Patents

Literature

329results about How to "Proof of accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

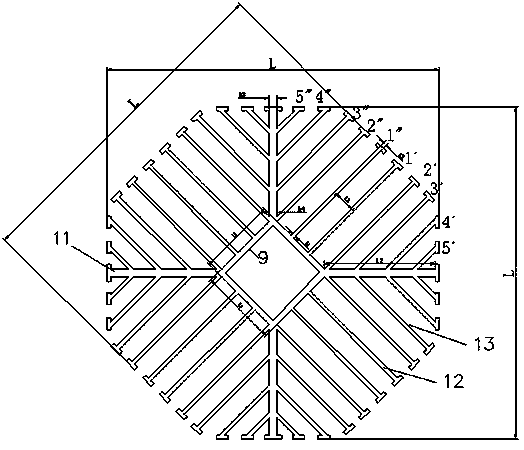

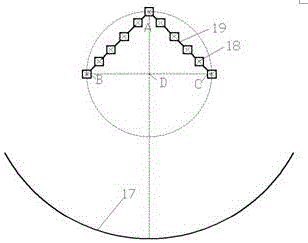

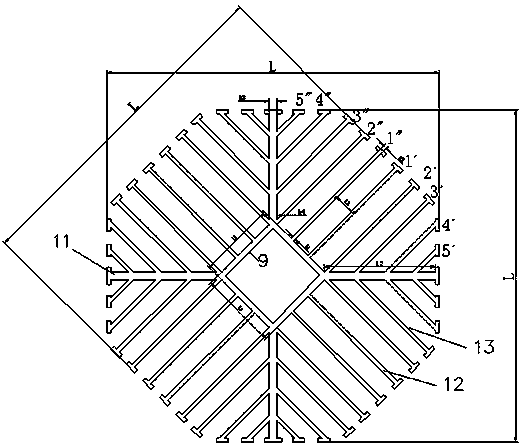

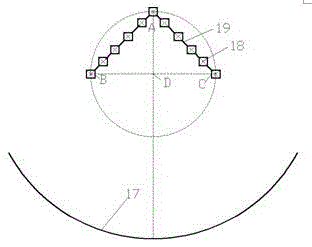

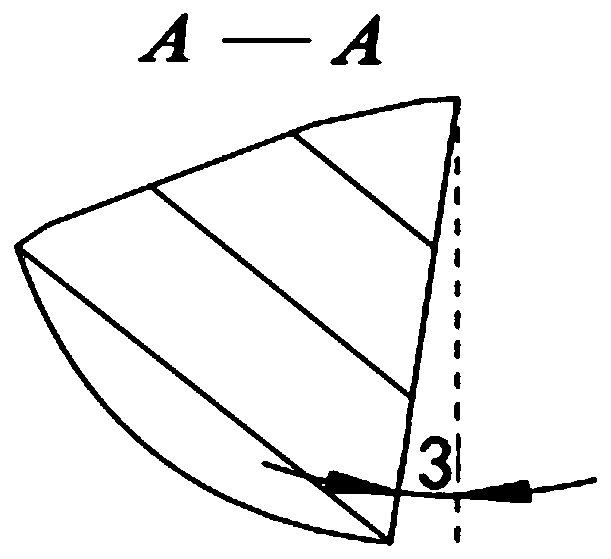

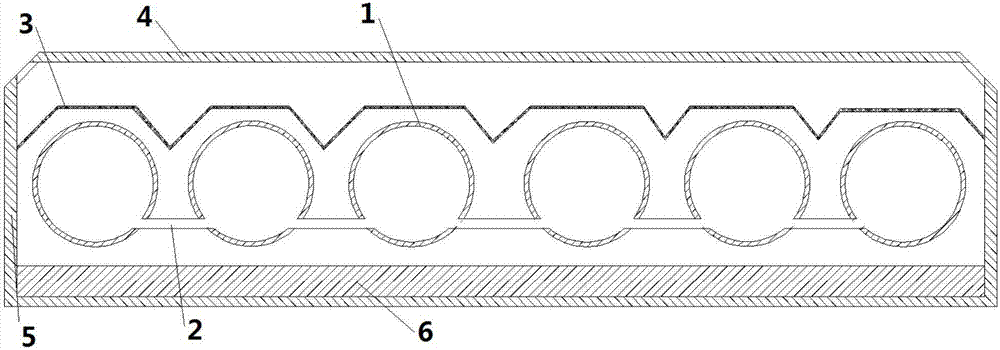

Arc tube plate type solar thermal collector system

ActiveCN104075463ATake advantage ofAvoid lostSolar heating energySolar heat devicesEngineeringSolar heat

The invention provides a solar thermal collector system which comprises thermal collection tubes, a reflecting mirror and thermal collection plates. Two adjacent thermal collection tubes are connected through the thermal collection plates, and therefore a tube plate structure is formed between the multiple thermal collection tubes and the adjacent thermal collection plates. The tube plate structure is a parabolic-shaped structure or an arc-shaped structure, the bending direction of a parabola or an arc is opposite to the parabolic structure of the reflecting mirror, the focus of the tube plate structure and the focus of the reflecting mirror are on an identical point. According to the solar thermal collector system, solar energy can be taken full advantages of, losses of solar heat are avoided, and the effect of environmental protection and energy saving is achieved.

