Patents

Literature

342results about How to "Improve welding reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

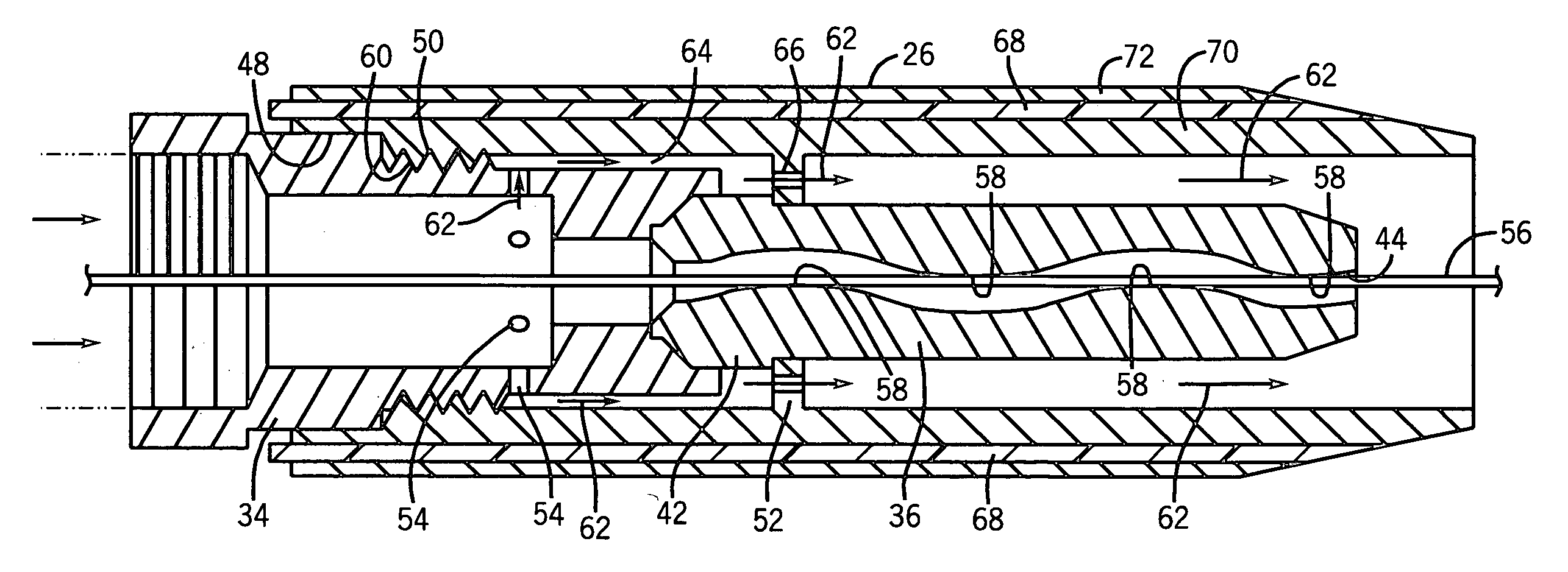

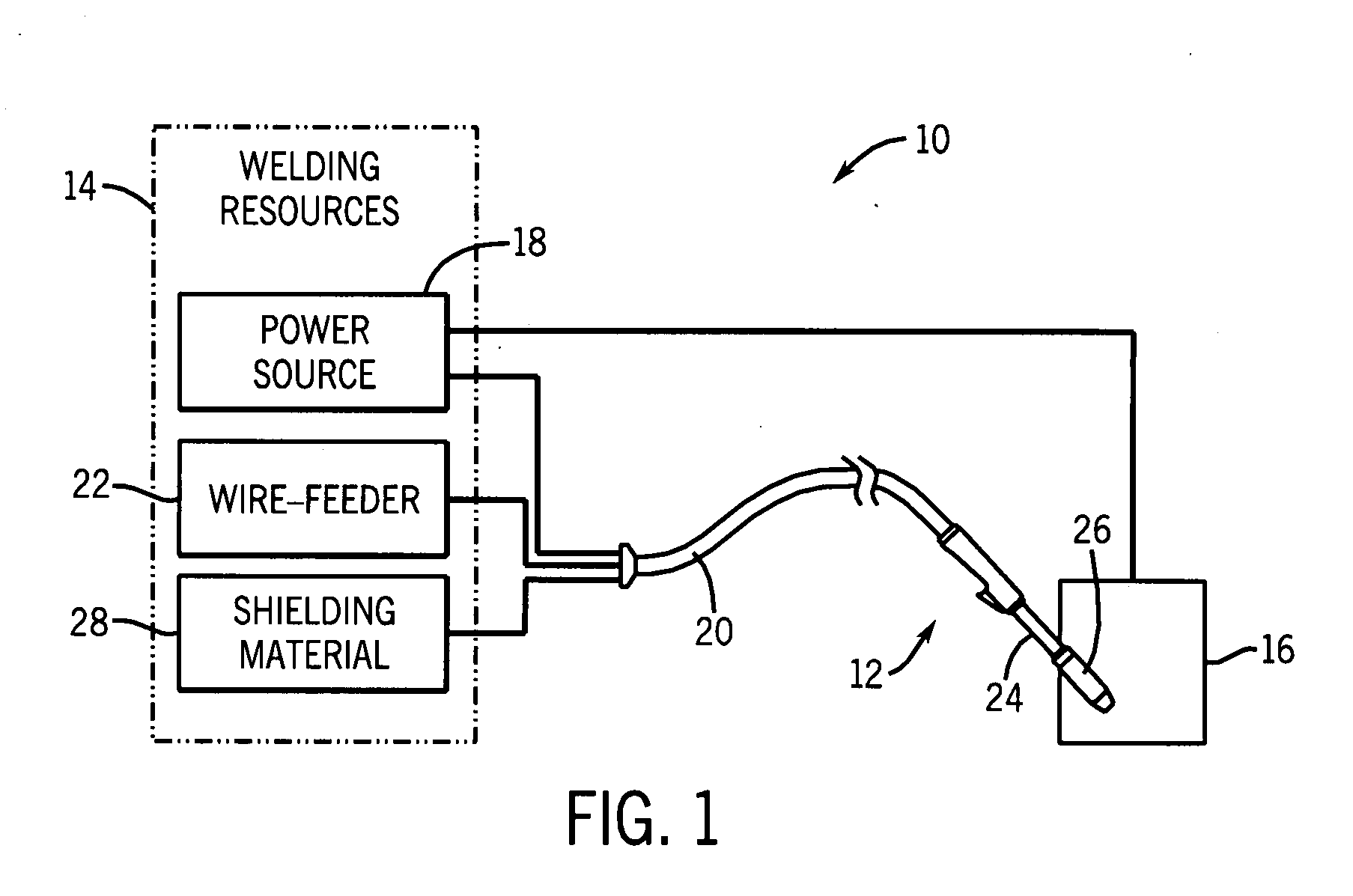

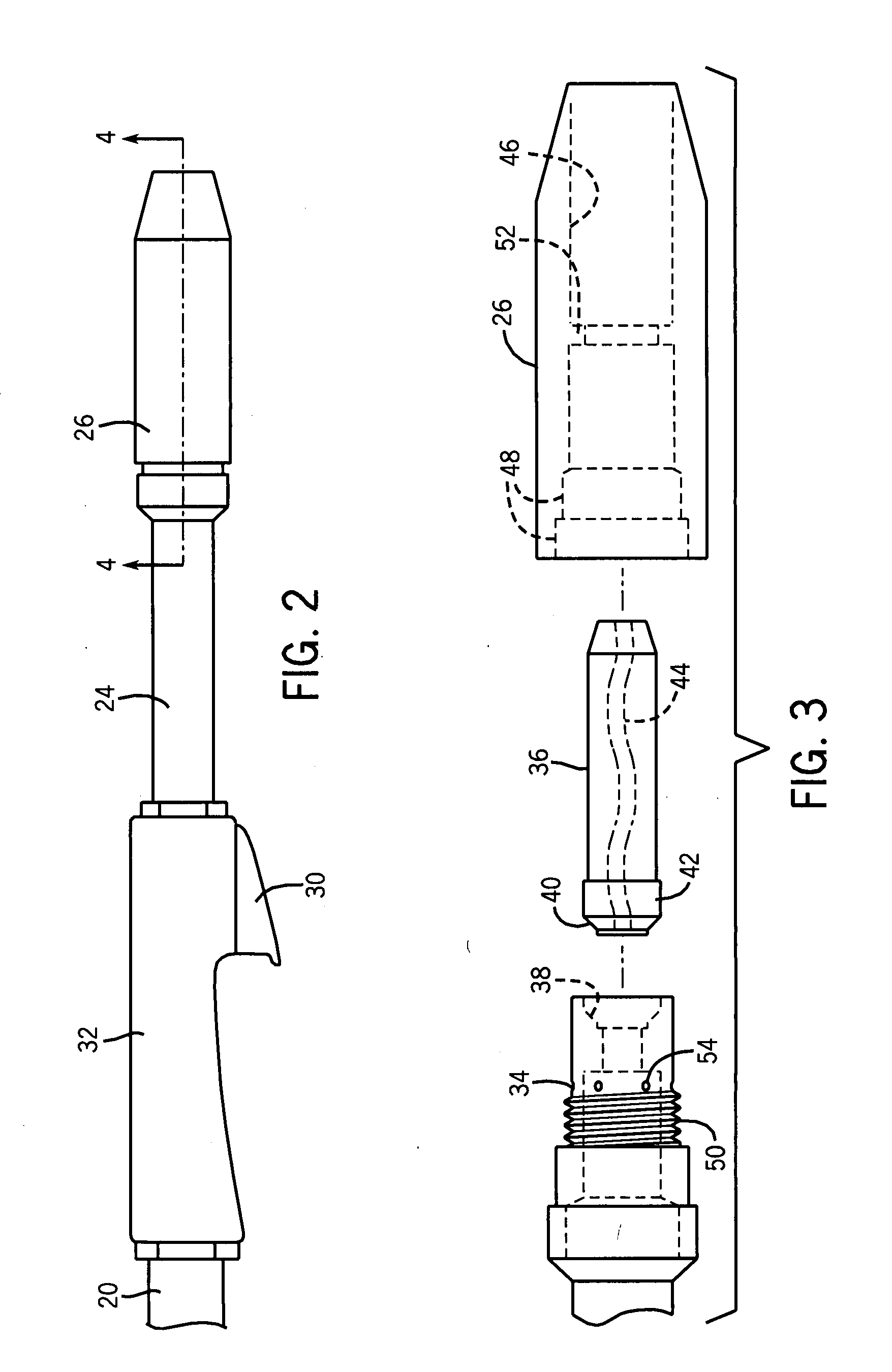

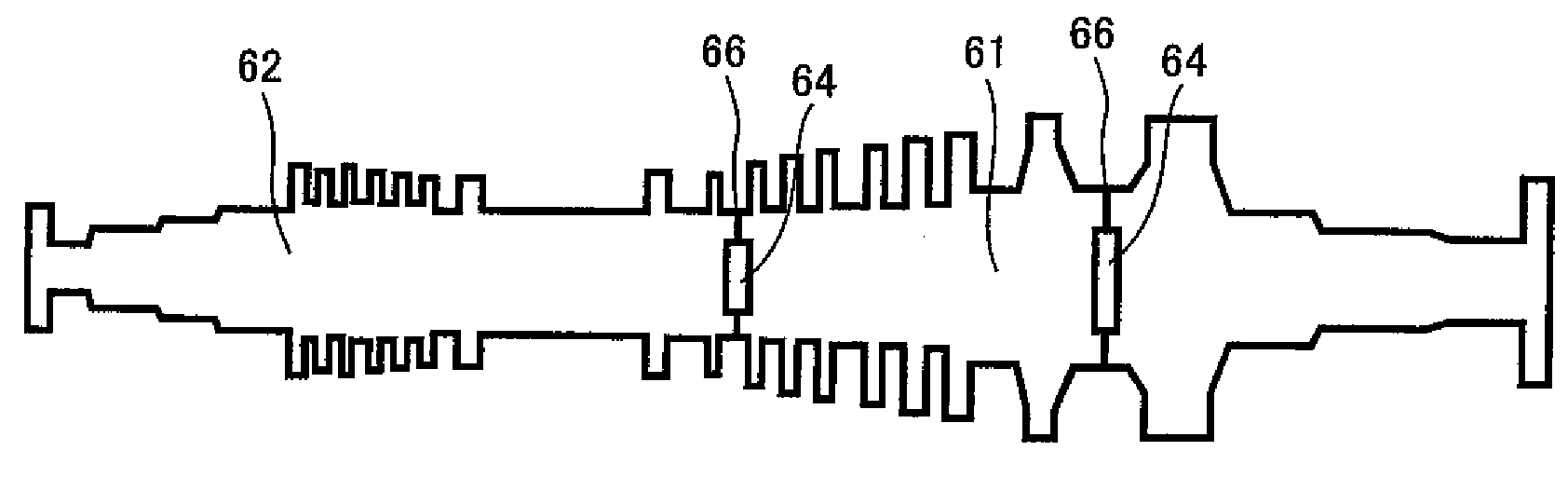

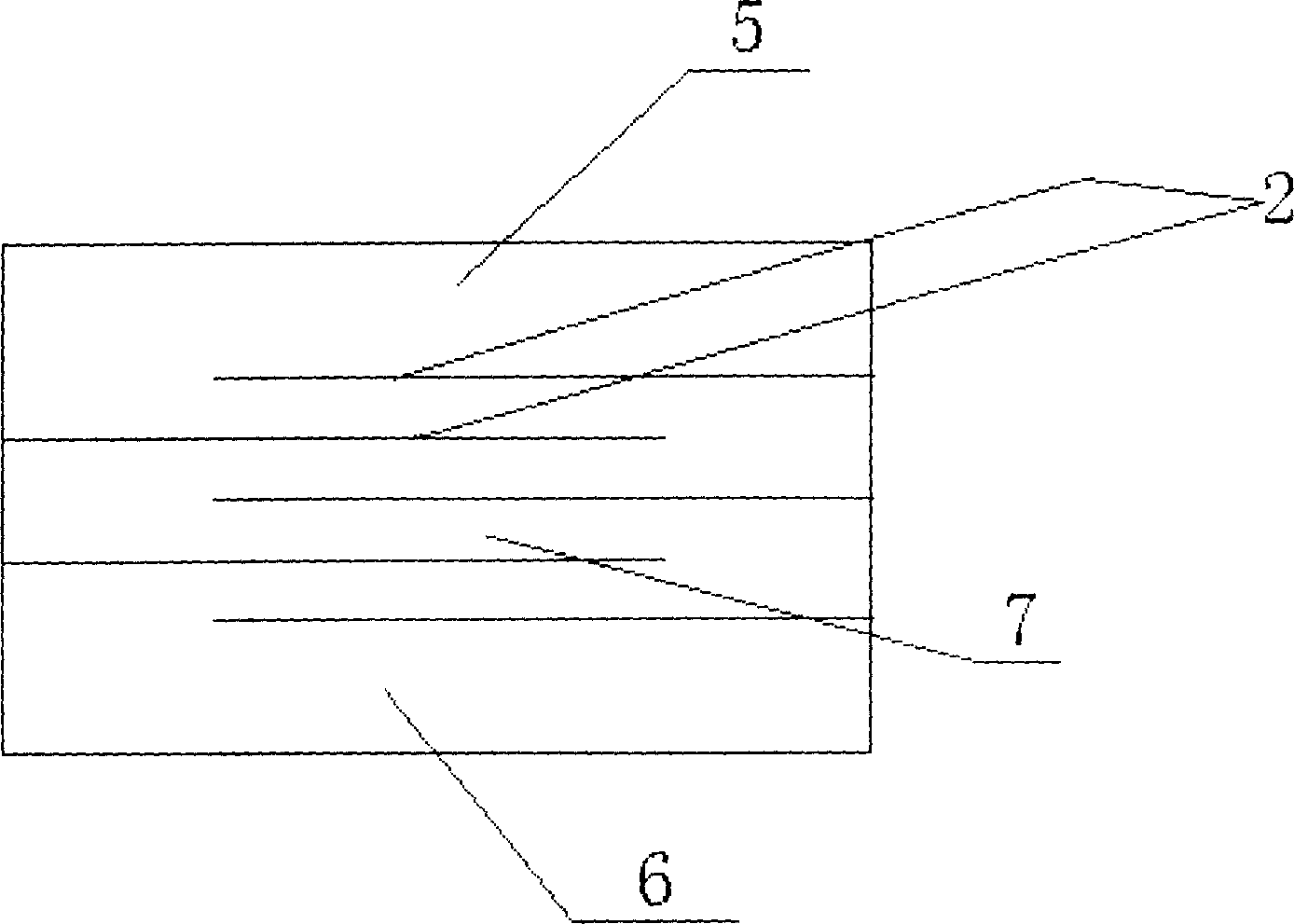

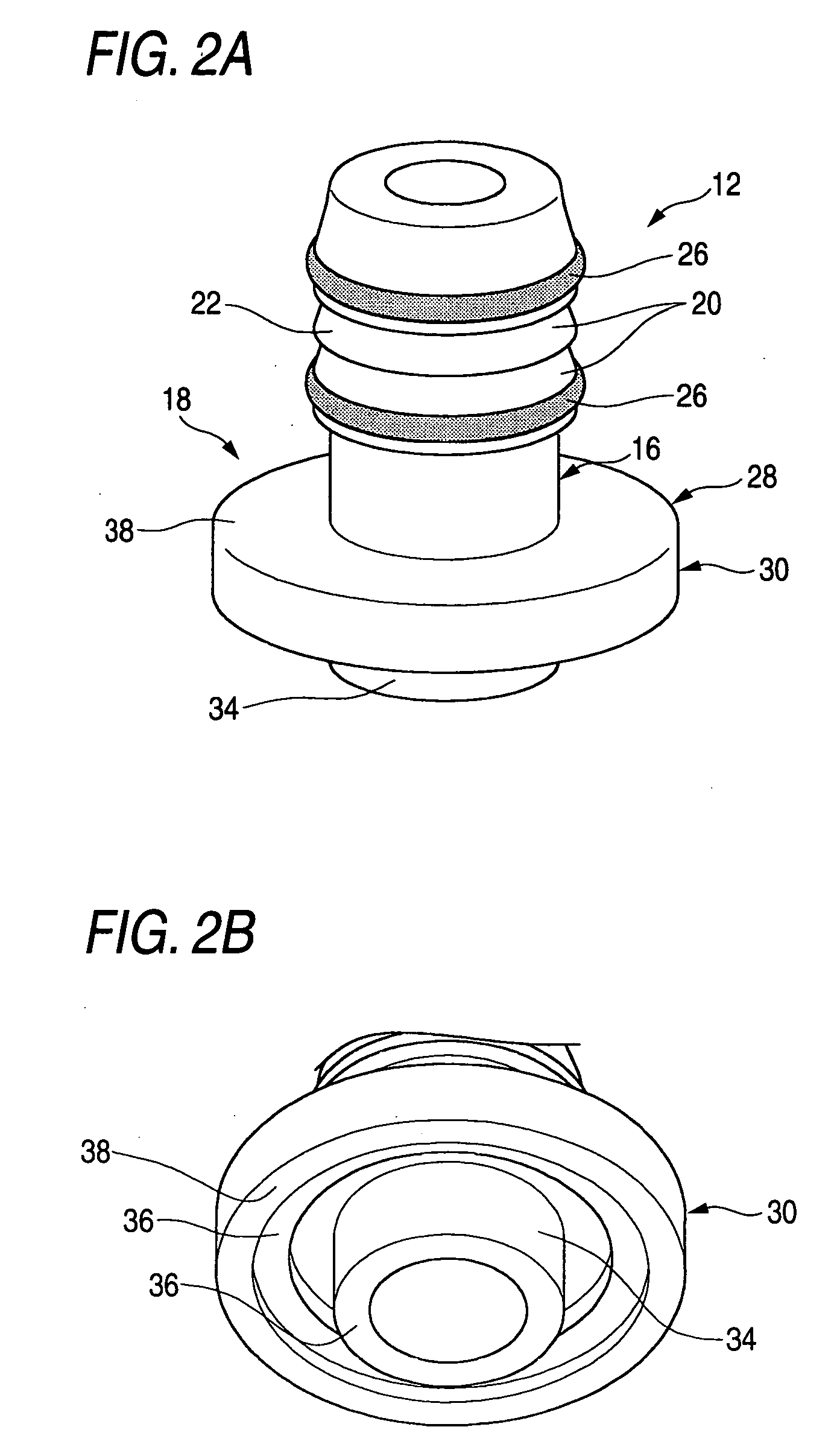

Contact tip and assembly

InactiveUS20080035623A1Extended contact lifeLow densityShielding gas supply/evacuation devicesElectrode supporting devicesManufacturing technologyConductive materials

A contact tip for a welding torch is provided. In one embodiment, the contact tip includes a body formed of an electrically conductive material and a non-linear passage that extends through the body. The non-linear passage of this embodiment is configured to receive a wire electrode and to facilitate electrical communication between the body and the wire electrode. Various contact tip assemblies and manufacturing techniques for forming contact tips are also provided.

