Patents

Literature

38results about How to "Improve sealing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

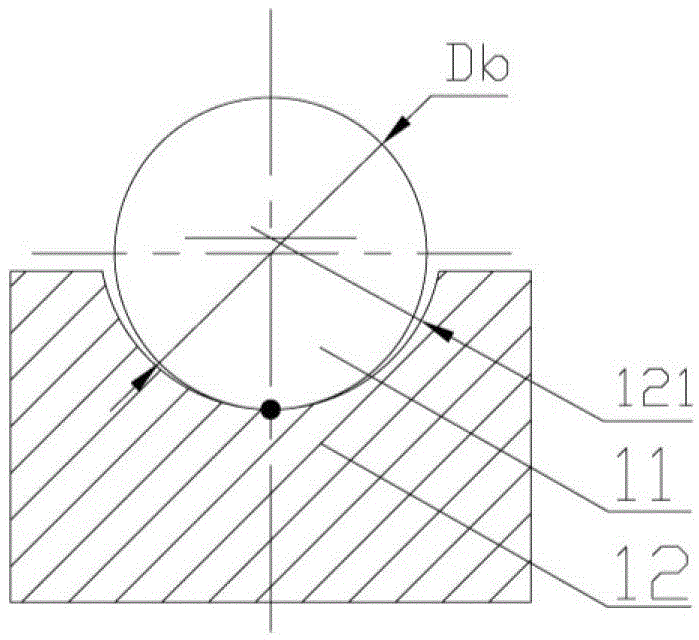

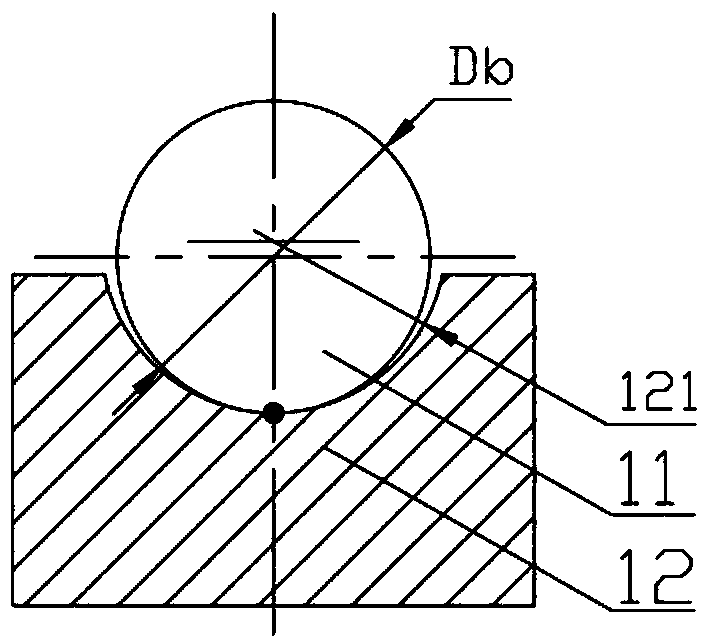

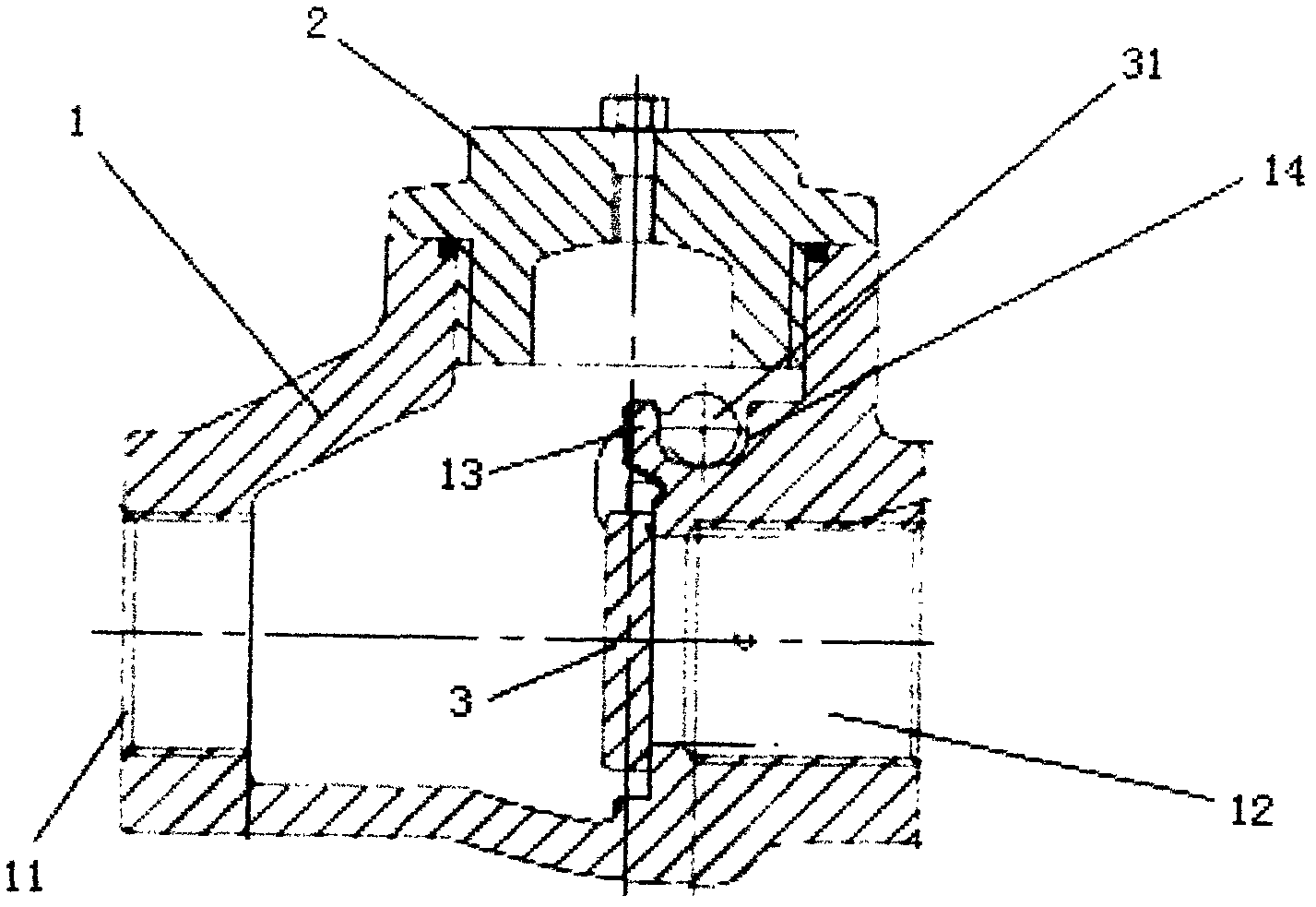

Machining method of rolling bearing formed by whole and precise hard turning and molding of sleeve ring

InactiveCN103331456AHigh mutual position accuracyImprove shape and position accuracyRolling contact bearingsTurning machinesParticle adhesionEnvironmental resistance

The invention provides a machining method of a rolling bearing formed by whole and precise hard turning and molding of a sleeve ring. The machining method is characterized by comprising the following steps: after quenching and annealing heat treatment of the sleeve ring, carrying out the whole and precise hard turning and molding; and then combining and assembling a rolling body, wherein a sleeve ring rolling path comprises a fixed-curvature-groove-shape rolling path, a non-groove-shaped rolling path, a variable-curvature-shaped rolling path and a non-groove-shaped rolling path according to section shapes. The machining method disclosed by the invention overcomes the defects in the prior art that (1) performance defects on a machining surface, including grinding burn, a grinding metamorphic layer, grinding tensile stress, abrasive particle adhesion, scratches and the like, are caused by grinding and molding the sleeve ring; (2) shape defects on the machining surface that mutual position precision of all parts is not high, the shape of the rolling path cannot be accurately guaranteed and the like, are caused by carrying out a plurality of times of machining on different surfaces, even the same surface; (3) the defects that large investment of equipment, a tool clamp and personnel, and high machining cost are caused; and (4) the defects that a cutting solution needs to be used and the machining method is not environment-friendly enough are caused. The invention provides an anti-fatigue and green machining method which has the very great engineering actual meanings.

Owner:SHANGHAI F&S BEARING TECH

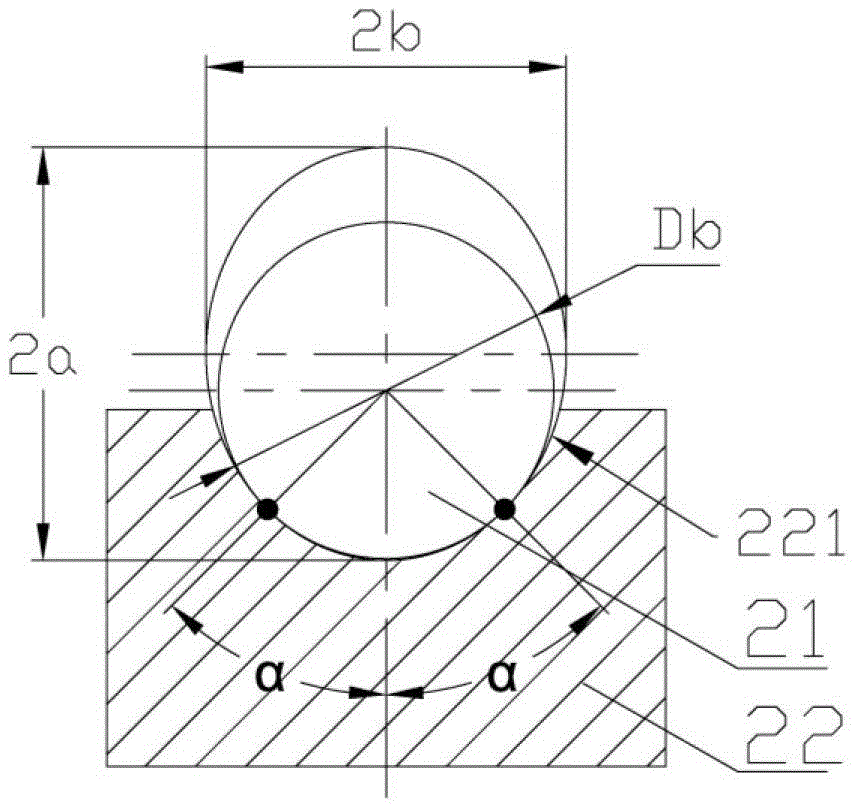

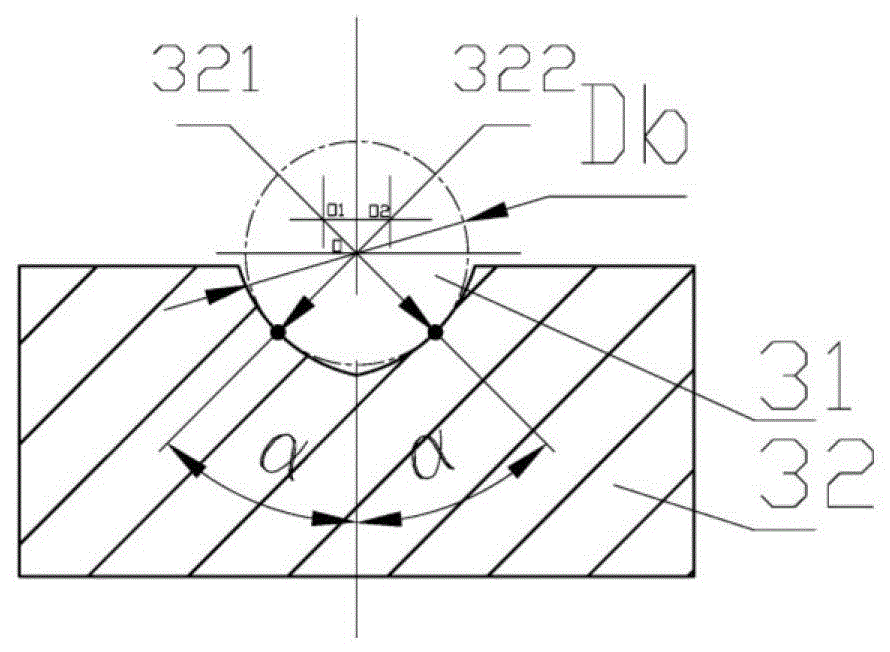

Machining method for rolling bearing with ring precisely shaped by hard finishing

ActiveCN103737024AHigh mutual position accuracyImprove shape and position accuracyRolling contact bearingsTurning machinesRolling-element bearingBurn injury

Disclosed is a machining method for a rolling bearing with a ring precisely shaped by hard finishing. The machining method is characterized in that an inner ring and an outer ring of the bearing are integrally precisely shaped by hard finishing or the key surface of a ring part is precisely shaped by hard finishing; the key surface comprises raceways, raceway flanges, raceway oil grooves, seal grooves, ring flanges, grooved raceway edge chamfers and the like; precise shaping by hard finishing takes the place of grinding (such as the raceways) shaping and shaping by soft finishing (such as the sealing grooves), so that technical and quality problems of limited shape design of a raceway section, grinding badness even burn injuries and the like are solved; the technical and quality problems of low machining precision, heat treatment distortion and the like existing in shaping surfaces of the sealing grooves, the grooved raceway edge chamfers and the like by soft finishing are solved by precise hard finishing, so that the surfaces of the ring can be designed according to the operating condition and can be shaped precisely in a quite high mode, and the key surface of the ring can be controlled in shape and performance, and designing and manufacturing of the high-performance rolling bearing high in sealability and reliability and the like are of great practical engineering significance.

Owner:SHANGHAI F&S BEARING TECH

Method for manufacturing and sealing exhaust port in vacuum glass and system thereof

InactiveCN102557410AImprove sealing accuracyNo surface bumpsGlass reforming apparatusFlat glassGalvanometer

The invention relates to a method for manufacturing and sealing an exhaust port in vacuum glass, which comprises the following steps: directly carrying out layer-by-layer three-dimensional carving in plate glass by using laser so as to form the exhaust port, carrying out three-dimensional carving on a glass block by using laser so as to form a glass sealing plug, laying sealant between the plug body and the exhaust port, then welding and sealing the plug body and the exhaust port by using laser. The invention also provides a system for manufacturing and sealing the exhaust port in the vacuum glass, which comprises a laser carving device, a laser welding device, a vacuum chuck and a glass sealing plug installing device, wherein the laser carving device comprises a laser device, a laser power controller, a first galvanometer system and a computer; the laser welding device comprises a laser system and a second galvanometer system; the vacuum chuck is connected with a vacuum pump through a connecting tube; a magnet coil is arranged on the top of the vacuum chuck; and the glass sealing plug installing device is composed of a magnet driving device. The sealing exhaust port in vacuum glass of the invention has the advantages of high sealing accuracy and no surface embossment so as to improve vacuum sealing performance and safety performance, and is easy for on-line implementation so as to improve work efficiency.

Owner:上海镭立激光科技有限公司

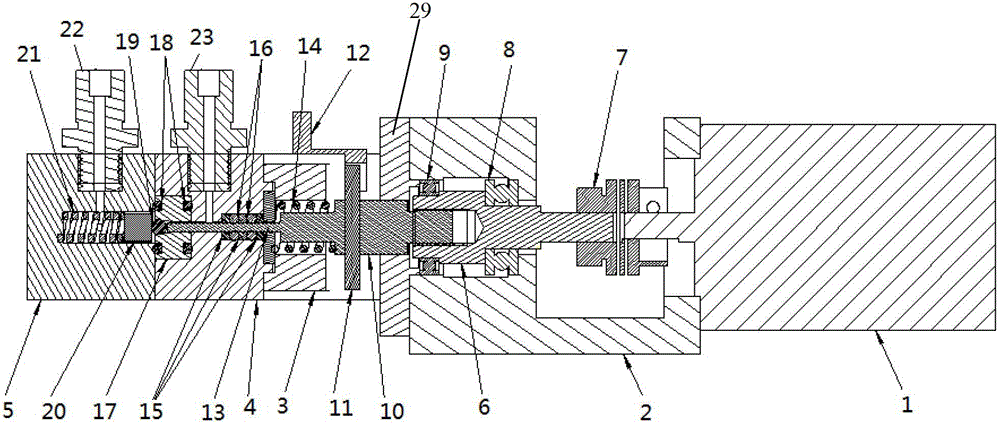

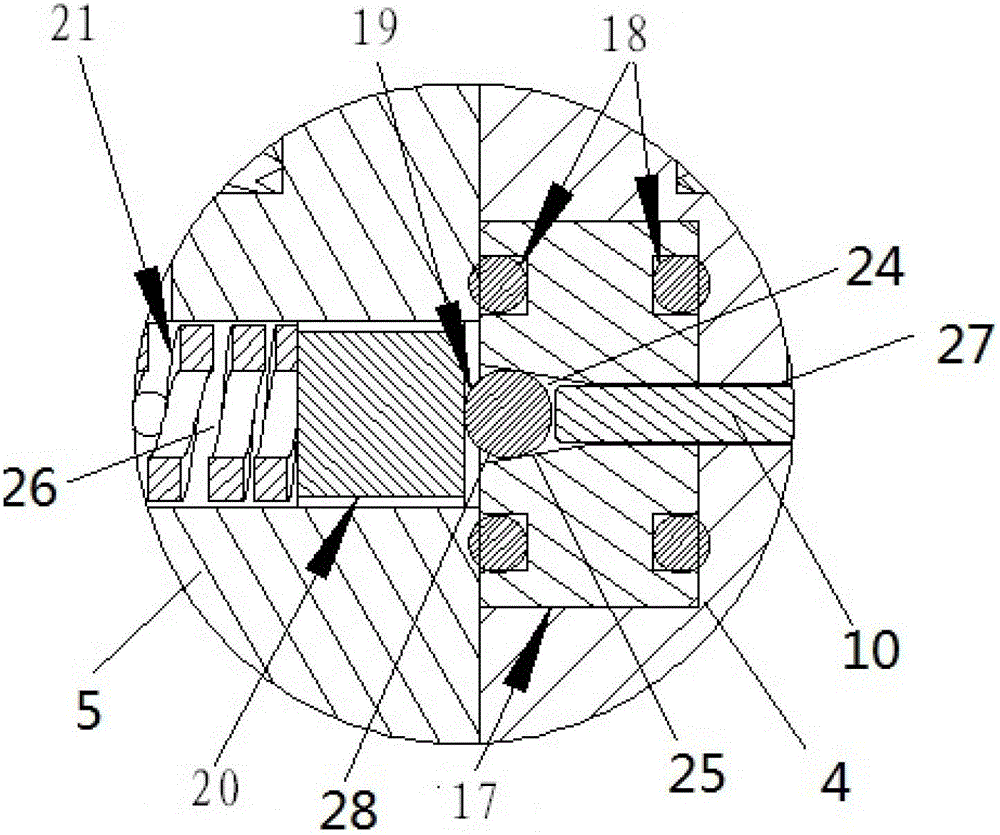

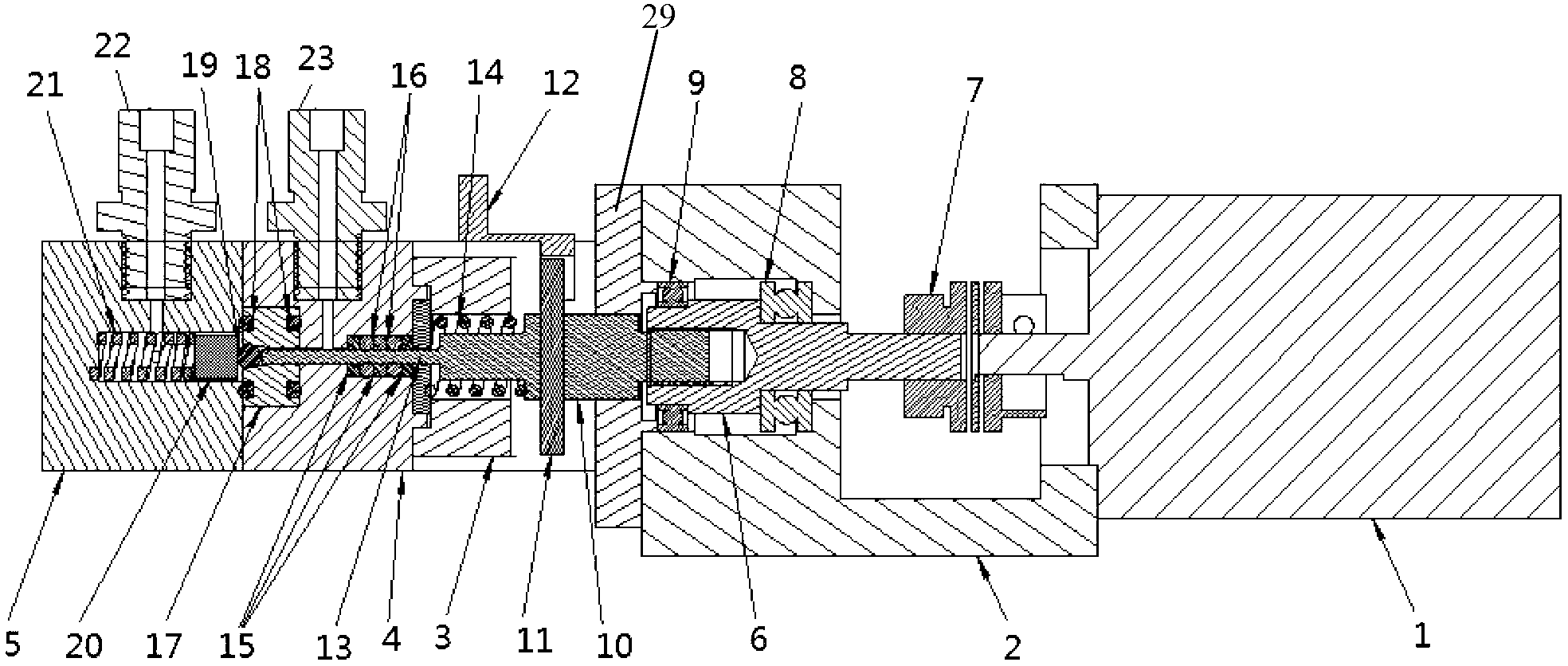

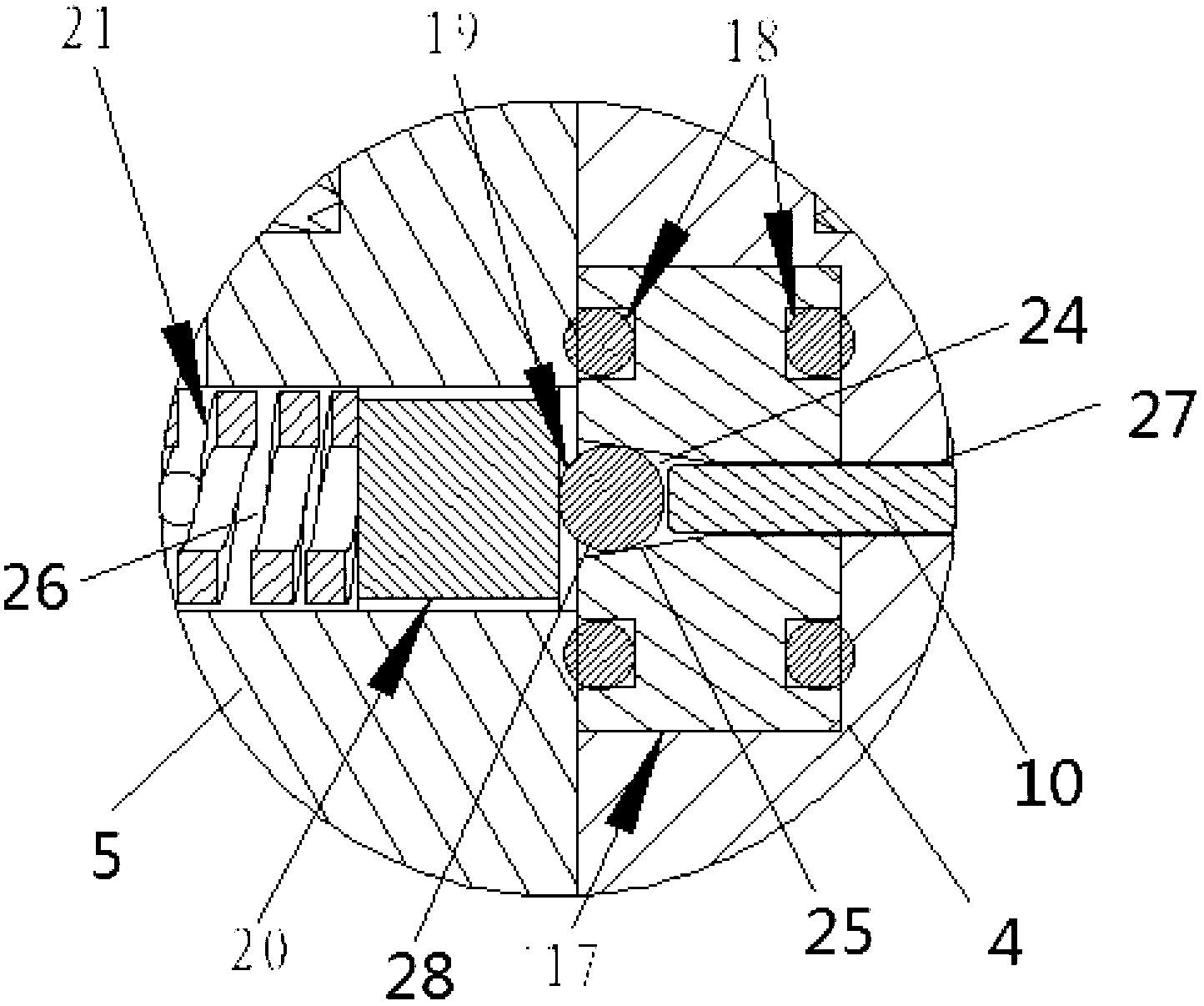

Pilot-operated electromagnetic valve and assembling method thereof

InactiveCN103912708AReduce the accuracy requirements of the inner wallSimple structurePiston ringsOperating means/releasing devices for valvesSolenoid valveCombined method