Owner:河北蓝屋顶清洁能源科技有限公司

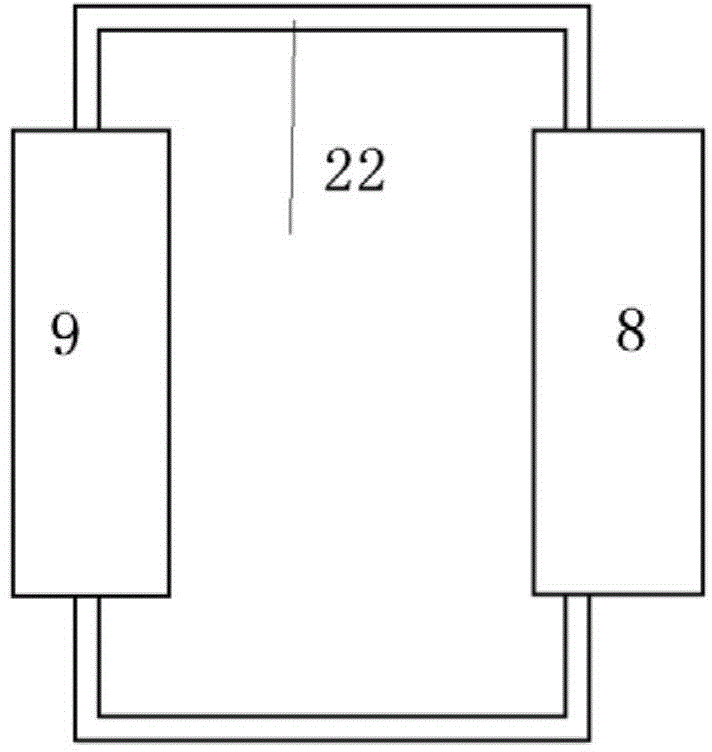

Solar heat storage system

InactiveCN104819579AAvoid wastingEven heat absorptionSolar heating energySolar heat devicesEngineeringSolar heat

The invention provides a solar heat storage system. The solar heat storage system comprises a heat collector, a water tank and a heat storage drive, wherein water in the heat collector is heated, and then input into the water tank, the water tank is connected with the heat storage drive, the heated water in the water tank enters the heat storage drive, and an insulating layer is arranged on the exterior of the heat storage device. The solar heat storage system saves energy, and improves heat utilization ability of solar energy.

