Patents

Literature

100 results about "Motor selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

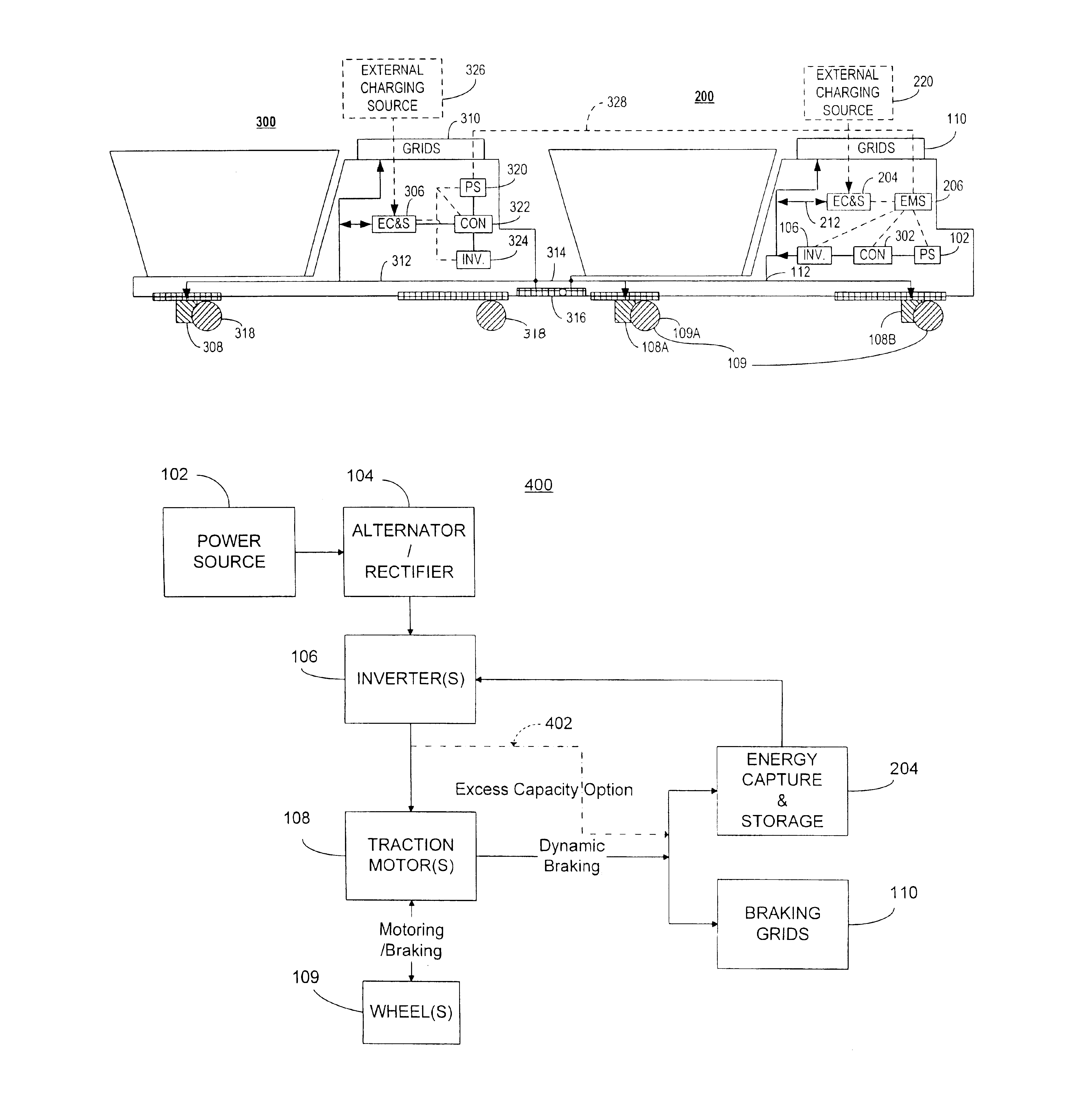

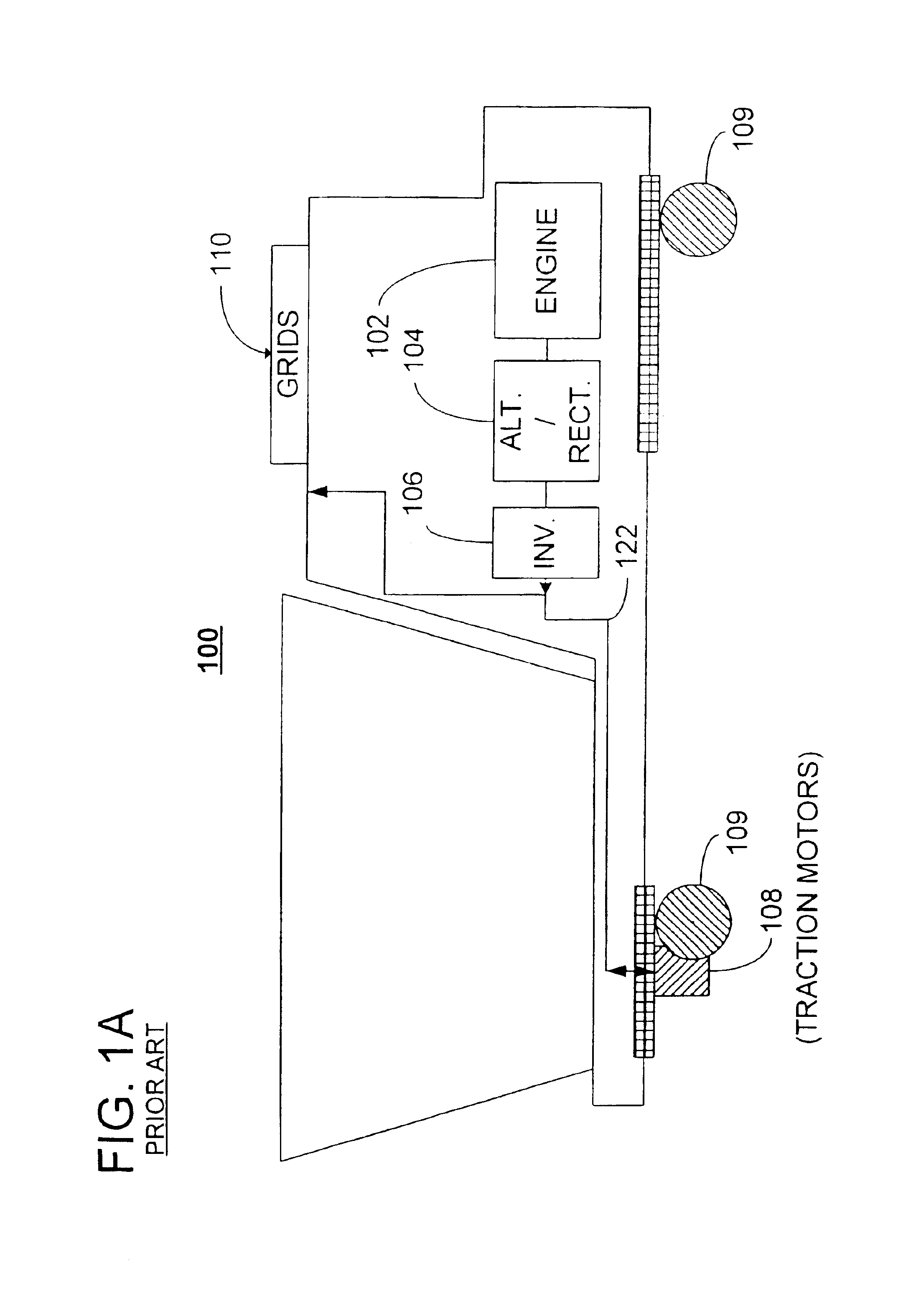

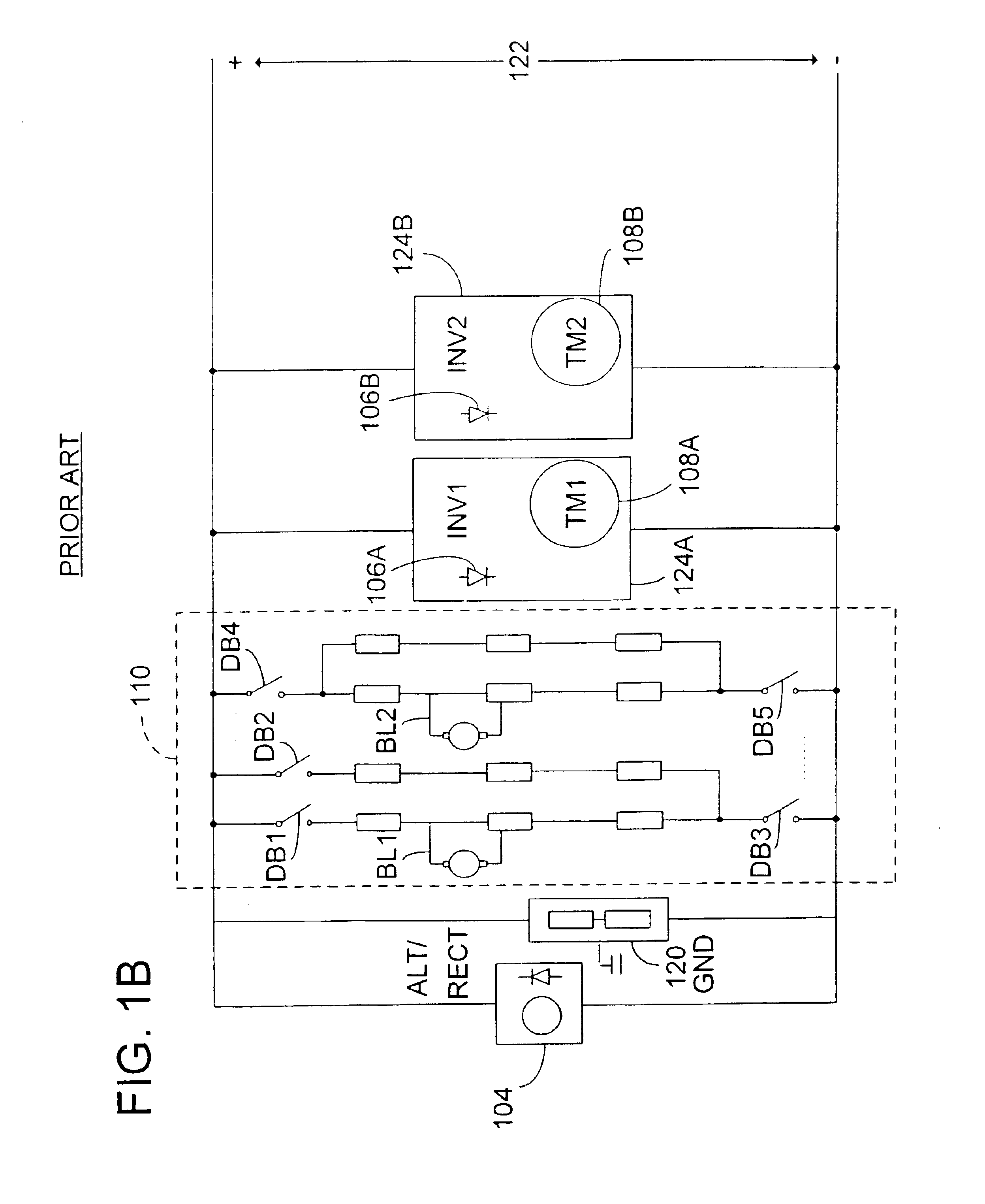

Hybrid energy off highway vehicle electric power storage system and method

InactiveUS6973880B2Auxillary drivesPlural diverse prime-mover propulsion mountingControl signalOperation mode

An electrical energy capture system for use in connection with a hybrid energy off highway vehicle system of a off highway vehicle. The hybrid energy off highway vehicle system includes an off highway vehicle, a primary power source, and an off highway vehicle traction motor propelling the off highway vehicle in response to the primary electric power. The off highway vehicle traction motor has a dynamic braking mode of operation generating electrical energy. The electrical energy capture system includes an energy management processor carried on the off highway vehicle. The capture system also includes an off highway vehicle electric generator connected to and driven by the primary power source for selectively supplying primary electric power, wherein the generator is responsive to said processor. An electrical energy storage device is carried on a off highway vehicle and is in electrical communication with the off highway vehicle traction motor. The storage device is responsive to the processor, selectively stores electrical energy generated in the dynamic braking mode, and selectively provides secondary electric power from said stored electricity electrical energy to the off highway vehicle traction motor. The off highway vehicle traction motor is responsive to the secondary electric power. The processor provides a first control signal to the electrical energy storage device to control the selective storing of the electrical energy generated in the dynamic braking mode, and to control the selective providing of secondary electric power to the off highway vehicle traction motor. The processor also provides a second control signal to the generator for controlling the selective supplying of primary electric power to the off highway vehicle traction motor.

Owner:GENERAL ELECTRIC CO

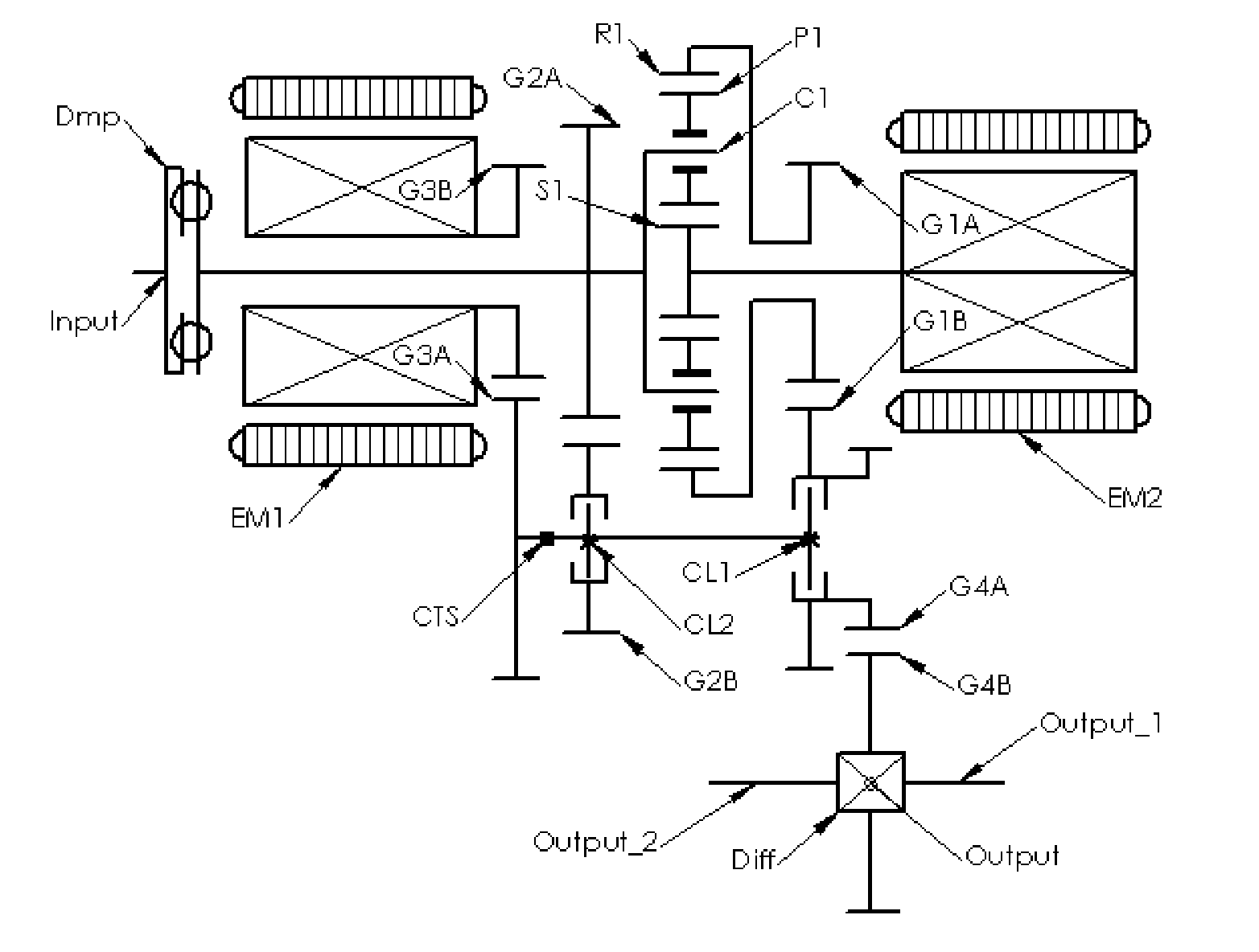

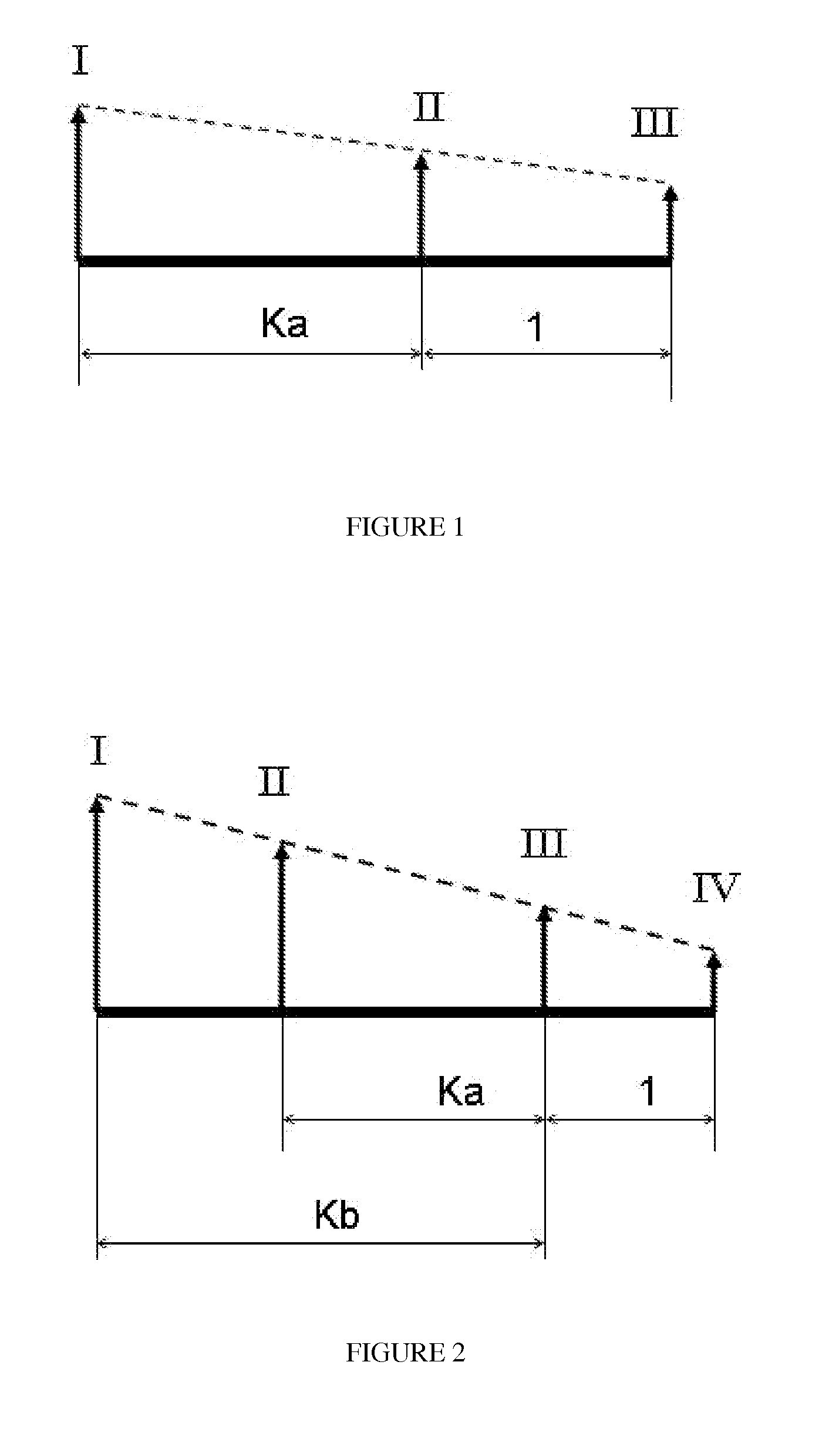

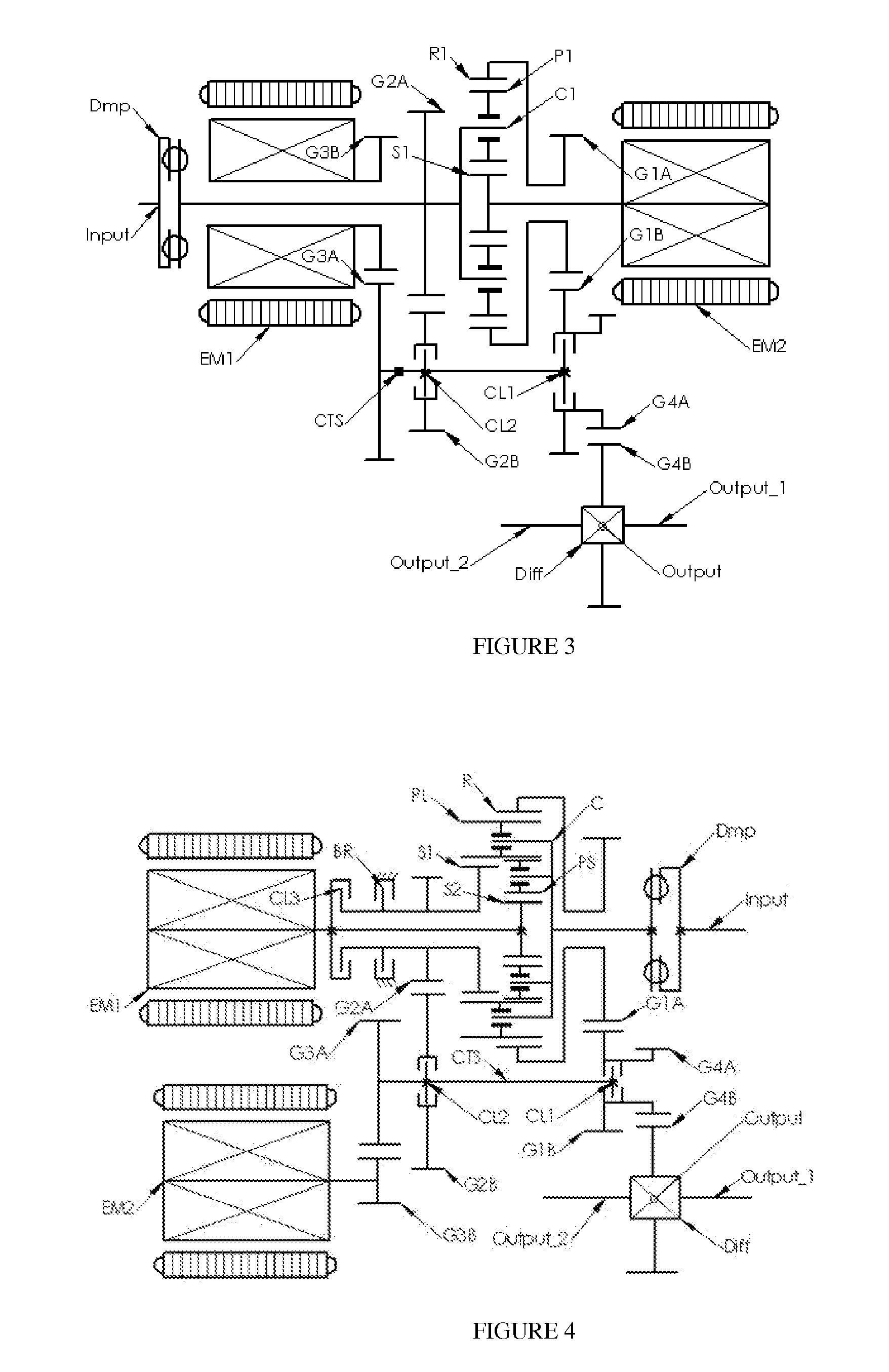

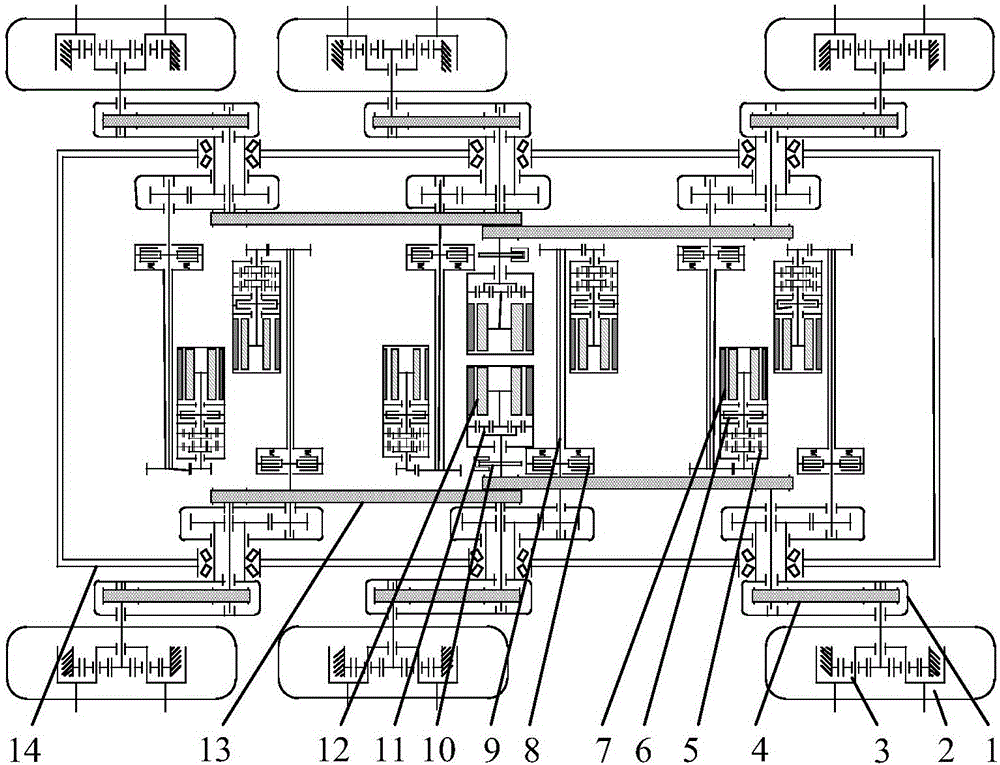

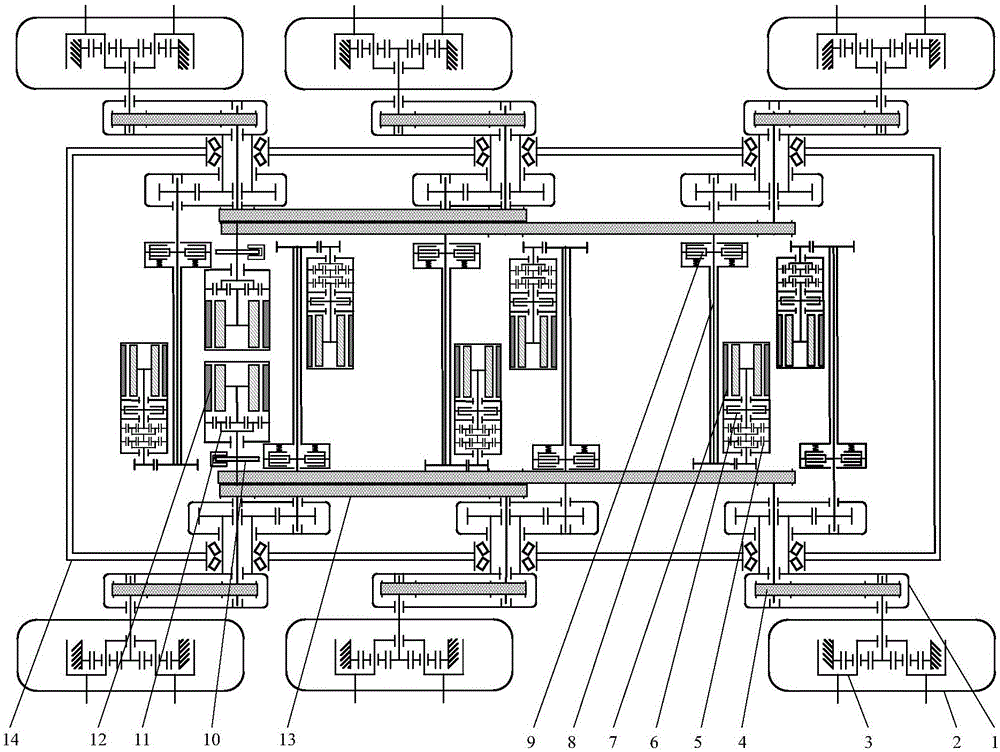

Dual-mode electromechanical variable speed transmission apparatus and method of control

InactiveUS20100261565A1Improve transmission efficiencyAvoid powerHybrid vehiclesElectric propulsion mountingDual modeElectric machine

The current invention discloses a dual-mode electro-mechanical variable speed transmission. Said transmission includes an input shaft, an output shaft system, a planetary gear system having at least three co-axial rotating members, two electric machines along with the associated controllers for the electric machines, and at least a clutch. Said planetary gear system has at least three branches; each branch corresponds to a co-axial rotating member. The first branch couples to the first electric machine with a fixed speed ratio; another branch couples to the input shaft with a fixed speed ratio; and yet anther branch couples to the output shaft system with a fixed speed ratio; the second electric machine couples selectively to two of the branches in the planetary gear system with different speed ratios. Said two branches are not the first branch and one of the said two branches is connected to the output shaft system. Said dual-mode electro-mechanical variable speed transmission is capable of providing at least two power splitting operation modes, including an output power splitting mode. Different operation modes cover different speed ratio regimes. At the mode switching point, the corresponding clutch or clutches is automatically synchronized. Thus the speeds of the rotation members of the transmission are continuous, and the transmission is free from shock loads at the operating mode switching point. In addition, said transmission is capable of providing operations with at least a fixed input-to-output speed ratio.