Owner:ILLINOIS TOOL WORKS INC

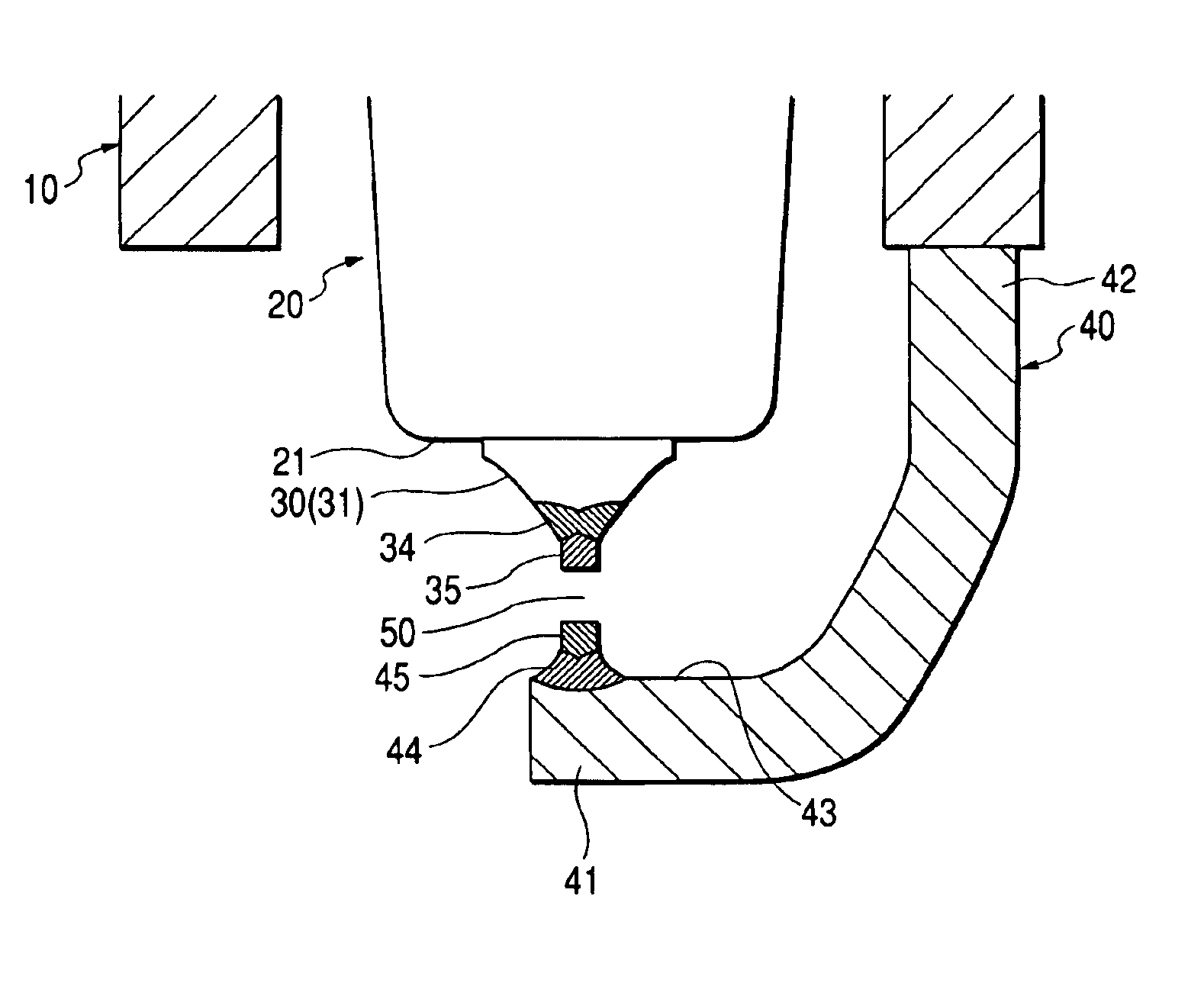

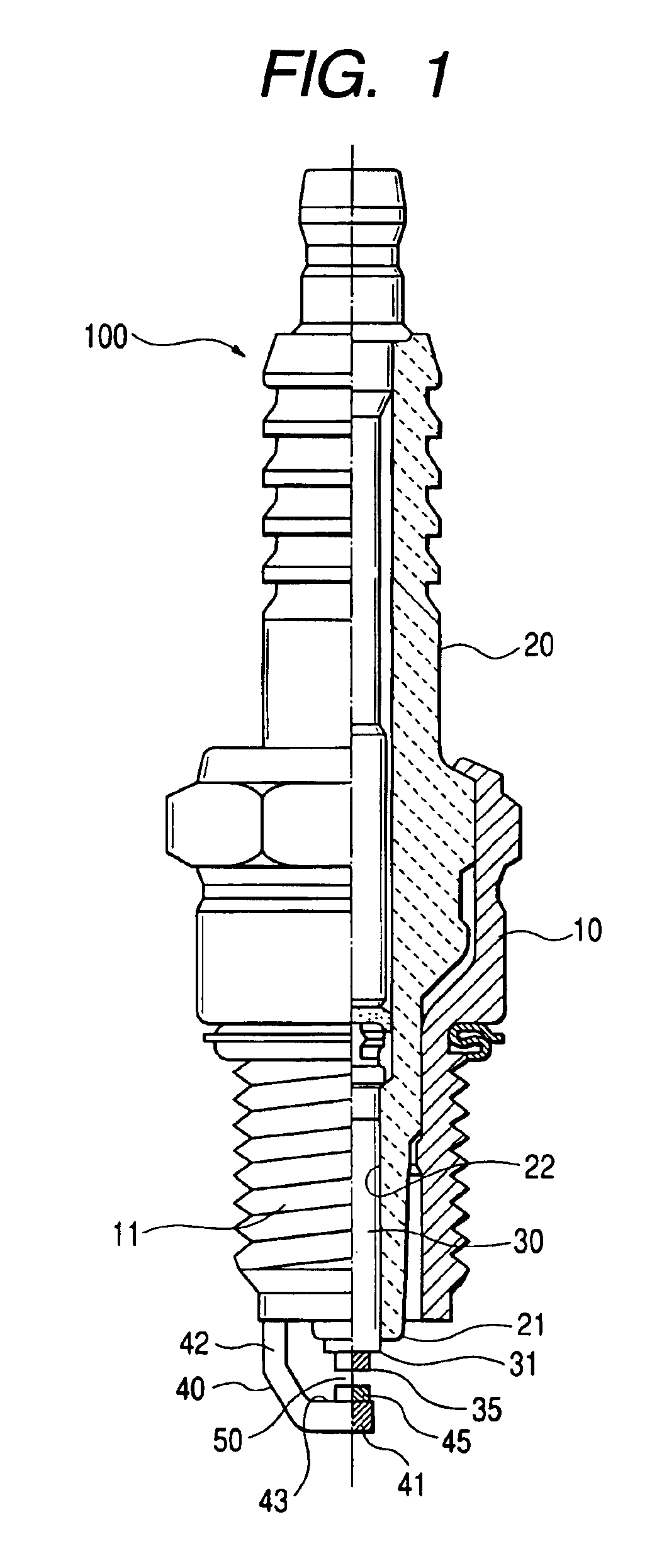

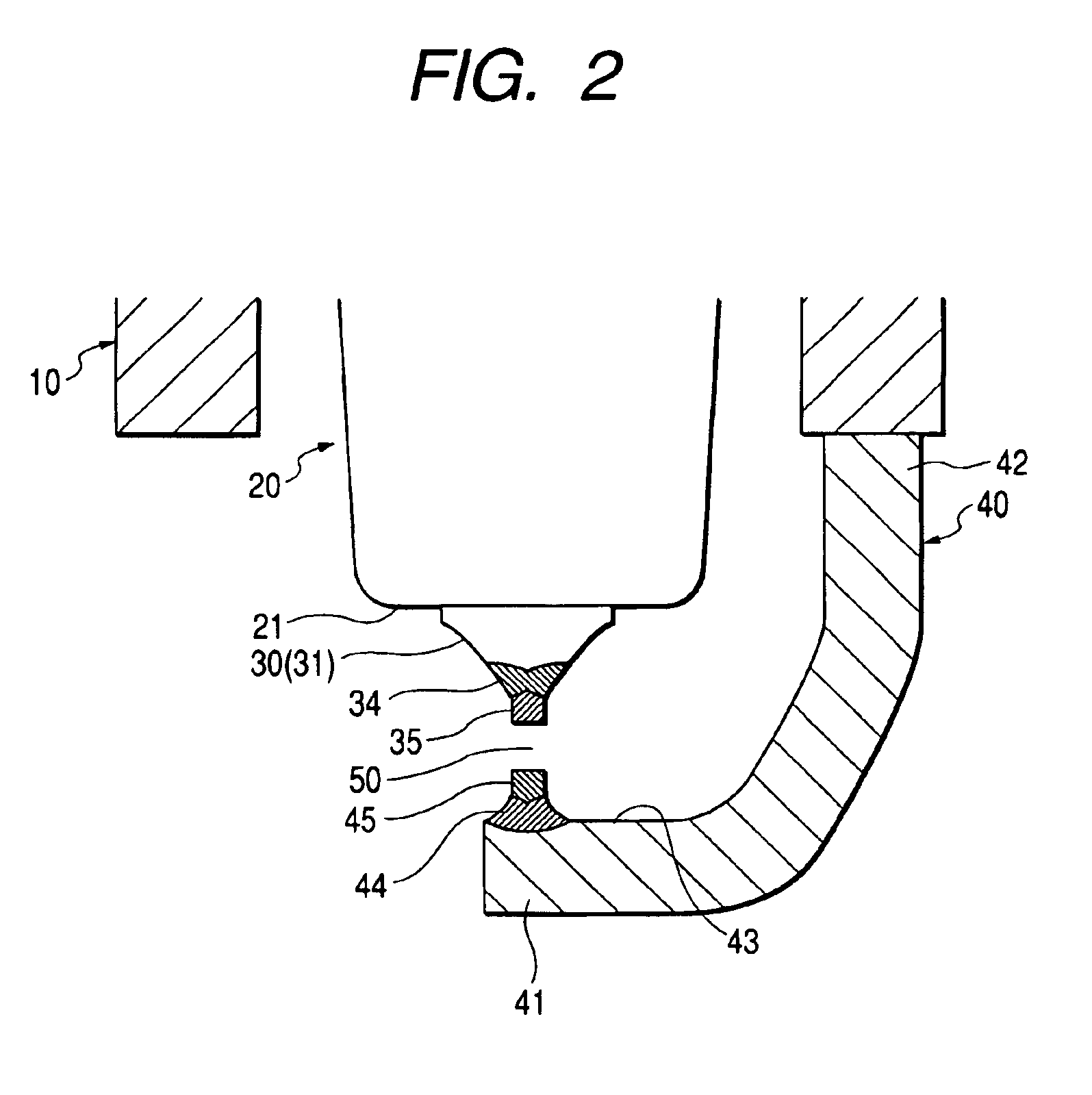

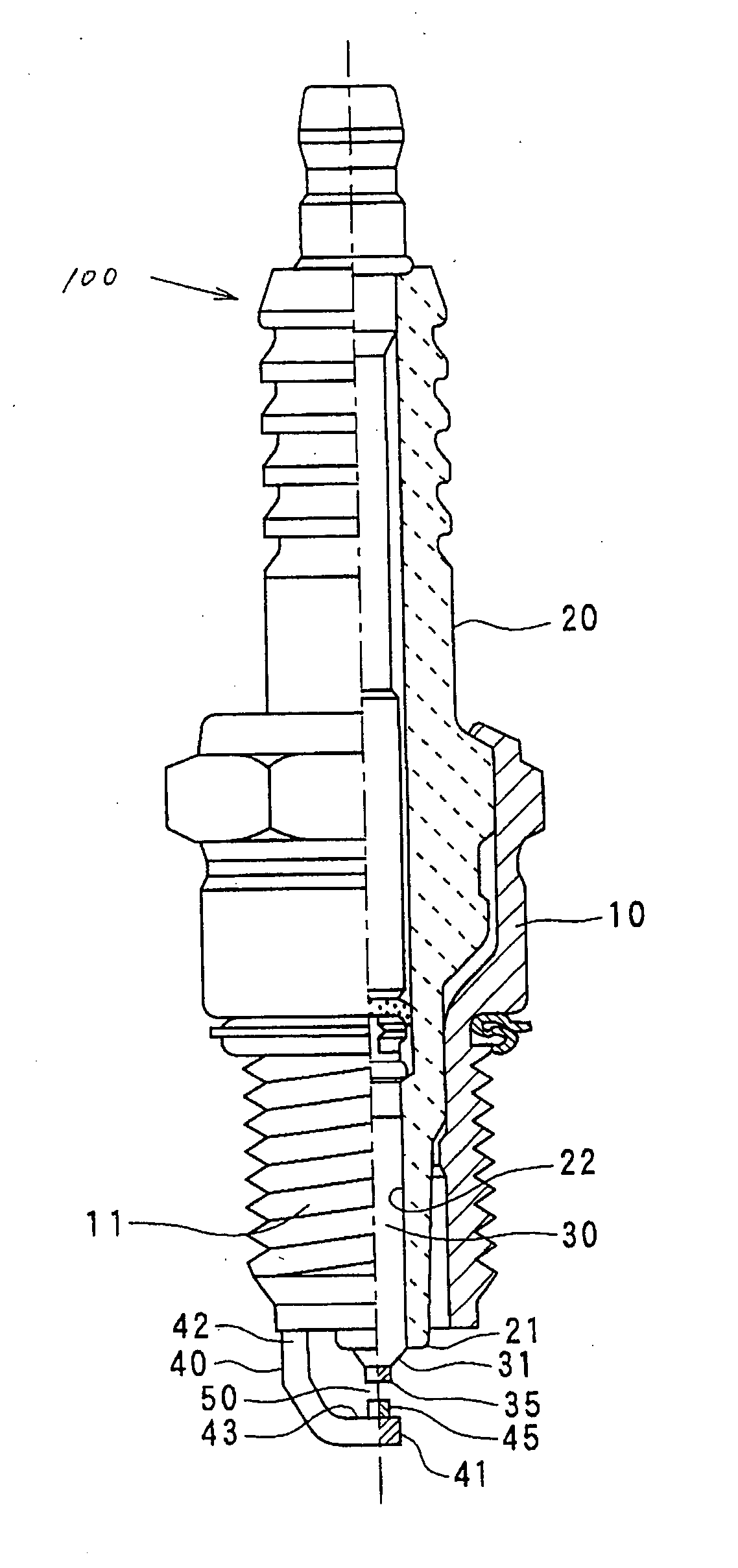

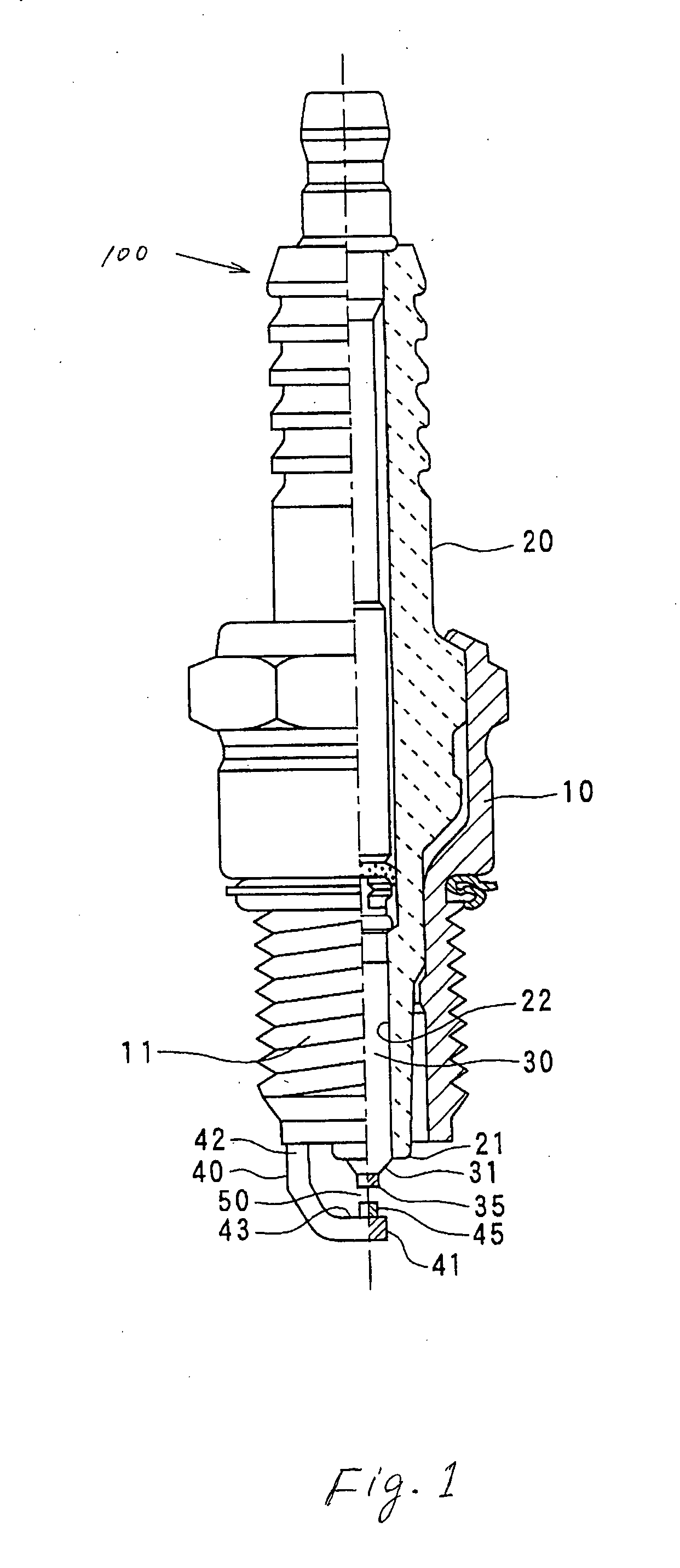

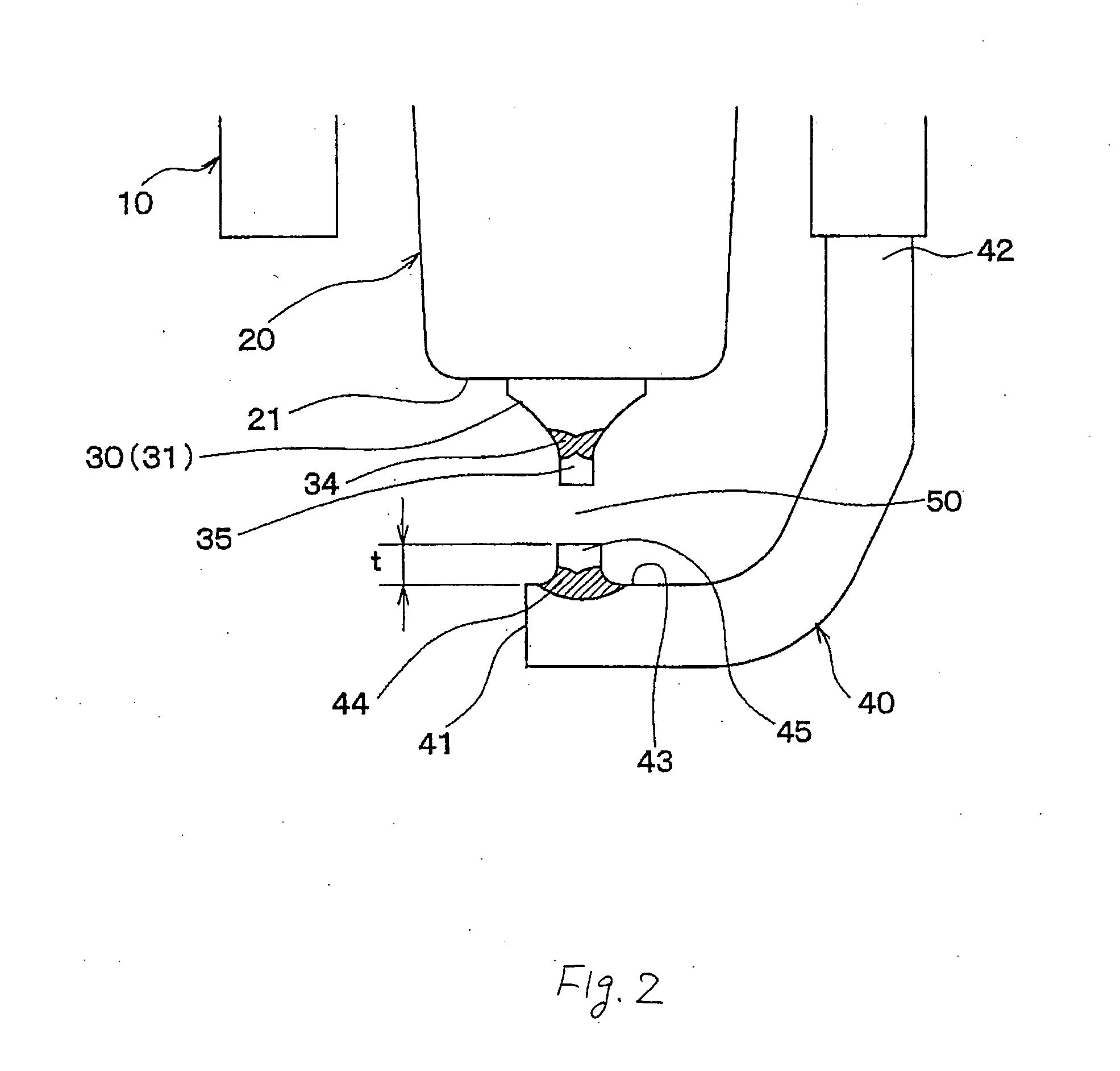

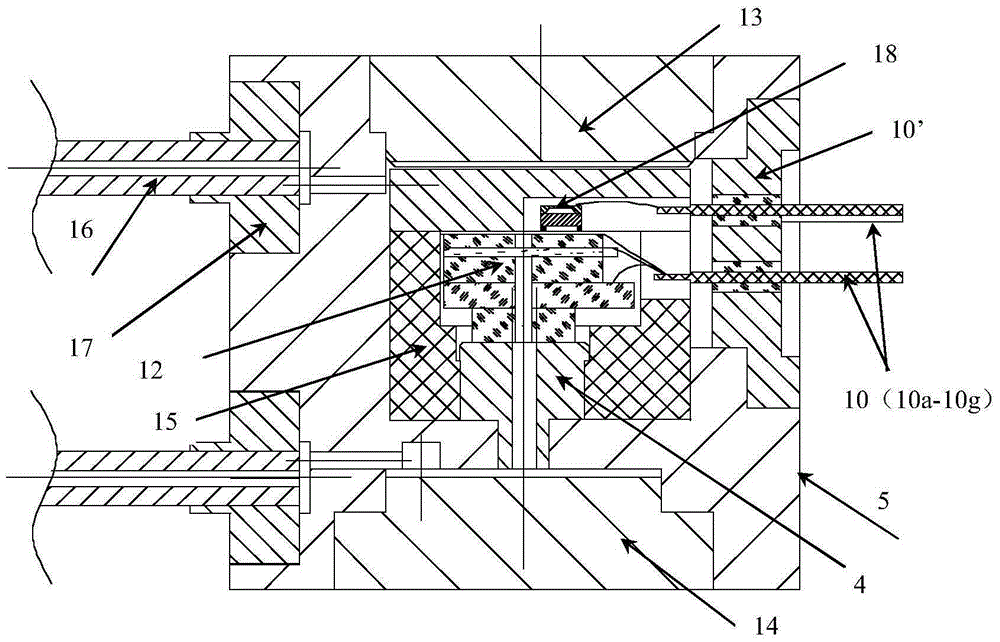

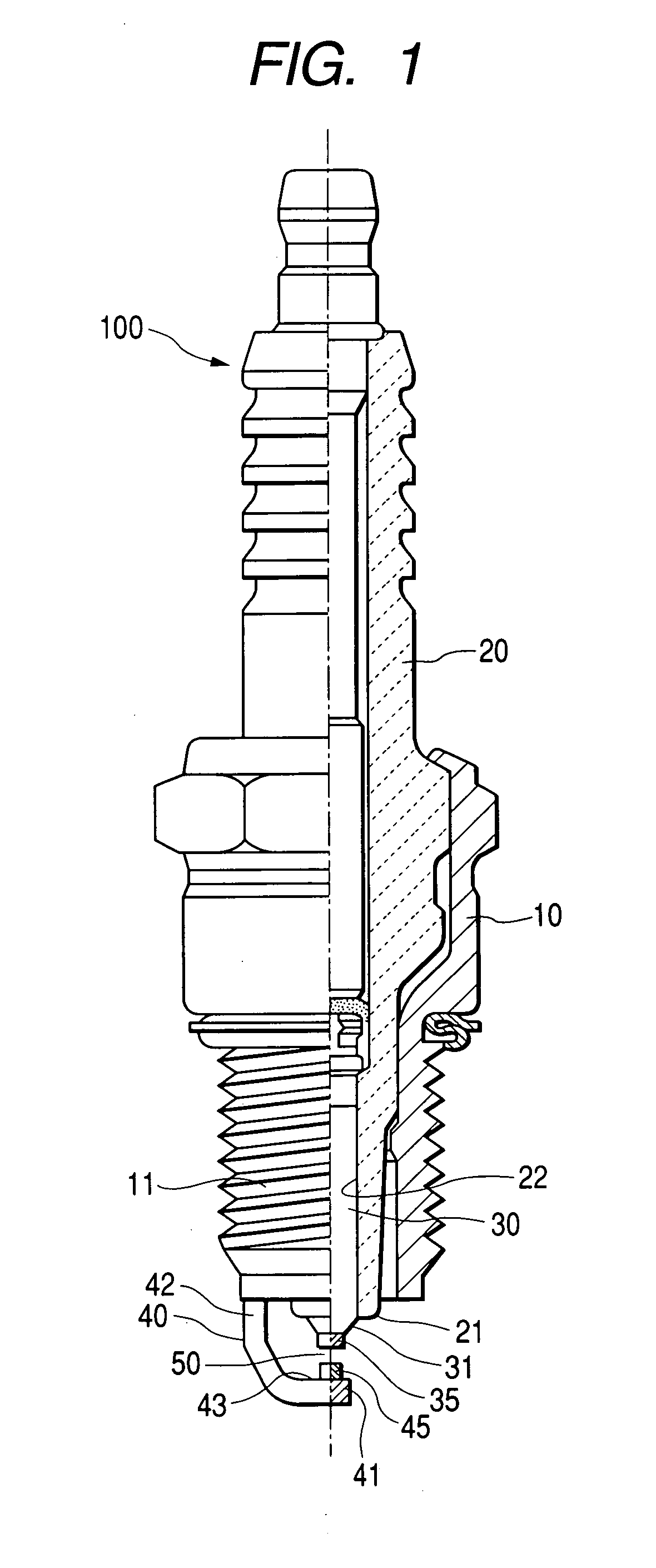

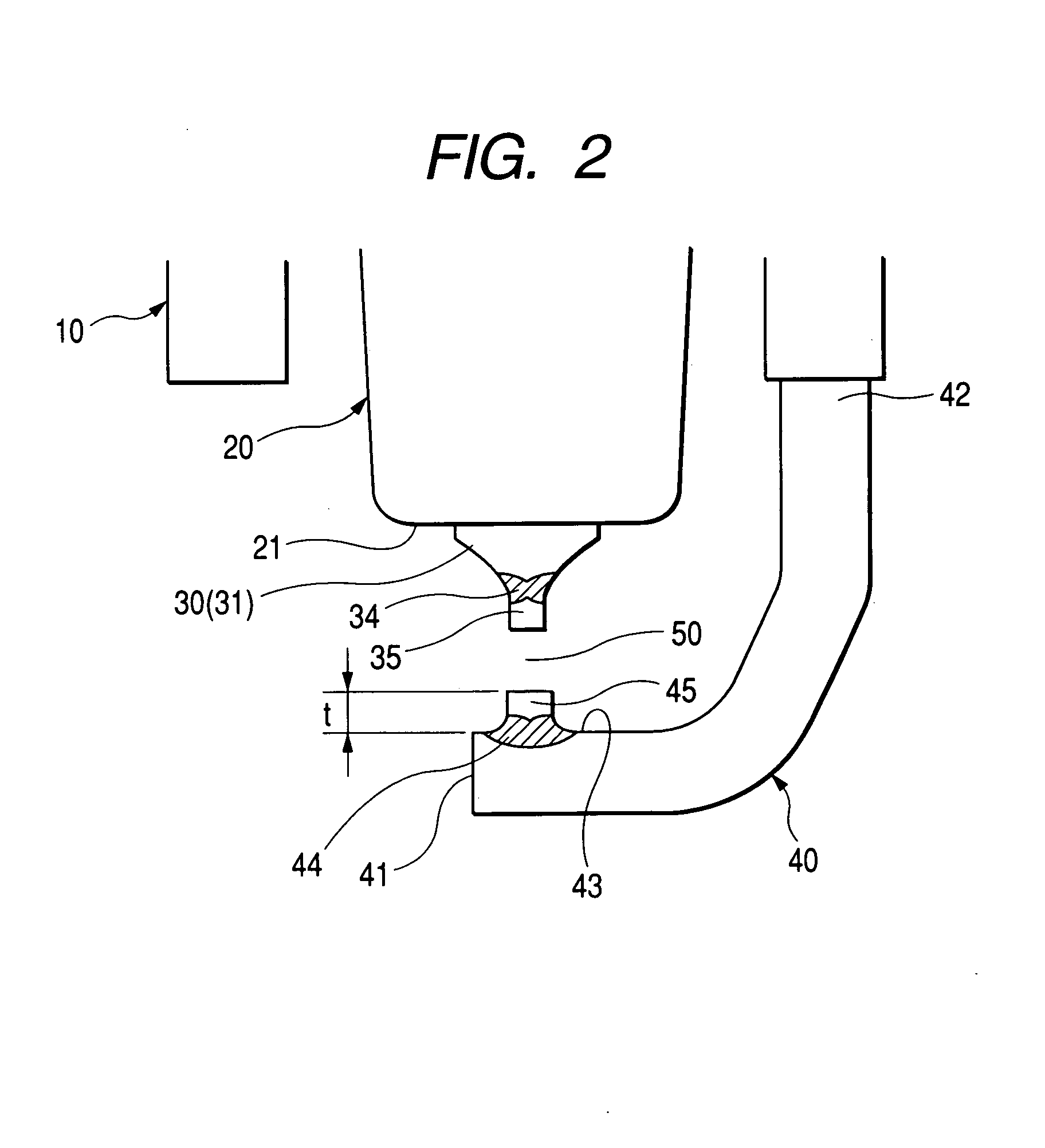

Structure of spark plug designed to provide higher durability and ignitability of fuel

InactiveUS6853116B2Improve welding reliabilityImprove flammabilitySpark gapsFuel injection apparatusMaximum depthEngineering

An improved structure of a spark plug which provides higher durability and ignitability of a gaseous fuel. The spark plug consists of a center electrode, a ground electrode, a noble metal chip joined to a center electrode-opposed surface of the ground electrode by laser welding, and a fused portion that forms a weld of the noble metal chip and the ground electrode formed by materials of the ground electrode and the noble metal chip melted together. A sectional area of the noble metal chip traversing a length thereof is between 0.1 mm2 and 0.6 mm2. An unfused sectional area percentage that is a percentage of a sectional area of an unfused portion of a joined end of the noble metal chip within a range of a sectional area of the noble metal chip closest to the fused portion traversing the length of the noble metal chip is less than or equal to 50%. A melt angle that is an angle which a line extending through the fused portion along a maximum depth of the fused portion makes with the center electrode-opposed surface of the ground electrode is less than or equal to 60°.