Owner:SHANDONG UNIV

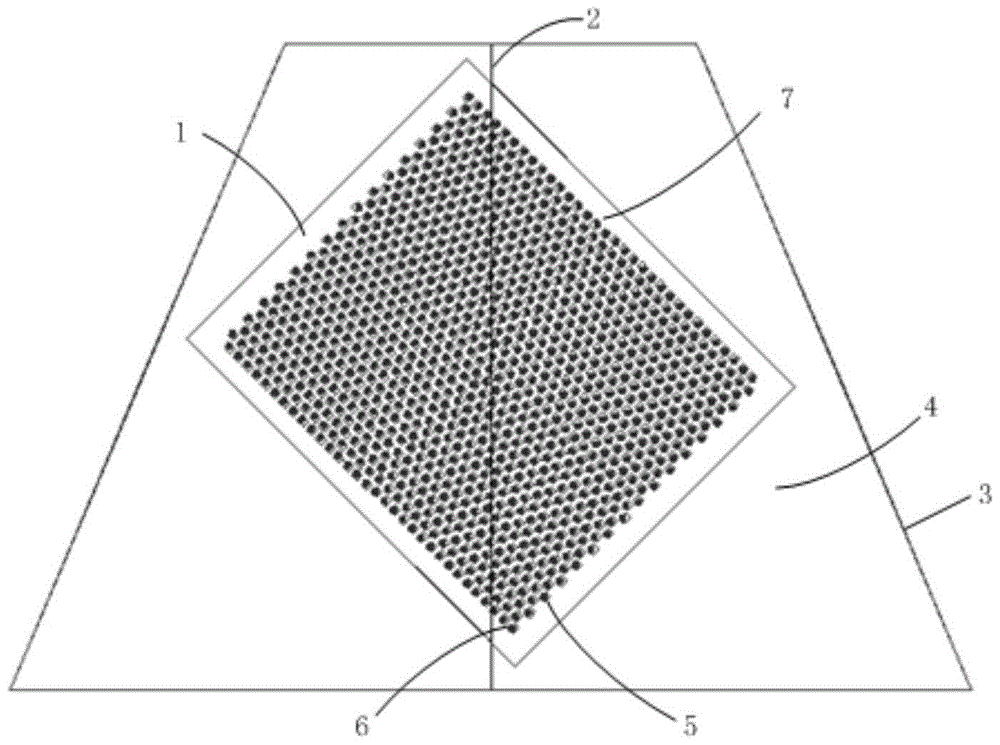

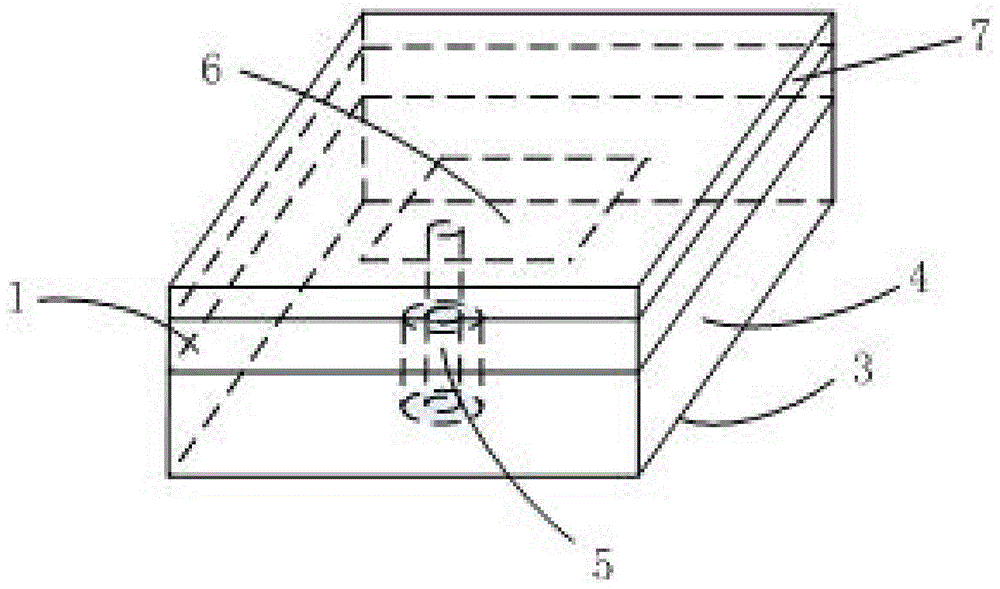

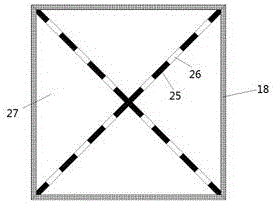

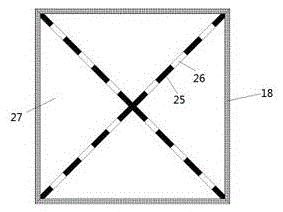

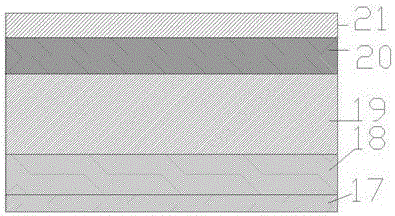

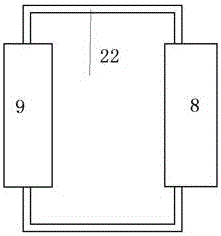

Large K-waveband conformal antenna array plane and preparation method thereof

ActiveCN106099337AGood axial ratioWide bandwidth and good angular axis ratioParticular array feeding systemsRadiating elements structural formsMicrostrip patch antennaElectrical conductor

The invention discloses a large K-waveband conformal antenna array plane and aims to provide a conformal phased array antenna array plane which does not generate a frequency deviation or a relatively high derotation component, and has a good broadband wide-angle scanning gain characteristics and good broadband wide-angle scanning circular polarization characteristics. The large K-waveband conformal antenna array plane is realized through the following technical scheme: conductor patches are divided into four groups and are arranged on an upper surface of a lower dielectric substrate in a form of a quadrant sequence rotation array, and projections of feeding points of a micro-strip patch antenna on a plane plate are arranged triangularly; the conductor patches are sandwiched between an upper dielectric substrate and the lower dielectric substrate; a radio frequency coaxial connector sequentially passes through the plane plate, a metal cone and the lower dielectric substrate to jointly form the micro-strip patch antenna; the radio frequency coaxial connector carries out coaxial probe feeding on the micro-strip patch antenna; and a pair of orthogonal polarization degenerate modes which have equal amplitudes and a phase difference of 90 degrees are excited on the conductor patches to form the conformal phased array antenna array plane for radiating right-handed circular polarization electromagnetic waves.