Owner:SHANDONG LIANCHENG GREENMAX TECH

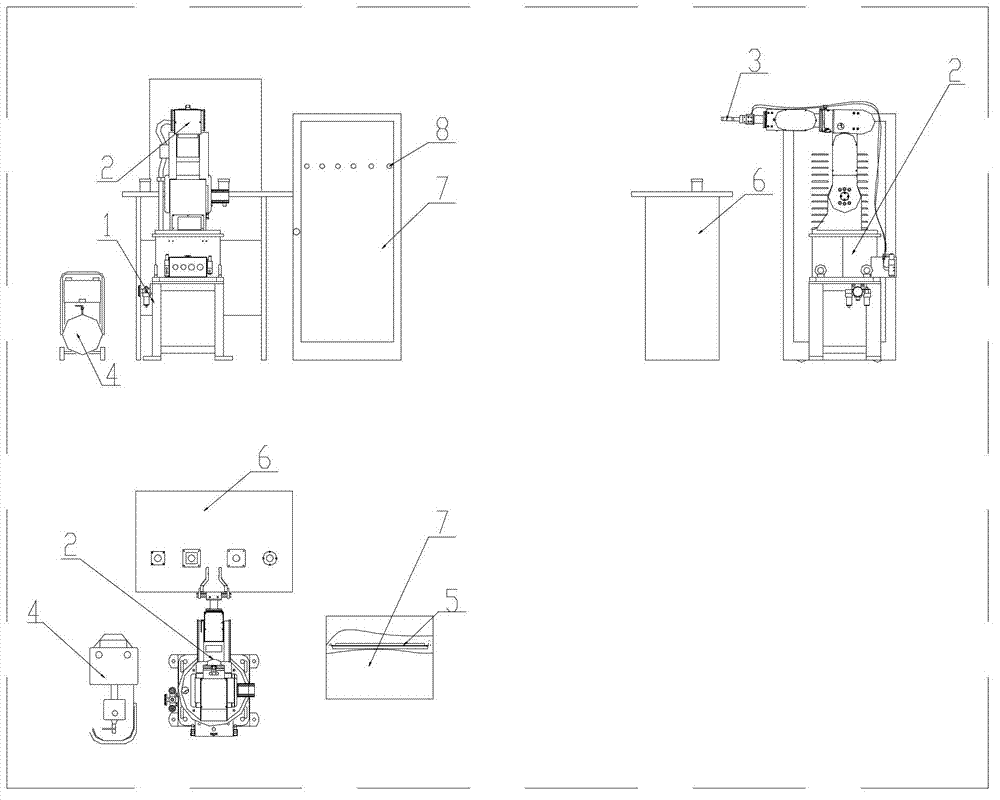

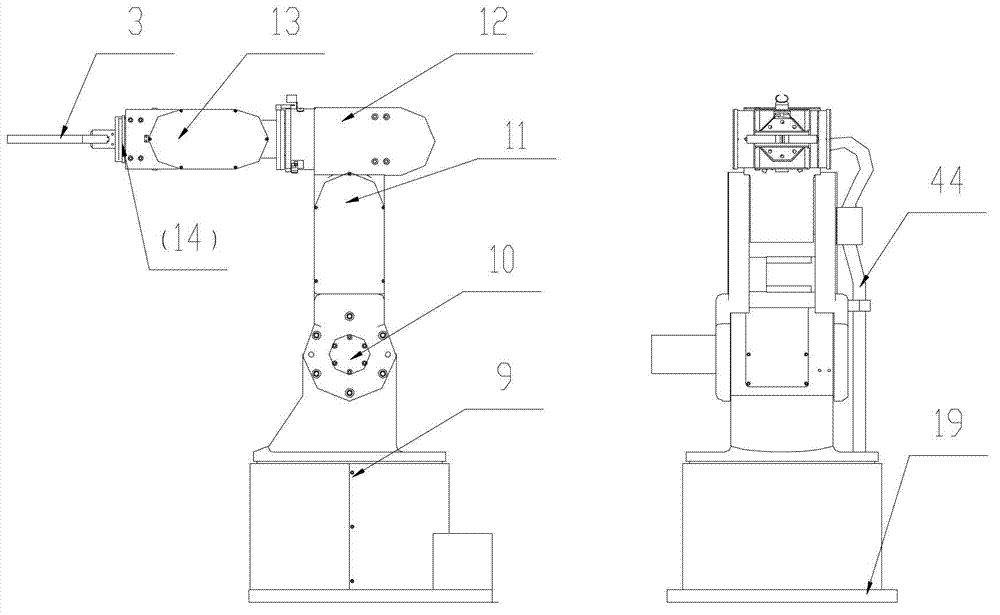

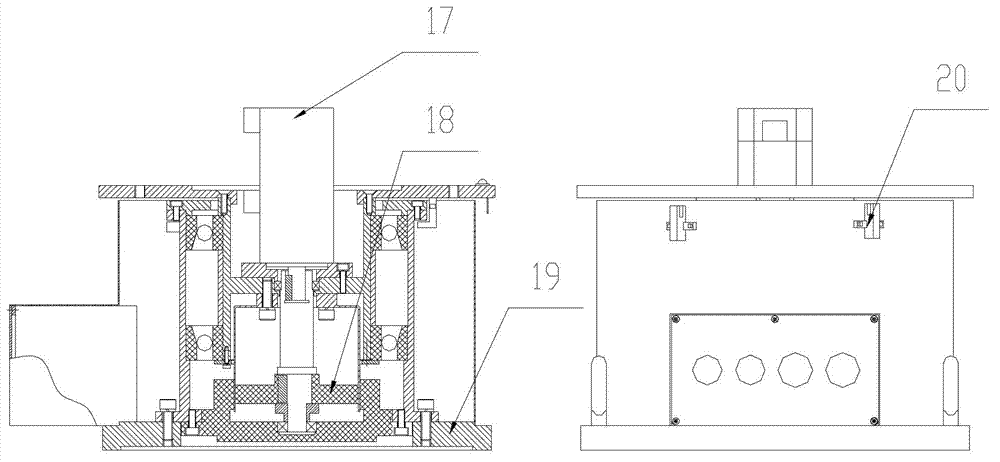

Six-degree-of-freedom medium serial teaching robot

The invention relates to a six-degree-of-freedom medium serial teaching robot. The robot comprises a robot base, a six-degree-of-freedom medium serial teaching robot body, a tool at the tail end of the robot, a gas path system, a robot control system and a workpiece test bed. Based on low cost and industrial series consistency design, the six-degree-of-freedom medium serial teaching robot body is provided with a visual mechanical system and a fully-open control system, is operated by a teaching box consistent with industrial series, and has a teaching playback work mode commonly used by an industrial serial robot, so that students can comprehensively master the technologies of selection and assembly of mechanical drive parts of an industrial robot, structural part designs, sensor selection and use, motor selection and use, computer programming and debugging, and so on, and the capability of designing, assembling and debugging a robot and an electromechanical system of students is improved. Therefore, the six-degree-of-freedom medium serial teaching robot has important meanings for accelerating training of high-quality skilled personnel and promoting great-leap-forward economic and social developments.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD

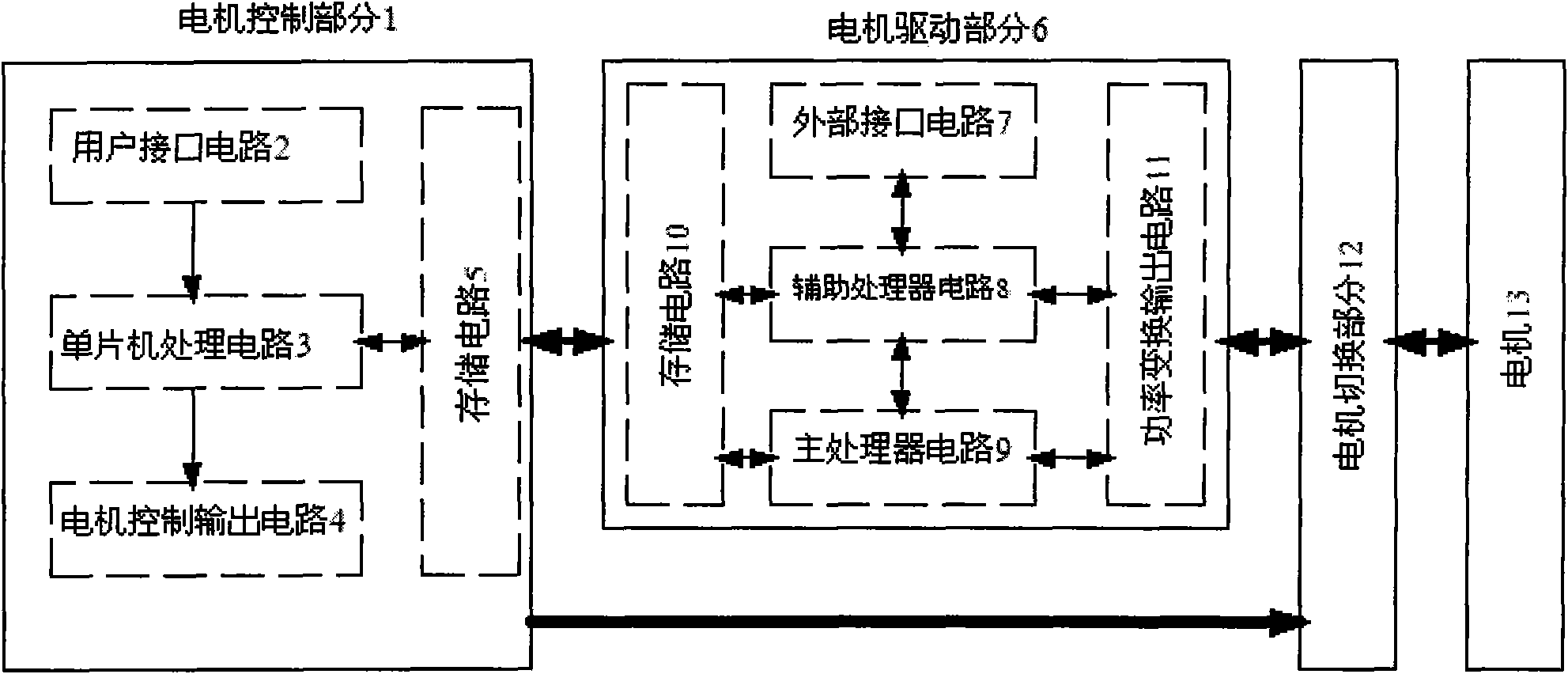

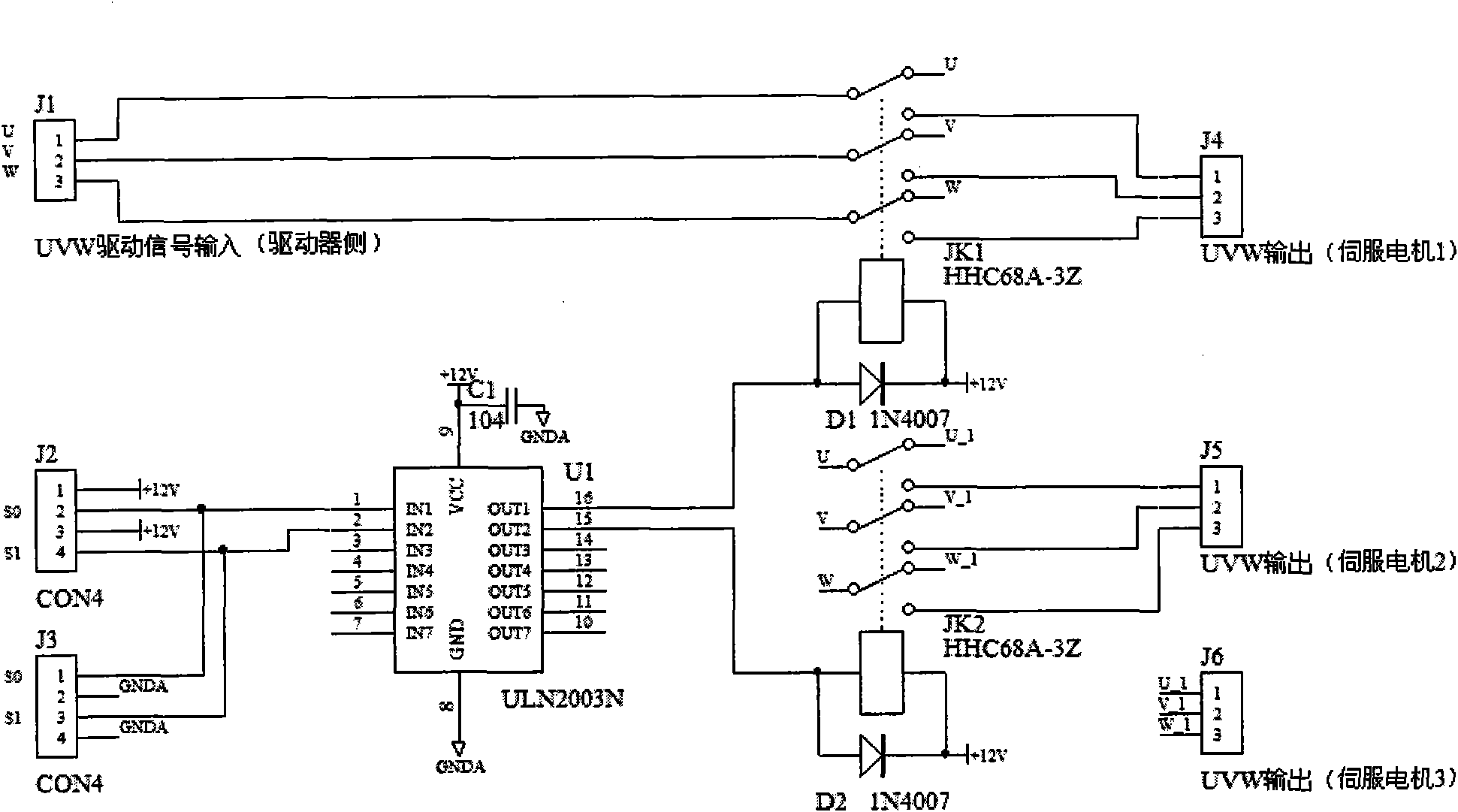

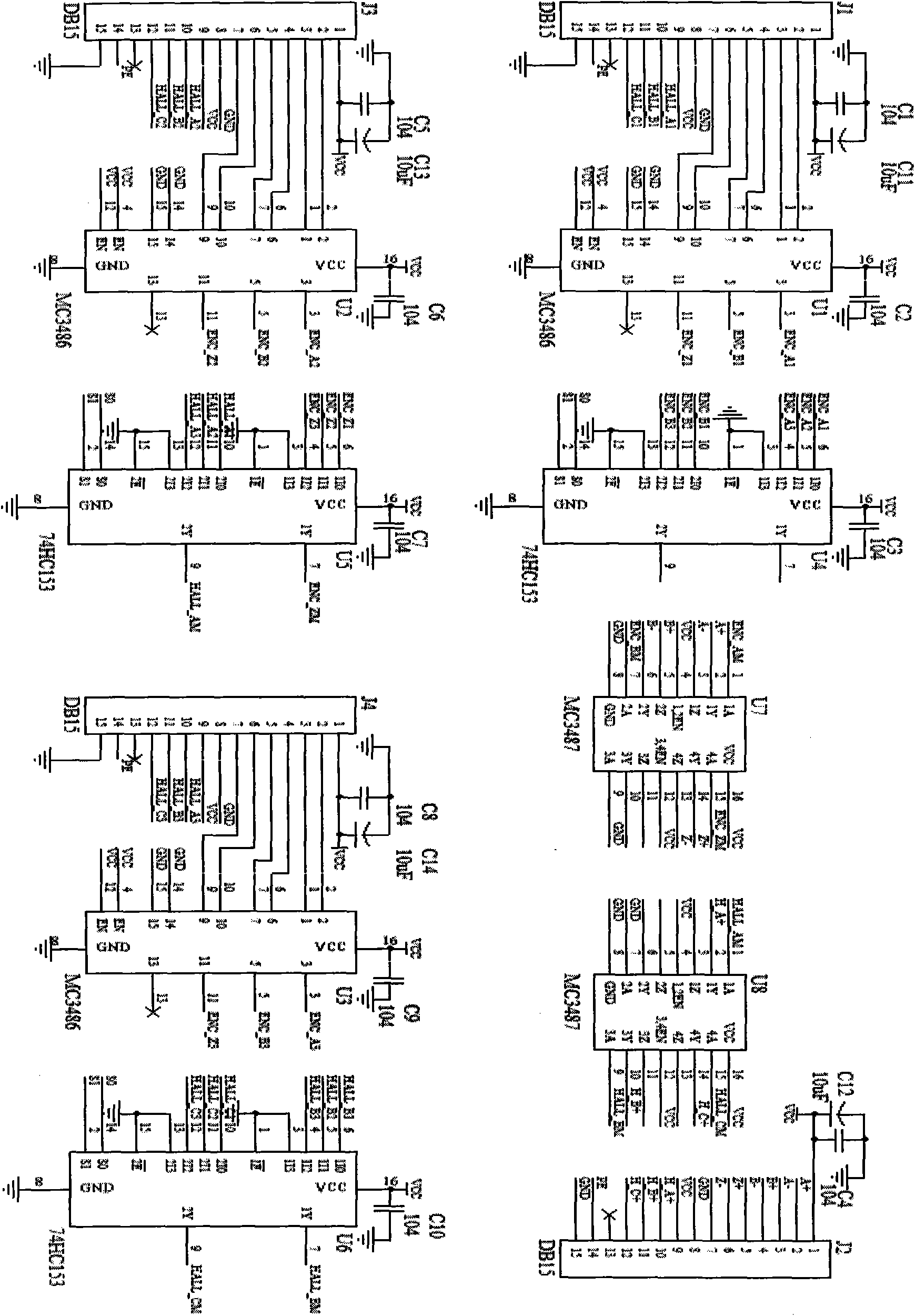

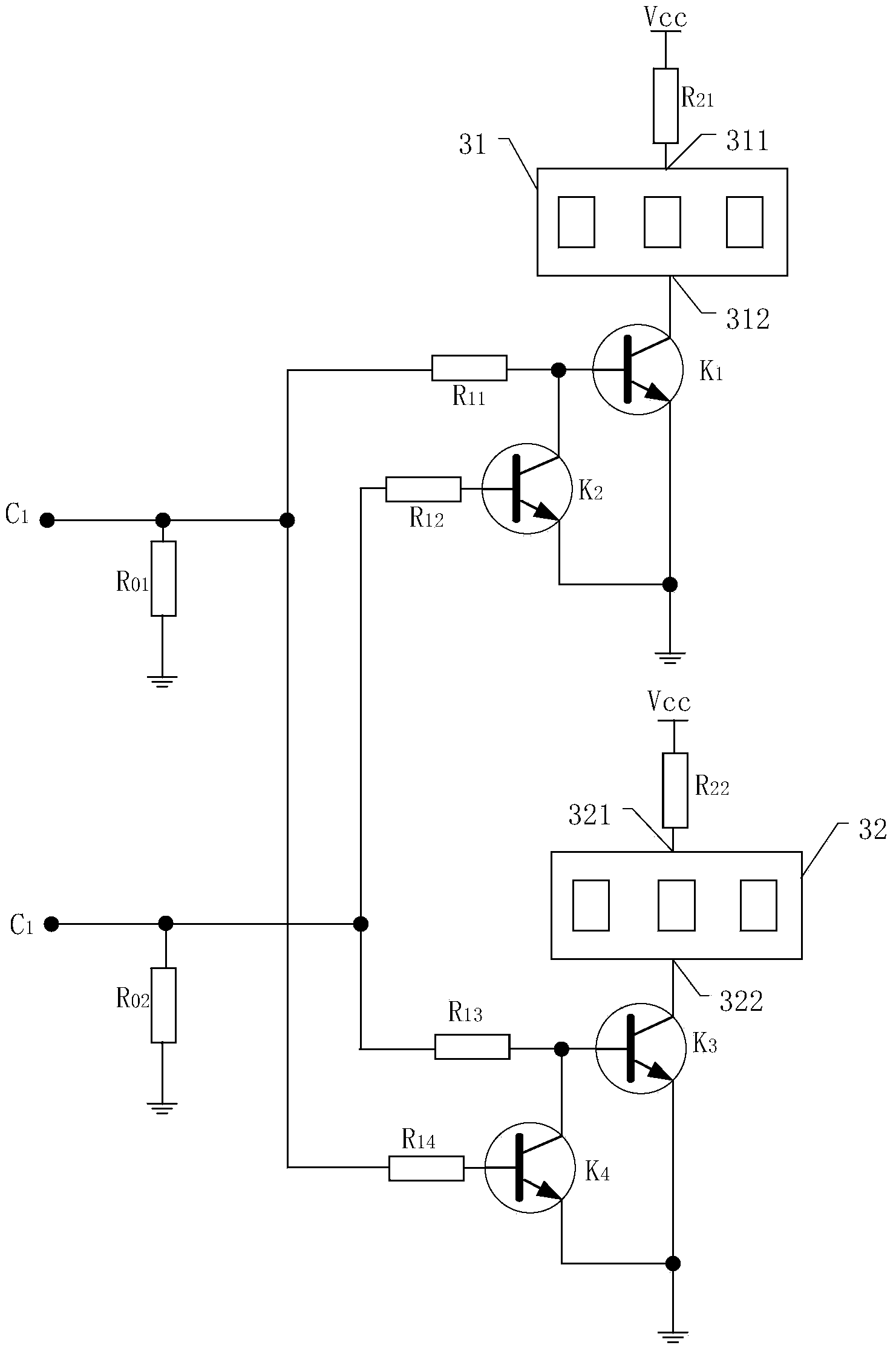

Alternating-current servo control system with single driver and multiple motors

InactiveCN102611366AEasy to controlReduce usageMultiple ac dynamo-electric motors controlMicrocontrollerAlternating current

The invention discloses an alternating-current servo control system with a single driver and multiple motors, belonging to the technical field of medical apparatus and instruments. The alternating-current servo control system mainly comprises a motor control part, a motor driving part, a motor switching part and a motor, wherein the motor control part comprises a user interface circuit, a single-chip microcomputer processing circuit, a motor control output circuit and a storage circuit; and the motor driving part comprises an external interface circuit, an auxiliary processor circuit, a main processor circuit, a storage circuit and a power conversion output circuit. A control instruction of a user end or a former control circuit is received by the motor control part, the control instruction and a motor selection instruction are sent to the motor driving part after identification is carried out, and finally, the motor driving part controls the motor. With the adoption of the alternating-current servo control system disclosed by the invention, a plurality of alternating-current servo motors are driven by an alternating-current servo driver, so that the cost is saved, medical apparatus and instruments can be automatically controlled, and the alternating-current servo control system can be applied to controlling servo systems in other fields.

Owner:NANJING PERLOVE RADIAL VIDEO EQUIP

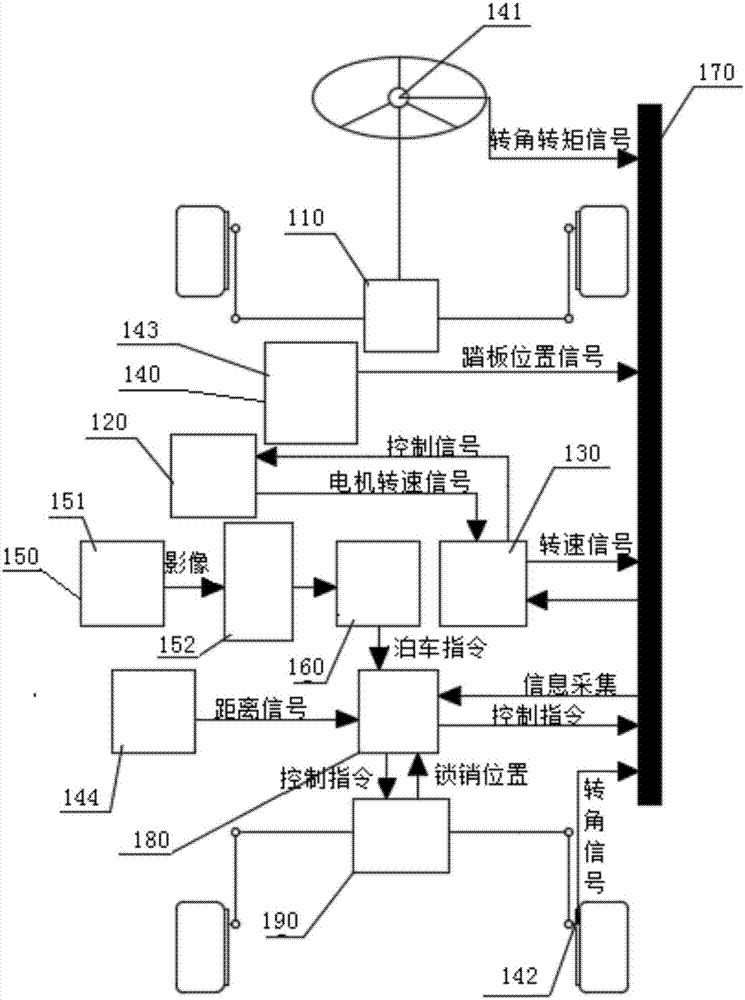

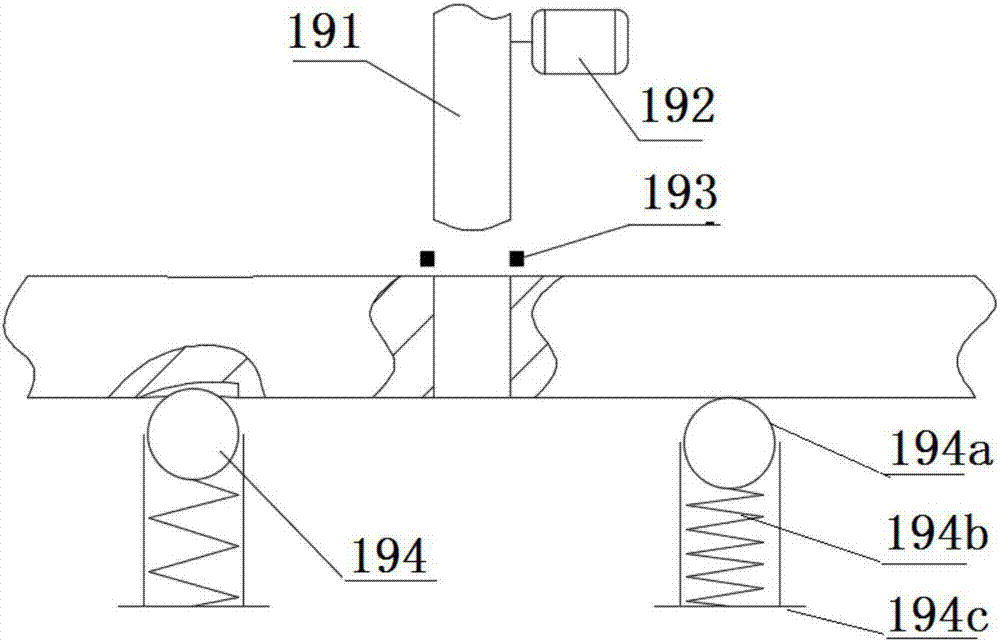

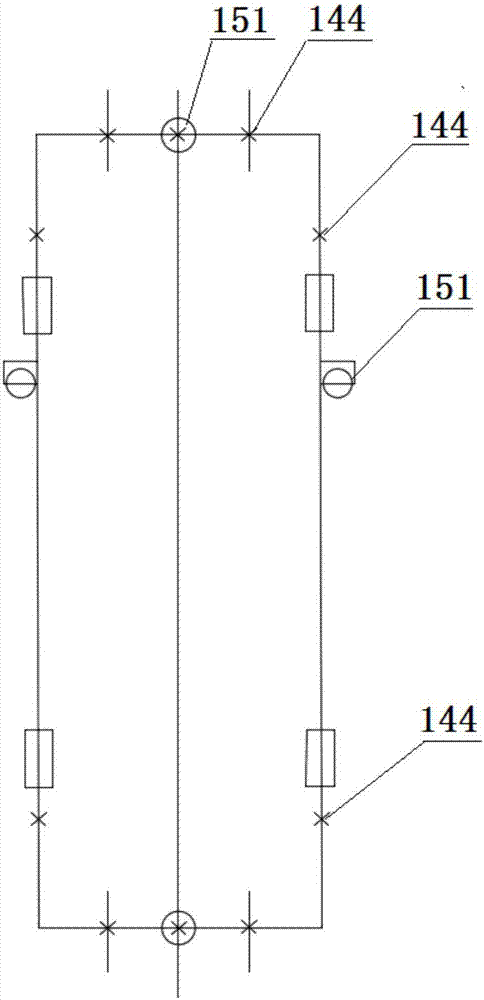

Full-automatic parking device and method of electric-wheel automobile

ActiveCN106985908ASimple structureSmall turning radiusSteering partsOptical viewingElectric machineryDrive motor

The invention discloses a full-automatic parking device of an electric-wheel automobile. The full-automatic parking device comprises wheels, wheel hub motors, lock pin driving mechanisms and a vehicle controller. The wheels are connected to an automobile body by adoption of independent suspension frames. The wheel hub motors are mounted in the wheels and used for driving the wheels to independently rotate. The lock pin driving mechanisms utilize lock pin driving motors to be inserted into or exit out of lock pins at center-line through holes of rear shaft steering transverse pull rods selectively and are used for locking or unlocking the rear shaft steering function. The vehicle controller controls the lock pin driving motors to work, receives all sensor signals and formulates a parking strategy according to the signals so as to control the wheel hub motors to rotate. The parking algorithm is higher in automation degree, under the premise that safety is ensured, the needed space for parking is reduced, and convenience is improved; and certain application prospects are also achieved in traditional automobiles.

Owner:JILIN UNIV

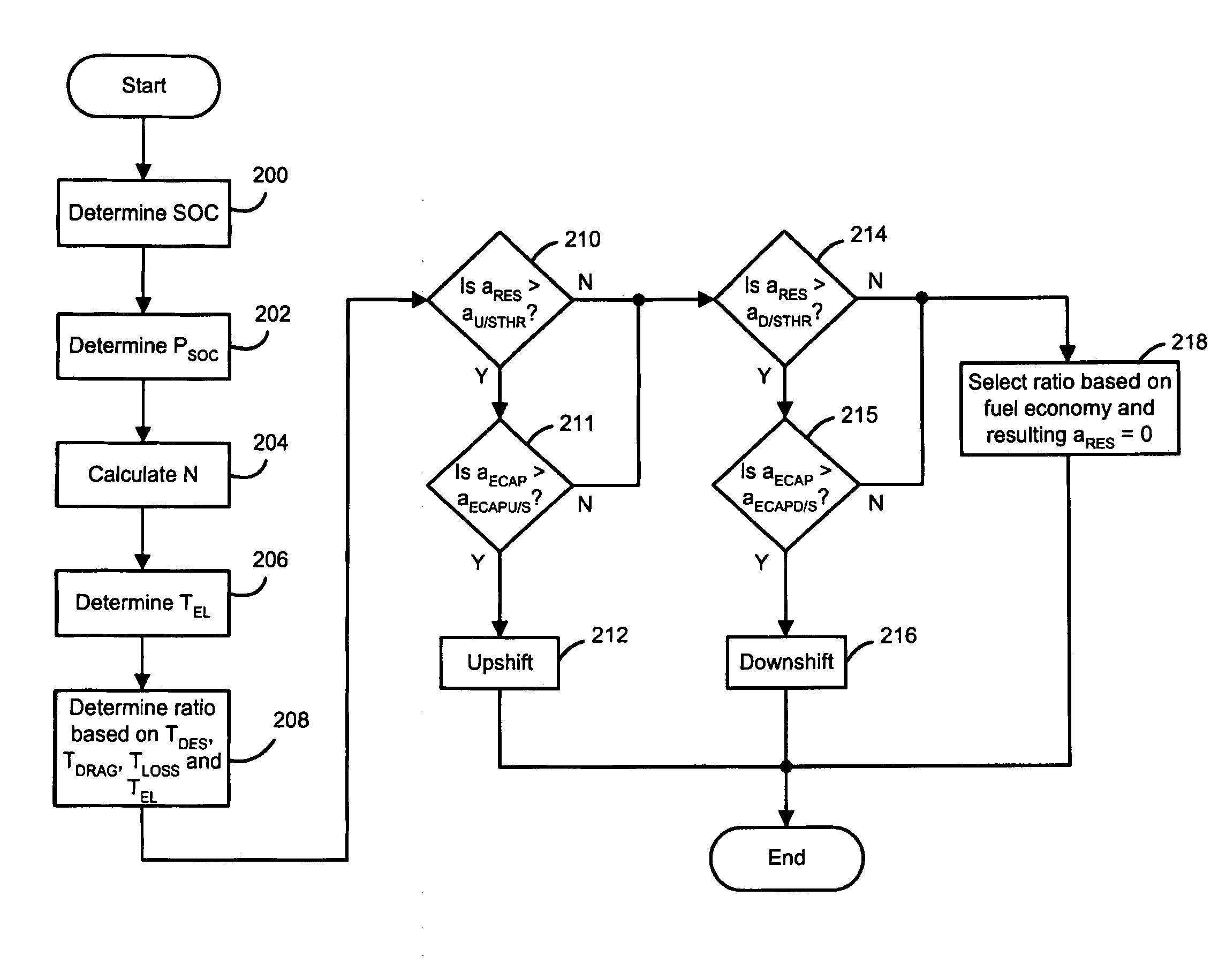

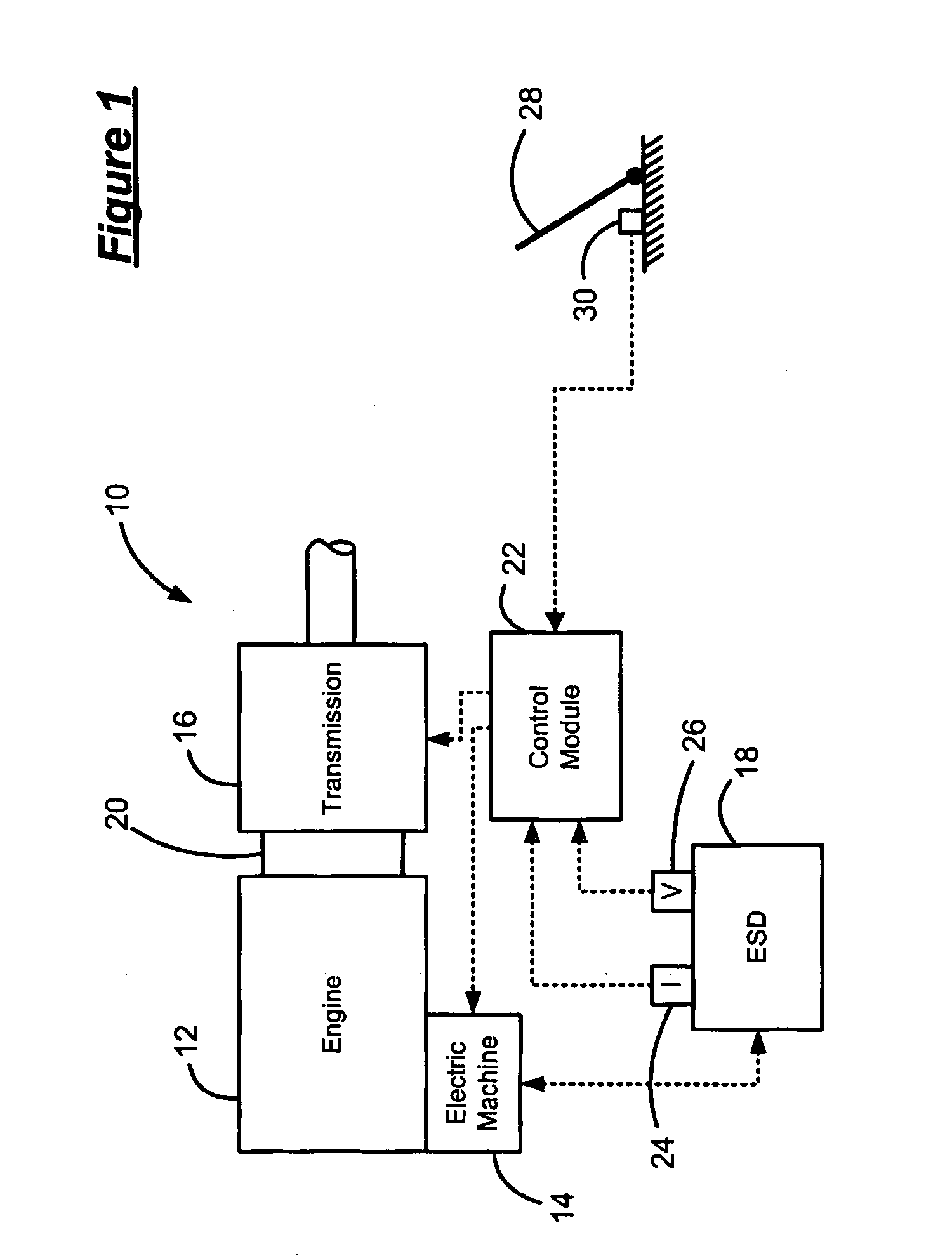

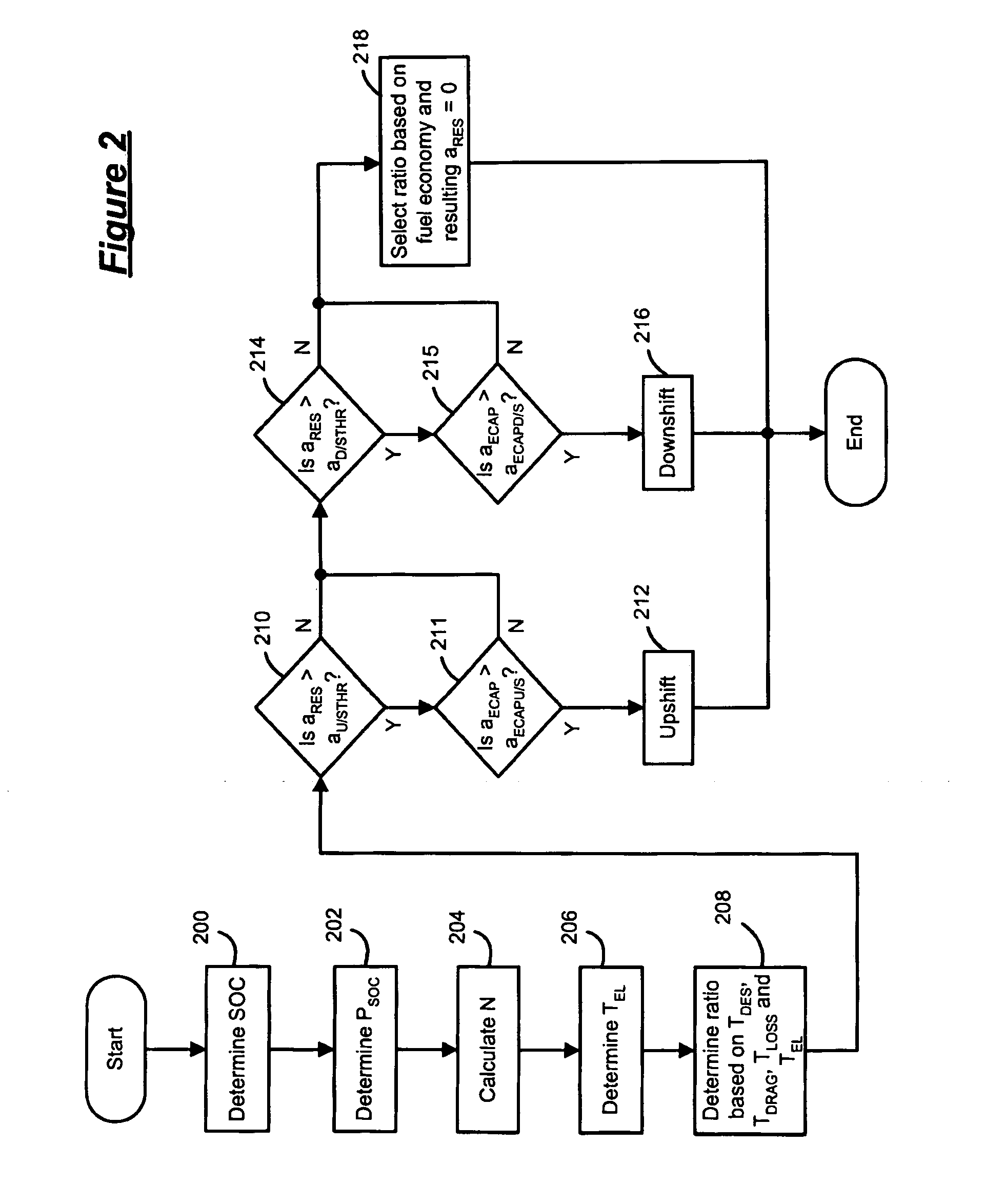

Hybrid powertrain optimum ratio selection

A transmission control system for a hybrid electric vehicle including an electric machine includes an energy storage device that is selectively charged by the electric machine and that selectively powers the electric machine. A driver input device generates a driver input signal. A control module receives the driver input signal, determines a torque load of the electric machine based on a state of charge (SOC) of the energy storage device and determines a transmission ratio based on the torque load and the driver input signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

