Automatic recognition mechanical gripper special for tray

An automatic identification and mechanical grasping technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of long standby time, small maintenance space, small rack and pinion structure, etc., and achieve the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

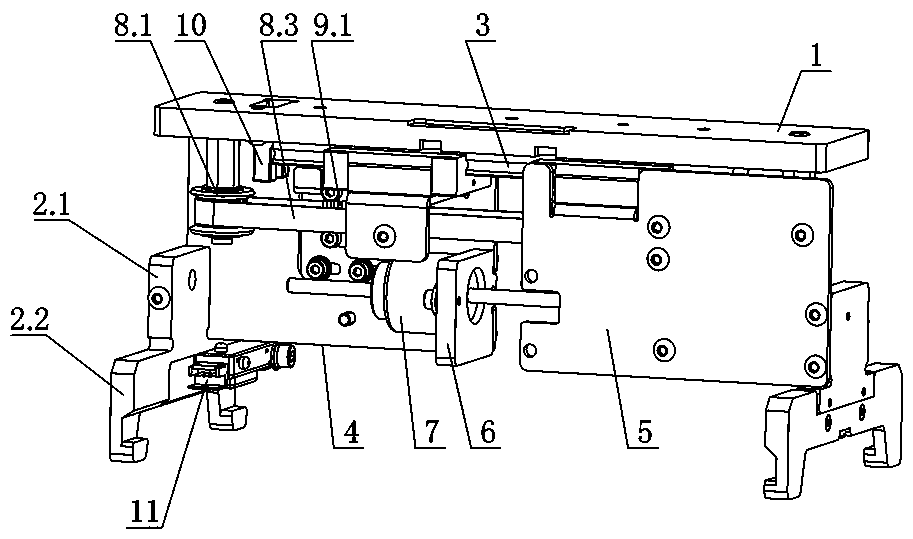

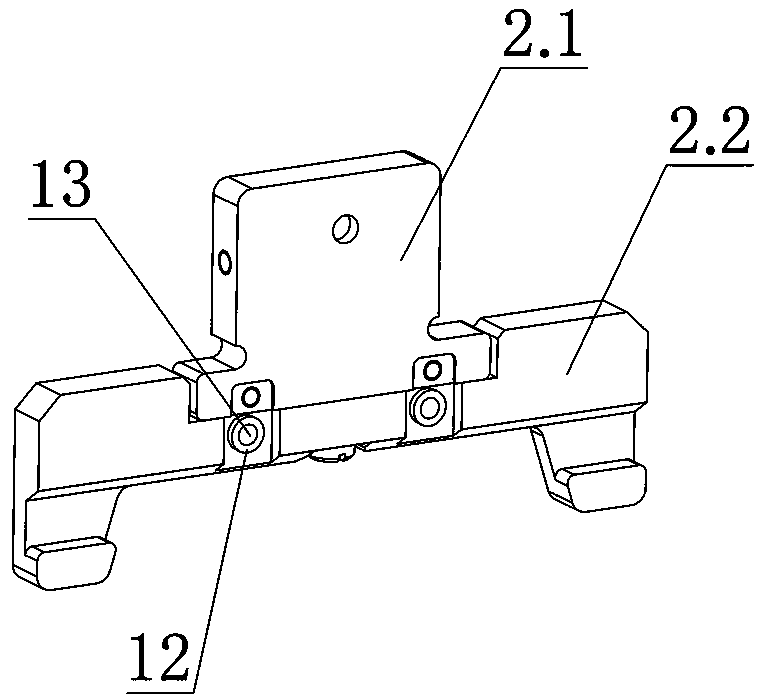

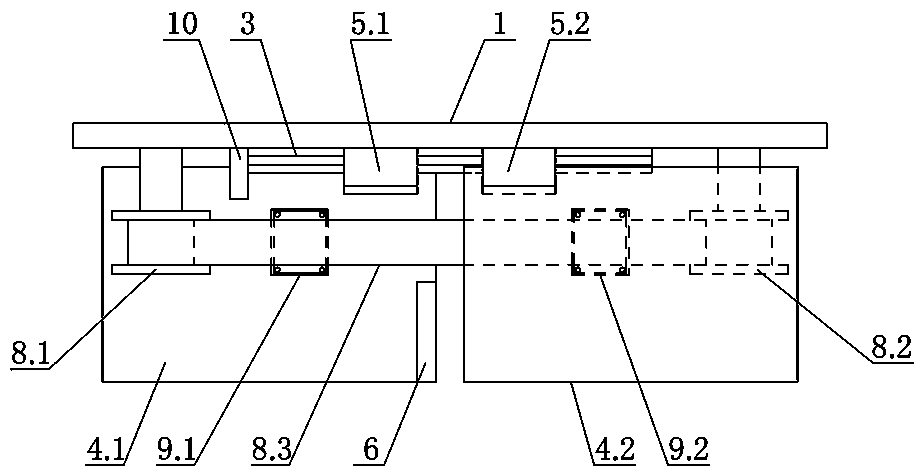

[0020] like figure 1 As shown, the automatically identifiable pallet-specific mechanical gripper of the present invention includes an installation base 1, and the left and right sides of the installation base 1 are respectively provided with a first gripper unit and a second gripper unit driven by a power unit to open and close. The gripper unit, the first gripper unit and the second gripper unit have the same structure, and both include a vertical plate 2.1, and the bottom of the vertical plate 2.1 is provided with a gripper 2.2 extending in the front and rear direction, the gripper 2.2 of the first gripper unit and The gripper 2.2 of the second gripper unit is left-right symmetrical, and the gripping groove of the gripper 2.2 cooperates with the outward flange on the top of the tray to ensure that the tray can be clamped;

[0021] like figure 1 As shown, the lower surface of the installation base 1 is provided with a linear guide 3 (the linear guide 3 is a guide rail, of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com