Owner:10TH RES INST OF CETC

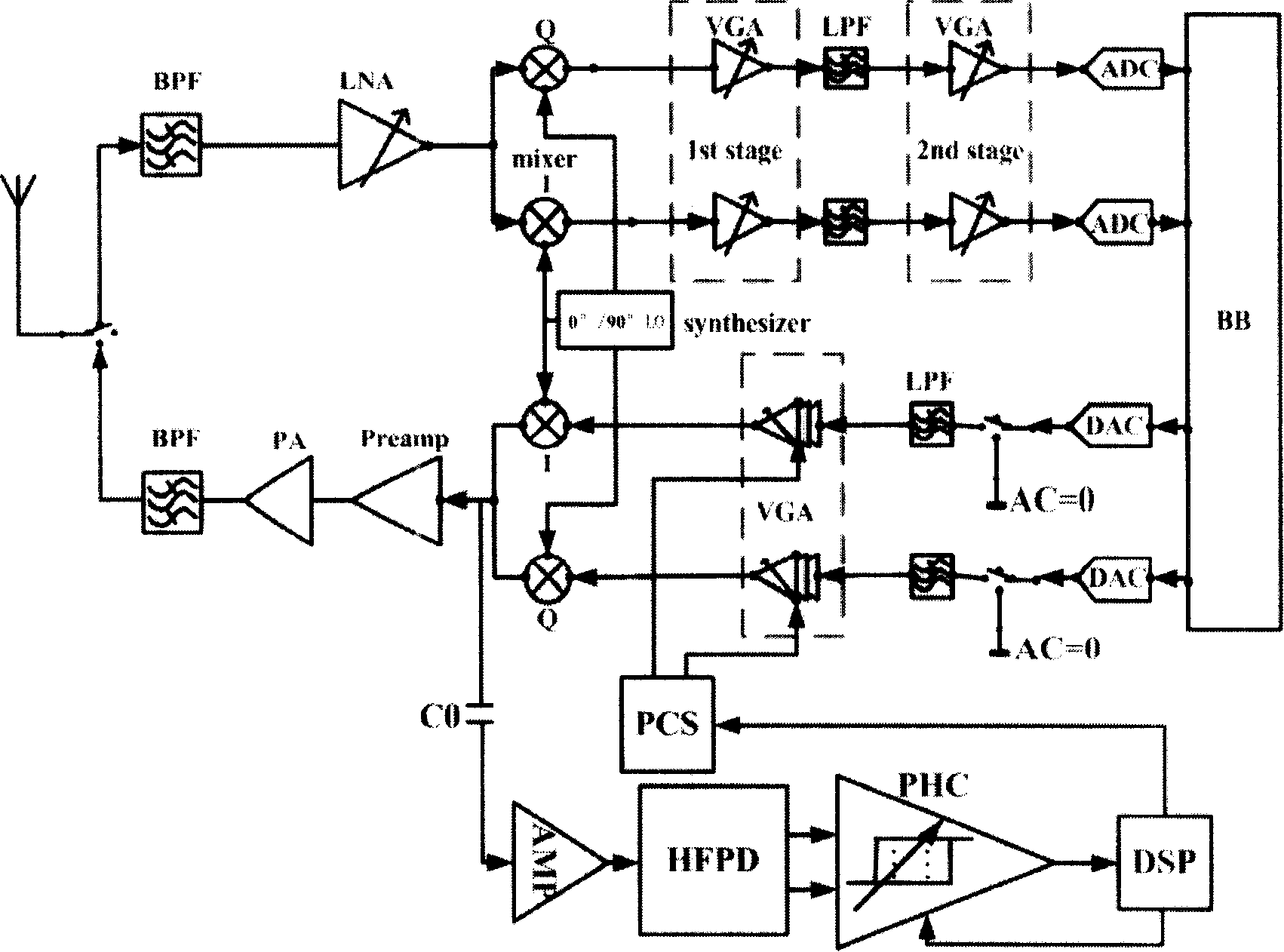

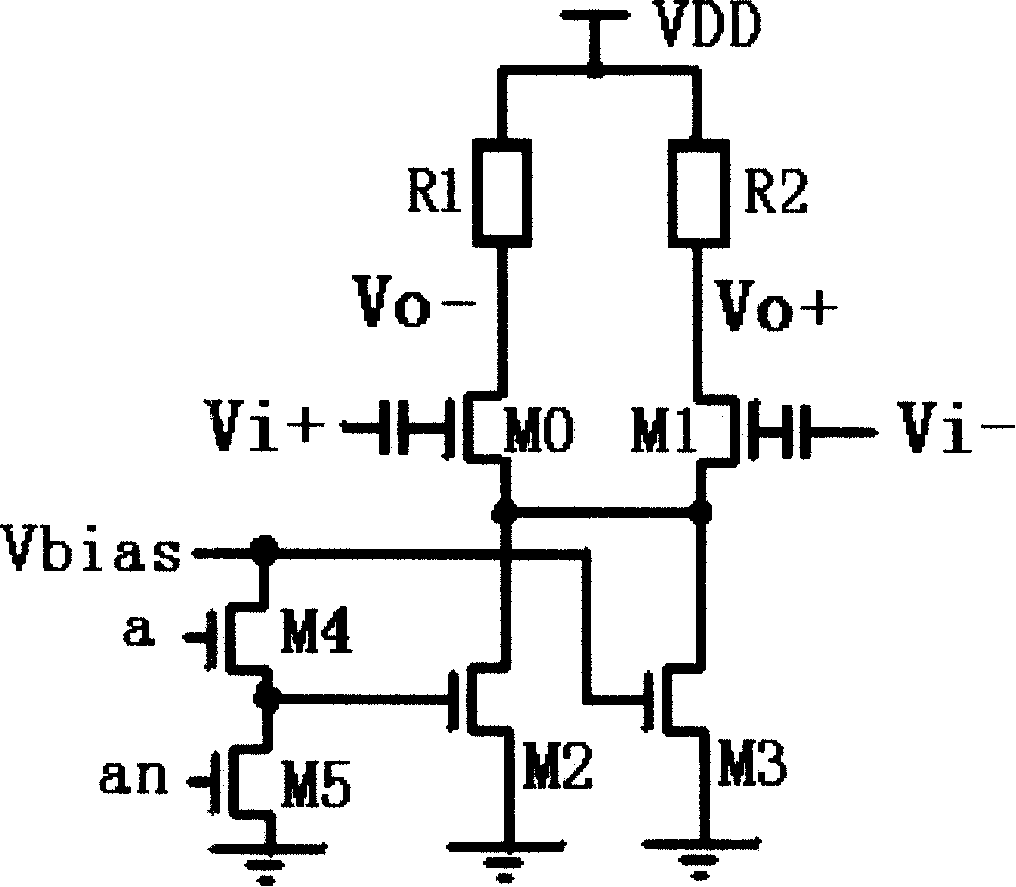

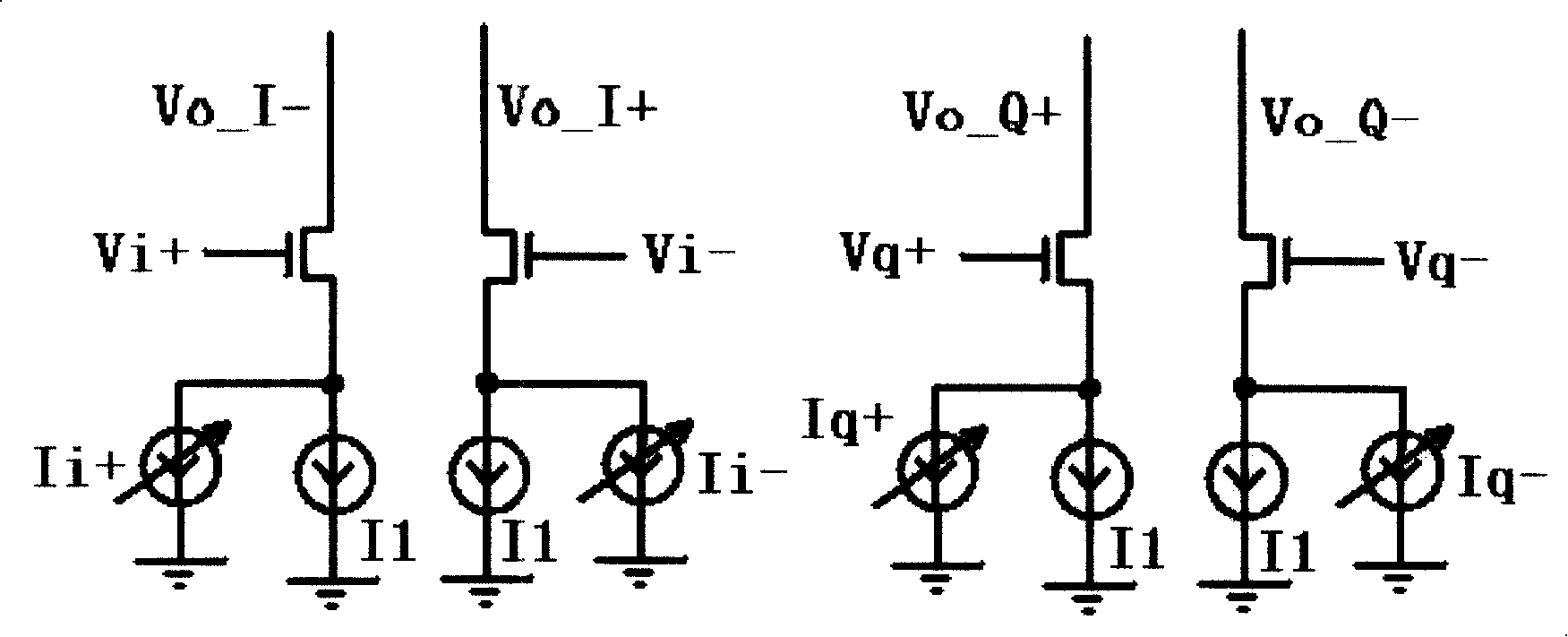

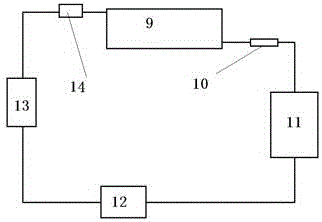

Local oscillator leakage automatic eliminator

InactiveCN101162910AIncrease effective powerProof of accuracyPulse automatic controlTransmissionCapacitanceDigital signal processing

The invention discloses a local-oscillation leakage automatic removing device, comprising a coupling capacitance used to test the local-oscillation leakage signal, an amplifier used to amplify the detected local-oscillation leakage signal, a high-frequency peak detector used for demodulation of the amplified signal and output DC signal, a programmable lag comparator used to compare the DC signal and reference signal after demodulation. According to the result of comparison, the control signal is exported to control the programmable current source to export compensation signals to remove local-oscillation leakage, and at the same time, control the digital signal processing module of the programmable lag comparator to change the size of he lag window. The invention is capable to remove the local-oscillation leakage in a CMOS wireless radio-frequency transceiver, and improve the effective power of signals.