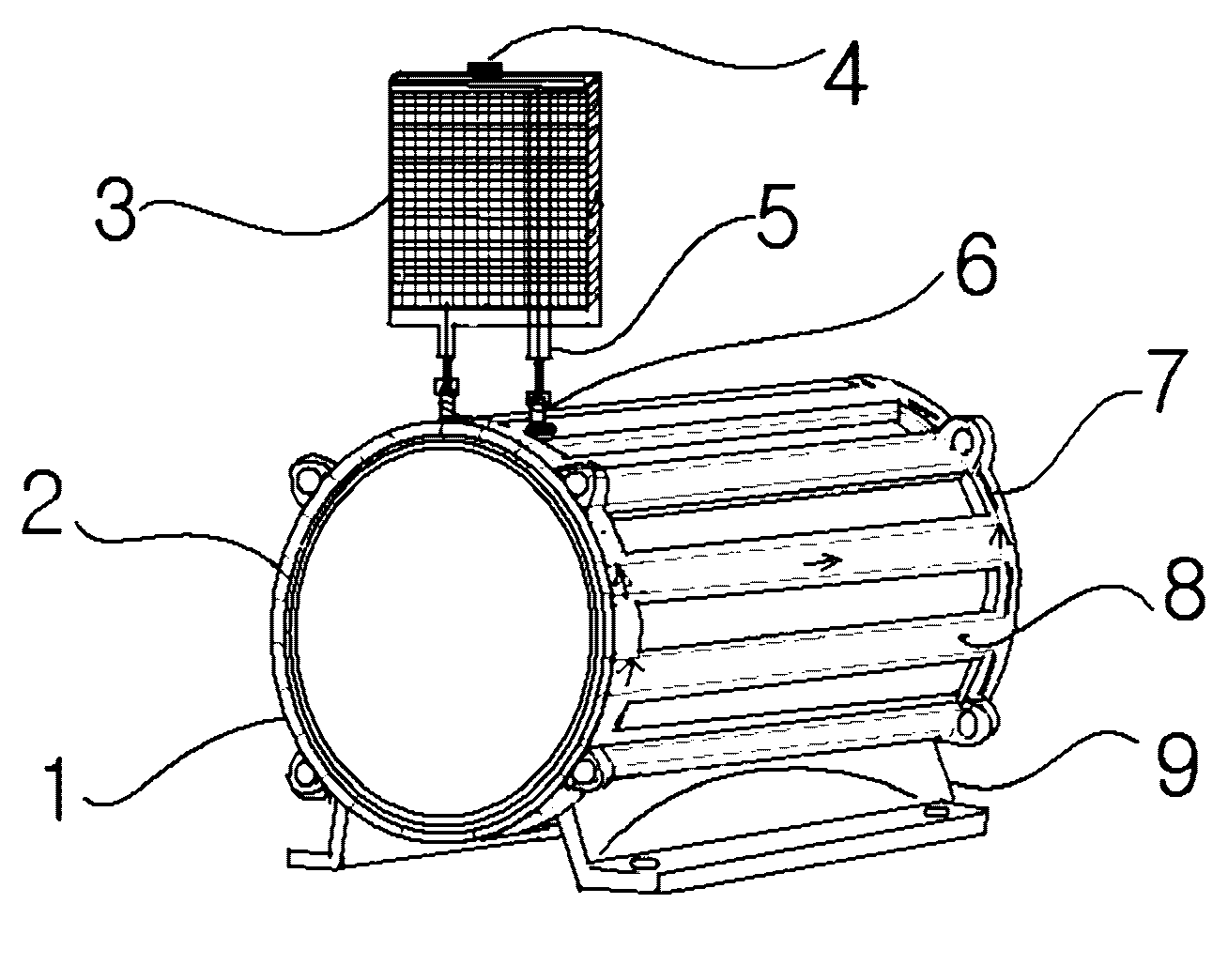

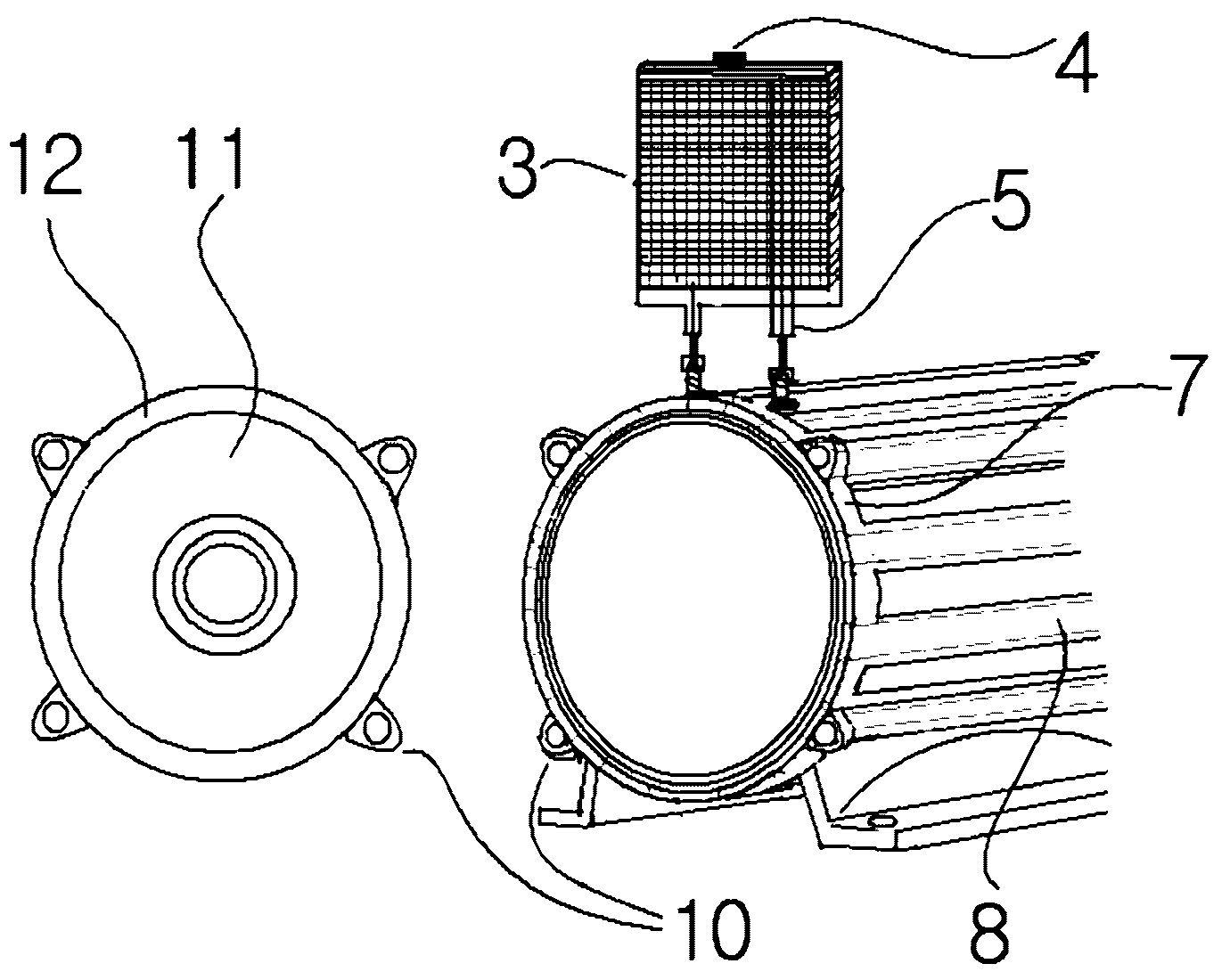

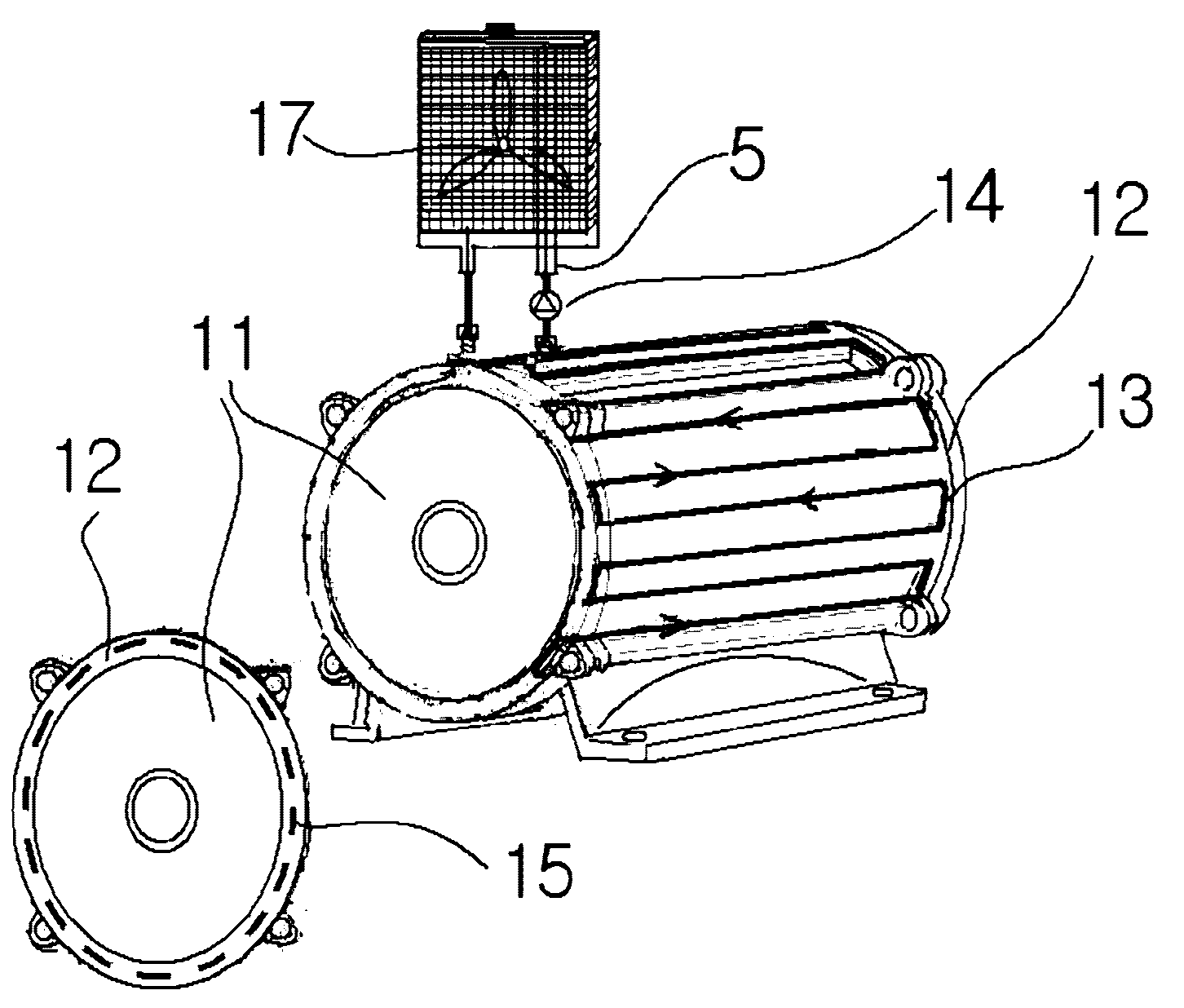

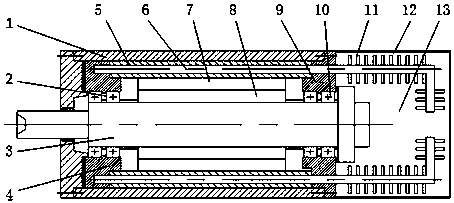

Conducting and radiating energy-saving motor

InactiveCN102223010ADistribute quicklyImprove cooling efficiencyCooling/ventillation arrangementSupports/enclosures/casingsElectric machineOil field

The invention relates to a conducting and radiating energy-saving motor. A motor stator heat-conducting shell (1) is connected with a distributive sheet hollow radiating slot (8) and hollow radiating chambers (7) at two ends; the upper part of the motor stator heat-conducting shell (1) is connected with a radiator (3) by a connector (6); the radiator (3) consists of a branch pipe (5) pipeline, a radiating fin and an oil filler (4); heat-conducting oil is used as a conducting device; all hollow radiating chambers distributed on the stator heat-conducting shell (1) conduct internal heat to the external radiator by the heat-conducting oil for radiating; two radiating methods, namely an automatic radiating method or a forcible radiating method, can be selected by the motor, thus eliminating a motor radiating flywheel fan and a wind-guiding cover; the radiating ribbon ventilation passage of the shell is changed into the hollow radiating chamber, thus improving the heat conduction efficiency; therefore, the big problem on the heat dissipation of the motor is effectively solved; the service life of the motor is prolonged; and the conducting and radiating energy-saving motor is particularly applicable to the radiating systems of the oil field motors, various closed low-noise power generator units and the high-speed motors in the field severe environments with high and low temperatures and insolation.

Owner:谢逢华

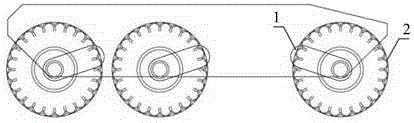

Differential-steering unmanned motor vehicle

InactiveCN106314111AReduced Dimensional Weight RequirementsReduce unsprung massElectric propulsion mountingResilient suspensionsDrive motorHigh power density

The invention discloses a differential-steering unmanned motor vehicle. The differential-steering unmanned motor vehicle adopts an in-elbow drive technology, and a driving motor is put in a vehicle body. Compared with an adopted hub motor scheme, the size and weight requirements for the motor is reduced, the motor selection and adapting difficulty is greatly reduced, meanwhile a high-rotating-speed and high-power-density motor can be selected, higher power can be provided under the requirement that the vehicle weight is limited, and the maneuvering performance, especially the cross-country maneuvering performance of the vehicle is greatly improved. In addition, the motor and other large-mass parts are arranged inside a compartment, the unsprung mass of a suspension system is reduced, the response capability of a suspension is improved, meanwhile the moving load of the suspension is decreased, and the cross-country performance can be greatly improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

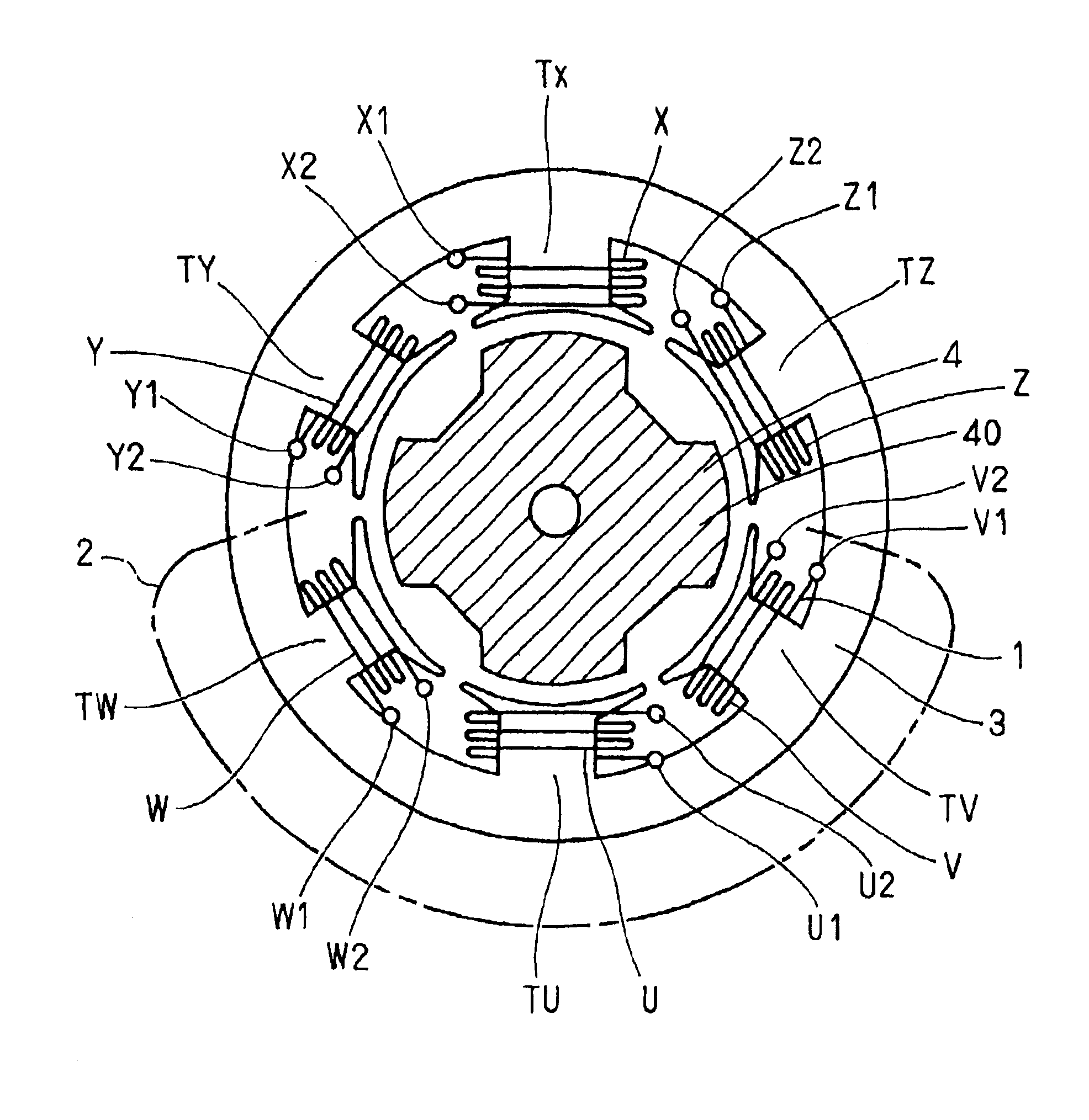

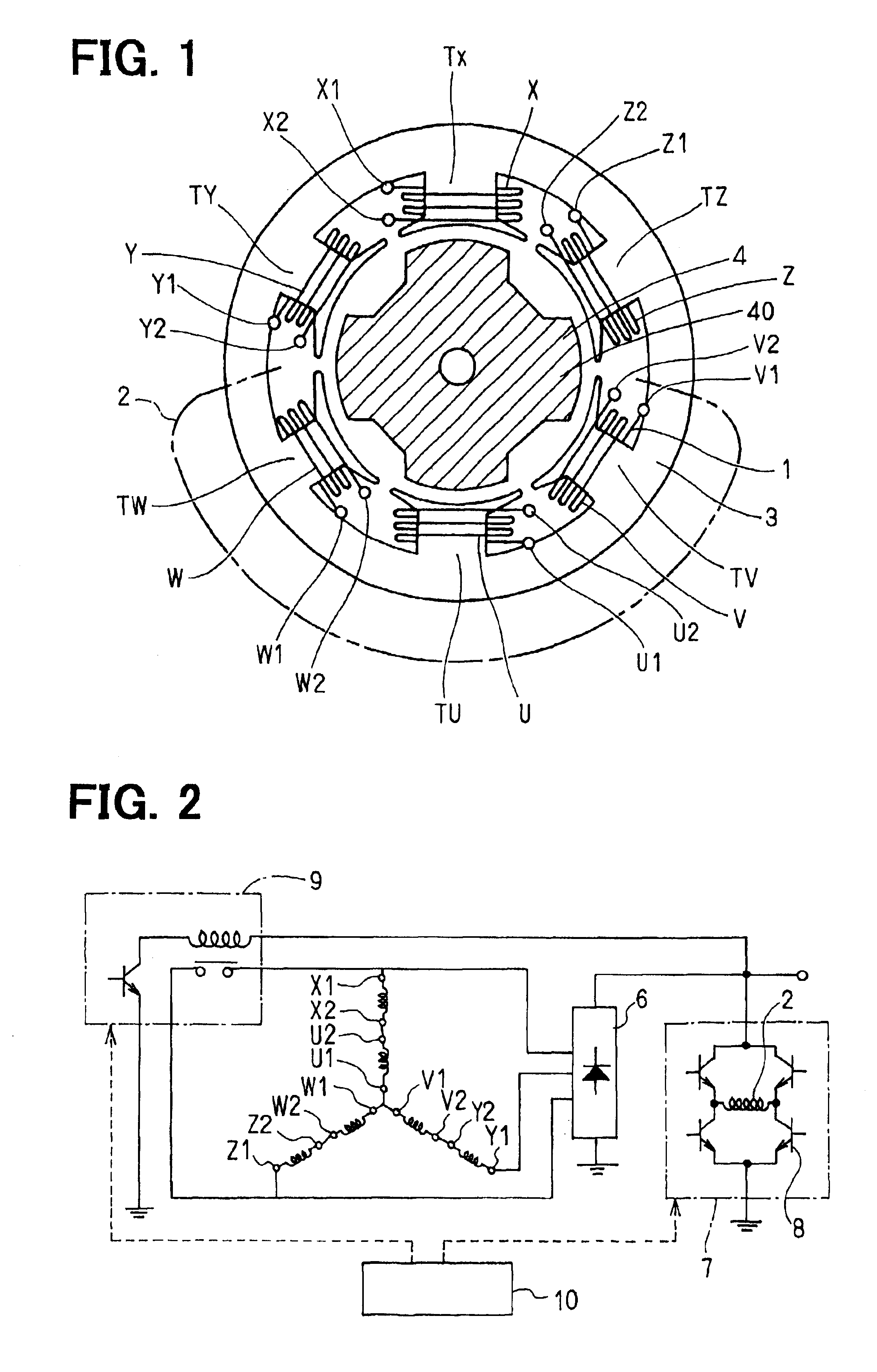

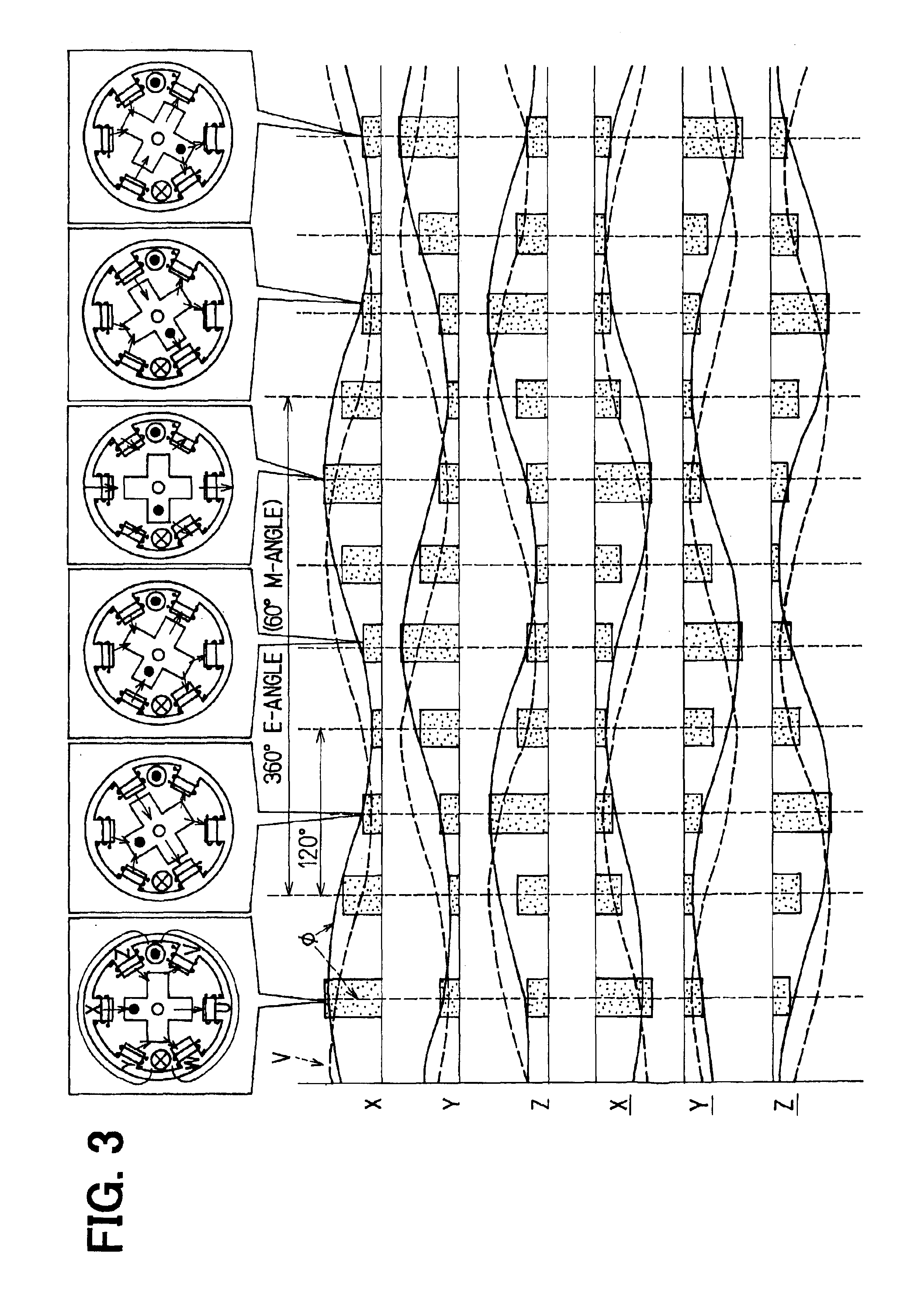

Induction machine with motor and generator operation modes

An electric machine selectively operates as a generator mode or a motor mode. The electric machine includes a stator core, a multi-phase armature winding, a field coil, a moving core having a plurality of salient poles so as to move relative to the stator core to cross the magnetic field. Field current is supplied to the field coil differently according to operation mode. A portion of the armature winding is short-circuited to form an additional magnetic field that has a phase different from the magnetic field of the field coil. Therefore, the rotary core moves relative to the stator core when the operation mode is in the motor mode.