Owner:DENSO CORP

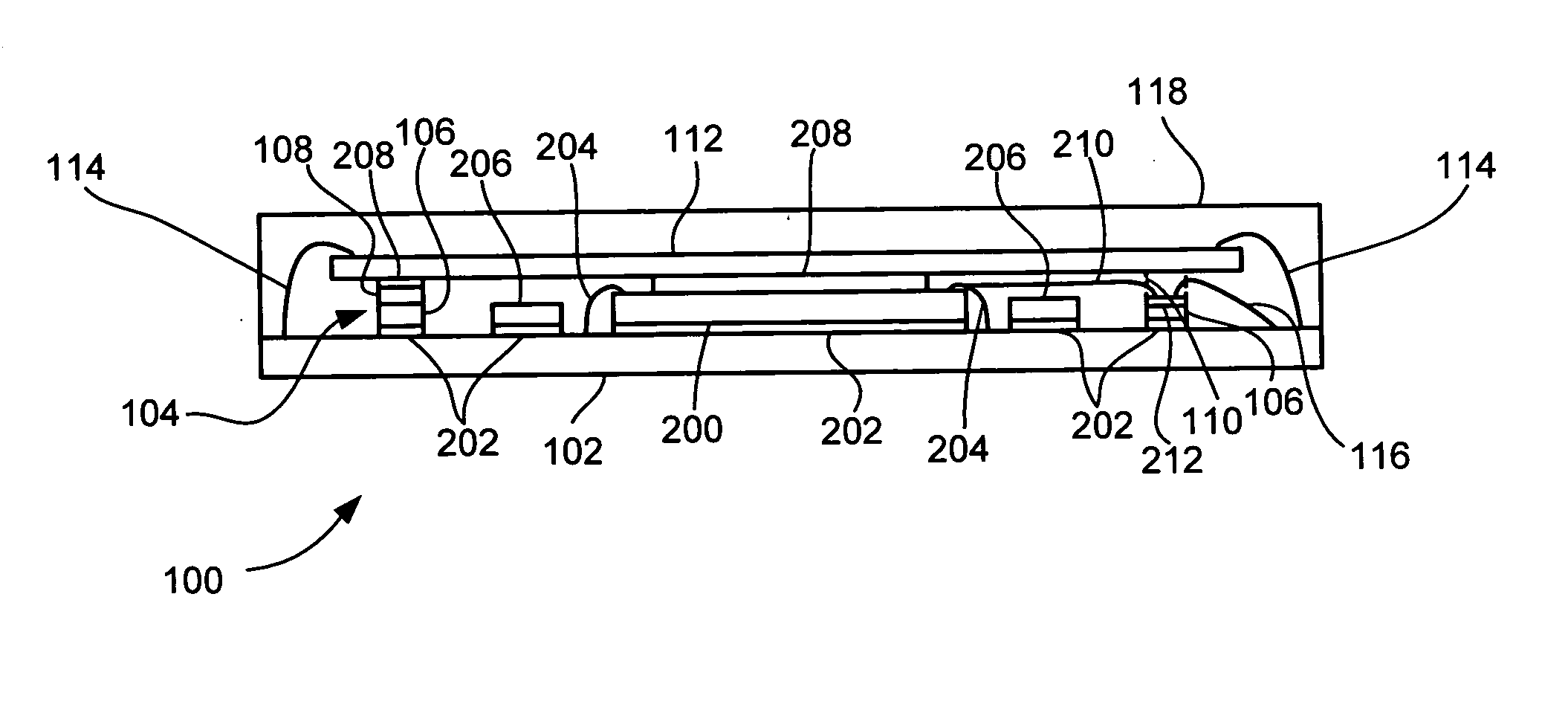

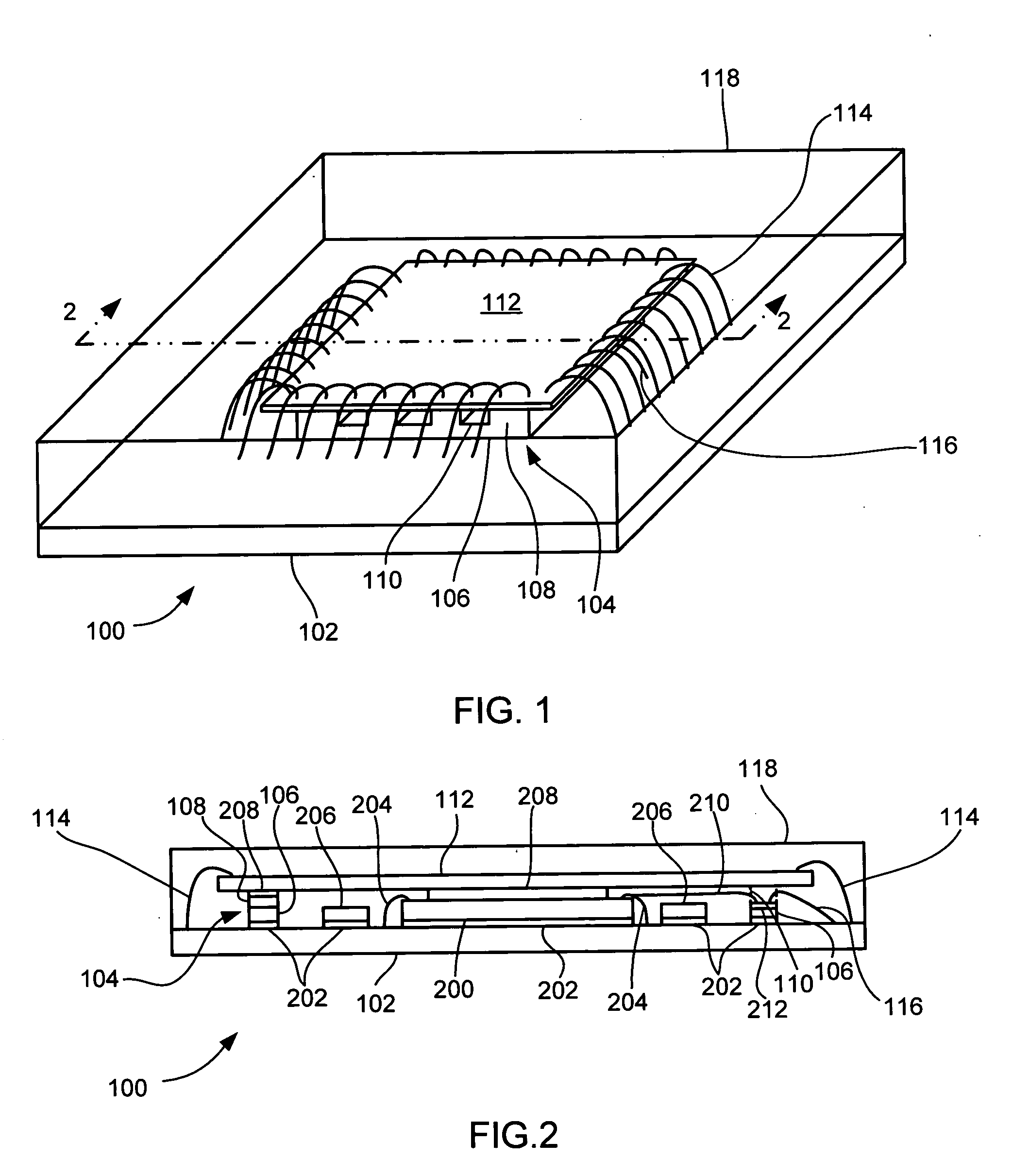

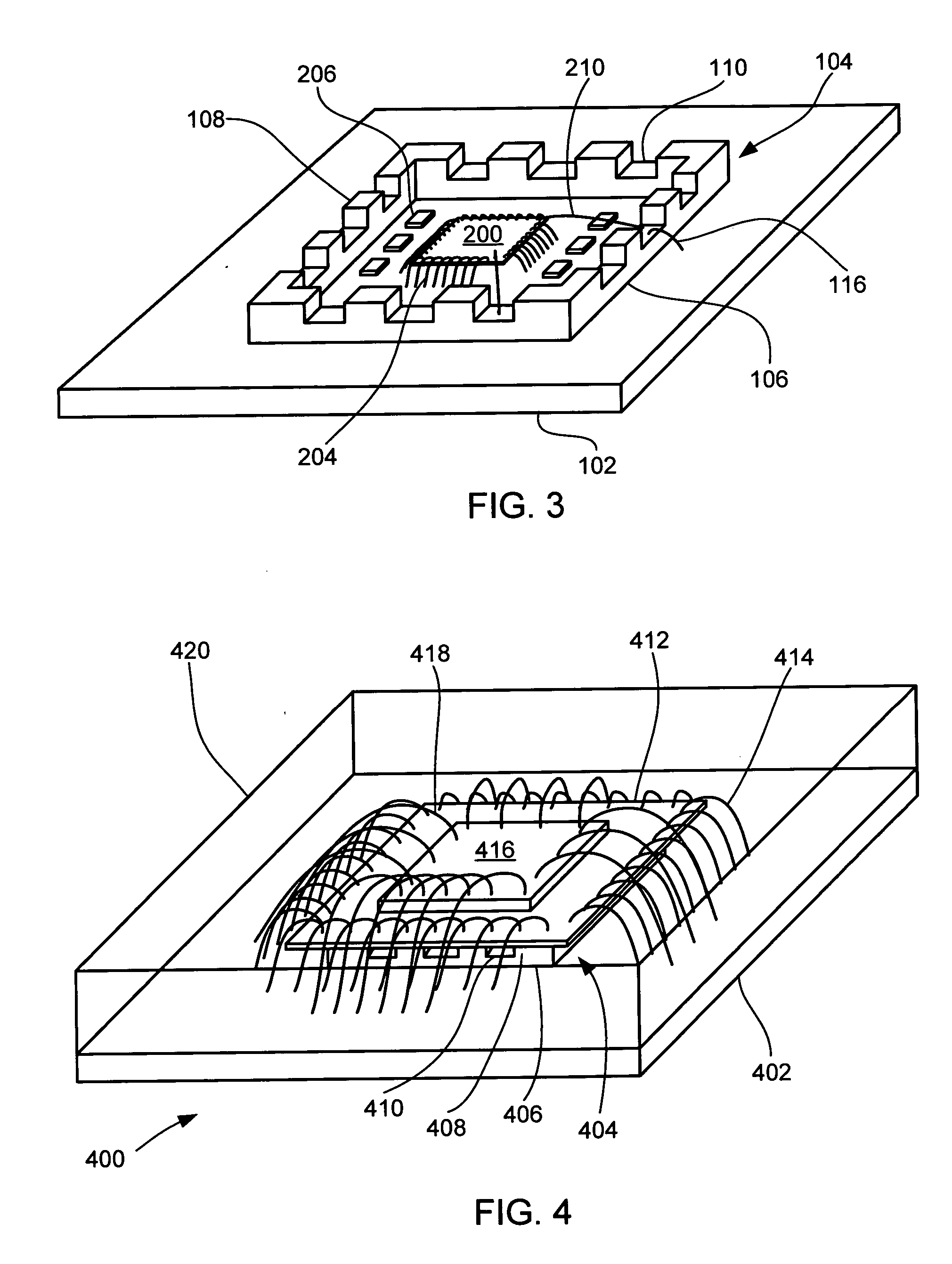

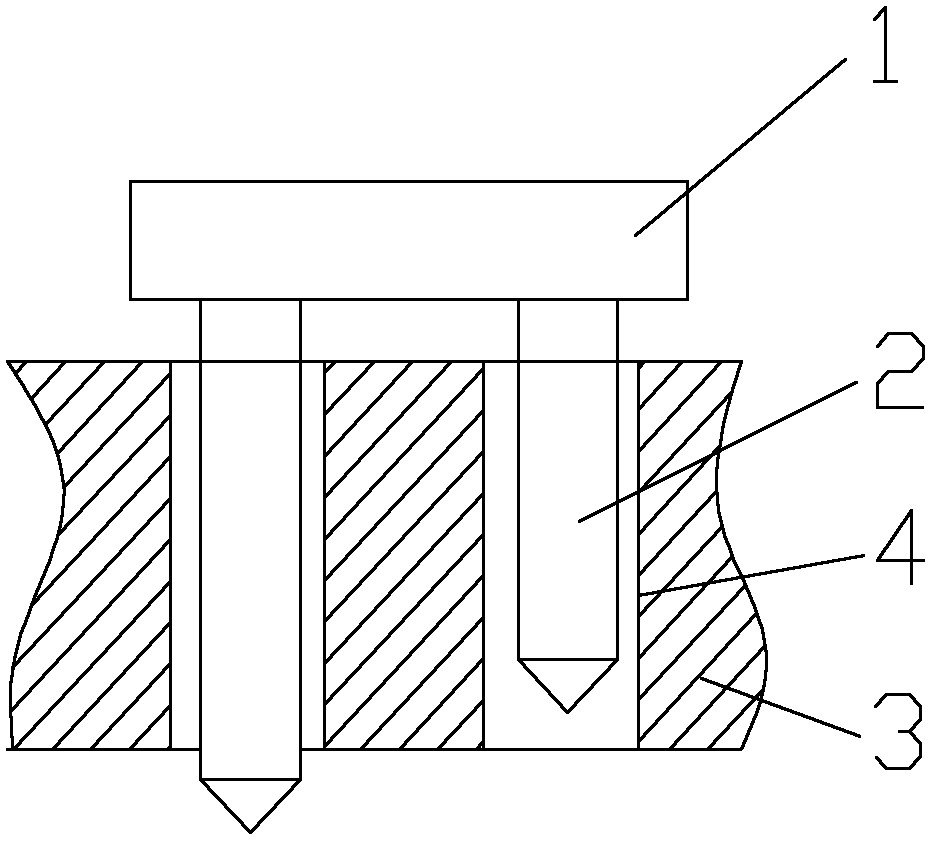

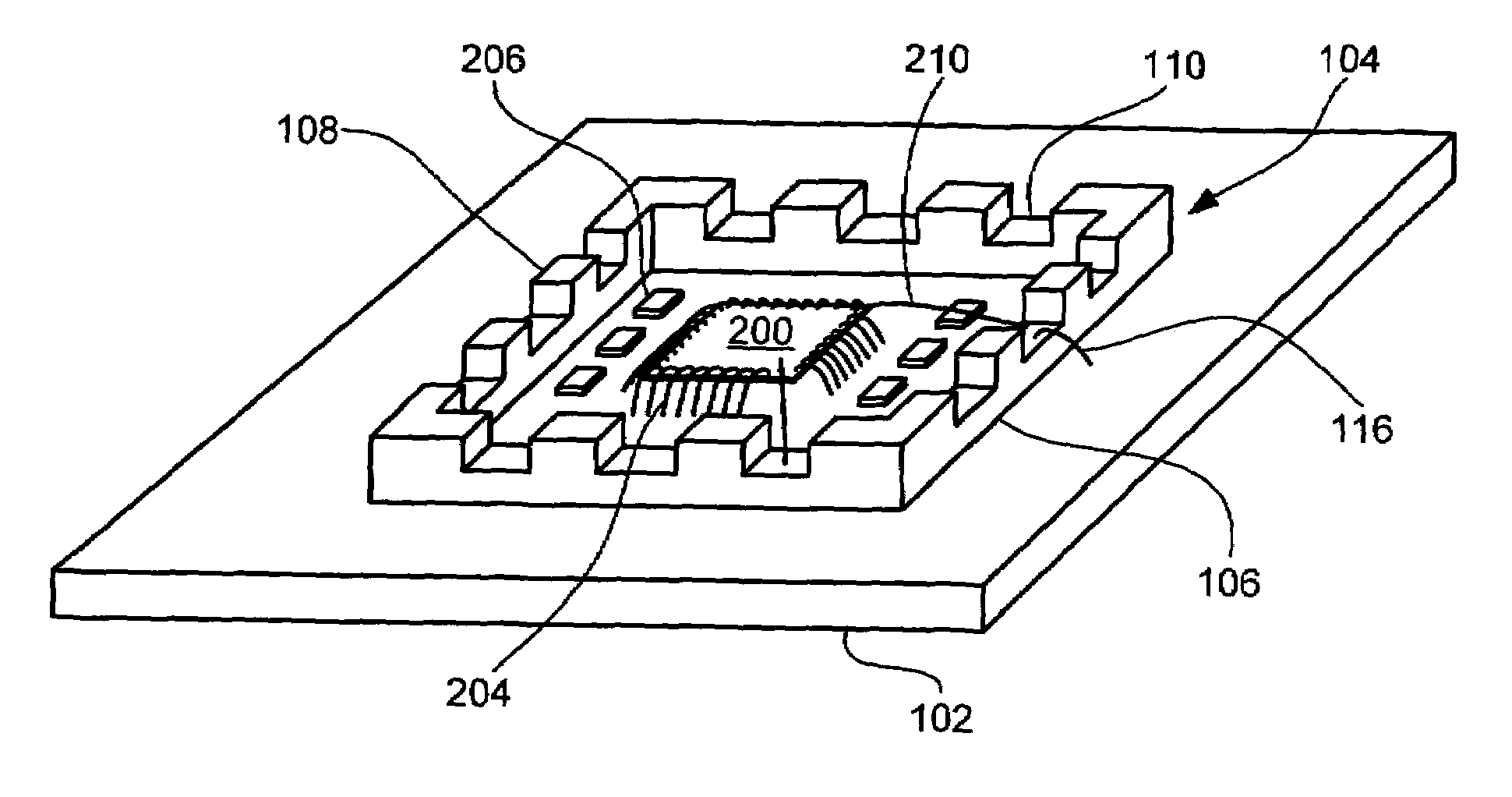

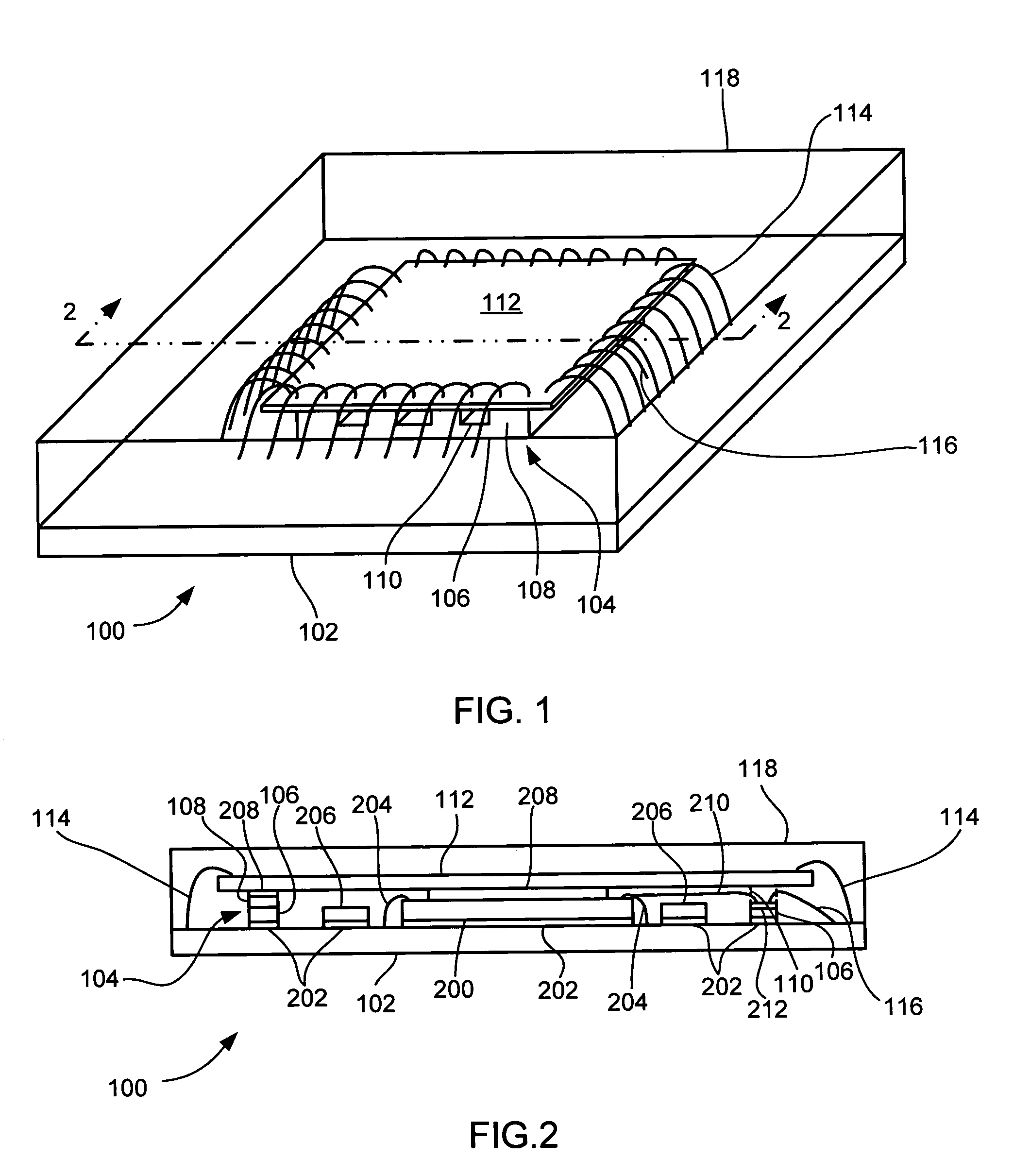

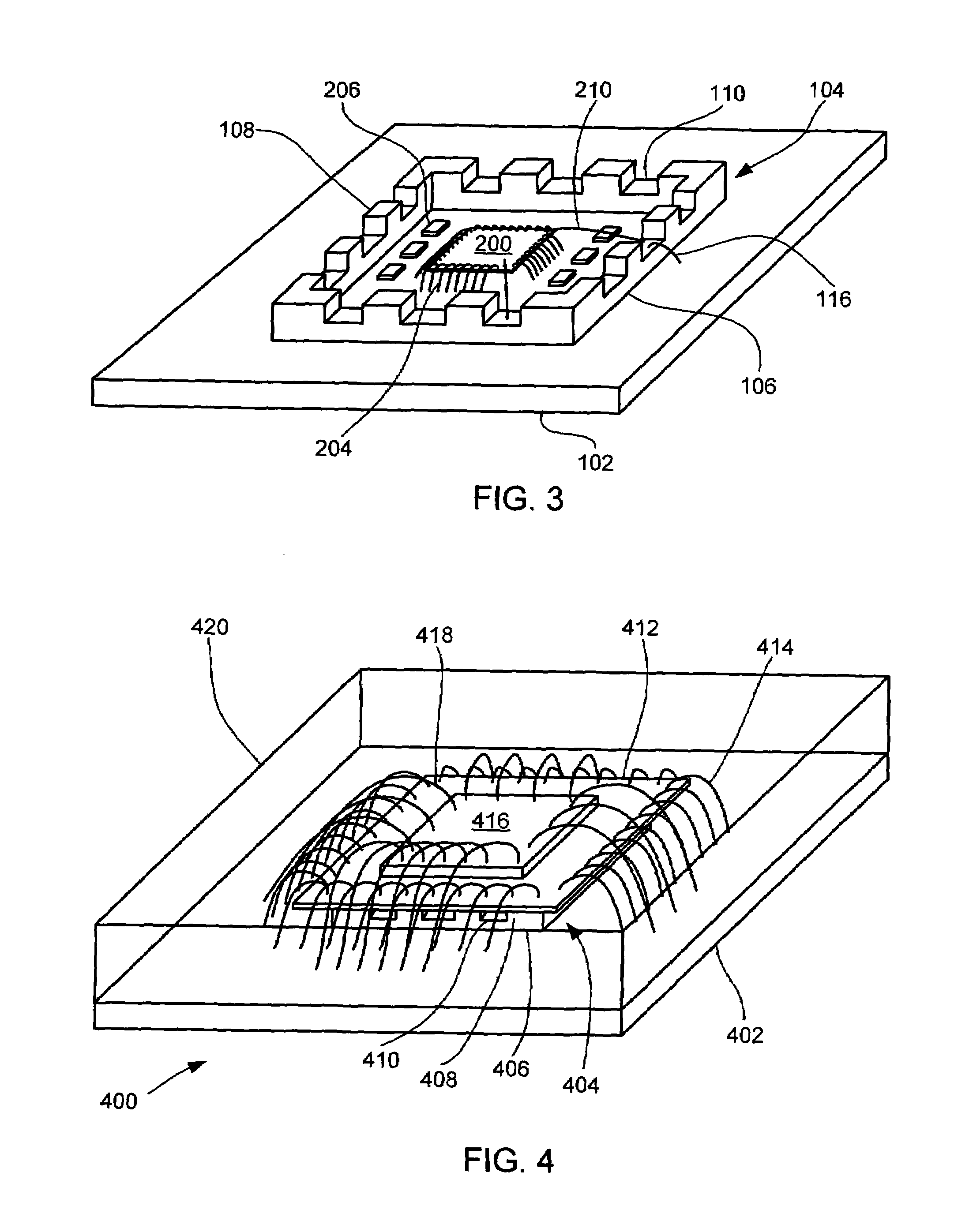

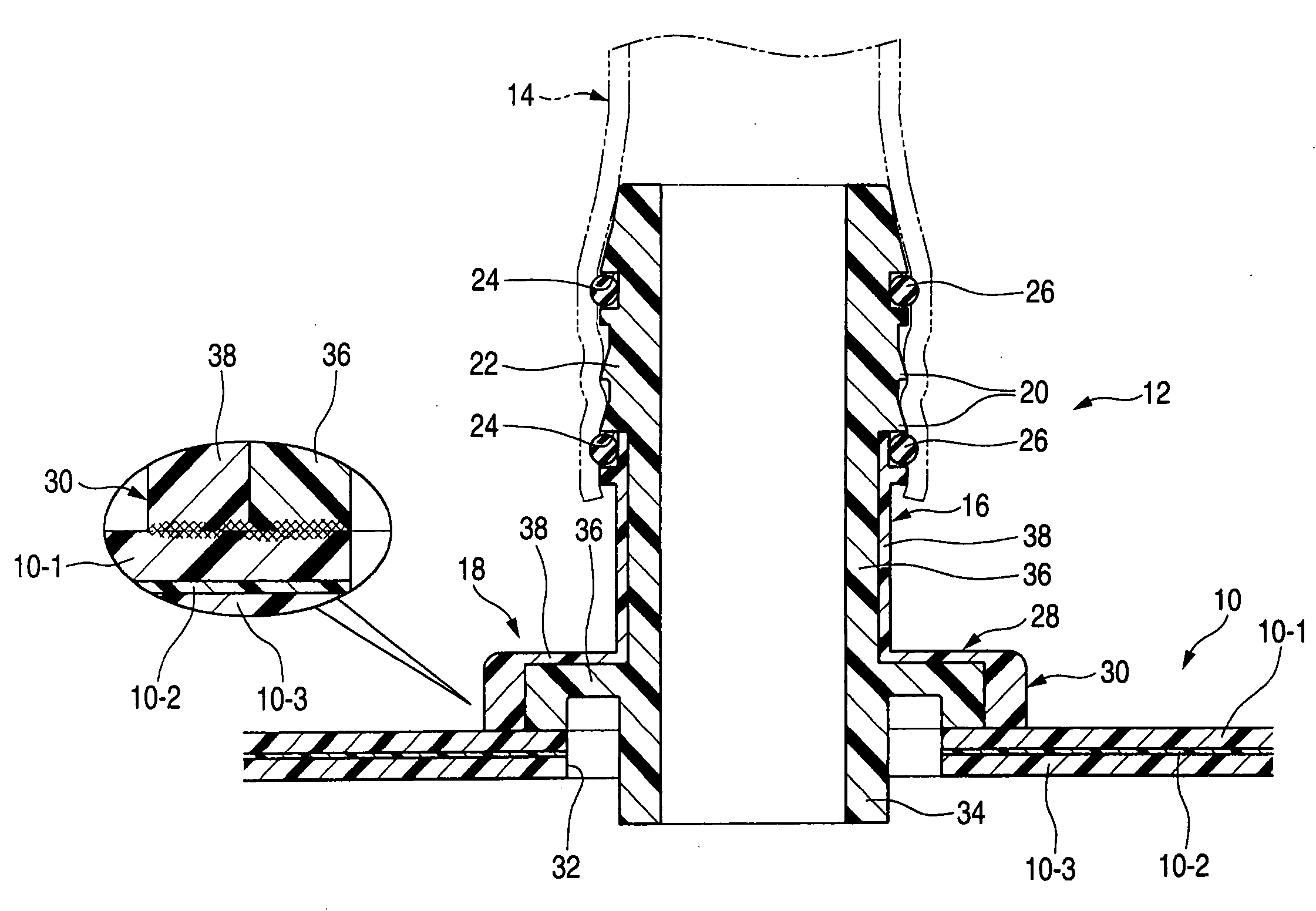

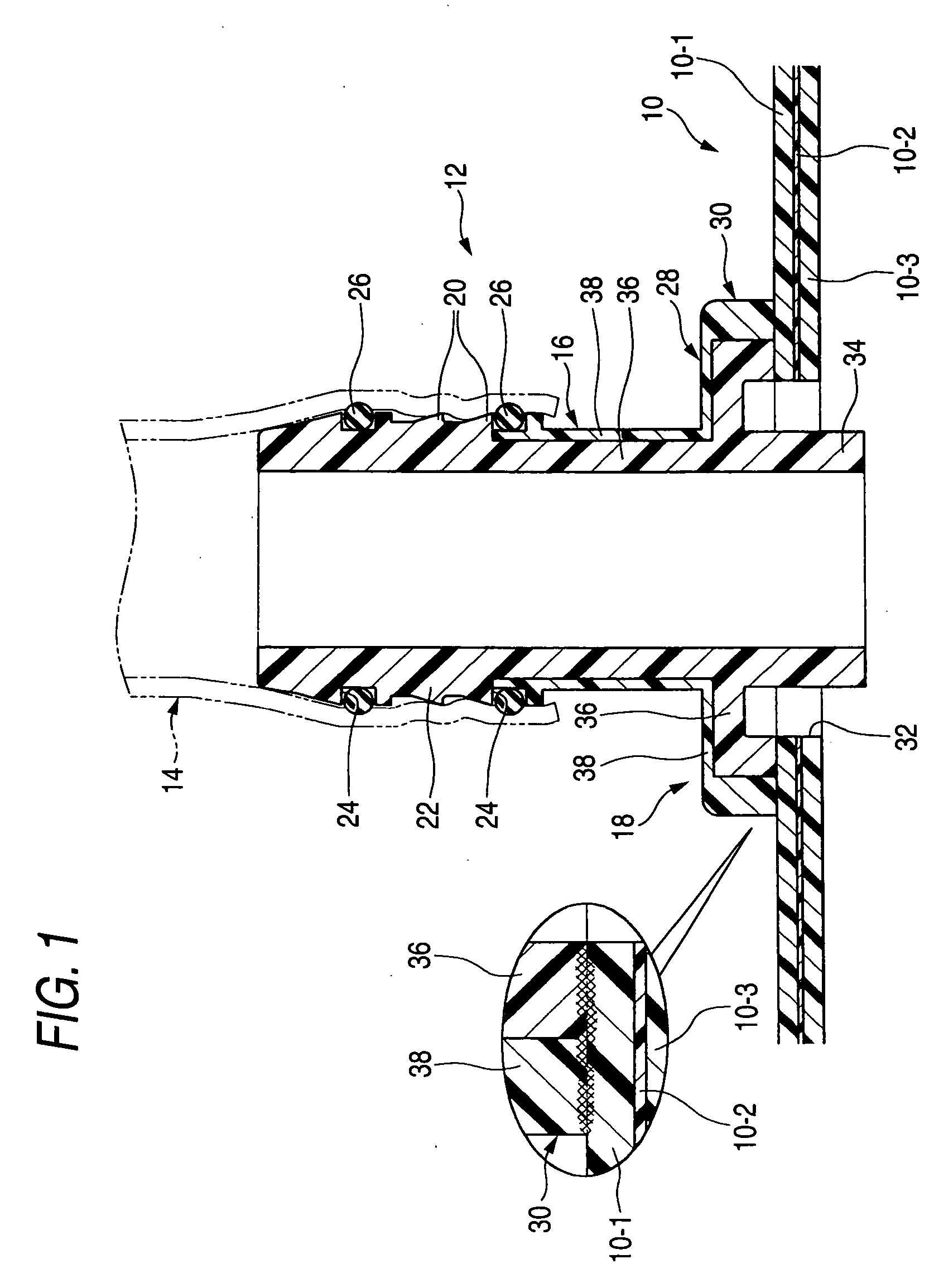

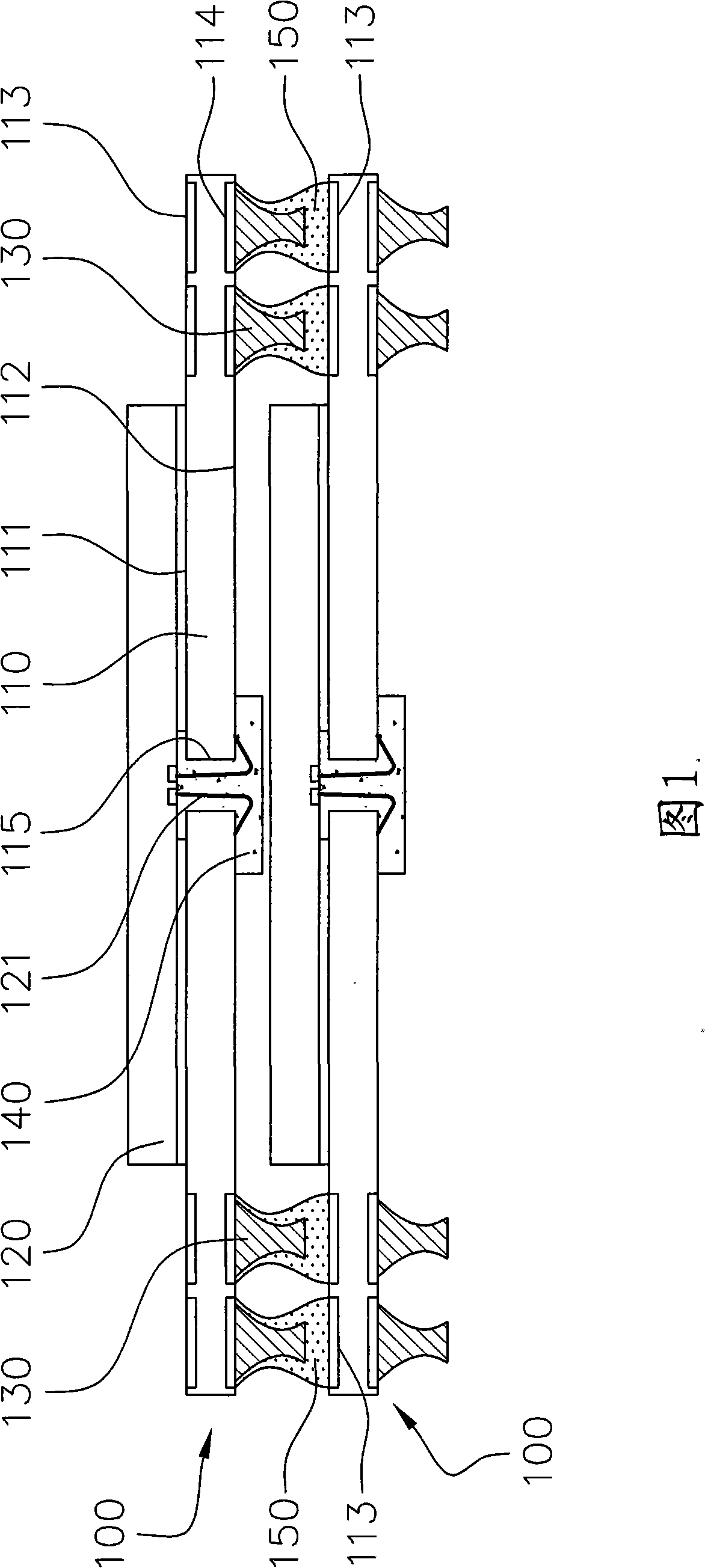

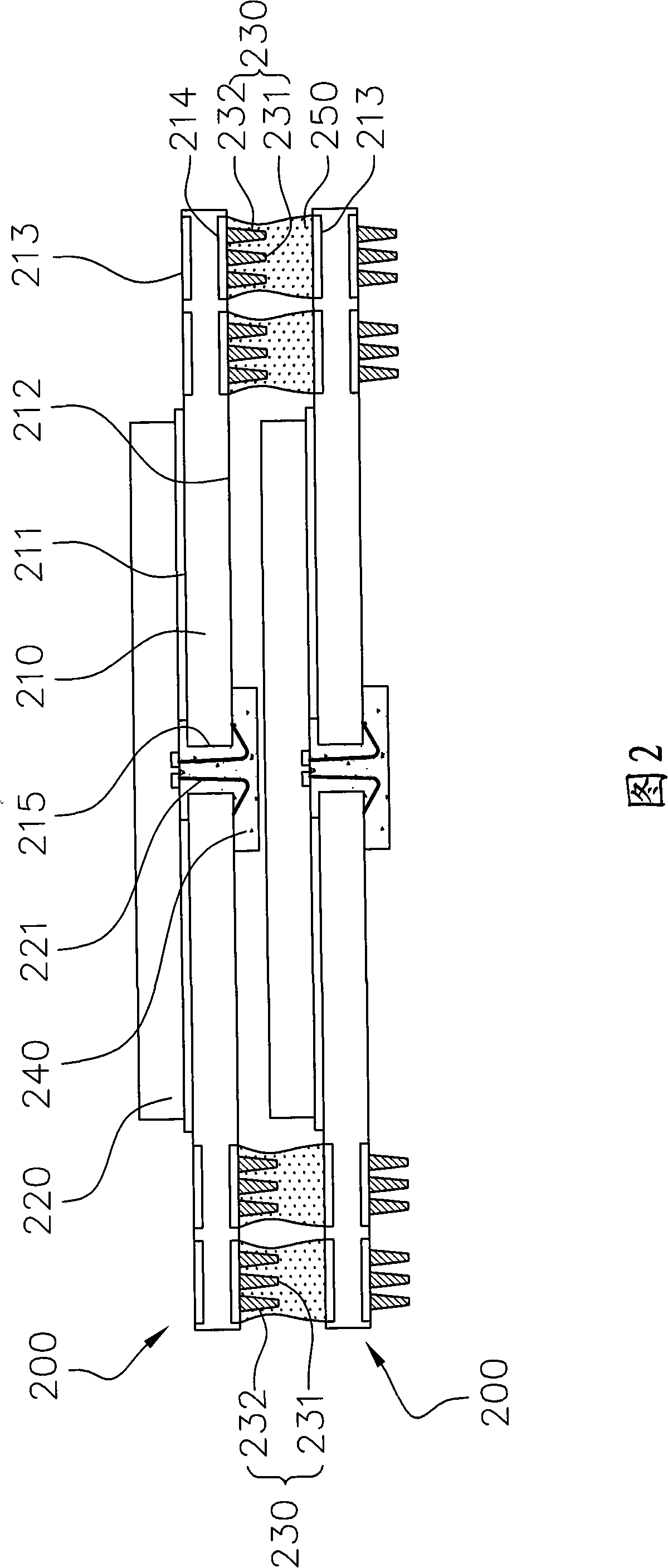

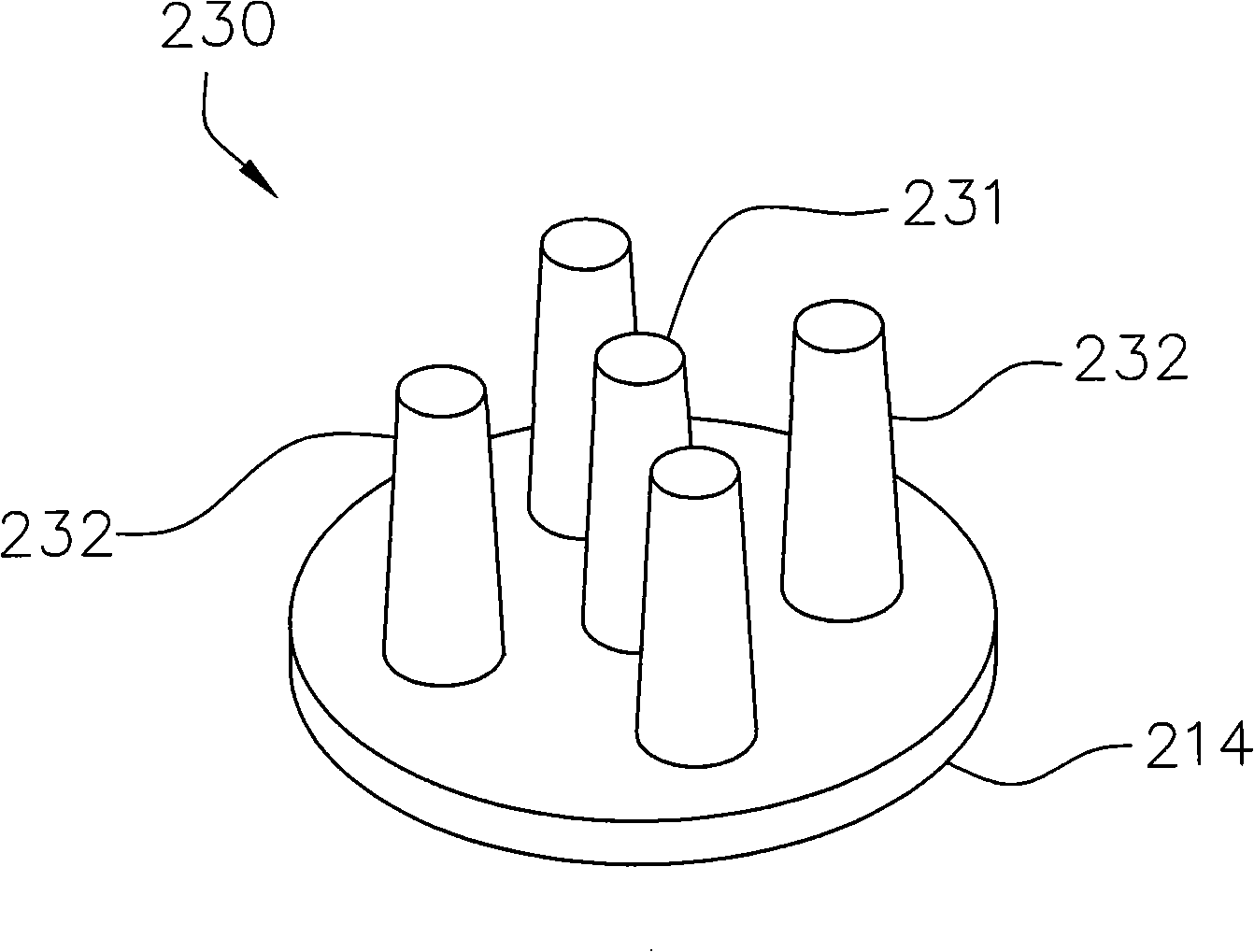

Stacked die packaging and fabrication method

ActiveUS20060043559A1Designing can be facilitatedImprove welding reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package includes a substrate. A crenellated spacer is attached to the substrate. At least one top die is attached to the crenellated spacer. The at least one top die is wire bonded to the substrate, and an encapsulant is formed over the crenellated spacer and the at least one top die.

Owner:STATS CHIPPAC LTD

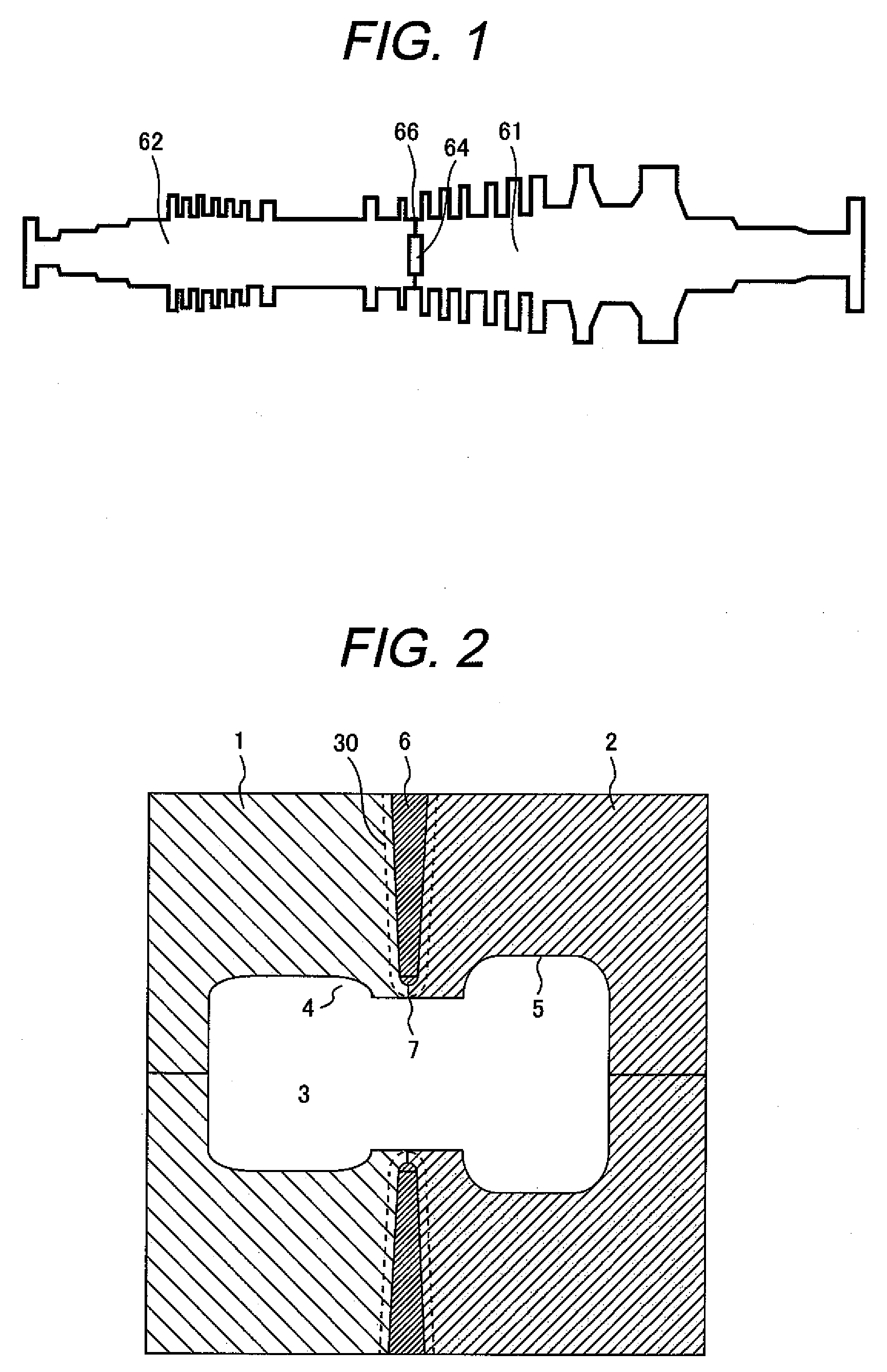

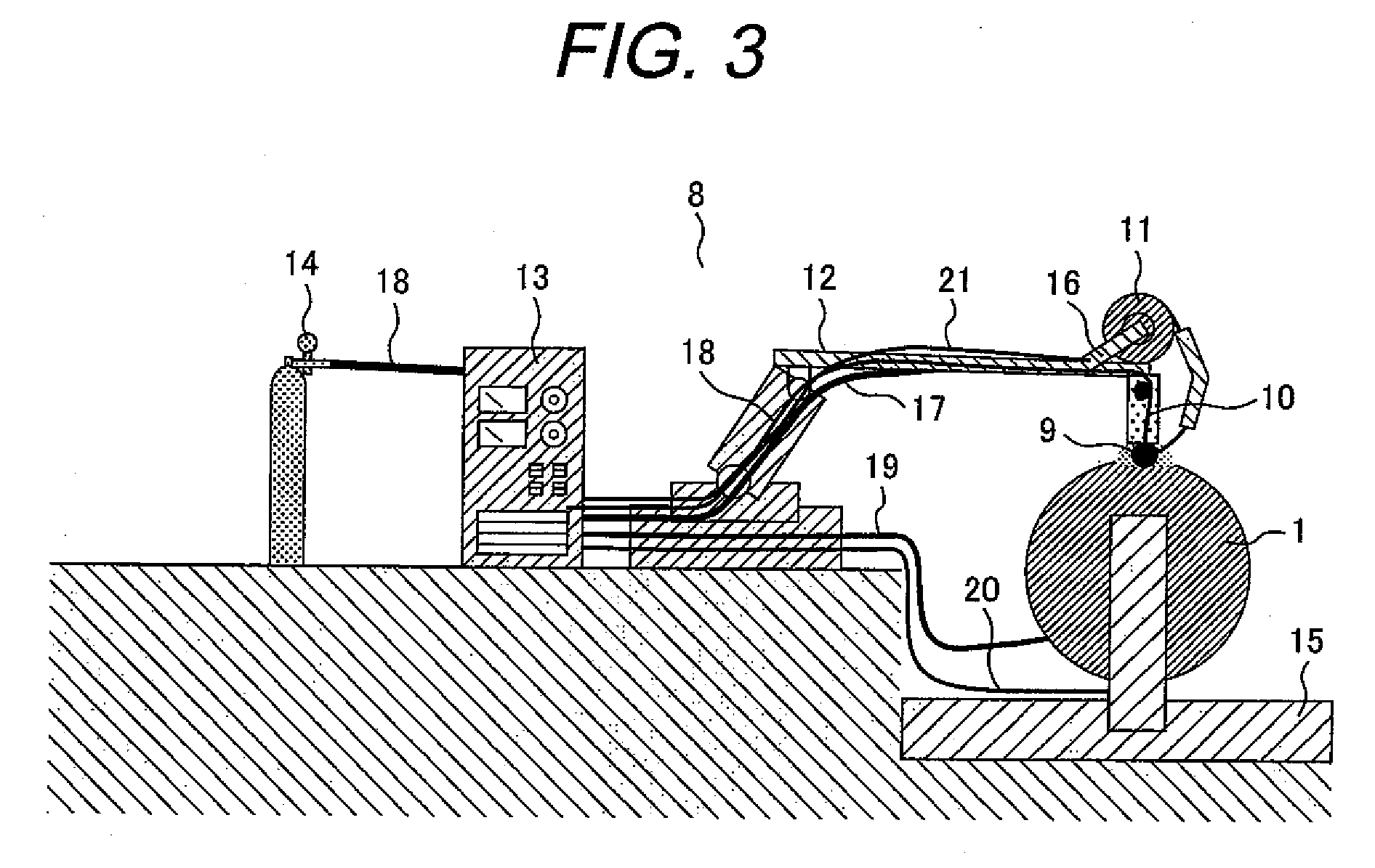

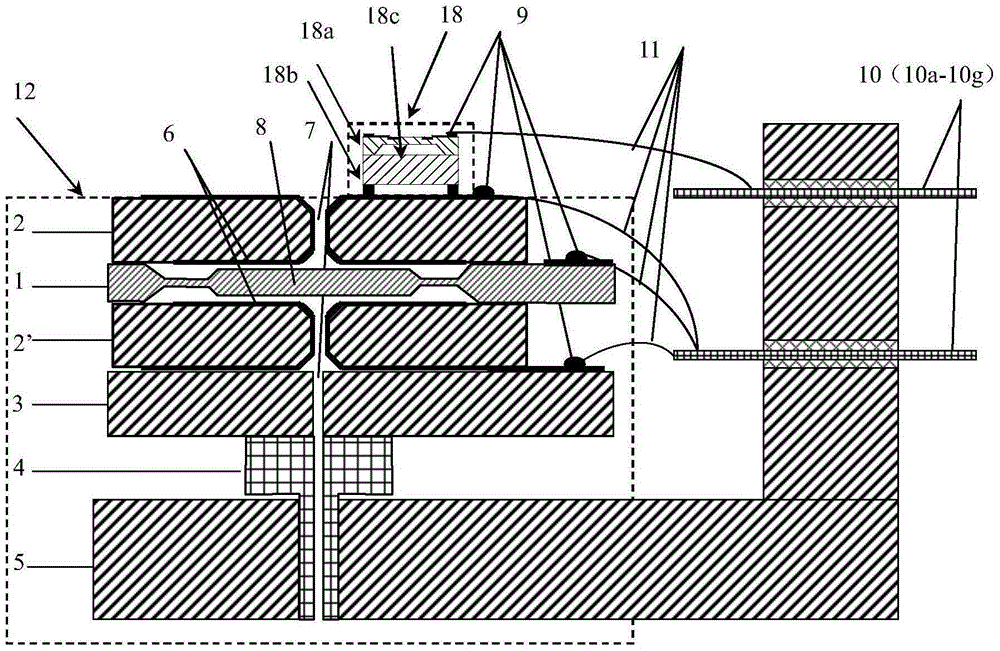

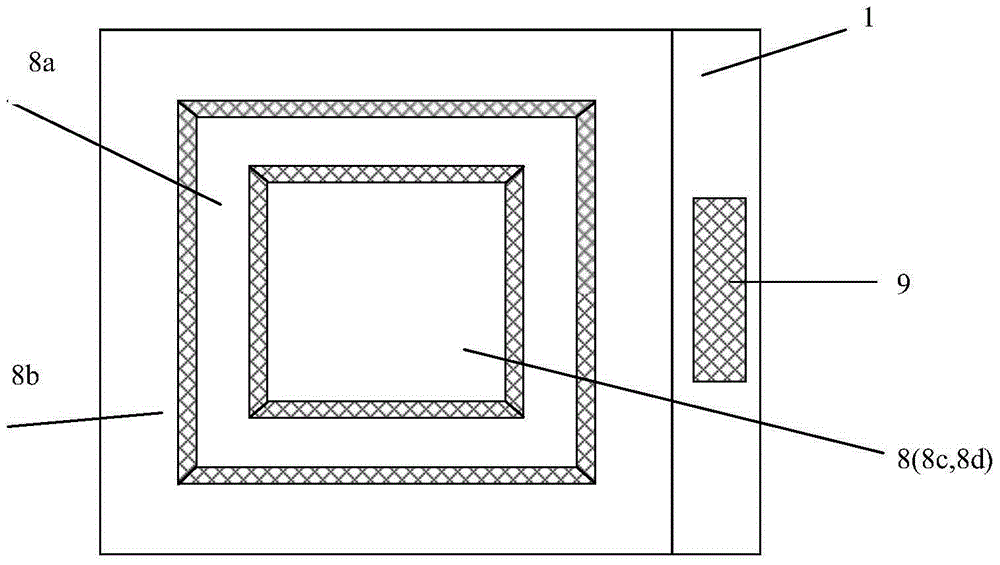

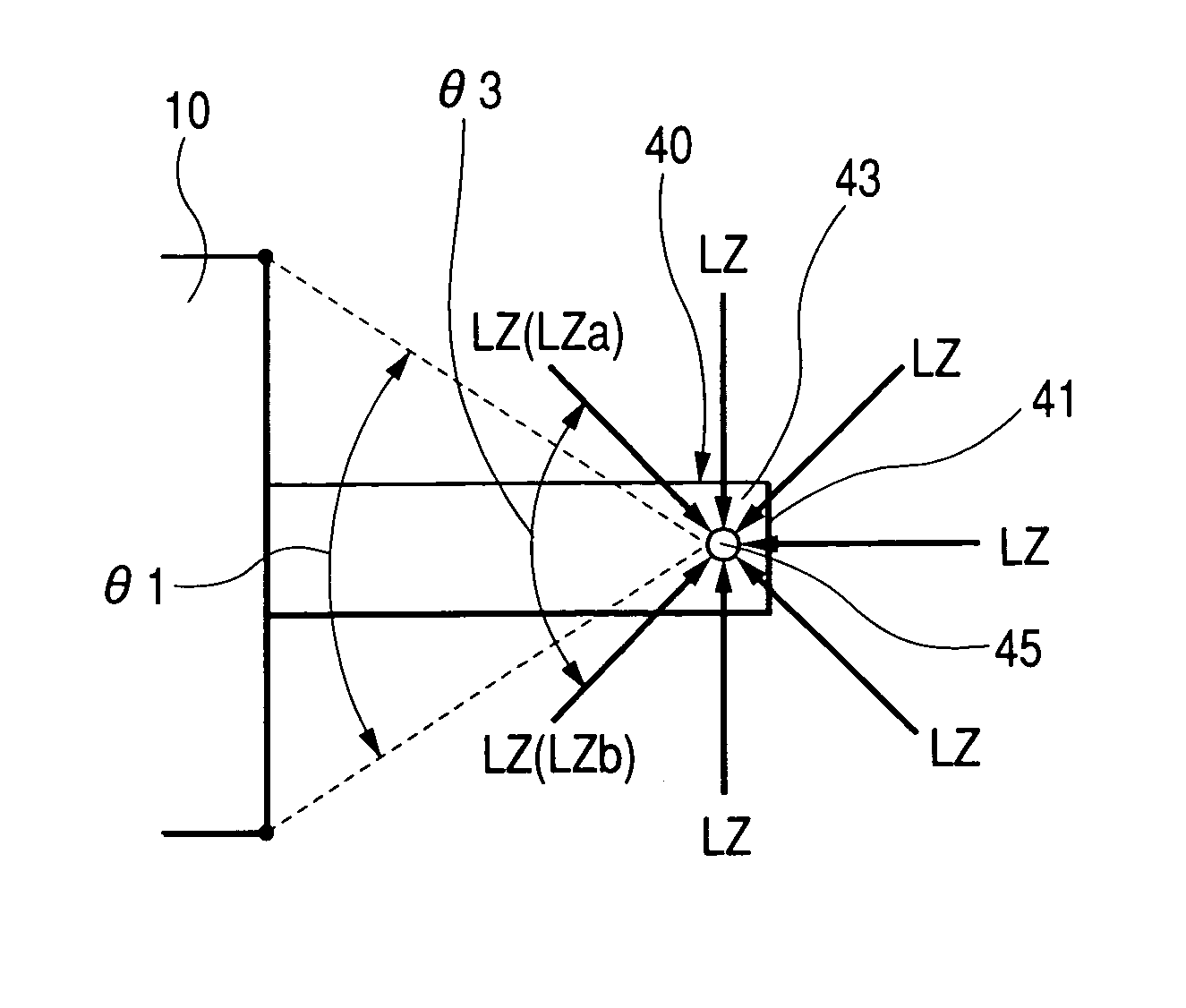

Spark plug with noble metal chip joined by unique laser welding and fabrication method thereof

ActiveUS20050023949A1Improve welding reliabilitySacrifice productivityFuel injection apparatusMachines/enginesMaterials scienceLaser soldering

A spark plug is provided which ensures the reliability of a weld between a noble metal chip and a ground electrode as well as higher durability and ignitability of fuel. The ground electrode is joined to a metal shell, after which the noble metal chip is laser-welded to the ground electrode. The laser welding is achieved by emitting laser beams around an interface between the noble metal chip and the ground electrode outside a given angular range within which the metal shell will be an obstruction to the traveling of the laser beams. Specifically, the laser beams are emitted without any optical interference with the metal shell. This permits the angle between the orientation of each of the laser beams and the surface of the ground electrode to be minimized regardless of the metal shell, thus ensuring a desired depth of the fused portions in the noble metal chip.

