Three-phase flat wire motor stator and motor

A motor stator and flat wire technology, applied in the stator structure field of three-phase motors, to achieve the effects of improving welding reliability, reducing end height, and reducing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

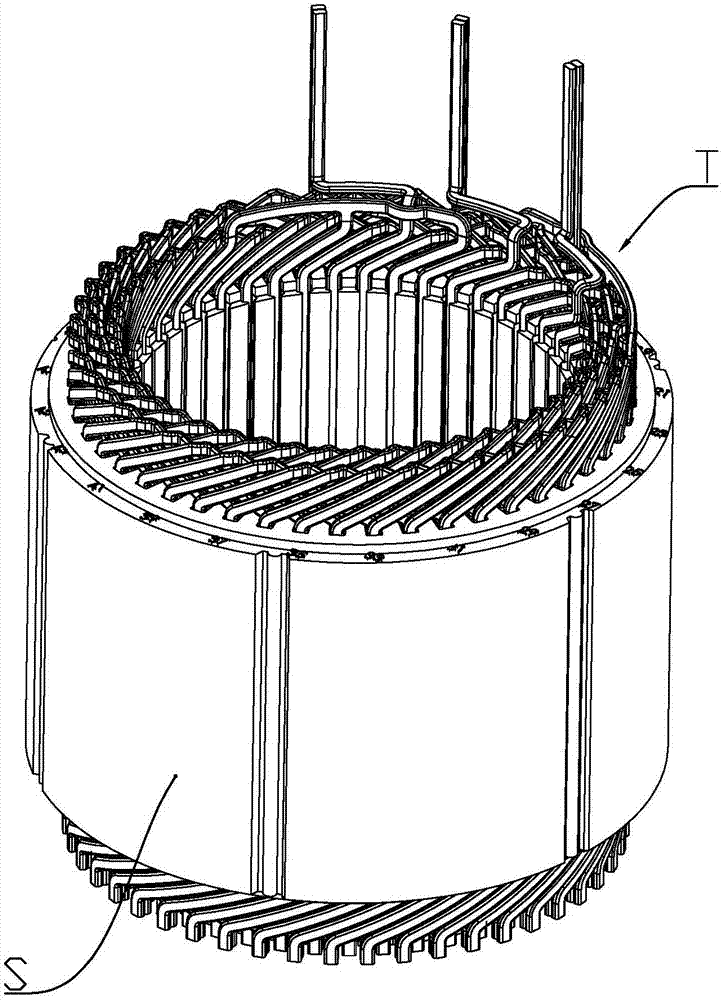

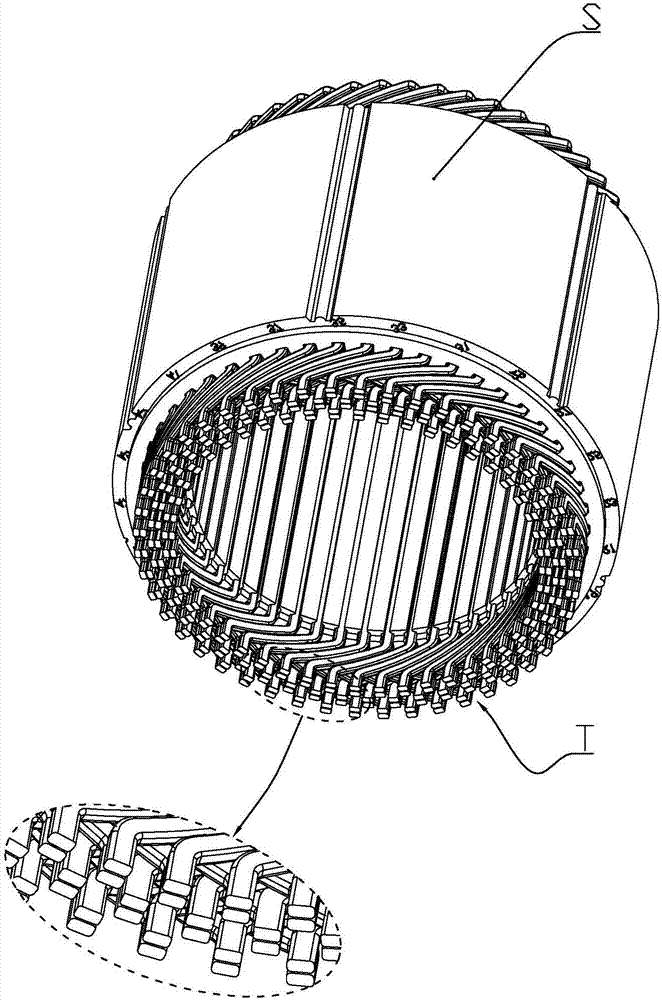

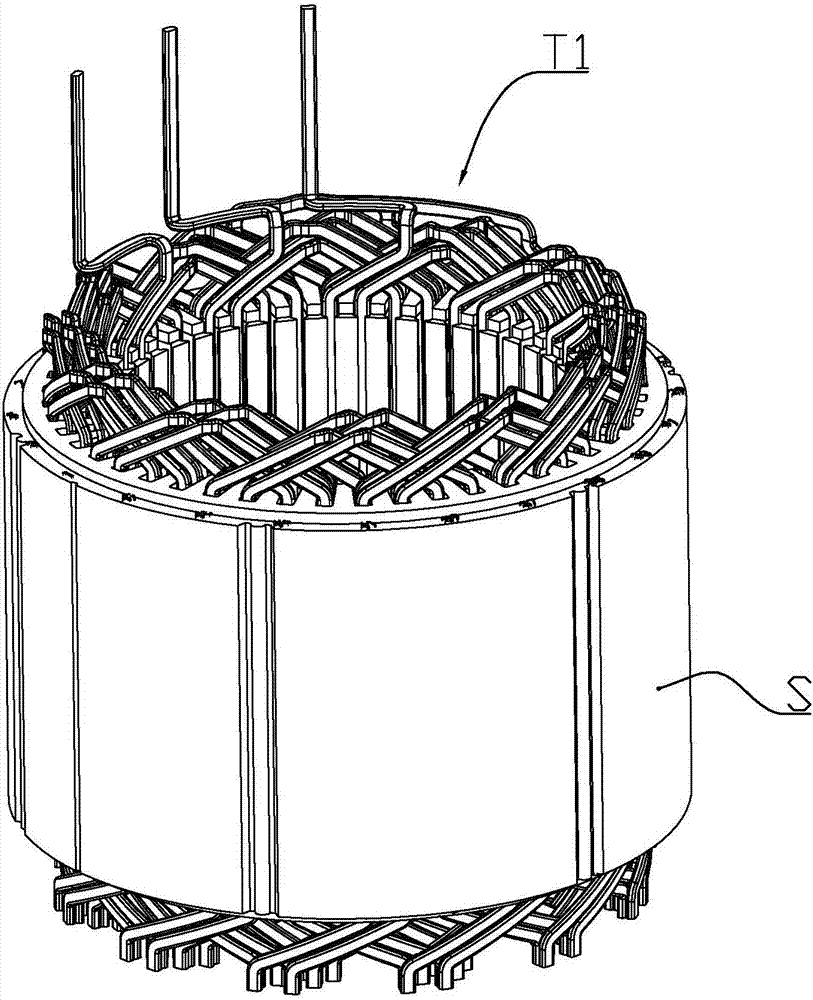

[0048] according to Figure 1 to Figure 12 As shown, the present embodiment provides a three-phase flat wire motor stator, which includes an annular stator core S and a stator winding T installed on the stator core.

[0049] The stator winding includes two winding units connected in parallel, including image 3 shown in the first winding unit T1 and Figure 4 The second winding unit T2 is shown. Each winding unit includes 3 phase windings T0 ( Figure 5 The phase winding shown is one of the phase windings in the second winding unit), each phase winding is composed of 23 guide bars connected end to end, and one end of each phase winding is connected with a lead wire, which belongs to the same winding unit The other ends of the three phase windings are connected by a neutral wire.

[0050] The inner wall of the stator core has 48 slots S1 equidistantly arranged along the circumference of the stator core for accommodating the stator windings, and the openings of each slot fac...

Embodiment 2

[0071] This embodiment provides a three-phase flat wire motor, including the stator of Embodiment 1 and a rotor located on the inner periphery of the stator and coaxially arranged with the stator; the stator is fixedly installed in the motor housing, and the rotor passes through the bearing installed in the motor housing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com