Owner:DENSO CORP

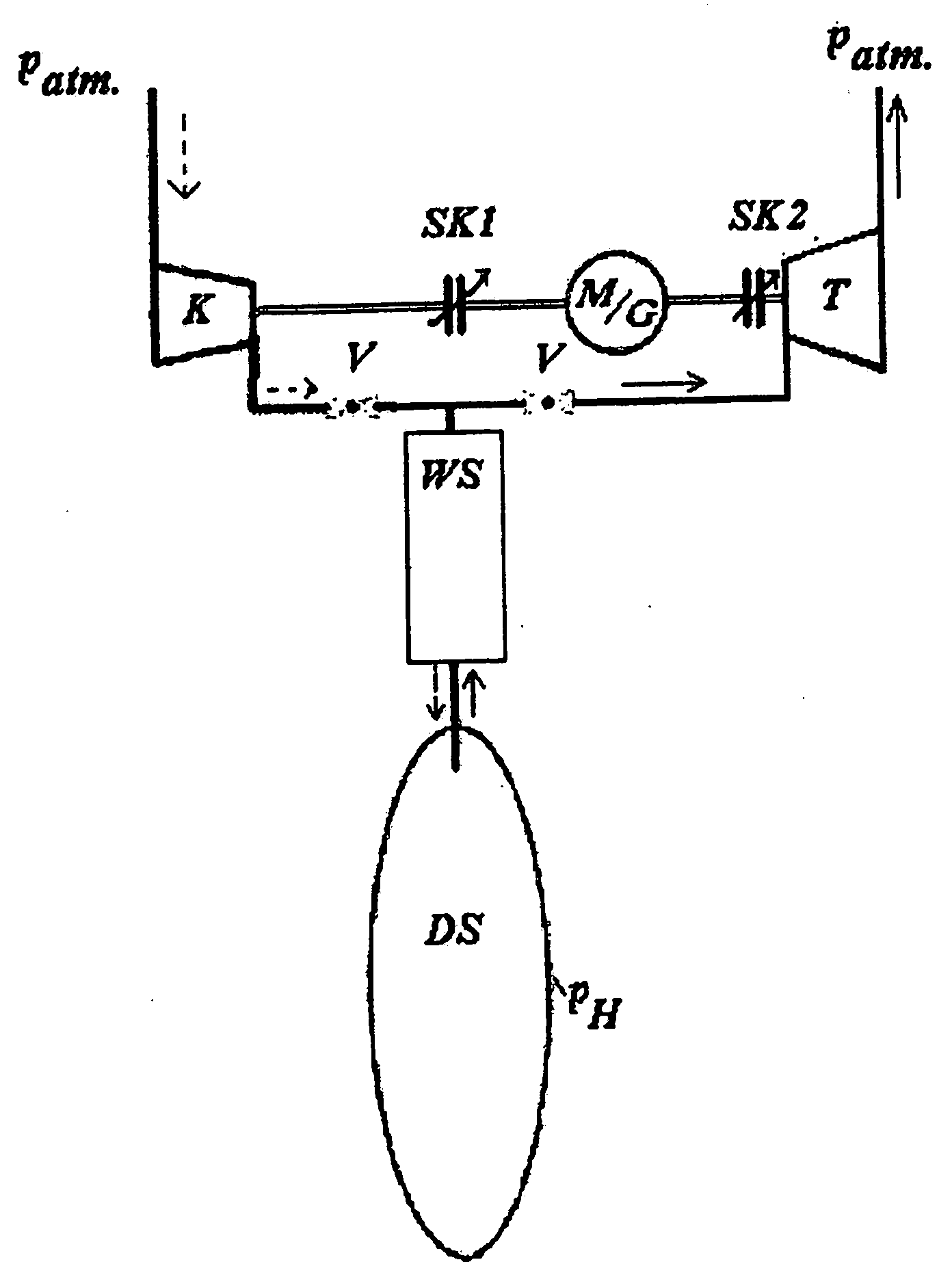

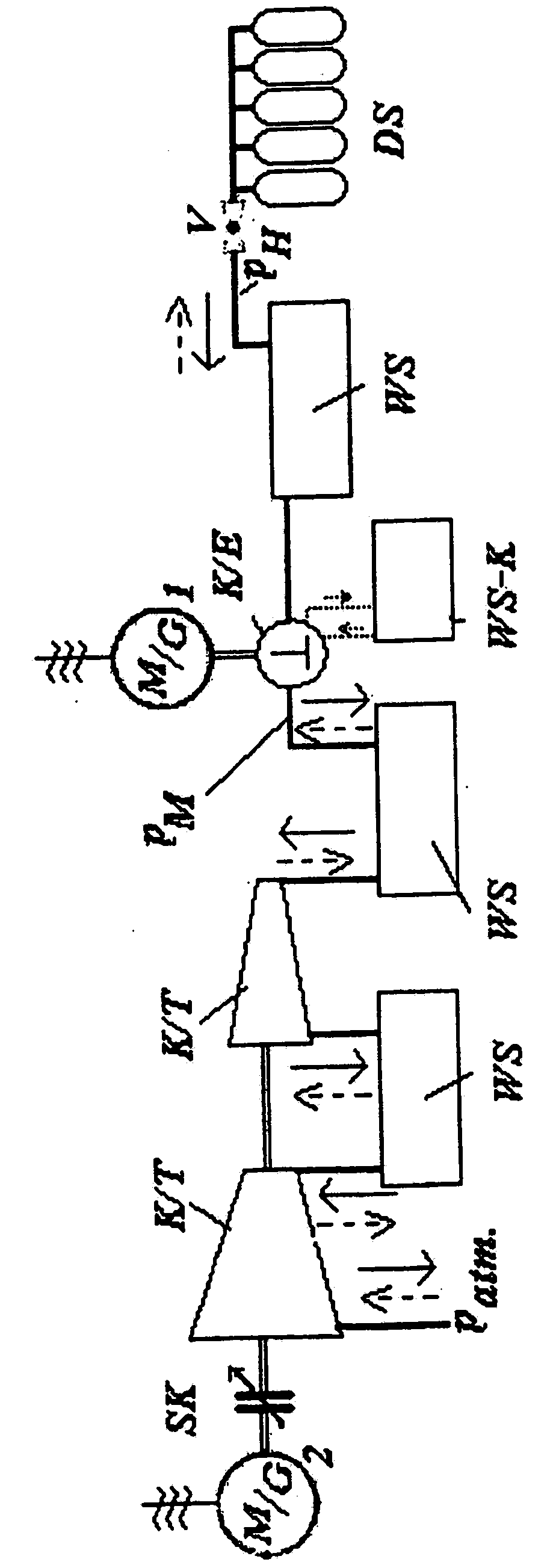

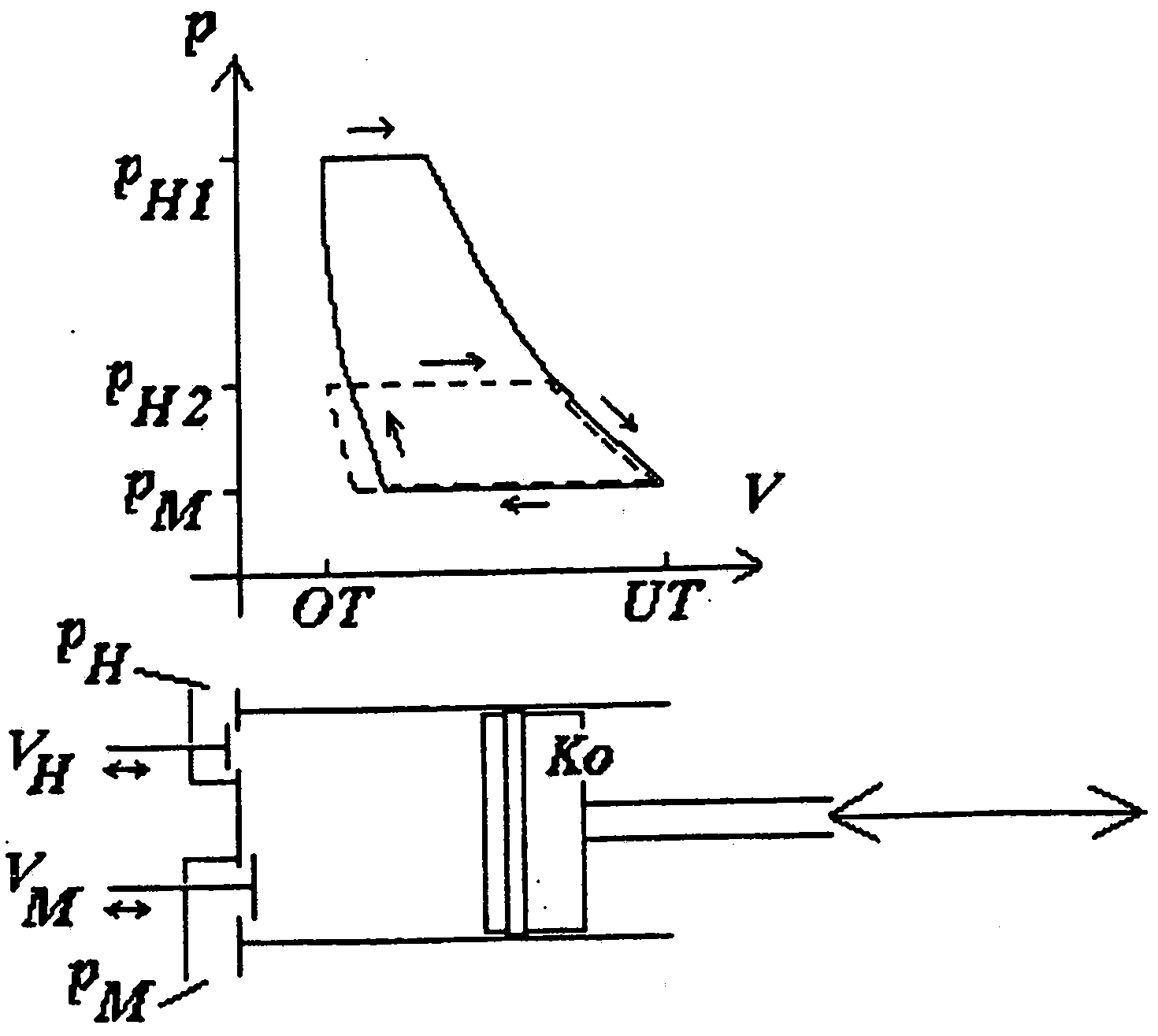

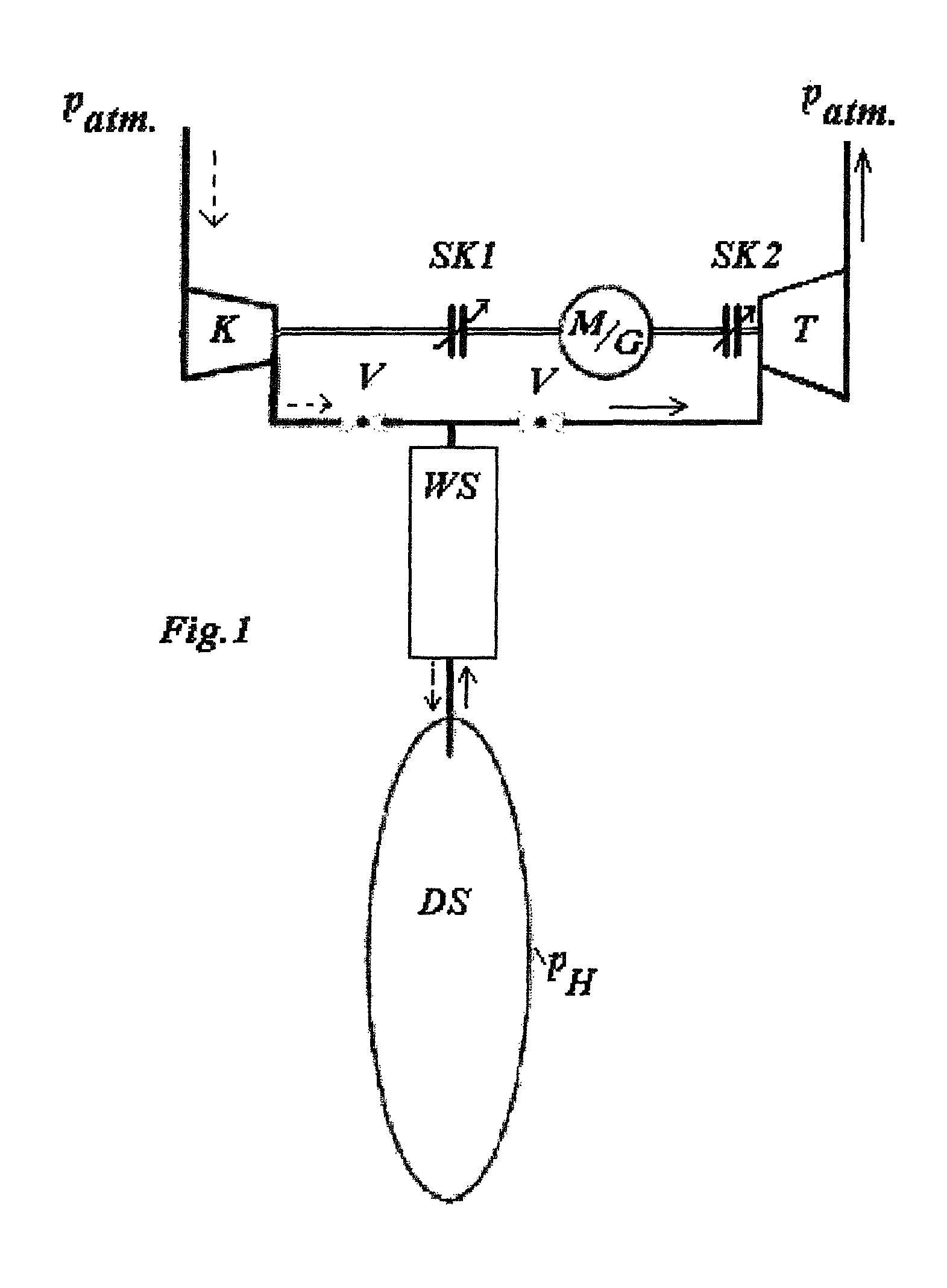

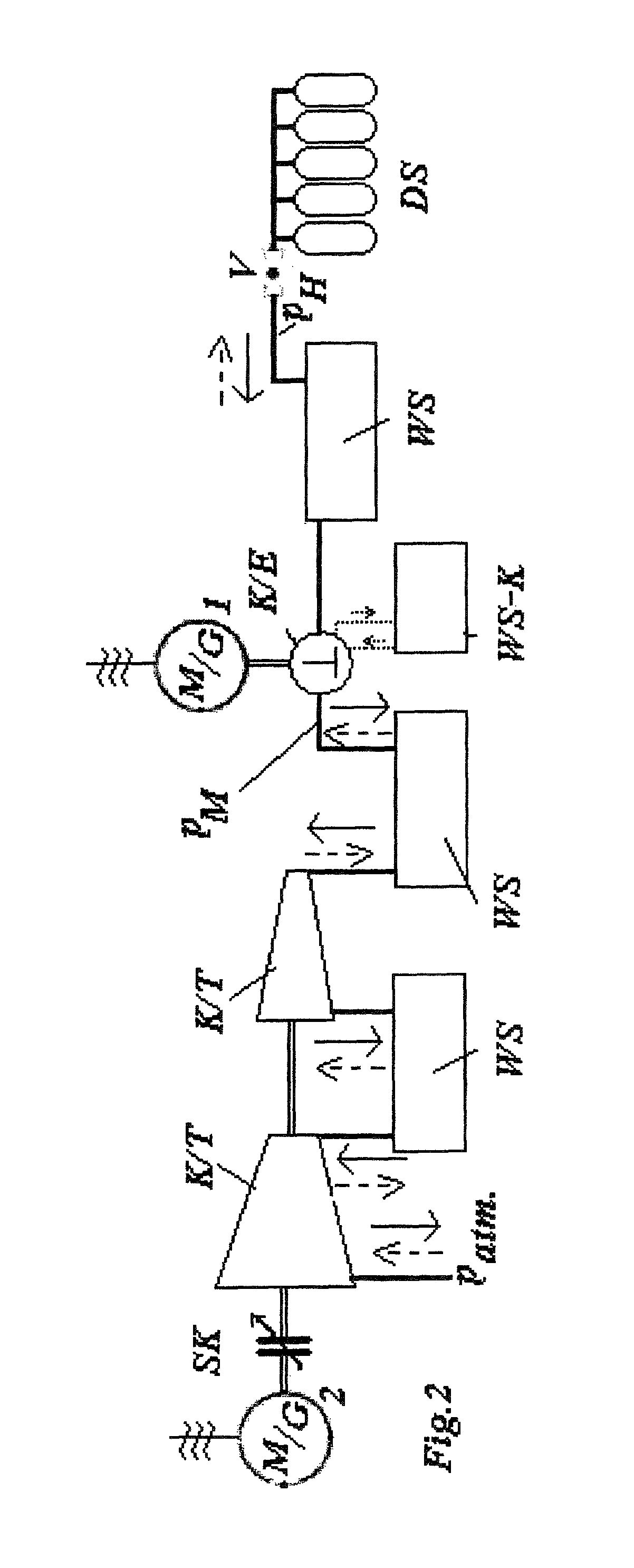

System for storing energy by means of compressed air

ActiveCN103906909AAccumulator installationsWind energy with garvitational potential energyElectric machineEngineering

A plant for storing energy by means of compressed air, in which: a storage volume accommodates air at elevated pressure pH; for energy storage, ambient air is compressed and introduced into the storage volume; for removal from storage, compressed air is extracted from the storage volume and discharged into the environment, performing work; at least one low-pressure turbomachine for alternate compression and expansion respectively compresses ambient air to a medium pressure pM and expands said ambient air from said pressure; at least one high-pressure machine for alternate compression and expansion respectively compresses air from the medium pressure pM to the store pressure pH and expands said air from the latter pressure; and said low-pressure turbomachine and high-pressure machine are connected in series in terms of flow and are mechanically coupled to in each case one, or to one common, electric machine that operates selectively as a motor and generator.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

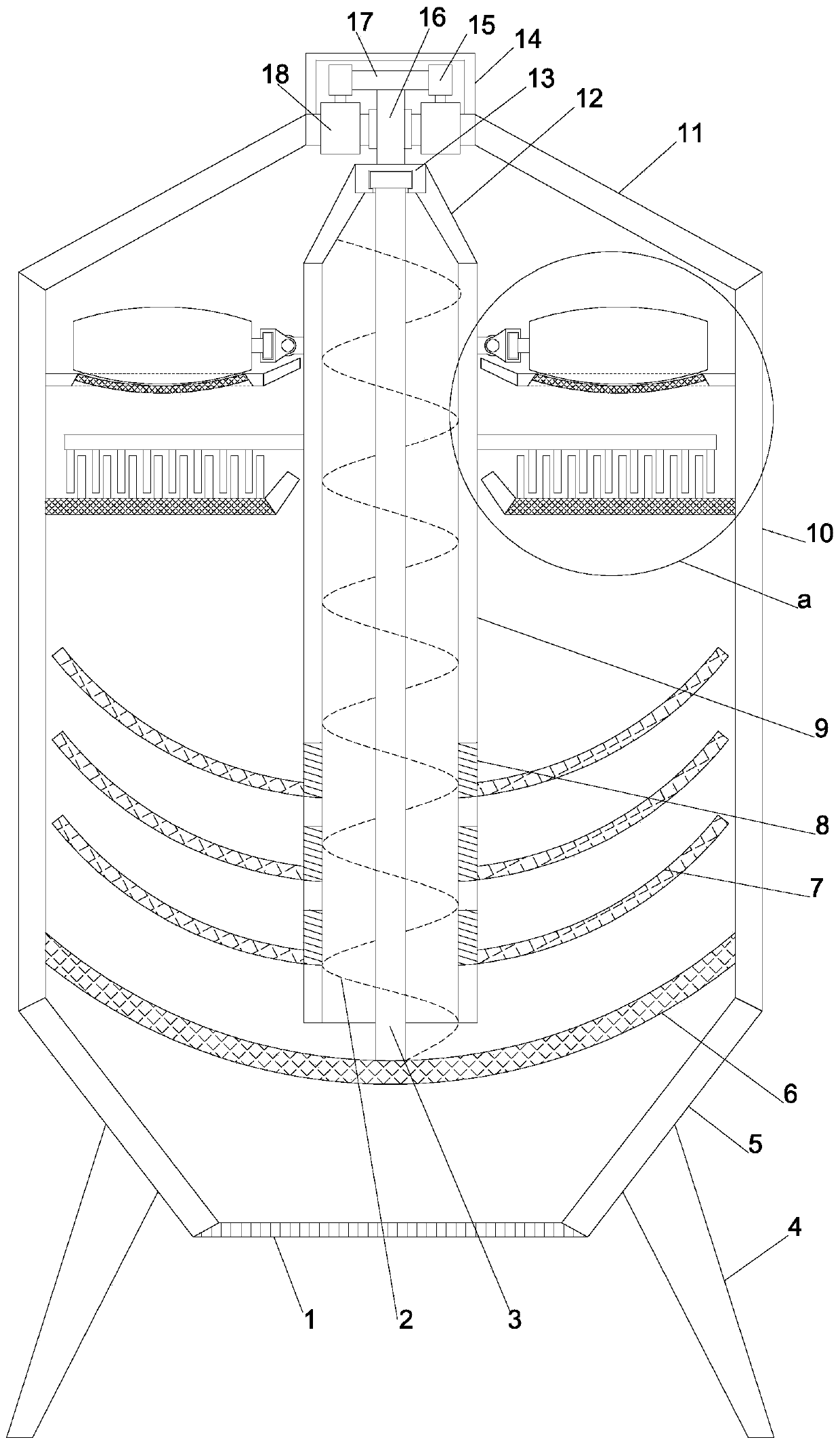

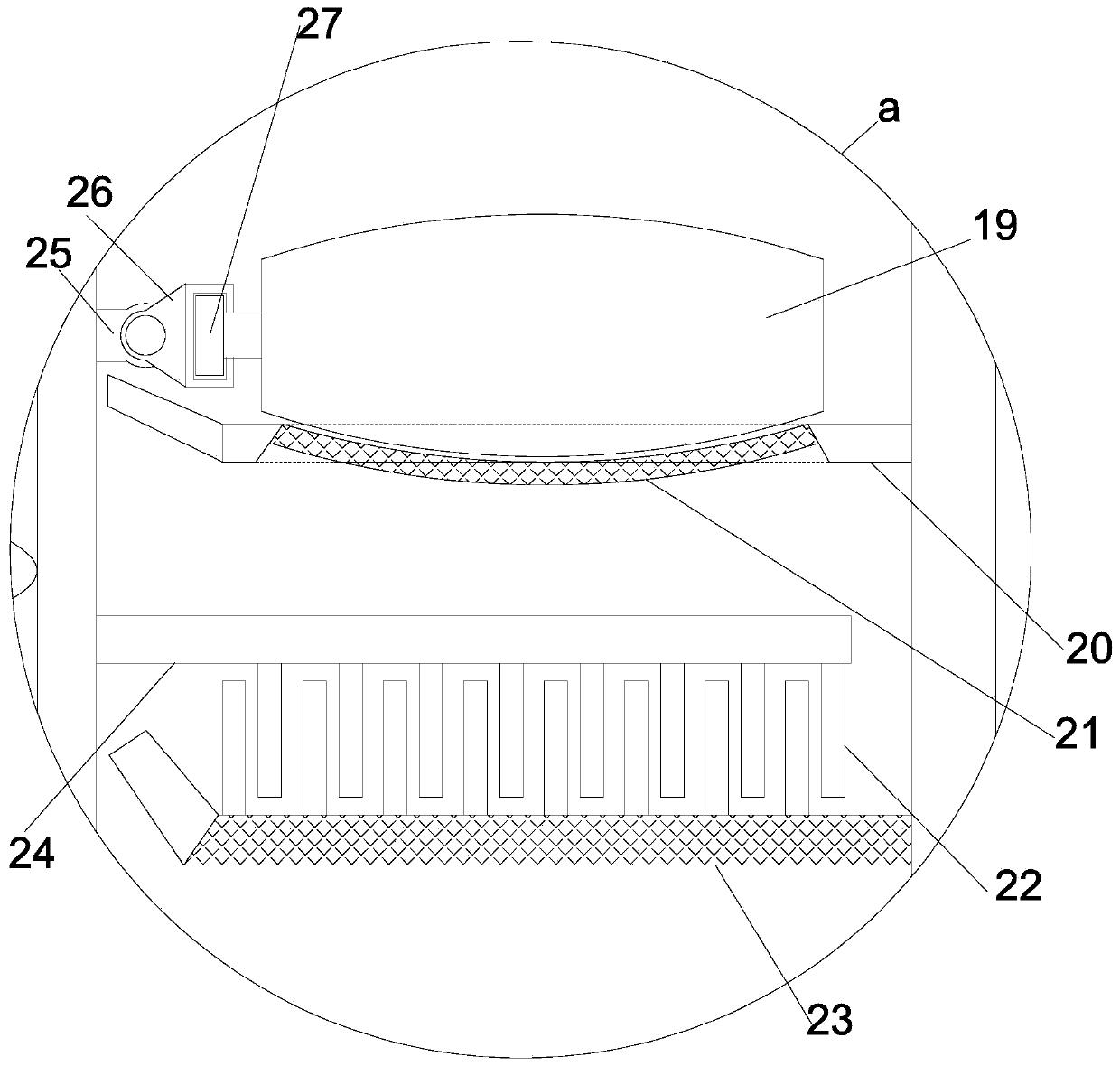

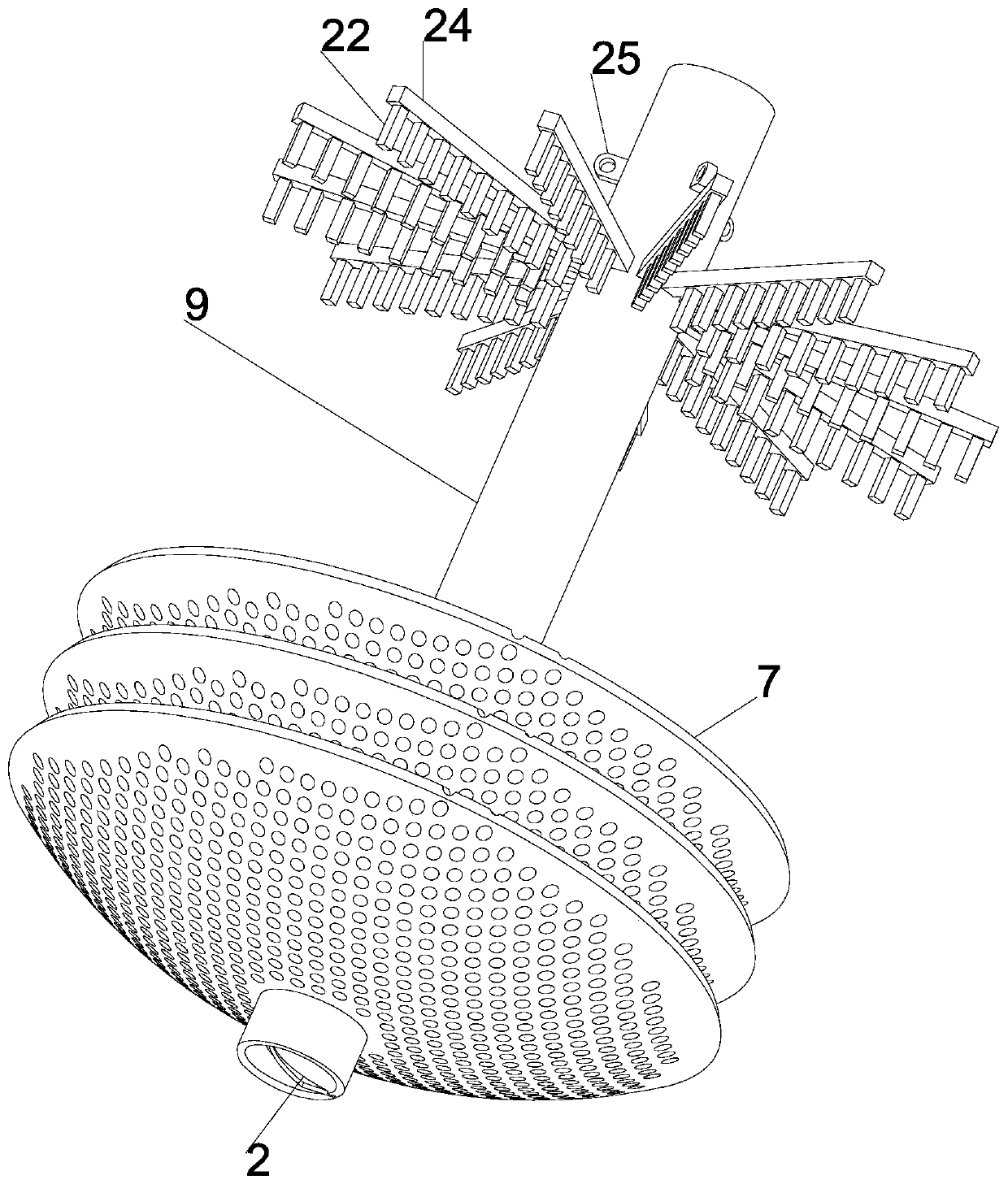

Circulation lifting and screening type multistage grain crushing device

ActiveCN110420715AReduce selection requirementsImprove processing qualityGrain treatmentsEngineeringGrain crushing

The invention relates to the field of agricultural production, and particularly relates to a circulation lifting and screening type multistage grain crushing device. The device comprises a vertically-arranged supporting mounting cylinder, the lower end of the supporting installation cylinder is provided with a conical surface guide cylinder, a discharging hole is formed in the lower end of the conical surface guide cylinder, a plurality of supporting mounting columns are arranged at equal angles on the outer side of the conical surface guide cylinder, a driving installation cover is verticallyarranged right above the supporting installation cylinder, and the outer ends of the feeding mounting columns are connected with the upper end of the supporting mounting cylinder. Through the multi-motor planetary gear driving structure, the transmission efficiency of the device is high, the requirement for motor selection is reduced, two-stage crushing is realized through the synchronous drivingstructure, so that the transmission efficiency of the device is high, the crushing quality is good, the crushing quality of the device is further improved through the structural design of circulatingscreening and lifting, and the processing quality of cereals is remarkably improved.

Owner:安徽省东全米业股份有限公司

Automatic brake mechanism

InactiveUS20050242333A1Avoids application of braking forcePrevent rotationWinding mechanismsDrive shaftElectric machinery

Braking mechanism and a winch having the braking mechanism. The braking mechanism allows a winch with which it is associated to hold a load once the winch has dragged the load up an incline. The winch includes a motor, a drive shaft selectively driven in opposite rotative directions by the motor, a gearbox, a rotatable drum and a cable wrapped around the drum. The motor provides torque, which through the gearbox turns the drum of the winch. When the motor is stopped, and the load on the cable attempts to pull the cable back off the winch drum, the torque that is fed back from the drum into the gearbox and into the drive shaft engages the brake.

Owner:SUPERWINCH

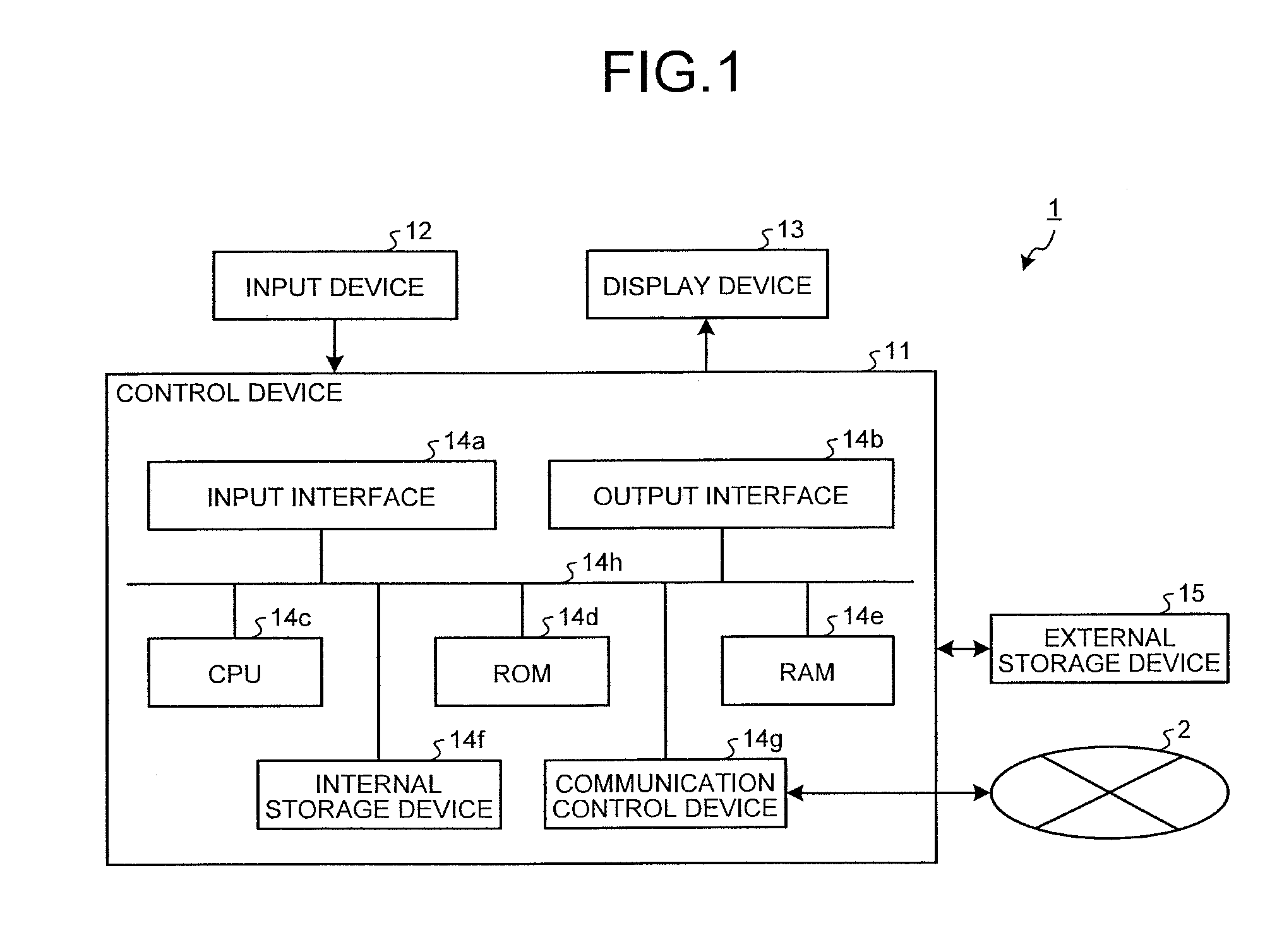

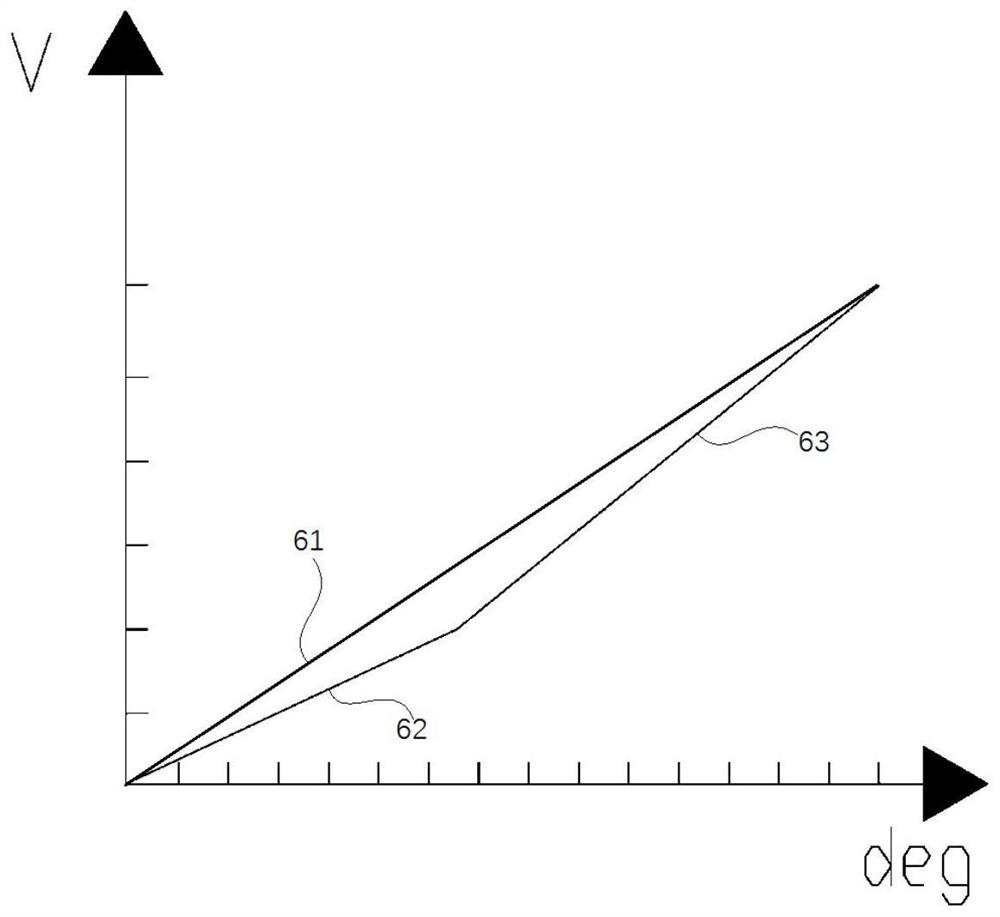

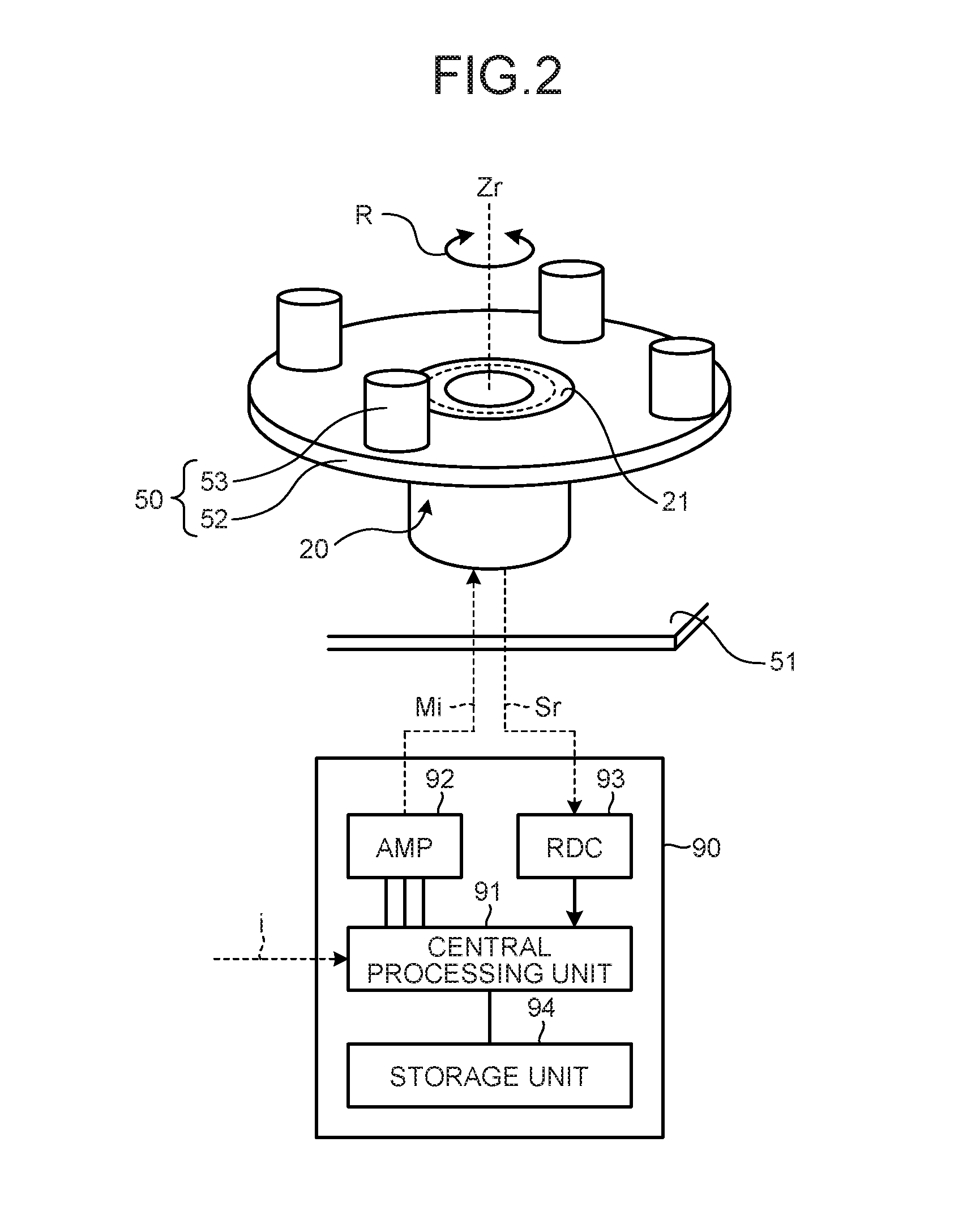

Optimal operation pattern selection method for motor, optimal operation pattern selection program for motor, and motor selection device

ActiveUS20160140264A1Lighten the computational burdenShorten cycle timeElectric motor controlGeneral control strategiesPosition angleStop time

In an optimal operation pattern selection method, a plurality of selectable motors is selected and an optimal operation pattern from among the motor operation pattern defined by positioning time to rotate a motor output shaft of the motor to rotate a load by a positioning angle and stop time to stop the motor output shaft is suggested. The optimal operation pattern selection method includes a comprehensive determination step of calculating a comprehensive determination result according to an adaptable item, and storing the comprehensive determination result linked to each of the motors; and a list display step of displaying a list of the motors to enable to receive selection of one of the motors, together with the comprehensive determination result stored in the comprehensive determination step.

