Preparation method for jointly preparing beta-ionone

A technology for combined preparation of ionone and β-ionone, which is applied in the field of joint preparation of β-ionone, can solve the problems of cumbersome process and difficult operation, and achieve the effect of simple operation, high yield, and low requirements for raw materials and reaction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

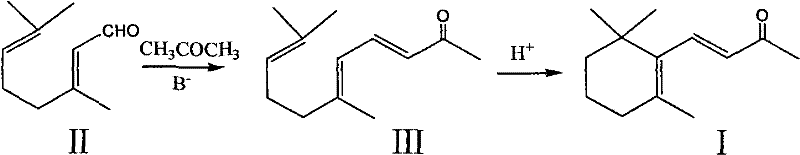

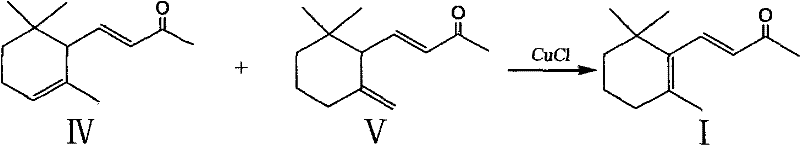

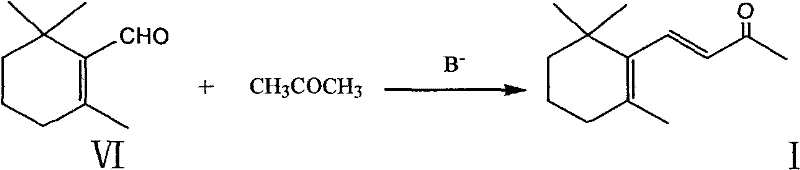

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of α-cyclic citral (VII)

[0031]

[0032] Dilute 45.6g (0.3mol) of citral with 45ml of dichloroethane and add it to a 250ml four-neck flask, keep warm in a water bath, and slowly drop into a solution of 30.0g of aniline in 30ml of dichloroethane while stirring at room temperature. After the dropwise addition was completed, the mixture was stirred for another half an hour, and the TLC reaction was completed (developing solvent: ethyl acetate:petroleum ether=1:3). The reaction mixture was dried with 8 g of anhydrous sodium sulfate, and the dried dichloroethane solution of citralimine could be directly used in the cyclization reaction. Add 120ml of 98% concentrated sulfuric acid and 140ml of dichloroethane into a 500ml four-necked bottle, mix and stir, cool in a cold bath to -20~-25°C, and slowly drop the imine solution prepared above into it under vigorous stirring. The temperature was controlled at about -20°C, the addition was complete...

Embodiment 2

[0037] Embodiment 2: the preparation of β-cyclic citral (VI)

[0038]

[0039]Dilute 0.3g KOH with 60ml of methanol and add it into a 250ml three-neck flask, and add 30.4g (0.2mol) of α-cyclocitral dropwise under stirring at room temperature. After the dropwise addition was completed, the stirring was continued for about 1 hour. The reaction was followed by gas chromatography, and then 1.2 g of concentrated hydrochloric acid was added to terminate the reaction. The solvent was recovered, the residue was distilled under reduced pressure, and 25.5 g of 60-65°C / 1mmHg fraction was collected as a colorless transparent liquid with a gas phase content of 98.5% and a yield of 83.9%. Product structure verification:

[0040] GC-MS (m / e): 152, 137 (100%), 123, 109, 95, 91, 81, 67, 55, 43, 41; IR (v / cm -1 ): 1672 (-CHO, characteristic peak of aldehydes), 1612 (double bond);

[0041] 1 HNMR (δ, ppm, 400MHz, CDCl 3 ): 1.19 (s, 6H, -CH 3 ), 1.43-1.46 (m, 2H, CH 2 -C), 1.60-1.66(m, ...

Embodiment 3

[0043] Embodiment 3: the mixture of α-cyclic citral (VII) and β-cyclic citral (VI) prepares β-ionone

[0044] In a 500ml four-necked bottle, add α-cyclocitral 15.4g, β-cyclocitral 15.0g (0.2mol in total) and 250g acetone, then add 5% sodium hydroxide aqueous solution 3ml, stir under the protection of nitrogen at 35- React at 45°C. After about 6 hours, the gas chromatography tracked that the raw material basically disappeared, and 1ml of acetic acid was added, and the acetone was recovered under normal pressure, and the oil pump vacuum distillation collected the 85-89°C / 1mmHg fraction to obtain 30.4g of the product (gas phase content 94.5%), and the yield was 74.8%. The first portion 9.4 grams is a mixture of α-cyclic citral, β-cyclic citral, α-ionone, and β-ionone (gas phase content 10.5%: 29.2%: 22.4%: 36.1%), which can be applied mechanically to the next batch reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com