Owner:DENSO CORP

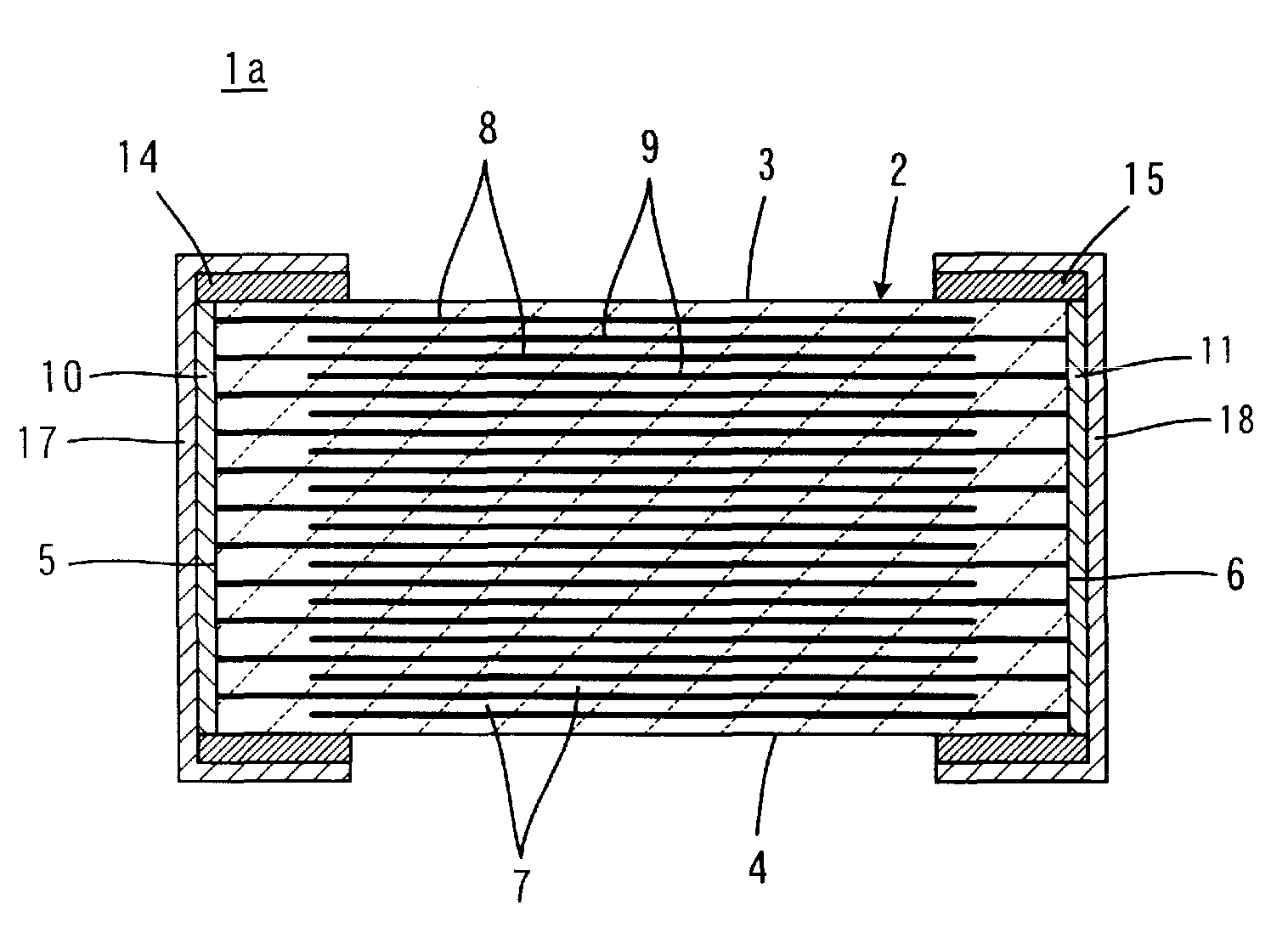

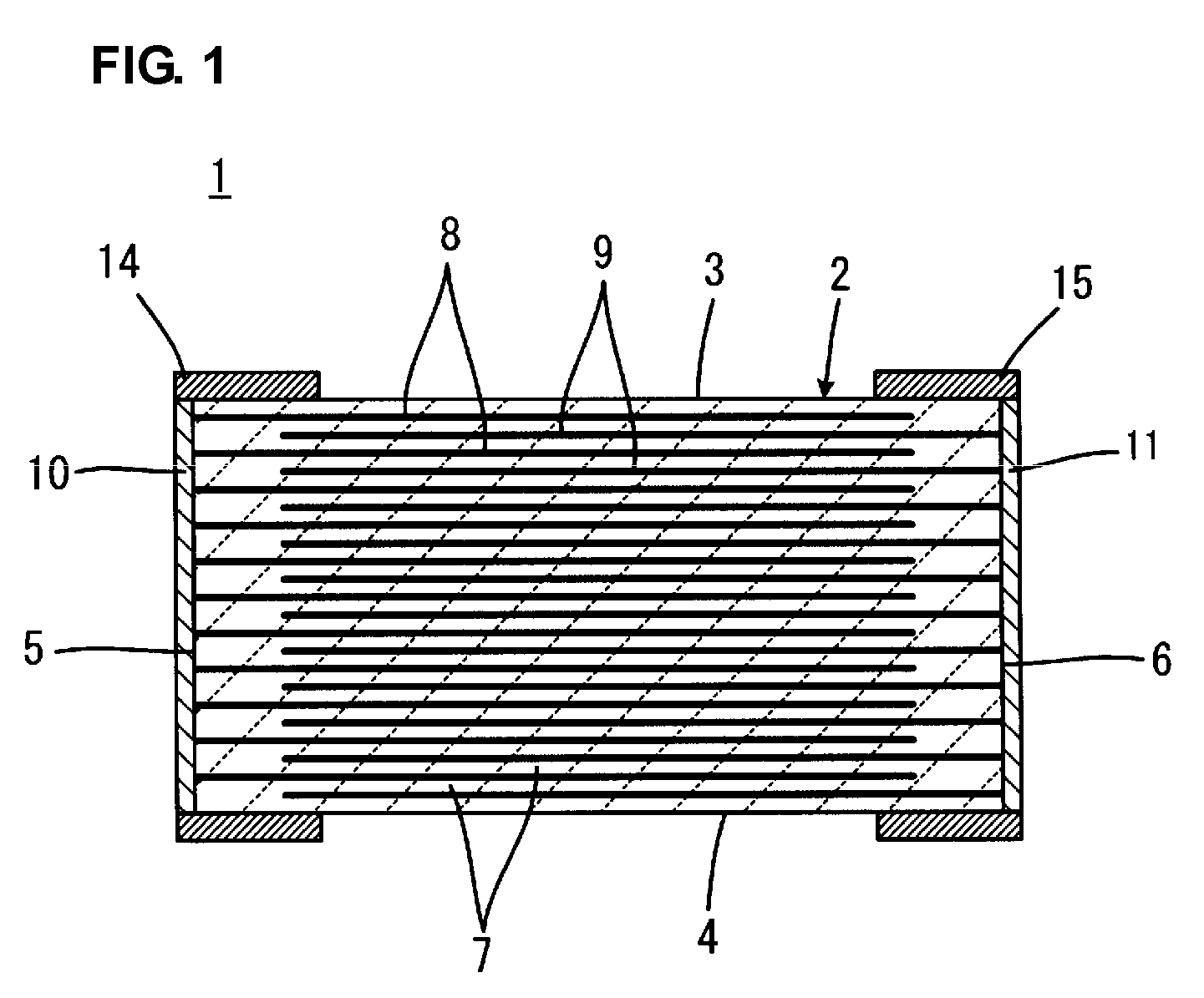

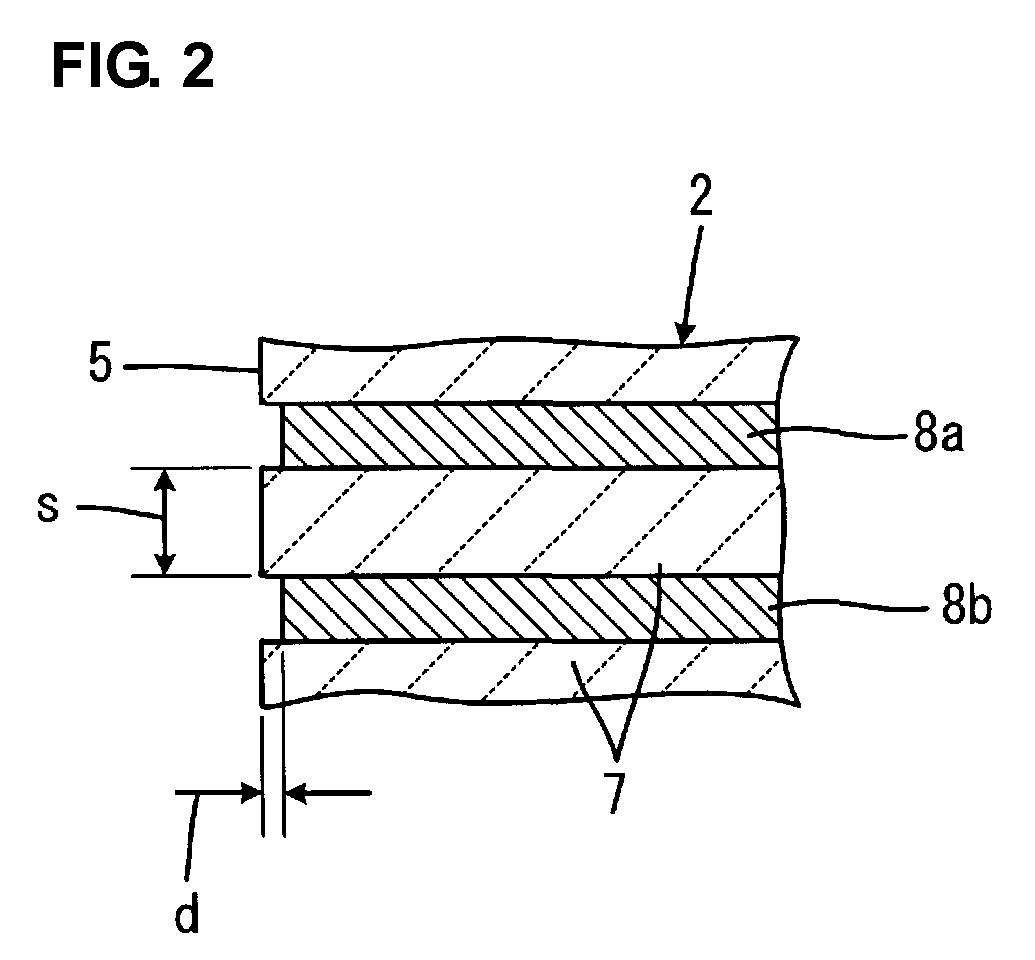

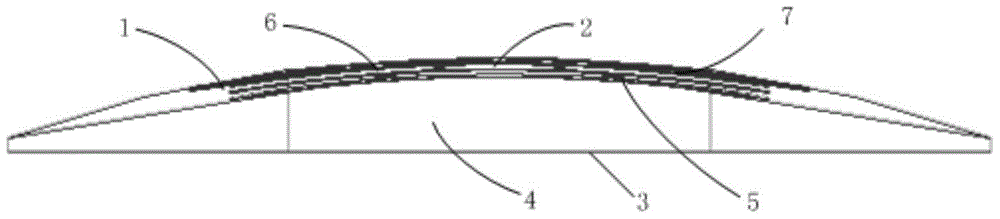

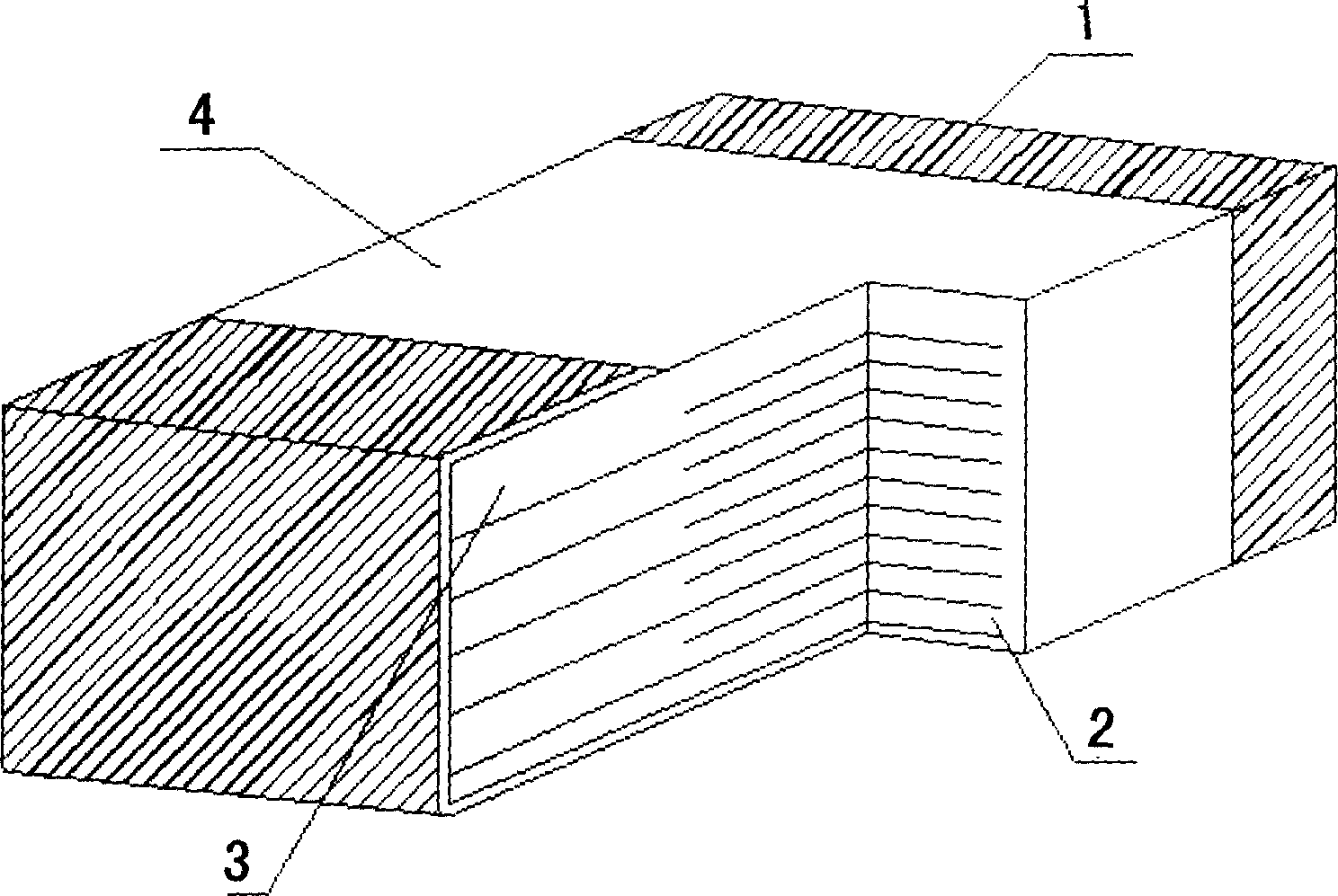

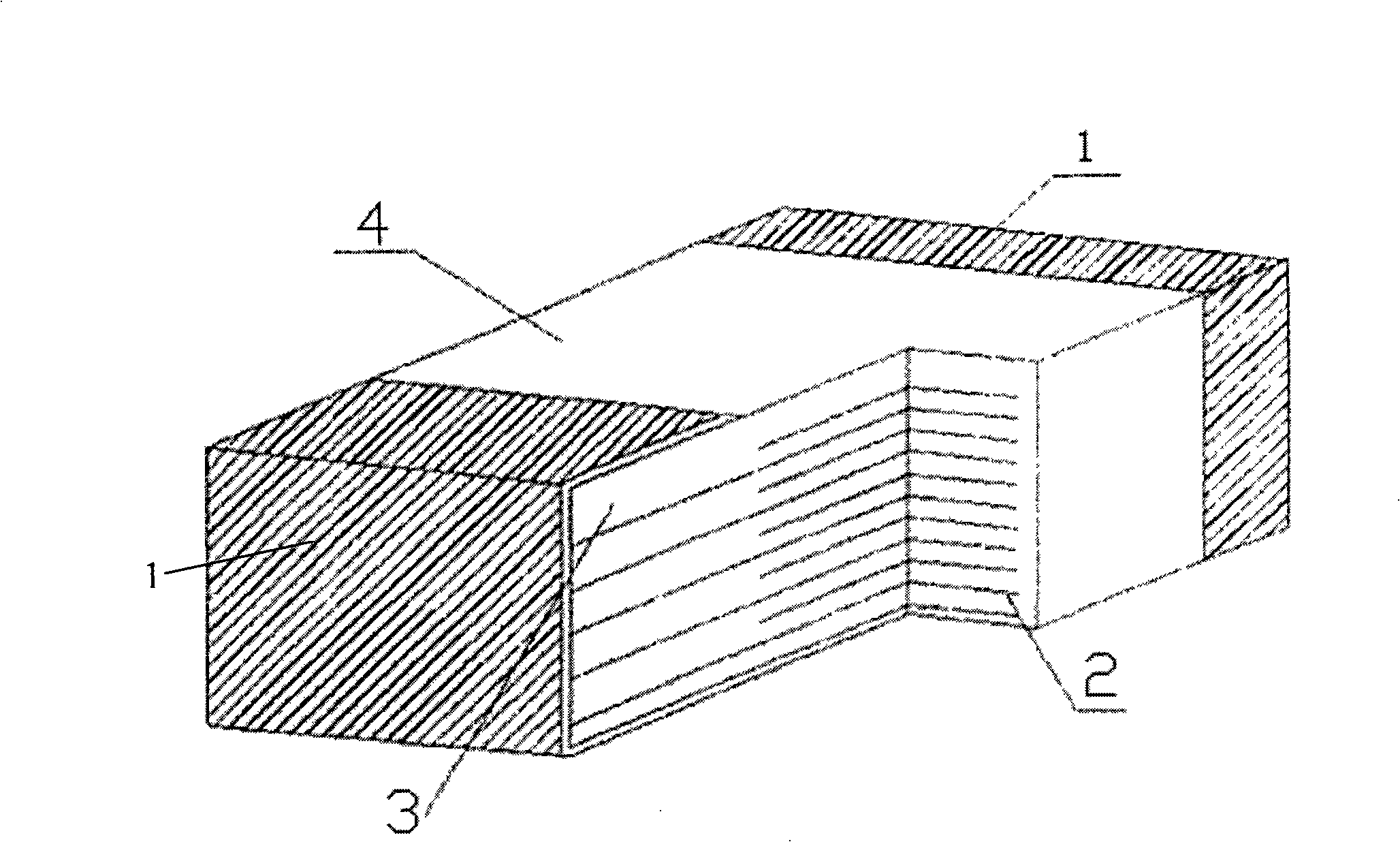

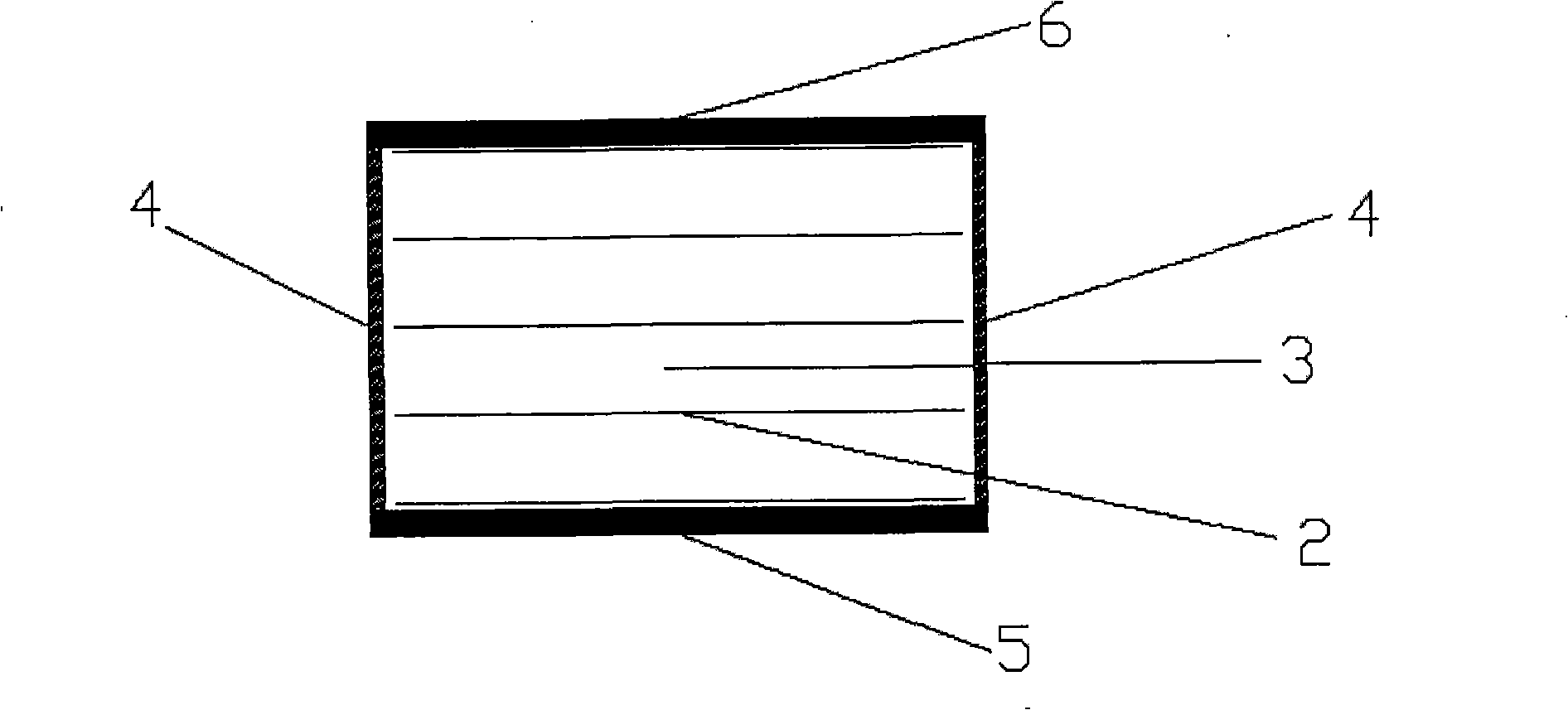

Multilayer electronic component and method for manufacturing multilayer electronic component

ActiveUS7933113B2Large volumeImprove welding reliabilityStacked capacitorsFixed capacitor terminalsConductive pasteCeramic capacitor

A method for manufacturing a laminated ceramic capacitor includes a step of preparing a laminate which has a first principal surface, a second principal surface, a first end surface, a second end surface, a first side surface, and a second side surface and which includes insulating layers and internal electrodes having end portions exposed at the first or second end surface; a step of forming external electrodes on the first and second end surfaces such that plating deposits are formed on the exposed end portions of the internal electrodes so as to be connected to each other; and a step of forming thick end electrodes electrically connected to the external electrodes such that a conductive paste is applied onto edge portions of the first and second principal surfaces and first and second side surfaces of the laminate and then baked.

Owner:MURATA MFG CO LTD

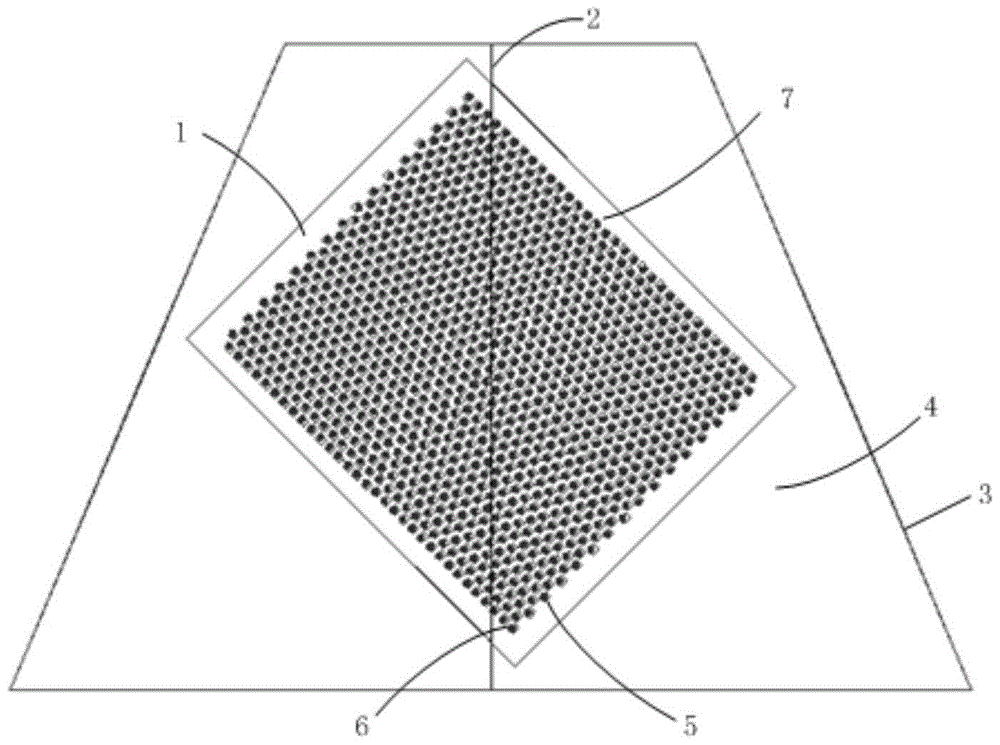

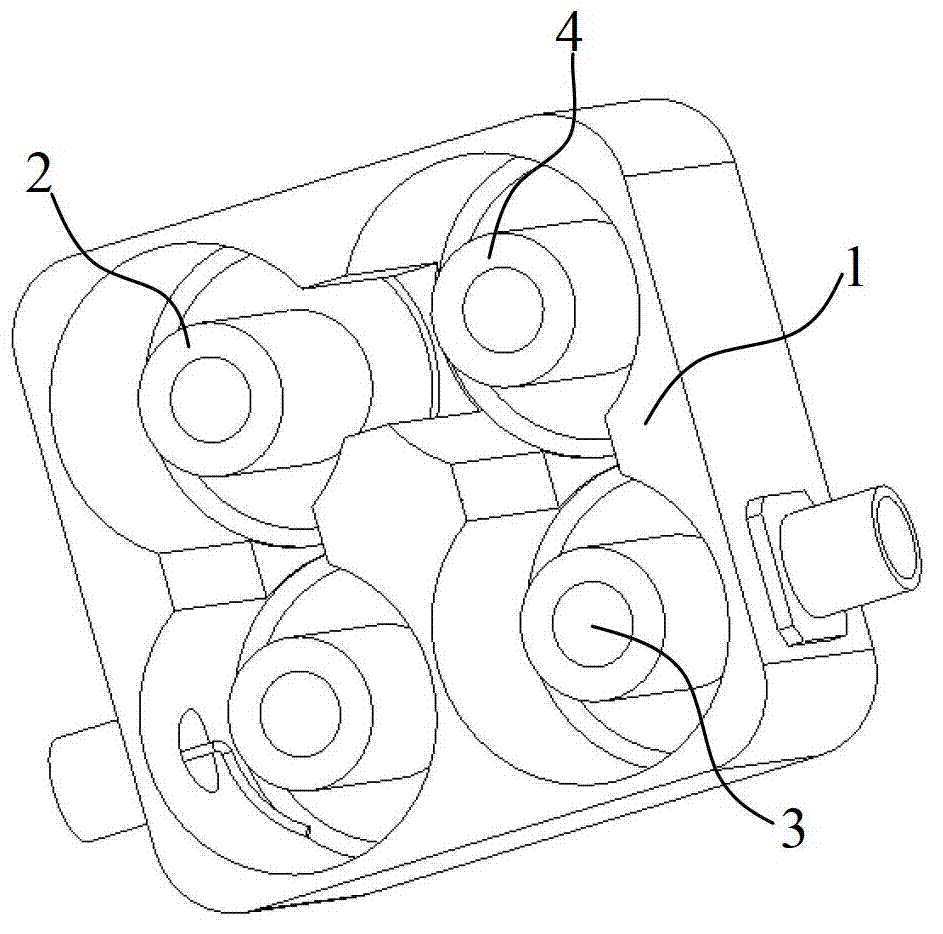

Large K-waveband conformal antenna array plane and preparation method thereof

ActiveCN106099337AGood axial ratioWide bandwidth and good angular axis ratioParticular array feeding systemsRadiating elements structural formsMicrostrip patch antennaElectrical conductor

The invention discloses a large K-waveband conformal antenna array plane and aims to provide a conformal phased array antenna array plane which does not generate a frequency deviation or a relatively high derotation component, and has a good broadband wide-angle scanning gain characteristics and good broadband wide-angle scanning circular polarization characteristics. The large K-waveband conformal antenna array plane is realized through the following technical scheme: conductor patches are divided into four groups and are arranged on an upper surface of a lower dielectric substrate in a form of a quadrant sequence rotation array, and projections of feeding points of a micro-strip patch antenna on a plane plate are arranged triangularly; the conductor patches are sandwiched between an upper dielectric substrate and the lower dielectric substrate; a radio frequency coaxial connector sequentially passes through the plane plate, a metal cone and the lower dielectric substrate to jointly form the micro-strip patch antenna; the radio frequency coaxial connector carries out coaxial probe feeding on the micro-strip patch antenna; and a pair of orthogonal polarization degenerate modes which have equal amplitudes and a phase difference of 90 degrees are excited on the conductor patches to form the conformal phased array antenna array plane for radiating right-handed circular polarization electromagnetic waves.

