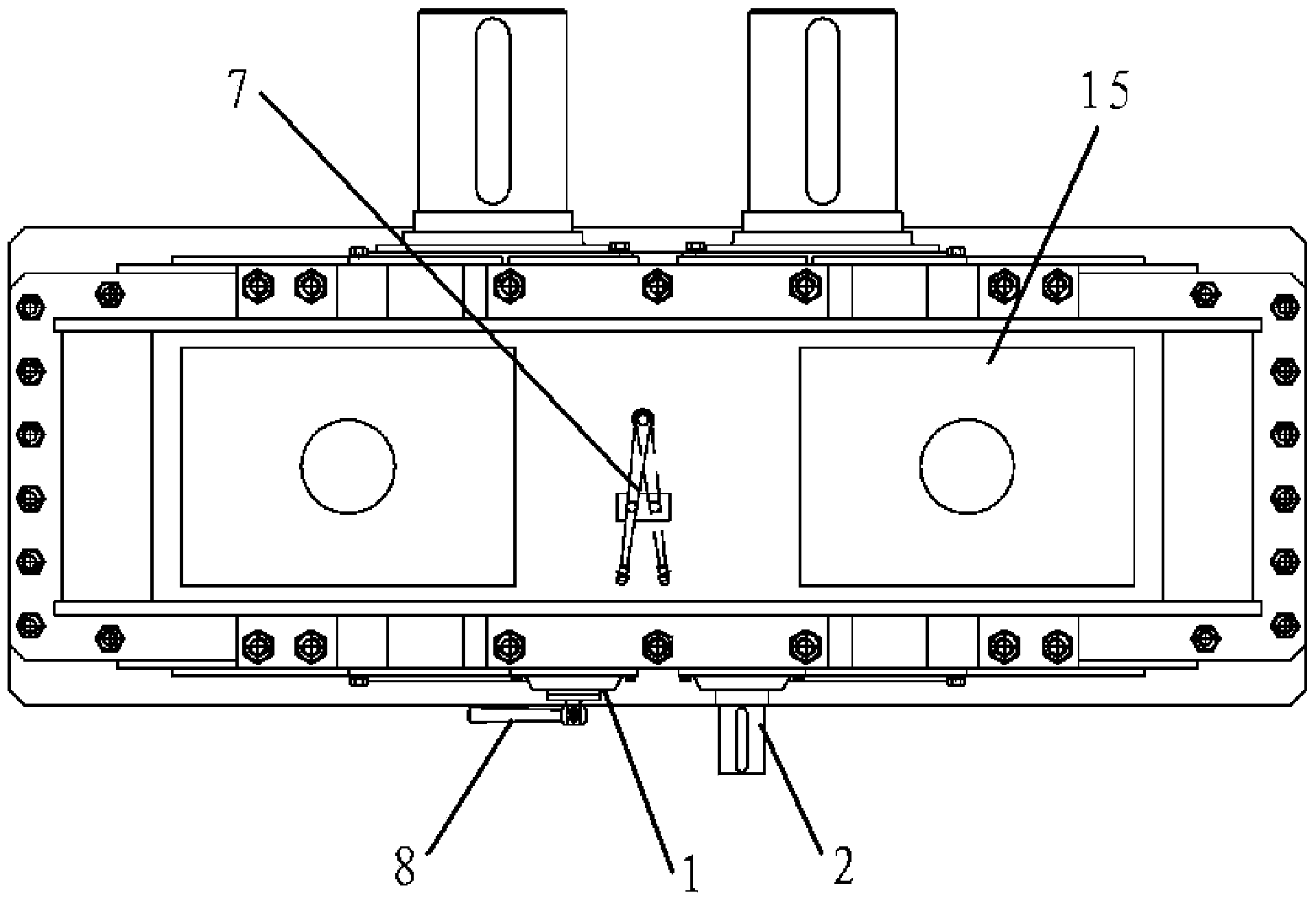

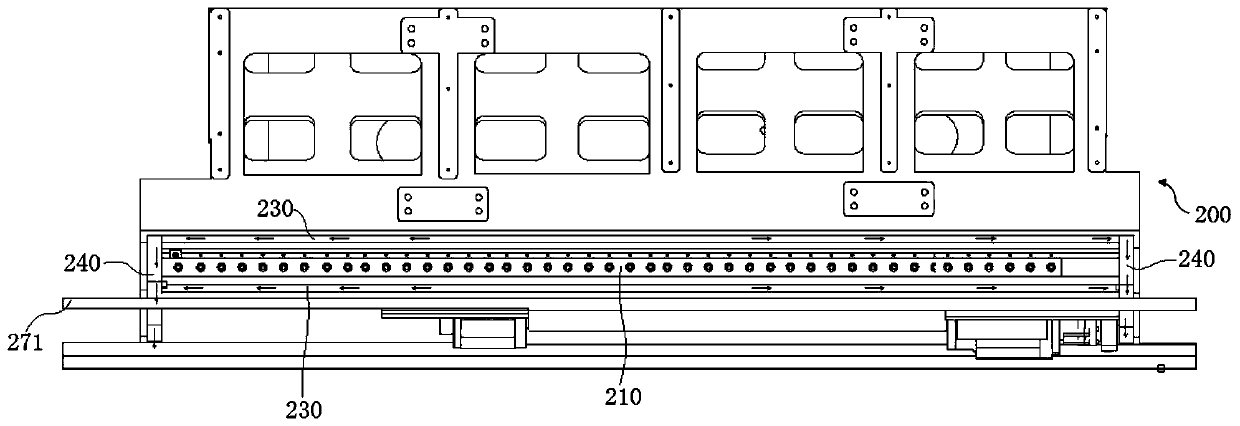

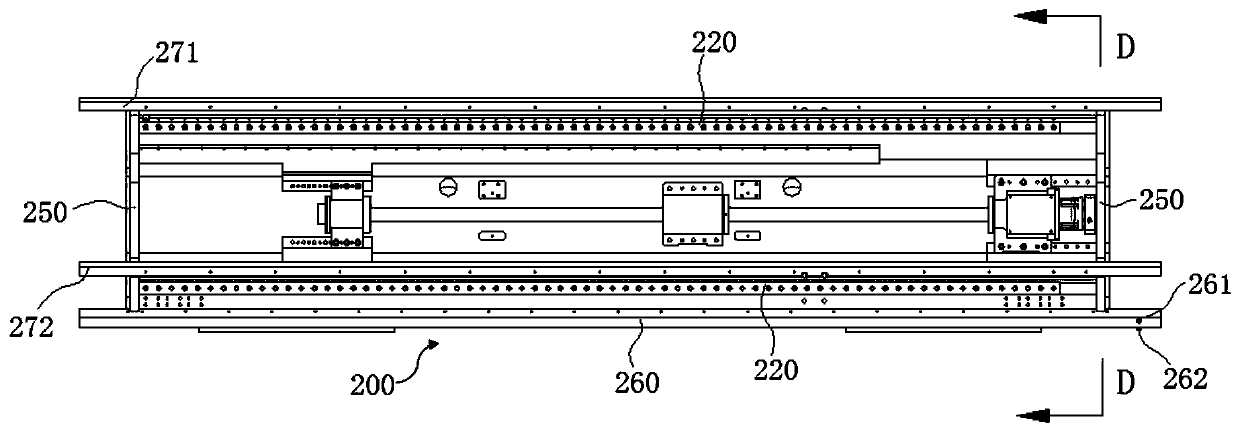

Planomiller system

ActiveCN111299666AEasy to guideStop the spreadMilling machinesFeeding apparatusEngineeringMachining process

The invention discloses a planomiller system, and belongs to the technical field of planomillers. The planomiller system comprises oil guiding grooves which are formed in the two sides of a beam in the width direction of a top line rail, collecting grooves are formed in the two sides of the oil guiding grooves, lubricating oil collected in the oil guiding grooves is discharged in the collecting grooves in the two sides, a guiding groove is formed in the portion, corresponding to the collecting grooves in position, in the side wall face of the beam and communicates with the collecting grooves,a cavity is formed in each column, X-shaped reinforcing rib plates are arranged on the inner side walls of the peripheries of the columns, and connecting struts are furthermore connected into the portion between the left inner side walls and the right inner side walls of the columns in the length direction of the beam. The invention aims at overcoming the defects that in the process of machining abeam of an existing planomiller, lubricating oil is likely to splash out, and the rigidity of the columns is poor, and provides the planomiller system. By means of the planomiller system, the waste oil in the machining process can be effectively guided and collected, the rigidity of the columns can also be improved, and thus the machining precision of the planomiller is guaranteed.

