Butterfly valve with inflation seal valve plate

A technology of inflatable sealing and valve plate, which is applied in the directions of lift valves, valve devices, engine components, etc., can solve the problems of difficult manufacturing, large opening torque, large sealing specific pressure, etc., and achieve the effect of ingenious design and saving transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

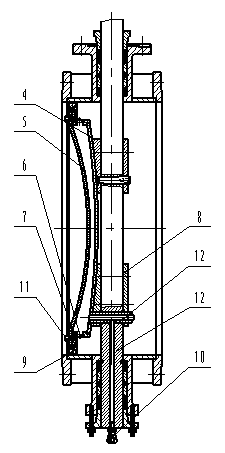

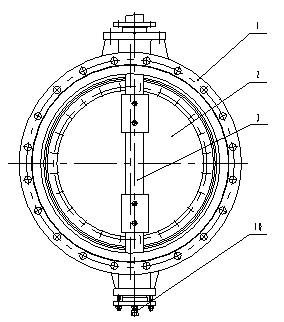

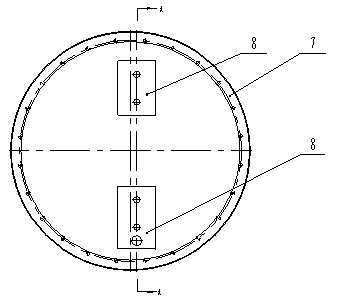

[0018] The present invention consists of a valve body 1, a valve plate 2, a valve stem 3 and a valve body seal ring 9. The valve plate 2 is fixedly connected with a support 8, and the support 8 is connected with the valve stem 3 through a taper pin.

[0019] As shown in the figure, the improvement of the present invention is that the valve plate 2 of the butterfly valve is a double-layer hollow form, consisting of upper and lower spherical panels with different radii of curvature, and the upper spherical panel 4 and the lower spherical panel 5 are connected with Stainless steel elastic ring 6 and seal seat ring 7, seal ring 11 is housed on the seal seat ring 7.

[0020] As shown in the figure, the convex and concave surfaces of the upper ball panel 4 and the lower ball panel 5 are opposite, and the spherical centers of the upper ball panel 4 and the lower ball panel 5 are on the same side on the same straight line, and the elastic ring 6 and the sealing seat ring 7 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com