Owner:10TH RES INST OF CETC

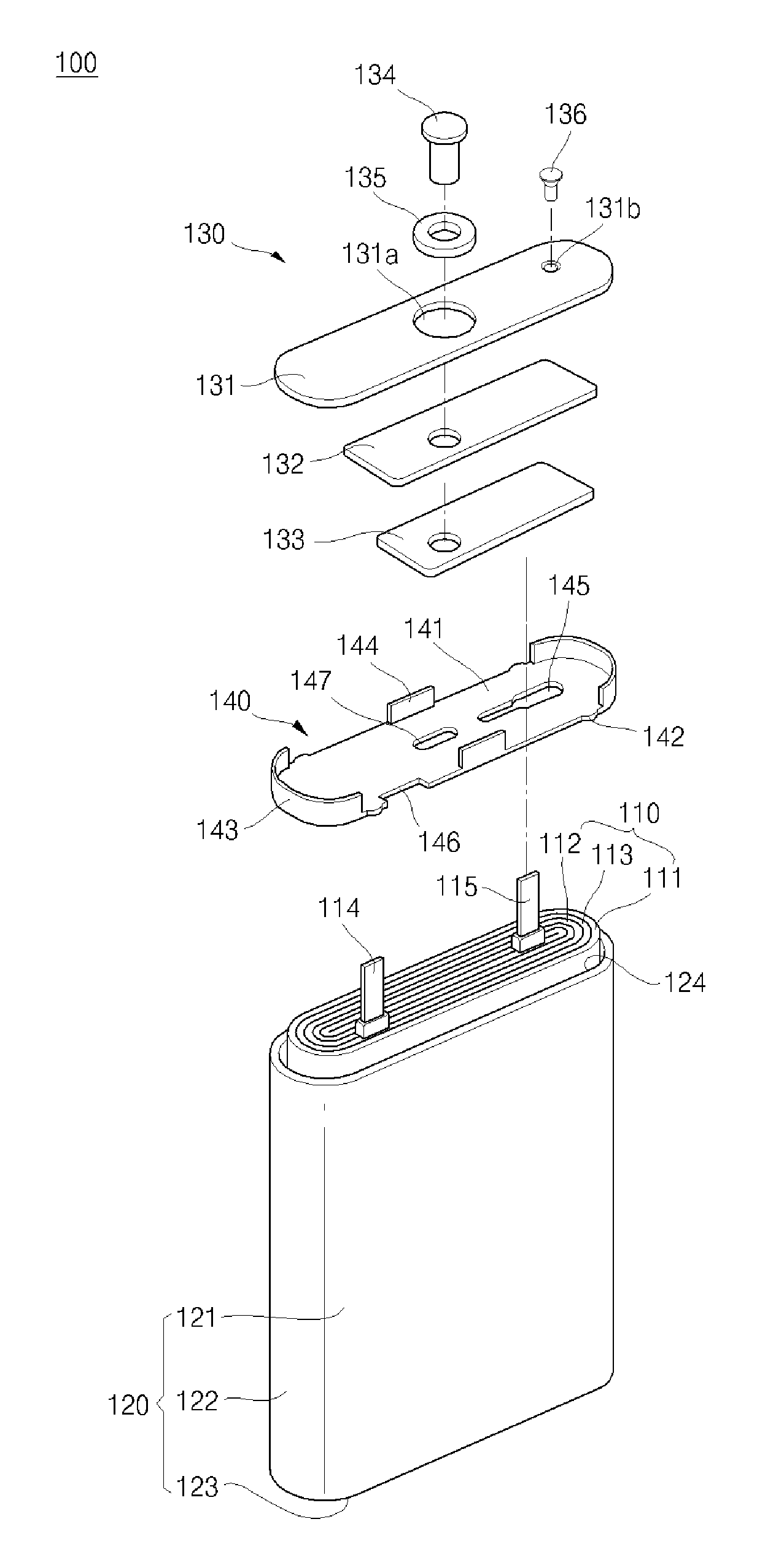

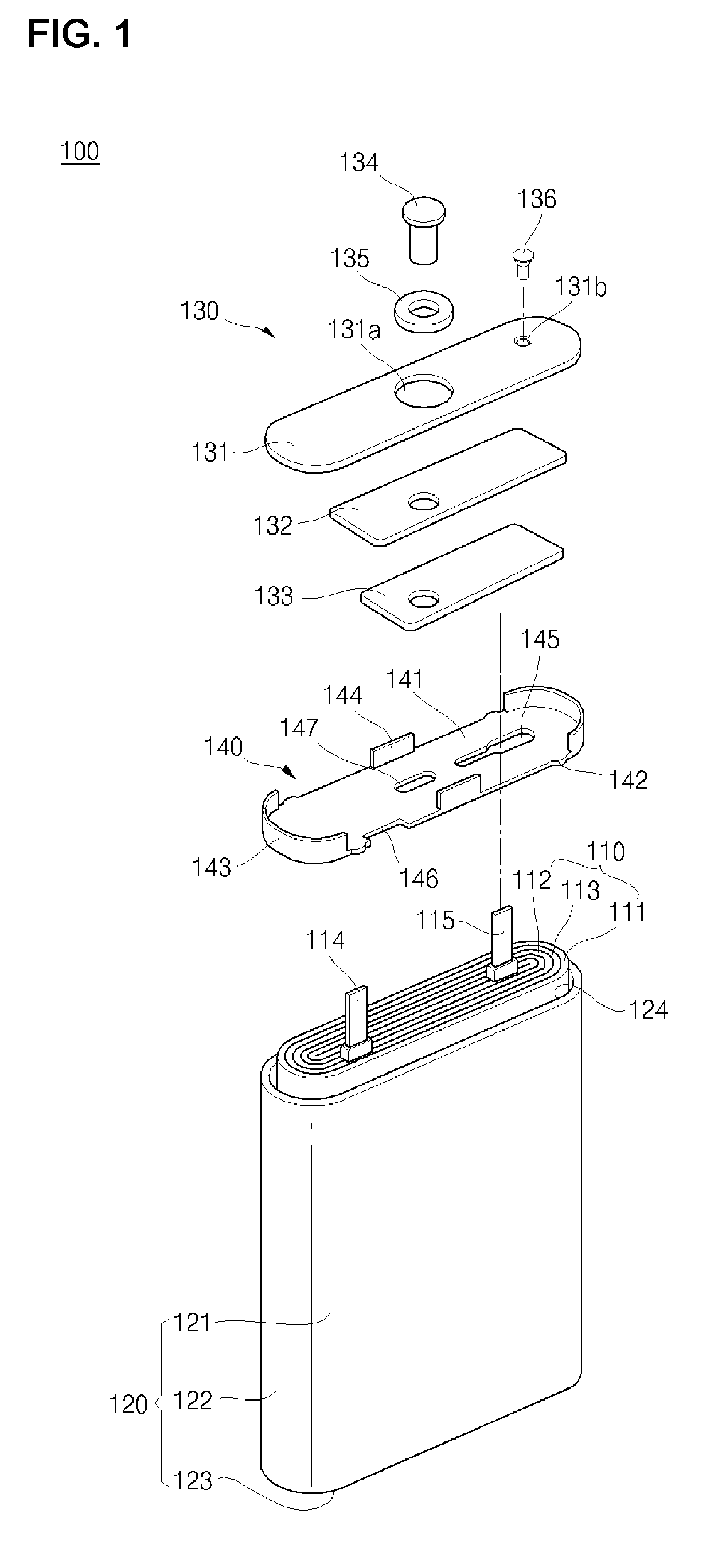

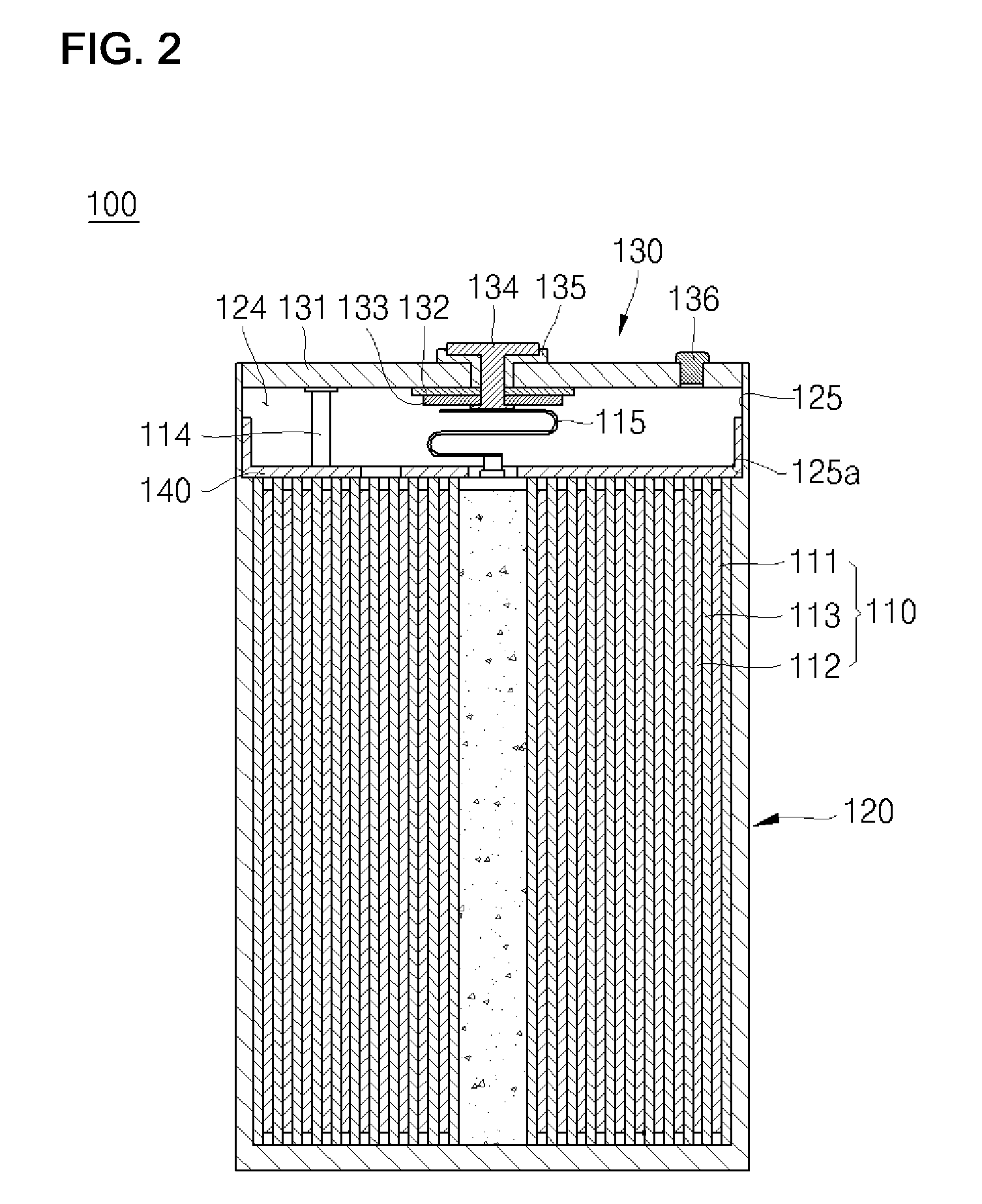

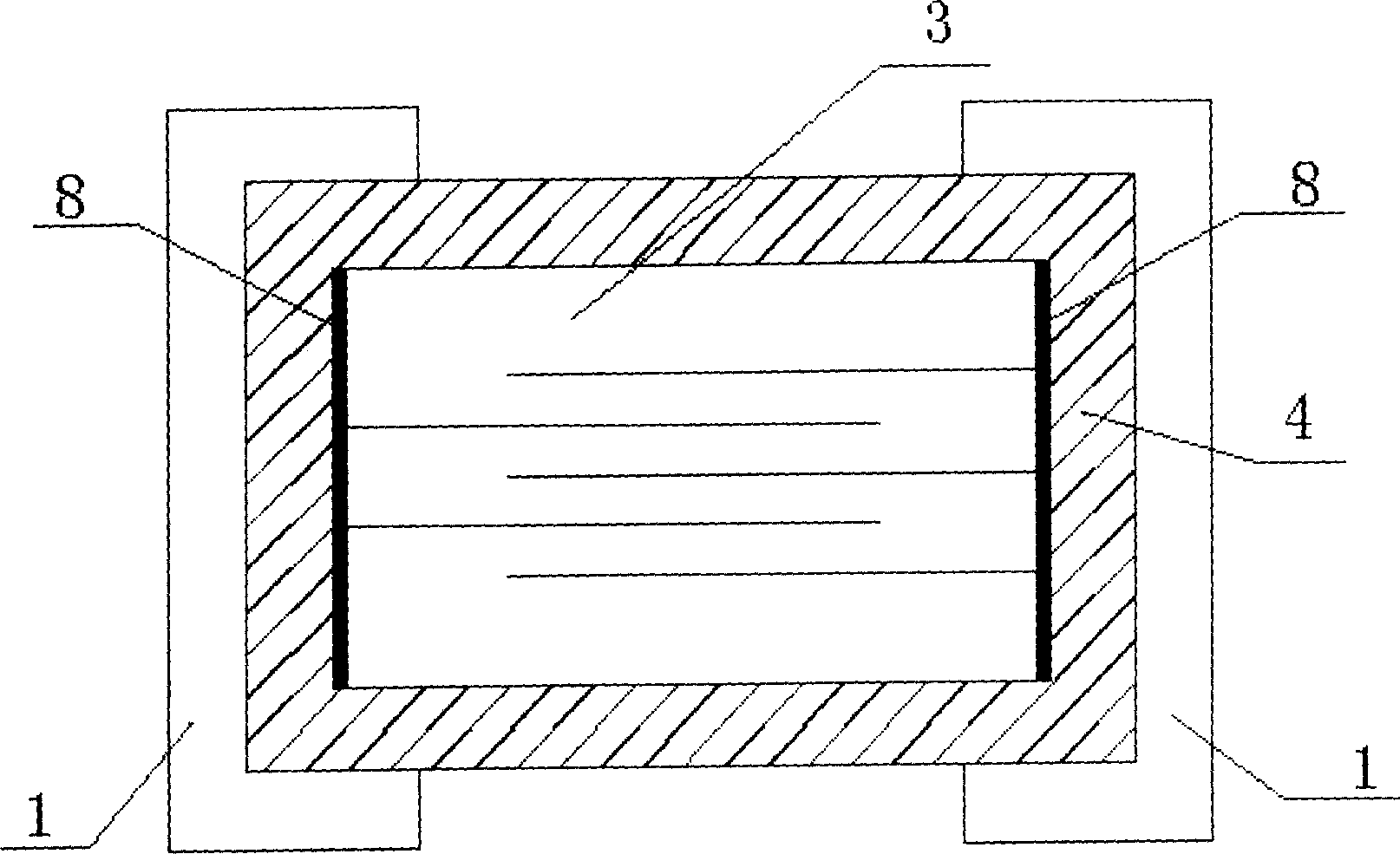

Secondary battery

InactiveUS20090311594A1Improve assembly workabilityImprove welding reliabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsBiomedical engineeringElectrode

Disclosed is a secondary battery, which includes: an electrode assembly; a can receiving the electrode assembly; and an insulation case provided at an upper part of the electrode assembly inside the can, where a stepped part thinner than the can is formed on an inner surface of an upper part of the can. The insulation case can be inserted to the stepped part and the cap plate can be seated on a second stepped part formed at the upper part of the stepped part. The insulation case and cap plate are stably assembled to the can, thereby improving reliability of the process to weld the cap plate to the upper part of the can.

Owner:SAMSUNG SDI CO LTD

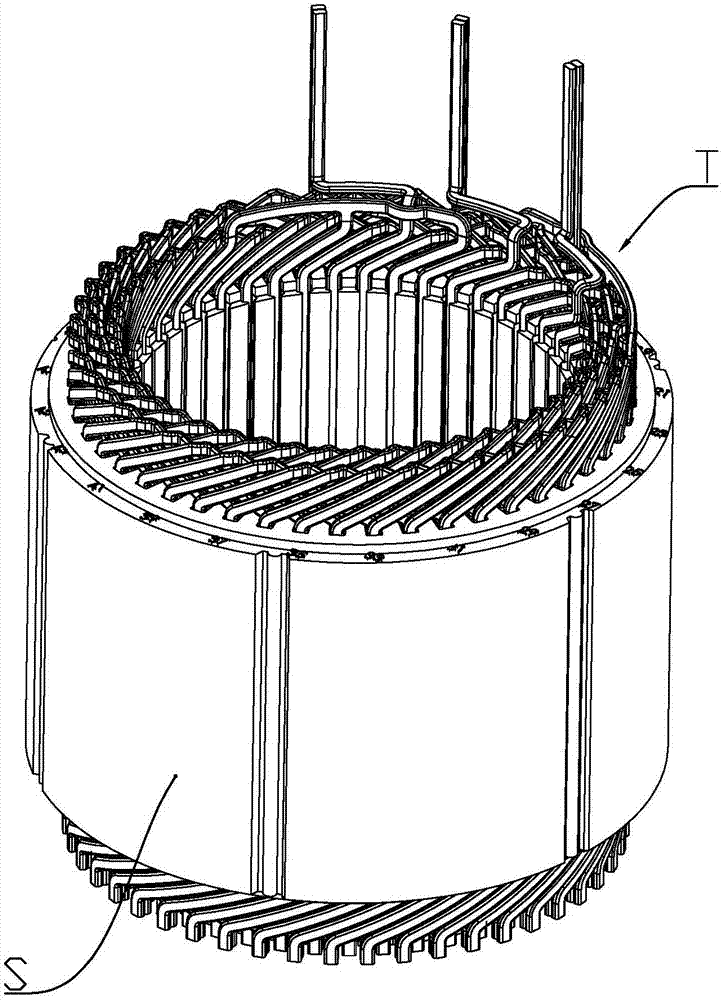

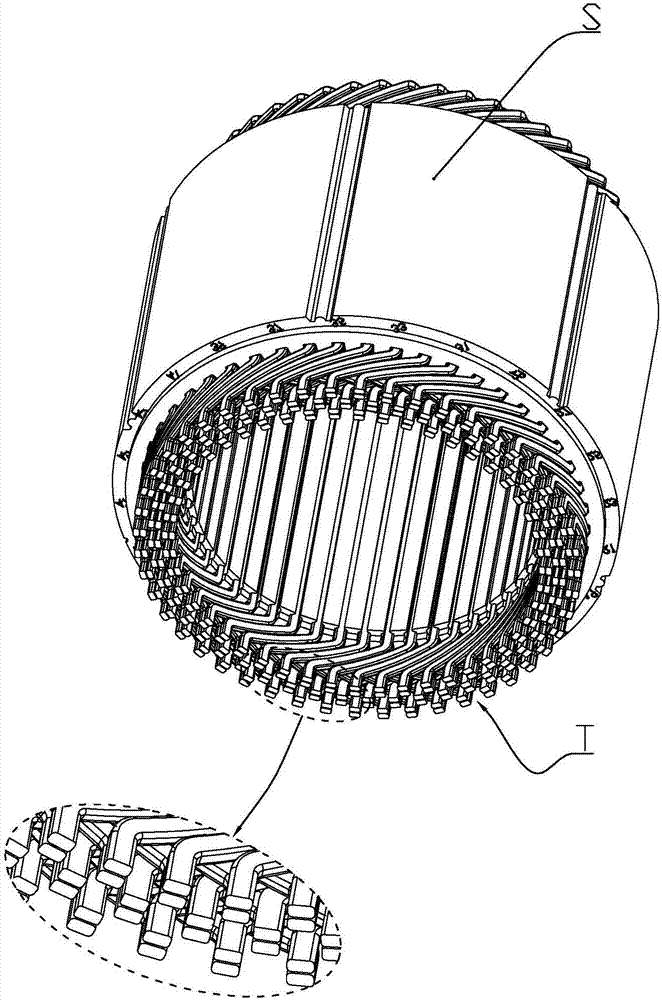

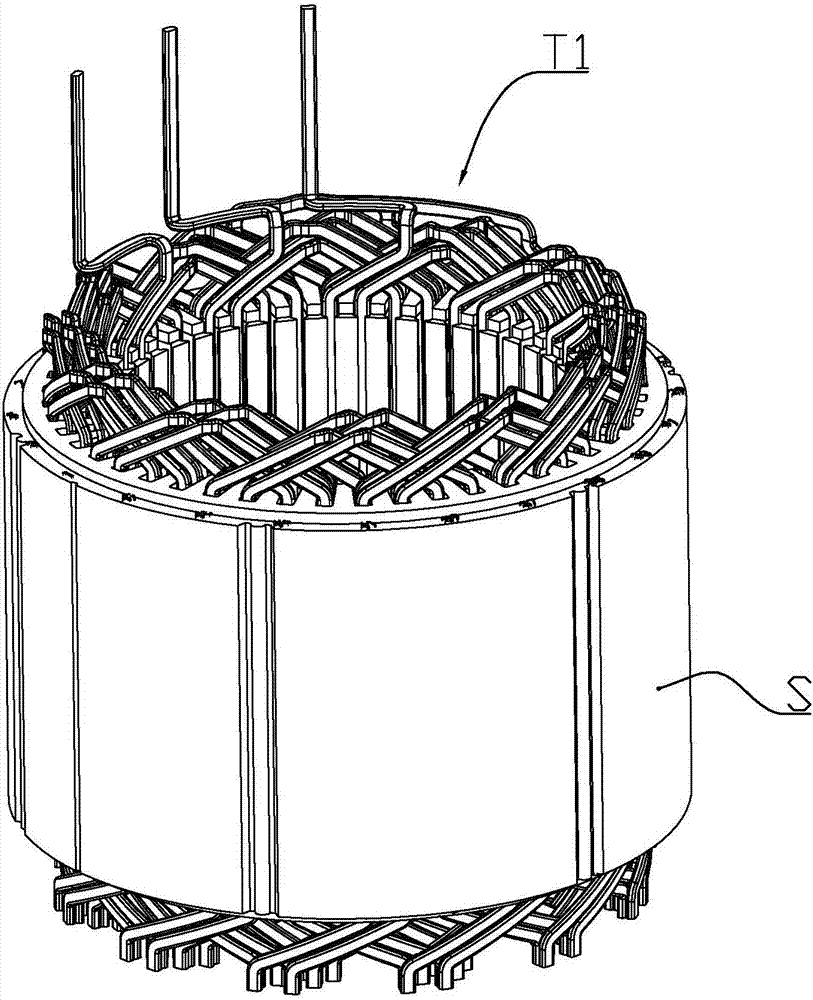

Three-phase flat wire motor stator and motor

PendingCN107546877AReduce typesReduce manufacturing costMagnetic circuit stationary partsWindings conductor shape/form/constructionNeutral lineConductor Coil

The invention discloses a three-phase flat wire motor stator and a motor. The stator comprises an annular stator iron core and a stator winding installed on the stator iron core; the stator winding comprises two winding units connected in parallel, each winding unit comprises three phase windings connected in a star shape, each phase winding is formed by connecting 23 guiding strips in an end-to-end mode, a lead wire is connected to one end of each phase winding, and the other ends of the three phase windings belongs to the same winding unit are connected through a neutral line; 48 insertion grooves are formed in the inner wall of the stator iron core, arrayed at equal intervals in the circumferential direction of the stator iron core and used for containing the stator winding, and containing portions are arranged in the insertion grooves in the radius direction of the stator iron core and can contain 6 layers of the guiding strips or lead wires or neutral lines. By optimizing the arrangement mode of the guiding strips of the stator winding, only 12 kinds of guiding strips remain and include the neutral lines and the lead wires, in this way, the production cost for the guiding strips is lowered, and assembly difficulty is also lowered.

Owner:ZHEJIANG FOUNDER MOTOR

Turbine Rotor

InactiveUS20100028155A1Improve welding reliabilityBlade accessoriesReaction enginesHigh pressureSteam turbine rotor

An object of the present invention is to provide a turbine rotor with high reliability of strength. The turbine rotor includes two rotors which are connected at the butted portions of the rotors via a weld without forming penetration beads. Specifically, the turbine rotor includes a rotor for low pressure, a rotor for high pressure, and a center hole formed at a center portion of the turbine rotor. The rotors for low pressure and for high pressure are integrated together into a steam turbine rotor by welding respective ends of the rotors to each other. The respective ends of the rotors are in contact with each other via at least two contact faces in a radial direction and an axial direction of the turbine rotor. At least parts of the respective ends are welded together.

Owner:HITACHI LTD

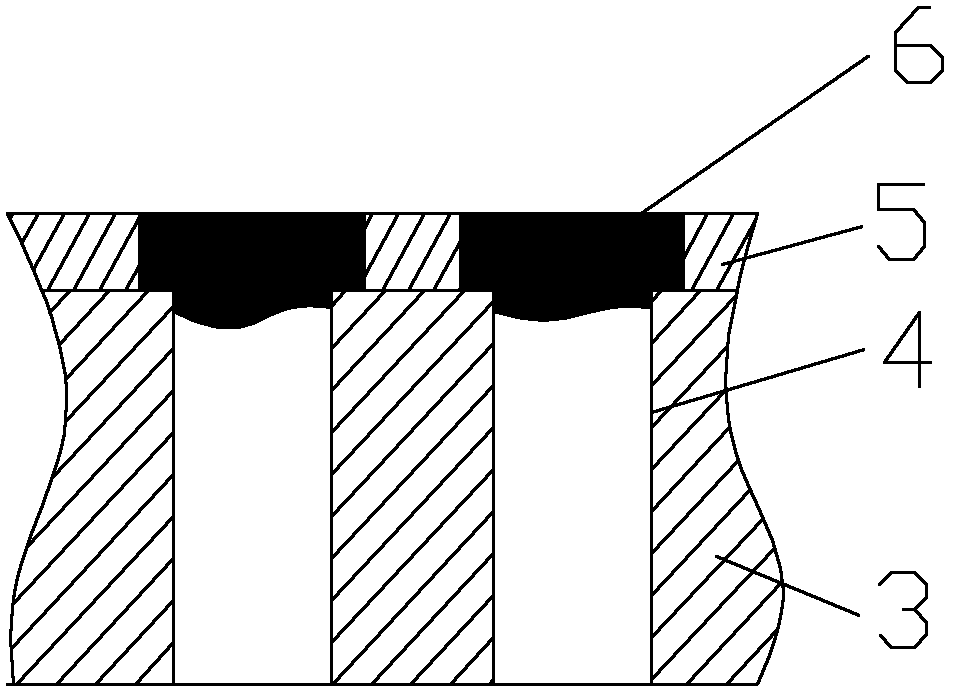

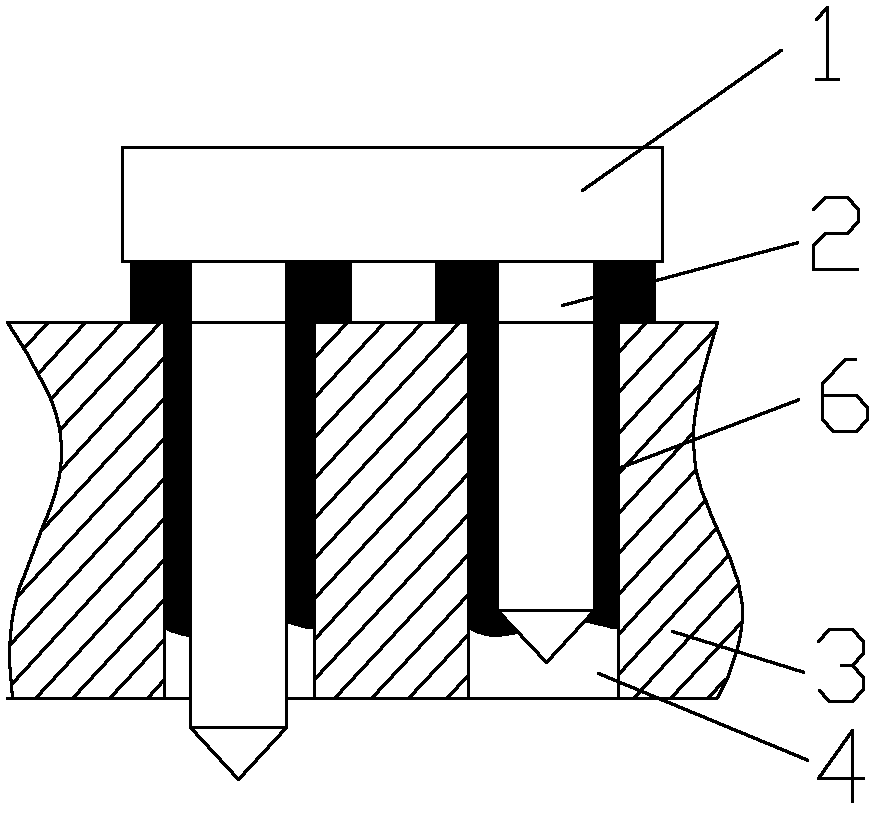

A method for through-hole reflow soldering

ActiveCN102291945AThe operation process is simple and convenientHigh welding quality and reliabilityPrinted circuit assemblingReflow solderingSolder paste

The invention relates to a through-hole reflow soldering method. The method is characterized by printing solder at the plug-in hole positions where exposed pins can not meet the wave soldering requirement on a PCB (printed circuit board), inserting pins of a corresponding plug-in component into plug-in holes, the pins bringing part of solder paste in the plug-in hole walls and then carrying out reflow soldering. The method has the following advantages: temperature damage to the plug-in component is not easy to cause, the lack of space for manual repair soldering during manual repair solderingis avoided, cold soldering, poor soldering and other soldering defects are not easy to cause, the soldering quality is good, the reliability is high, and the soldering efficiency is high, and the method is suitable for soldering of the plug-in components with the exposed pins failing to meet the wave soldering requirement.

Owner:南通卓效自动化有限公司

Multiple field sheet type piezoresistor and its producing method

ActiveCN1909122AStrong moisture resistanceImprove solderabilityResistor manufactureVaristor coresHigh volume manufacturingAdhesive

The invention relates to a multi-layer voltage-sensitive resistance and relative production, wherein it has the types as internal electrode and end electrode inside the insulated layer; the internal electrode and end electrode are connected directly; and the end electrode and the base board are directly connected; and the production comprises: preparing slurry, laminating layers, slicing, discharging adhesive, sintering, surface treating the insulated slurry of base board, producing two end electrodes and electrically plating. The invention insulated treats the surface of multi-layer sheet voltage-sensitive resistance without end electrodes, without water adsorption, and it plates nickel and tin on the surface of end electrode, to improve the welding property and the welding reliability, with lower cost and batch production.

Owner:SHENZHEN SUNLORD ELECTRONICS

Stacked die packaging and fabrication method

ActiveUS7064430B2Designing can be facilitatedImprove welding reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package includes a substrate. A crenellated spacer is attached to the substrate. At least one top die is attached to the crenellated spacer. The at least one top die is wire bonded to the substrate, and an encapsulant is formed over the crenellated spacer and the at least one top die.

Owner:STATS CHIPPAC LTD

Silicon-based pressure sensor and manufacturing method thereof

ActiveCN105181187ASimple processImprove production yieldForce measurementDifferential pressureDevice form

The invention relates to a silicon-based pressure sensor and a manufacturing method thereof. The sensor comprises a differential pressure sensitive device, a static pressure compensation unit and a packaging structure, wherein the differential pressure sensitive device employs a differential capacitor structure, the differential pressure sensitive device is characterized in by comprising an upper glass fixing pole board, a movable silicon sensitive chip pole board, a lower glass fixing pole board, a glass bottom board and a pressure guide tube from up to down through packaging; the static pressure compensation unit employs a silicon piezoresistive chip in an absolute packaging mode to measure static pressure magnitude and is characterized by employing a point type suspension mode to be fixed above the differential pressure sensitive device, signal drifting amount is small, space is saved, and the static pressure compensation unit and the differential pressure sensitive device form a compound stacked structure welded in the packaging structure in a suspension mode; the packaging structure comprises a sensor foundation, a pressure leading guide tube and a wire leading seat and is characterized by employing a suspension type structure, the compound differential and static pressure structure is packaged in the sensor foundation in a suspension mode, the wire leading seat is arranged at one end of the foundation, the pressure leading guide tube is arranged at the other end of the foundation, each part is welded on the sensor foundation through the improved welding technology.

Owner:SHENYANG ACAD OF INSTR SCI

Spark plug with noble metal chip joined by unique laser welding and fabrication method thereof

ActiveUS7199511B2Improve welding reliabilitySacrifice productivityFuel injection apparatusMachines/enginesEngineeringLaser beams

A spark plug is provided which ensures the reliability of a weld between a noble metal chip and a ground electrode as well as higher durability and ignitability of fuel. The ground electrode is joined to a metal shell, after which the noble metal chip is laser-welded to the ground electrode. The laser welding is achieved by emitting laser beams around an interface between the noble metal chip and the ground electrode outside a given angular range within which the metal shell will be an obstruction to the traveling of the laser beams. Specifically, the laser beams are emitted without any optical interference with the metal shell. This permits the angle between the orientation of each of the laser beams and the surface of the ground electrode to be minimized regardless of the metal shell, thus ensuring a desired depth of the fused portions in the noble metal chip.

Owner:DENSO CORP

Welding joint for fuel tank

InactiveUS20070000928A1Improve welding strengthReliable calculationSynthetic resin layered productsLarge containersFuel tankWeldability

A welding joint for a fuel tank includes a cylindrical portion and an annular weld portion. The weld portion has a multi-layer structure formed by layering an inner layer member made of a resin alloy material obtained by alloying a modified HDPE, to which a functional group having a high affinity to a hydroxyl group of EVOH is introduced, and EVOH, or by alloying the modified HDPE, normal HDPE and EVOH, and an outer layer member which uses the HDPE resin and / or modified HDPE resin and has high weldability to the fuel tank. Each of the inner and outer layer members is heat-welded to the fuel tank at a corresponding welding end surface. In a vicinity of at least one of the welding end surfaces of the inner outer layer members, a flow preventing portion that prevent a molten part of the inner layer member from flowing the outer layer member is provided.

Owner:SUMITOMO RIKO CO LTD

Unleaded halogen-free soldering paste with high wettability

InactiveCN102069315AImprove wettabilityLess corrosiveWelding/cutting media/materialsSoldering mediaActive agentSolvent

The invention relates to a soldering assistant chemical used for electronic assembly, in particular to an unleaded halogen-free soldering paste in the field of brazing material used for electronic surface assembly, which consists of 80-93 percent by weight of solder alloy powder and 7-20 percent by weight of flux, wherein the solder alloy powder is unleaded alloy, and the flux comprises 30-55 percent by weight of resin, 20-50 percent by weight of solvent, 1-8 percent by weight of thixotropic agent and 0.01-20 percent by weight of active agent, and the active agent comprises amino acid p-toluenesulfonic acid salt and / or amino-acid ester p-toluenesulfonic acid salt. The soldering paste has higher wettability, reduces corrosivity, has good storage stability, is unleaded and halogen-free, meets the requirement of environmental protection, and can be applied to the electronic industry.