Owner:NSK LTD

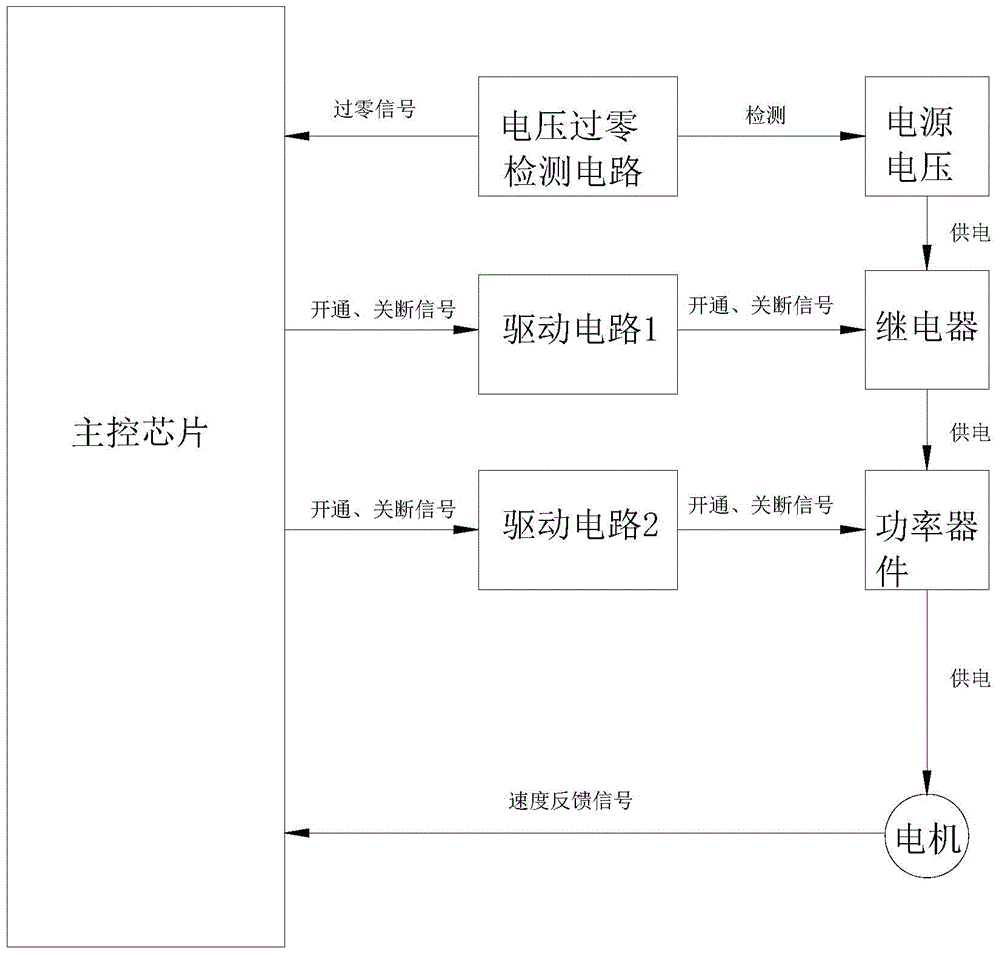

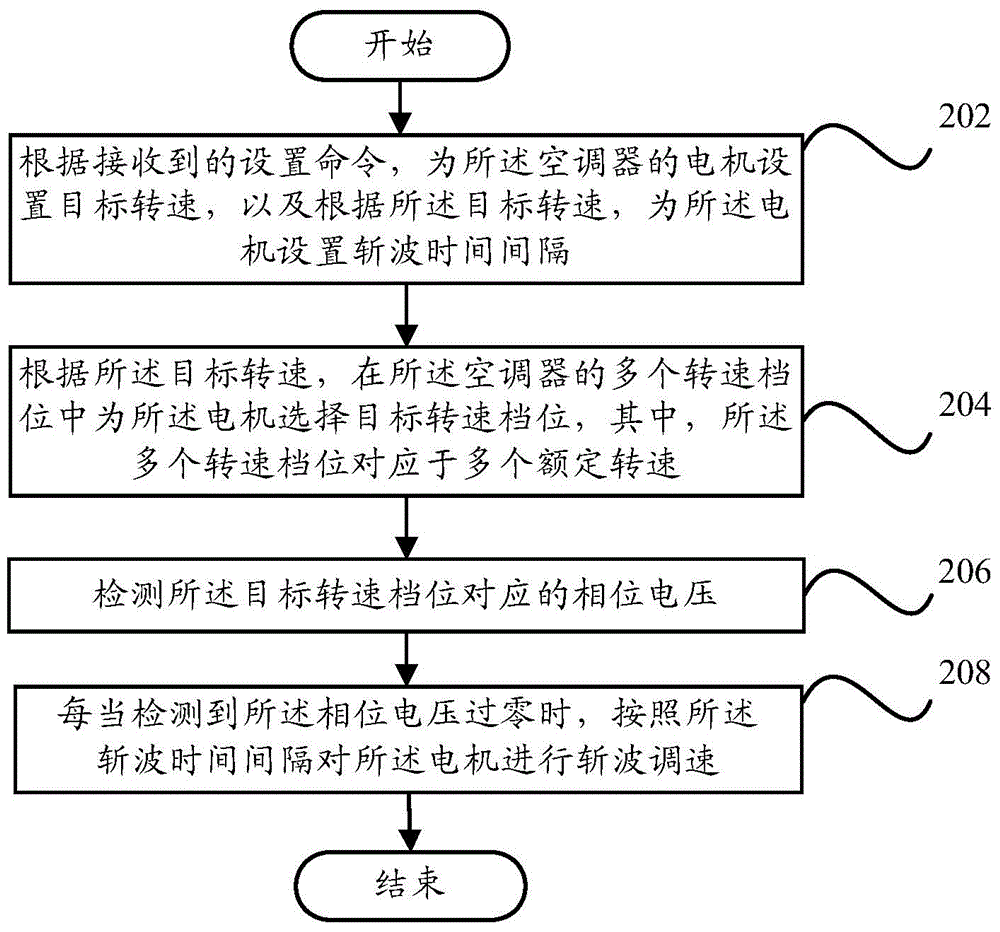

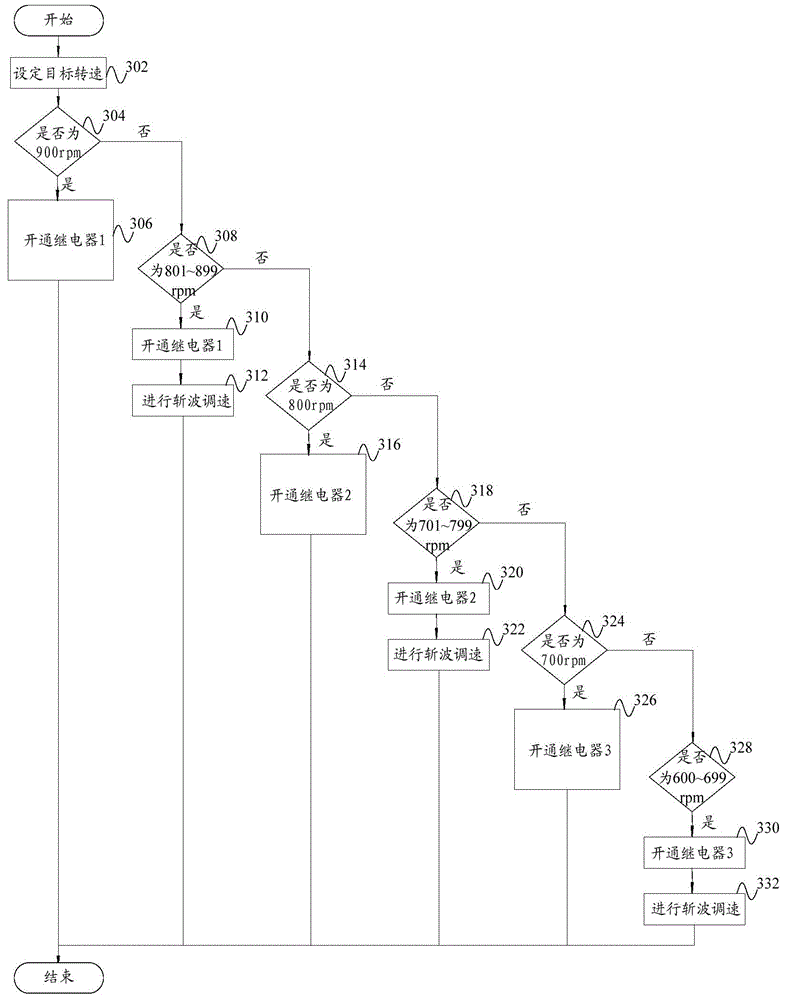

Motor rotating speed adjusting method, motor rotating speed adjusting system, and air conditioner

ActiveCN104539213AIncrease quietnessReduce the amount of choppingMotor control for motor oscillations dampingDistortionZero crossing

The invention provides a motor rotating speed adjusting method, a motor rotating speed adjusting system, and an air conditioner. The motor rotating speed adjusting method comprises: according to a received setting command, a target rotating speed of a motor of an air conditioner is set and a chopping time interval is set for the motor based on the target rotating speed; on the basis of the target rotating speed, a target rotating speed gear is selected from multiple rotating speed gears of the air conditioner for the motor; a voltage of the target rotating speed gear is detected; and when the voltage of the target rotating speed gear is detected to be in a zero-crossing mode, chopping speed modulation is carried out on the motor according to the chopping time interval. On the basis of the technical scheme, tap speed regulation is carried out on the motor of the air conditioner; a gear capable of providing a rotating speed closest to the target rotating speed is selected; and then chopping speed modulation is carried out on the motor. Therefore, the chopping amount of the motor voltage is substantially reduced; the vibration and noise caused by voltage and current distortion under the chopping speed modulation can be reduced; the quiet degree of the air conditioner running is improved; and the user experience is enhanced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

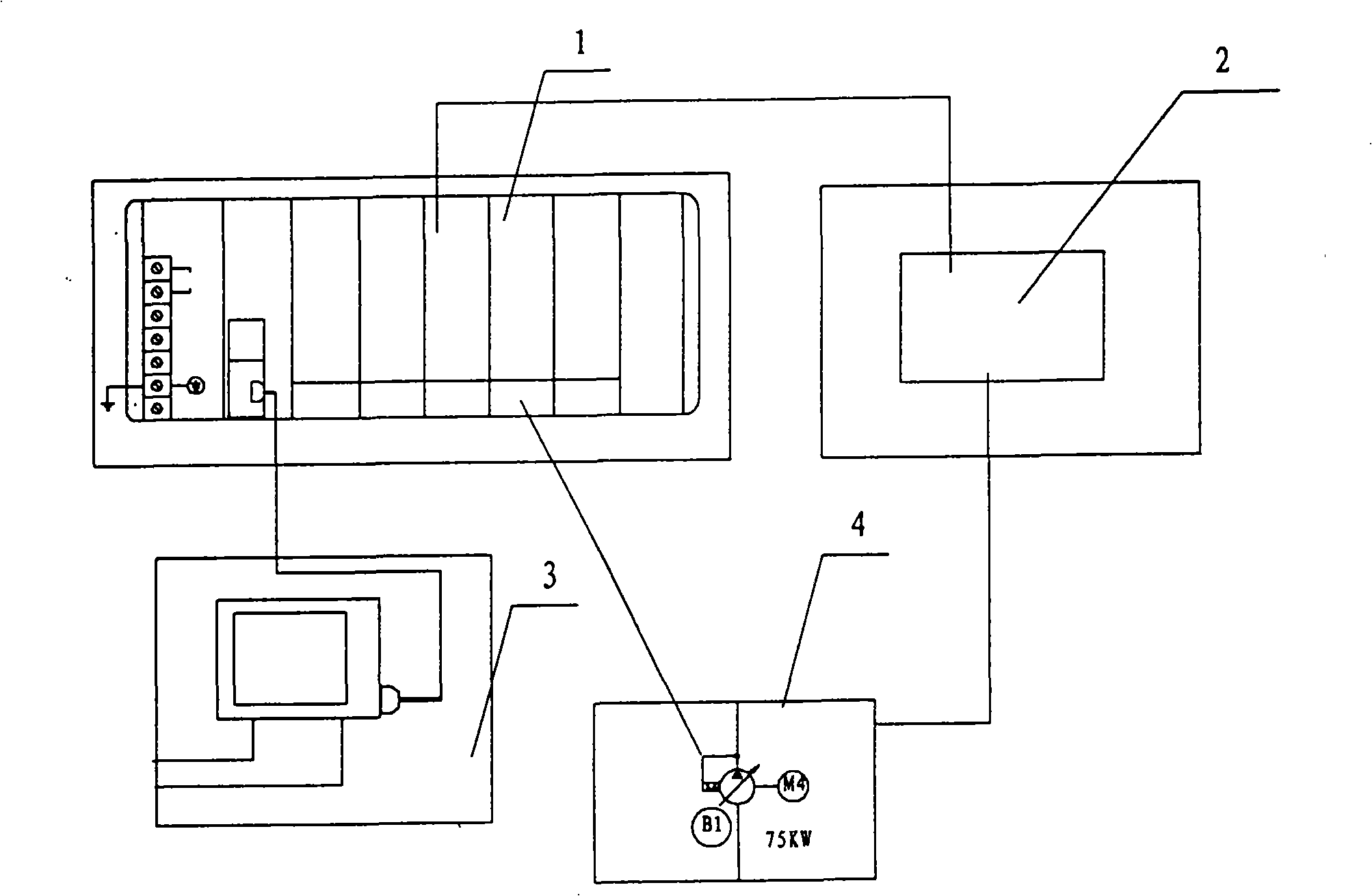

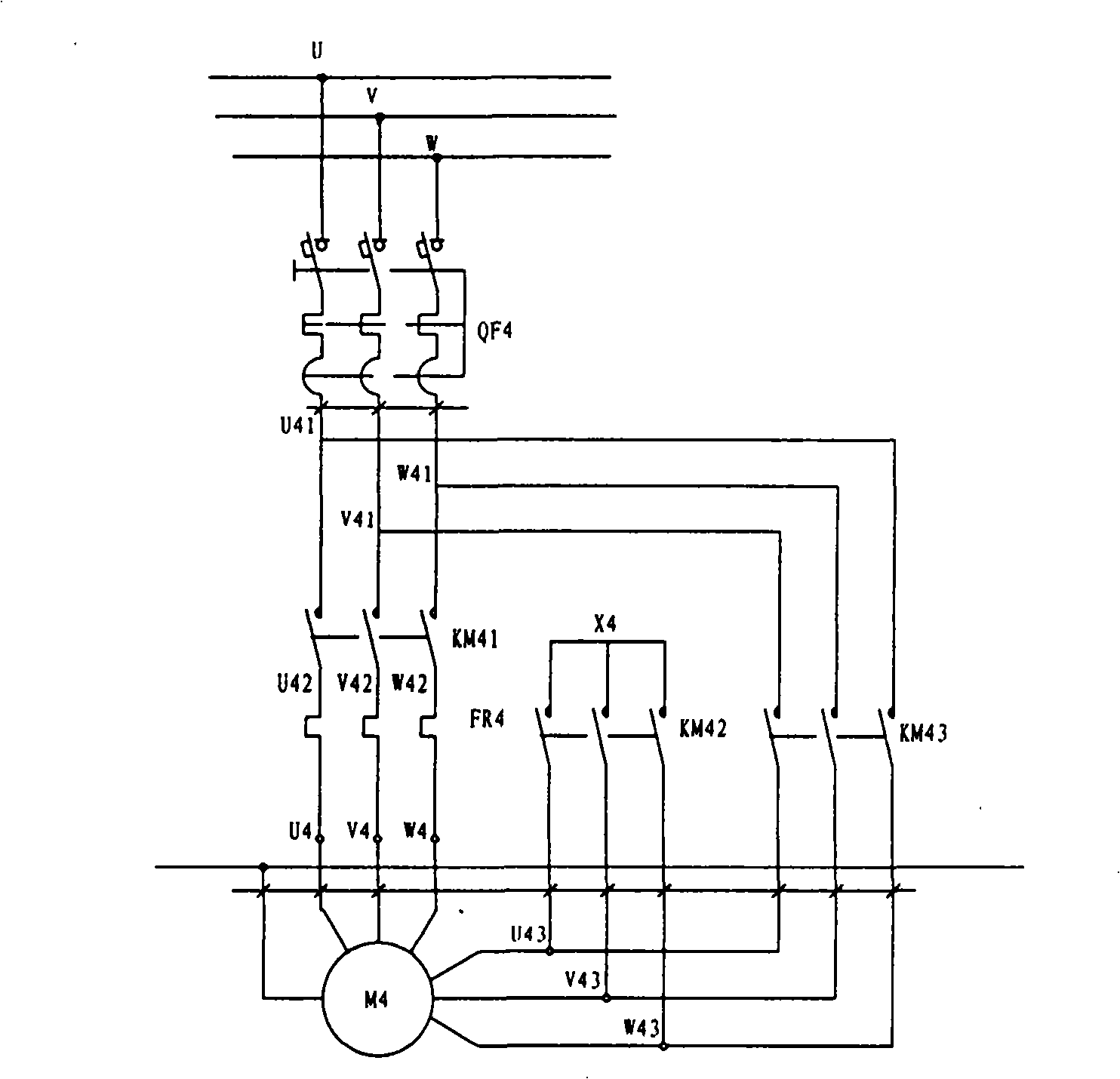

Motor matching control system for hydraulic machine

The invention relates to a motor matching control system for a hydraulic machine, which comprises a hydraulic machine PLC, a motor starting switch assembly connected with the hydraulic machine PLC and arranged in a control box of the hydraulic machine, hydraulic system motors connected with the motor starting switch assembly, a touch screen connected with the hydraulic machine PLC, and a motor starting circuit and a hydraulic machine PLC input-output circuit connected with the hydraulic machine PLC and the hydraulic system motors respectively. The motor starting circuit comprises a main circuit connected with a motor and a motor starting control circuit connected with the hydraulic machine PLC. The main circuit adopts star-triangle reduced-voltage starting to start the motor, and comprises a plurality of groups of circuit breakers of which one end is connected with a three-phase power supply and the number is the same as that of the hydraulic system motors, wherein the other end of each group of the circuit breakers is connected with one motor through two groups of switching contacts of a corresponding AC contactor, and the motor is also connected with another group of switching contacts of the AC contactor. The motor matching control system is provided with a 'motor selection' frame[,] so that a user can flexibly change the motor matching according to technological requirements.

Owner:TIANJIN TIANDUAN PRESS CO LTD

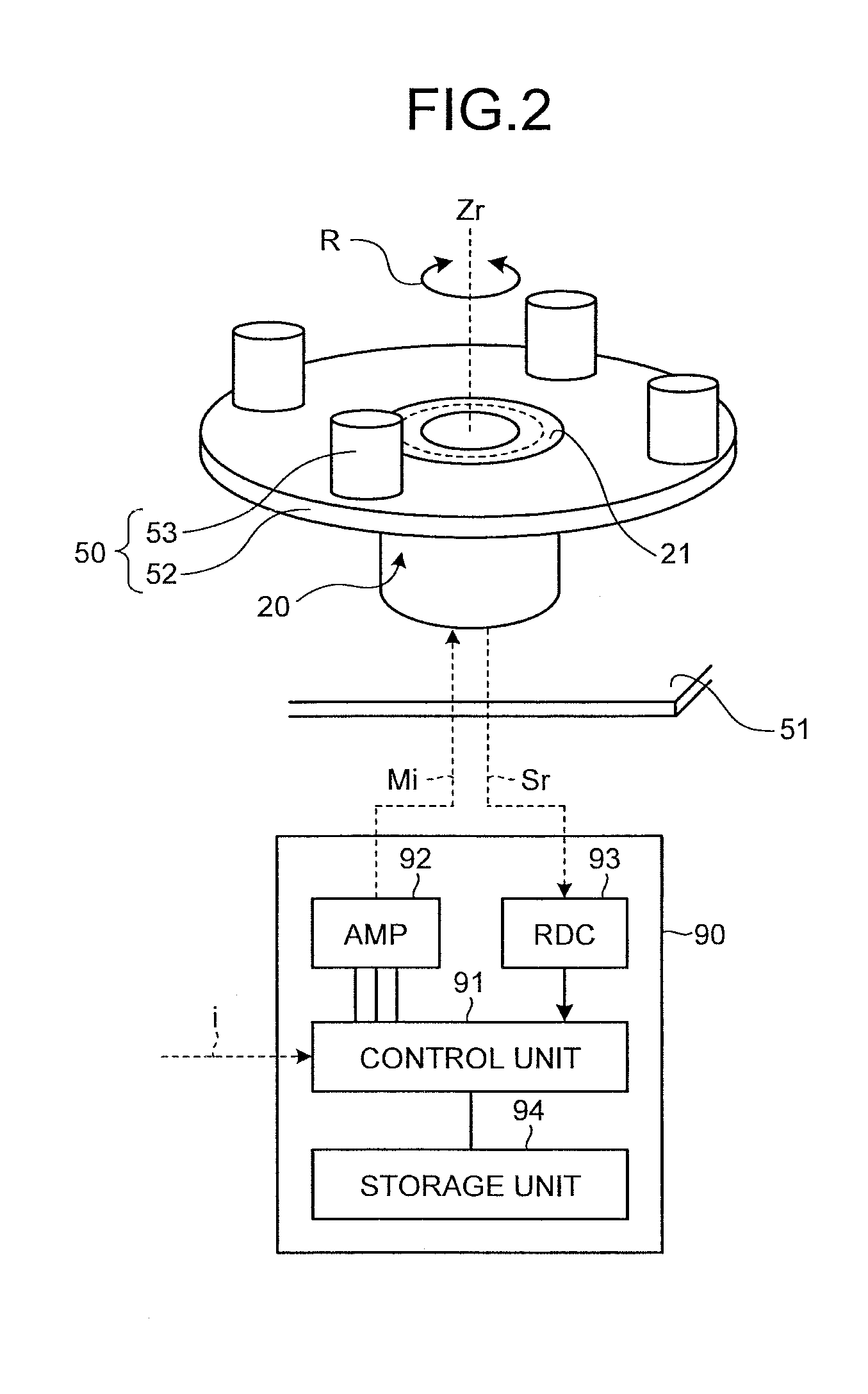

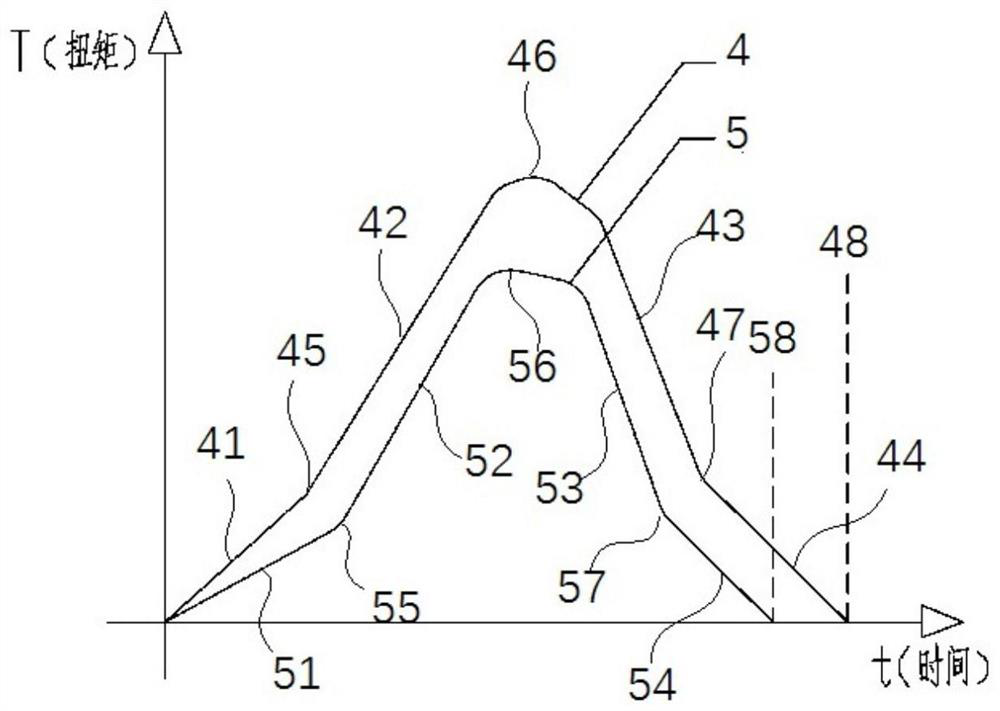

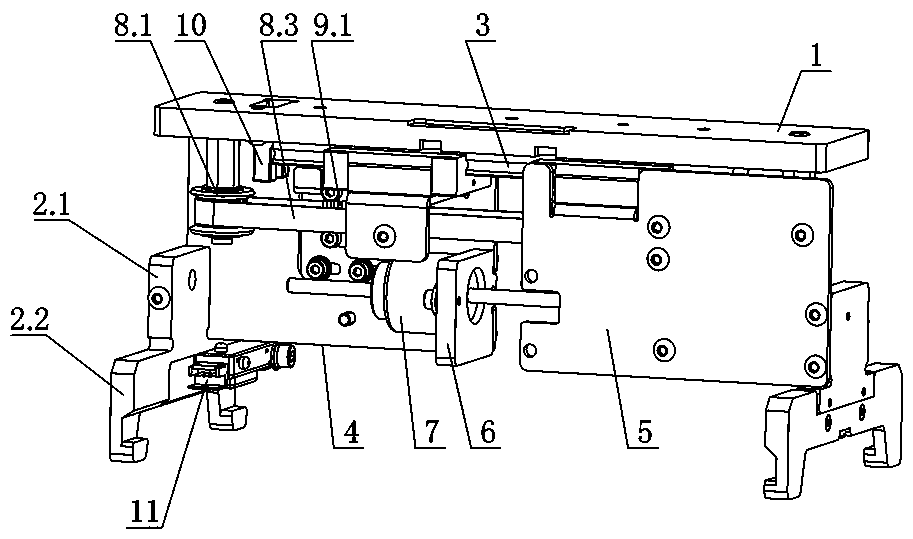

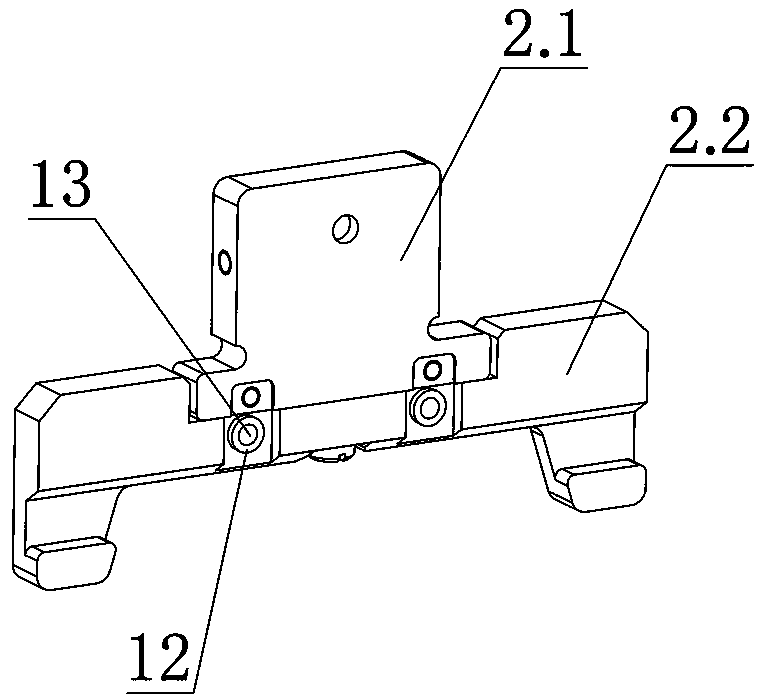

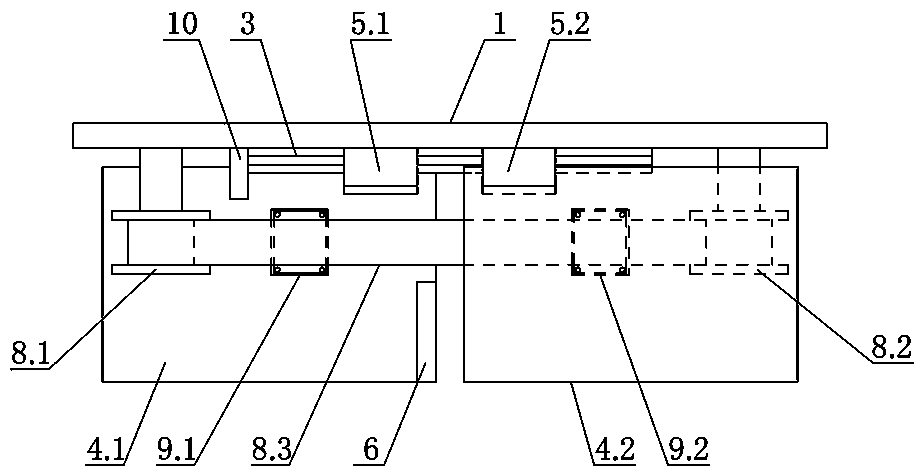

Motor selection apparatus

A motor selection apparatus includes: a mechanical condition obtainment unit that obtains information pertaining to a distance between a center of mass of a workpiece and a rotation center of a motor; an operating pattern obtainment unit that obtains information pertaining to an operating pattern; a motor information obtainment unit that obtains information pertaining to instantaneous torque; an eccentric load torque calculation unit that calculates eccentric load torque, which is load torque acting on the motor in accordance with the rotation phase of the motor; an acceleration / deceleration torque calculation unit that calculates acceleration / deceleration torque; a required torque calculation unit that calculates a required torque from a sum of the eccentric load torque and the acceleration / deceleration torque; and a motor selection unit that determines whether a motor can be selected, based on whether the required torque is less than or equal to the instantaneous torque of the motor.