The invention relates to the technical field of the electromagnetic valves, and in particular relates to a pilot-operated electromagnetic valve and an assembling method thereof. The pilot-operated electromagnetic valve comprises a valve bush with a first inner circular part and a second inner circular part, a fixed iron core, a valve seat, an excitation coil, a movable iron core, a piston, an inlet adapter and an outlet adapter; the assembling method of the pilot-operated electromagnetic valve comprises welding the inlet adapter on the valve bush, welding the outlet adapter on the valve seat, welding the fixed iron core in the valve bush at one end, mounting the movable iron core and the piston in the valve bush orderly, welding the valve seat in the valve bush at the other end, and fixing the coil outside the valve bush. The pilot-operated electromagnetic valve and the assembling method thereof have the advantages that the processing cost of the electromagnetic valve can be reduced, the materials applied can be reduced, and miniaturization of the product is realized.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

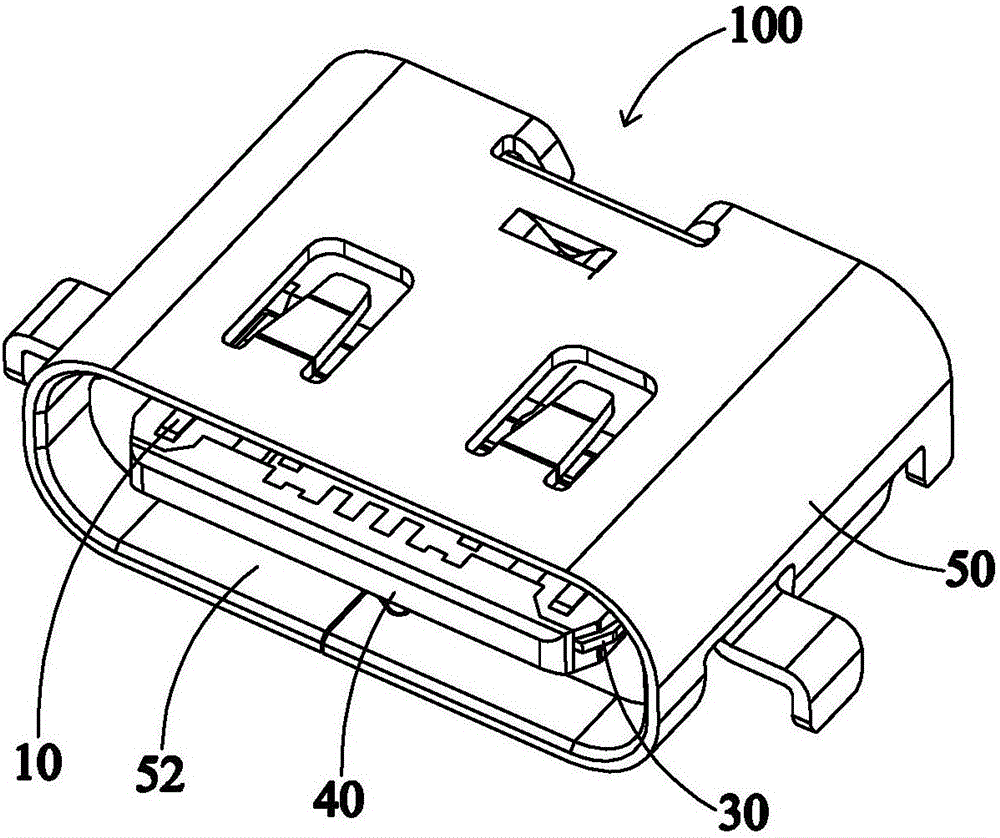

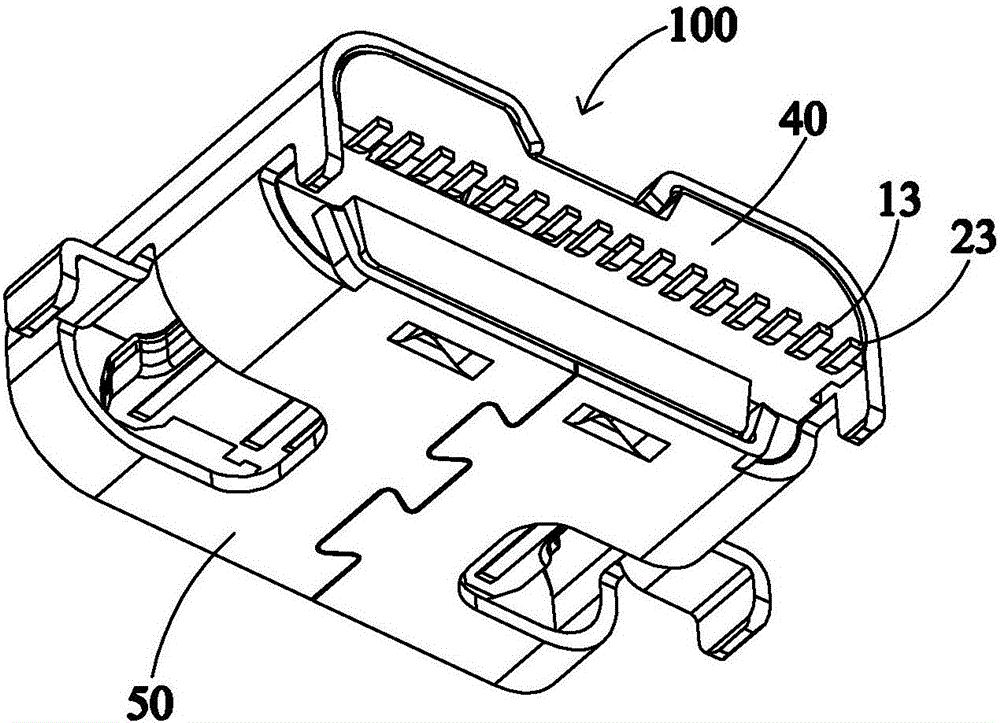

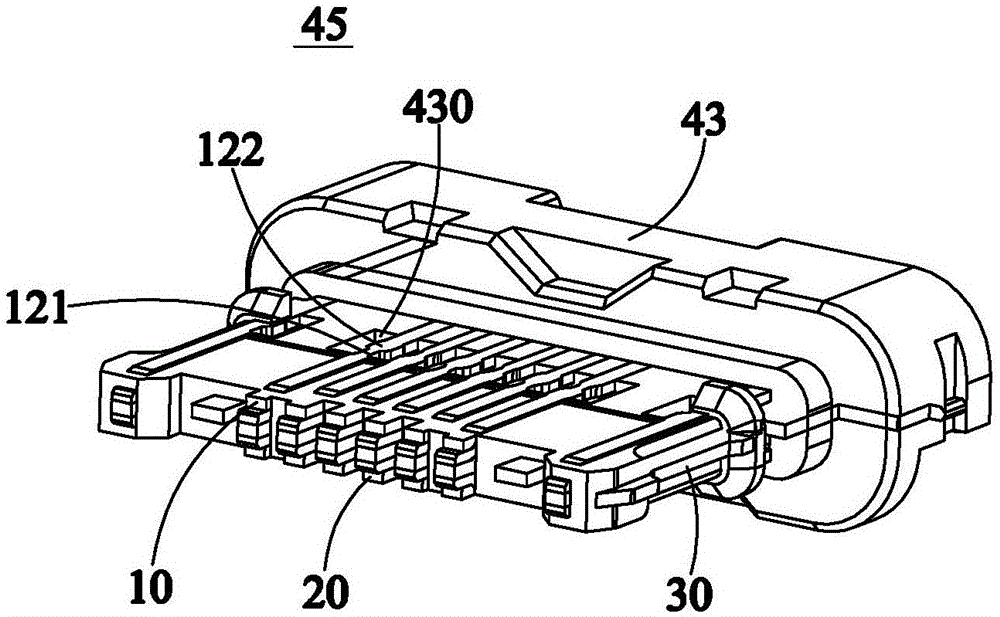

Electrical connector and manufacturing method thereof

ActiveCN106848696ASimplify the manufacturing processImprove structural strengthContact member assembly/disassemblyCoupling contact membersElectricityInjection moulding

Owner:LINKCONN ELECTRONICS

Swing vortex check valve

InactiveCN102322543AImprove sealing accuracyEconomical processingCheck valvesLift valveEngineeringCheck valve

The invention discloses a swing vortex check valve. The valve comprises a valve body, a valve cover, a valve flap and a valve plate, wherein the upper and lower inner walls of an inlet part of the valve body have an asymmetric structure, and the front side of the valve flap is provided with an oval concave surface, so that fluid forms a vortex field to increase seal moment. The invention has the advantages that: the swing vortex check valve has new breakthrough in aspects of mechanisms and processes, and the characteristic that the check valve can realize seal pressurization by means of backflow of a medium is achieved; and through implementation, compared with the conventional product, the swing vortex check valve has incomparable advantages in aspects of cost price and performance.