Owner:SICHUAN UNIV +1

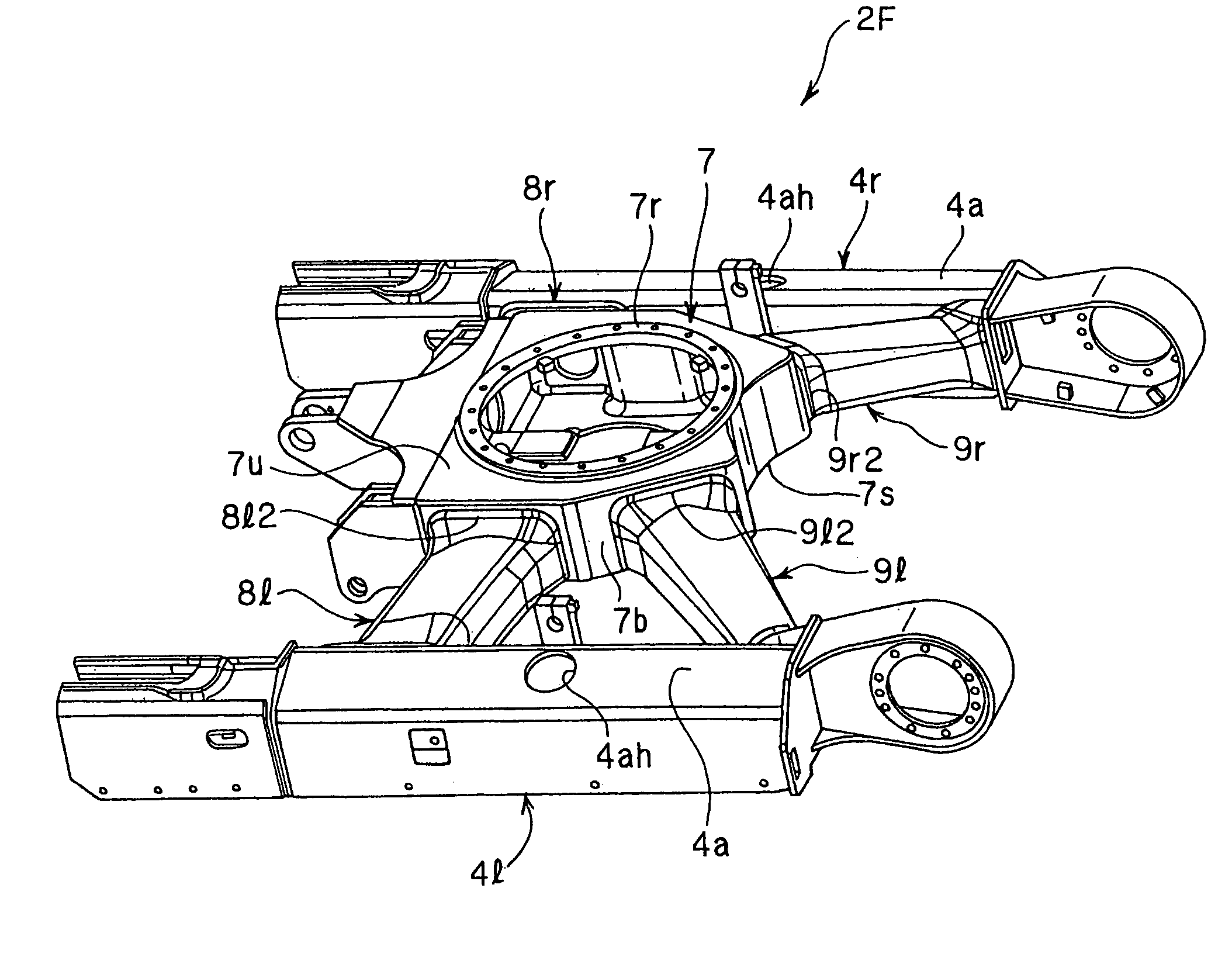

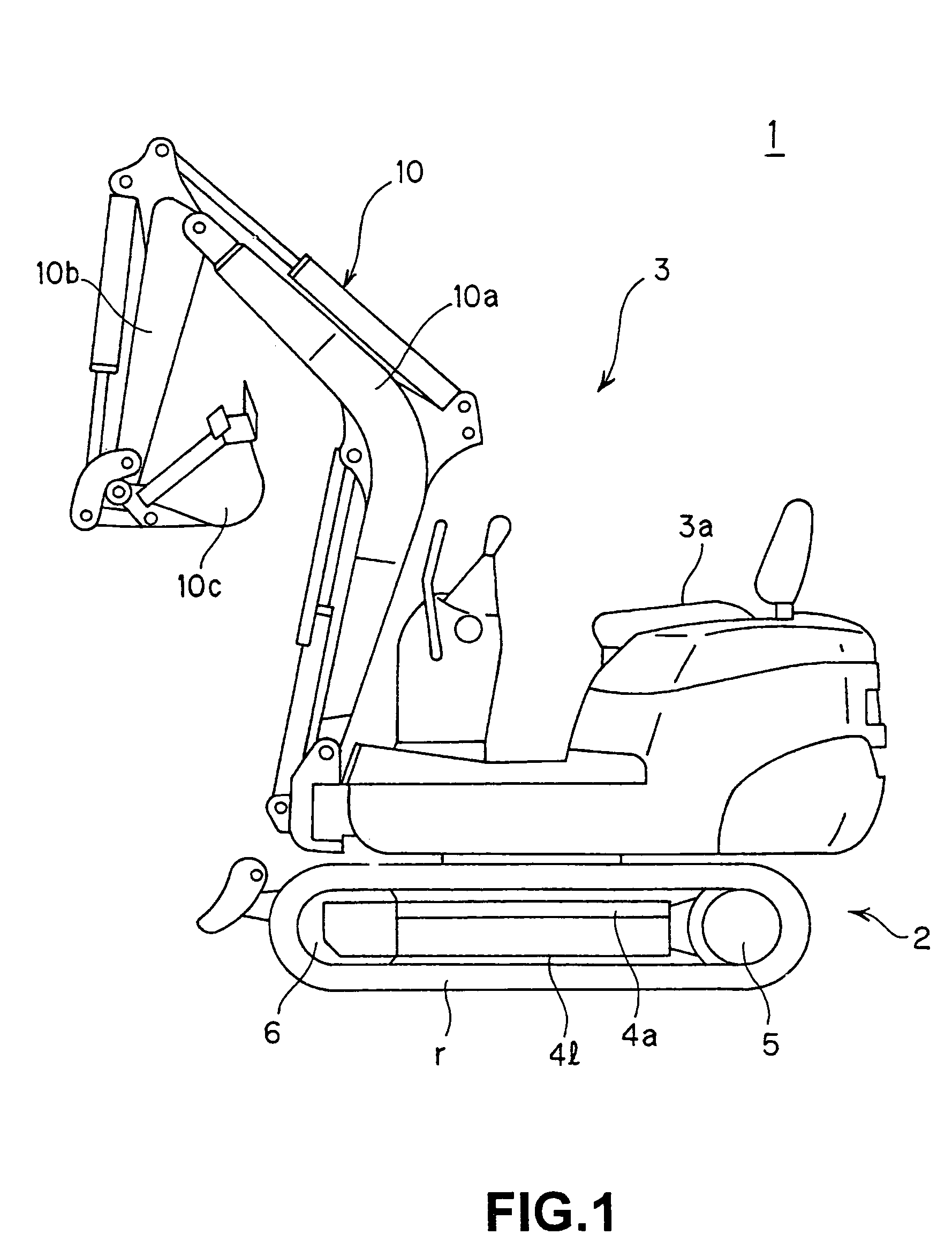

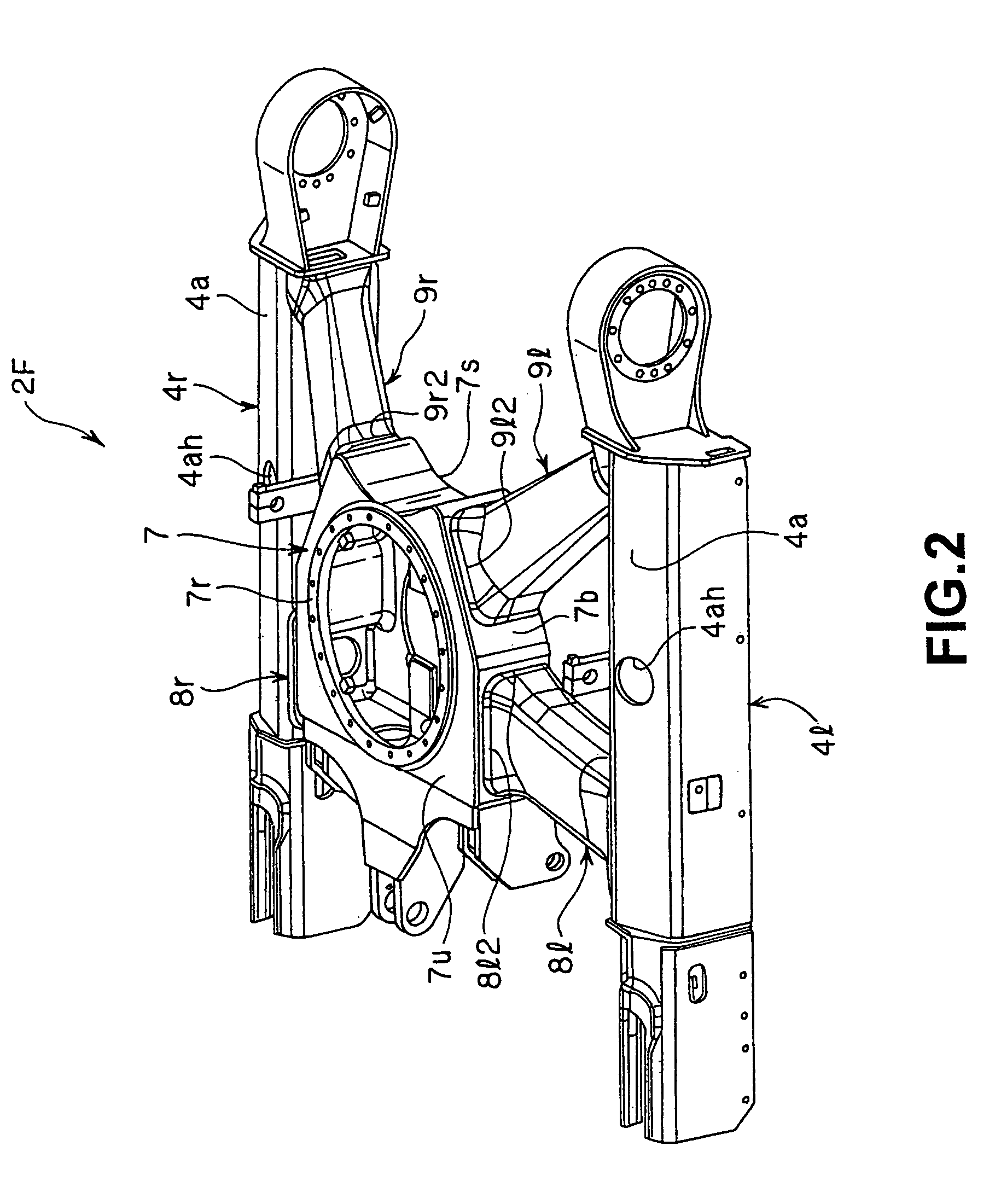

Construction machine

InactiveUS7204518B2Improve rigidityHigh mechanical reliabilityVehicle seatsIndoor gamesHeight differenceLower face

A construction machine where a load acting on a vehicle body during an operation is transferred to ensure the strength of the vehicle body, thereby improving reliability including welding reliability. In the construction machine, at least one of the height differences between an upper face or a lower face of the center frame at a joining portion between the center frame and the connecting member and an upper face or a lower face of a center joining portion of the connecting member is set respectively at a dimension that is approximately equal to or less than the thickness of an upper face plate or a lower face plate of the center frame.

Owner:KOMATSU LTD +1

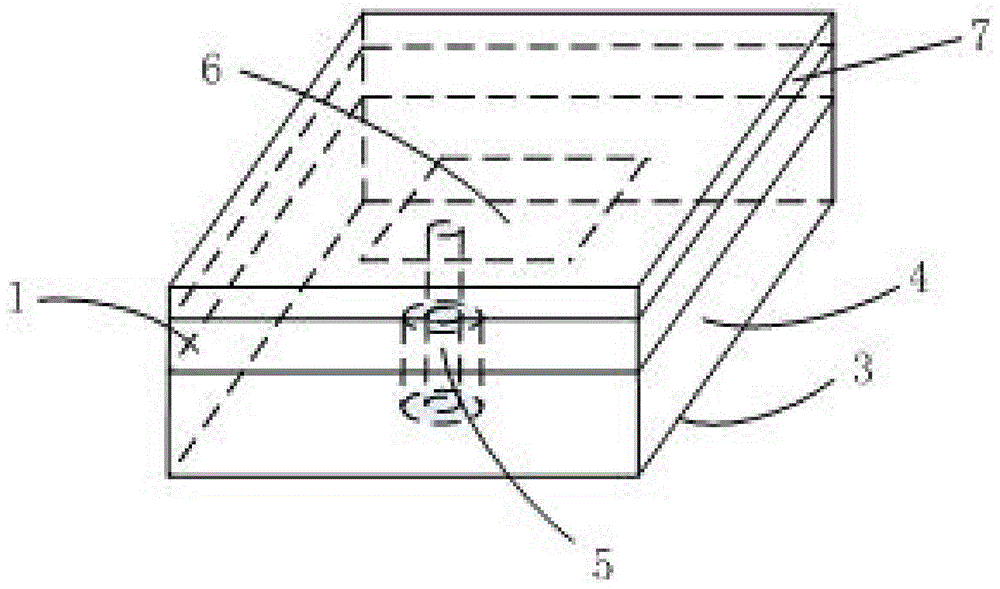

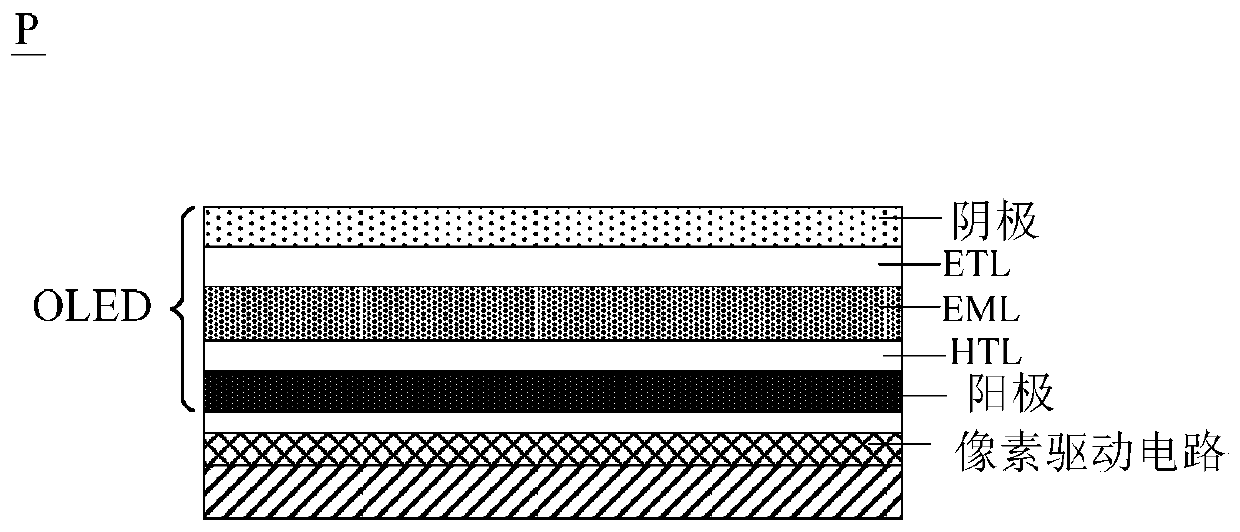

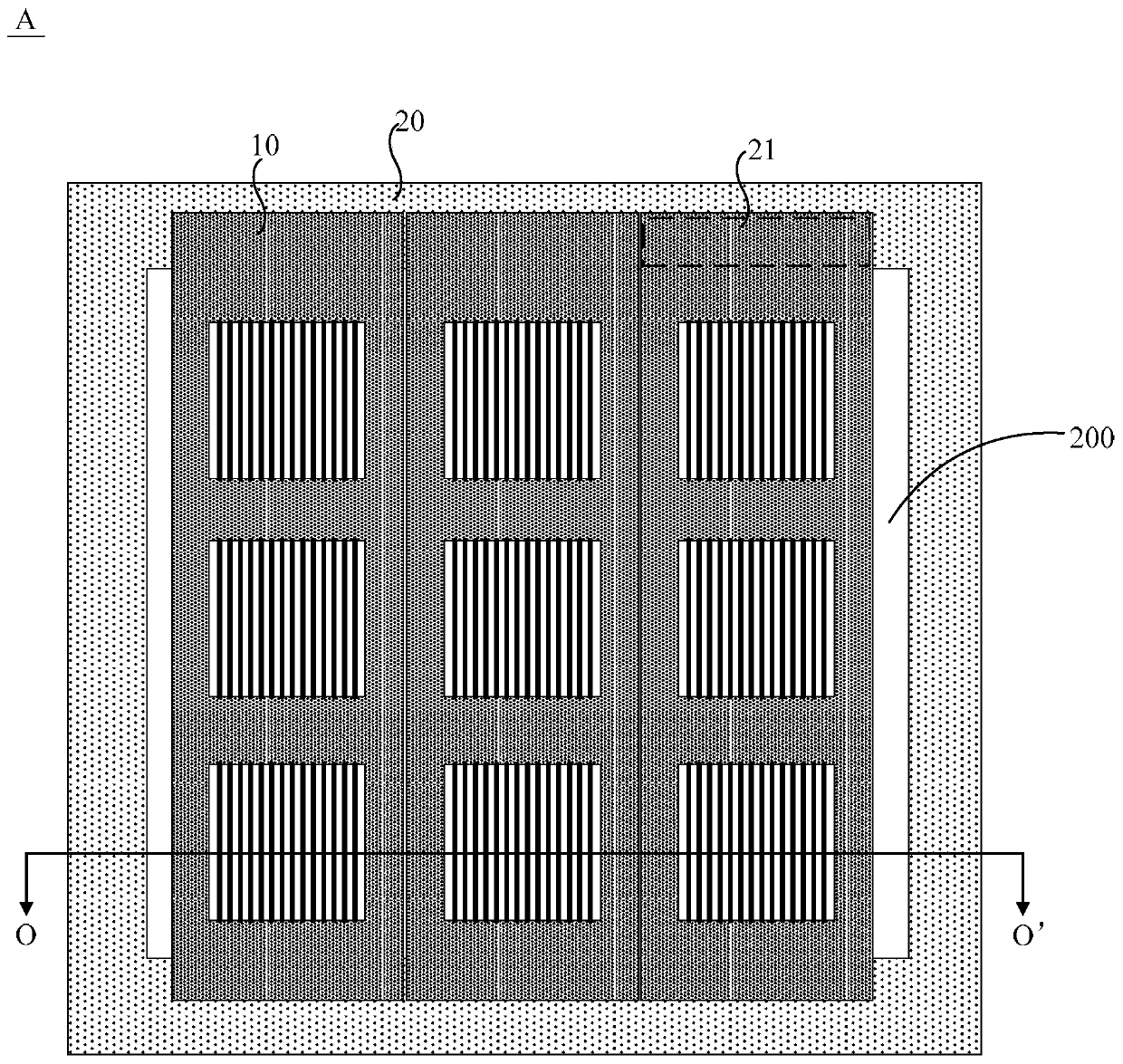

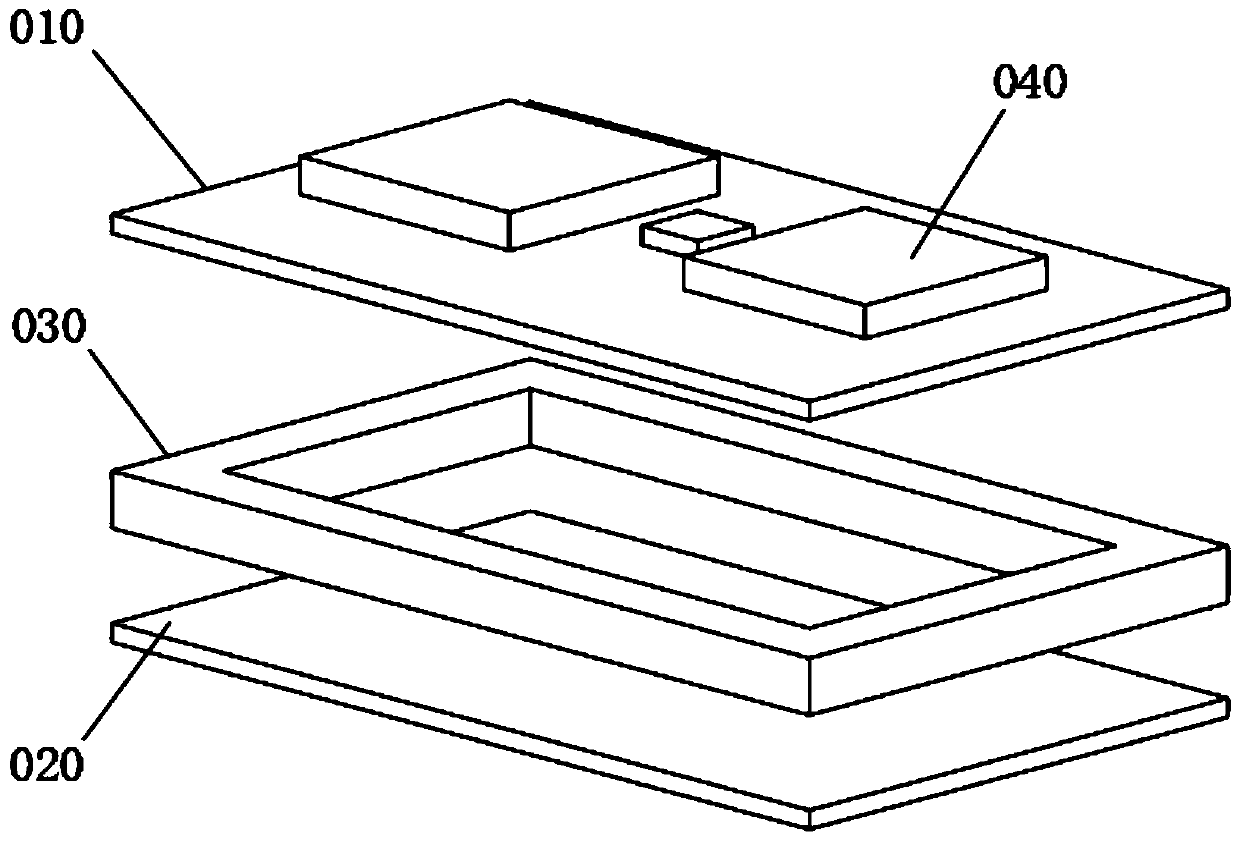

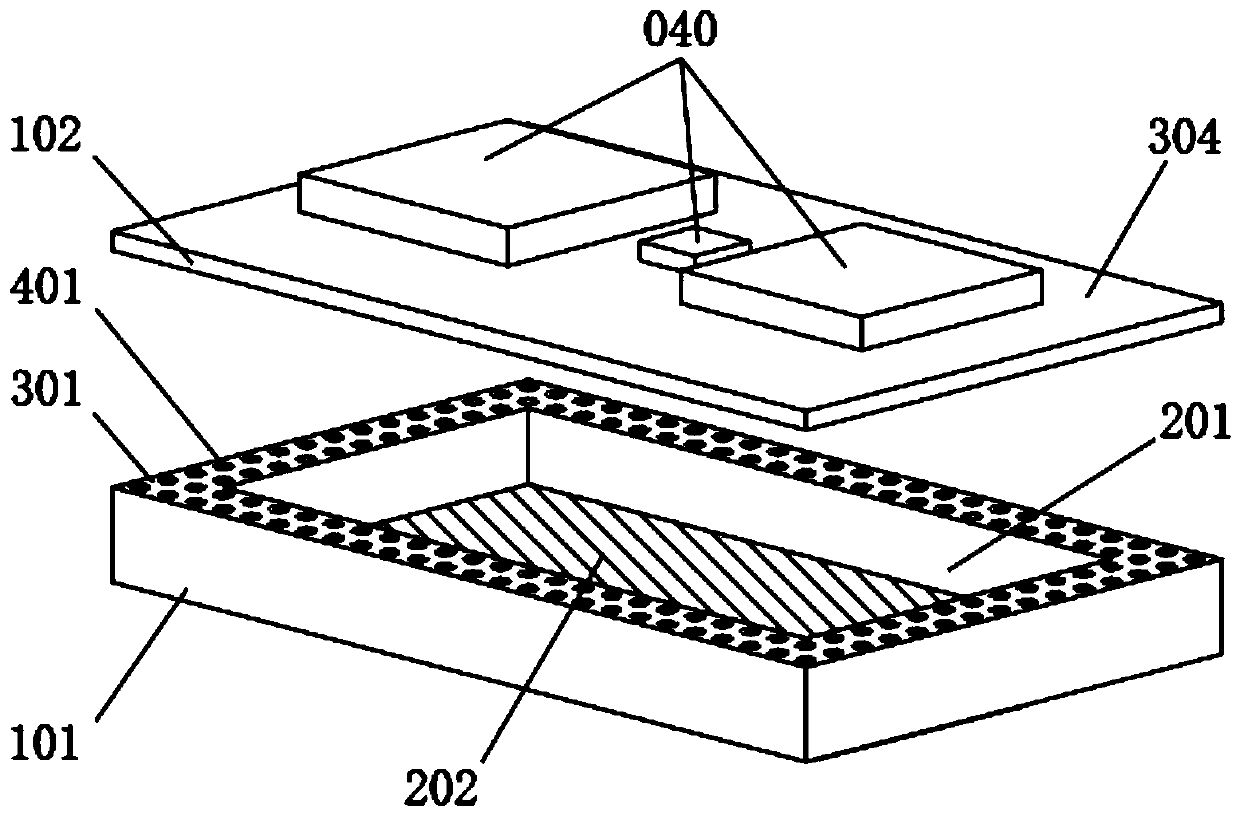

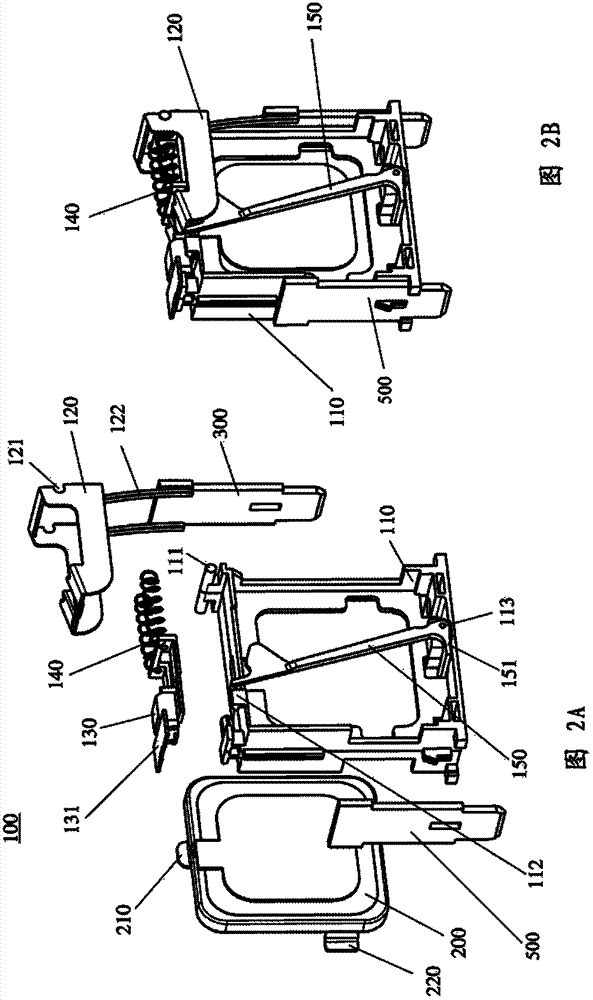

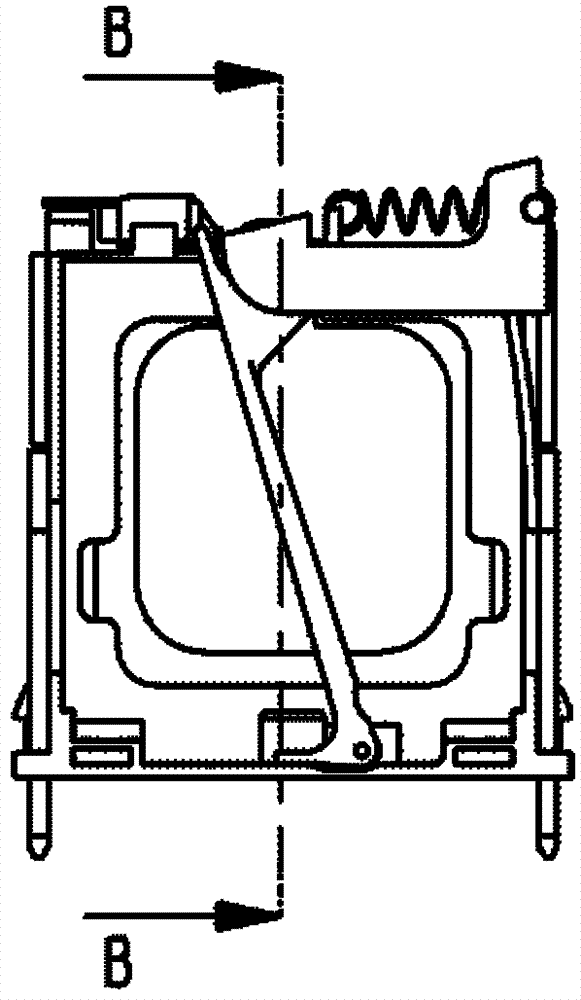

Mask, manufacturing method of mask and mask assembly

ActiveCN109778116AEasy to controlImprove welding reliabilityVacuum evaporation coatingSputtering coatingEvaporationEngineering

The embodiment of the invention provides a mask, a manufacturing method of the mask and a mask assembly, and relates to the field of masks. The problem that welding failures are caused by the fact that laser energy is difficult to control during welding can be solved; the mask includes a mask pattern region and a non-mask pattern region around the mask pattern region; the mask pattern region includes at least one effective mask region; the effective mask region includes a plurality of evaporation holes and shielding strips located between the evaporation holes; the mask is provided with a soldering region in the non-masking pattern region; and at least the thickness of the soldering region of the non-masking pattern region of the mask is larger than the thickness of the shielding strips inthe effective mask region of the mask.

Owner:BOE TECH GRP CO LTD +1

Stacking slice type piezoresistor and manufacturing method thereof

ActiveCN101350240AAddressing poor performanceImprove welding reliabilityResistor housing/enclosing/embeddingResistor manufactureVaristorNickel

The invention provides a laminated slice type voltage-sensitive resistor and the manufacturing method of the voltage-sensitive resistor, which is suitable for electronic enterprises, the resistor comprises a lower cover, an upper cover, a voltage-sensitive resistor unit and a terminal electrode, wherein the voltage-sensitive resistor unit is arranged between the upper and the lower covers, the upper and the lower covers are made of ceramic protecting materials, the voltage-sensitive resistor unit is composed of an internal electrode, voltage-sensitive resistor film and ceramic protecting film, wherein the internal electrode and the voltage-sensitive resistor film are overprinted, the ceramic protecting film is overprinted on both sides of the overprinted internal electrode and the overprinted voltage-sensitive resistor film. The manufacturing method comprises the processes of batching, pulping, tape preparing, printing, hot-water voltage-sharing, slicing, dumping, sintering, end capping, electroplating and the like. The invention adopts the ceramic protecting materials and the method of overprinting the voltage-sensitive resistor film to form a homogenous, compact and moisture-proof protecting layer on the other four surfaces except both ends of the voltage-sensitive resistor, thereby the product can be easily electroplated with nickel and tin, and the reliability of the welding of the product is greatly improved.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

Stackable semiconductor encapsulation construct for multi-cylinder body

InactiveCN101355070AIncrease joint areaIncreased complexitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor package

The invention relates to a polycylinder stackable semiconductor packaging structure. The structure mainly comprises a wafer carrier, a wafer and a plurality of downwards convex block groups, wherein the wafer carrier has a plurality of switchover pads on an upper surface and a plurality of external pads on a lower surface; the wafer is arranged on and is electrically connected with the wafer carrier; the downwards convex block groups are correspondingly arranged on the external pads, and each downwards convex block group connected with each external pad consists of a plurality of conducting cylinders; and a solder filling gap is arranged between adjacent conducting cylinders of the same downwards convex block group. The stackable semiconductor packaging structure is used to increase welding area and perplex the shape of a welding interface, thereby achieving high durability of welding spots and reducing the growing possibility of cracks. In addition, the convex block group arranged on each external pad has the solder filling gap, solder can be filled and stored in the convex block group, so that a plaque does not extrude the solder to cause bridging short circuit even when inclined or warped; therefore, the structure is particularly suitable for practical use.

Owner:POWERTECH TECHNOLOGY

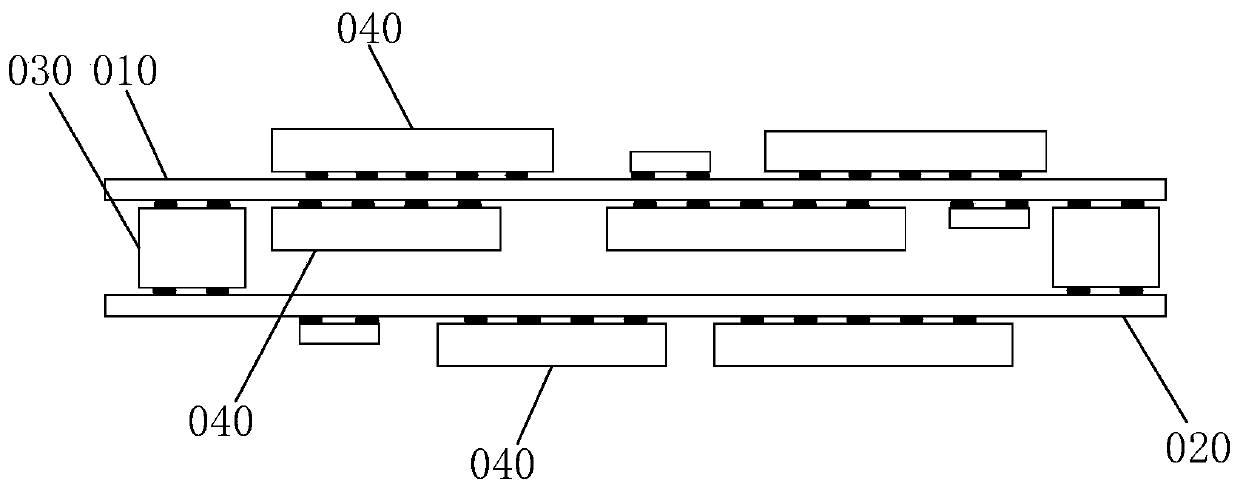

Printed circuit board, manufacturing method thereof and electronic equipment

InactiveCN110149762AAvoid warpingAvoid the consequences of electrical connection failuresPrinted circuit assemblingPrinted circuits structural associationsSurface mountingEngineering

The embodiment of the invention provides a printed circuit board, a manufacturing method thereof and electronic equipment. The printed circuit board comprises a first printed circuit board. The firstprinted circuit board comprises a first surface and a second surface, and the first surface and the second surface are opposite in direction. The first printed circuit board is provided with a first groove, and an opening of the first groove faces the first surface. The first surface is provided with a first bonding pad. An electronic element is mounted on the second surface. The printed circuit board also comprises a second printed circuit board which comprises a third surface and a fourth surface, and the third surface and the fourth surface are opposite in direction. The third surface is provided with a second bonding pad, and the second bonding pad corresponds to the first bonding pad in position. The third surface and the fourth surface are respectively provided with electronic elements. The first printed circuit board and the second printed circuit board are welded through the first bonding pad and the second bonding pad to form a stacked structure. The printed circuit board provided by the invention is not likely to warp, has stronger stress deformation resistance, and can prolong the service life of electronic equipment.