Owner:FANUC LTD

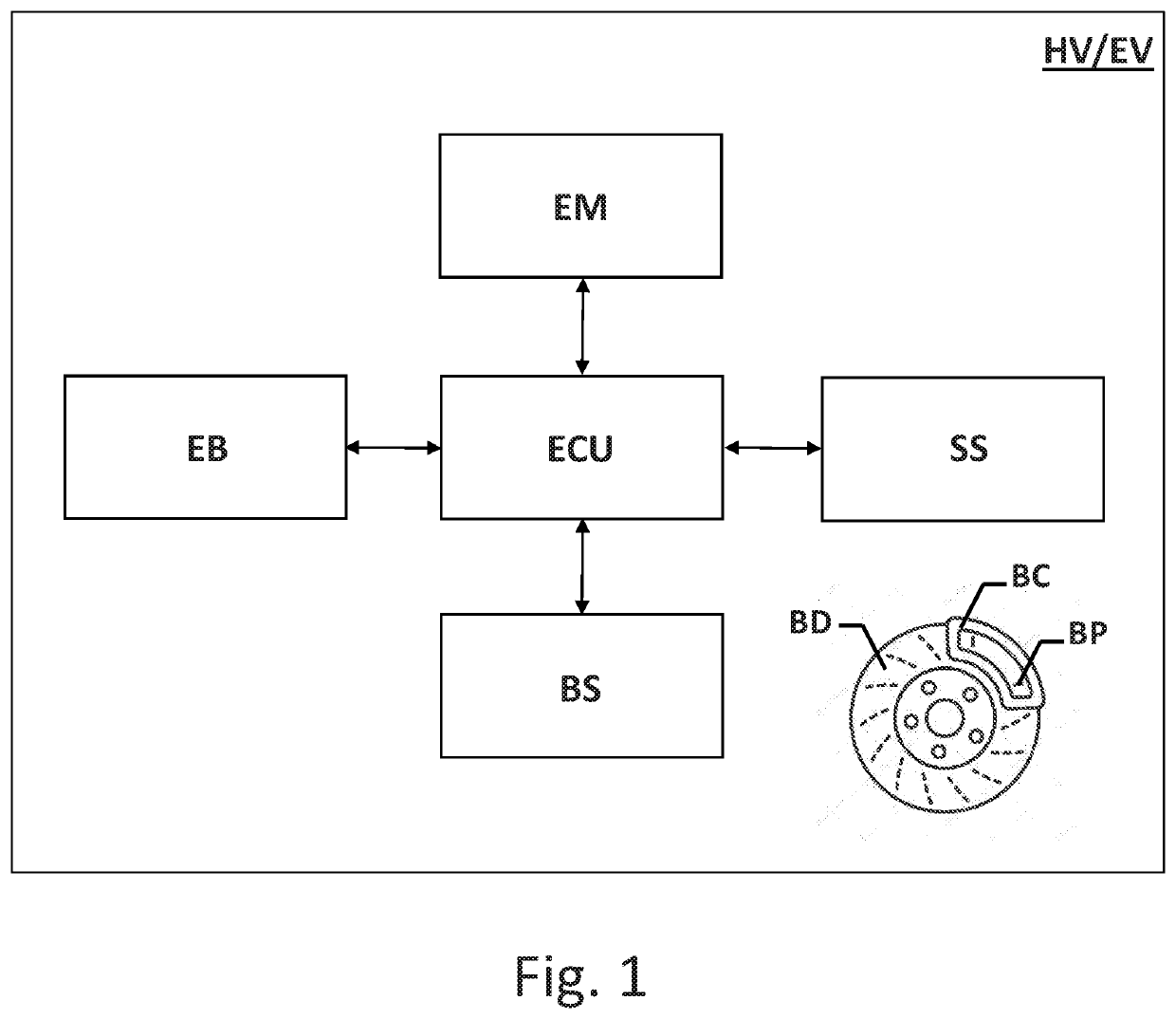

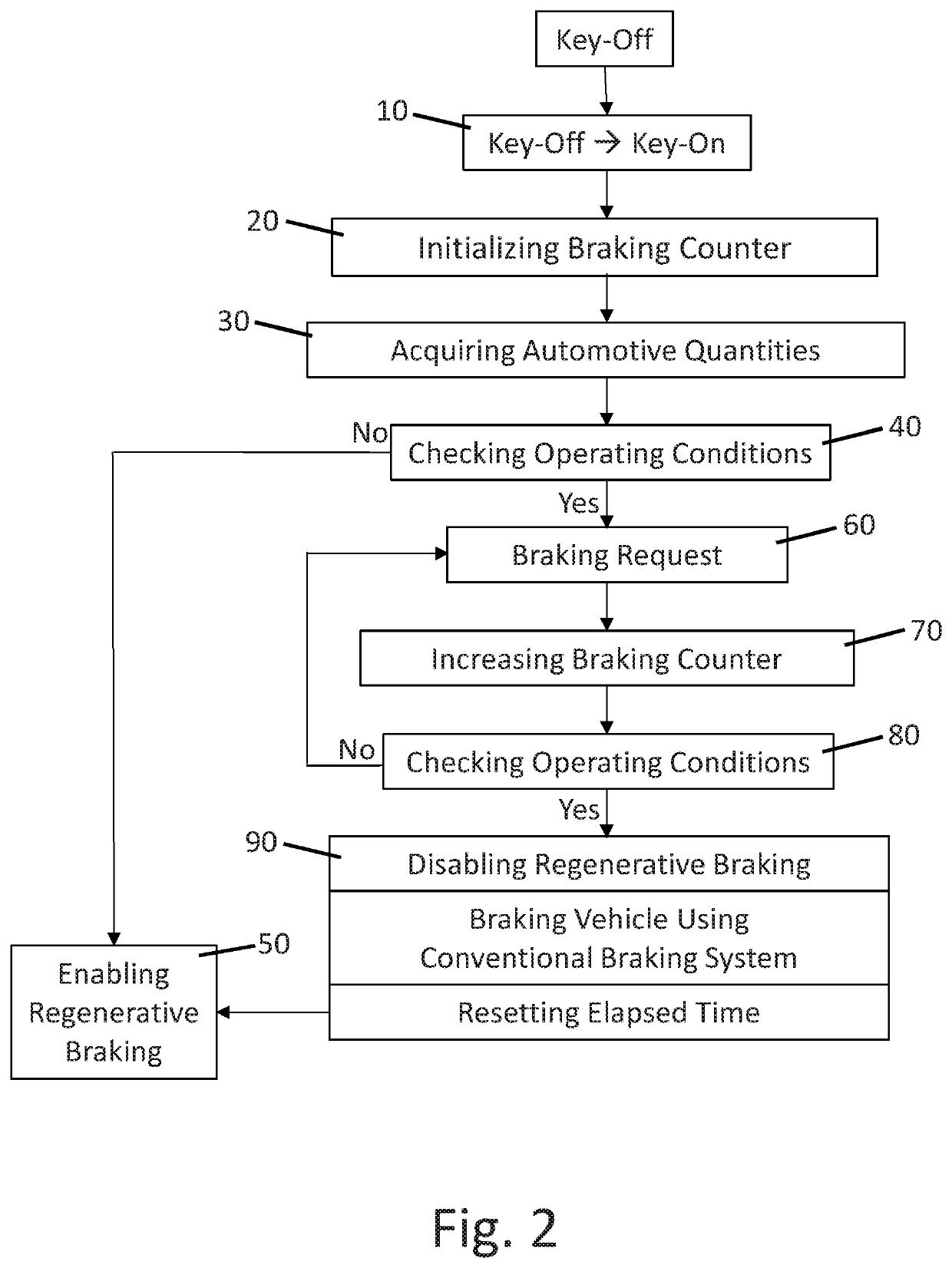

Management of the cleaning of friction bodies of automotive braking systems

ActiveUS20210094546A1Effects lifeEffects performanceHybrid vehiclesBraking element arrangementsElectric carsElectric vehicle

Hybrid or fully electric vehicle comprising: a conventional braking system based on friction bodies to brake the motor vehicle by interaction of the friction bodies in response to the operation of a brake pedal or any other equivalent control member, a reversible electric machine operatively coupled to the wheels of the vehicle and electronically controllable to operate selectively as an electric engine to generate a mechanical power to propel to the vehicle and as an electric generator to convert the kinetic energy of the motor vehicle into electrical energy, and an automotive electronic control system comprising a sensory system to measure automotive quantities, and an electronic control unit to control operation of the conventional braking system and of the electric machine in response to the operation of the brake pedal or any other operationally equivalent control member. The electronic control unit is further configured to control operation of: the electric machine to selectively perform one or more functions including regenerative braking, in which the electric machine is operated as an electric generator to recover the kinetic energy of the motor vehicle during braking and convert it into electrical energy, and the conventional braking system to clean the friction bodies of the conventional braking system based on the number of brakings performed by the conventional braking system and counted starting from the start-up of the motor vehicle.

Owner:FCA ITAL

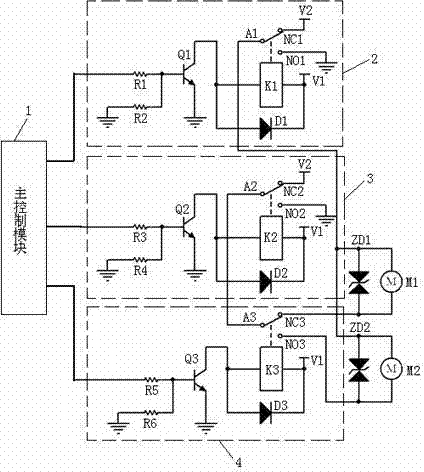

Motor switching circuit of full automatic coffee machine

ActiveCN103110355ALow costReduce energy consumptionMultiple dynamo-motor startersBeverage vesselsComputer moduleRotation control

The invention discloses a motor switching circuit of a full automatic coffee machine. The motor switching circuit of the full automatic coffee machine comprises a master control module, a motor forward rotation control module, a motor reverse rotation control module and a motor selection control device. The motor selection control module comprises a third single-pole double-throw electromagnetic switch, wherein the third single-pole double-throw electromagnetic switch comprises a third fixed end, a fifth contact and a sixth contact, the fifth contact is electrically connected with a first end of a first motor, and the sixth contact is electrically connected with a first end of a second motor. The motor forward rotation control module comprises a first single-pole double-throw electromagnetic switch, wherein a fixed end of the first single-pole double-throw electromagnetic switch is respectively electrically connected with a second end of the first motor and a second end of the second motor. The motor reverse rotation control module comprises a second single-pole double-throw electromagnetic switch, wherein a fixed end of the second single-pole double-throw electromagnetic switch is connected with the third fixed end. The motor switching circuit of the full automatic coffee machine uses three relays to control forward rotation and reverse rotation of two motors, saves cost and reduces energy consumption.

Owner:SUZHOU IND PARK KALERM ELECTRIC APPLIANCES CO LTD

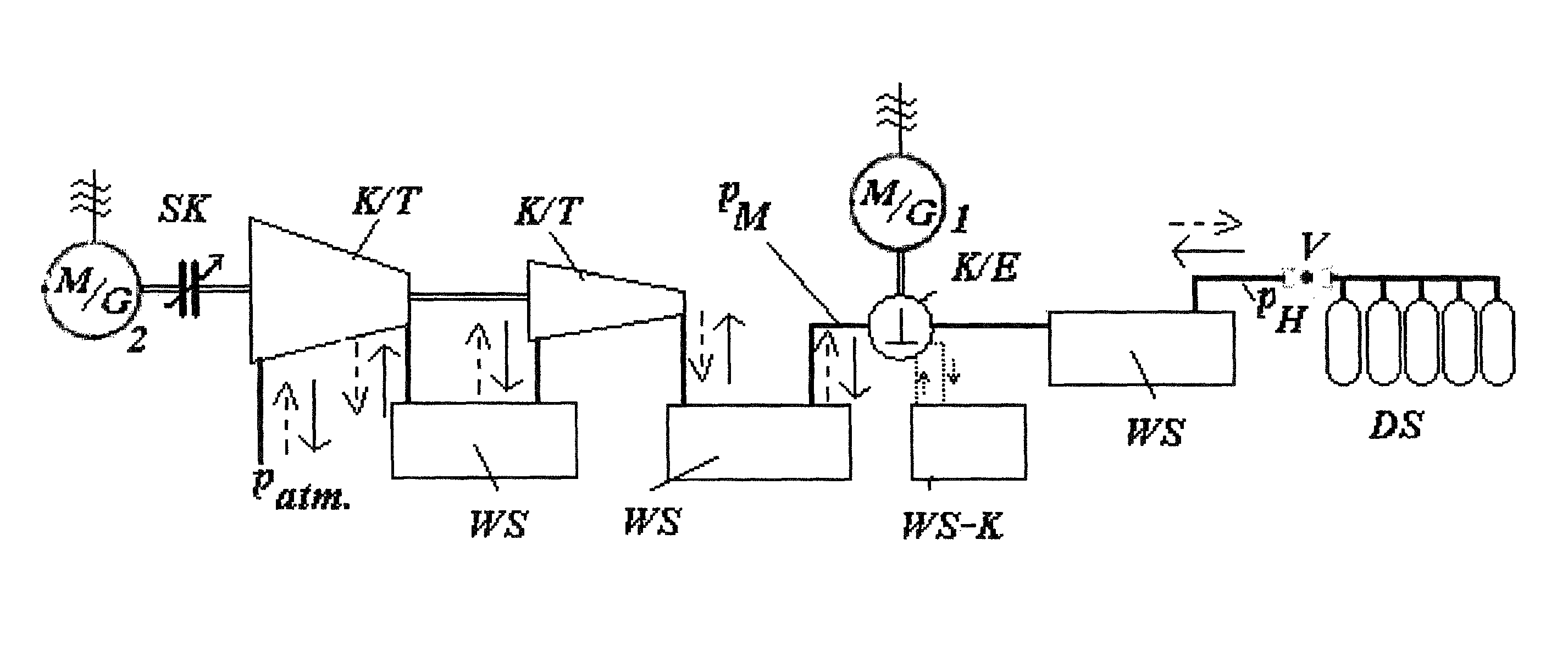

System for storing energy by means of compressed air

ActiveUS9404512B2Increase profitImprove effectivenessAccumulator installationsWind energy with garvitational potential energyElectric machineEngineering

A plant for storing energy by means of compressed air, in which: a storage volume accommodates air at elevated pressure pH; for energy storage, ambient air is compressed and introduced into the storage volume; for removal from storage, compressed air is extracted from the storage volume and discharged into the environment, performing work; at least one low-pressure turbomachine for alternate compression and expansion respectively compresses ambient air to a medium pressure pM and expands said ambient air from said pressure; at least one high-pressure machine for alternate compression and expansion respectively compresses air from the medium pressure pM to the store pressure pH and expands said air from the latter pressure; and said low-pressure turbomachine and high-pressure machine are connected in series in terms of flow and are mechanically coupled to in each case one, or to one common, electric machine that operates selectively as a motor and generator.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

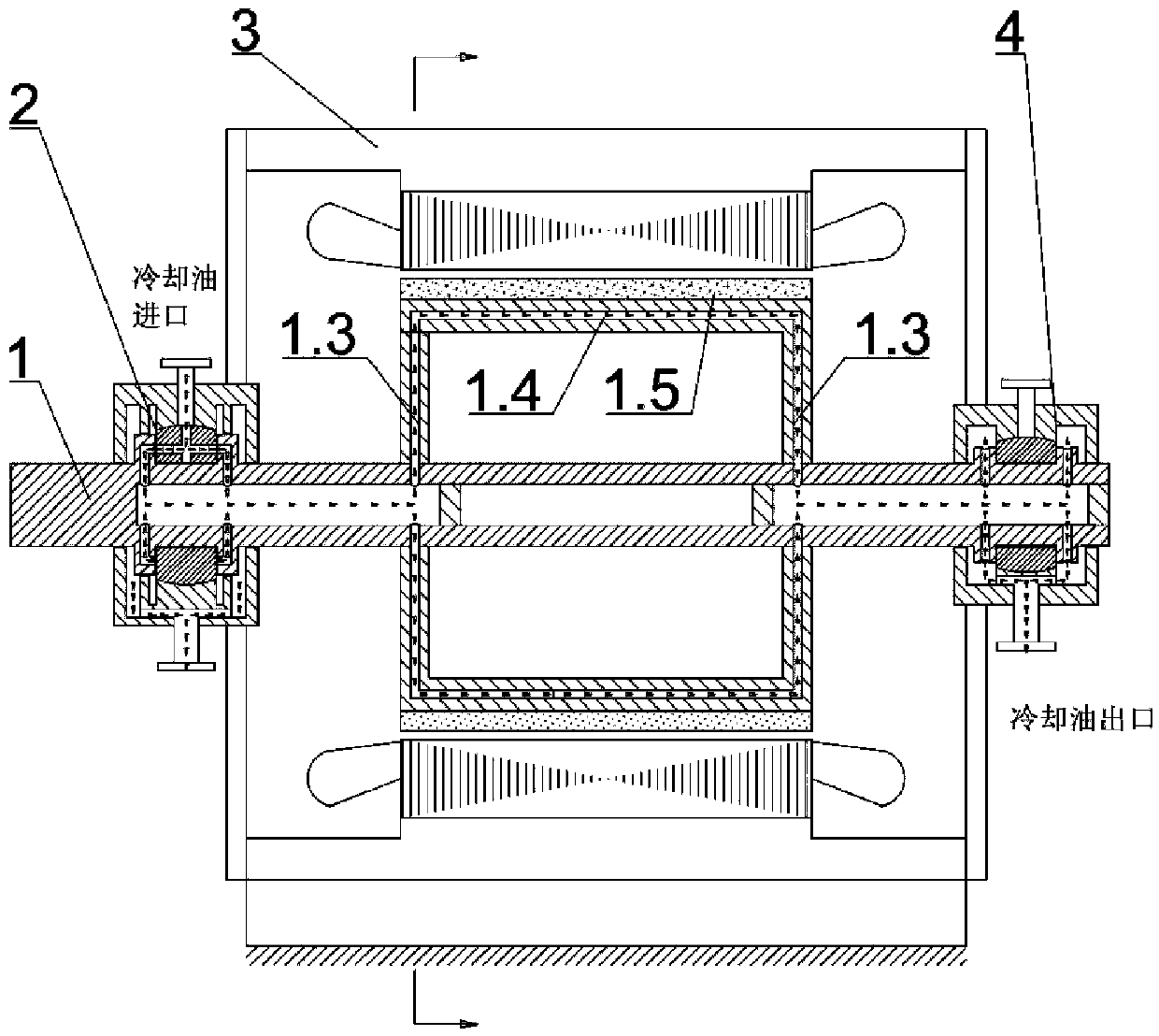

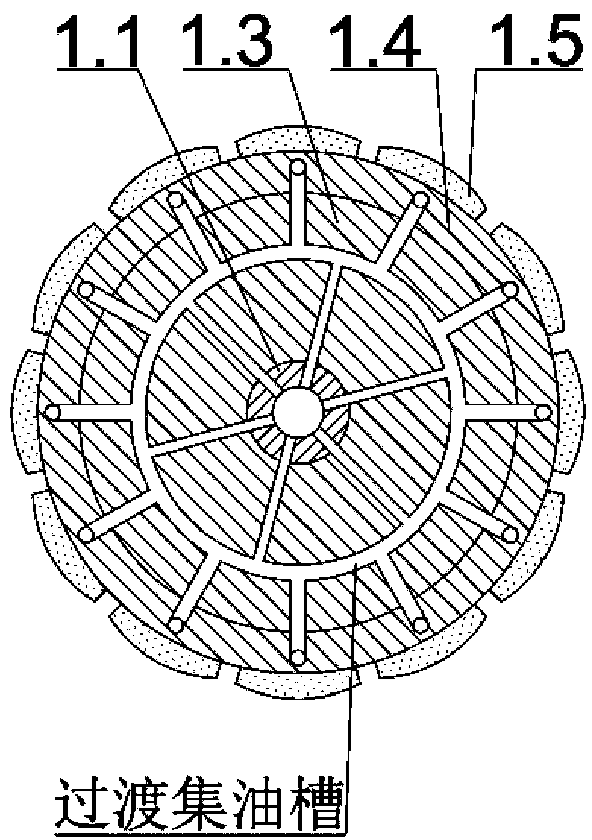

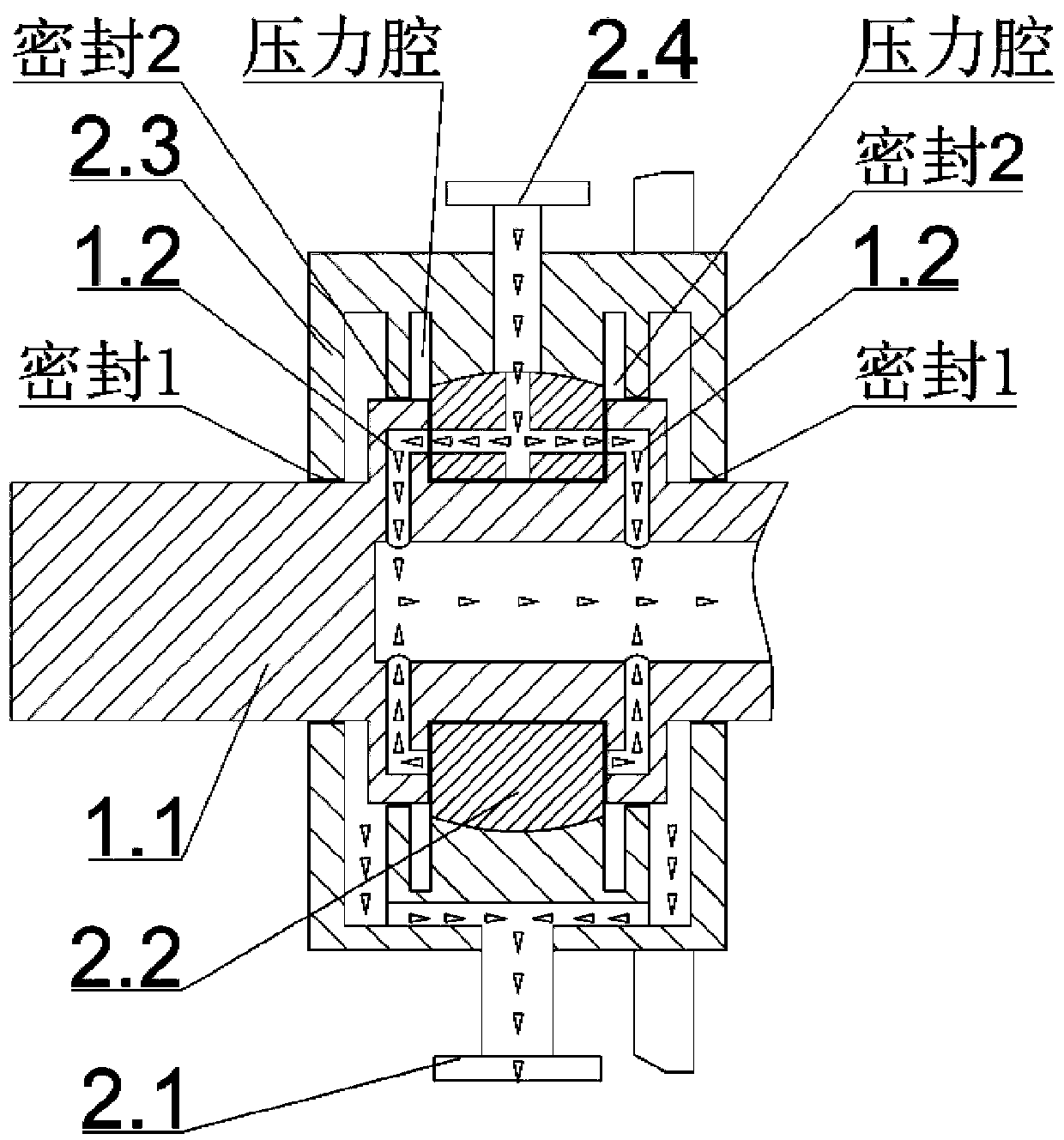

Rotor oil-cooled permanent magnet motor

ActiveCN111342597AWithout adding bulk and weightReduce complexityMagnetic circuit rotating partsCooling/ventillation arrangementPermanent magnet rotorSlider bearing

The invention discloses a rotor oil-cooled permanent magnet motor. The rotor oil-cooled permanent magnet motor is composed of a stator assembly, a permanent magnet rotor, a first sliding bearing and asecond sliding bearing which are arranged at the left and right sides respectively. The permanent magnet rotor comprises a rotating shaft, a rotor bracket, a rotor yoke part and a permanent magnet pole, a central runner is arranged in a central hole of the rotating shaft, and the first sliding bearing generates a lubricating oil pressure cavity to press the lubricating oil to flow through the central runner, so that the permanent magnet pole is cooled. The application object of the invention is the low-speed permanent magnet motor provided with the sliding bearings, the original lubricating oil for lubricating and cooling the sliding bearings is fully utilized, and the direct oil cooling of the permanent magnet pole is realized only by slightly improving the runners formed at the rotatingshaft and the rotor yoke part. According to the invention, the size and weight of an original motor are not increased basically, the complexity of the sliding bearings is not increased, the cooling effect is obviously superior to that of the traditional air cooling, and extra noise is not generated. According to a static pressure and dynamic pressure scheme provided by the invention, the runner and a heat pipe structure can be selected by motors with different rotating speeds.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

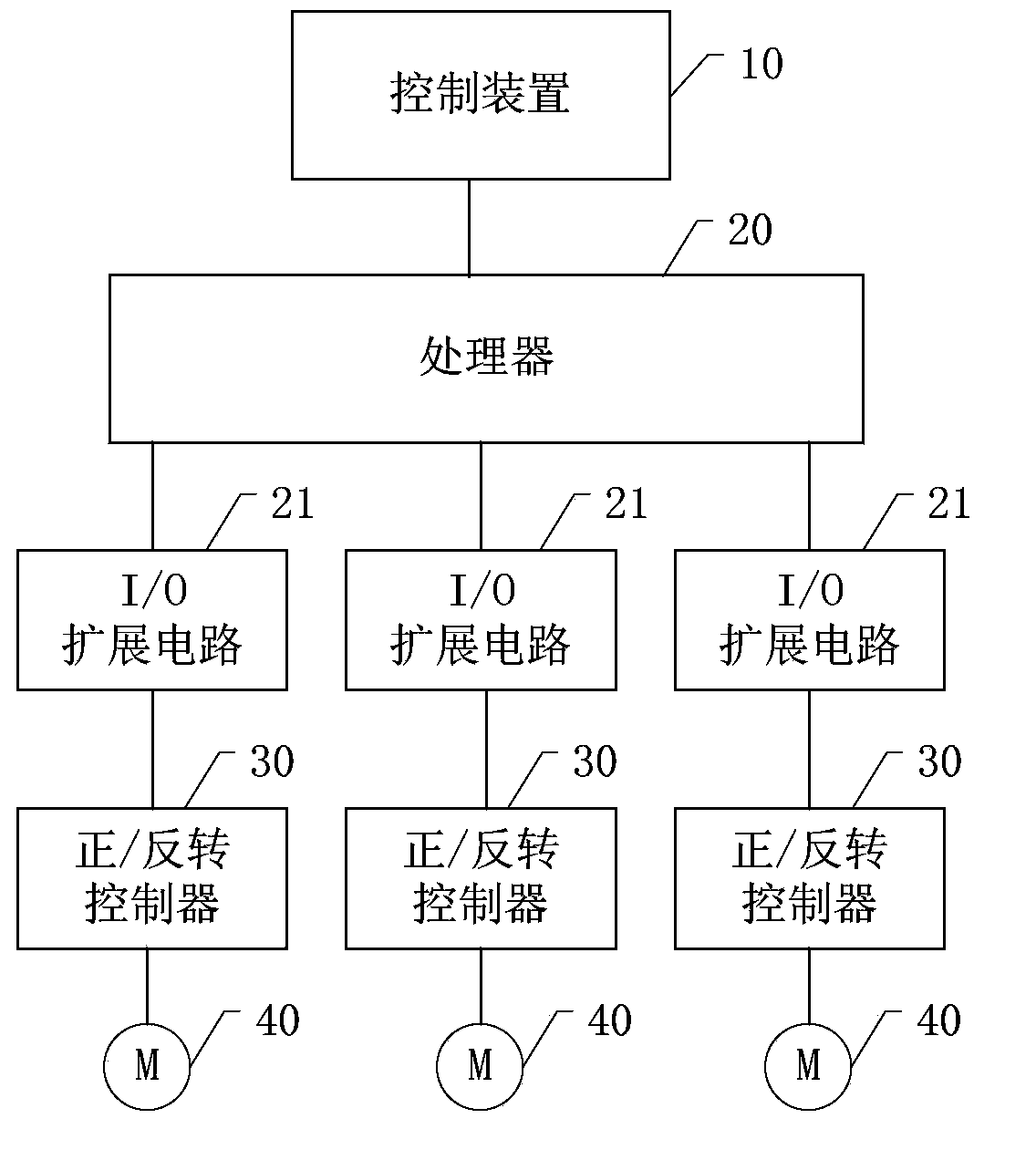

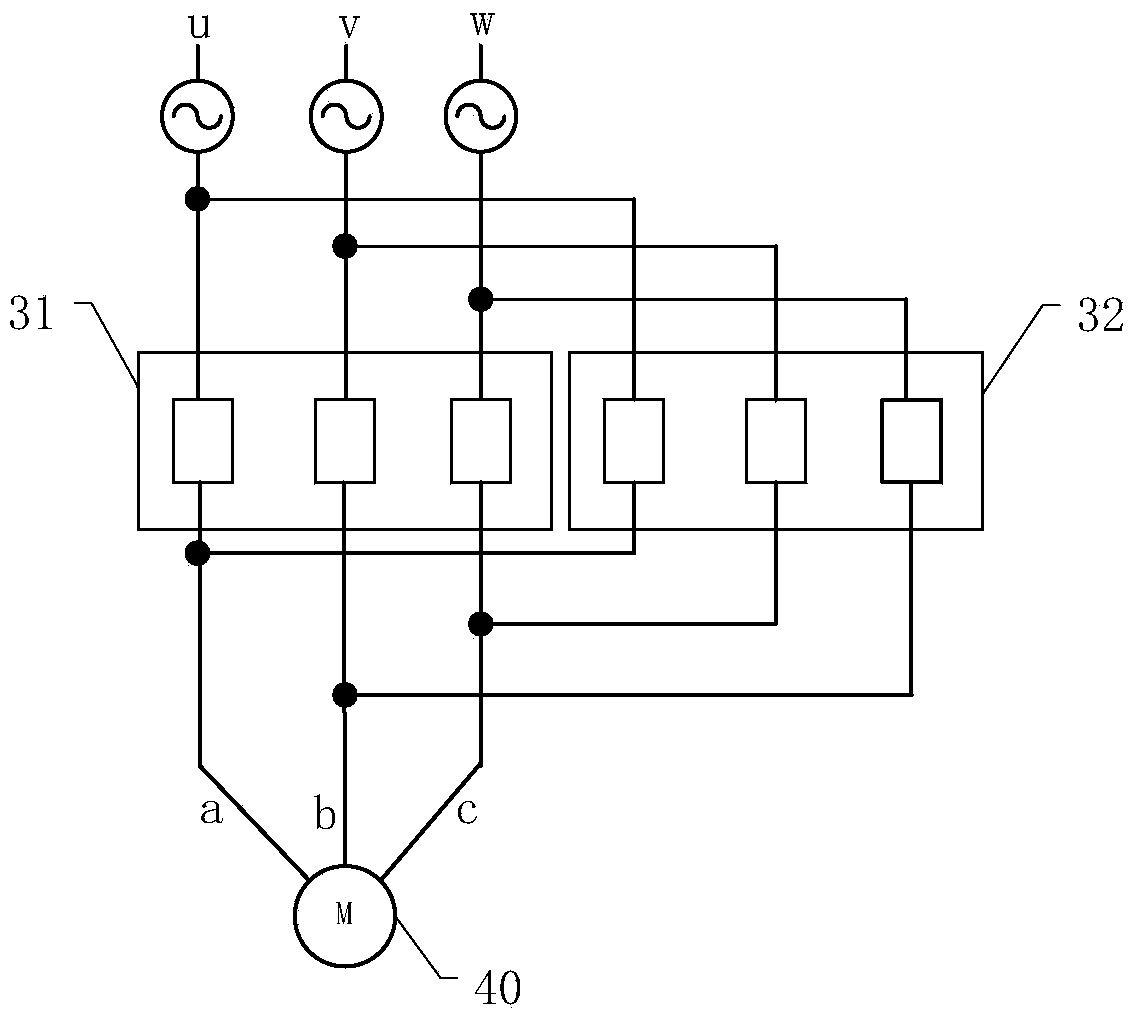

Motor control system

The invention discloses a motor control system which is used for controlling the operation directions of a plurality of motors. The motor control system comprises a control device, a processor and a plurality of forward / backward rotating controllers. The control device is connected with the processor and is used for receiving a motor selection order and forward / backward rotating signals, wherein the motor selection order and the forward / backward rotating signals are sent by a user; the forward / backward rotating signals are output to one or more forward / backward rotating controllers by the processor according to the motor selection order; the forward / backward rotating controllers are connected with the motors respectively and correspondingly and used for controlling the motors connected with the forward / backward rotating controllers to rotate forwards or backwards according to the forward / backward rotating signals; according to the technical scheme, in the motor control system, according to the motor selection order, the forward / backward rotating signals are output to the corresponding forward / backward rotating controllers by the processor so that the forward / backward rotating controllers can work independently without interference with each other, and therefore the motors can be controlled to operate in different modes at the same time.