Owner:ZHEJIANG GENERAL VALVE CO LTD

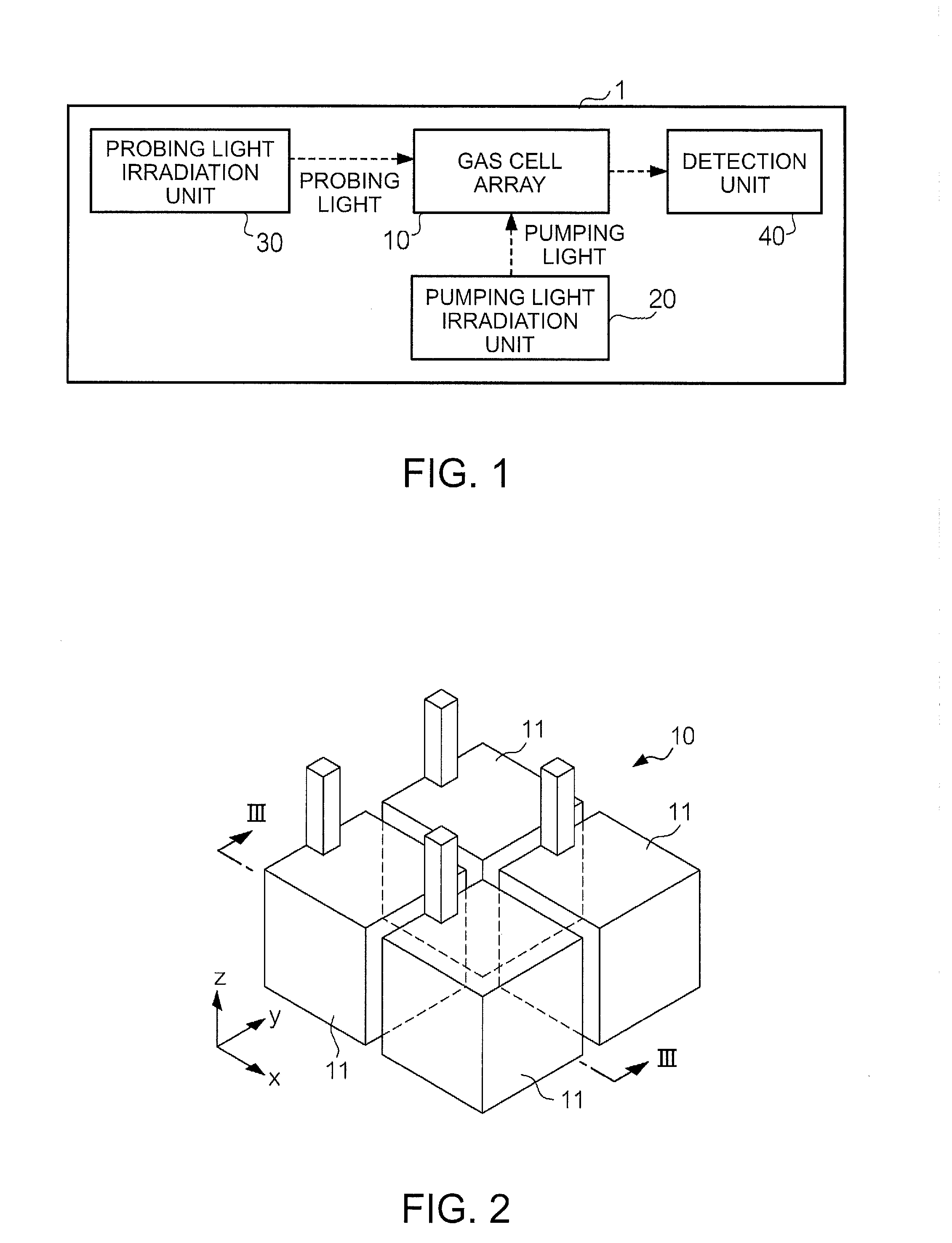

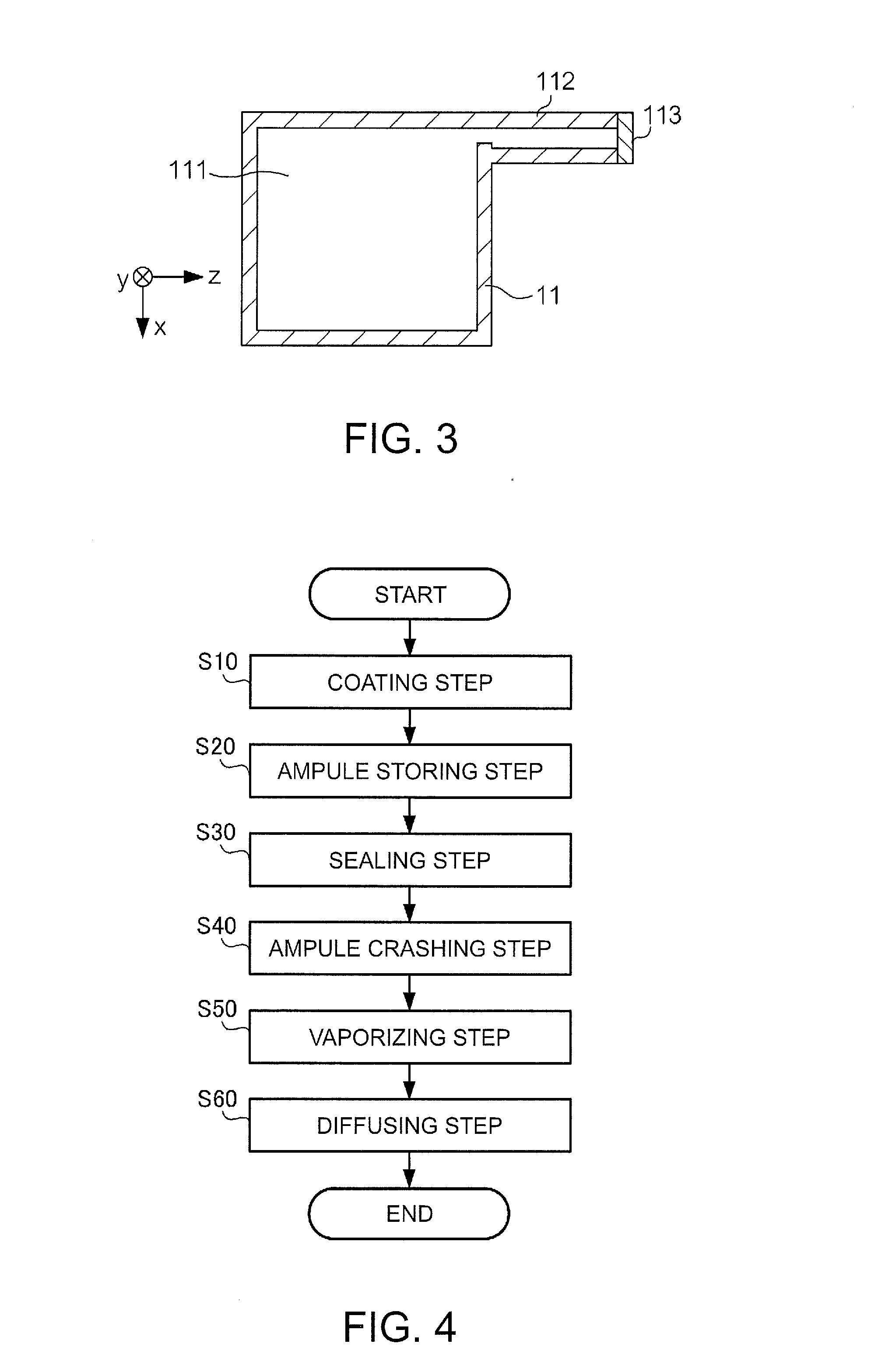

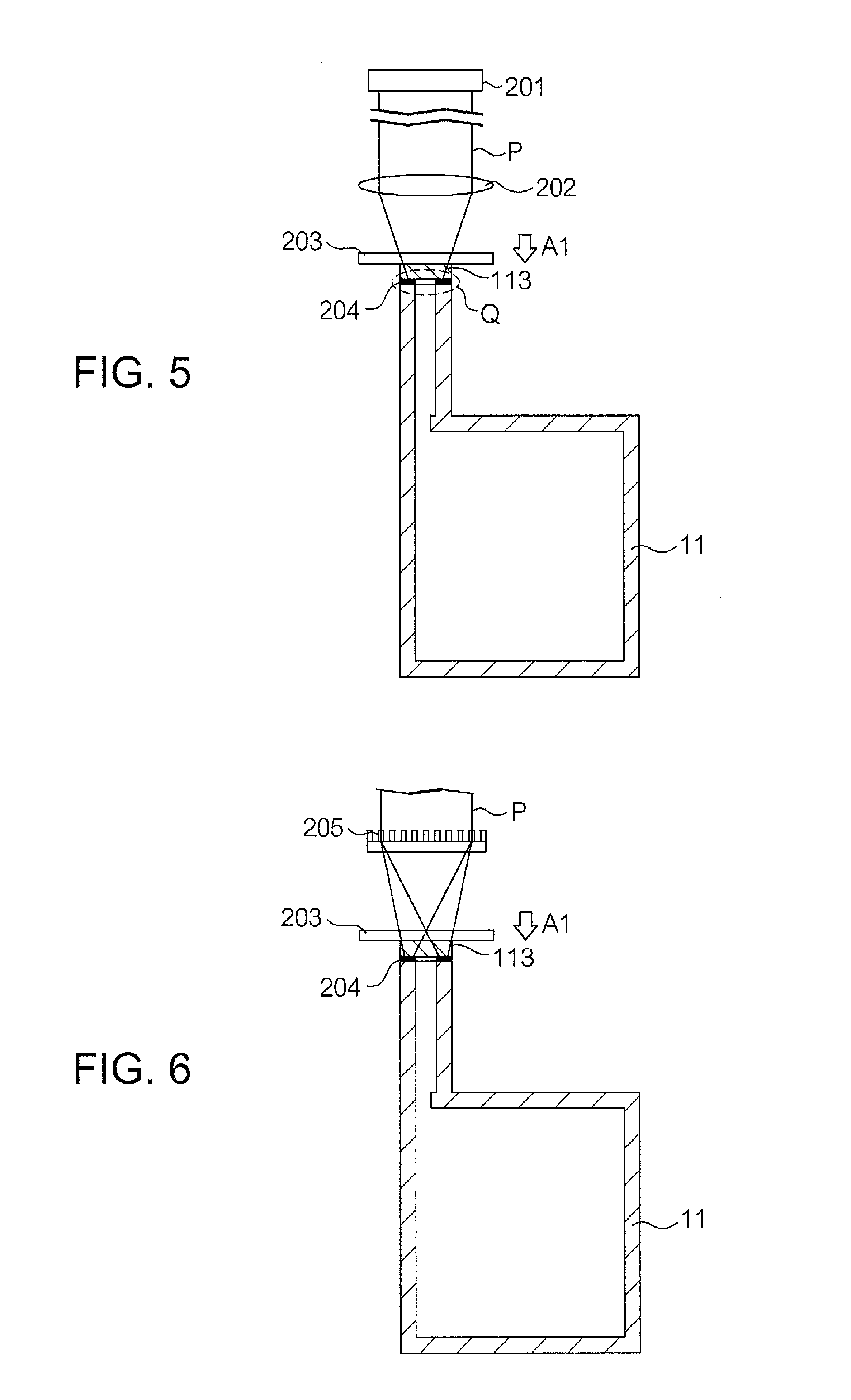

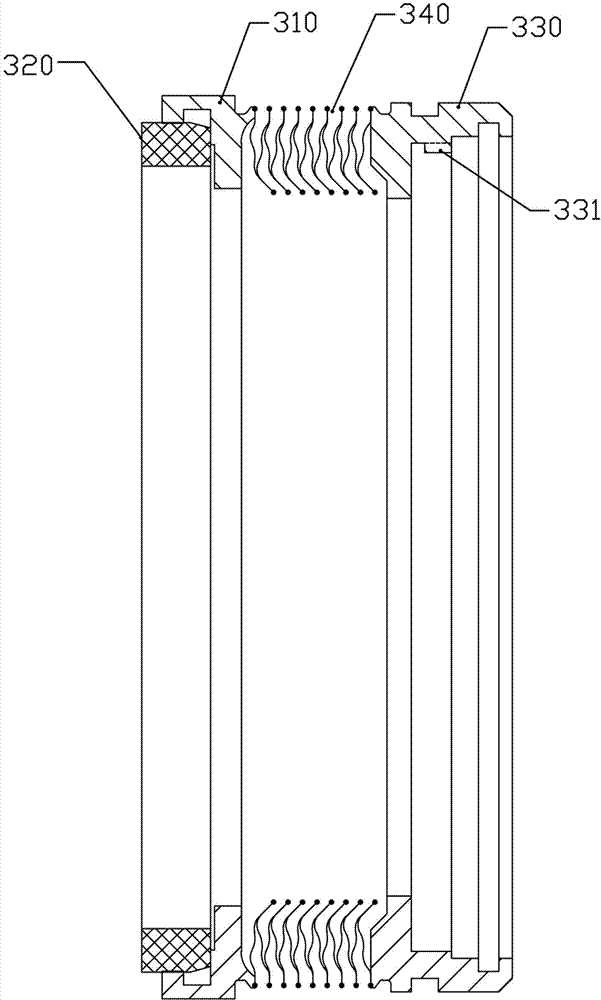

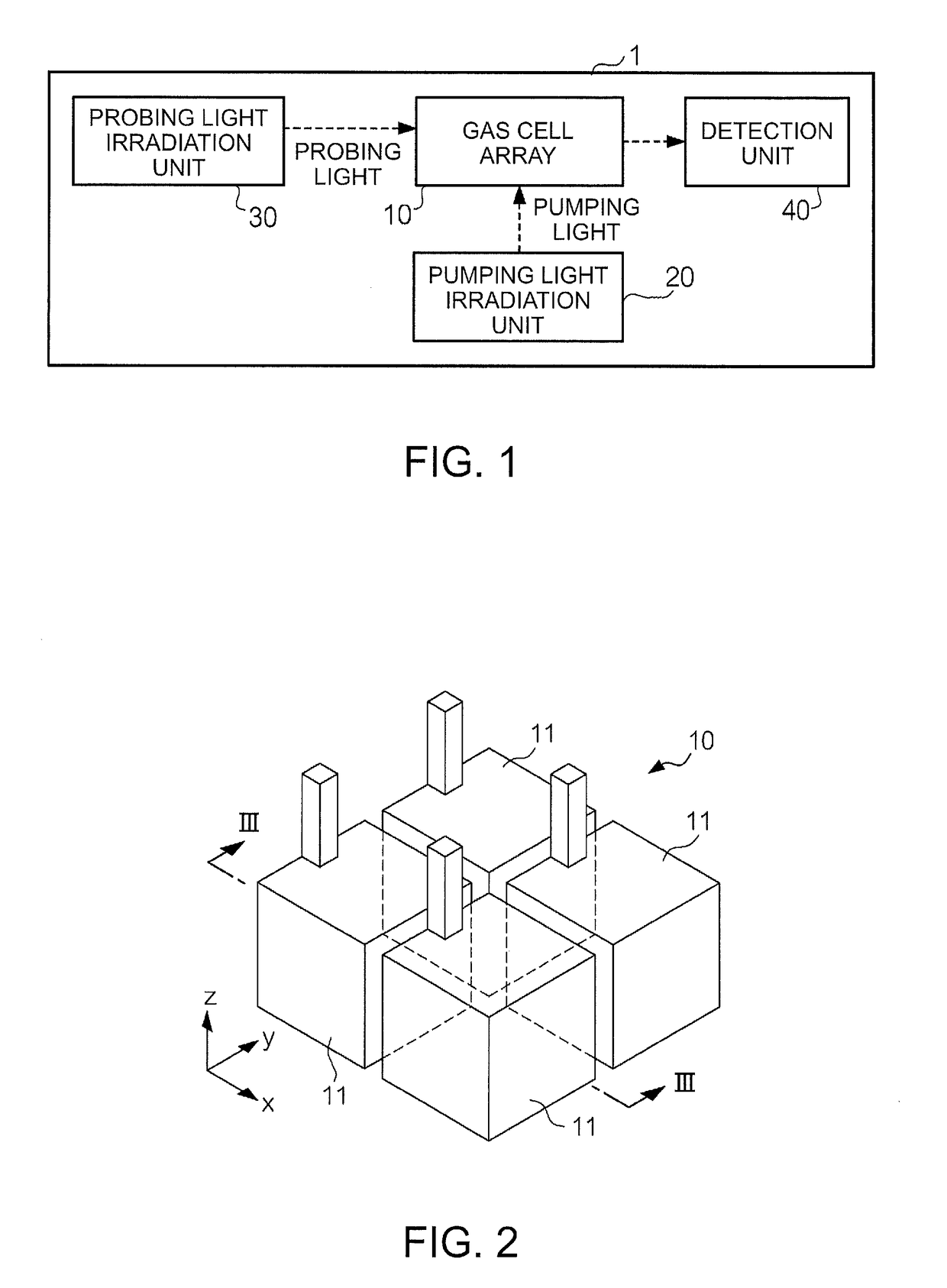

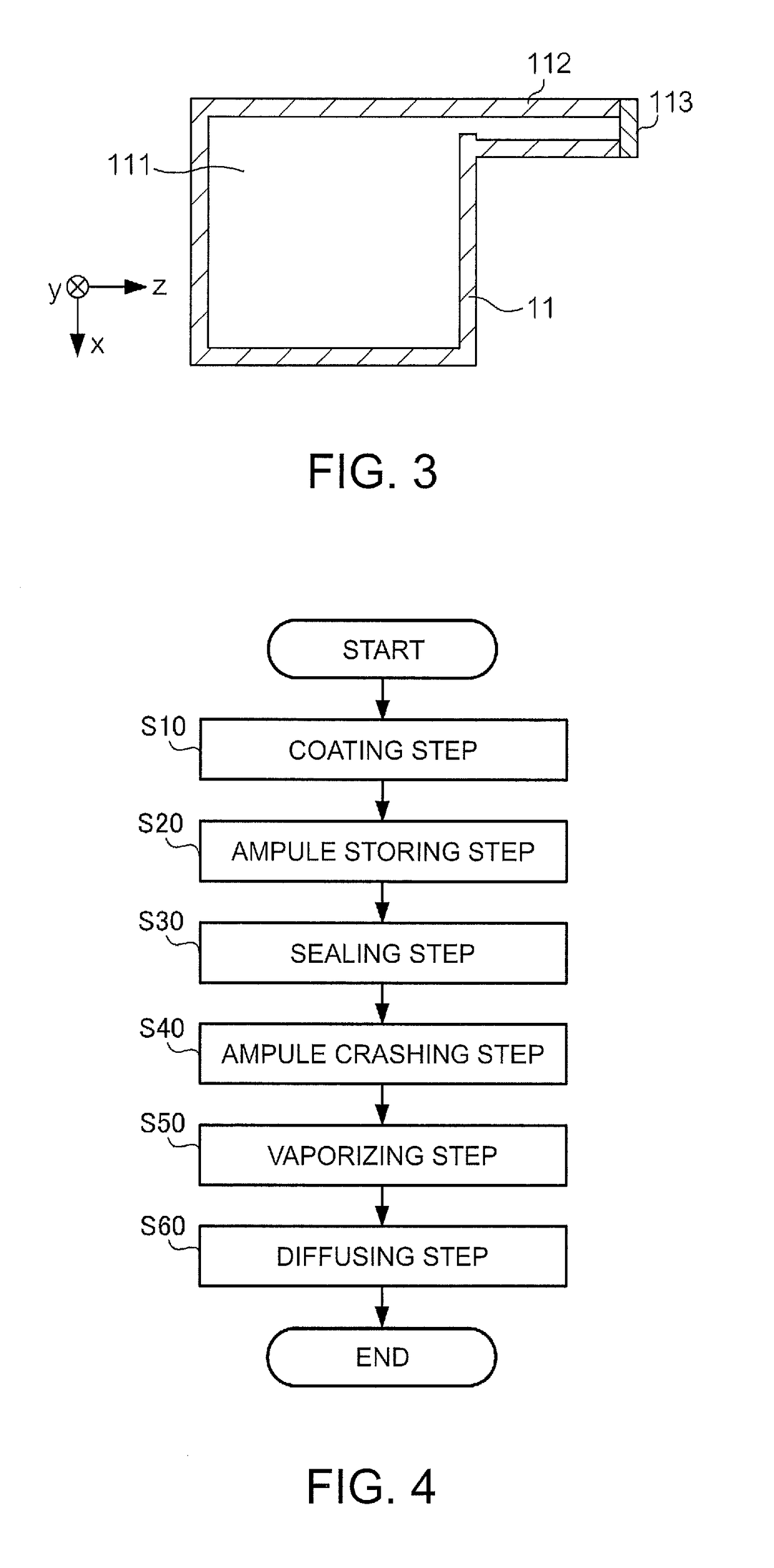

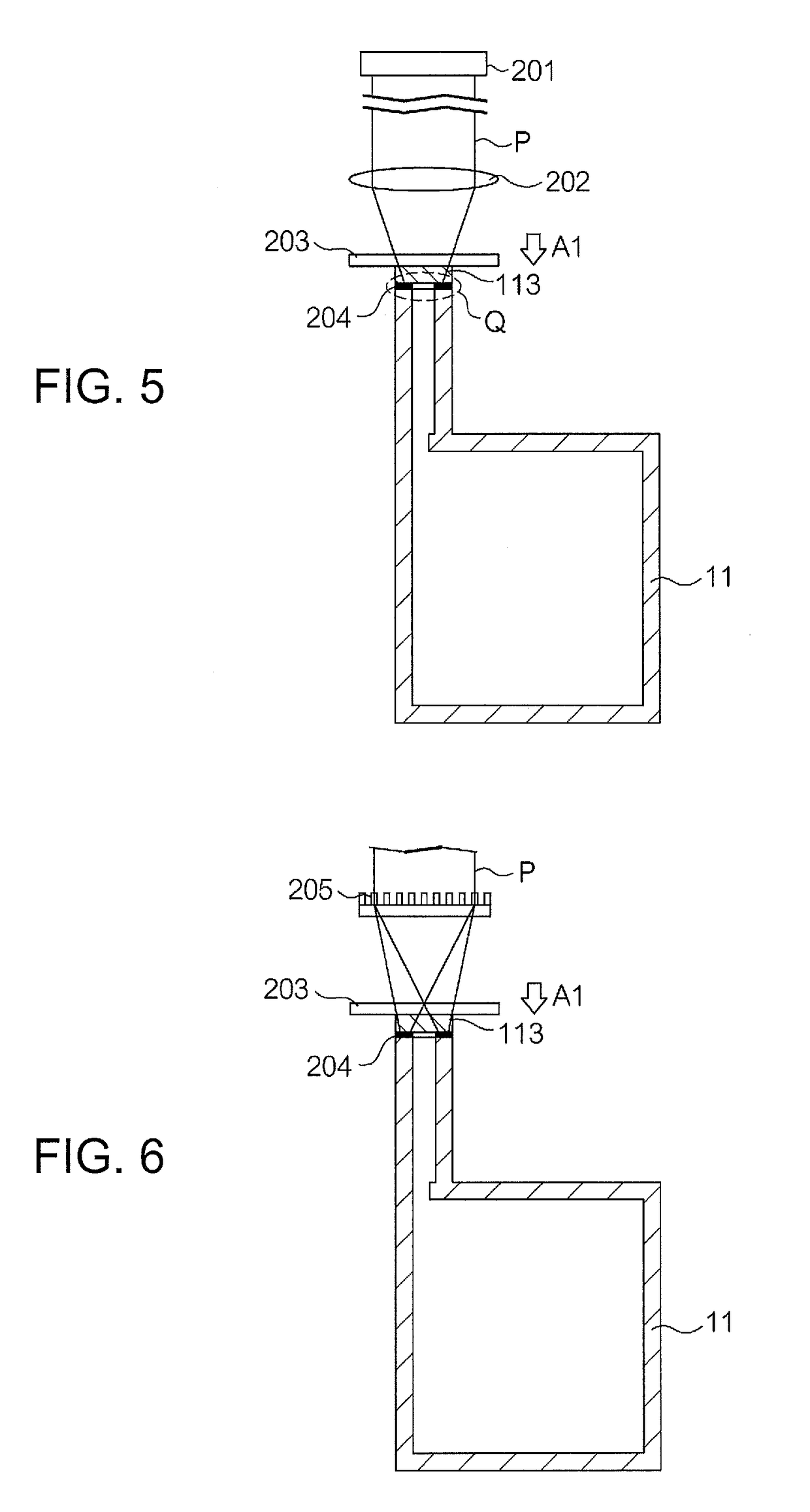

Gas cell sealing method

InactiveUS20160023401A1Improve sealing accuracyImprove sealingLamination ancillary operationsLaminationLaser lightSealant

A gas cell sealing method includes bonding step in which a bonding portion of a gas cell main body having an opening and a lid for closing the opening where a sealant for bonding the gas cell main body and the lid is provided is heated by converging a laser beam from a laser light source through an optical element, and the lid is bonded to the gas cell main body by applying pressure in a direction that presses the lid against the gas cell main body, the pressure being applied while the laser beam is being converged to the bonding portion.

Owner:SEIKO EPSON CORP

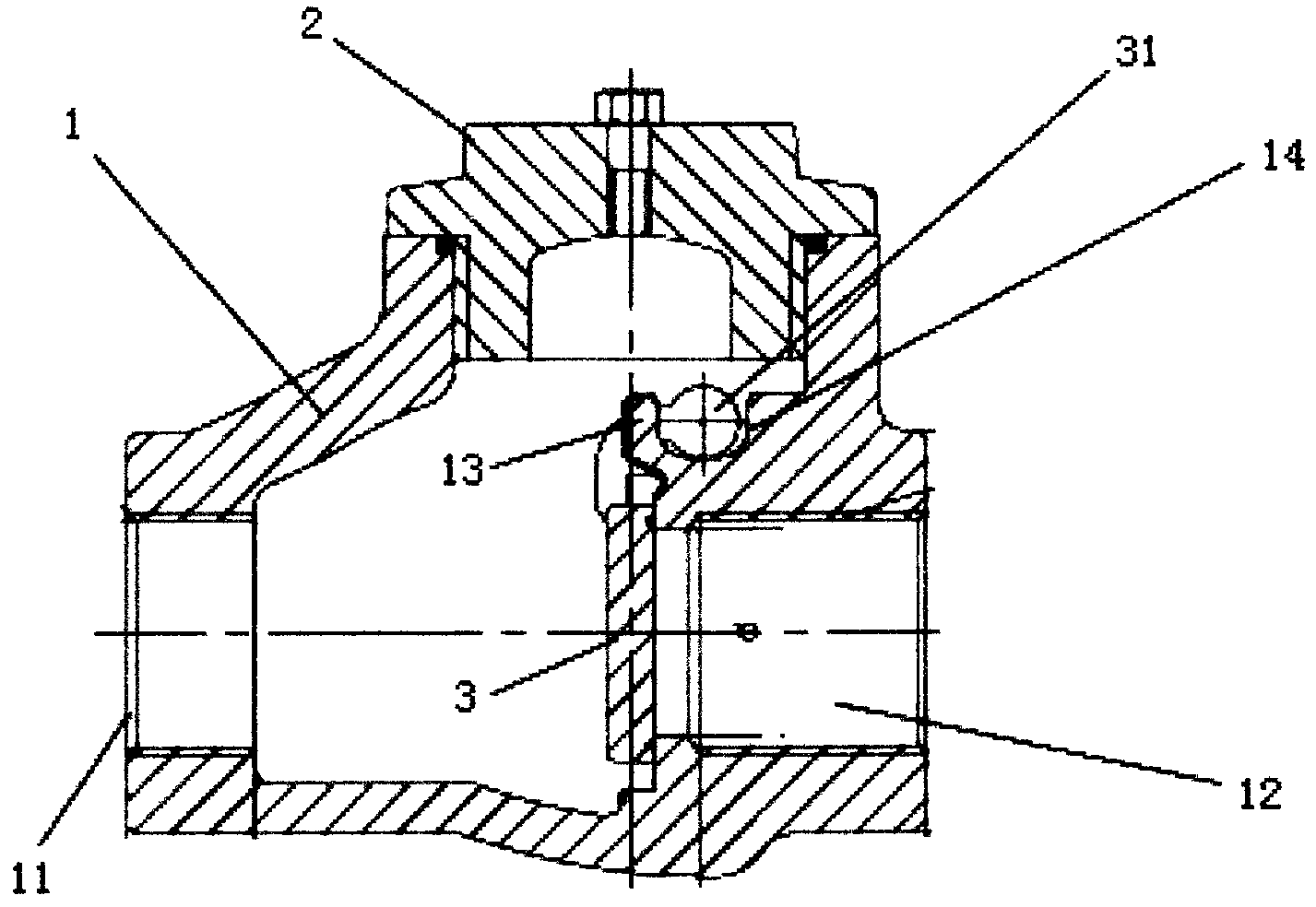

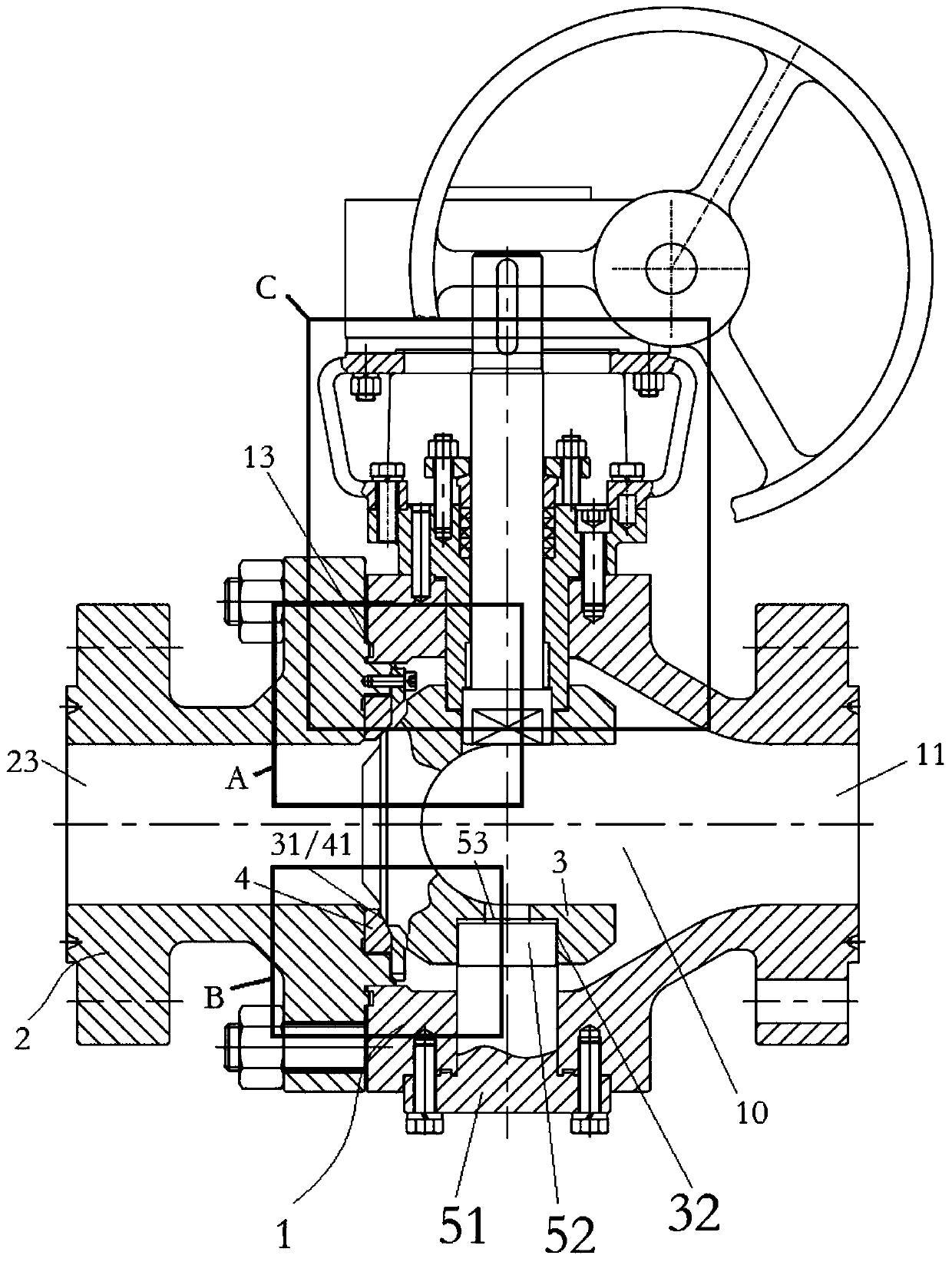

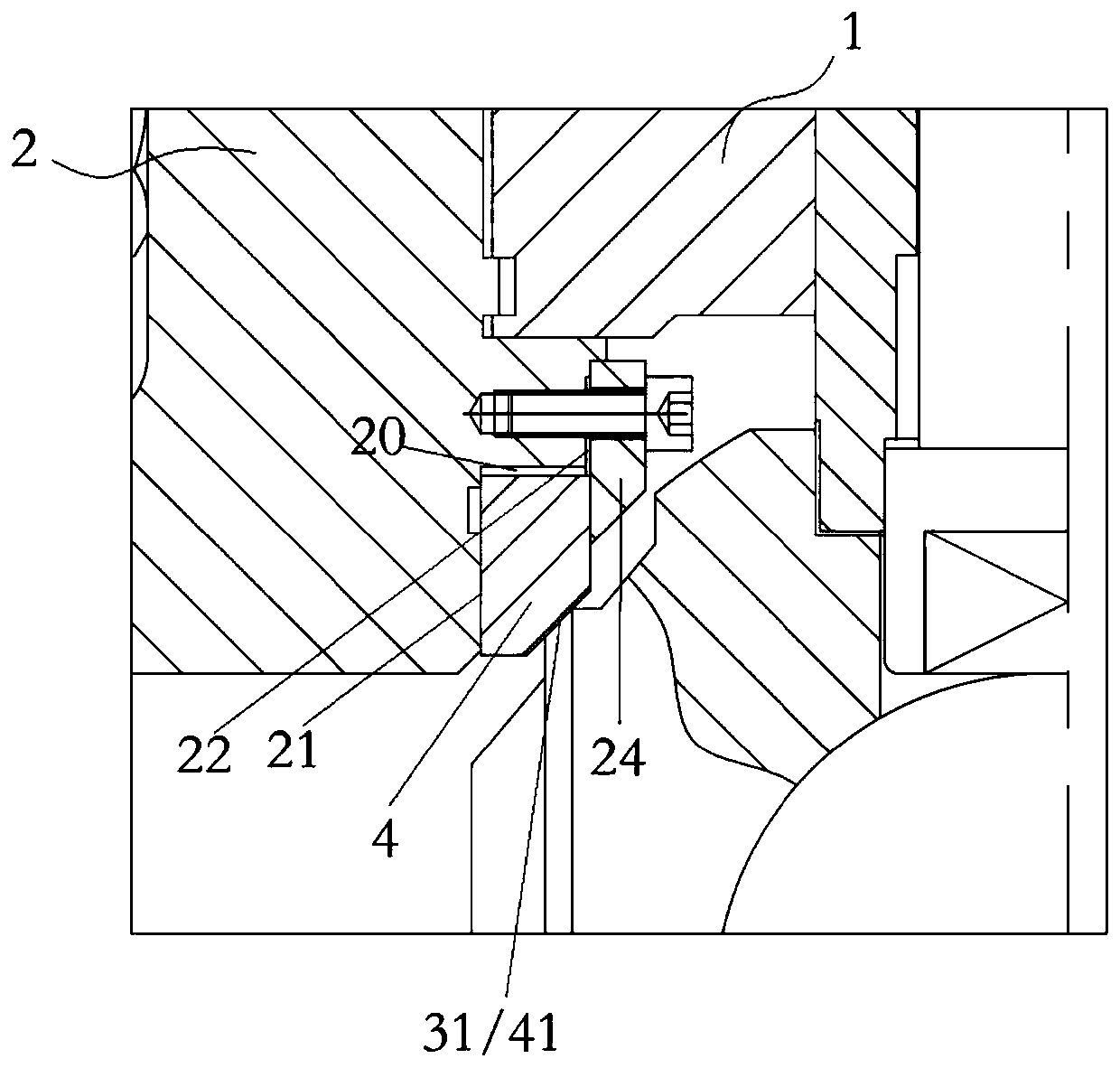

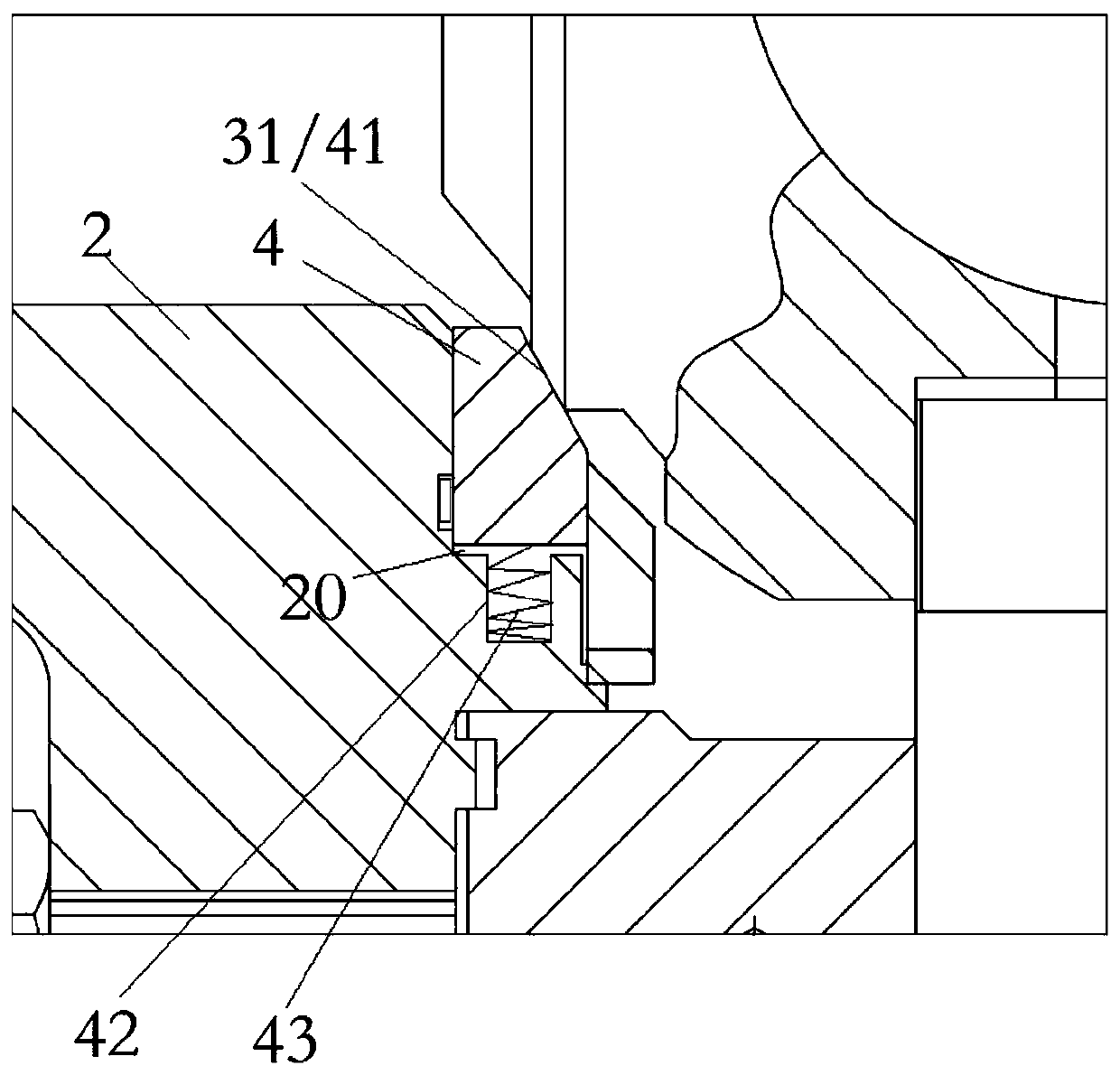

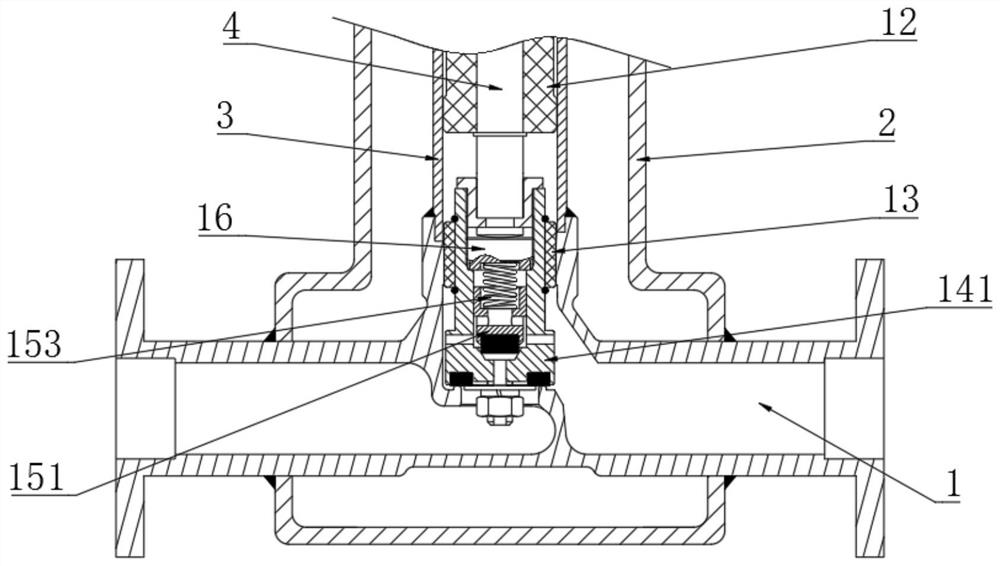

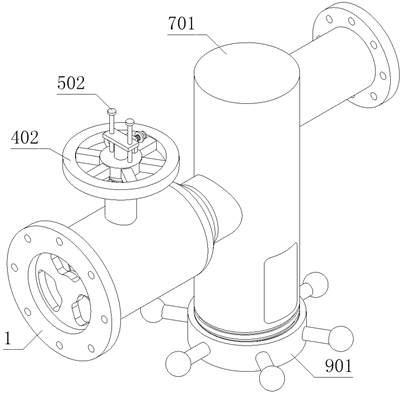

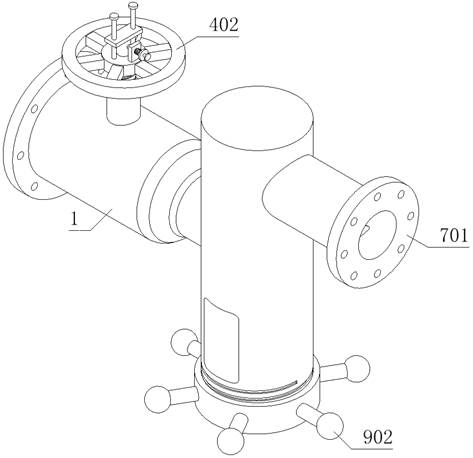

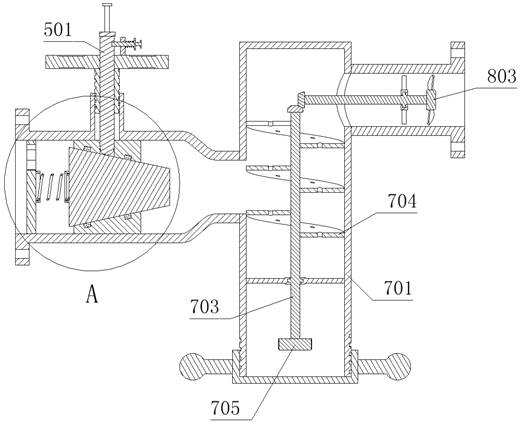

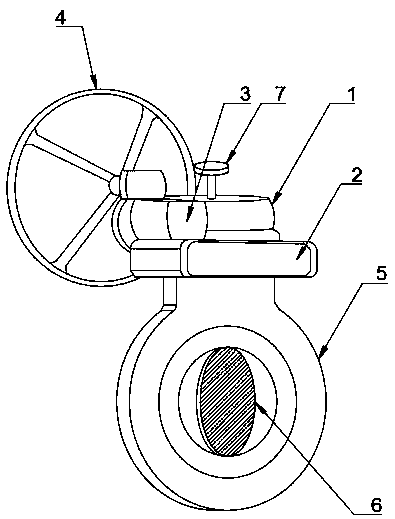

An eccentric ball valve

ActiveCN108980400BReduce the difficulty of assemblyAchieve high-precision bidirectional sealing performancePlug valvesValve housingsEngineeringValve seat

The invention provides an eccentric ball valve. The eccentric ball valve comprises a valve body, a valve cover, a valve ball and a valve seat; the valve body is provided with a middle cavity and a first fluid channel communicating with the middle cavity; the valve cover is detachably connected with the valve body and is provided with a second fluid channel; after the valve cover and the valve bodyare connected, the second fluid channel communicates with the middle cavity; the valve ball is rotationally installed inside the middle cavity through an operation mechanism and is provided with a valve ball sealing face; the valve seat is installed on the valve cover and is provided with a valve seat sealing face capable of extruding the valve ball sealing face to seal the second fluid channel;and the valve seat is installed on the valve cover through an adjustable installing structure in a manner of being capable of finely moving, under driving of the operation mechanism, the valve ball rotates to enable the valve ball sealing face and the valve seat sealing face to be in extrusion contact gradually, the valve seat can finely move, and even-pressure sealing can be achieved between thevalve ball sealing face and the valve seat sealing face. By means of the eccentric ball valve, continuous abrasion of the valve ball and the valve seat can be avoided, and the good sealing performanceis achieved.