Owner:BEIJING LHWT MICROELECTRONICS

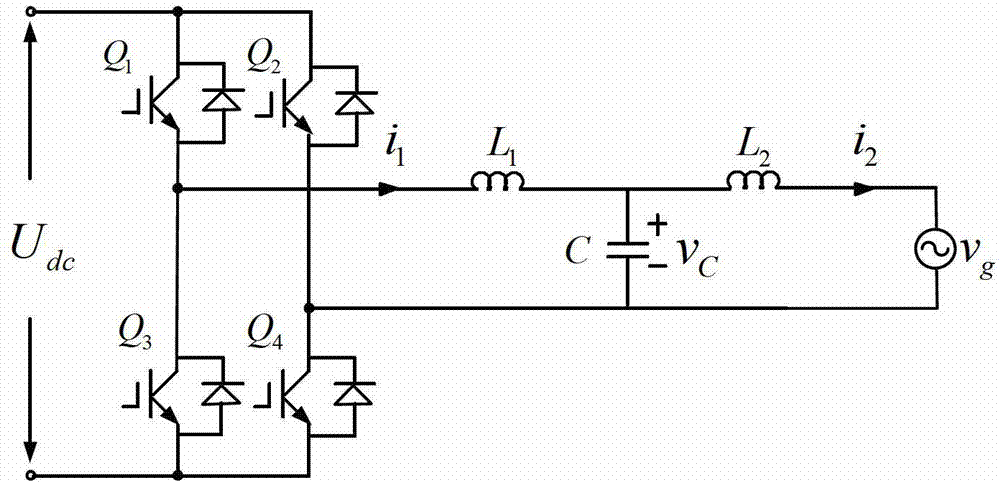

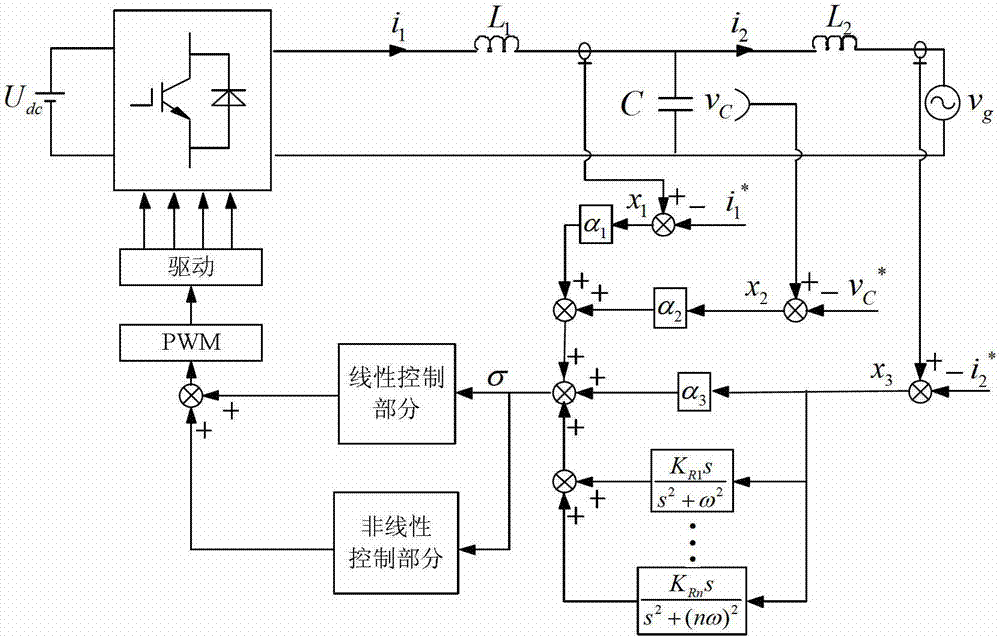

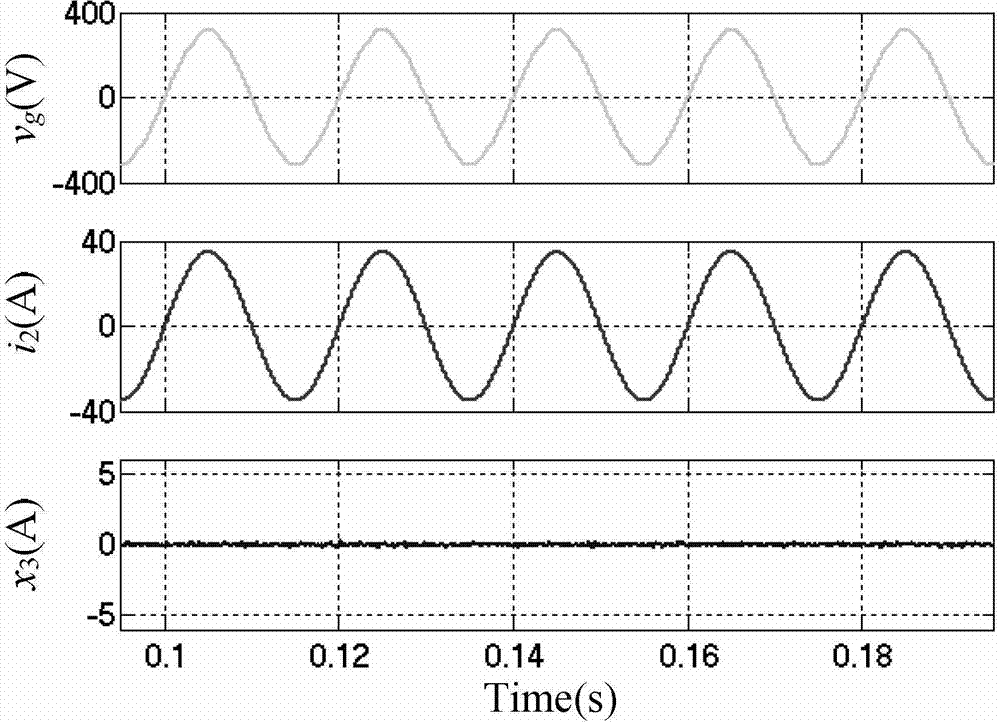

Sliding-mode variable structure control method of single phase grid-connected inverter based on multi-resonant sliding mode surface

ActiveCN102868183AImprove robustnessImprove dynamic response performanceSingle network parallel feeding arrangementsHarmonic reduction arrangementLinear state feedbackCarrier signal

The invention discloses a sliding-mode variable structure control method of a single phase grid-connected inverter based on a multi-resonant sliding mode surface. The method comprises the steps of: firstly, building a linear sliding mode surface according to detected current i1 of an inverter side filter inductor of the single phase grid-connected inverter, the voltage vc of a filter capacitor, the current i2 of a network side filter inductor, and the target output current i1* of a grid-connected inverter system, the target voltage vC* of the filter capacitor and the grid-connected target current i2*; adding a resonant item into the linear sliding mode surface so as to obtain the multi-resonant sliding mode surface; designing a sliding-mode variable structure controller by the multi-resonant sliding mode surface, leading a linear state feedback controller to an original nonlinear controller to obtain a final control quantity modulation wave d(s), and finally comparing the modulation wave with a carrier wave to generate a driving signal for driving a switch tube to act. According to the control method disclosed by the invention, the robustness and dynamic response ability of the grid-connected inverter system are improved; the tracking accuracy of grid-connected current is also improved; the harmonic content is removed, and the control method is simple and easy to achieve.

Owner:XI AN JIAOTONG UNIV