Owner:HUAWEI TECH CO LTD

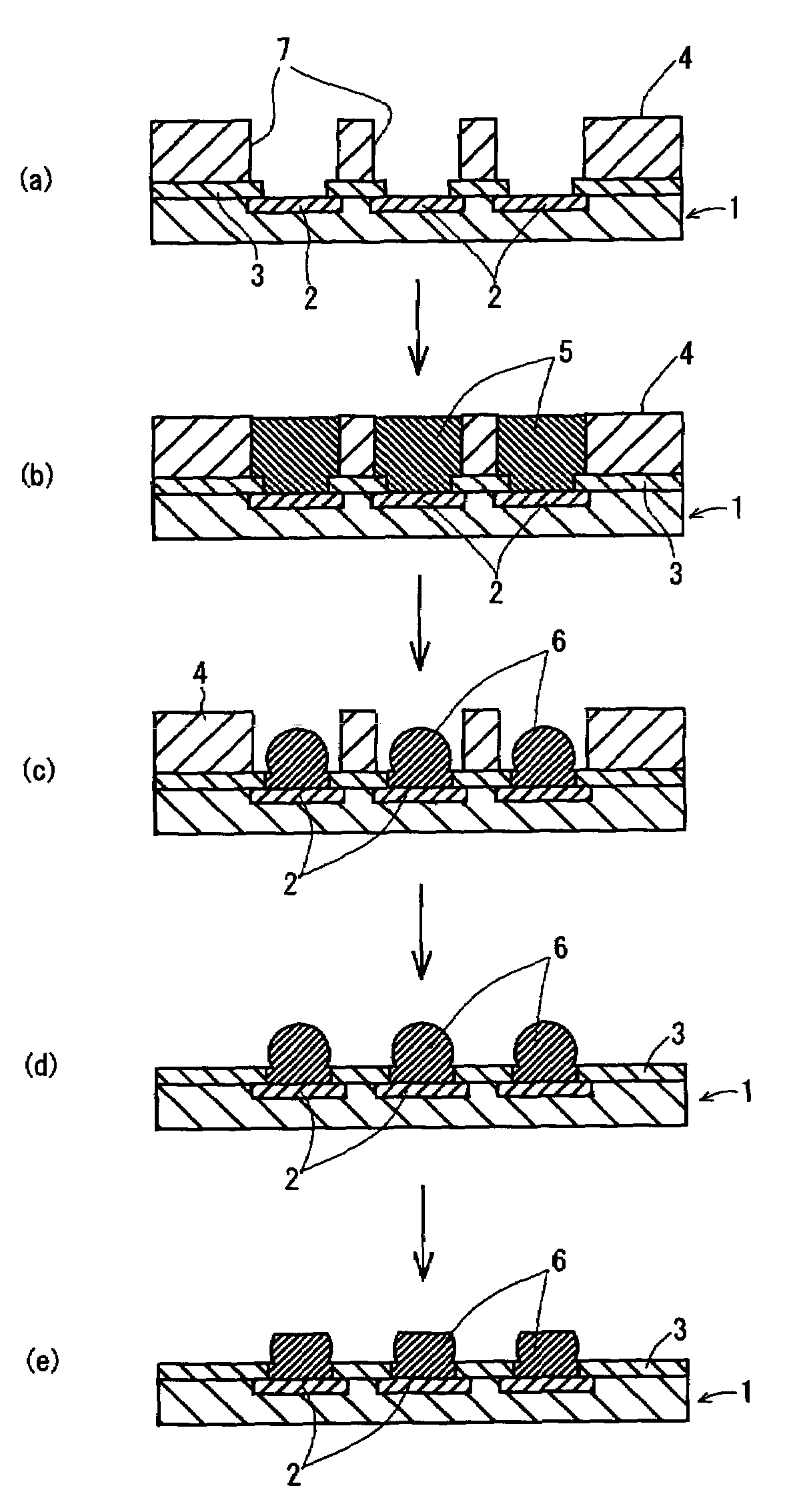

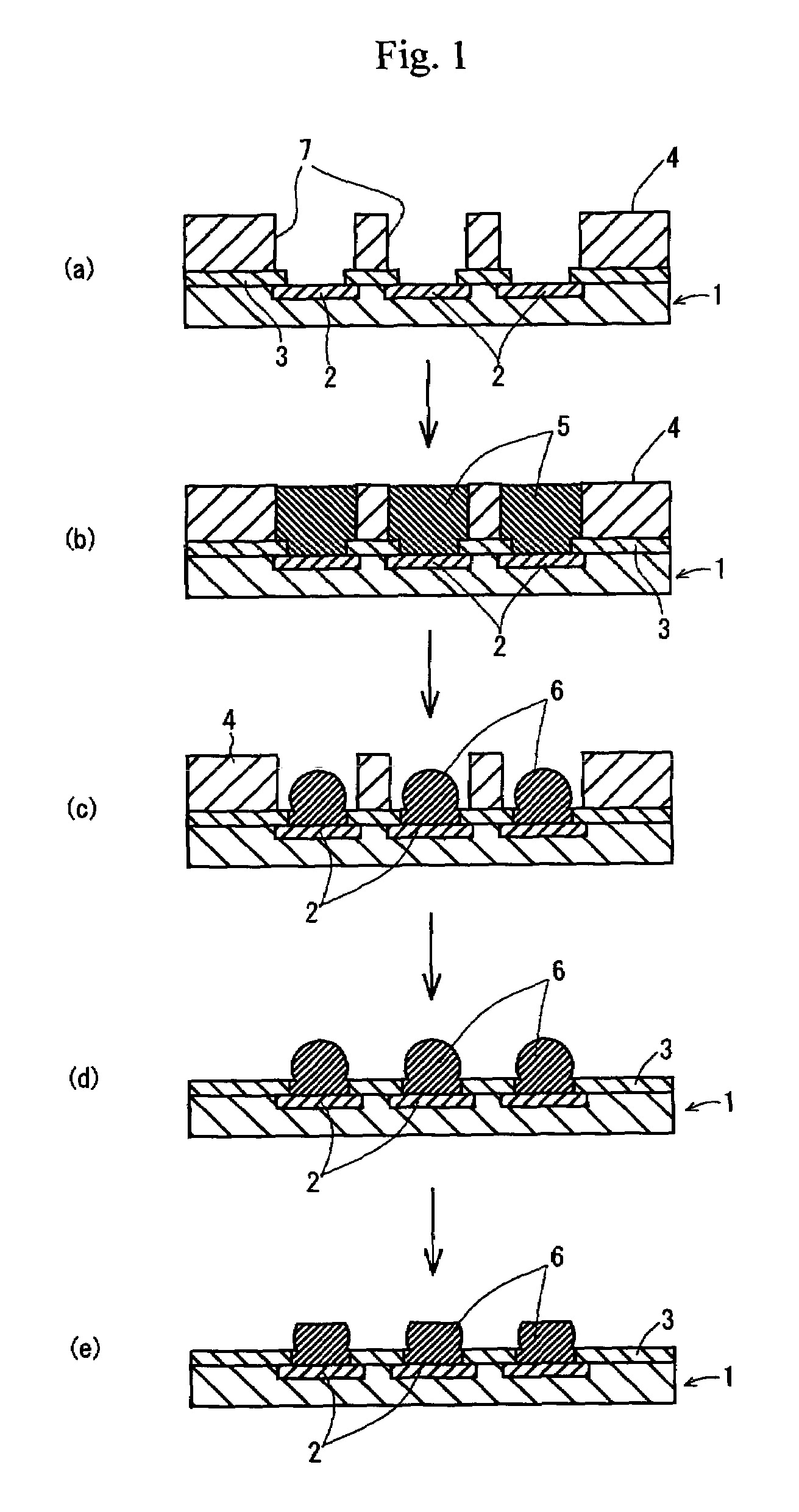

Method for removing resin mask layer and method for manufacturing solder bumped substrate

ActiveUS7291517B2Easy to disassembleShort timeDecorative surface effectsSolid-state devicesResistHeat treated

Using a dry film resist that is a photosensitive resin, a resin mask layer is formed around electrodes on a substrate. A solder precipitating composition is applied on the substrate, and this solder precipitating composition is heated to precipitate solder on the surface of the electrodes. Subsequently, in removing the resin mask layer, at least one selected from glycol ethers and aminoalcohols is used. Thereby, the resin mask layer is removed after heating process. This makes it possible to easily remove the heat-processed resin mask layer in a short period of time without damaging solder resist and solder bumps on the substrate.

Owner:HARIMA CHEM INC

Method for actively sealing sapphire sheet and metal

ActiveCN103949742AGuaranteed wall thicknessReduce the chance of burstingSoldering apparatusThermal dilatationTitanium zirconium

The invention provides a method for actively sealing a sapphire sheet and metal. The method is low in welding temperature, high in efficiency, good in reliability and low in cost. According to the method, high-temperature metallization is not required, expensive vacuum coating equipment and precious metal targets are also not required, the defects of long intermediate treatment process and time consumption are overcome, the total welding time is shortened, and the production efficiency is improved; the defect that flatness with high precise size and demanding requirement is required to be machined when welding sheets are adopted is avoided, and active titanium, zirconium, copper and nickel welding flux is directly adopted; the thickness of the wall of the sealing part of a metal piece is small, so that the thermal stress effect caused by the reaction of extrusion to the metal piece by the thermal expansion of the sapphire sheet during welding is reduced, and the probability of explosion of the sapphire sheet is reduced; meanwhile, welding can be accomplished at one step when the vacuum atmosphere temperature is lower than 1000 DEG C, the requirement on welding equipment is low, the product welding reliability and the yield are high, the air impermeability is good when baking is performed at the high temperature of 560 DEG C for 36 hours, and the requirement on the air impermeability of ultrahigh frequency electron tubes can be guaranteed.

Owner:XI AN JIAOTONG UNIV +1

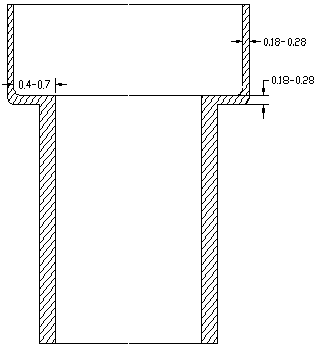

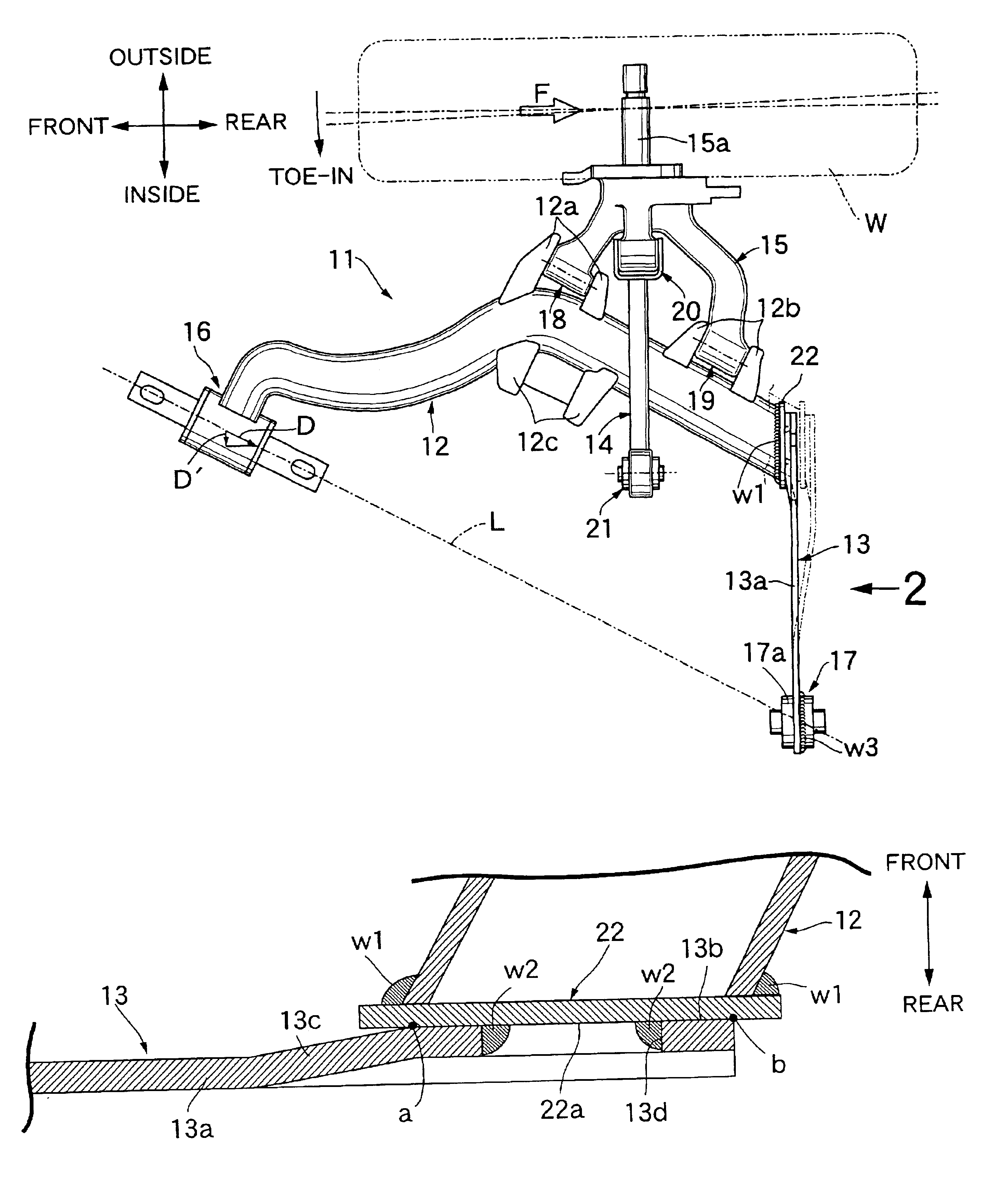

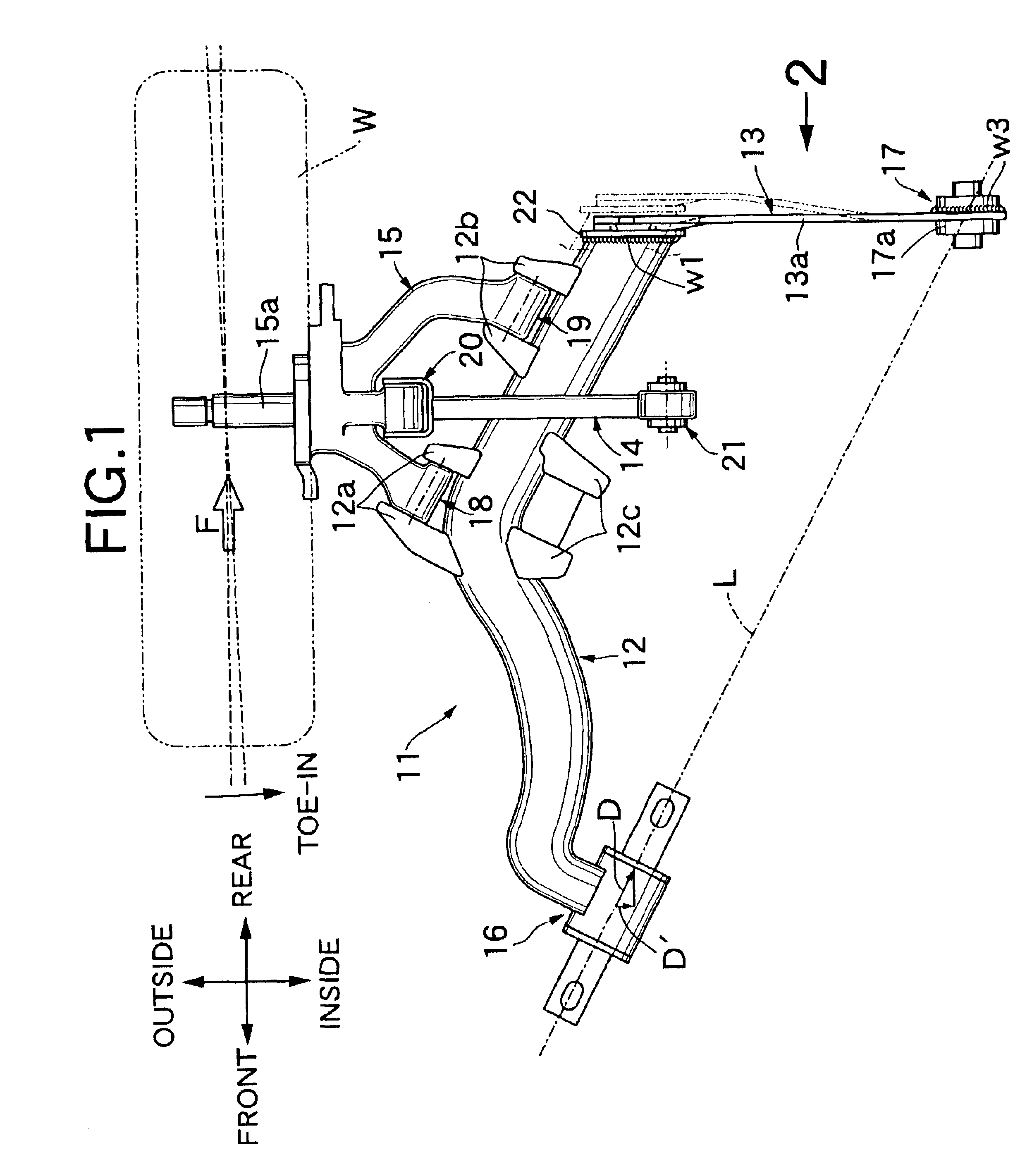

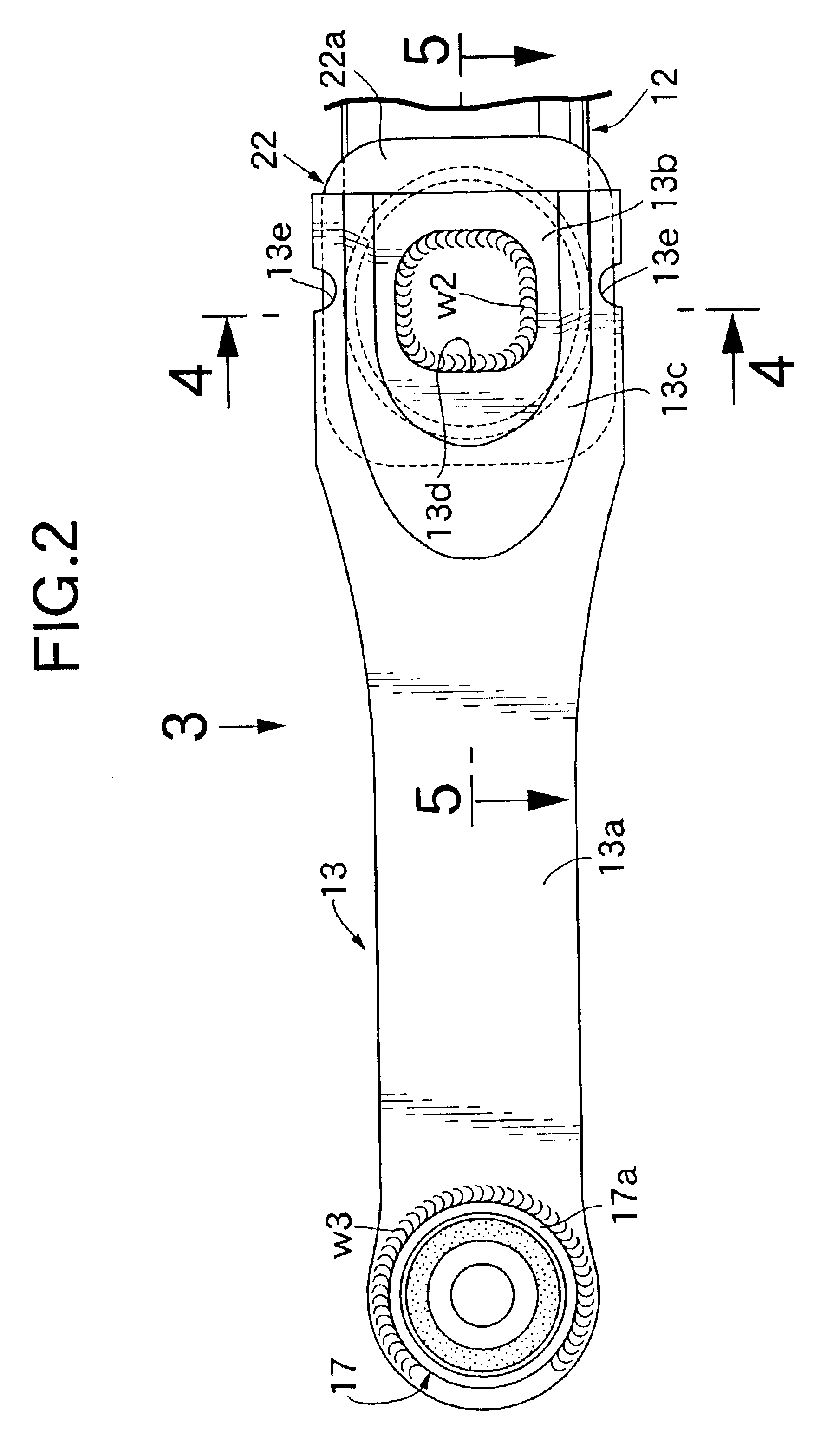

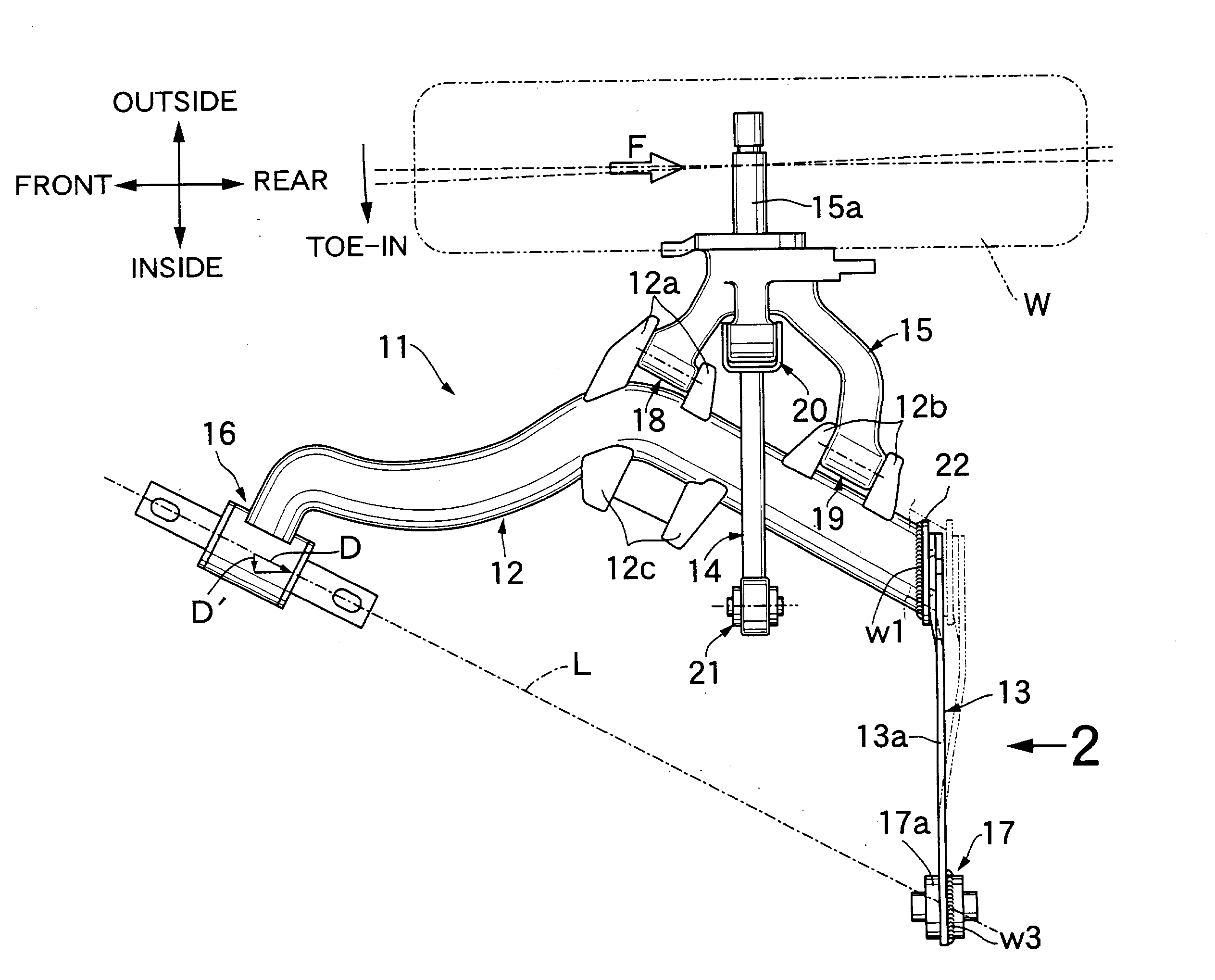

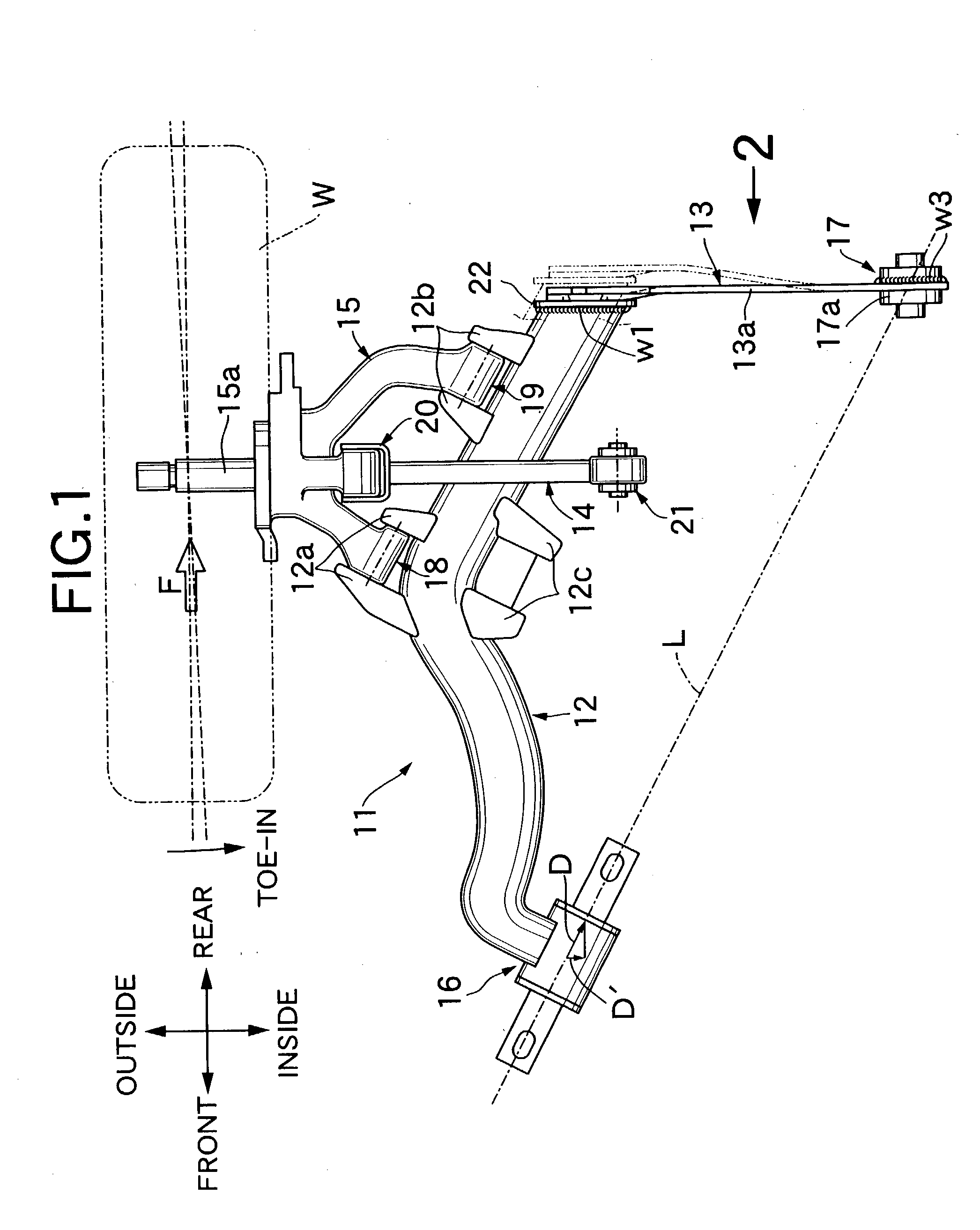

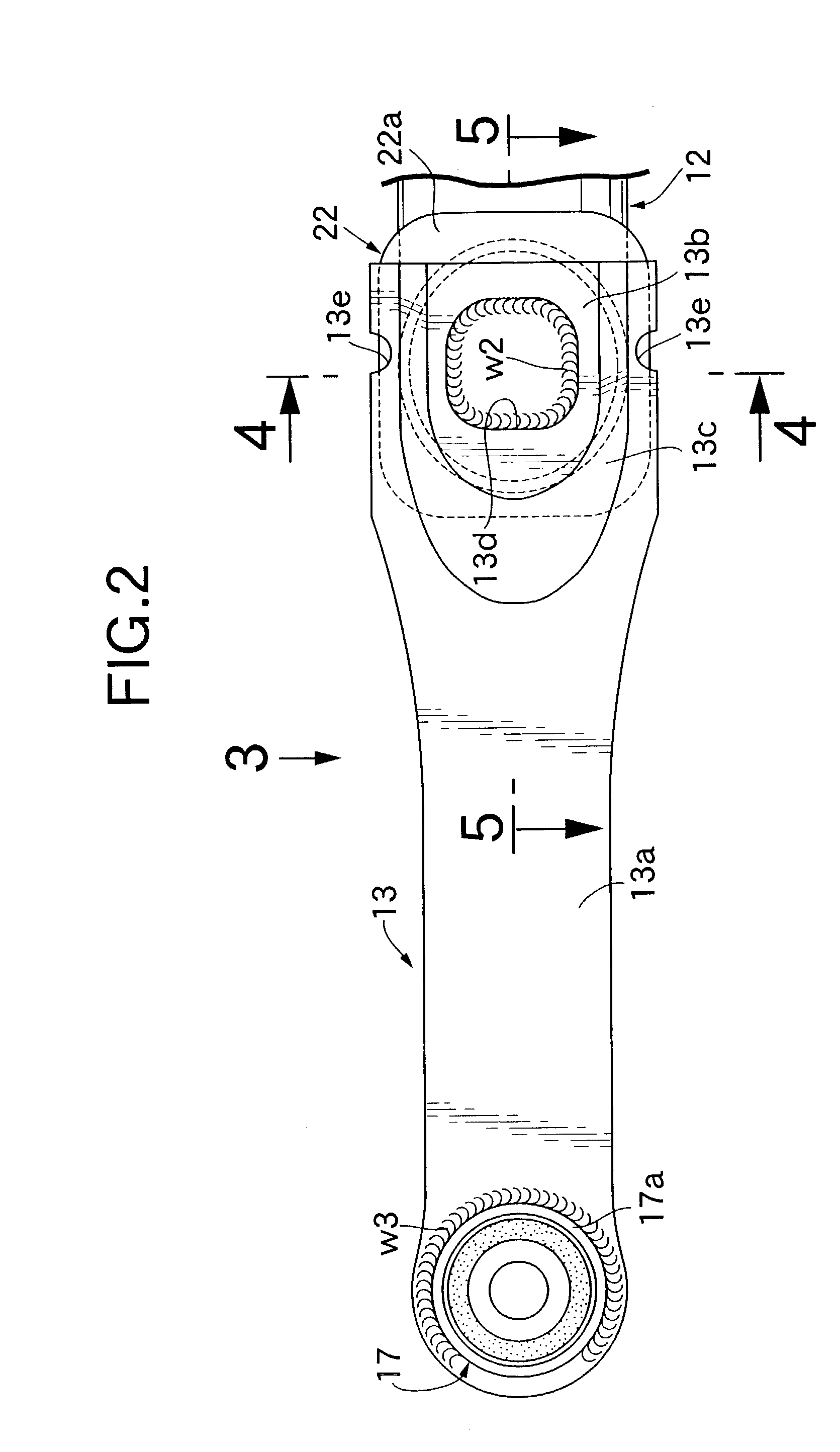

Vehicular suspension

InactiveUS6843492B2Improve workabilitySmall sizeResilient suspensionsPivoted suspension armsTrailing armEngineering

A vehicular suspension includes a trailing arm and a substantially plate-like lower arm. The trailing arm is pivotably supported at its front end on a vehicle body via an elastic joint and extends from the front end toward the rear of the vehicle body. The lower arm extends in the vehicle width direction with its inner end pivotably supported on the vehicle body and its outer end fixed to a rear part of the trailing arm. A flat first seating surface of an end plate welded to the rear end of the trailing arm is superimposed on a flat second seating surface provided at the outer end of the lower arm, and an inner periphery of a closed rectangular opening formed on the second seating surface is welded to the first seating surface by a weld. The second seating surface of the lower arm protrudes from a main body portion via a slant surface.

Owner:F TECH INC

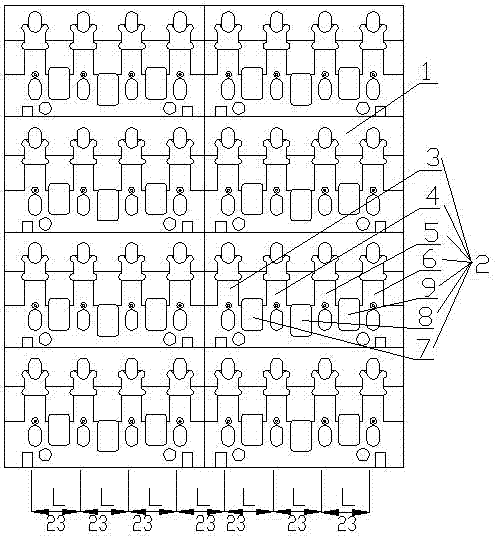

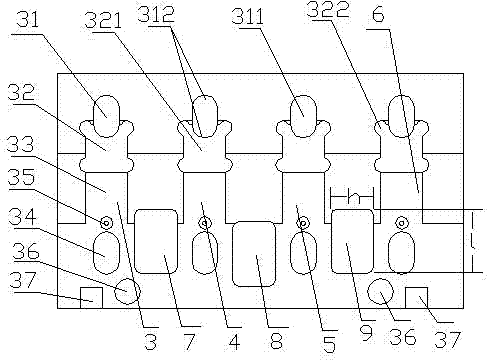

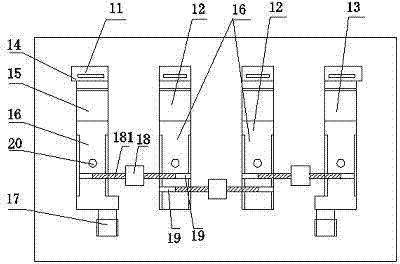

Metal assembly welding tool

ActiveCN103894700AEasy to fixThe process is simple and fastMetal working apparatusSoldering auxillary devicesEngineeringMetal

The invention relates to a metal assembly welding tool. The metal assembly welding tool comprises a base provided with eight sets of metal locating modules, wherein each metal locating module is composed of four metal assembly locating molds and three diode locating molds, and each diode locating mold is located between the corresponding two metal assembly locating molds. The metal assembly welding tool can be used for assembling a metal assembly in a photovoltaic junction box, the metal assembly can be conveniently and rapidly welded, and work efficiency is greatly improved.

Owner:JIANGSU HAITIAN MICROELECTRONICS TECH

Vehicular suspension

InactiveUS20040100062A1Enhancing strength and durabilityImprove welding reliabilityResilient suspensionsPivoted suspension armsTrailing armEngineering

A vehicular suspension includes a trailing arm and a substantially plate-like lower arm. The trailing arm is pivotably supported at its front end on a vehicle body via an elastic joint and extends from the front end toward the rear of the vehicle body. The lower arm extends in the vehicle width direction with its inner end pivotably supported on the vehicle body and its outer end fixed to a rear part of the trailing arm. A flat first seating surface of an end plate welded to the rear end of the trailing arm is superimposed on a flat second seating surface provided at the outer end of the lower arm, and an inner periphery of a closed rectangular opening formed on the second seating surface is welded to the first seating surface by a weld. The second seating surface of the lower arm protrudes from a main body portion via a slant surface.

