Mechanical seal structure for narrow seal chamber

A technology of mechanical seal device and seal cavity, which is applied in the field of mechanical seal device of pumps, can solve the problems of fast wear of seal surface, frequent replacement, short seal life, etc., achieve balanced and stable elastic compensation, simple and compact structure, axial small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

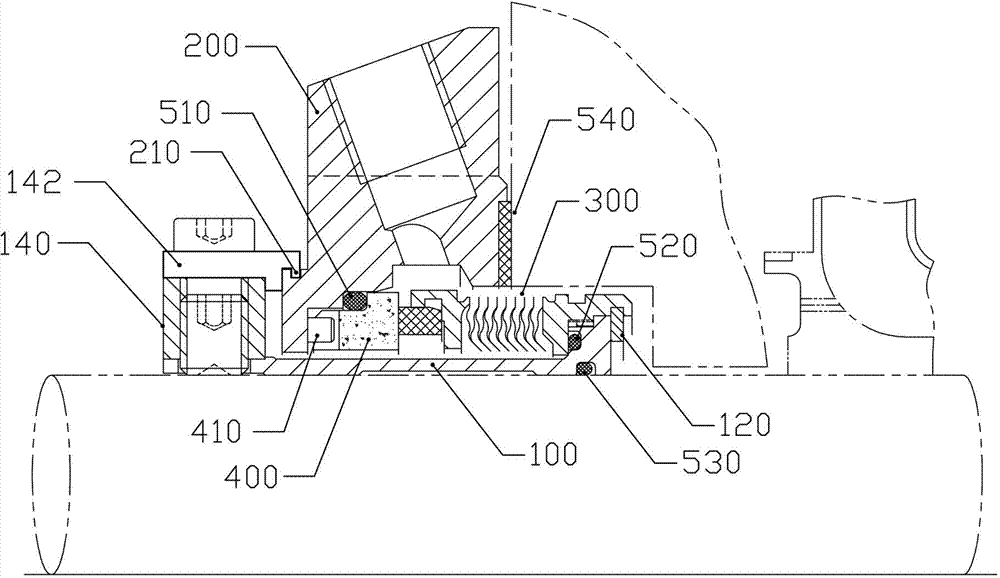

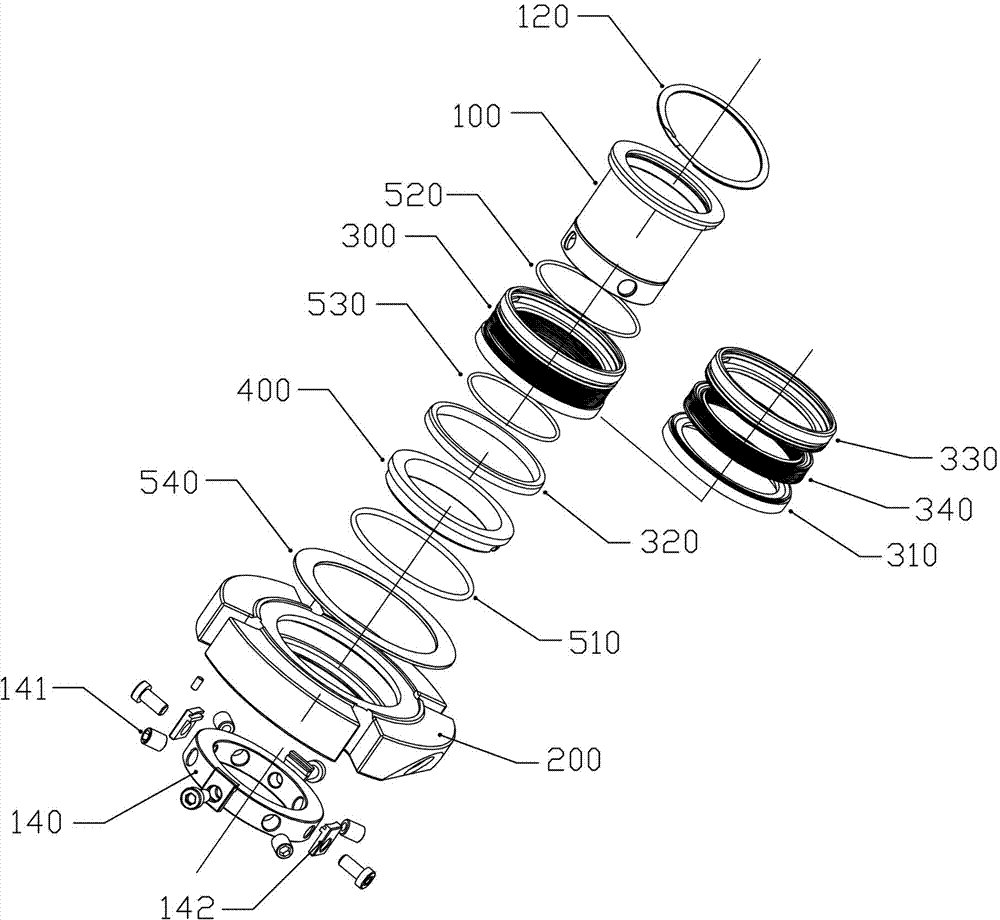

[0019] refer to figure 1 and figure 2 , a mechanical seal device for a narrow sealing cavity, including a shaft sleeve 100, a sealing gland 200, a moving ring assembly 300, a stationary ring 400 and an auxiliary seal.

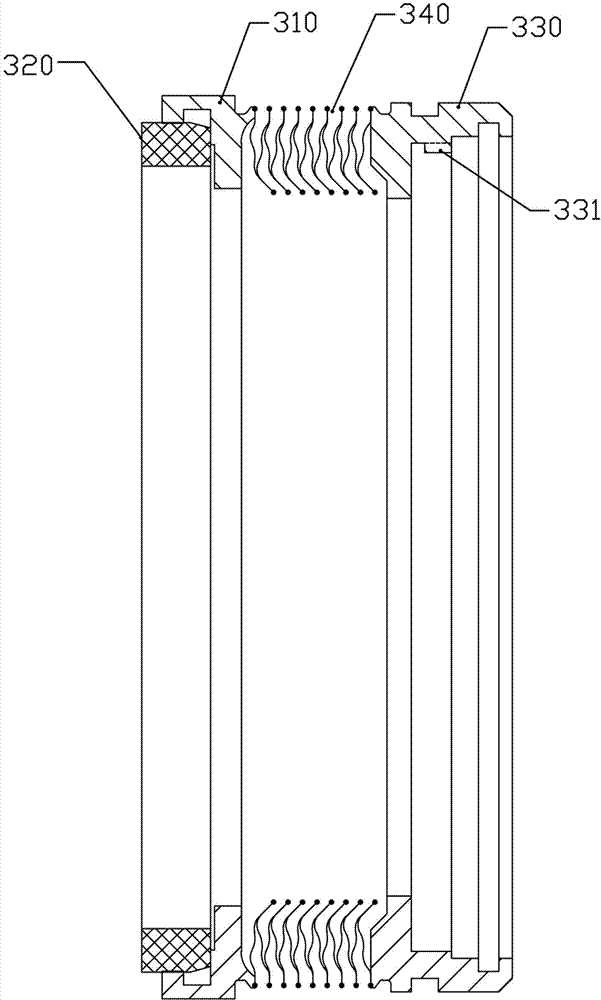

[0020] refer to image 3 The moving ring assembly 300 includes a ring base 310 , a moving ring 320 embedded in the ring base 310 , a base ring 330 , and a welded bellows 340 whose two ends are hermetically connected to the ring base 310 and the base ring 330 . The moving ring assembly 300 is a welded bellows assembly type, which can be used in modules. Compared with the single spring structure, the elastic compensation is balanced and stable; and the moving ring assembly 300 is axially flattened, with a small radial dimension, and is suitable for sealing shafts to A structure with insufficient inner diameter space at the seal cavity.

[0021] refer to Figure 4 The welded bellows 340 includes a protruding piece 341 and a concave piece 342, both of which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com