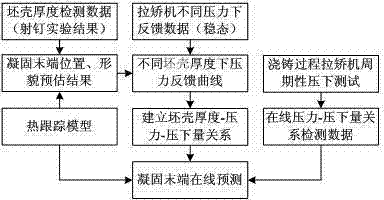

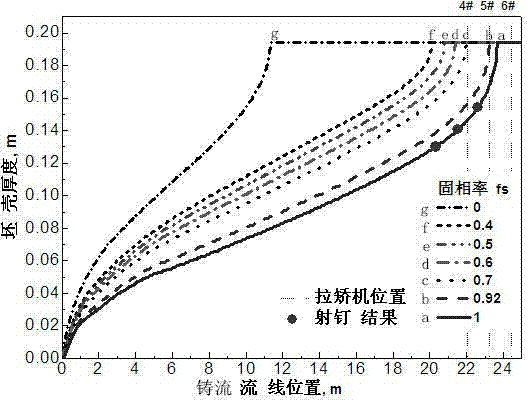

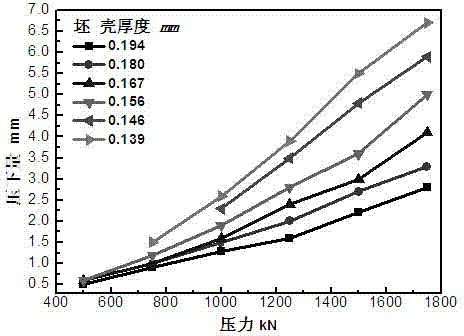

Online detection method for solidified bottom end position in bloom continuous casting production process

ActiveCN104493121AHigh precisionAccurate thickness-pressure-reduction relationshipRelational databaseTracking model

The invention belongs to the technical field of bloom production and particularly relates to an online detection method for a solidified bottom end position in the bloom continuous casting production process. The online detection method comprises the following steps: first, measuring solidified bloom shell thicknesses by a nail shooting process, establishing a thermal tracking model, calculating to obtain the pre-measurement results of the bloom shell thicknesses at different solid ratios, at different casting temperatures and at different drawing rates in the strand direction, then measuring the rolling reductions of different bloom shell thickness parts when the blooms are rolled by withdrawal and straightening units, establishing a relation curve of bloom shell thickness, pressure and rolling reduction, and establishing a corresponding relational database of steel type, bloom shell thickness, pressure and rolling reduction; in the actual production process, measuring on line when periodical rolling is carried out by each withdrawal and straightening unit, comparing the corresponding relational data of steel type, pressure and rolling reduction with the database, judging the actual bloom shell thickness of the current continuously cast bloom and determining the solidified bottom end position. The method is tightly combined with bloom continuous casting production reality, detection equipment does not need to be increased, and the online detection process of the solidified bottom end is finished by the existing withdrawal and straightening unit.