Owner:SHANDONG AFA FLOW CONTROL

Hard alloy composite sealing structure and preparing technology thereof

InactiveCN107269859AReach frictionZero frictionLift valveValve member-seat contactsMachine partsAlloy composite

The invention relates to a hard alloy composite sealing structure and a preparing technology thereof. The hard alloy composite sealing structure comprises a valve seat machining part and a sealing ring machining part. In the valve seat machining part, a casting is fixedly arranged on a valve seat machining clamp inclining by 4-15 degrees, and after the sealing face thickness of 4-8 mm is reserved, a sealing face of the valve seat is roughly turned, and surfacing of a first hard alloy layer is conducted on the sealing face of the valve seat; and in the sealing ring machining part, a sealing ring blank is arranged on a sealing ring machining clamp of a lathe, and after the sealing face of the sealing ring is finely turned, surfacing of a second hard alloy layer is conducted on the sealing face of the sealing ring. According to the hard alloy composite sealing structure and the preparing technology thereof, the machining technology cost is low, the sealing precision is high, the product can achieve zero friction, zero leakage and both-way pressure bearing and achieves real high performance, a sealing pair is all metal, and once after closing is conducted in place, sealing is very reliable, and the application temperature range is wide.

Owner:SHANGHAI LEIFU VALVE MFG CO LTD

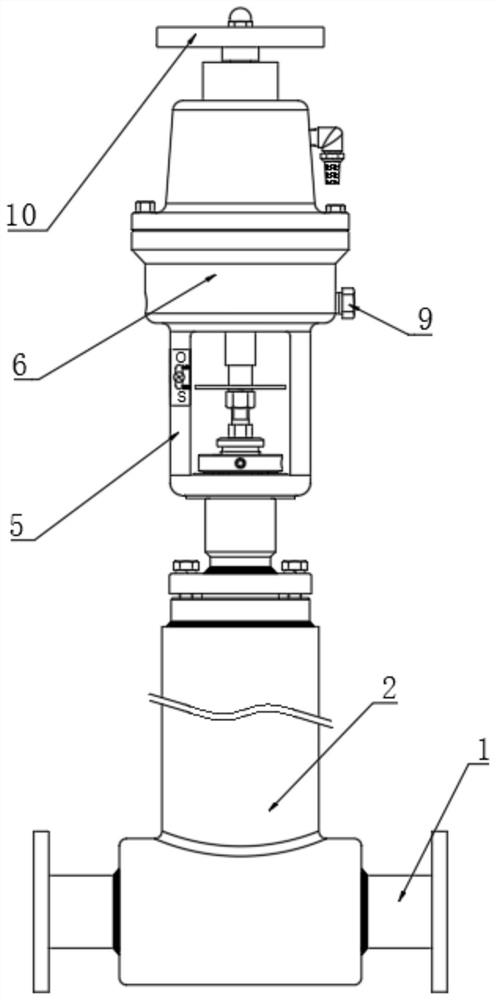

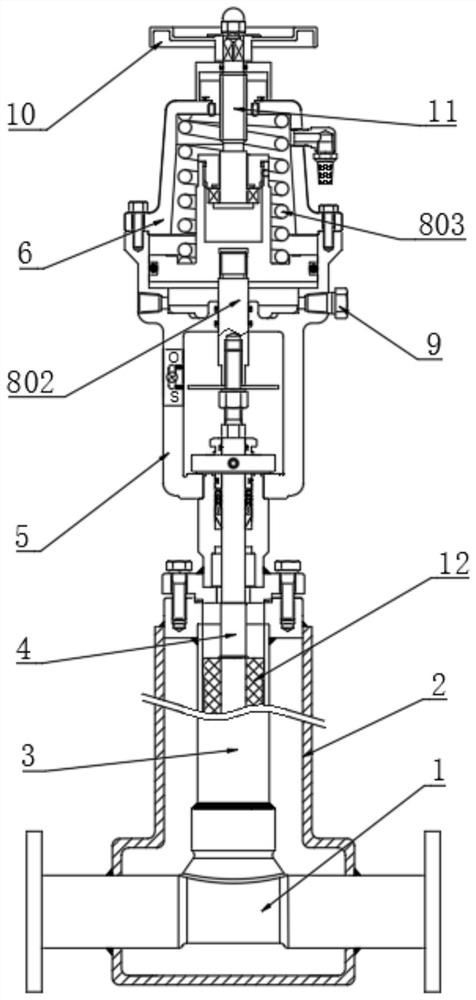

Vacuum jacket low-temperature pneumatic emergency cut-off valve

PendingCN114508617AInsulation space shortenedLow costFlanged jointsThermal insulationEngineeringPiston

The invention discloses a vacuum jacket low-temperature pneumatic emergency cut-off valve, and belongs to the technical field of valves. The pressure relief valve comprises a valve body, a valve element assembly is arranged in the valve body, the valve element assembly blocks the valve body, the valve element assembly further conducts pressure relief protection on a pipeline, a transmission assembly is arranged on the upper portion of the valve body, an air cylinder assembly is arranged on the upper portion of the transmission assembly, and the transmission assembly connects the valve element assembly and the air cylinder assembly. A small valve element is installed in a large valve element, a piston spring and a valve element spring are arranged in the valve element, a vacuum clamping sleeve is arranged outside the valve element and used for heat insulation between the valve element and the outside, butt joint assemblies are arranged at the input end and the output end of the valve element correspondingly, and the butt joint assemblies are used for connection between the valve element and a pipeline system. After the valve is emergently cut off, the valve is locked through the pressure of backflow liquid, pressure relief is conducted in time when the pressure of a pipeline system reaches a dangerous range, and the pipeline system is protected.

Owner:宁波杜肯阀门制造有限公司

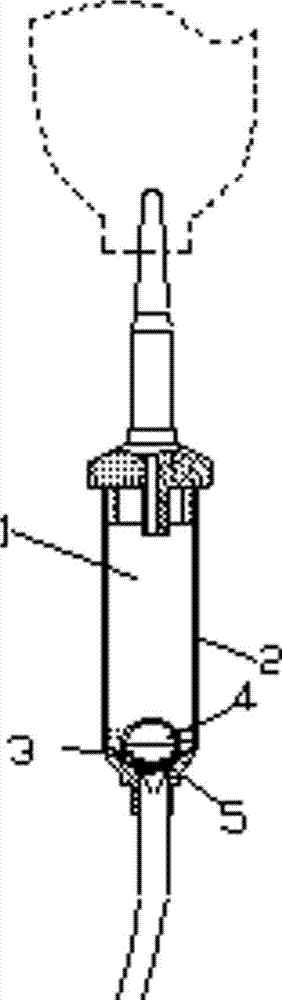

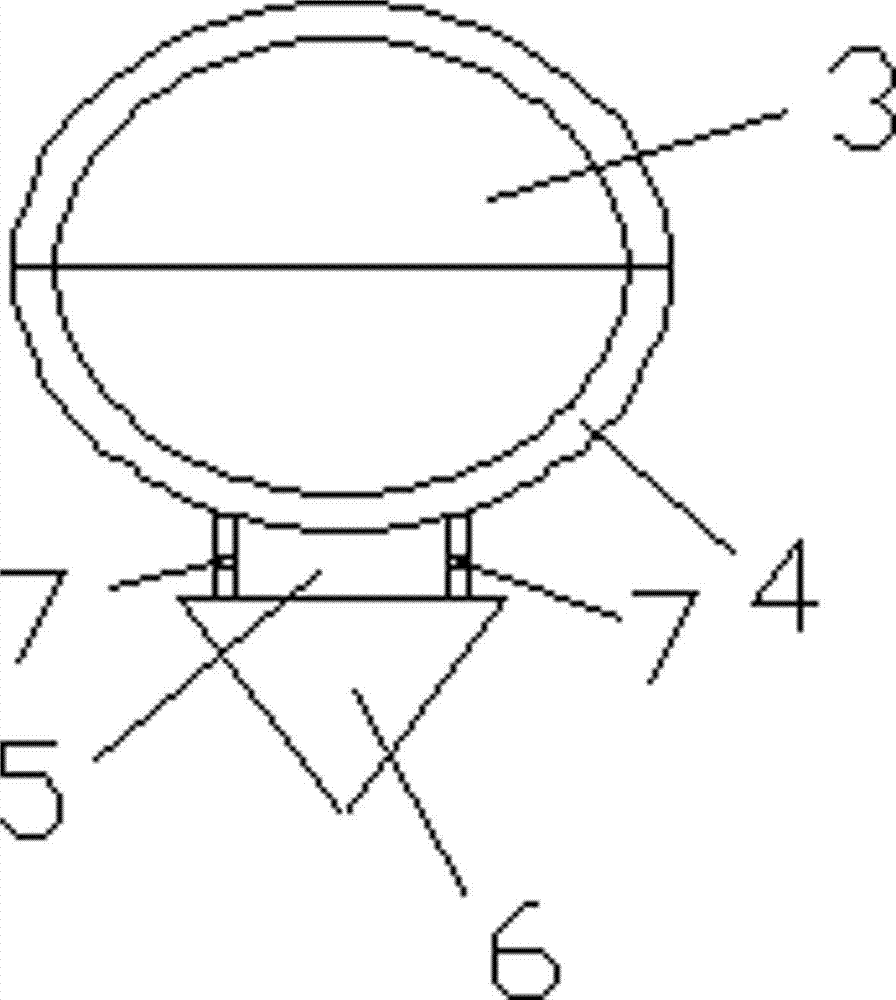

Fluid infusion multi-times multi-face sealing control device

A fluid infusion multi-times multi-face sealing control device comprises a drop syringe (1) and is characterized in that a soft sealing body (3) is arranged in a drip chamber (2) of the drop syringe (1). The device has the advantages that after injection of injection liquid is about to finish, the lower outer surface of a thin-wall soft bag seals the inner wall of a water outlet of the drip chamber, the injection liquid in the thin-wall soft bag flows out from a water inlet and outlet of the soft sealing body under the action of gravity of a floating body, the thin-wall soft bag carries out secondary two-face sealing on the end face of the water outlet of the drip chamber, sealing precision is high, almost no air or liquid flows into a transparent pipe outside a liquid outlet of the drip chamber, after the liquid is replaced, the liquid flows into the drip chamber again, the soft sealing body can float easily under the action of buoyancy, and therefore the liquid can be injected again. The control device is simple in structure, convenient to operate and firm in sealing, and meanwhile the soft sealing body can float easily.