Owner:F TECH INC

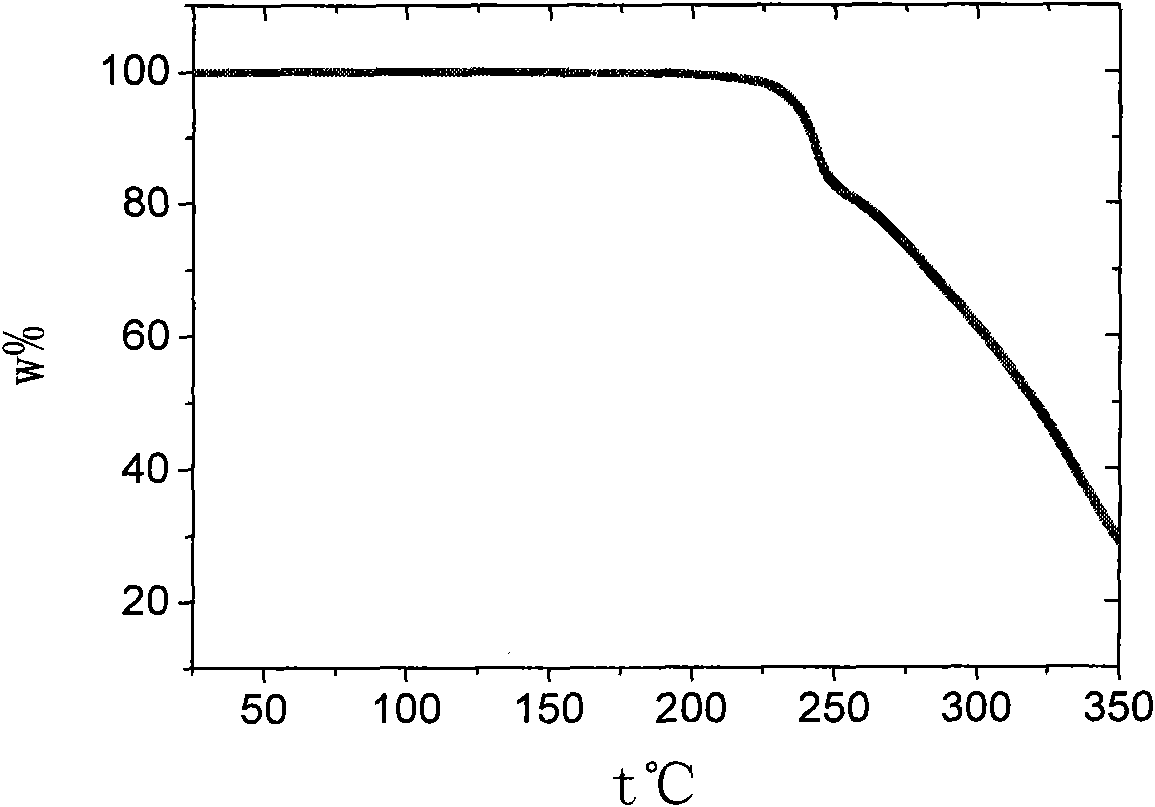

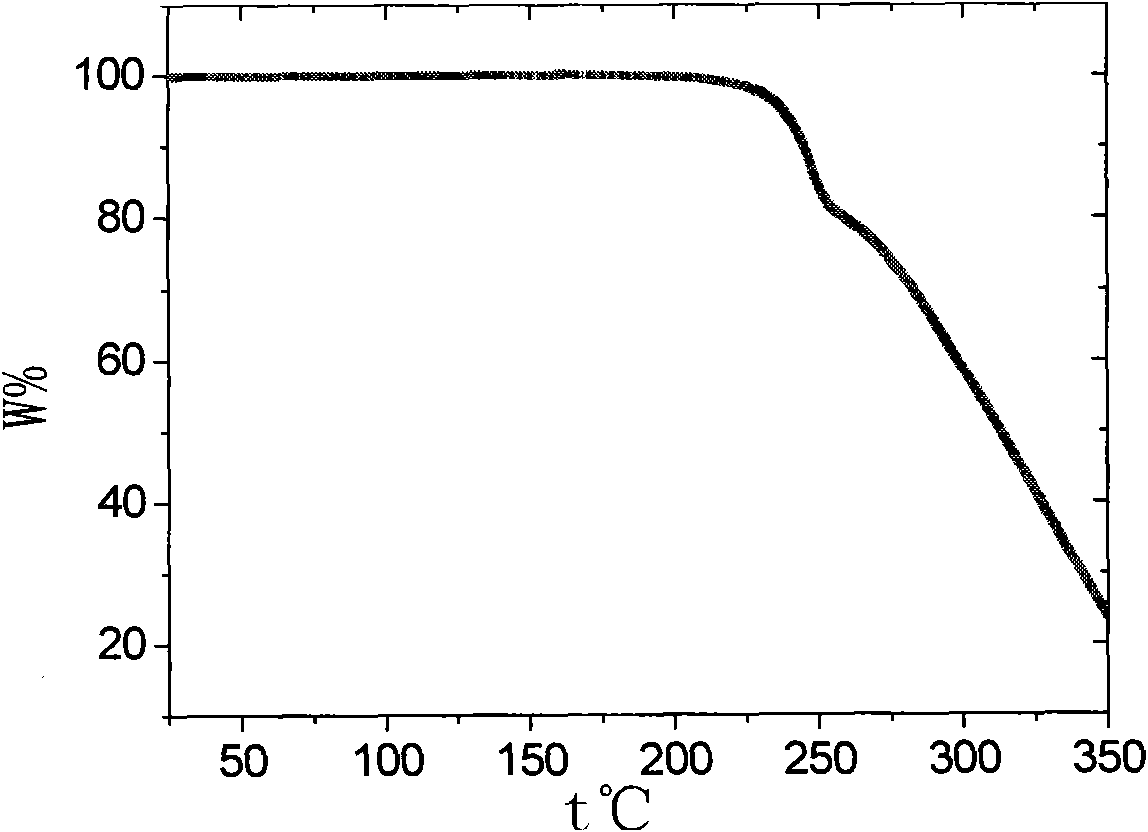

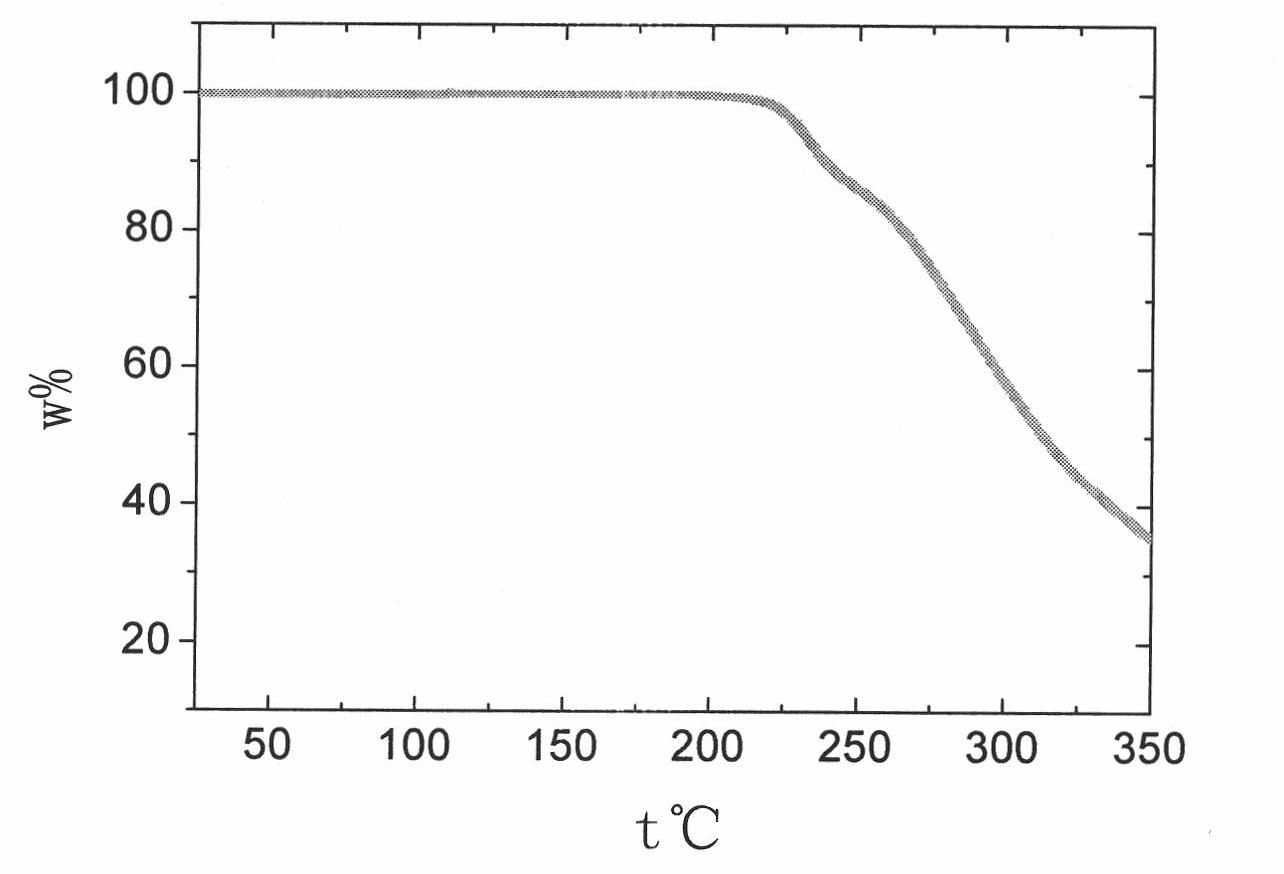

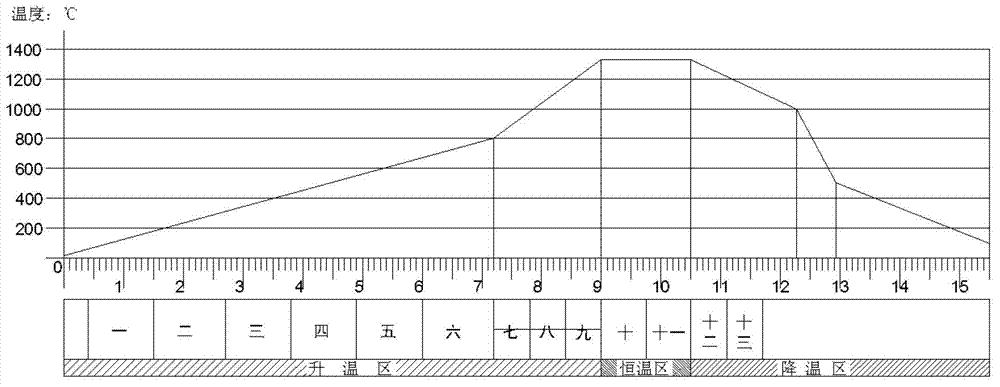

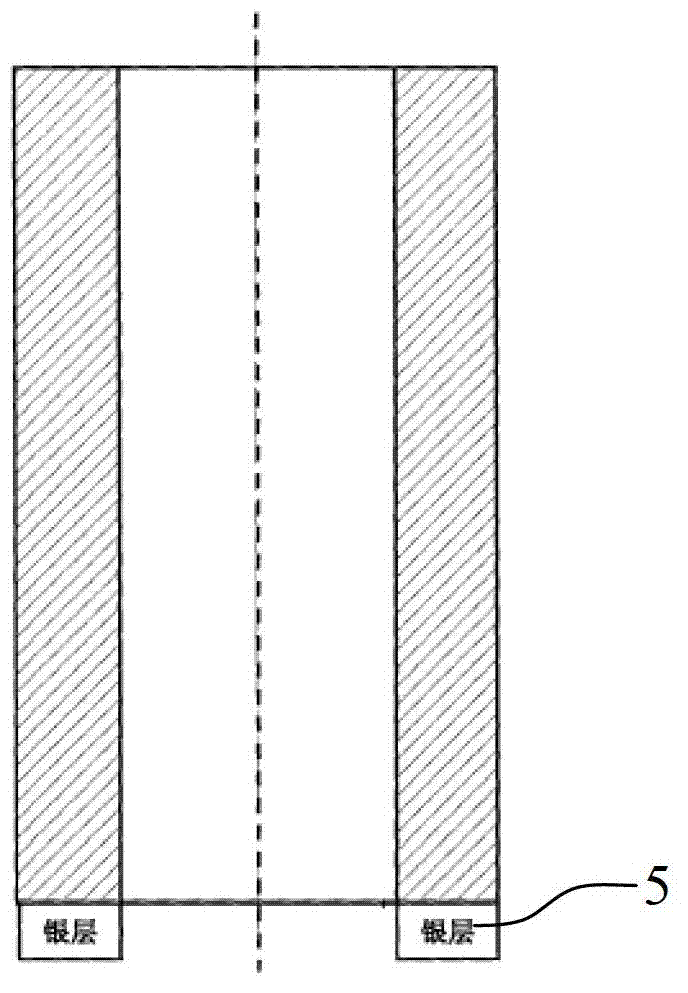

Novel medium cavity filter with cavity

ActiveCN102969549AReduce lossSteep frequency characteristicResonatorsThermal expansionTemperature coefficient

The invention discloses a novel medium cavity filter with a cavity. The novel medium cavity filter comprises the cavity and medium resonators, wherein each medium resonator is a cylinder with a through hole and is prepared from the following components according to mass percent: 29%-32% of calcium carbonate with purity of 97.5%, 9%-11% of aluminum oxide with purity of 97.5%, 21%-25% of neodymium oxide with purity of 99.5%, and 35%-38% of titanium dioxide with purity of 99.6%; a silver layer is coated at one end of each medium resonator, and the other end of the medium resonator is welded inside the cavity; the cavity is prepared from the following components according to mass percent: 95%-96% of aluminum oxide, 2%-3% of calcium carbonate, 0.8%-1.5% of lanthanum oxide, and 0.2%-0.5% of samarium oxide; and the dielectric constant of the cavity is 9.5. The medium cavity filter disclosed by the invention is high in Q value, small in size and adjustable in temperature coefficient, and can ensure high reliability of a product structure and good consistency of thermal expansion coefficients of the cavity and the medium resonators.

Owner:江苏灿勤科技股份有限公司

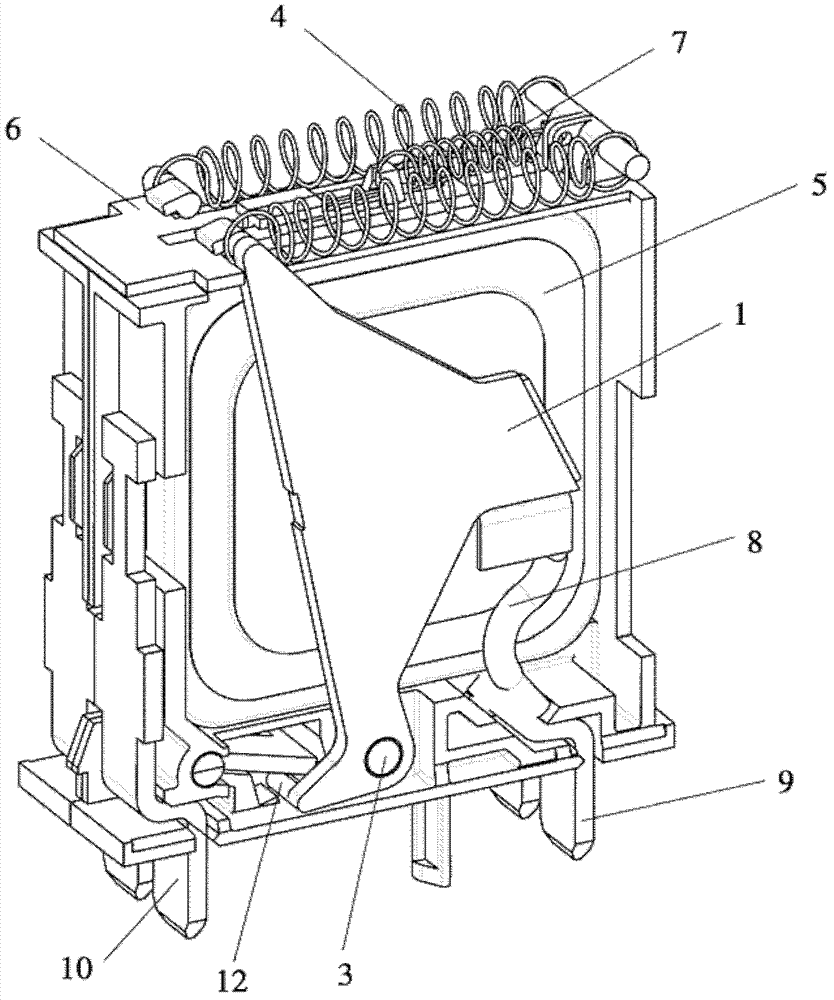

Surge protective device (SPD) and trip mechanism thereof

ActiveCN103094013AGuaranteed electrical distanceEasy to achieve synchronous trippingSpark gap detailsSwitch operated by excess voltageEngineeringSoldering

The invention discloses a surge protective device (SPD) and a trip mechanism of the SPD. The trip mechanism comprises a support and a trip rod, wherein the support is used for containing at least one metallic oxide rheostat, and the trip rod is arranged on the support in a pivotal mode and connected with one of electrodes of the metallic oxide rheostat through low-temperature soldering flux. The trip mechanism further comprises a sliding block, the sliding block is arranged between a first position and a second position on the support in a sliding mode and obliquely pressed to a trip position, and under the normal working condition, the sliding block is maintained in the first position due to the fact that the oblique press is overcome by the trip rod. under the trip condition, under the action of the oblique press, the sliding block slides towards the second position to cause the trip rod to pivotally rotate along the direction which is far from the electrodes of the metallic oxide rheostat.

Owner:SCHNEIDER ELECTRIC IND SAS

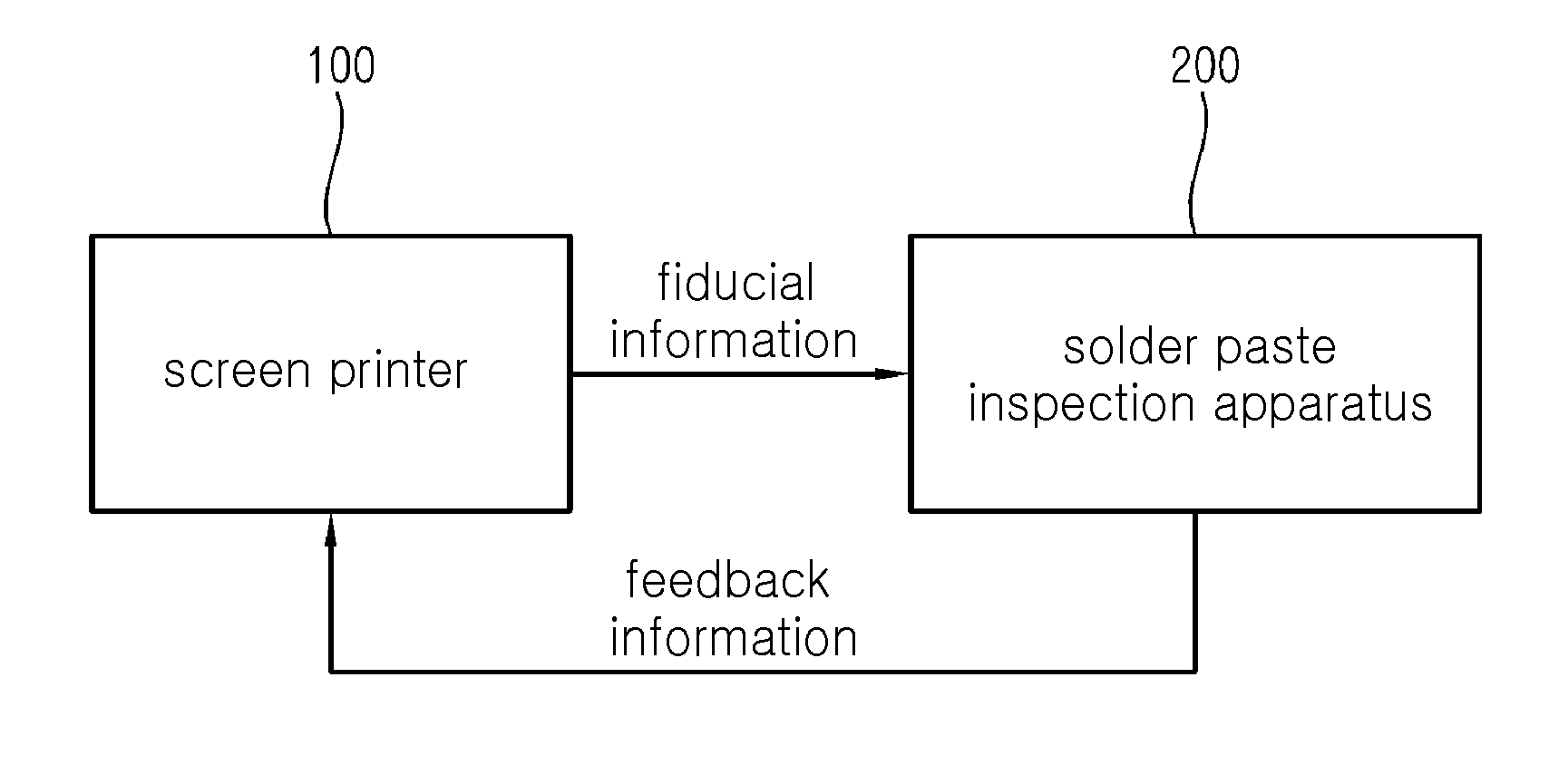

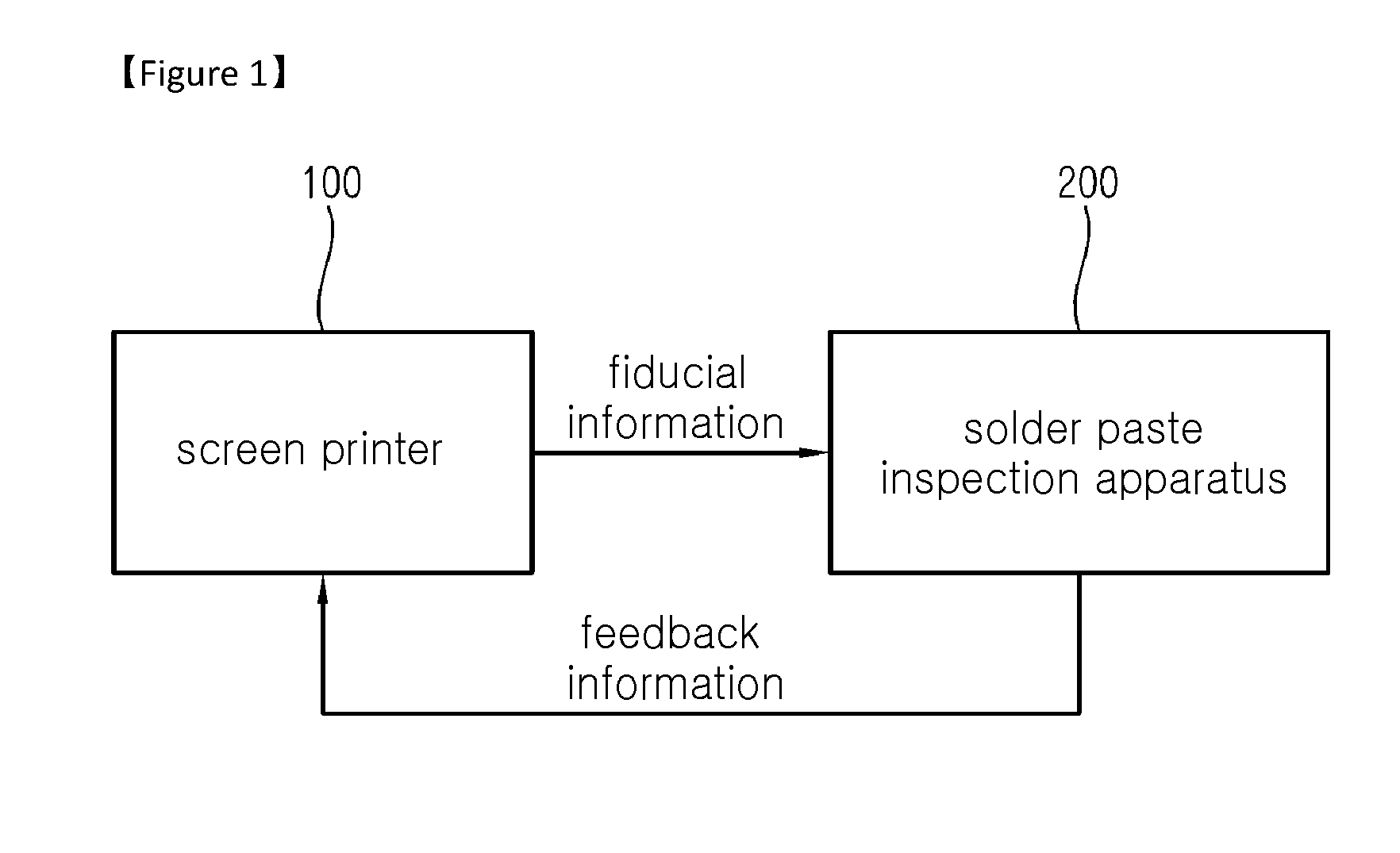

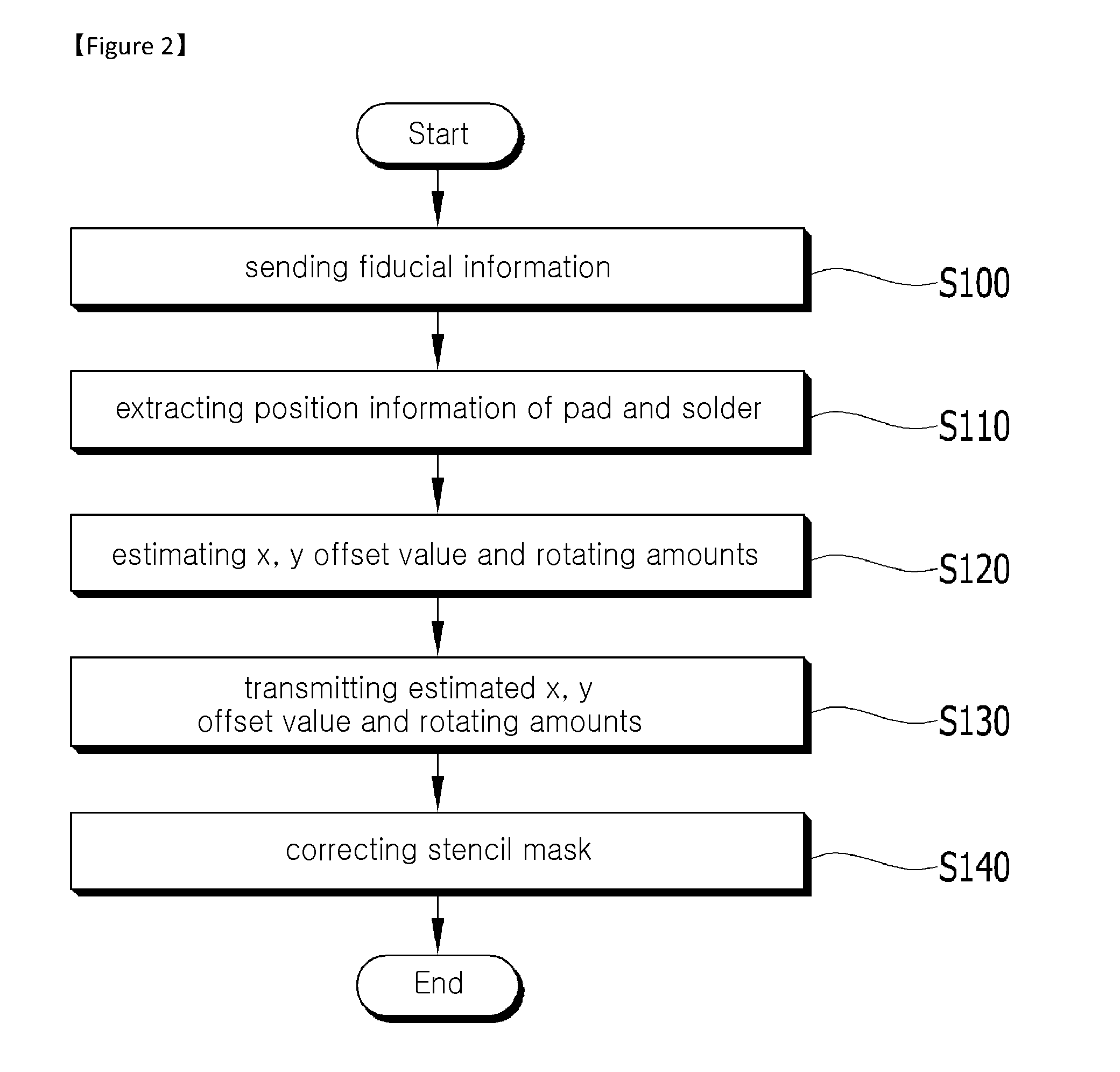

Method of correcting a screen printer and a board inspection system using the same

ActiveUS20150210064A1Improve welding reliabilityPrecise positioningPrinted circuit assemblingScreen printersEngineeringPrinting press

The present invention relates to a method of correcting a position of a stencil mask which comprises receiving fiducial information from a screen printer, extracting position information of a pad and position information of a solder formed on a board through measuring by a solder paste inspection apparatus, estimating an x, y offset value and a rotating amount of a stencil mask based on the fiducial information by using the position information of the pad and the solder, and transmitting the x,y offset value and the rotating amount of the stencil mask to the screen printer. Thus, a reliability of solder forming process may be increased by correcting a stencil mask position by transmitting a feedback of an x,y offset value and a rotating amount of the stencil mask from a solder paste inspection apparatus, in which the x,y offset value and the rotating amount are estimated based on fiducial information transmitted from the screen printer.

Owner:KOHYOUNG TECH +1

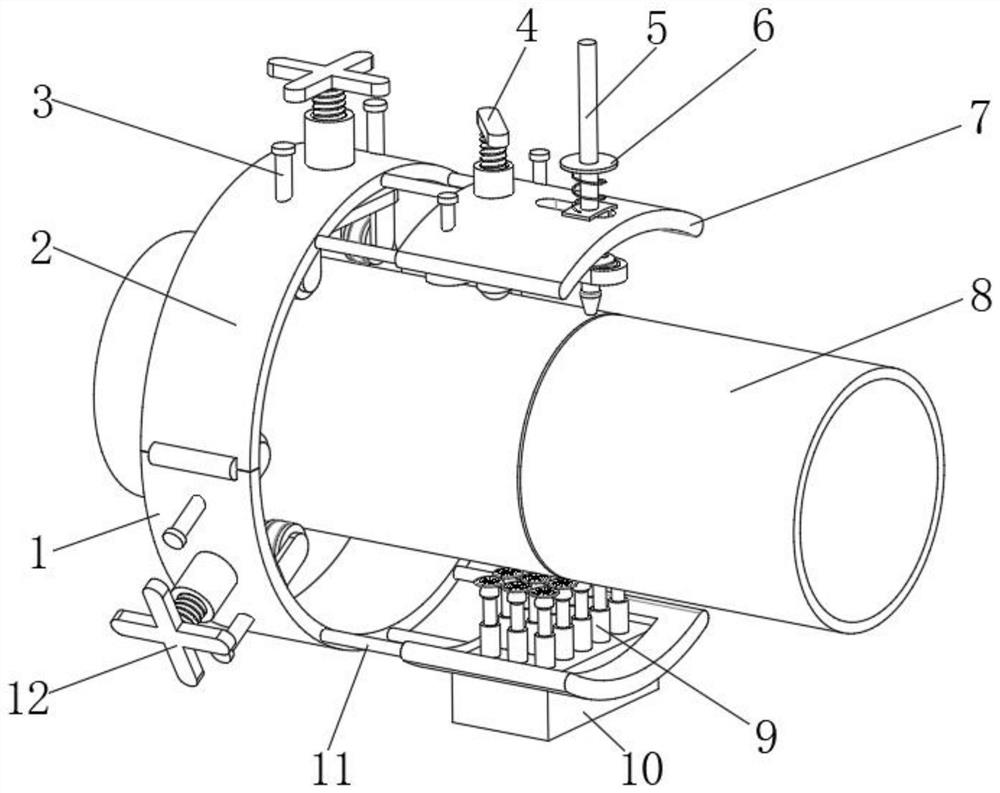

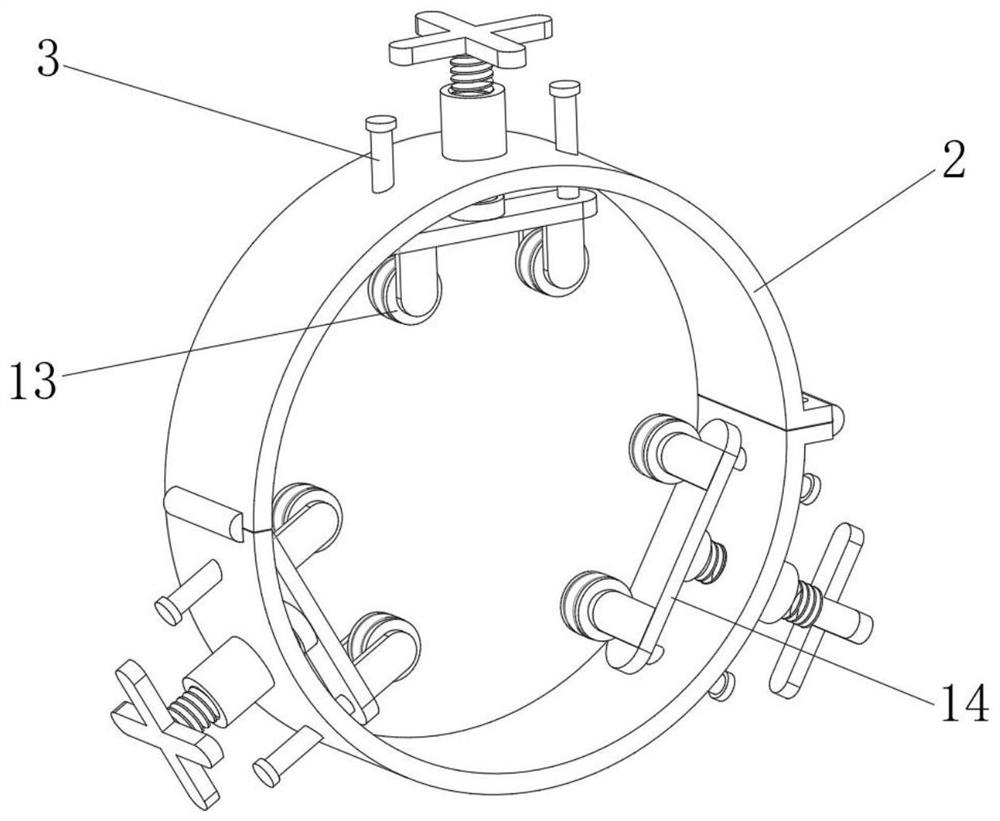

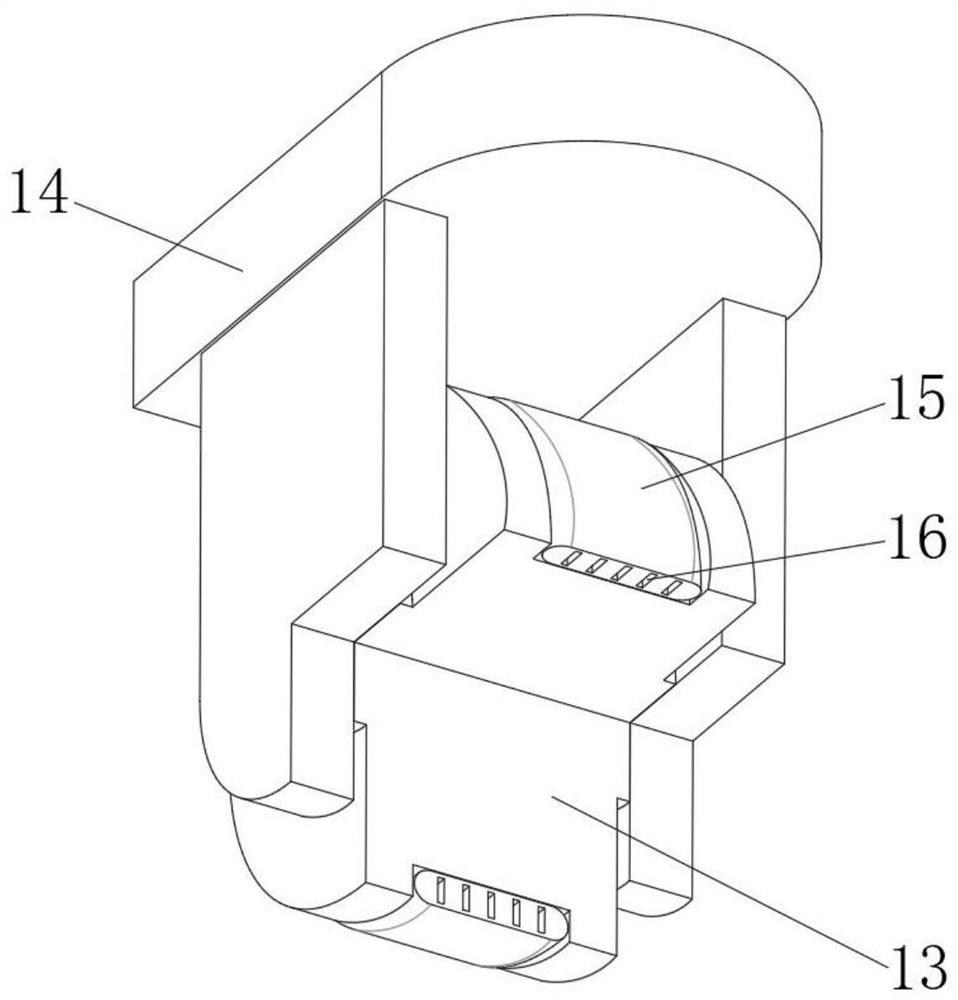

Welding device used for pipeline and using method of welding device

InactiveCN112846771AReliable weldingGuaranteed flatnessOther manufacturing equipments/toolsStructural engineeringPipe welding

The invention discloses a welding device used for a pipeline and a using method of the welding device, and relates to the technical field of pipeline welding. The portability and the grinding quality are both considered. The welding device comprises a lower fixing seat and an upper fixing seat which are installed on the pipeline, the lower fixing seat is fixed to the outer walls of the two ends of the upper fixing seat through hinges and clamping buckles, and the lower fixing seat and the upper fixing seat are both of matched semicircular structures; and the using method of the welding device comprises the following steps that the lower fixing seat and the upper fixing seat are installed on the pipeline through the clamping buckles, and the position of a mounting frame is adjusted through fixing rotary knobs, so that all rolling wheels are attached to the outer wall of the pipeline. According to the pipeline and the using method of the welding device, the fixing rotary knobs, the rolling wheels, a welding mechanism and other structures are arranged, the lower fixing seat and the upper fixing eat can be installed on a to-be-welded pipeline, reliable welding is carried out on the pipeline in a mode of rotating on the outer wall of the pipeline, and therefore the welding flatness is guaranteed, meanwhile, the welding device can adapt to pipelines of different sizes, and the universality and the welding quality are improved.

Owner:刘少波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com