Owner:HENAN JIANGHE HEAVY IND GROUP

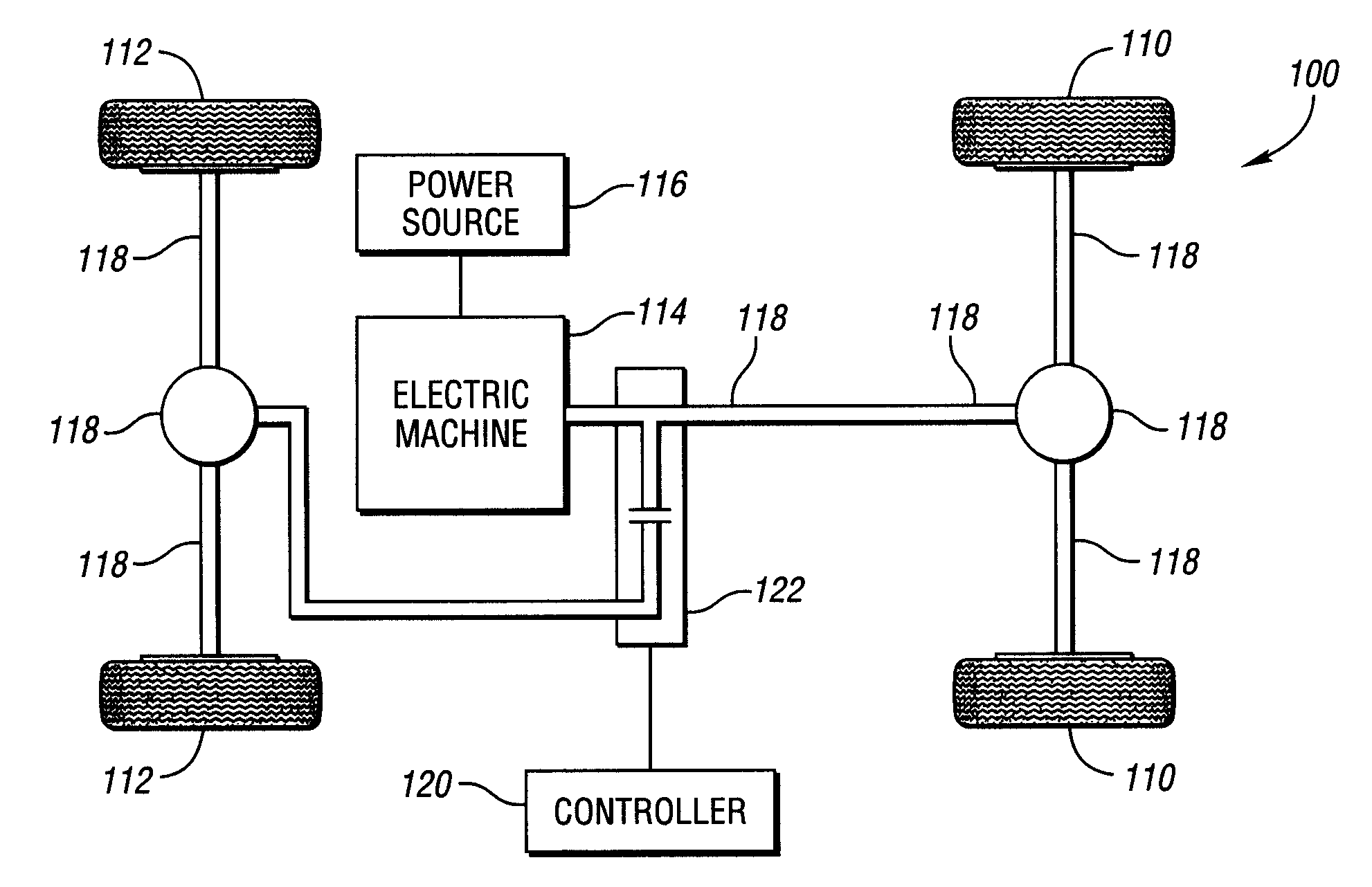

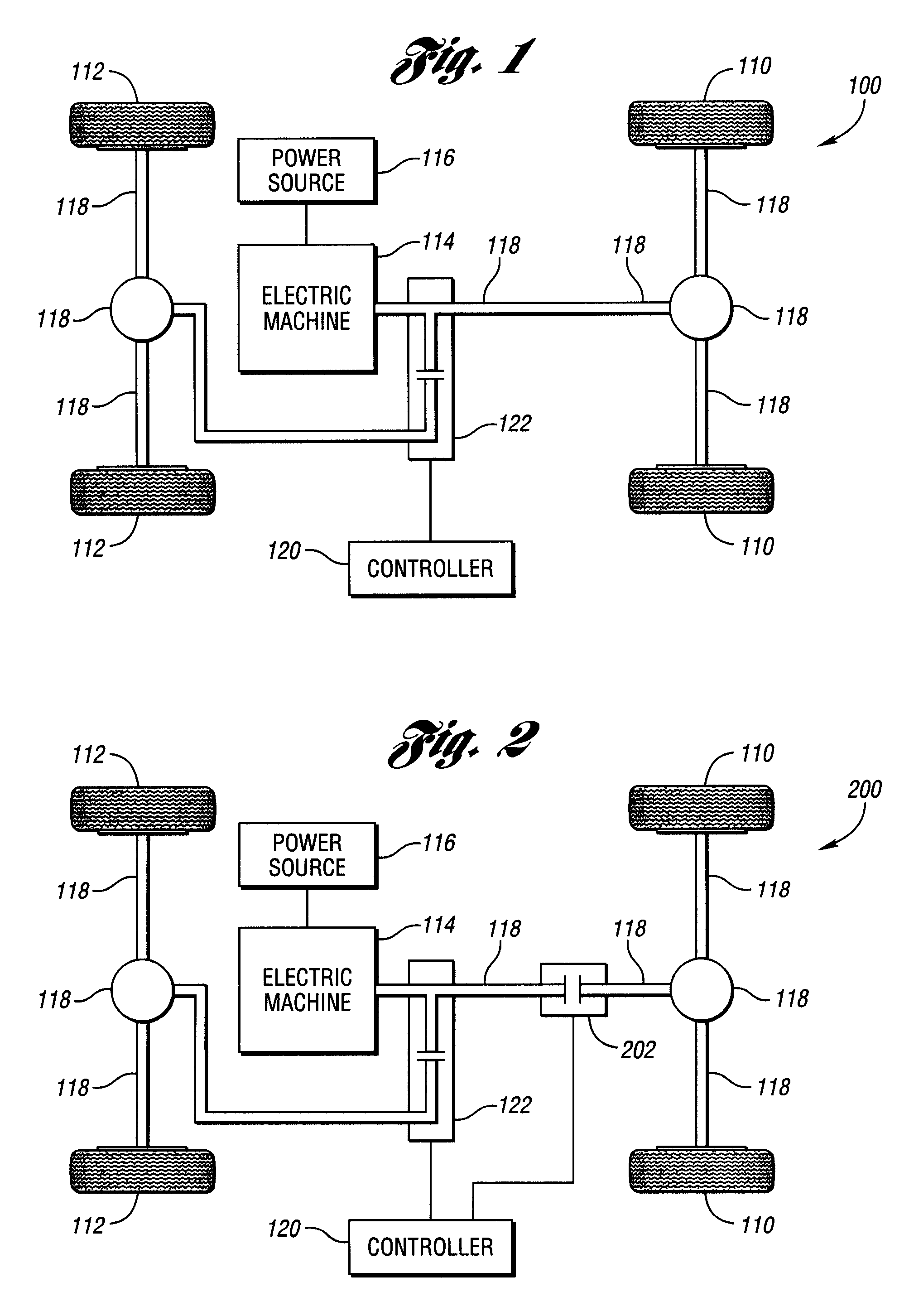

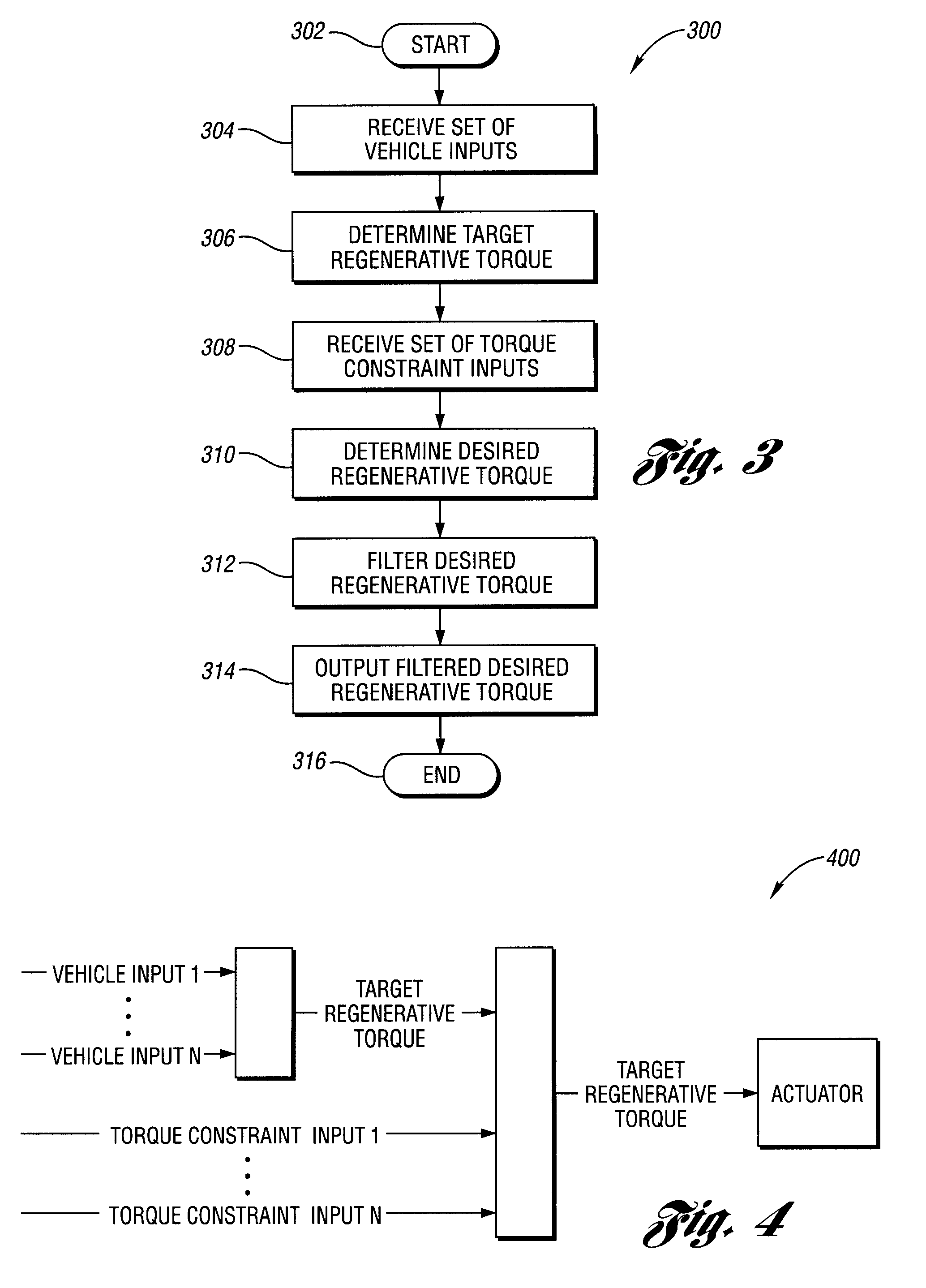

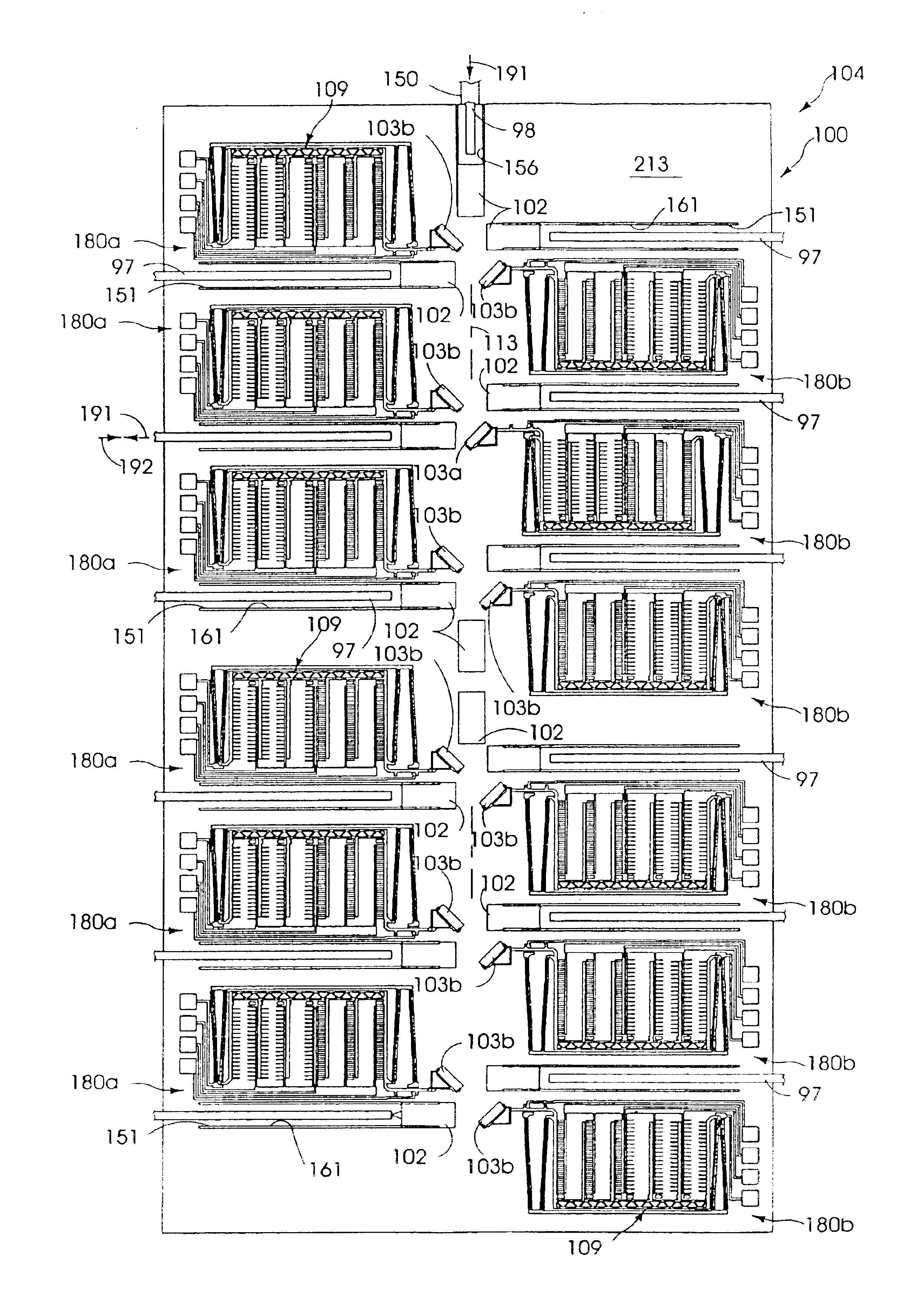

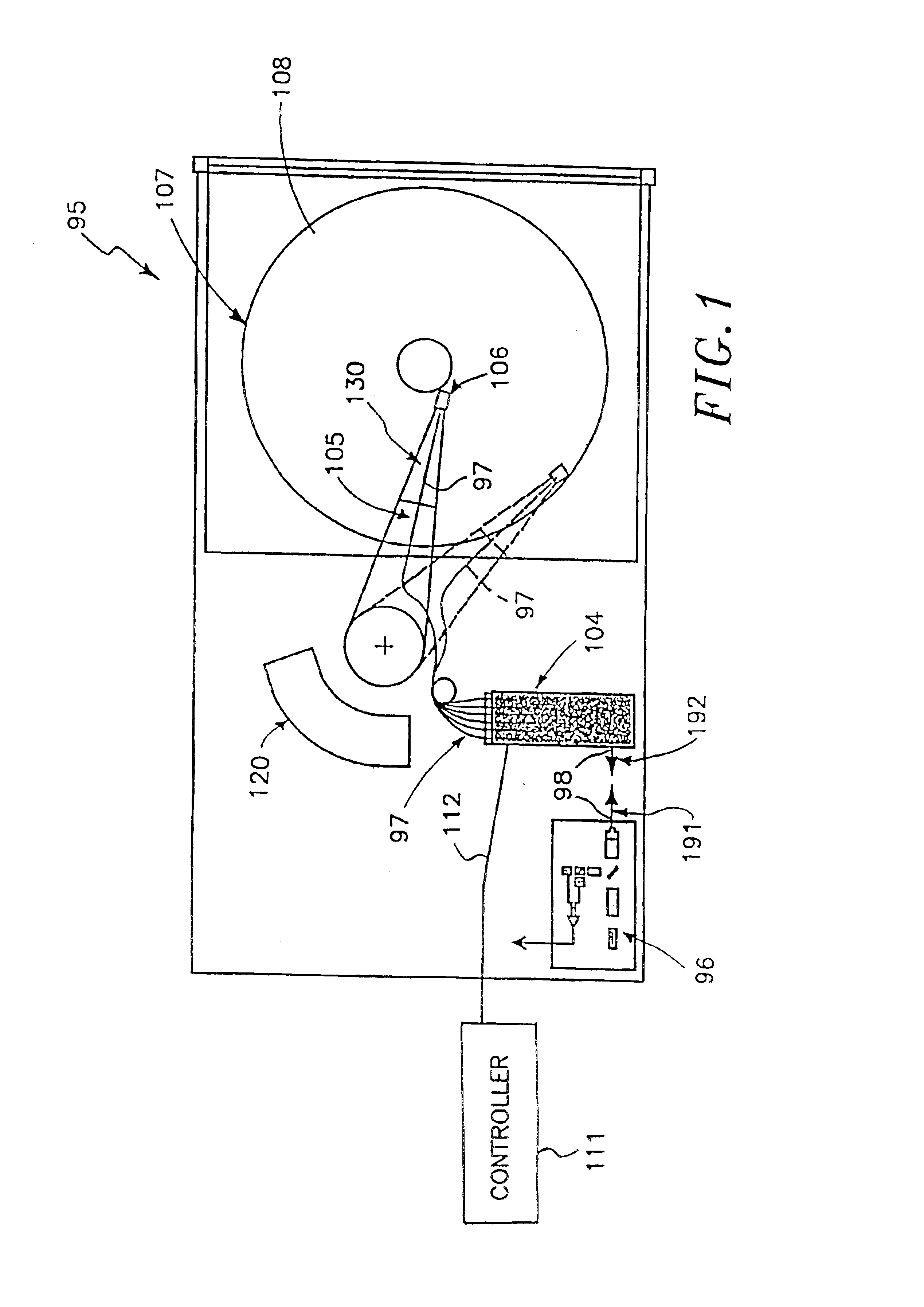

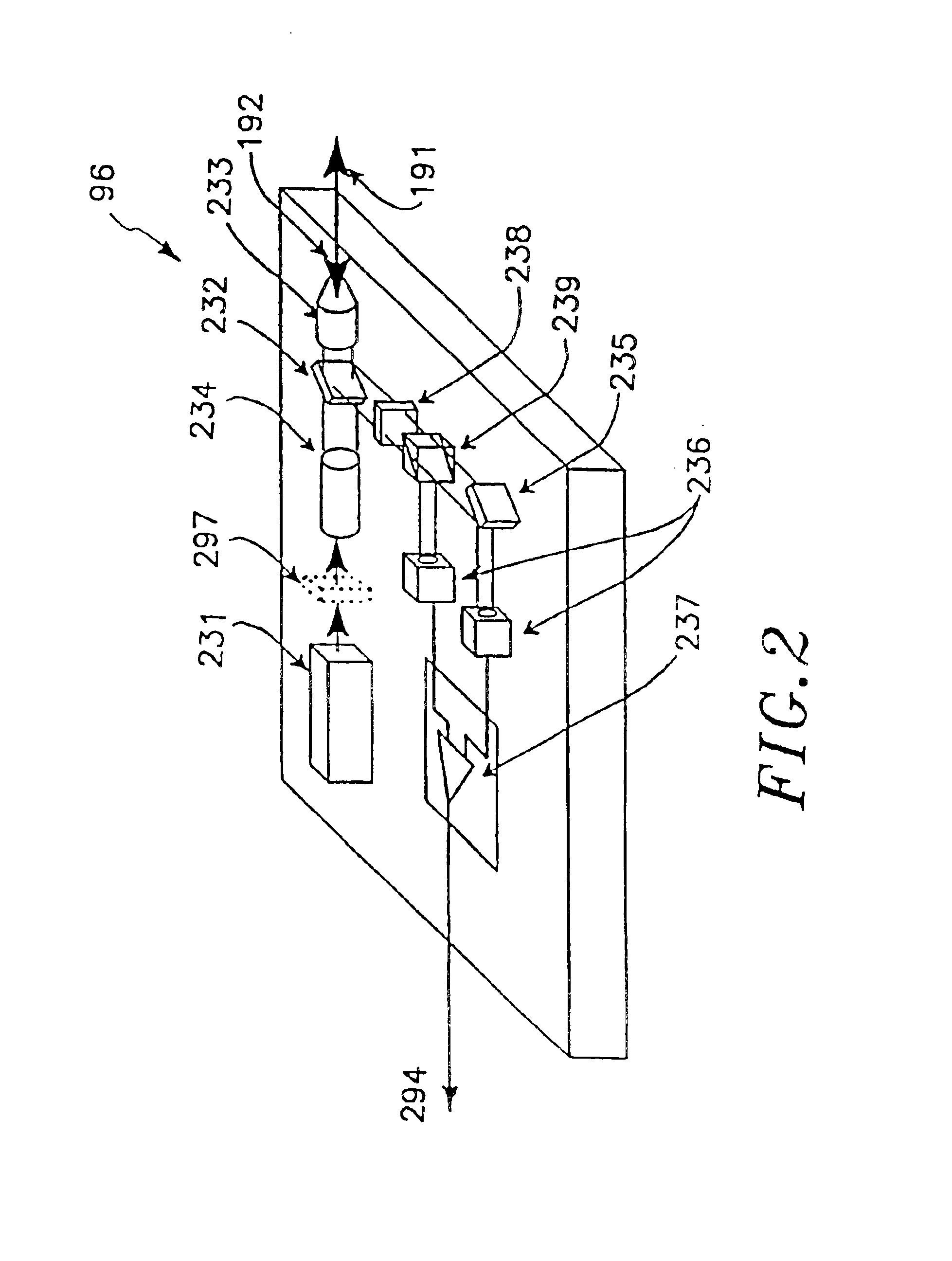

System and method for recovering regenerative power in a vehicle, and vehicle using the same

ActiveUS7464780B2Increasing regenerative power recoveredHybrid vehiclesAuxillary drivesElectricityCoupling

A system, method and vehicle using the same for increasing regenerative power recovered during vehicle deceleration. The system includes first and second sets of vehicle wheels, a controller, an electric machine, a regenerative power source, and a driveline. The electric machine performs as a motor / generator in a first / second mode of operation, respectively. The regenerative power source is electrically coupled to the electric machine and is configured to supply / receive power to / from the electric machine when the electric machine is in the first / second mode of operation, respectively. The driveline is coupled to the electric machine and the first set of vehicle wheels for transferring torque. The driveline includes a controllable coupling apparatus in electronic communication with the controller for selectively coupling, during vehicle deceleration, the electric machine to the second set of vehicle wheels.

Owner:FORD GLOBAL TECH LLC

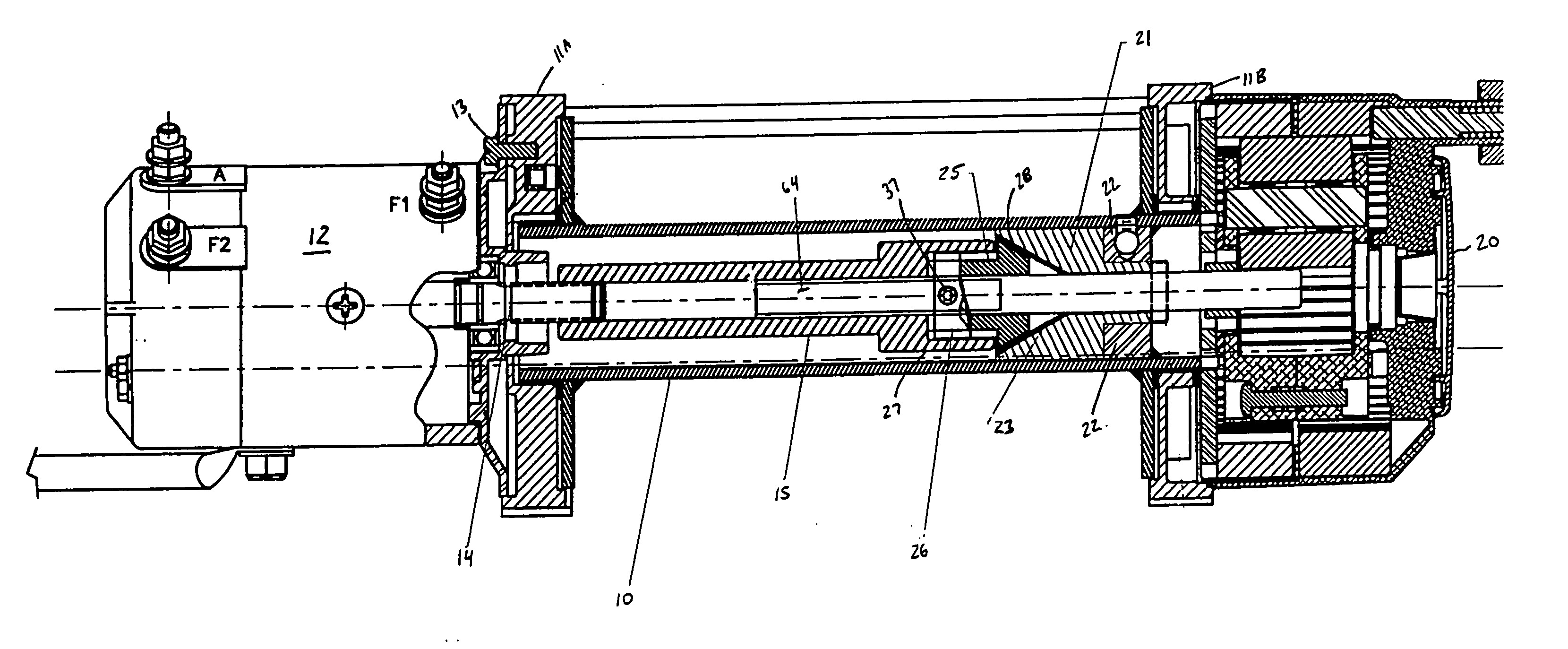

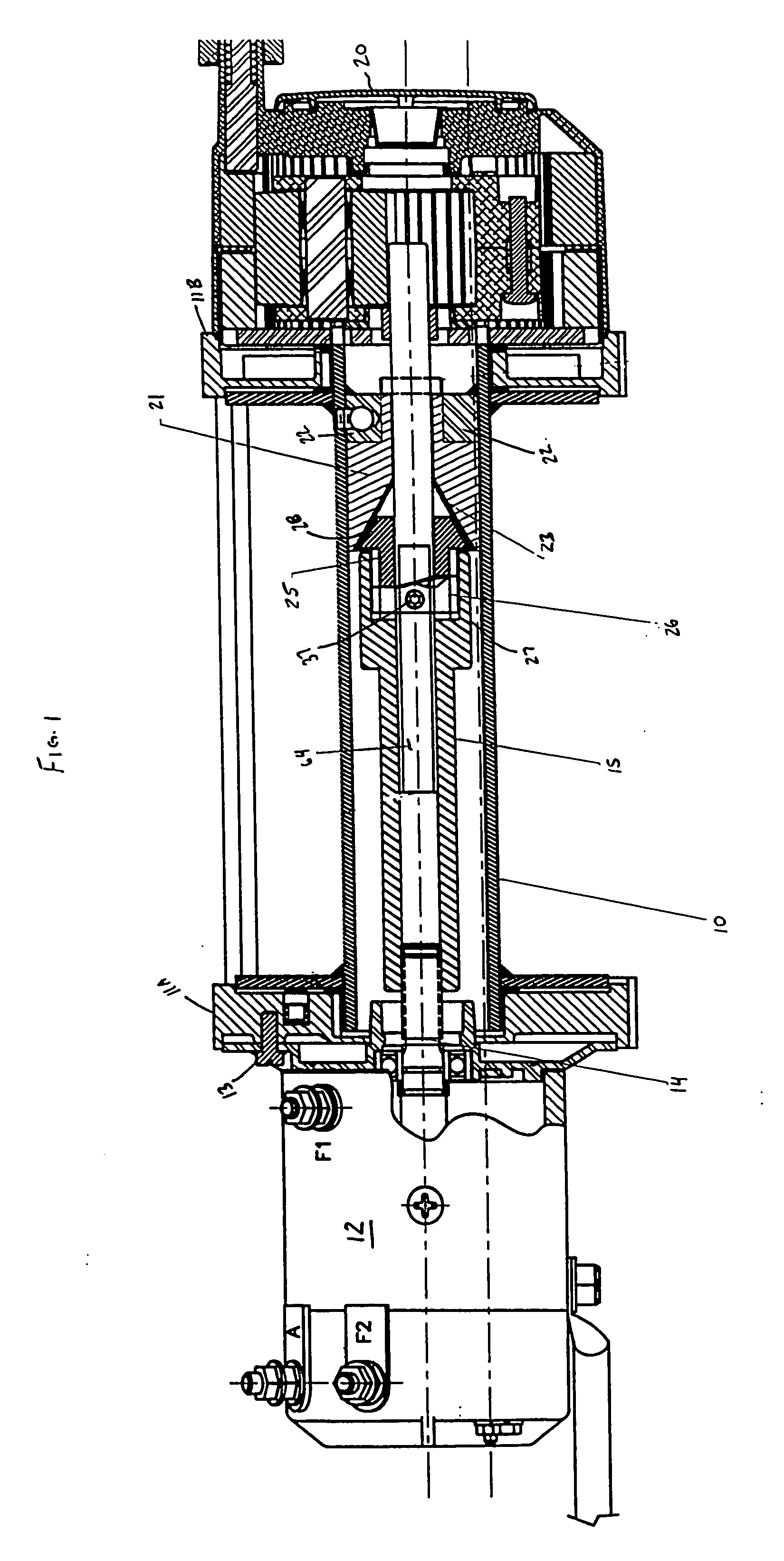

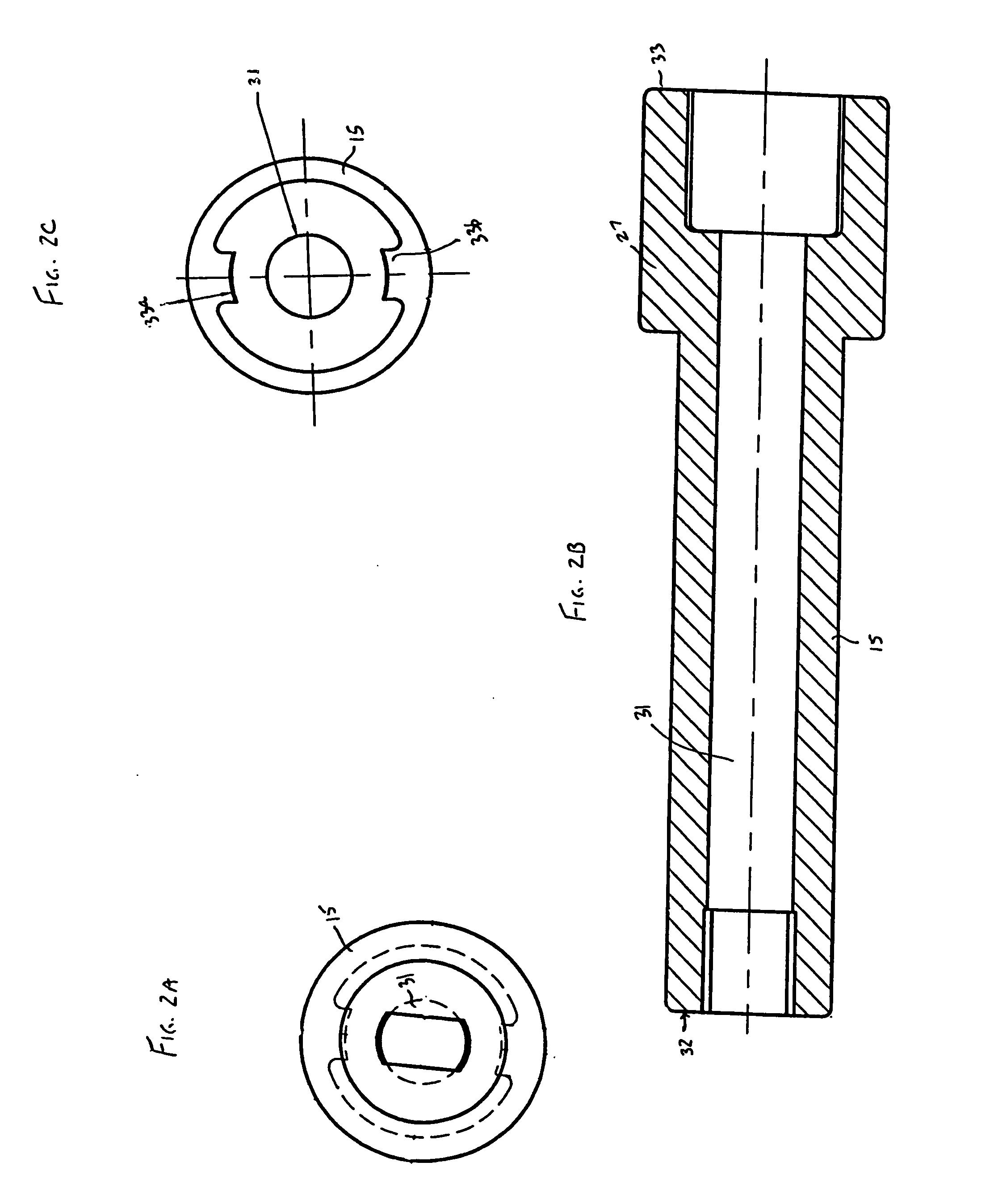

Permanent magnet synchronous heat pipe cooling electric spindle

InactiveCN108599466AAvoid lossLow calorific valueCooling/ventillation arrangementSupports/enclosures/casingsPermanent magnet synchronous motorEvaporation

The invention relates to a permanent magnet synchronous heat pipe cooling electric spindle, comprising a spindle housing, wherein a spindle is mounted in the spindle housing, the two ends of the spindle are respectively supported by a front bearing and a rear bearing, the front bearing and the rear bearing are respectively mounted on a front bearing assembly and a rear bearing assembly, and the heat generated by the front and rear bearings can be greatly transmitted; a heat pipe base is fixed in the middle of the spindle housing, a heat dissipation chamber is designed at the rear end of the spindle housing, and an inorganic heat pipe passes through the heat pipe base, with a condensation end inserted into the front bearing assembly and passing through the rear bearing assembly, and an evaporation end extending into the heat dissipation chamber to absorb the heat generated by the bearings and a motor stator to a certain extent; and at the same time, a heat sink is arranged at the evaporation end of the heat pipe. The electric spindle is improved relative to other spindle devices in internal structure, heat pipe mounting position, motor selection and cooling method; a permanent magnet synchronous motor is selected, so the rotor has low heat generation; and the overall structure is simple, the operation is stable, and the service life of the electric spindle can be prolonged.

Owner:HARBIN UNIV OF SCI & TECH

Optical microswitch

InactiveUS6836584B1Large vertical electrode areaIncrease stiffnessOptical flying-type headsRecord information storageControl signalComb drive

An optical microswitch for use with a laser beam that extends along a path comprising a body having an inlet port adapted to receive the laser beam and a plurality of outlet ports. A plurality of mirrors coupled to a plurality of micromotors carried by the body. The micromotors selectively move the mirrors from a first position out of the path of the laser beam to a second position into the path of the laser beam to direct the laser beam to one of the outlet ports. Each of the micromotors has at least one electrostatically-driven comb drive assembly therein for moving the respective mirror to one of the first and second positions. A controller is electrically coupled to the micromotors for providing control signals to the micromotors.