Owner:何前国

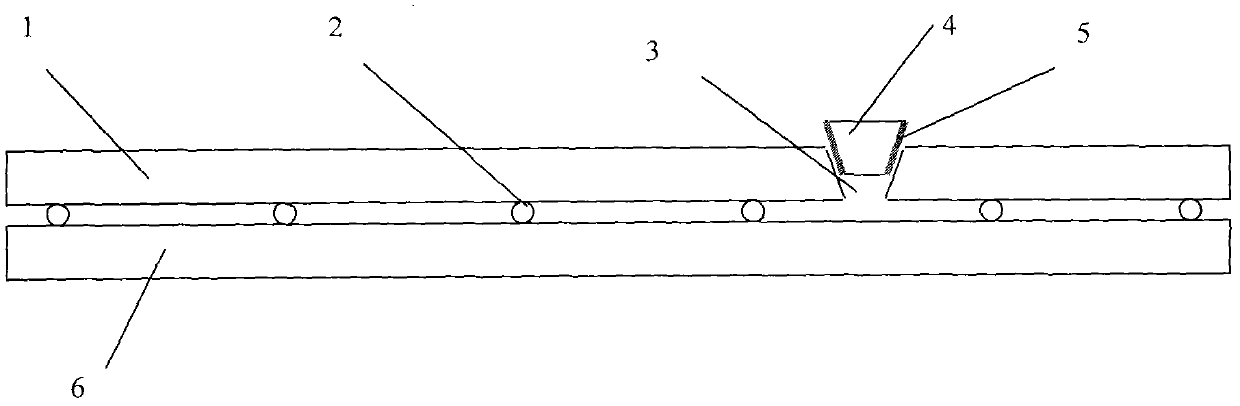

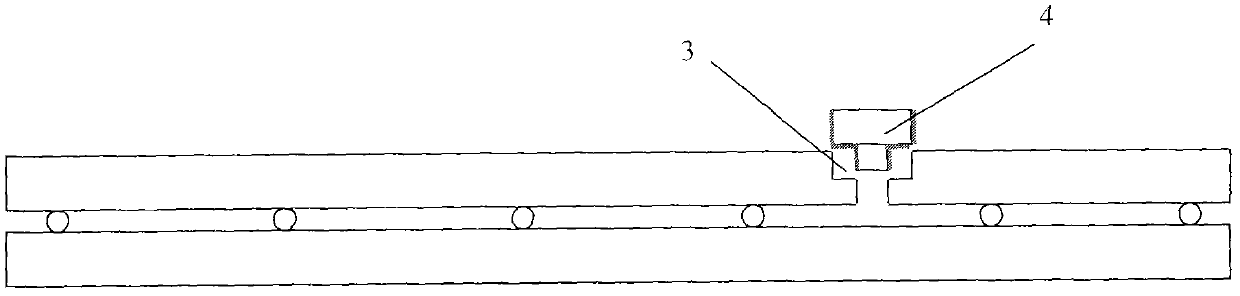

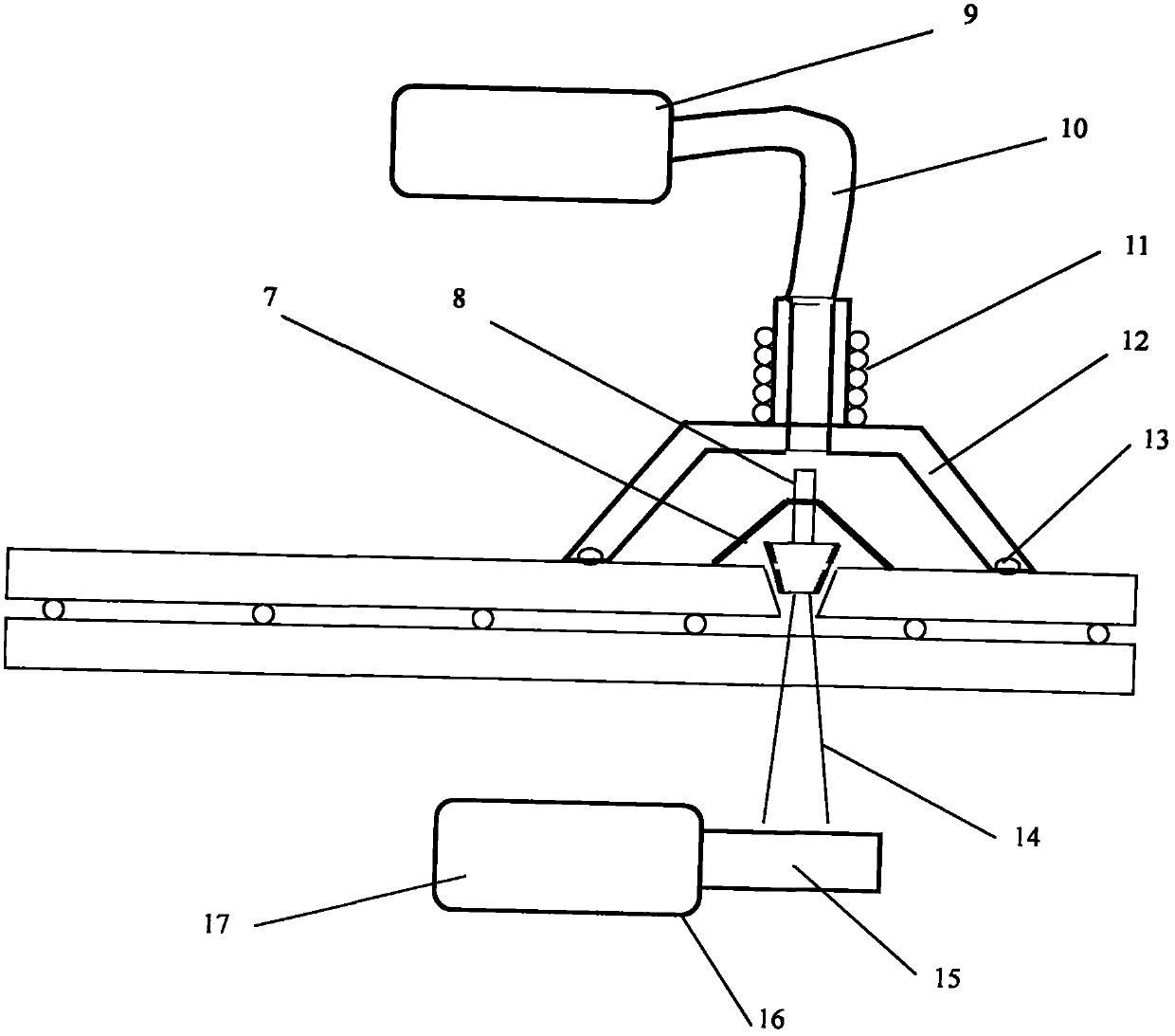

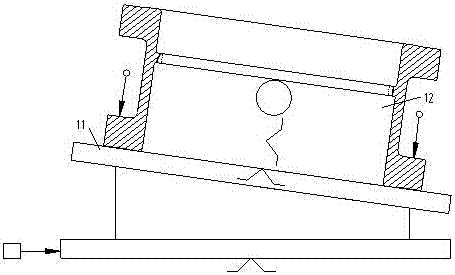

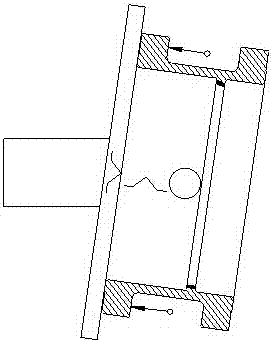

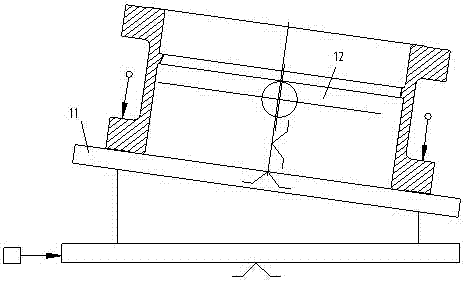

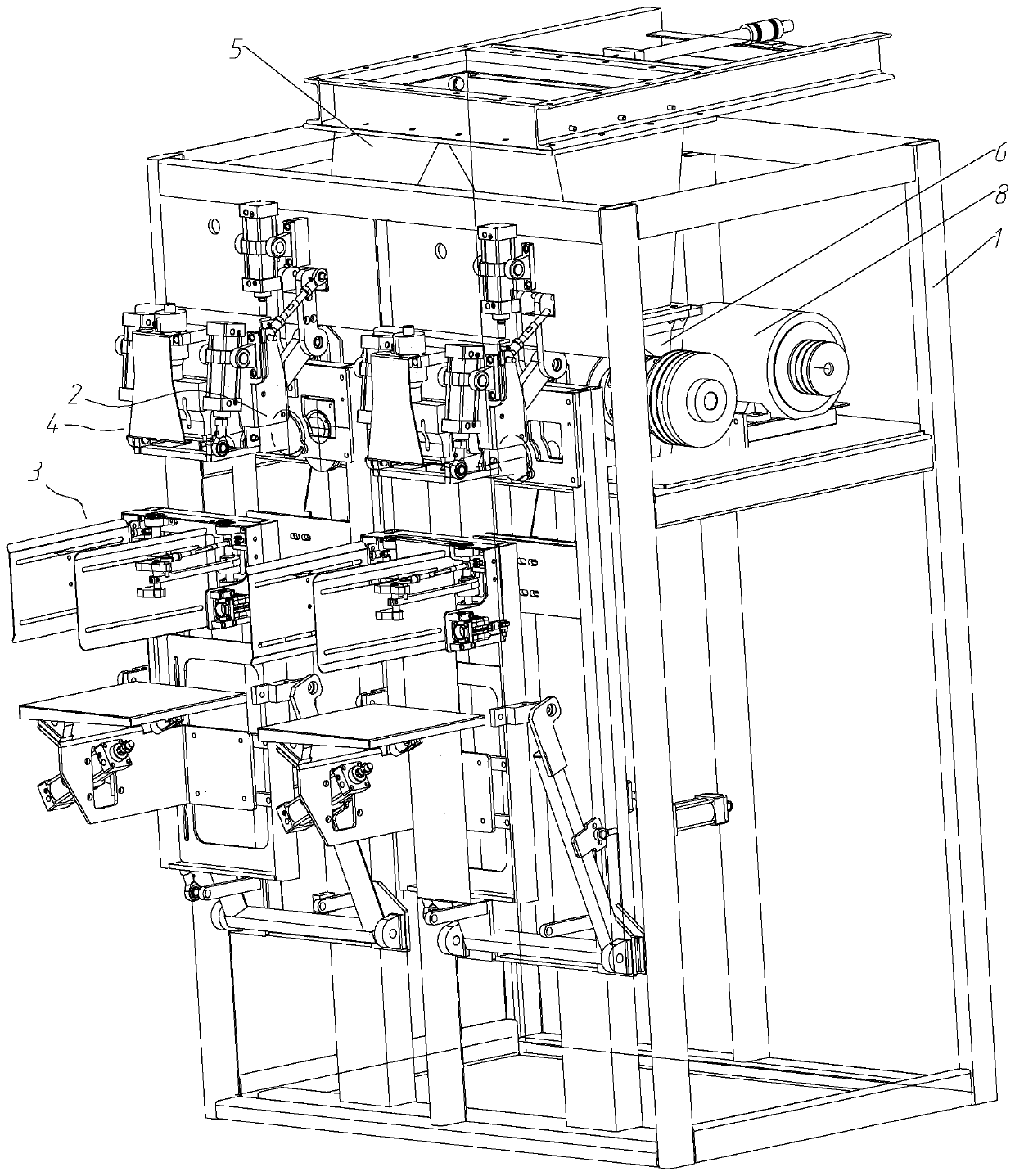

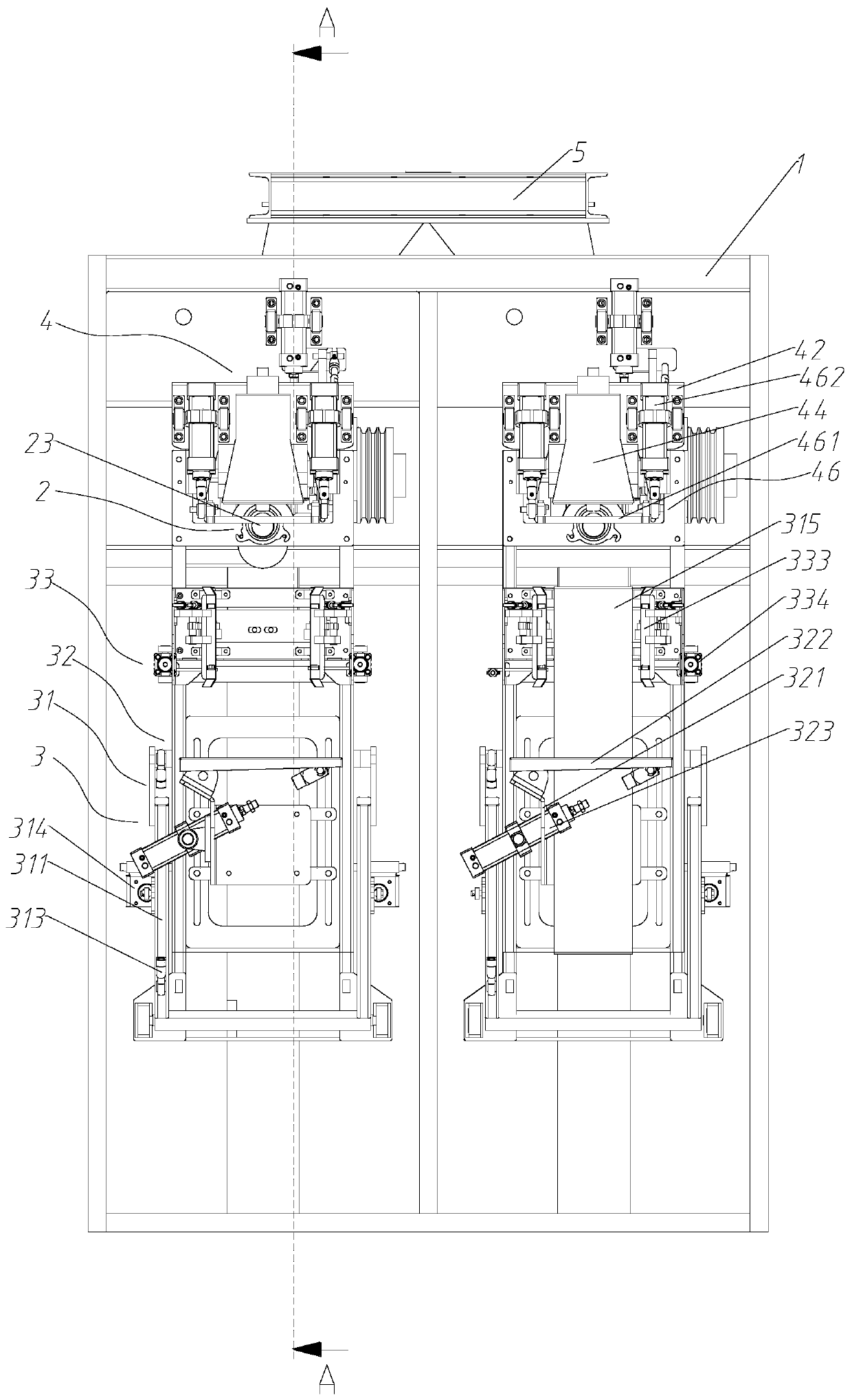

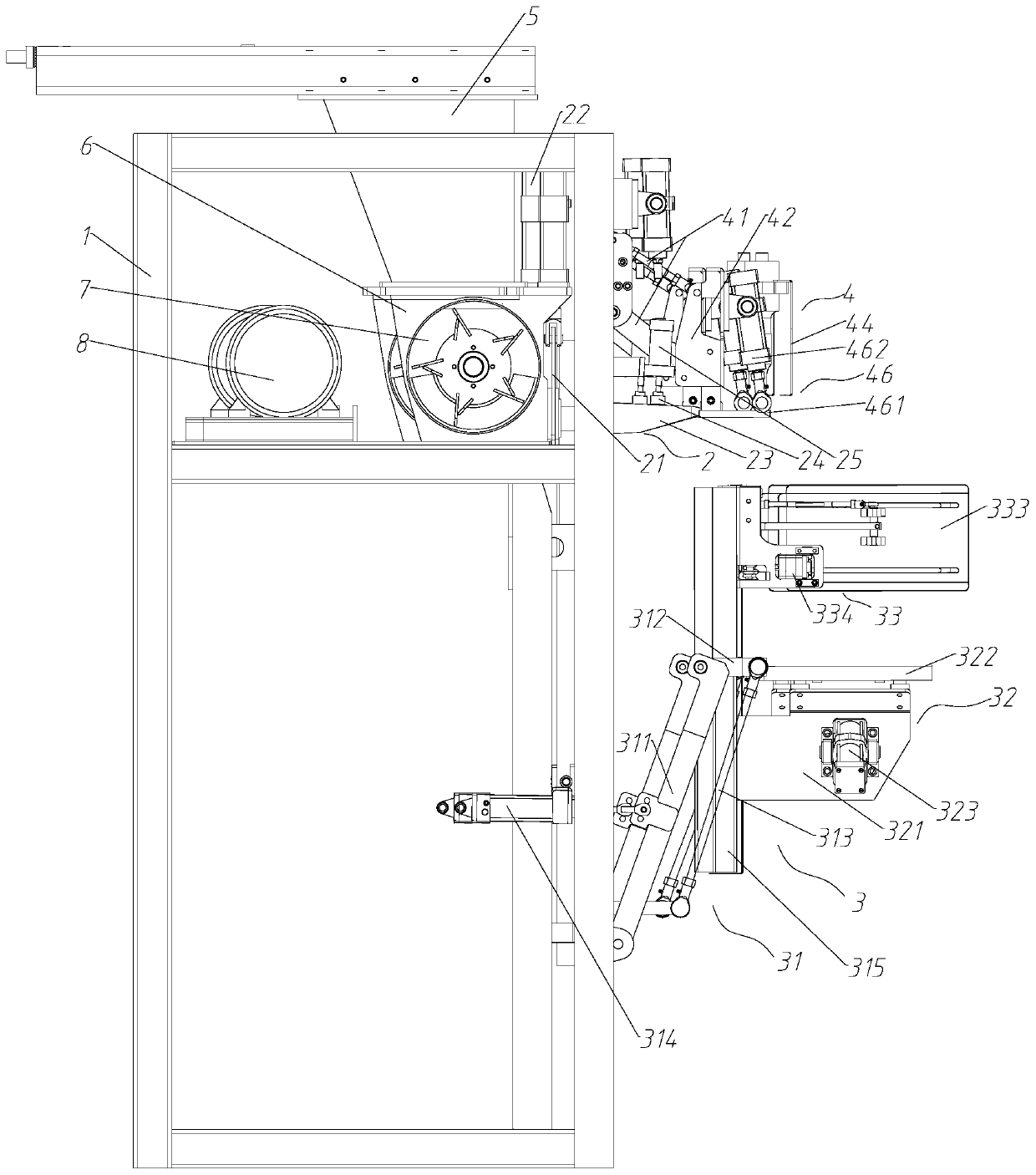

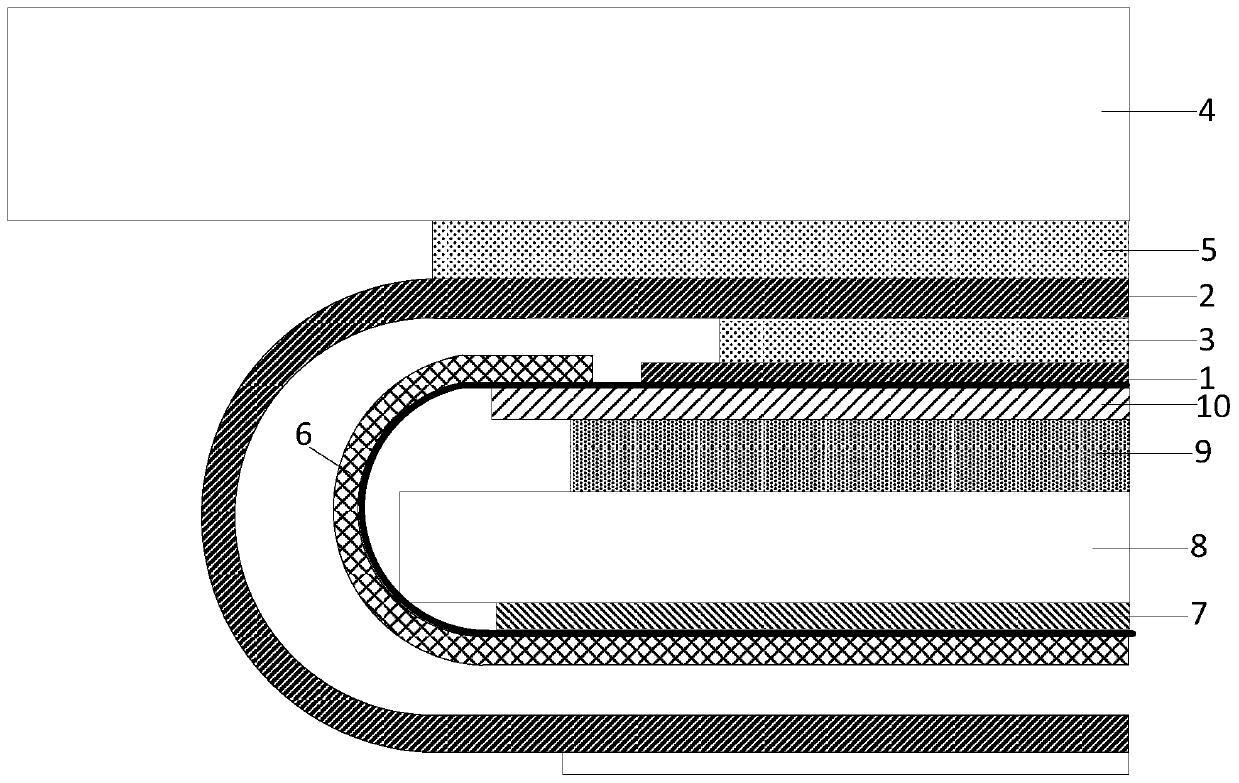

Heat seal packaging machine

InactiveCN110901969AUniform shapeMake sure the connection is firmWrapper twisting/gatheringSolid materialEngineeringPhysics

The invention belongs to the technical field of powder packaging equipment and provides a heat seal packaging machine. The heat seal packaging machine comprises a main rack, a filling nozzle and a bagsupporting mechanism; the filling nozzle is arranged on the main rack; the bag supporting mechanism is arranged on the main rack and located below the filling nozzle; the bag supporting mechanism comprises a bag pushing rack, a bag supporting bottom plate and bag blocking side plates; the bag pushing rack is arranged on the main rack; the bag supporting bottom plate is arranged on the bag pushingrack; and the two bag blocking side plates are arranged on the bag pushing rack; and the bag supporting bottom plate and the two bag blocking side plates form a material supporting space. By means ofthe above technical schemes, the problem that a material bag deforms and leaks materials in a powder packaging process in the prior art is solved.

Owner:唐山鑫宏达机械设备有限公司

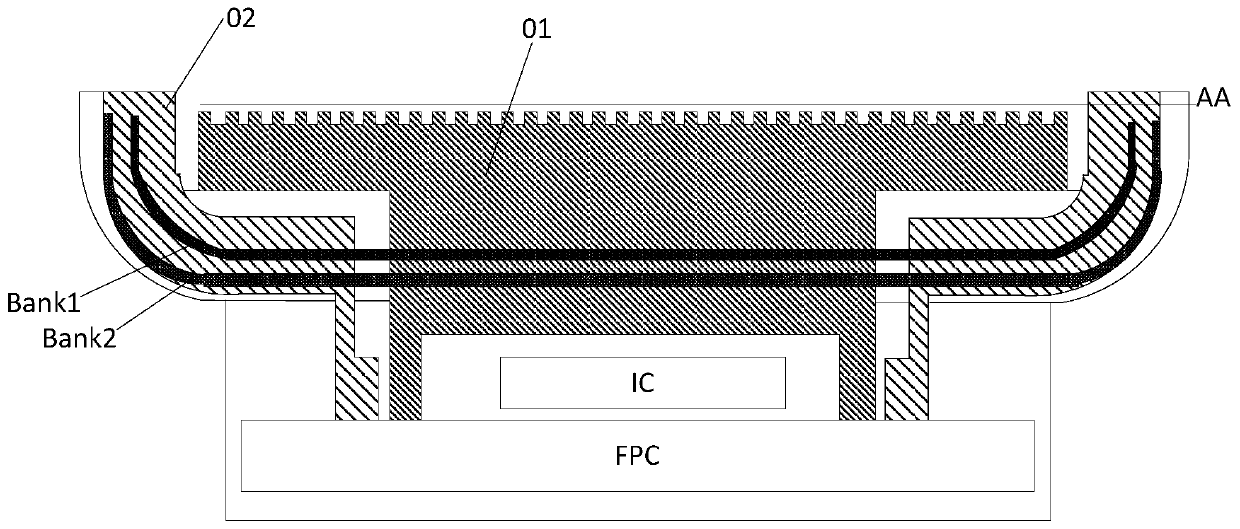

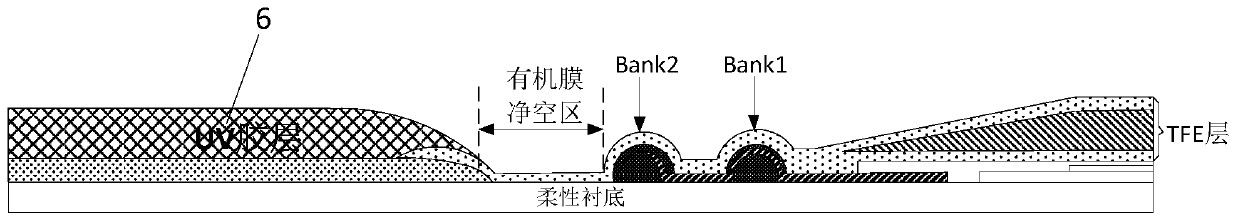

Organic light-emitting display panel and display device

InactiveCN110931536AGuaranteed smoothThere will be no sudden reduction in thicknessSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmDisplay device

The invention discloses an organic light-emitting display panel and a display device. A protective layer is generally made of UV glue. Because an organic film clearance zone is arranged between an outermost retaining wall and a protective layer, fluidity of material of the protective layer expands to a clearance area of an organic film, resulting in unflattening and drop in thickness when a bending area is coated with the material of the protective layer. At least one independent blocking structure is arranged between the retaining wall on the outermost side and the protective layer; in this way, when the bending area is coated with the material of the protective layer; the barrier structure closest to the protective layer can reduce the flow expansion of the protective layer material towards the display area. Therefore, it can be guaranteed that the protective layer is flat, the phenomenon that the thickness of the protective layer is suddenly reduced is avoided, the organic light-emitting display panel can improve the adhesive sealing precision of the protective layer, and the mechanical strength of the flexible display panel in the bending process is enhanced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

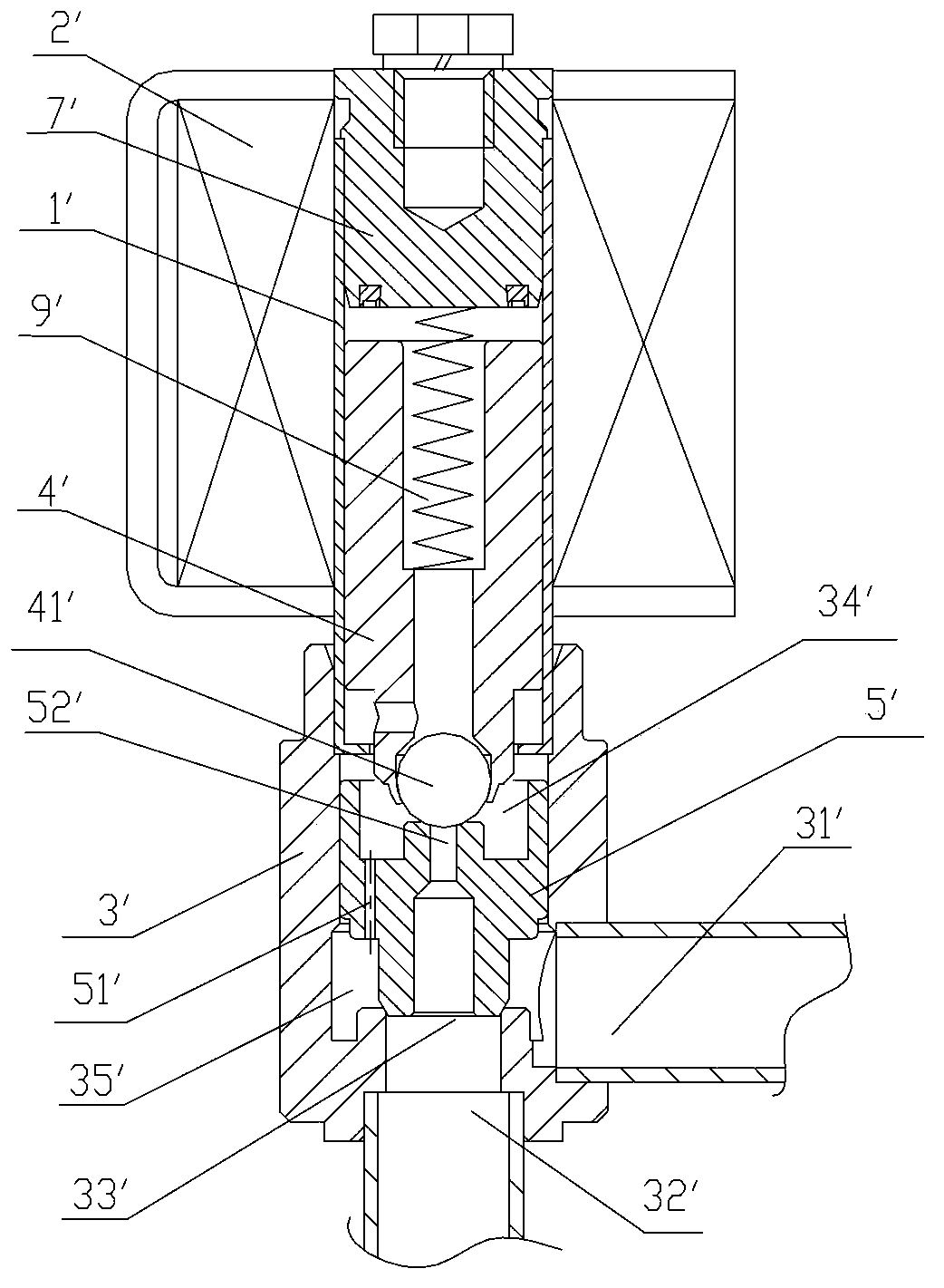

Sealing mechanism and wafer reaction equipment

ActiveCN114658863AImprove sealingImprove sealing accuracyOperating means/releasing devices for valvesSemiconductor/solid-state device manufacturingWaferEngineering

The invention discloses a sealing mechanism and wafer reaction equipment, and relates to the technical field of semiconductors. The sealing mechanism comprises a door body, a rack, a sealing assembly, an elastic piece, a lead screw, a driving assembly and a detection device, an opening is formed in the door body in a penetrating mode, the elastic piece, the driving assembly and the detection device are all arranged on the rack, the sealing assembly is matched with the lead screw through a ball, a stop piece is arranged on the lead screw, and the elastic piece is used for abutting against the stop piece in the forward direction. The driving assembly is in transmission connection with the lead screw and used for driving the lead screw to rotate so as to drive the sealing assembly to move forwards to be attached to the door body to seal the opening, and the driving assembly is further used for driving the lead screw to continue to rotate under the condition that the sealing assembly is attached to the door body so that the lead screw can drive the stop piece to move reversely and compress the elastic piece. The detection device is used for detecting the position of the lead screw, and the driving assembly is further used for stopping when the detection device detects that the lead screw reversely moves to the preset position. The sealing mechanism provided by the invention has higher sealing precision and better sealing performance.

Owner:江苏邑文微电子科技有限公司 +1

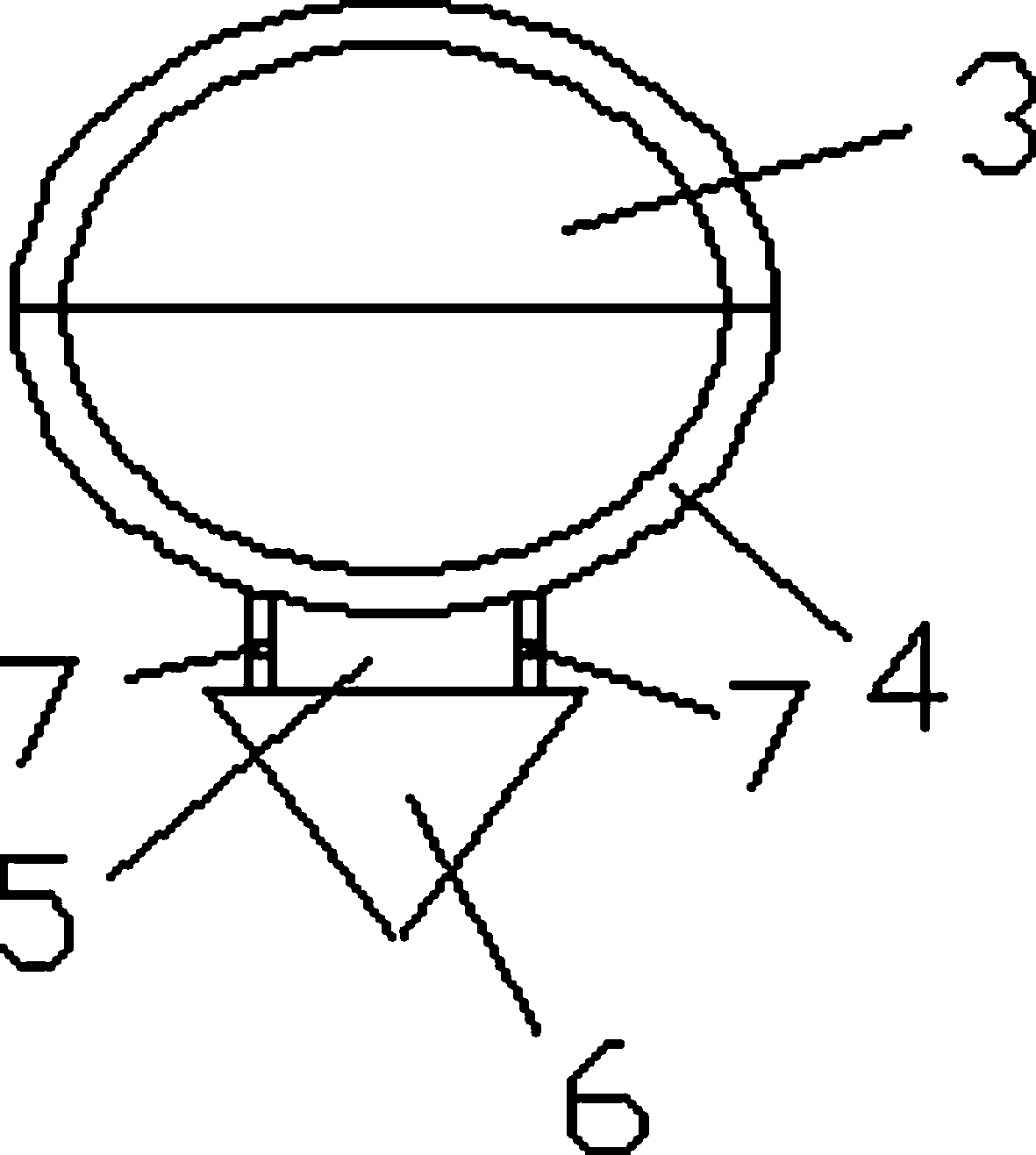

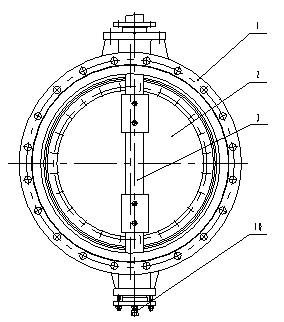

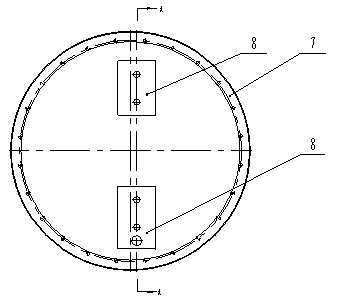

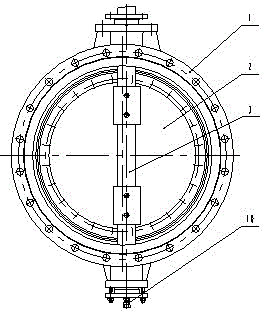

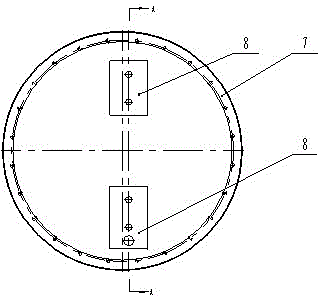

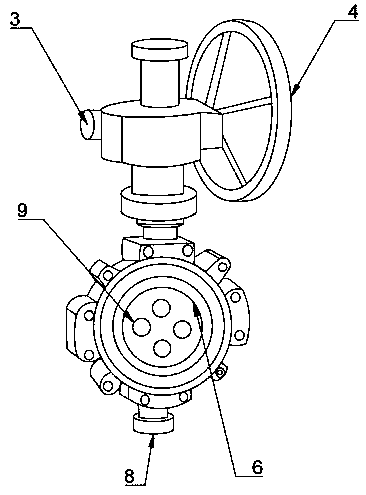

Butterfly valve with inflation seal valve plate

ActiveCN103075526AChange the traditional way of thinkingImprove sealing accuracyLift valveEngineeringButterfly valve

The invention discloses a butterfly valve with an inflation seal valve plate, belongs to the technical field of butterfly valves, and aims to provide a butterfly valve with a good seal effect and small sealing and opening resistance. According to a technical scheme, the valve plate of the butterfly valve consists of an upper ball panel, a lower ball panel, an elastic ring and a seal holder ring; radii of curvature of the upper and lower ball panels are positioned on the same side, and ball centers are opposite in the same line on the same side; the elastic ring and the seal holder ring are in parallel encircling connection between circumferences of the upper and lower ball panels; and an air source connector is communicated with a cavity formed among the upper ball panel, the lower ball panel, the elastic ring and the seal holder ring of the valve plate through air holes. A rigidity seal structure of the traditional butterfly valve is changed, an inflation hollow valve plate with a double-layer structure is adopted, and the whole working process of the valve is qualitatively changed. The seal accuracy of the butterfly valve can reach a high level. The butterfly valve is skillful in design and novel in style, is an innovation for the seal design of the butterfly valve, achieves unexpected good effect and deserves promotion and application.

