Dispersed-speed flexible motor

A flexible and speed-dissipating technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of lack of speed, low power factor, large wasteful power loss, etc., to reduce startup power consumption and transmission power consumption, reduce Starting and running conditions, the effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

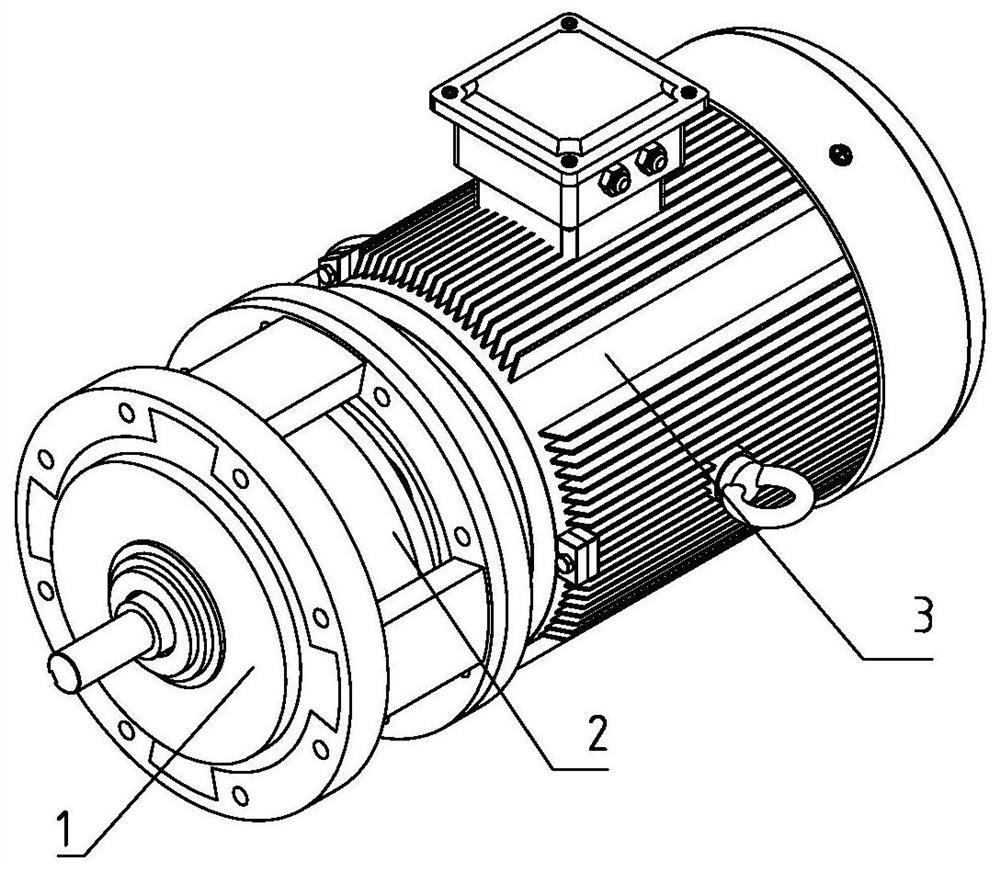

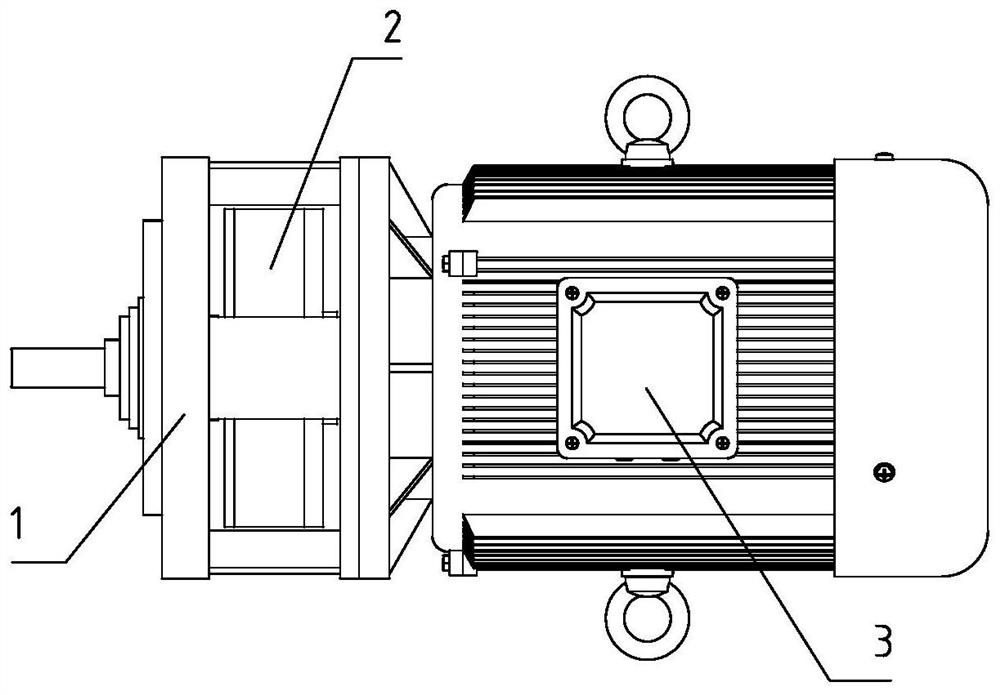

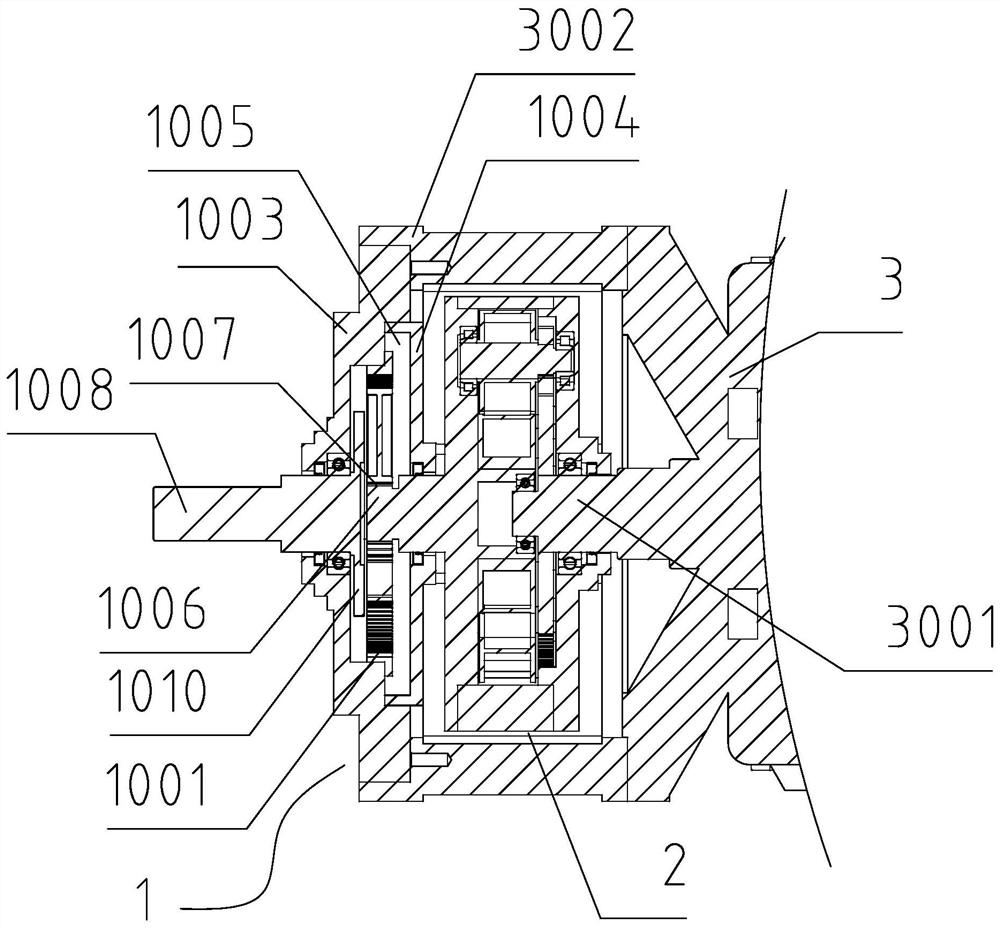

[0046] Figure 1-Figure 10 as well as Figure 17-Figure 20 It is an embodiment of a loose-speed flexible motor of the present invention. It can be seen in the figure that it includes a motor body 3, a continuously variable transmission 2 and a reducer 1. The front end of the motor body 3 is fixed with a mounting seat 3002, and the motor body The front end of 3 is rotated with a motor rotor output shaft 3001, the inside of the mounting base 3002 is provided with a continuously variable transmission 2, the outside of the mounting base 3002 is fixedly connected with the reducer 1, and one end of the continuously variable transmission 2 is connected with the motor rotor output shaft 3001, The other end of the continuously variable transmission 2 is provided with an intermediate transmission shaft 1006, and the continuously variable transmission 2 is rotationally connected with the reducer 1 through the intermediate transmission shaft 1006; the reducer 1 includes a reducer housing ...

Embodiment 2

[0058] Figure 11-Figure 20 It is another embodiment of a loose-speed flexible motor of the present invention. As can be seen in the figure, a loose-speed flexible motor includes a motor main body 3, a continuously variable transmission 2 and a reducer 1, and the front end of the motor main body 3 is fixed. There is a mounting base 3002, the front end of the motor main body 3 rotates and is provided with a motor rotor output shaft 3001, the inside of the mounting base 3002 is provided with a continuously variable transmission 2, the outside of the mounting base 3002 is fixedly connected with the reducer 1, and one end of the continuously variable transmission 2 is connected to the The motor rotor output shaft 3001 is connected, and the other end of the continuously variable transmission 2 is provided with an intermediate transmission shaft 1006, and the continuously variable transmission 2 is rotationally connected with the reducer 1 through the intermediate transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com