An eccentric ball valve

An eccentric ball and valve seat technology, applied in the field of eccentric ball valves, can solve the problems of sealing failure, reduced sealing strength, and high installation accuracy requirements, and achieve the effects of high sealing strength, improved sealing accuracy, and reduced assembly difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

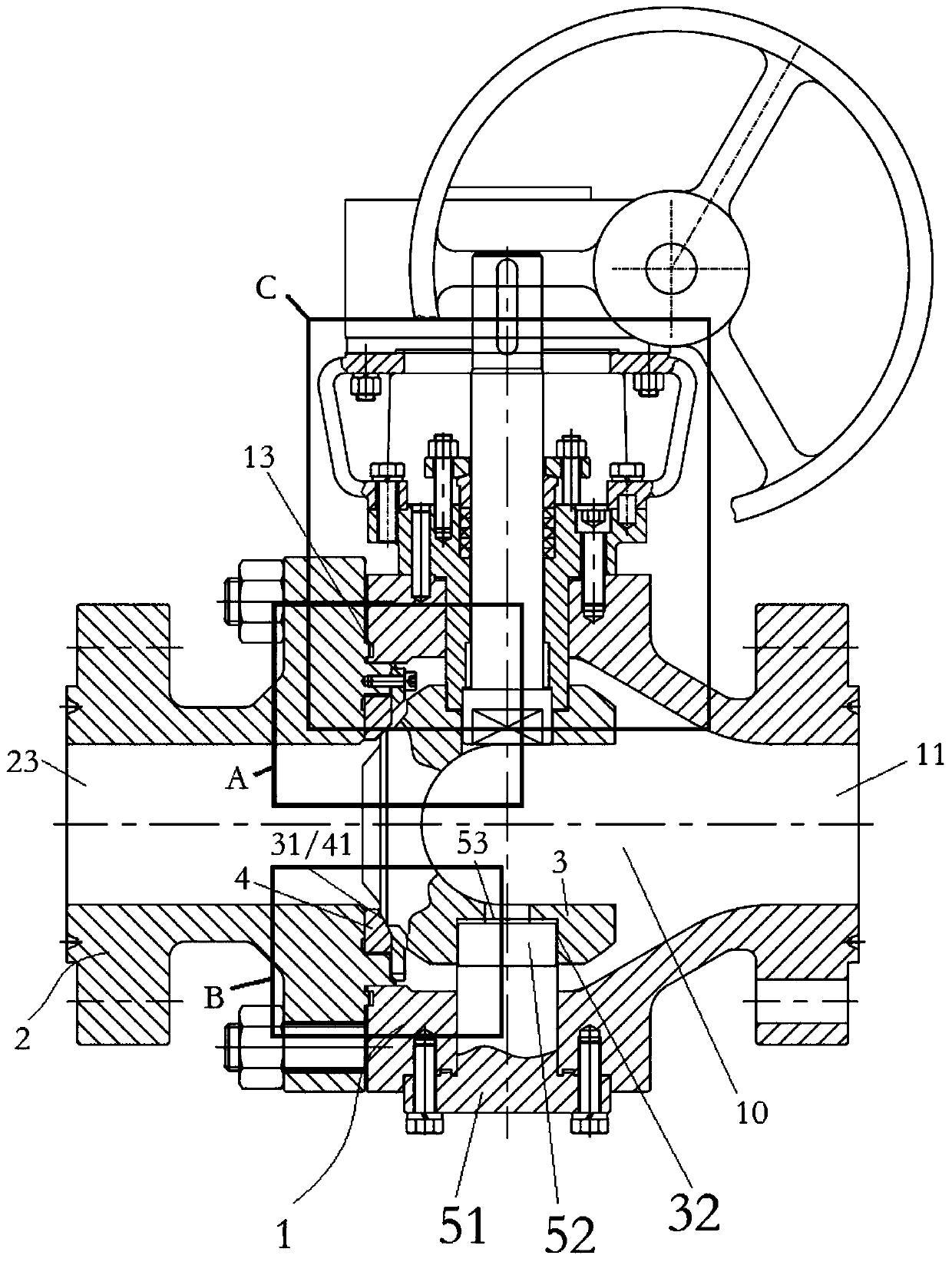

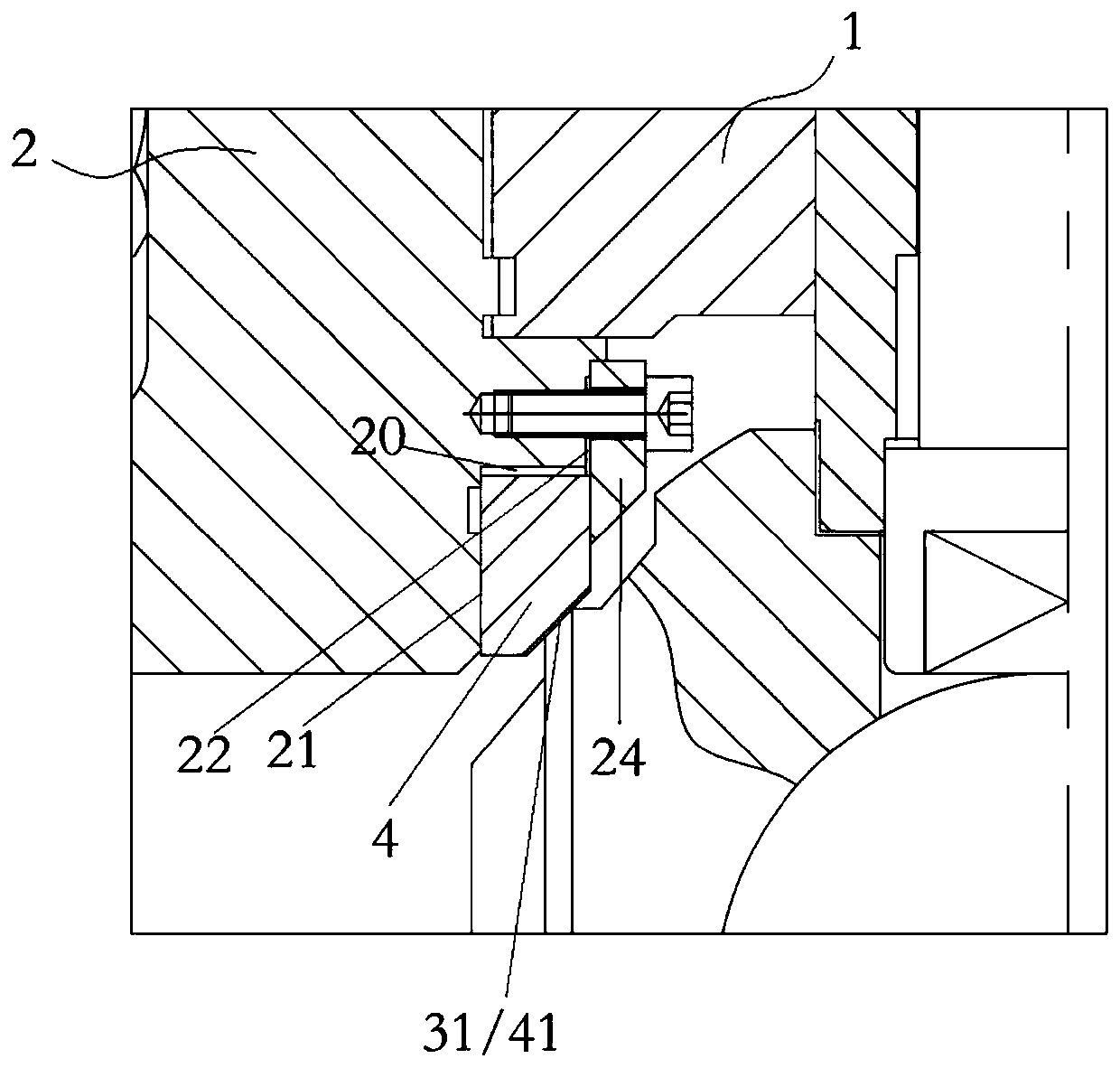

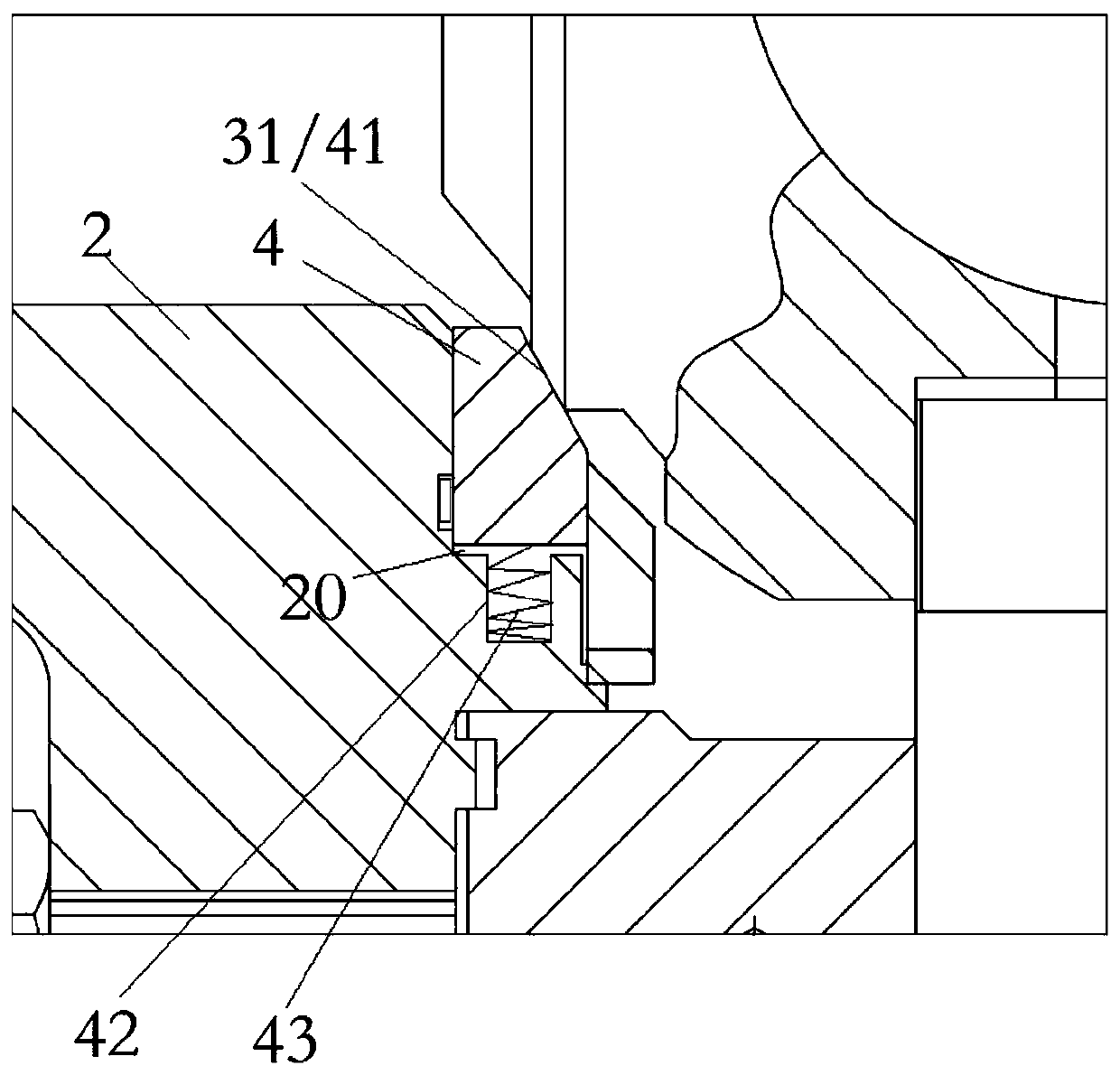

[0065] This embodiment provides an eccentric ball valve, such as figure 1 As shown, it includes: a valve body 1 with a middle chamber 10 and a first fluid passage 11 communicating with the middle chamber 10; a valve cover 2 detachably connected with the valve body 1 and with a second fluid passage 23 After the valve cover 2 is connected with the valve body 1, the second fluid channel 23 communicates with the middle chamber 10; the valve ball 3 is rotatably installed inside the middle chamber 10 through an operating mechanism, and has The valve ball sealing surface 31; the valve seat 4, installed on the valve cover 2, has a valve seat sealing surface 41 that can be squeezed with the valve ball sealing surface 31 to seal the second fluid passage 23; The valve seat 4 is mounted on the valve cover 2 in a small movable manner through an adjustable mounting structure. Driven by the operating mechanism, the valve ball 3 rotates until the sealing surface 31 of the valve ball is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com