Owner:HEBEI CHANGHONG VALVE CO LTD

Flow limiting valve with cleaning function for industrial water room

ActiveCN113483106AImprove the sealing effectImprove sealing accuracyOperating means/releasing devices for valvesLift valvePhysicsEngineering

The invention provides a flow limiting valve with a cleaning function for an industrial water room. The flow limiting valve comprises a valve body; a sealing device and a flow limiting mechanism are installed in the valve body, and the flow limiting mechanism is located on the left side of the sealing device; an adjusting device is mounted at the top of the valve body, a pushing part is mounted in the adjusting device, and a limiting part is mounted at the top of the adjusting device; and the cleaning device is installed on the right side of the valve body, a collecting device is installed at the bottom of the cleaning device, and a driving mechanism is installed in the cleaning device. A sealing block is fixedly connected with the valve body, and two sealing rings are fixedly installed in the sealing block, so that the sealing effect between the sealing block and a moving block is improved; and a spring is fixedly installed between a limiting disc and the moving block, so that the moving block moves rightwards under the action of the spring when the valve is closed, the section of the moving block is of a trapezoidal structure, and the sealing block and the moving block are tightly attached under the action of the spring and water flow pressure.

Owner:法图尔智能装备江苏有限公司

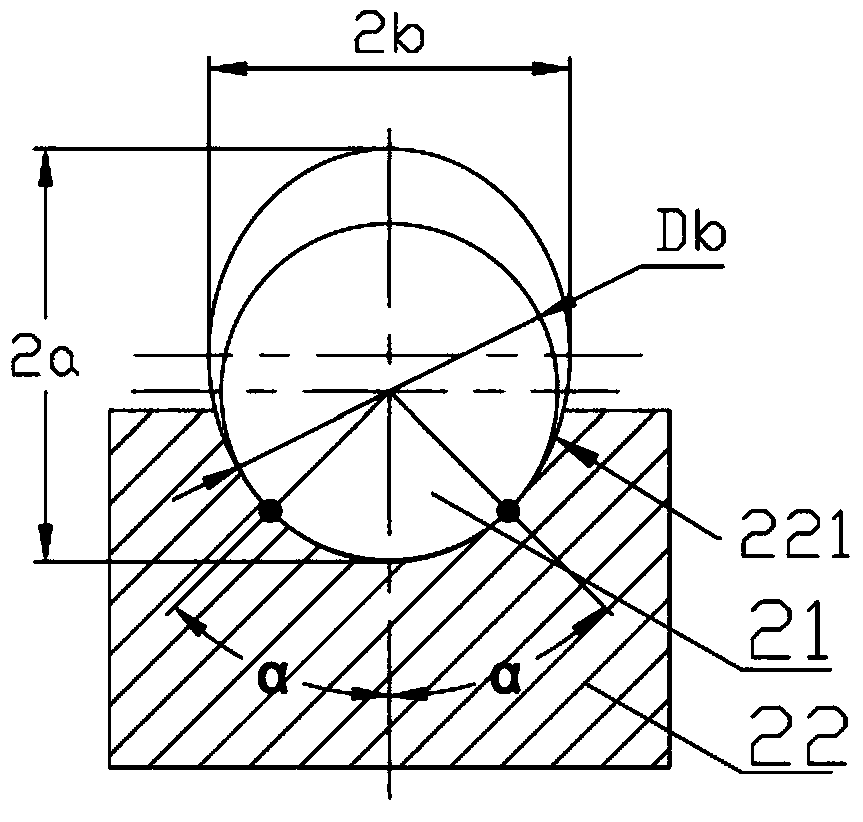

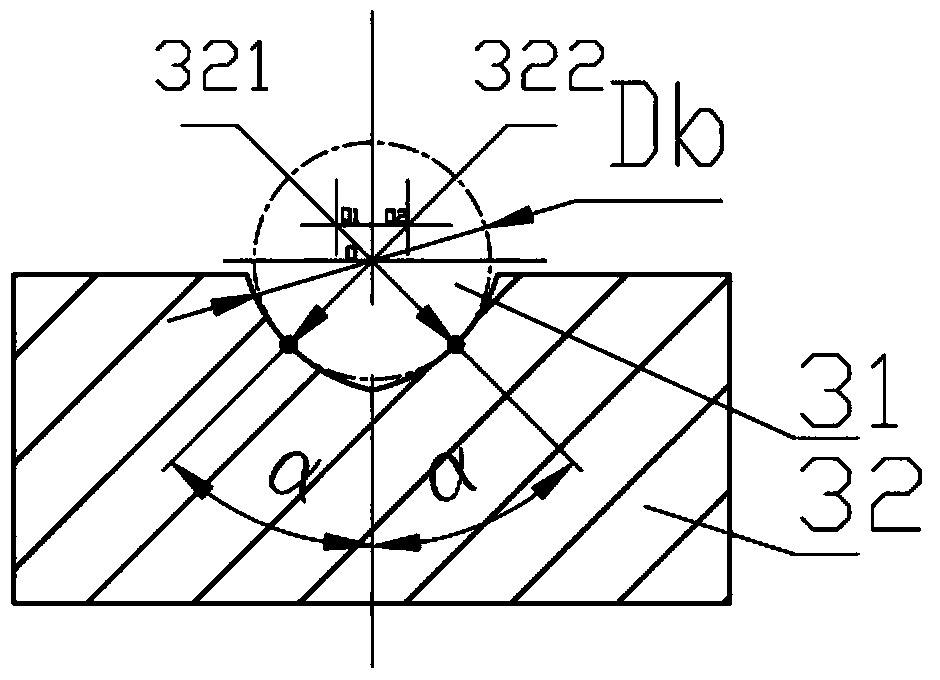

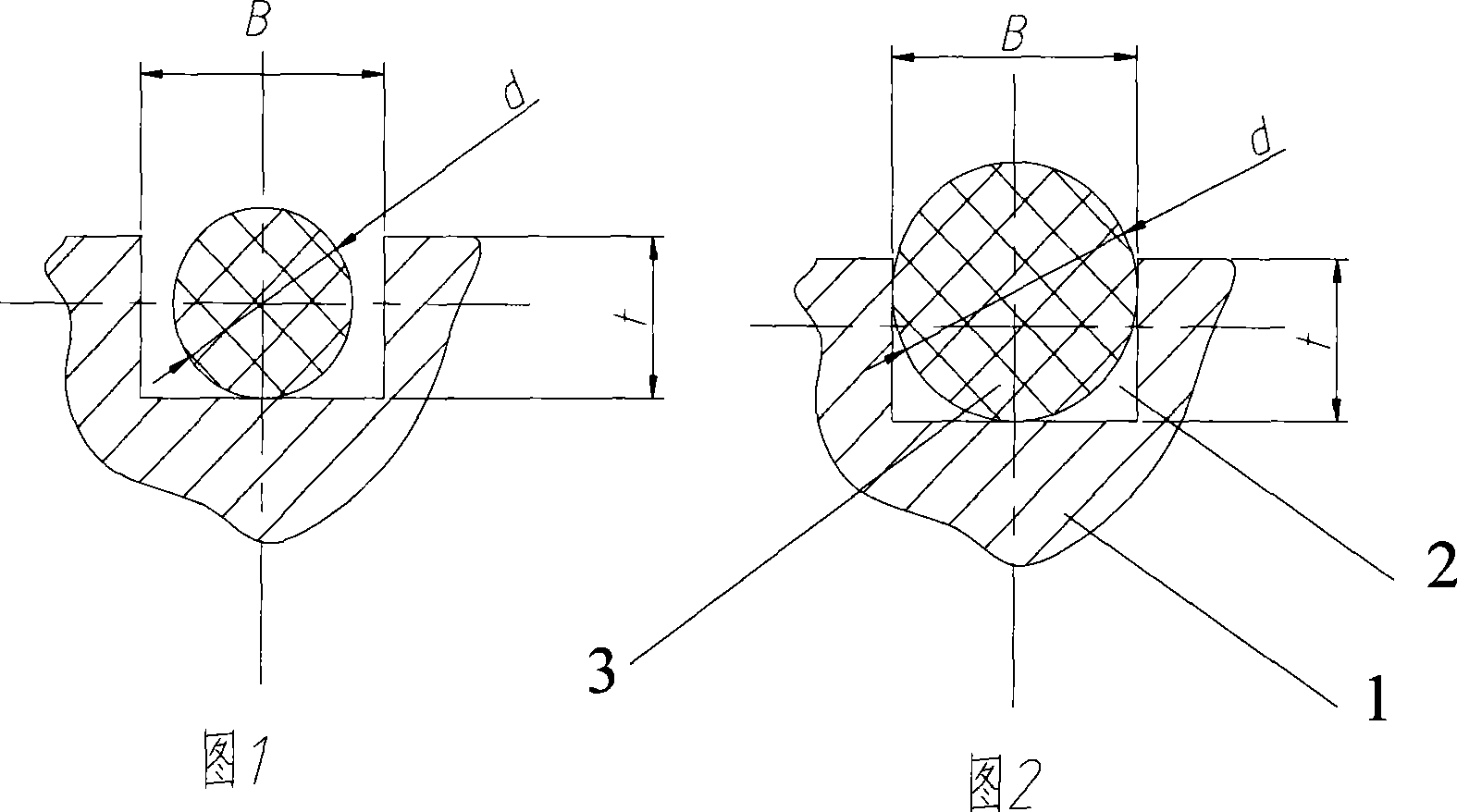

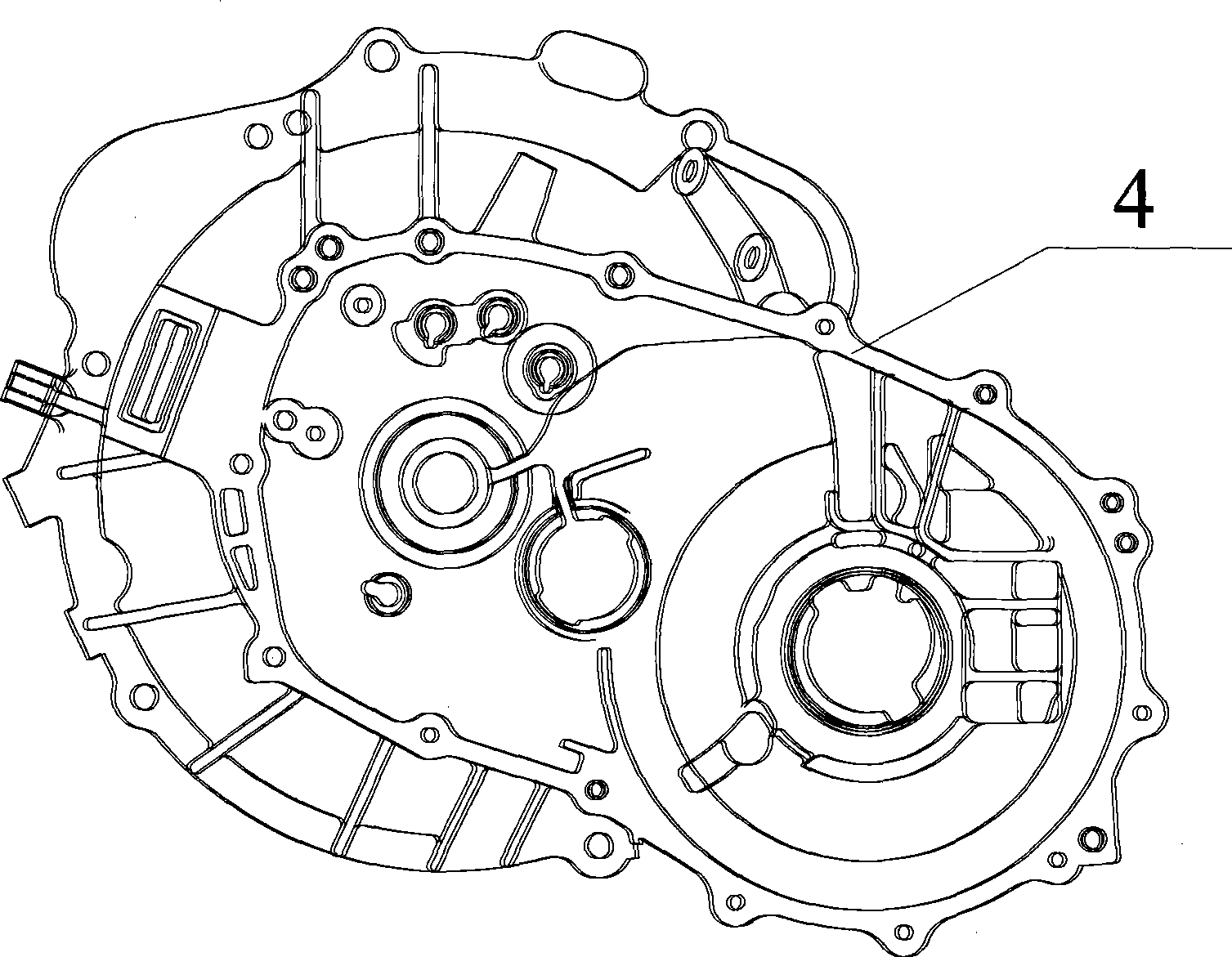

Seal structure design method for narrow sealing plane box parts with complex shape

The invention relates to a method for designing a linear sealing structure of box type parts provided with narrow (sealed) planes with complex shapes. When a standard O ring sealing structure is used for performing sealing on a narrow sealed plane with a complex shape, if the touched sealed plane has the complex shape and is too narrow, the sealing ring replacement or that the standard sealing groove width is bigger than that of the sealed plane is easily caused, so that the sealing cannot be formed. The invention develops a method for realizing sealing on the narrow sealed plane with the complex shape, which is different from the method for standard-sized O rings and grooves. Practices show that the linear sealing structure has good effect when the linear sealing structure is applied to the narrow sealed plane with the complex shape. The design method mainly comprises: firstly, the design of the width B of a sealing groove, which is to make B equal to 1.035 to 1.045 times of d, wherein d is the diameter of the cross section of an O-shaped sealing ring, and the depth t of the sealing groove is kept unchanged and still adopts the standard depth; and secondly, the design of the actual length L of the O-shaped sealing ring, which is to make L equal to 0.990 to 0.089 times of L0, wherein L0 is the theoretical length of the O-shaped sealing ring.

Owner:KEENLAND TIANJIN PRECISION MFG

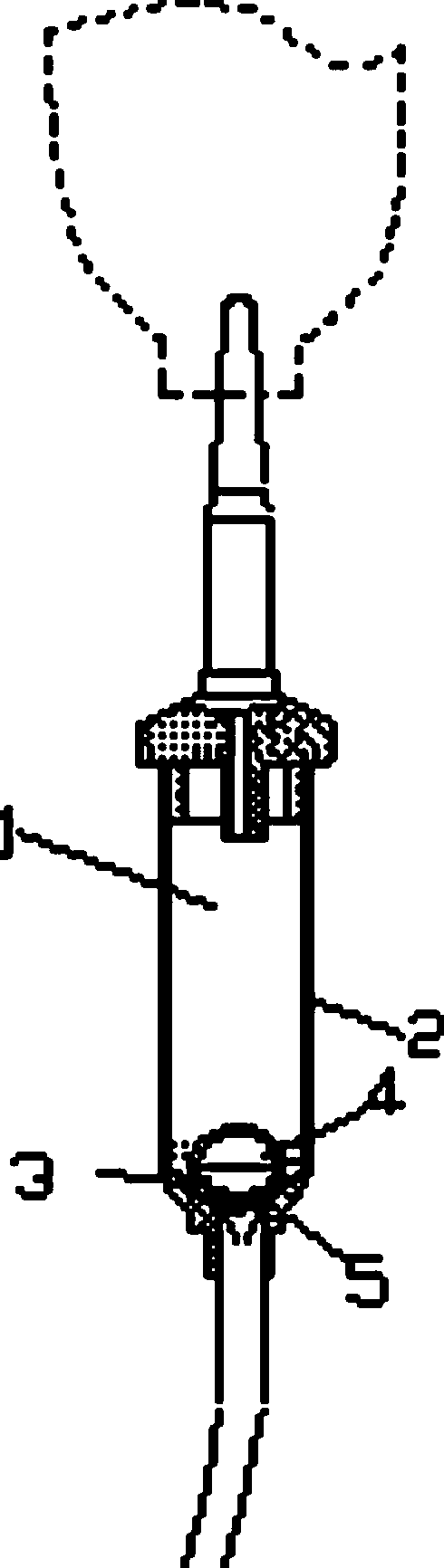

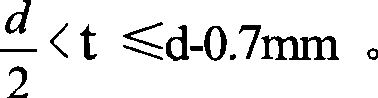

Efficient oil well pump for horizontal well

InactiveCN104088779ASolution can not be resetSolve reset notPositive displacement pump componentsFlexible member pumpsThree stageUpper joint

The invention provides an efficient oil well pump for a horizontal well. The efficient oil well pump comprises an upper joint, a pump cylinder, plunger center poles, plungers, center pole centering devices, a pin oil bleeder, a fixing valve assembly and a joint ball seat. The efficient oil well pump is characterized in that the plungers are two-stage type or three-stage type or four-stage type hollow plungers, the lower end face of each plunger is provided with a traveling valve arc-shaped valve seat, the center of each plunger is provided with one plunger center pole, the upper end of each plunger center pole is provided with one center pole centering device, the lower end of each plunger center pole is provided with a traveling valve arc-shaped valve element, and each traveling valve arc-shaped valve element is in threaded connection with the corresponding centering device and is in seal fit with the corresponding traveling valve arc-shaped valve seat, so that a traveling valve forced opening and forced closing mechanism is formed; each traveling valve arc-shaped valve element drives the corresponding plunger to conduct vertical linkage in the pump cylinder under the effect of vertical reciprocating movement of the corresponding plunger center pole, so that a plunger oil inlet and exhaust assembly is formed. According to the efficient oil well pump, the plunger oil inlet and exhaust assembly and the traveling valve forced opening and forced closing mechanism are adopted, so that the sealing effect is ensured, the pump efficiency is remarkably improved, and the service life of the pump is prolonged.

Owner:张国萍

Expansion sealing structure

ActiveCN108041994AGuaranteed sealing performanceIncrease in sizeCooking vesselsMechanical engineeringEngineering

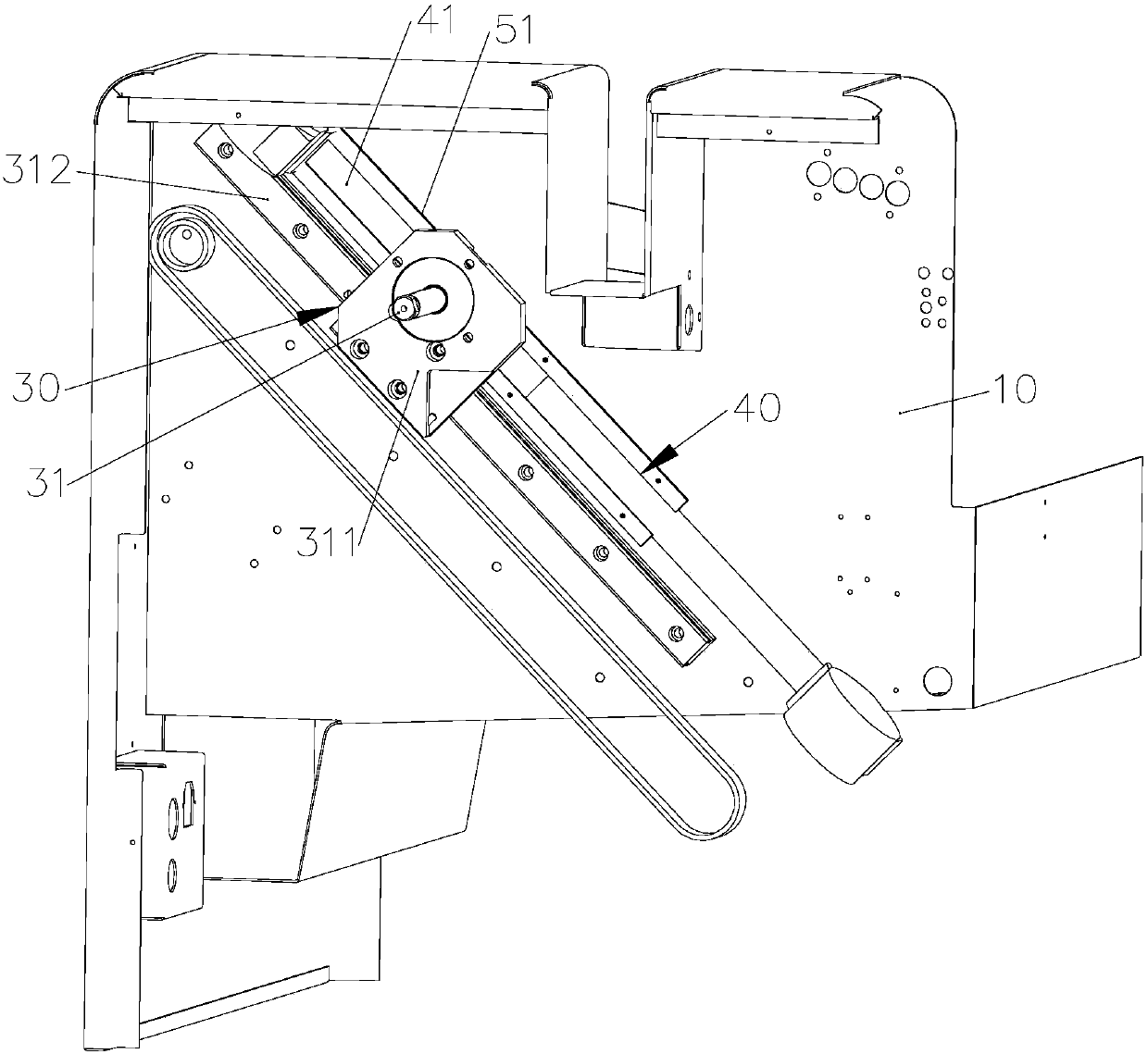

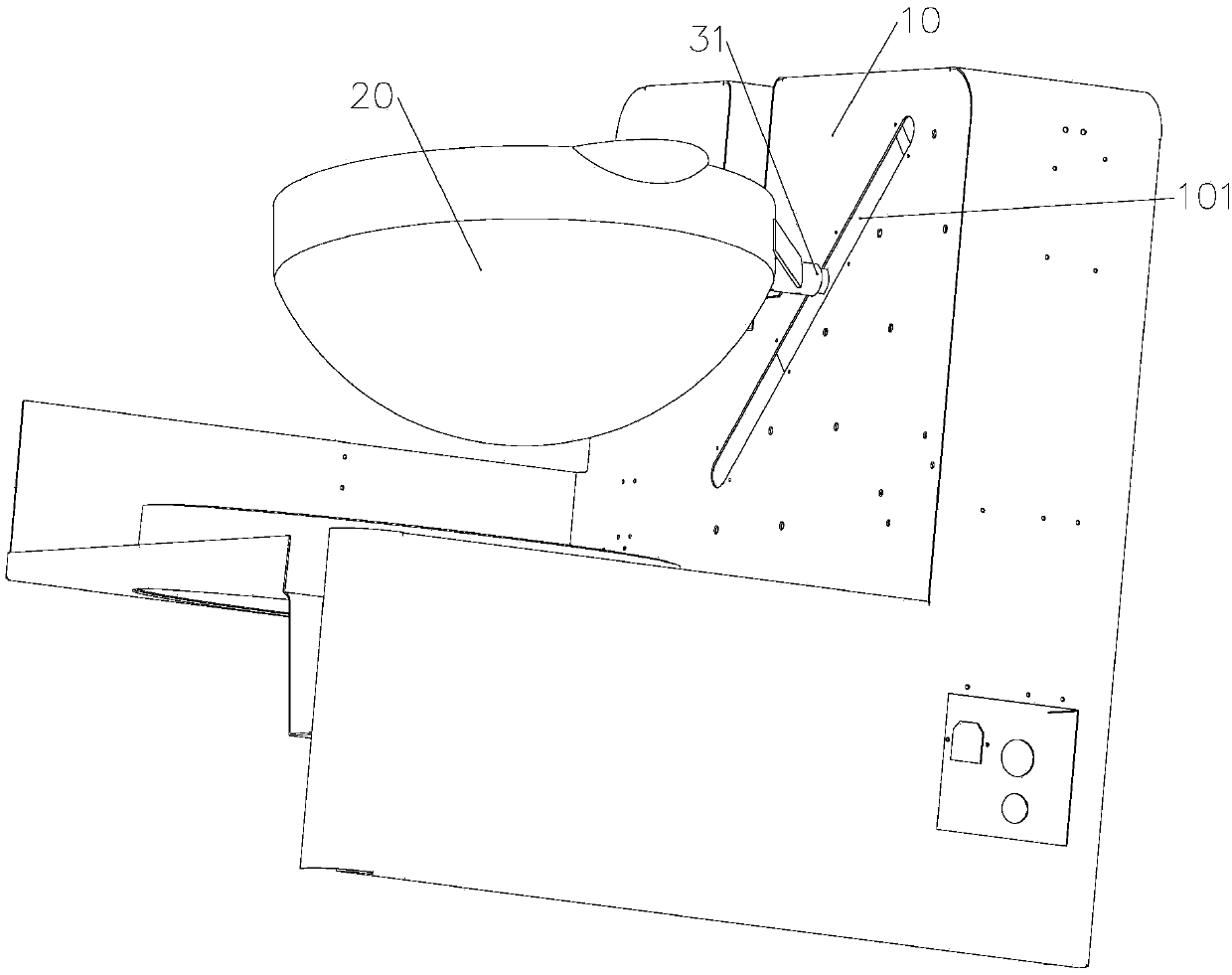

The invention discloses an expansion sealing structure arranged on an automatic cooker and comprising a mounting plate; the mounting plate is provided with a linear guide channel for guiding a motiontrajectory of a wok; two sides of the linear guide channel are provided with the wok and a driving device that drives the wok to reciprocate along the linear guide channel; the drive end of the driving device is at least partially passed through the linear guide channel and connected with the wok. An expansion seal for movably sealing the linear guide channel is arranged on the driving device sideof the mounting plate; the expansion seal is distributed on the linear guide channel along the extension direction of the linear guide channel; the expansion seal is connected with the linear guide channel such that, under the action of the driving device, the end, opposite to the moving direction of the driving device, of the expansion seal contracts inward, with the other end is expanded out tomovably seal the linear guide channel. The expansion sealing structure has good sealing effect and high sealing precision, small size, low weight, simple and compact structure, and low installation,manufacturing and operation costs.