Owner:COHERENT INC

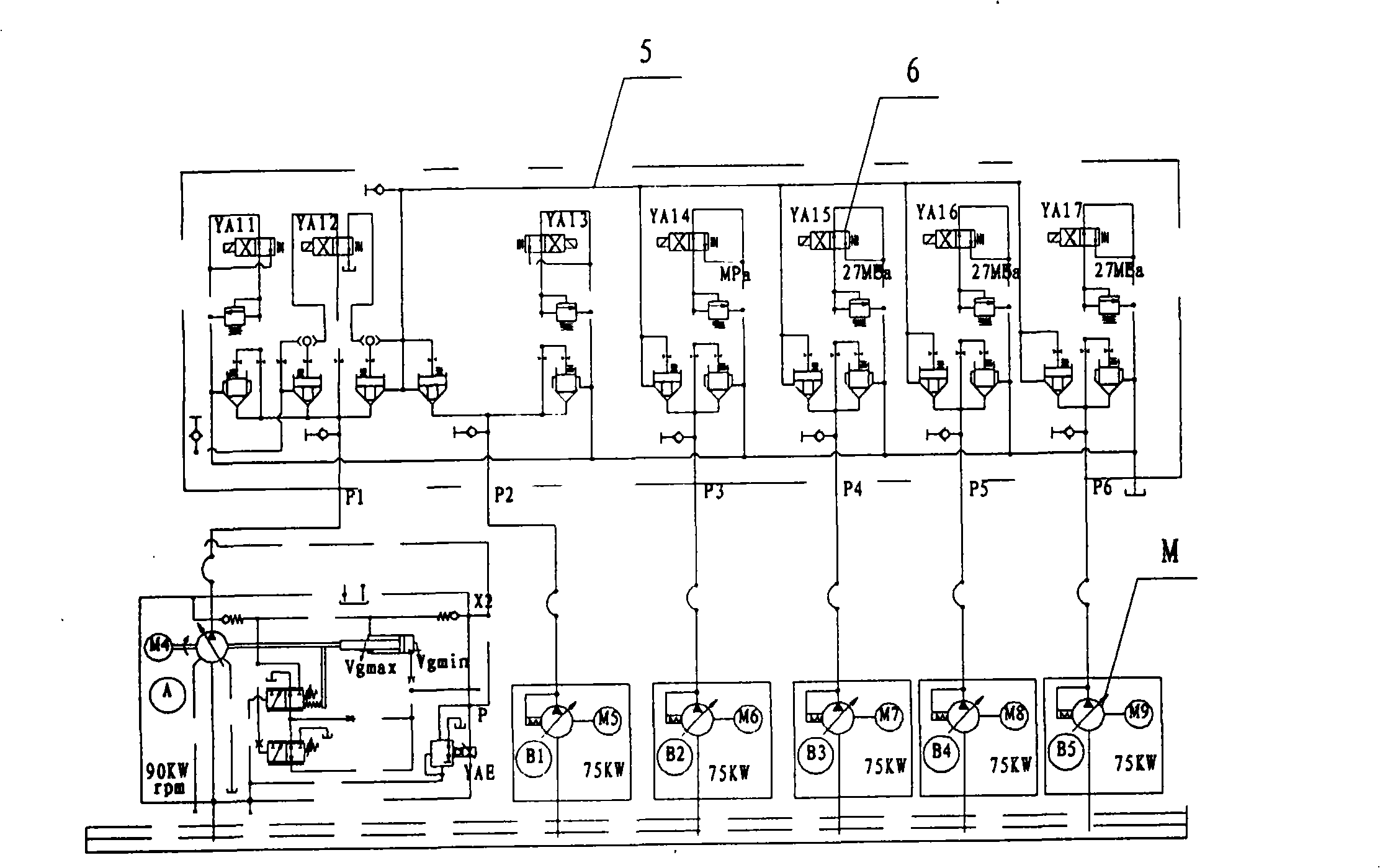

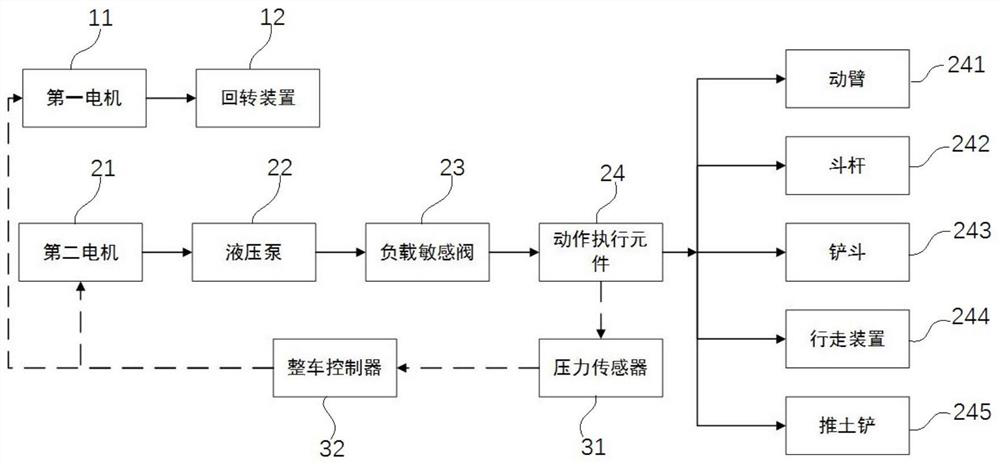

Compound drive system and control method of electric excavator

ActiveCN111962599AImprove coordinationImprove handlingSoil-shifting machines/dredgersElectric machineHydraulic pump

The invention relates to a compound drive system of an electric excavator. The compound drive system of the electric excavator comprises a first motor, a second motor, a load-sensitive valve, a pressure sensor and a vehicle control unit; the first motor is configured to drive a turning device of the electric excavator; the second motor is configured to drive a hydraulic pump so as to provide hydraulic oil for a plurality of action execution elements of the electric excavator; the load-sensitive valve is in communication between the hydraulic pump and the action execution elements and can adjust the oil supply pressure and flow according to the pressure and flow requirements of the action execution elements; the pressure sensor is configured to measure the pressure of a load-sensitive oil port of the load-sensitive valve; and the vehicle control unit is in communication connection with the pressure sensor and is configured to enable the first motor to selectively work in a single actionmode or a composite action mode according to a pressure measurement value of the pressure sensor. According to the embodiment of the compound drive system and control method of the electric excavator, the driving requirements of the electric excavator in the single action mode and the composite action mode can be considered, the coordination among actions of the electric excavator is improved, and then the controllability and the working efficiency of the electric excavator are improved.

Owner:XCMG EXCAVATOR MACHINERY

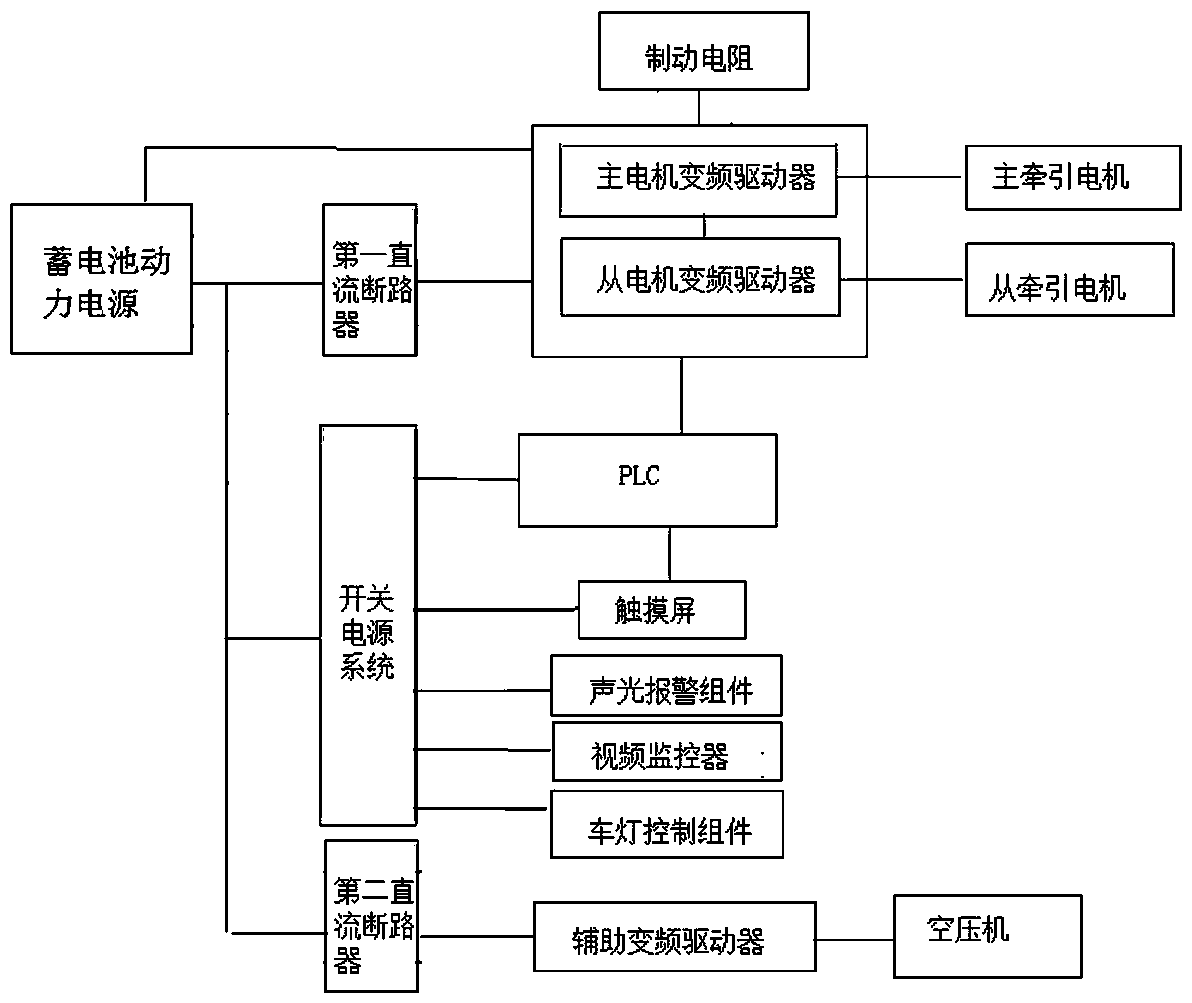

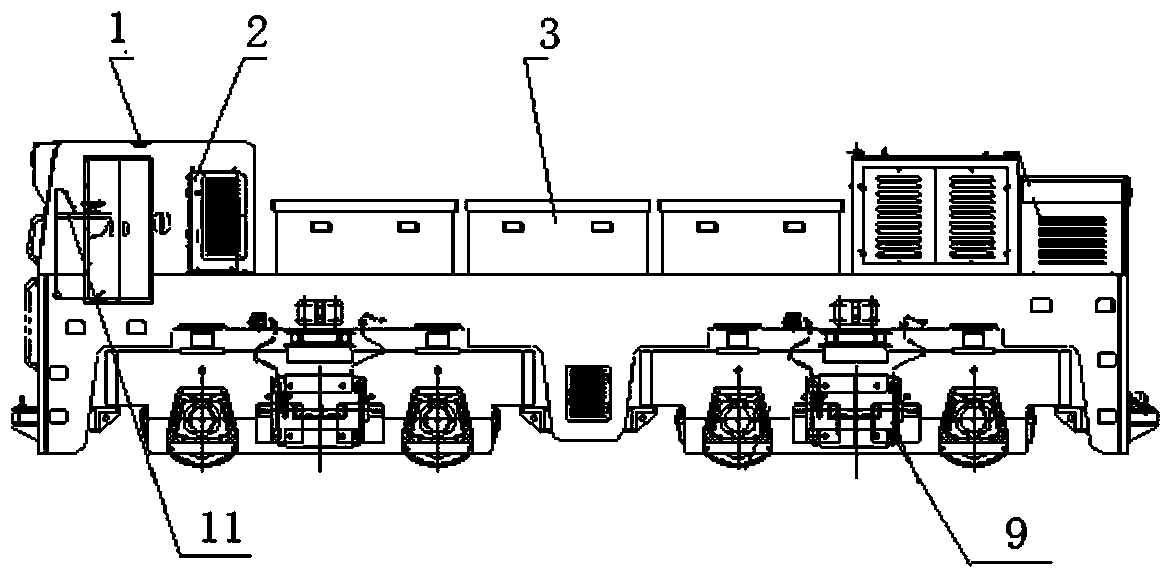

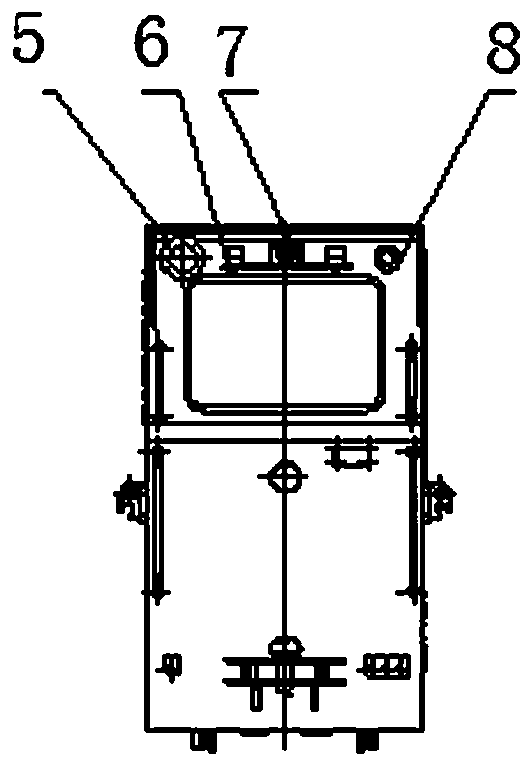

Large-tonnage tunnel engineering heavy haul train electrical control system

A large-tonnage tunnel engineering heavy haul train electrical control system comprises a storage battery power source, a main motor variable frequency driver, a slave motor variable frequency driver,a switch power source system, a PLC, a main traction motor, a slave traction motor, a touch screen, an audible and visual alarm assembly, a video monitor, a train lamp control assembly, an auxiliaryvariable frequency driver, an air compressor and a brake resistor. Both the main motor variable frequency driver and the slave motor variable frequency driver are connected with the storage battery power source. The main motor variable frequency driver and the slave motor variable frequency driver are connected. The main motor variable frequency driver is connected with the main traction motor. The slave motor variable frequency driver is connected with the slave traction motor. Both the main motor variable frequency driver and the slave motor variable frequency driver are connected with the brake resistor and the PLC. Compared with an existing vehicle, the large-tonnage tunnel engineering heavy haul train electrical control system achieves anti-dozing, fault detection, single-motor and double-motor selection functions, redundant energy is emitted through the brake resistor, and work reliability is high.

Owner:HUNAN XD HEAVY EQUIP

Electric cylinder selection system

ActiveCN104484496ASimple designImprove performanceSpecial data processing applicationsElectric machineryProcess engineering

The invention relates to an electric cylinder selection system, comprising a specification selection module, a technical requirement module, a motor selection module, a load characteristic module and a design report module. With adoption of the above manner, the electric cylinder selection system has the advantages of optimal design, novel system, stable performance, convenient operation, increased parameters, precision and accuracy, improved efficiency, convenience and practicability and has wide market prospect in the popularization of the electric cylinder selection system.

Owner:SUZHOU SHELE INTELLIGENT TECH CO LTD

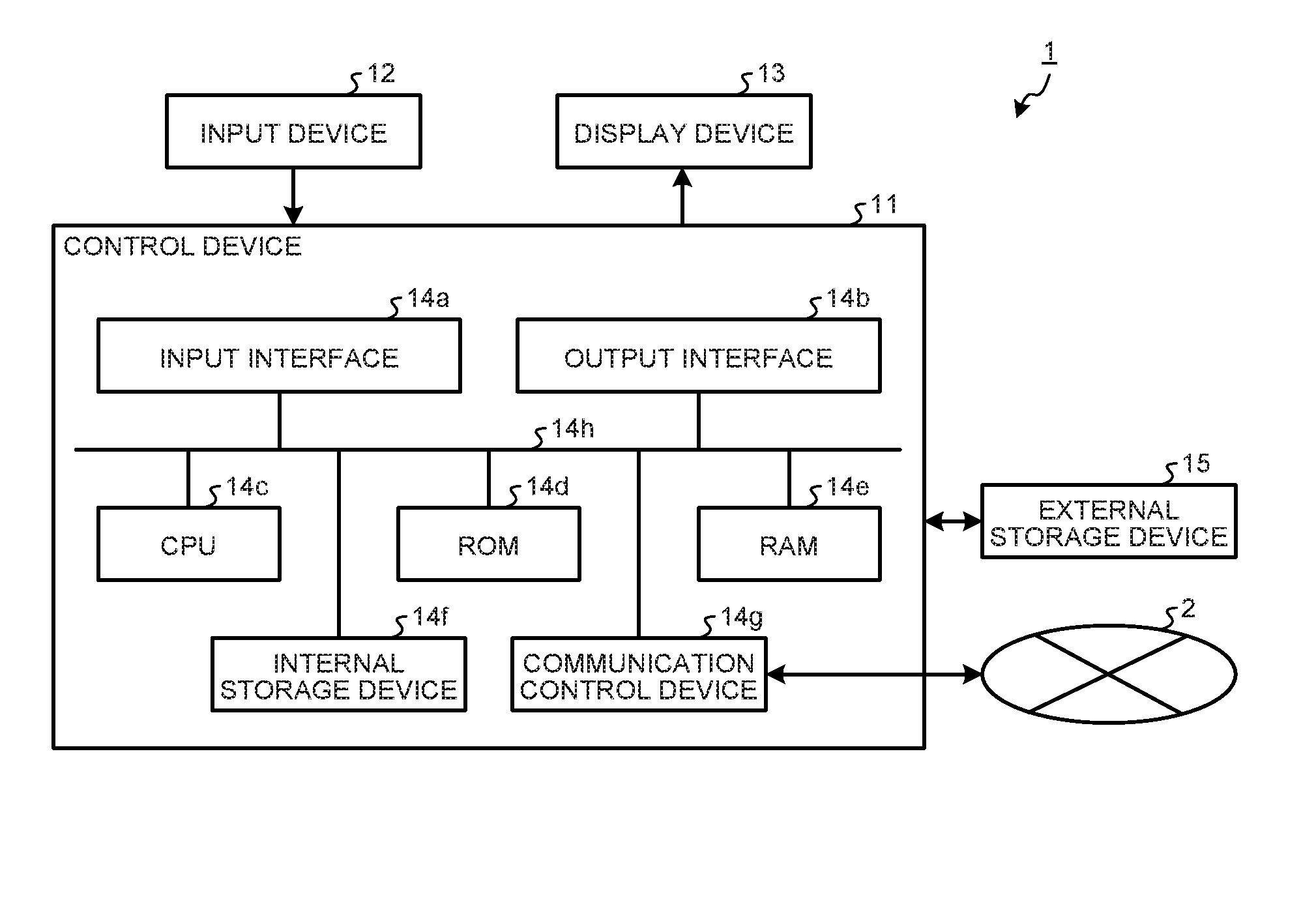

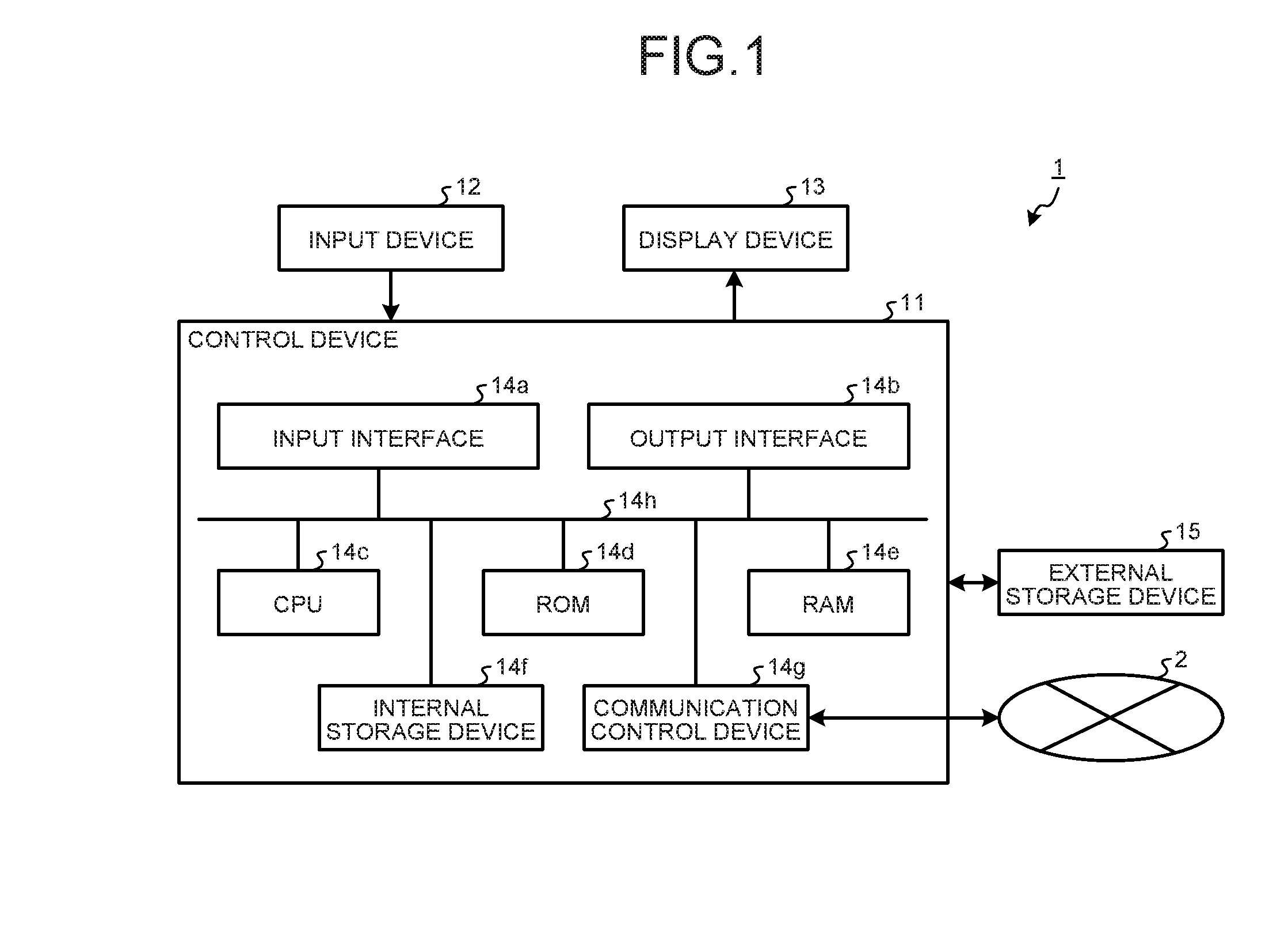

Motor selection device

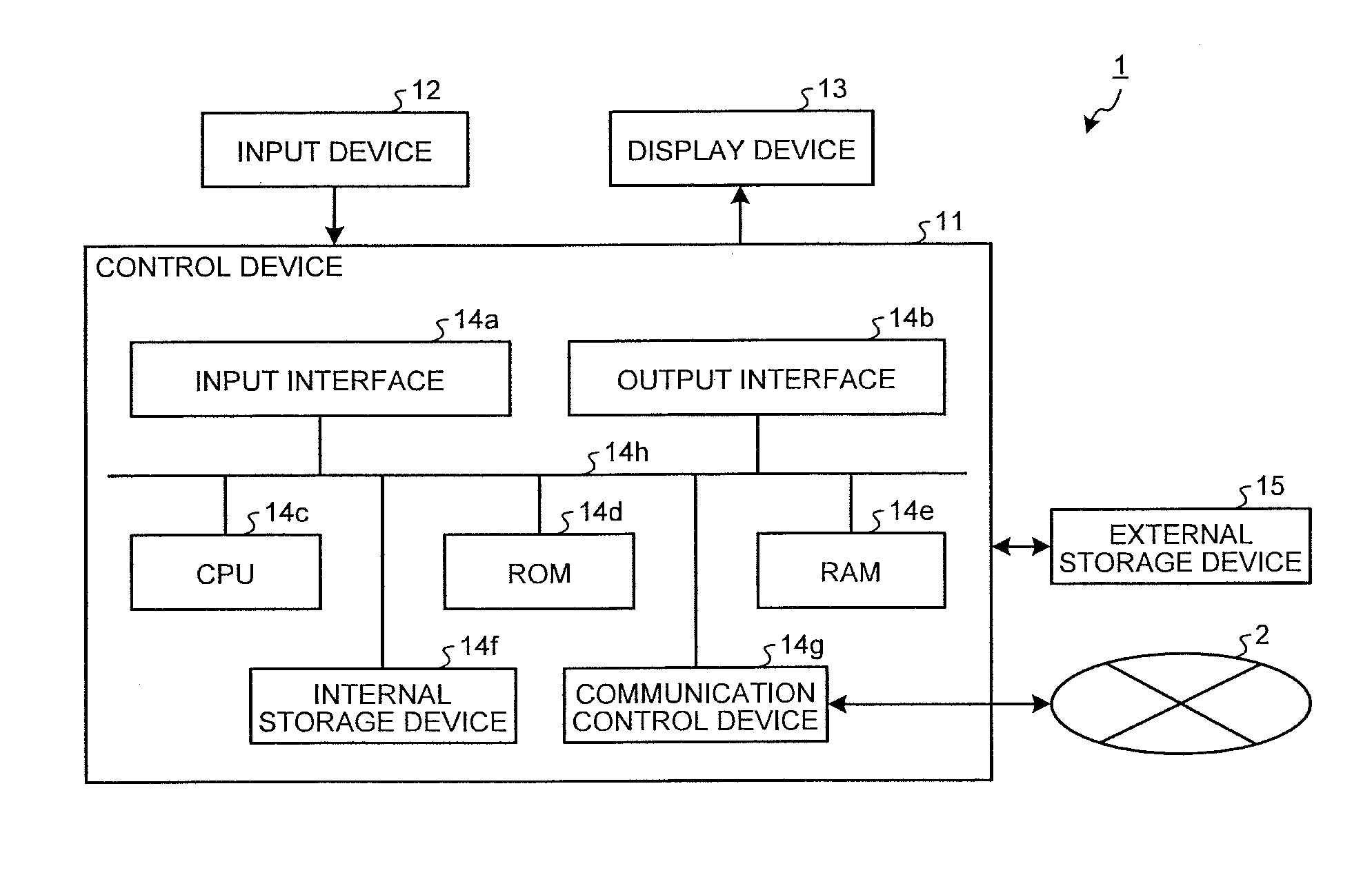

ActiveUS20160139583A1Reduce the possibilityEffective torque increasesElectric motor controlComputer controlConstant loadFriction torque

A motor selection device includes a computer including a storage device and a calculation device. The storage device stores data of acceleration time, constant speed time, deceleration time, stop time, maximum output torque for each motor, dynamic friction torque, and constant load torque. To select selectable motors and to suggest an optimal operation pattern among motor operation patterns, the calculation device includes a central processing unit (CPU) and performs effective torque calculation by calculating torque in the acceleration time, in the constant speed time, in the deceleration time, and in the stop time based on data stored in the storing unit, and calculating the effective torque by giving a first torque, a second torque, a third torque, a fourth torque, the acceleration time, the constant speed time, the deceleration time, and the stop time to a predetermined formula.

Owner:NSK LTD

Automatic recognition mechanical gripper special for tray

PendingCN110282426AWide range of optionsGuaranteed automatic correctionConveyorsConveyor partsElectric machineryPower unit

The invention discloses an automatic recognition mechanical gripper special for a tray. The gripper comprises a mounting base. A first gripper unit and a second gripper unit are arranged on the left and right sides of the mounting base correspondingly and driven by a power unit to open and close. The power unit comprises a power source and a linkage mechanism which are used for driving the first gripper unit and the second gripper unit to open and close synchronously. A recognition module is arranged on the first gripper unit or the second gripper unit. A single floating correction assembly is arranged on the first gripper unit or the second gripper unit. According to the automatic recognition mechanical gripper special for the tray, a penetration lead screw motor used as the power source and a synchronous belt transmission pair used as the linkage mechanism jointly achieve fast opening and closing of the first gripper unit and the second gripper unit, the linear moving trajectories of the two gripper units are limited through a linear guide component, the stability is good, and the motor selection range is wide.

Owner:AUTOBIO LABTEC INSTR CO LTD

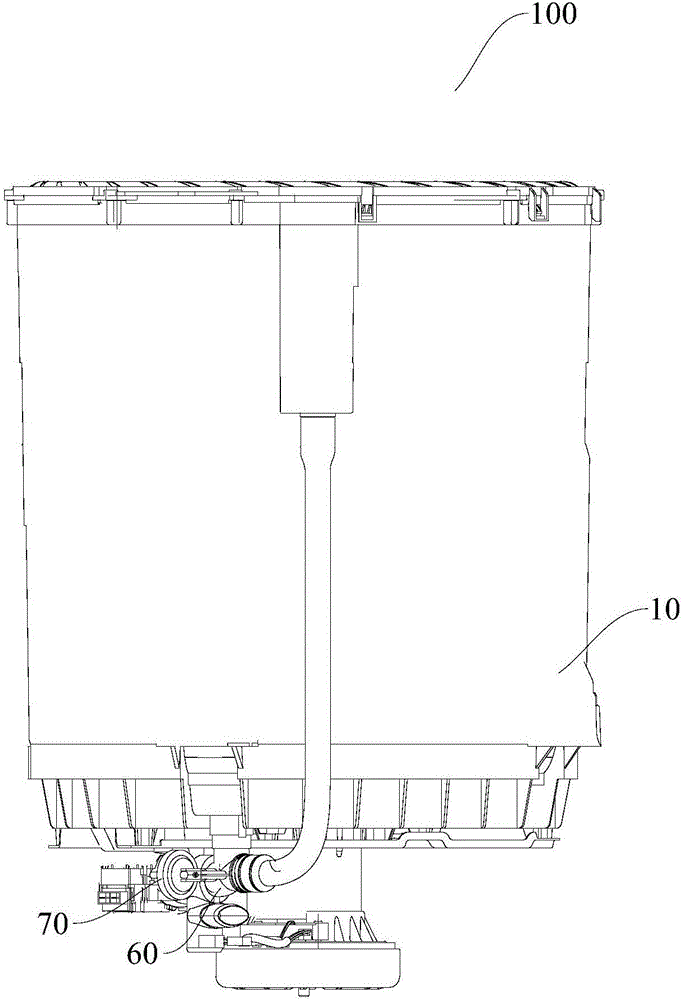

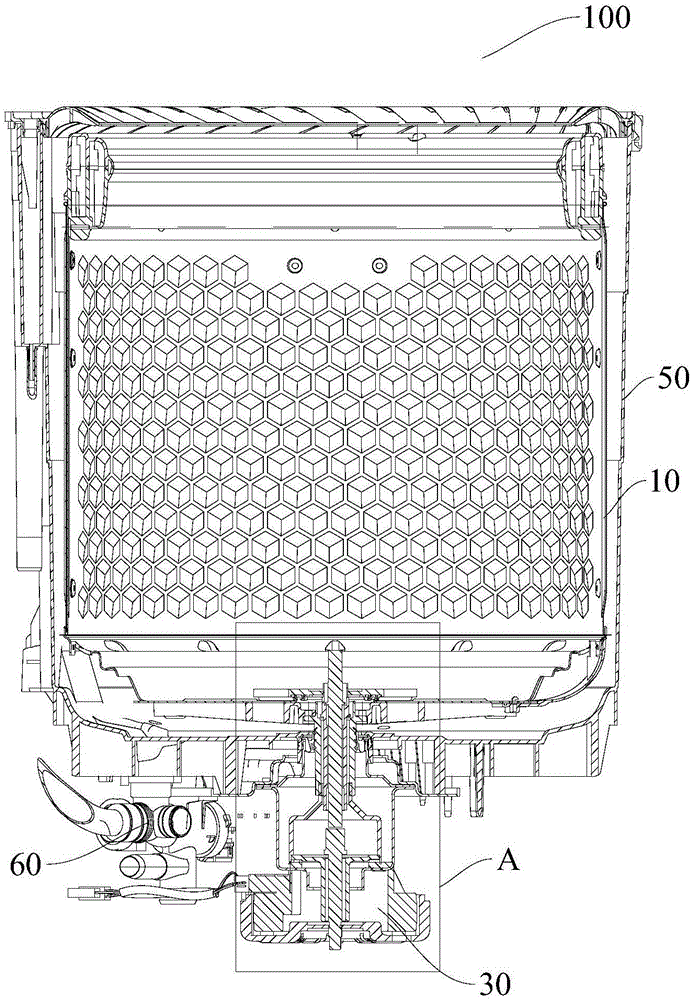

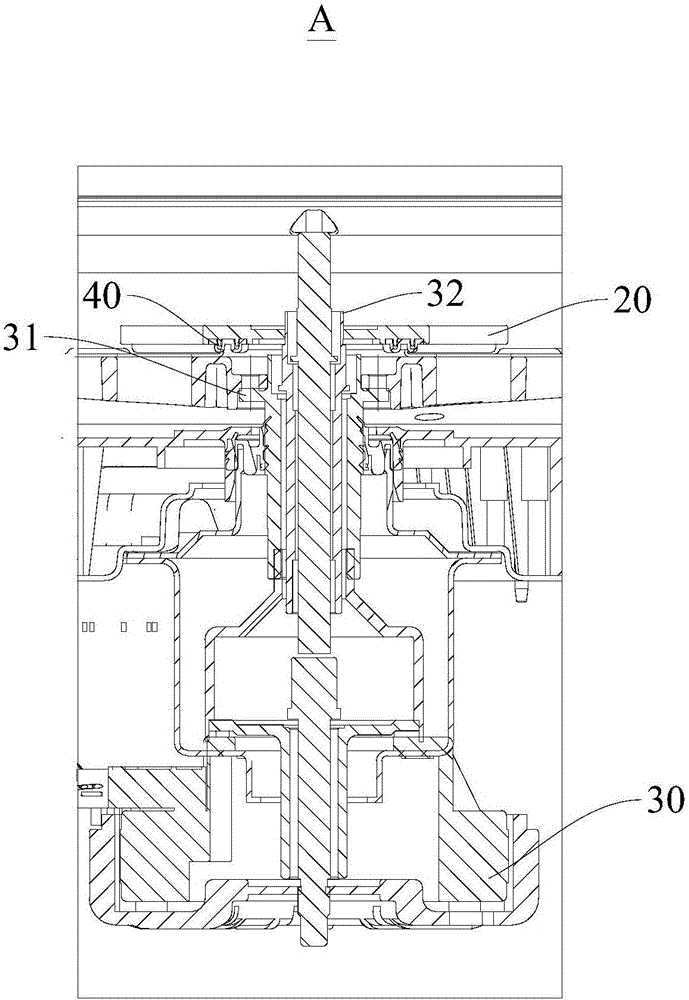

Washing machine

PendingCN106835628AReduce water consumptionEffective drainageOther washing machinesTextiles and paperLaundry washing machineElectric machinery

The invention discloses a washing machine. The washing machine comprises an inner drum, a sealing plate, a clutch and a motor, wherein drain holes are formed in the bottom of the inner drum; the sealing plate is rotationally mounted at the bottom of the inner drum and can open and close the drain holes through rotation; the clutch is arranged below the inner drum and comprises a first shaft and a second shaft, the first shaft is fixedly connected with the inner drum, and the second shaft is fixedly connected with the sealing plate; the motor selectively drives the first shaft and the second shaft. According to the washing machine, the sealing plate can seal the drain holes before water enters the washing machine, accordingly, water in the inner drum cannot flow into an outer drum, water consumption during clothes washing by the washing machine can be reduced, and water can be saved. When the washing machine finishes washing and needs to drain water, the sealing plate can open the drain holes, and a water sensor can effectively sense surplus water.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com