Owner:安徽鹏睿智能科技有限公司

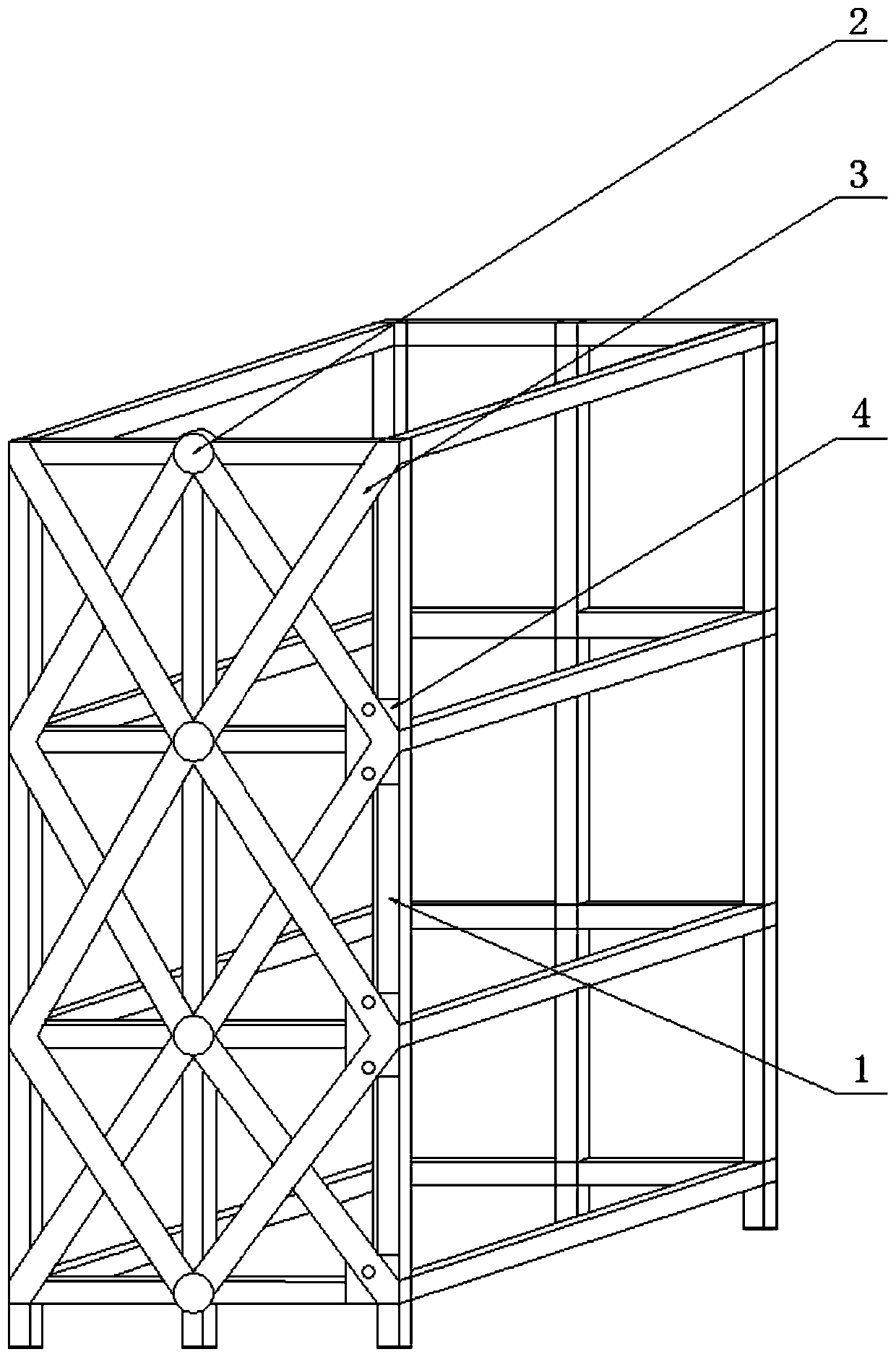

Torsion-resistant stereo garage frame structure

PendingCN110778176ASmall transmission torqueImprove stabilityBuilding constructionsParkingsCross overSquare Shape

The invention discloses a torsion-resistant stereo garage frame structure. The structure comprises a stereo garage, wherein the stereo garage comprises cross beams and longitudinal beams; the cross beams and the longitudinal beams are connected into a square shape in a staggered mode, fastening plates are arranged at the staggered positions of the cross beams and the longitudinal beams, supportingrods are arranged on the diagonal lines of the square-shaped structure, and the fastening plates are used for fastening and mounting the supporting rods on the staggered positions of the cross beamsand the longitudinal beams; and a fixing mechanism is further arranged between the adjacent longitudinal beams and used for fixing the cross beams and the longitudinal beams. According to the torsion-resistant stereo garage frame structure, the two mutually crossed supporting rods are rigidly fixed at the staggered positions of the cross beams and the longitudinal beams and are connected into a whole through bolts, so that the rigidity strength of a whole frame can be effectively adjusted, the transmission torque is remarkably reduced, and therefore the torsion-resistant effect is achieved; and a U-shaped plate is additionally arranged between the cross beams and the longitudinal beams by adopting the fixing mechanism, so that the stability and the torsion resistance of a garage frame areimproved, and then the limitation of the frame on the height of a stereo garage is reduced, so that the number of vehicles stored in the limited space of the stereo garage is improved, namely, the space utilization rate is high.

Owner:GUANGDONG SAMPU GARAGE CO LTD

Multi-angle display international trade display propaganda device

The invention discloses a multi-angle display international trade display propaganda device which comprises a bottom plate and a display box, an upper plate is fixedly connected to the bottom plate through stand columns, and the display box is arranged and installed on the upper plate through an adjusting assembly; and a control box is fixedly connected to the bottom plate. According to the device, through rotation of the lifting motor, vertical height adjustment of the sliding plate is effectively achieved; meanwhile, under the rotating action of the second motor, the angle of the mounting ring relative to the rotating plate is driven to be adjusted; the rotating axis, relative to the mounting ring, of the display box is perpendicular to the rotating axis of the rotating shaft, so that the angle of the display box is effectively adjusted through the rotating ring; when the angle is adjusted, the height is adjusted at the same time, and the display box can be effectively displayed along with rotation of the main shaft; the sliding plate is driven to move up and down through lead screw transmission, the characteristics of small transmission torque, accurate transmission and labor saving are achieved, and the motor load is reduced; and good application prospects are realized.

Owner:陈欣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com