Owner:湖南唐米力科技有限公司

Method and device for automatically sealing two contact surfaces twice for drip injection

The invention discloses a method and a device for automatically sealing two contact surfaces twice for a drip injection. The device comprises a drip injector (1), and is characterized by further comprising a soft sealing body (3) arranged in a dripping bucket (2) of the drip injector (1). The device has the following advantages that when the injection is almost injected, the lower outer surface of a thin-wall soft bag seals the inner wall of the water outlet of the dripping bucket; simultaneously, the injection in the thin-wall soft bag flows out from the water inlet-outlet of the soft sealing body under the gravity action of a floating body, and the thin-wall soft bag performs secondary two-surface sealing on the end surface of the water outlet of the dripping bucket; the sealing accuracy is high, and a gas or a liquid can hardly flow in a transparent tube outside the water outlet of the dripping bucket; simultaneously, after replacement, the injection flows in the dripping bucket again, and the soft sealing body is very easy to float under the action of buoyancy; and in this way, the injection can be injected again. The control device is simple in structure, convenient in operation, and firm in sealing; and simultaneously, the soft sealing body is easy to float.

Owner:何焱

Butterfly valve with inflation seal valve plate

ActiveCN103075526BChange the traditional way of thinkingImprove sealing accuracyLift valveEngineeringButterfly valve

The invention discloses a butterfly valve with an inflation seal valve plate, belongs to the technical field of butterfly valves, and aims to provide a butterfly valve with a good seal effect and small sealing and opening resistance. According to a technical scheme, the valve plate of the butterfly valve consists of an upper ball panel, a lower ball panel, an elastic ring and a seal holder ring; radii of curvature of the upper and lower ball panels are positioned on the same side, and ball centers are opposite in the same line on the same side; the elastic ring and the seal holder ring are in parallel encircling connection between circumferences of the upper and lower ball panels; and an air source connector is communicated with a cavity formed among the upper ball panel, the lower ball panel, the elastic ring and the seal holder ring of the valve plate through air holes. A rigidity seal structure of the traditional butterfly valve is changed, an inflation hollow valve plate with a double-layer structure is adopted, and the whole working process of the valve is qualitatively changed. The seal accuracy of the butterfly valve can reach a high level. The butterfly valve is skillful in design and novel in style, is an innovation for the seal design of the butterfly valve, achieves unexpected good effect and deserves promotion and application.

Owner:HEBEI CHANGHONG VALVE CO LTD

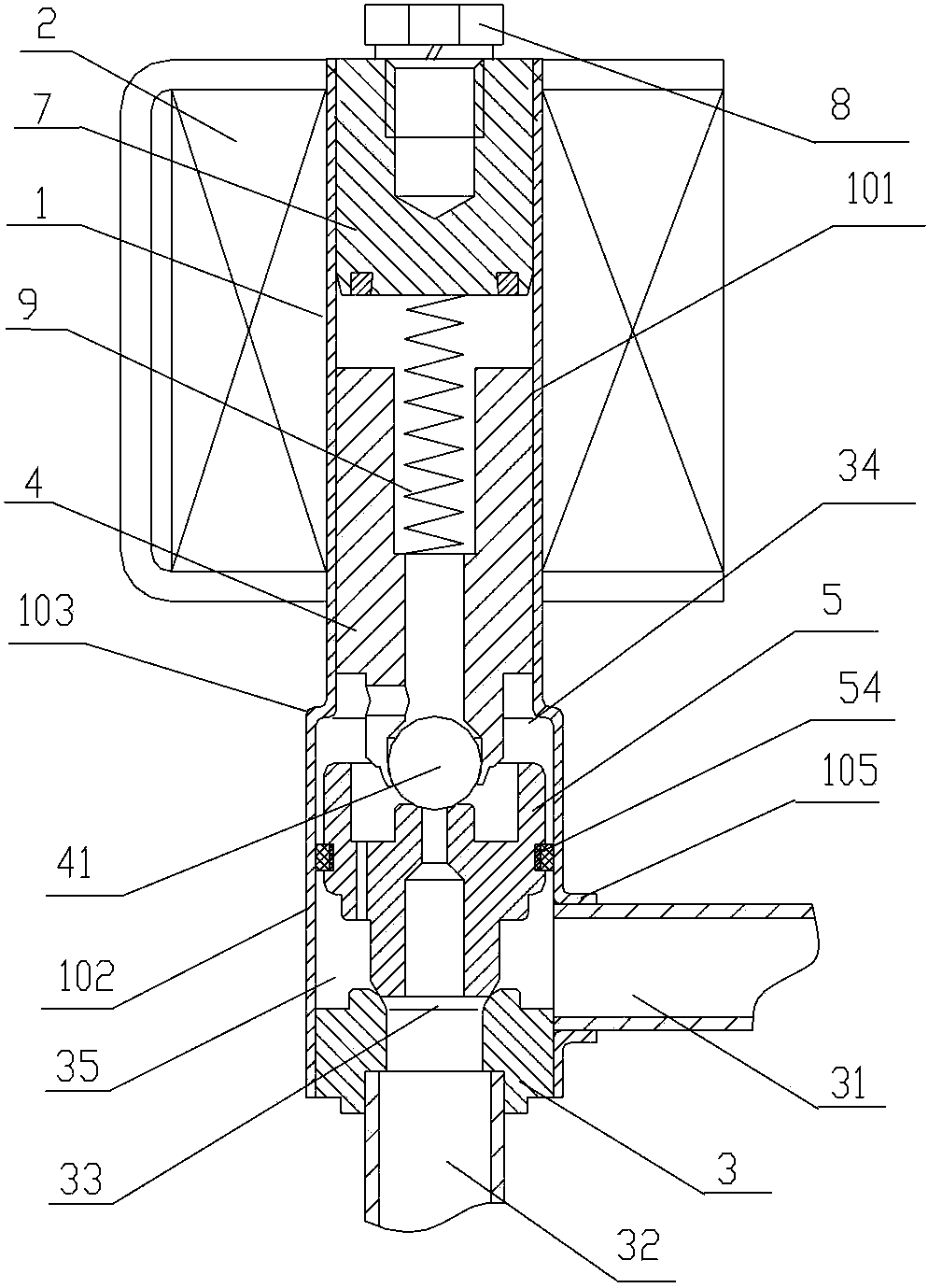

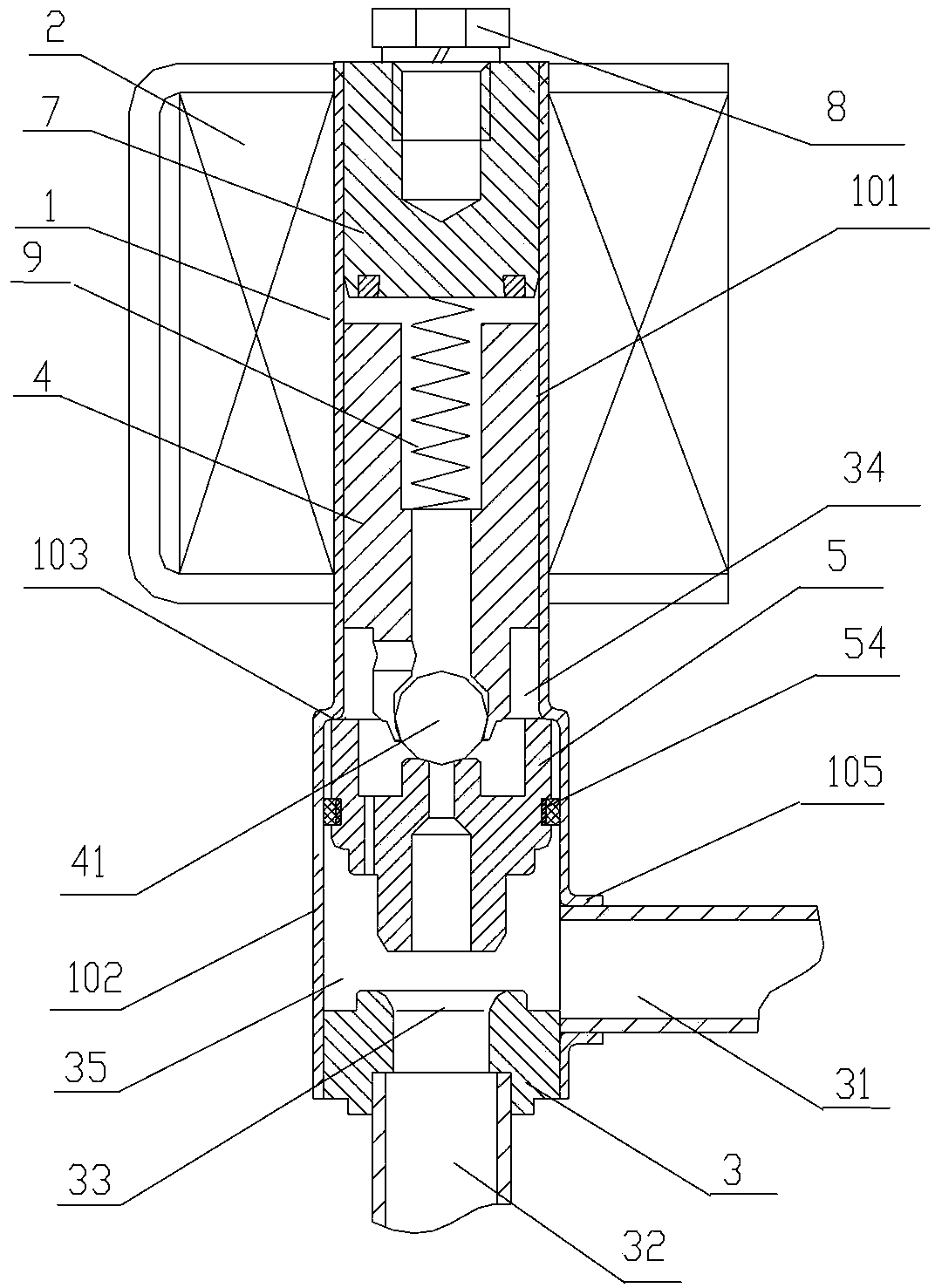

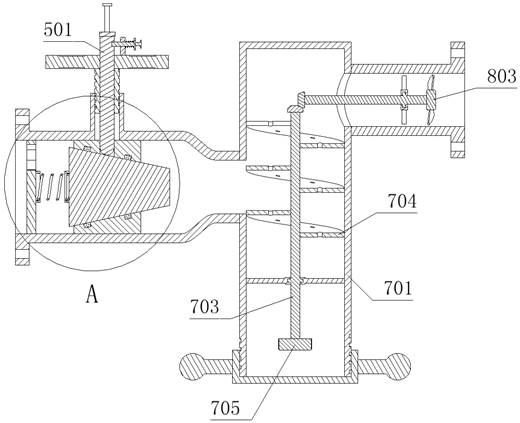

High-pressure regulation valve and pressure detection device

ActiveCN102840336BImprove sealing accuracyOperating means/releasing devices for valvesLift valveLinear motionControl system

The invention discloses a high-pressure regulation valve and a pressure detection device. The high-pressure regulation valve comprises a first joint, a transverse first valve cavity, a second joint, a transverse second valve cavity, a centre and a power source, wherein the first and second joints are communicated with the first and second valve cavities respectively; the first valve cavity and the second valve cavity are in butt joint; a conical cavity is arranged at the butt joint of the first valve cavity; the cavity wall of the conical cavity is a conical surface; the conical surface is matched with a sphere; the power source drives the centre to move transversely and linearly through a thread pair; and the centre drives the sphere to move transversely and linearly. The pressure regulation valve converts circular motion into linear motion by use of the lead screw principle; the centre pushes open the sphere to control blockage; the fluid flow is controlled by use of the size of an opening / closing gap of the sphere so as to control the pressure range of the system; and thus, the pressure regulation valve not only realizes a complete blockage function, but also can control the pressure of the system and loop.

Owner:CHOTEST TECH INC

High-pressure regulation valve and pressure detection device

ActiveCN102840336AImprove sealing accuracyOperating means/releasing devices for valvesLift valveCavity wallPressure range

The invention discloses a high-pressure regulation valve and a pressure detection device. The high-pressure regulation valve comprises a first joint, a transverse first valve cavity, a second joint, a transverse second valve cavity, a centre and a power source, wherein the first and second joints are communicated with the first and second valve cavities respectively; the first valve cavity and the second valve cavity are in butt joint; a conical cavity is arranged at the butt joint of the first valve cavity; the cavity wall of the conical cavity is a conical surface; the conical surface is matched with a sphere; the power source drives the centre to move transversely and linearly through a thread pair; and the centre drives the sphere to move transversely and linearly. The pressure regulation valve converts circular motion into linear motion by use of the lead screw principle; the centre pushes open the sphere to control blockage; the fluid flow is controlled by use of the size of an opening / closing gap of the sphere so as to control the pressure range of the system; and thus, the pressure regulation valve not only realizes a complete blockage function, but also can control the pressure of the system and loop.

Owner:CHOTEST TECH INC

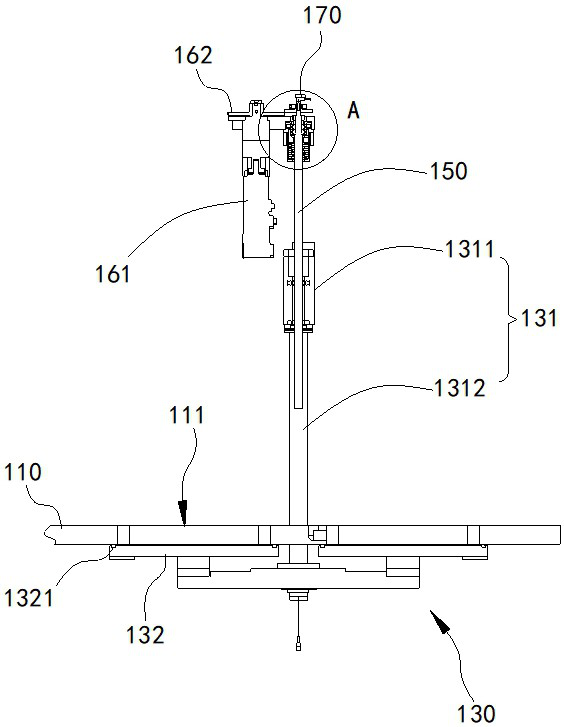

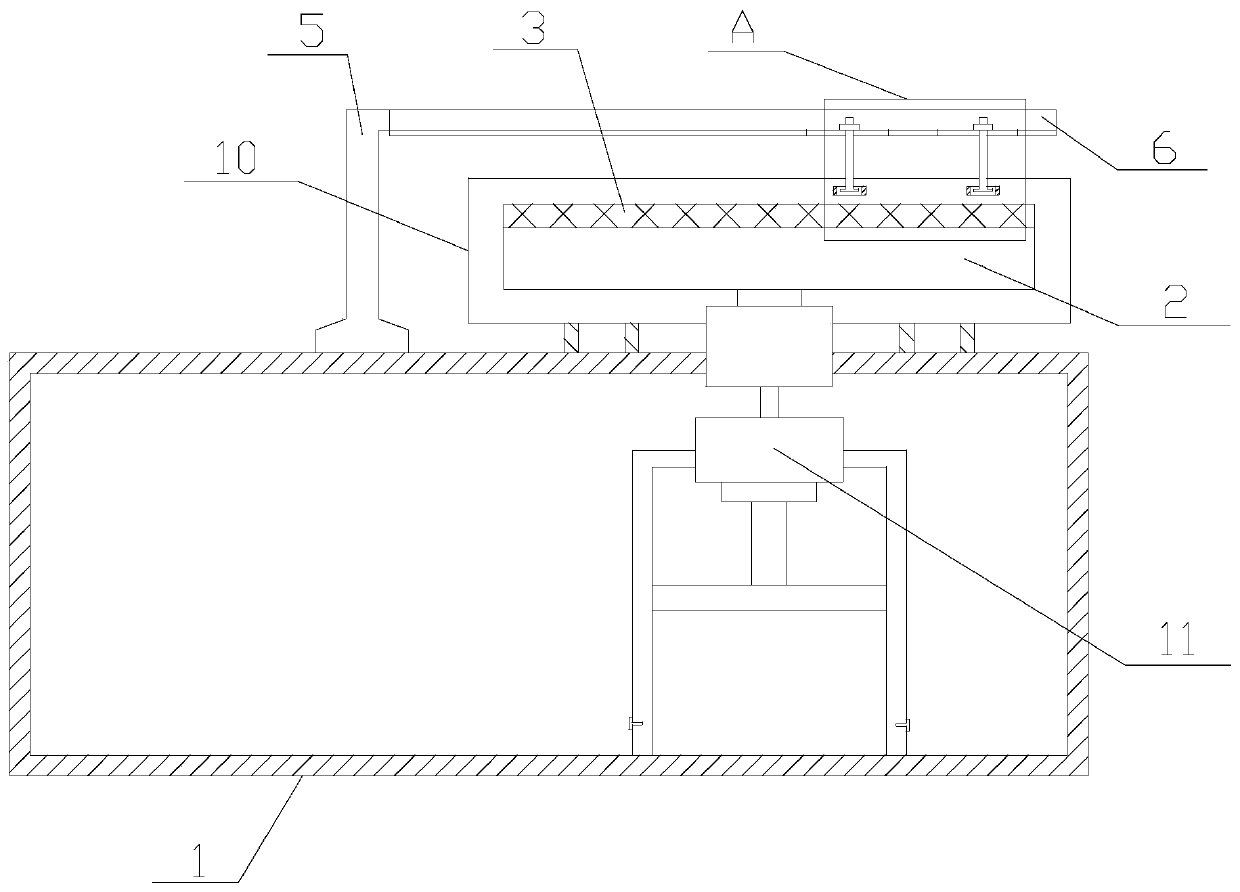

An automatic grinding machine for the sealing surface of a floating oil seal and its grinding process

ActiveCN105500133BLess squeezePrevent dentsGrinding work supportsPlane surface grinding machinesThermodynamicsAutomatic processing

An automatic grinding machine for the sealing surface of a floating oil seal comprises a working table, a grinding disc is arranged on the surface of the working table, and a mat layer is protruded on the surface of the grinding disc. The beneficial effects of the present invention are: the automatic grinding machine for the sealing surface of the floating oil seal of the present invention has a reasonable structure and is convenient to use, and the hemp surface layer made of linen can grind and polish the sealing surface of the floating oil seal, thereby improving the plane precision of the sealing surface of the floating oil seal , can also reduce the extrusion caused by grinding powder on the sealing surface of the floating oil seal, prevent the sealing surface of the floating oil seal from being concave inward, improve the plane accuracy of the sealing surface of the floating oil seal, improve the sealing accuracy of the floating oil seal, and realize the sealing surface of the floating oil seal. Automatic processing improves work efficiency and production efficiency, and can meet the use requirements of floating oil seals of any size. It has a wide range of applications, good practical application effects, and is conducive to popularization.

Owner:ZHEJIANG GUANGLI ENG MACHINERY

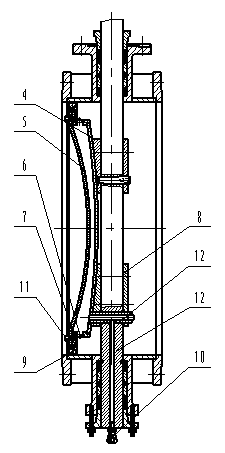

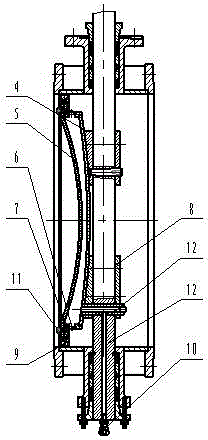

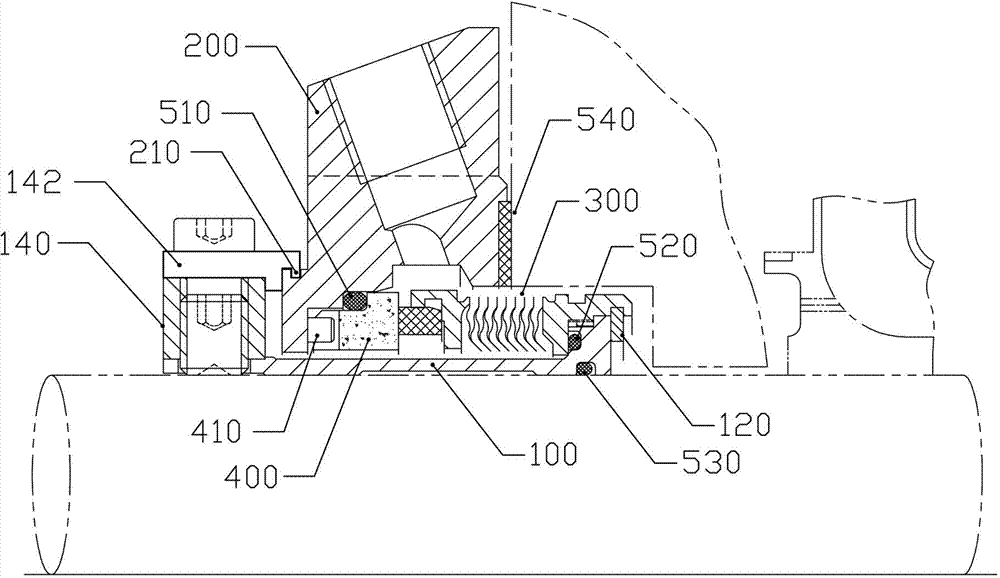

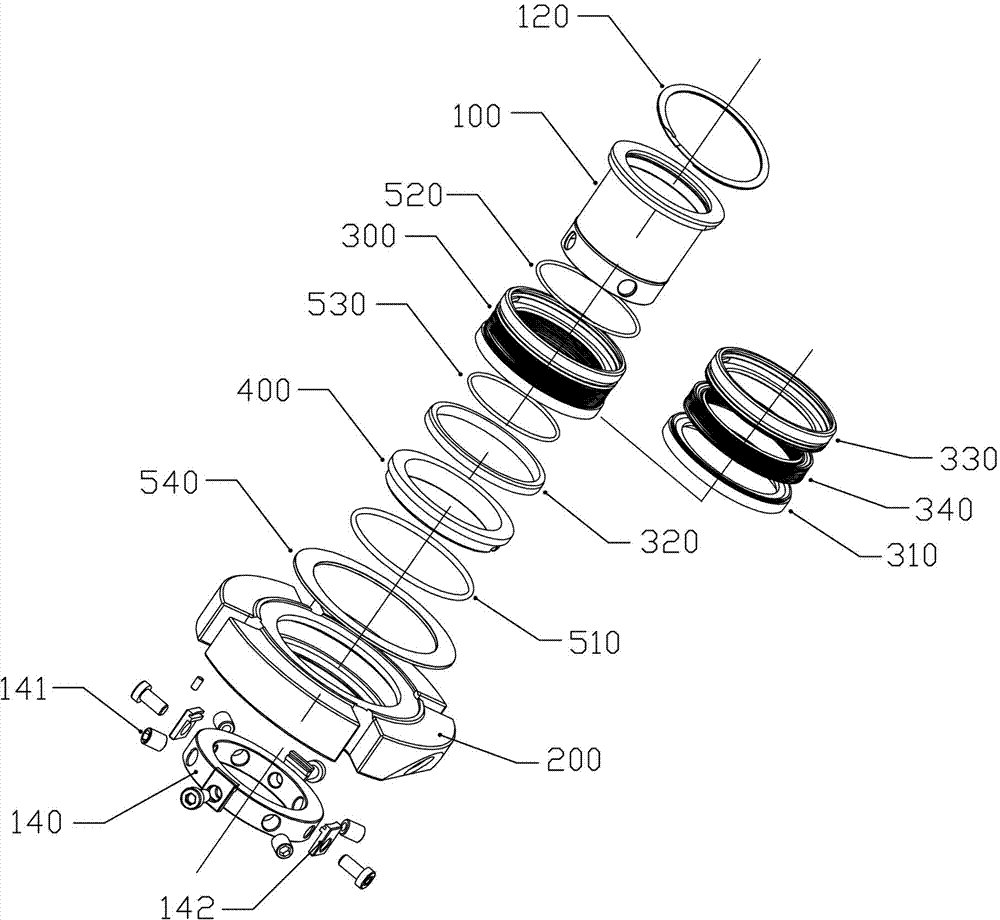

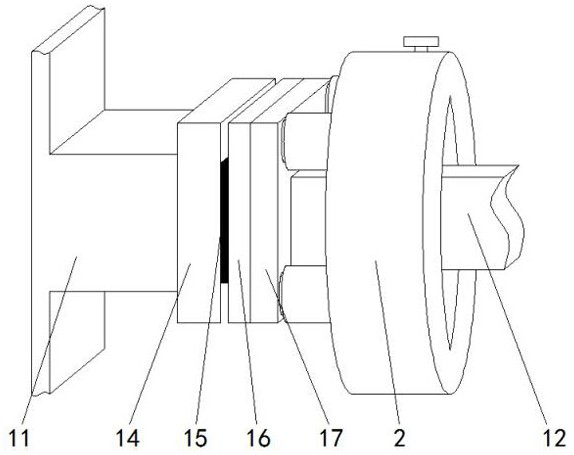

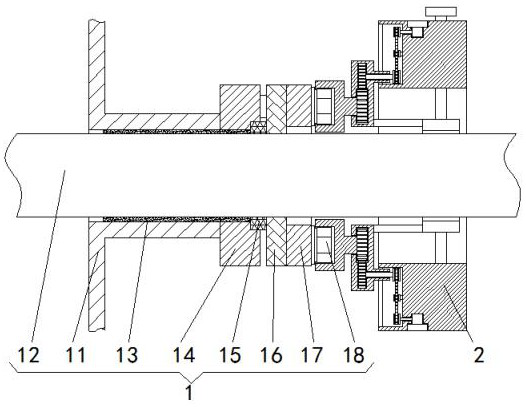

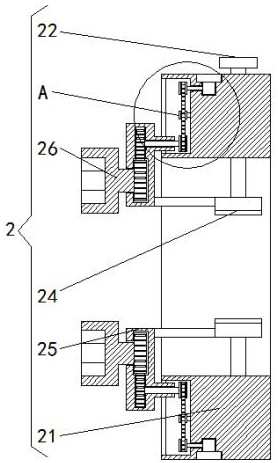

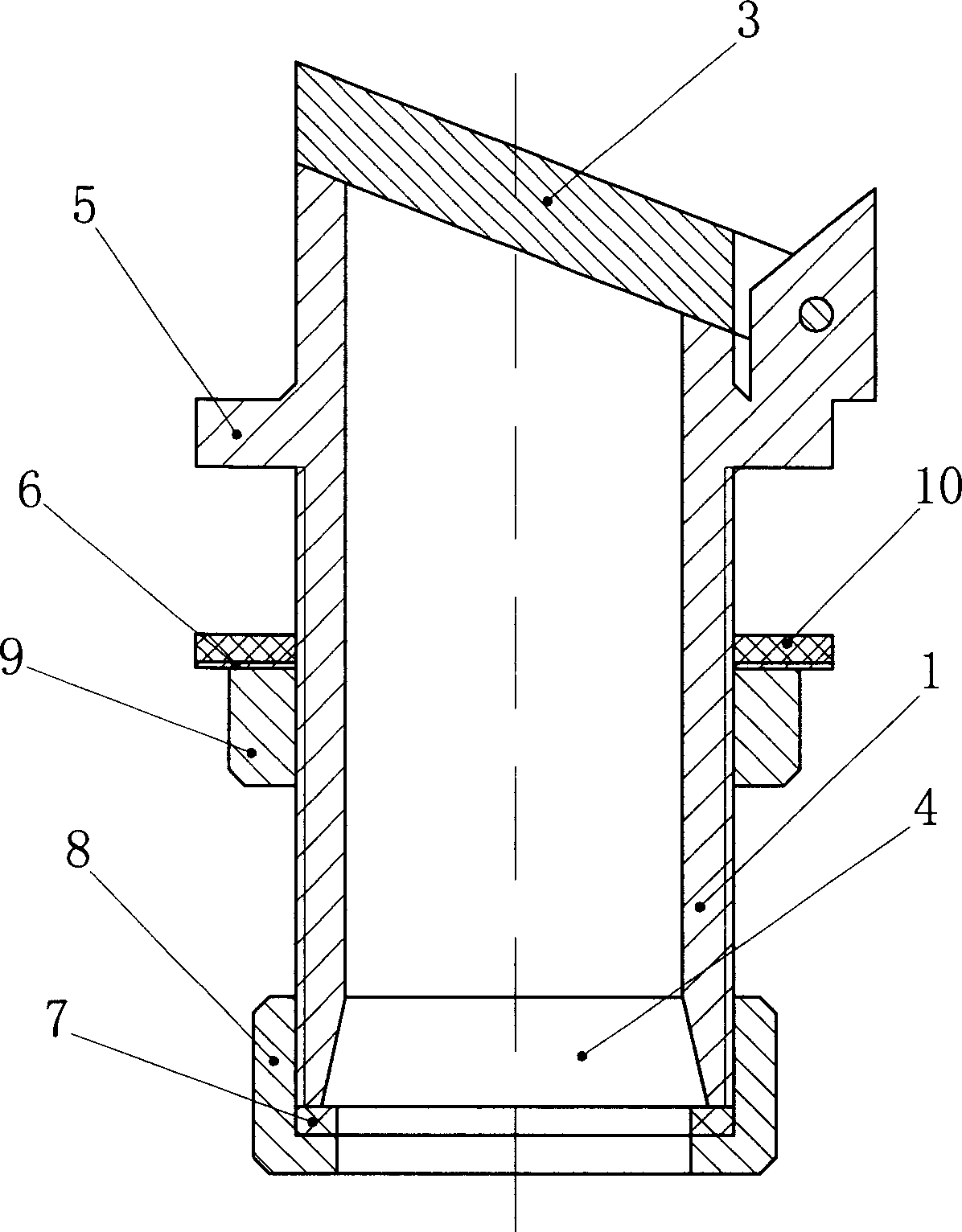

Mechanical seal structure for narrow seal chamber

ActiveCN102927040BReduce radial sizeElastic Compensation Equilibrium and StabilityPump componentsPumpsEngineeringMechanical engineering

The invention discloses a mechanical seal structure for a narrow seal chamber. A dynamic ring assembly of the device comprises a ring seat, a dynamic ring, a base ring and a welded corrugated pipe, wherein the dynamic ring and the base ring are embedded on the ring seat; the welded corrugated pipe is welded between the ring seat and the base ring; a boss is arranged on the external wall of the right end of a shaft sleeve; a sunken part is formed on the left end of the boss; an internal sunken platform with a bulge is arranged at the right end of the base ring; the bulge is engaged with the sunken part, so that the base ring can be linked with the shaft sleeve; a clamp spring propped against the right end of the shaft sleeve is arranged at the right end of the base ring; a static ring is arranged on the internal wall of the seal gland by a hinge pin; a transmission ring is arranged at the left end of the shaft sleeve in a sleeving way; the transmission ring and the shaft sleeve are fixed on a pump shaft by bolts; a plurality of F-shaped positioning blocks are uniformly distributed on the sidewall of the transmission ring; an annular groove is formed on the left end of the sealing gland; and one end of each positioning block is fixed on the sidewall of the transmission ring while the other end of each positioning block is blocked into the annular groove, so that the sealing gland and the transmission ring can be axially fixed and rotated relative to each other; and the sealing gland, the shaft sleeve, the dynamic ring assembly and the static ring form an integrated structure.

Owner:DONGGUAN HUAHUI PRECISION MASCH CO LTD

Gas cell sealing method

InactiveUS10145905B2Improve sealing accuracyImprove sealingMagnetic field measurement using magneto-optic devicesSingle device manufacturingLight beamLaser light

A gas cell sealing method includes bonding step in which a bonding portion of a gas cell main body having an opening and a lid for closing the opening where a sealant for bonding the gas cell main body and the lid is provided is heated by converging a laser beam from a laser light source through an optical element, and the lid is bonded to the gas cell main body by applying pressure in a direction that presses the lid against the gas cell main body, the pressure being applied while the laser beam is being converged to the bonding portion.

Owner:SEIKO EPSON CORP

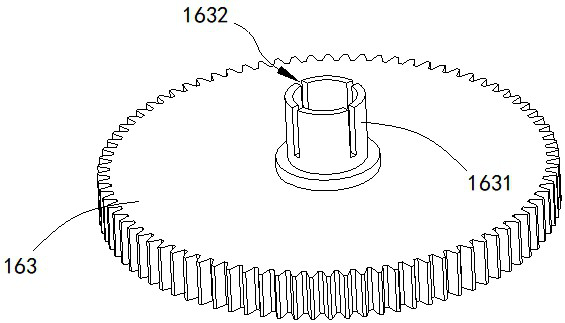

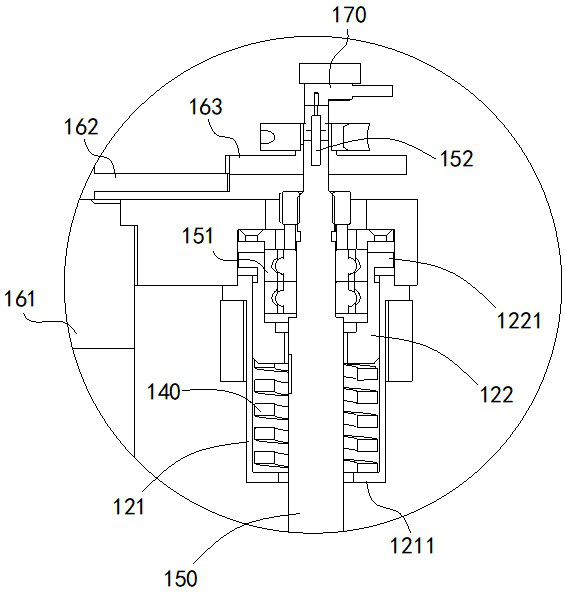

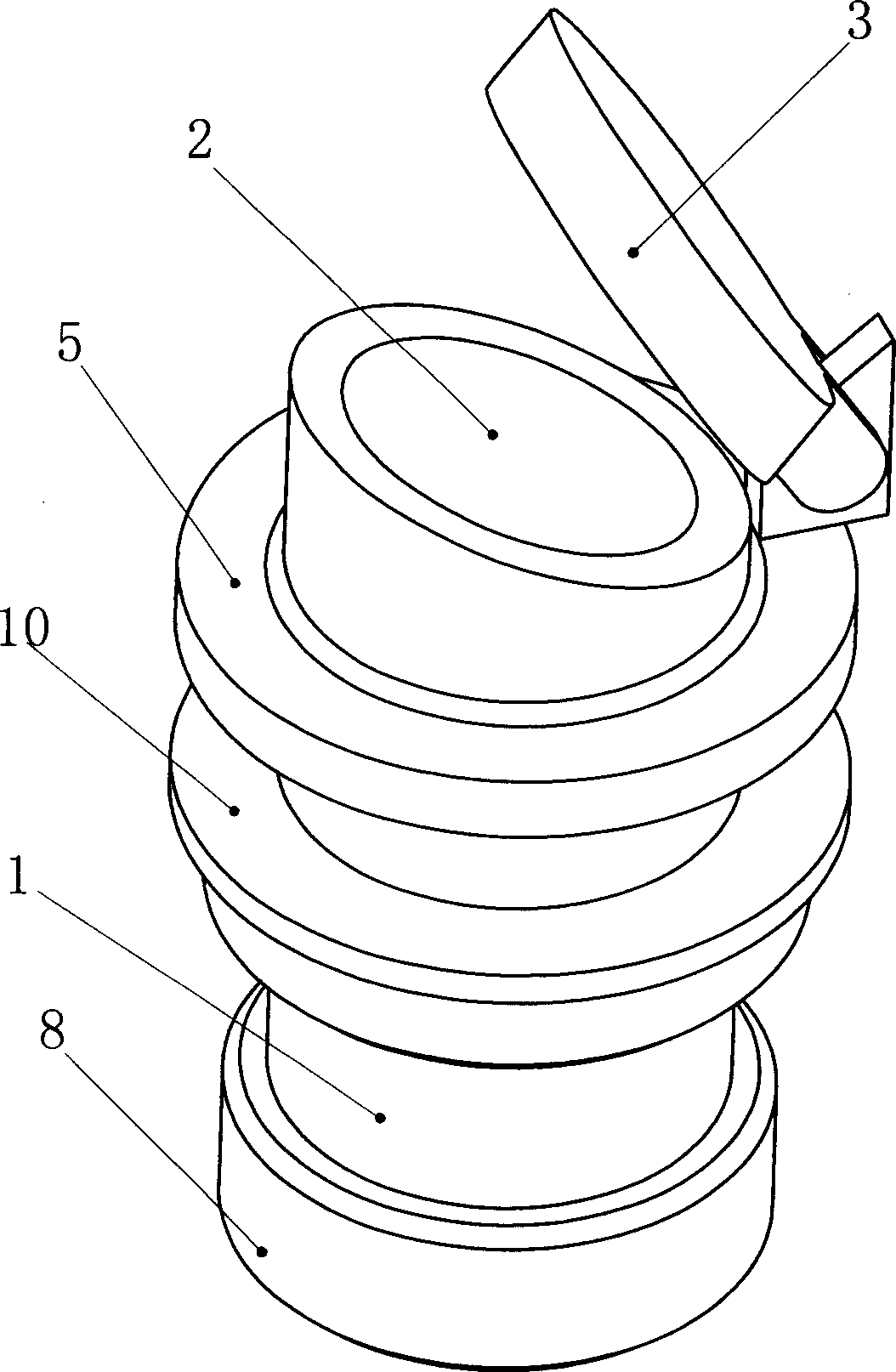

A superconducting magnet vpi mold joint insulation sealing device and its technology

ActiveCN114038676BEven by forceNot misplacedInductances/transformers/magnets manufactureSuperconducting magnets/coilsDrive wheelDrive shaft

The present invention provides a superconducting magnet VPI mold joint insulation and sealing device and its technology. The superconducting magnet VPI mold joint insulation and sealing device includes a sealing mechanism, and an assembly mechanism is sleeved on the outer side of the sealing mechanism. The assembly mechanism includes A collar, the inside of the collar is plugged with a screw, the outer side of the screw is connected to a drive wheel, the inner side of the collar is slidingly connected to a tensioning wheel, and the outer side of the tensioning wheel is fixedly connected to a tensioning wheel. spring. The superconducting magnet VPI mold joint insulation sealing device and its technology, drive the drive shaft to rotate through the rotation of the driving wheel, the drive shaft drives the sleeve to rotate, the sleeve drives the bolt to rotate, and at the same time the drive wheel drives the driven wheel to rotate, and the driven wheel makes the multiple sets The cylinder rotates synchronously, the sleeve rotates multiple sets of bolts synchronously, and the bolts force the gasket evenly without misalignment, thus achieving the effect of simultaneous tightening of multiple sets of bolts, uniform force, and high sealing accuracy.

Owner:JIANGSU YAWEI TRANSFORMER

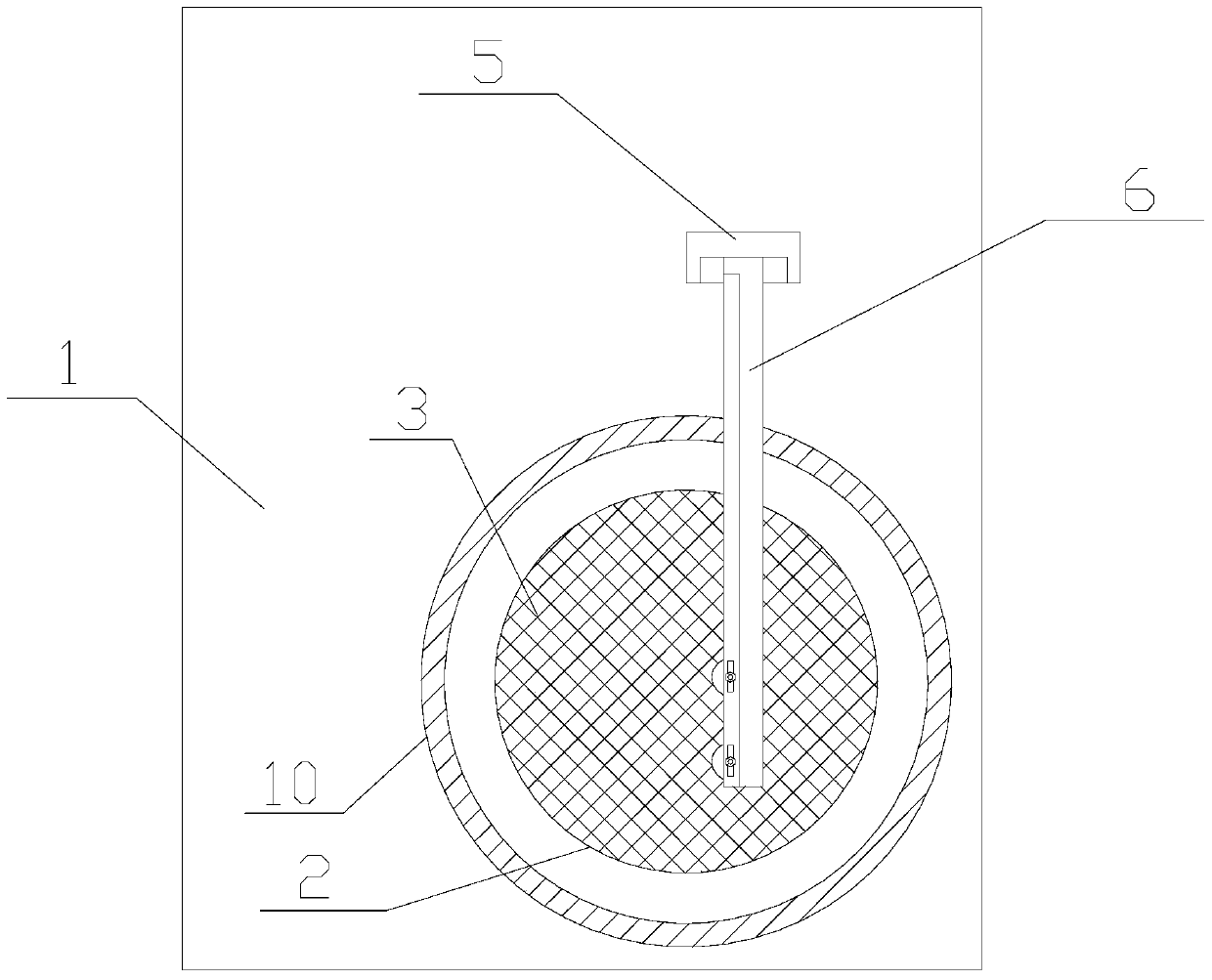

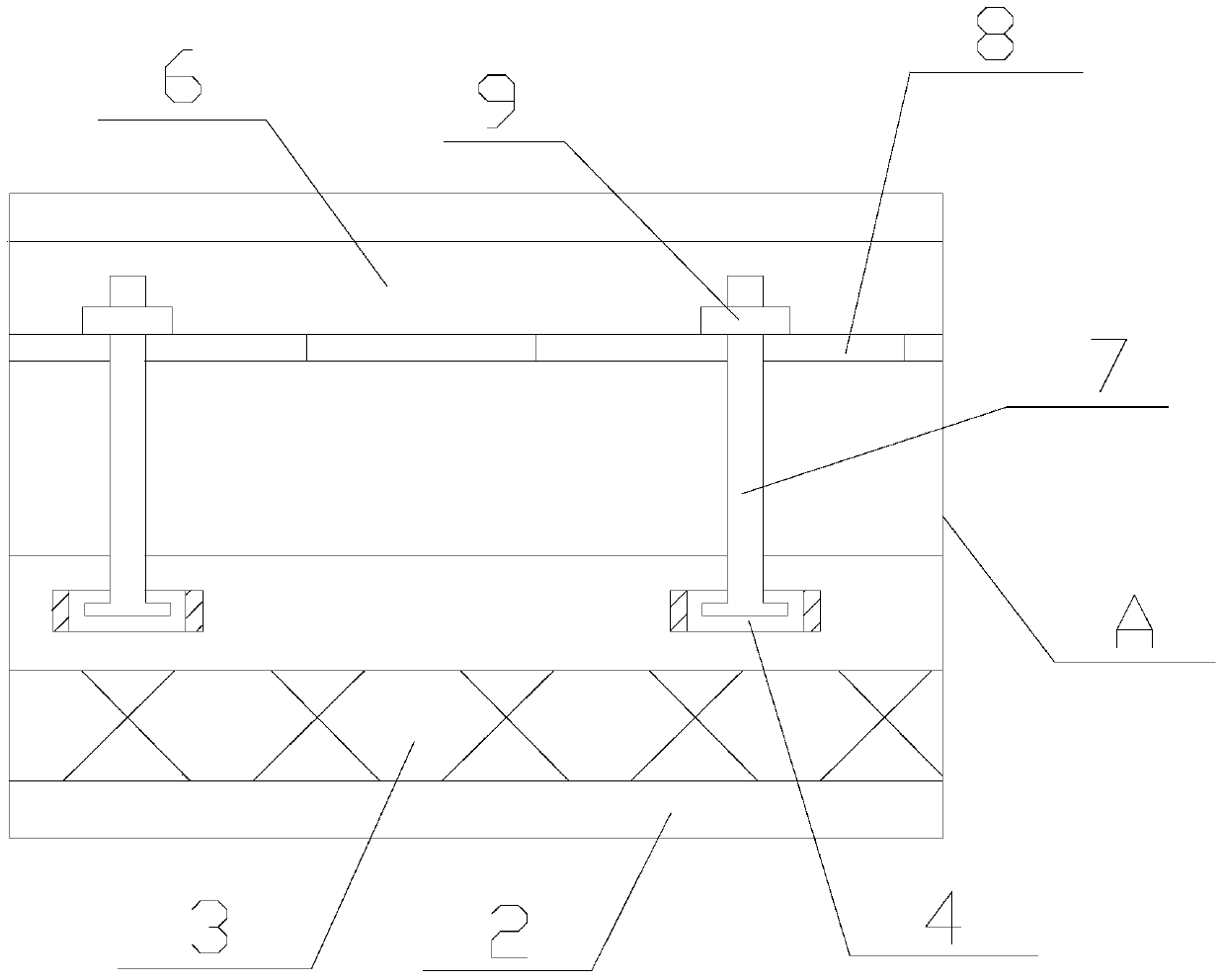

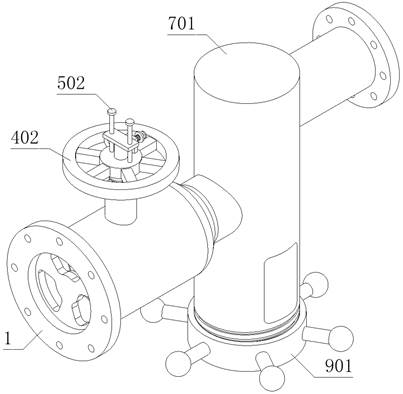

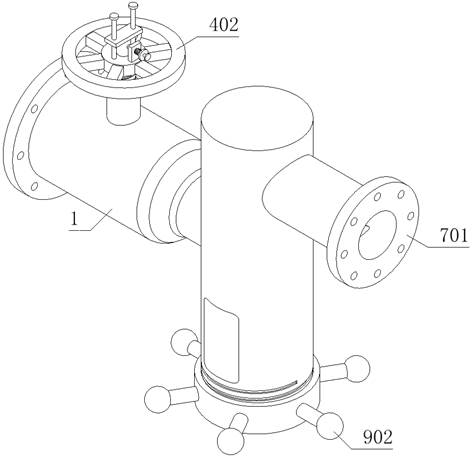

Groove valve

InactiveCN1800682AImprove sealing accuracyEasy to openLift valveValve housingsProduction lineEngineering

The invention relates to a groove valve which can be used as a wine-filling device in the production lines of Tokay and other wines. The groove valve has a pipe valve (1) whose upper end is the inlet (2); the inlet (2) has a valve cover (3) hinged on the valve (1); the lower end of valve (1) is the interface (4); the middle part of outer wall of valve (1) has a protruded annular step (5), from which to the end of interface (4) is a external screw thread, a sealing ring (10), a cushion ring (6) and a nut (9); the end of interface (4) has a sealing ring (7) and a locked screw cap (8) matching the external screw thread. The invention can avoid leakage with easy opening.

Owner:方建生

A flow limiting valve for industrial water room with self-cleaning function

ActiveCN113483106BImprove sealingImprove sealing accuracyOperating means/releasing devices for valvesLift valveWater flowEngineering

Owner:法图尔智能装备江苏有限公司

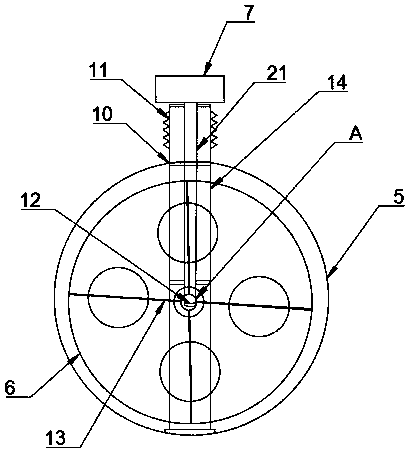

A Highly Flexible and Strong Erosion Resistant Butterfly Valve

ActiveCN108374899BIncrease flexibilityIncrease strong erosion resistanceSpindle sealingsOperating means/releasing devices for valvesDrive shaftGear wheel

The invention provides a strong impact corrosion-resistant butterfly valve with high flexibility and a use method thereof. The strong impact corrosion-resistant butterfly valve comprises a valve body,wherein a drive mechanism is arranged at the surface of the valve body; an outer casing is arranged at the bottom end of the drive mechanism; a first gearbox is arranged at one side of the drive mechanism, a first hand wheel is arranged at one end of the first gearbox, a first butterfly plate is arranged in the outer casing, and a fixed pipe is arranged in the first butterfly plate; the first gearbox is connected with the top end of the fixed pipe through a gear; a second drive shaft is arranged in the fixed pipe; a second hand wheel is arranged at the top end of the second drive shaft; a second gearbox is arranged at the bottom end of the second drive shaft; a first bevel gear is arranged at the outer side of the second drive shaft. The strong impact corrosion-resistant butterfly valve with high flexibility has the advantages that by arranging multiple second butterfly plates, the thickness of the first butterfly plate is at least 6cm, and the valve body is closed by two steps, so that the maximum flow drag of valve close is reduced, and the flexibility of the valve body is improved; the strong impact corrosion-resistant ability of the butterfly valve is improved, so that the application range of the butterfly valve is expanded, and the market competitiveness is improved.

Owner:TIANGONG VALVE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com