Owner:NORTHEASTERN UNIV

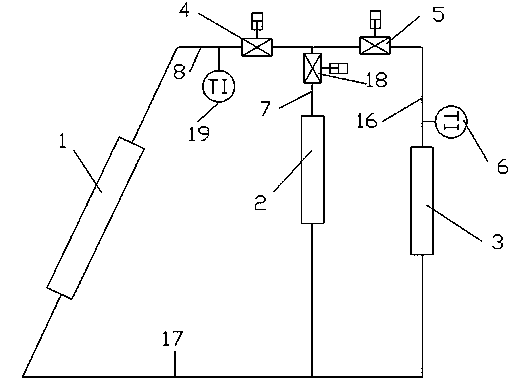

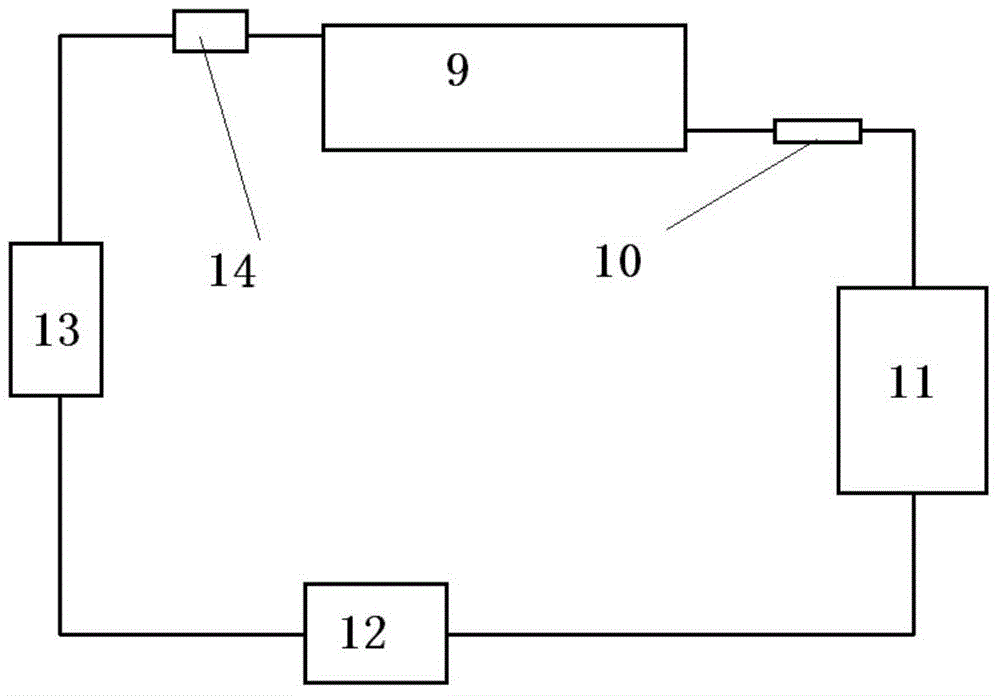

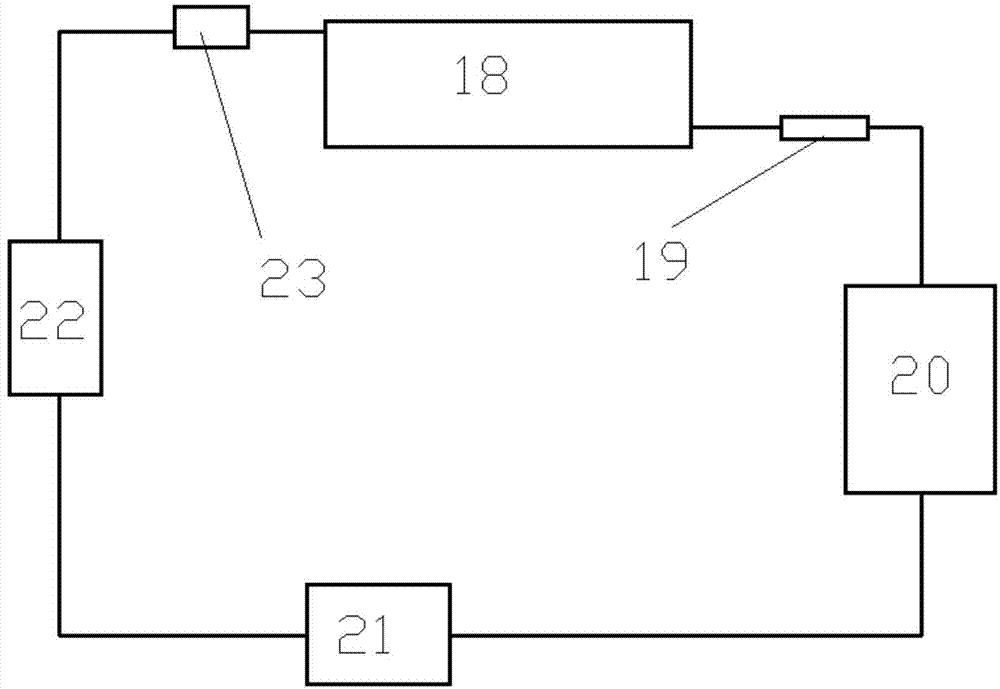

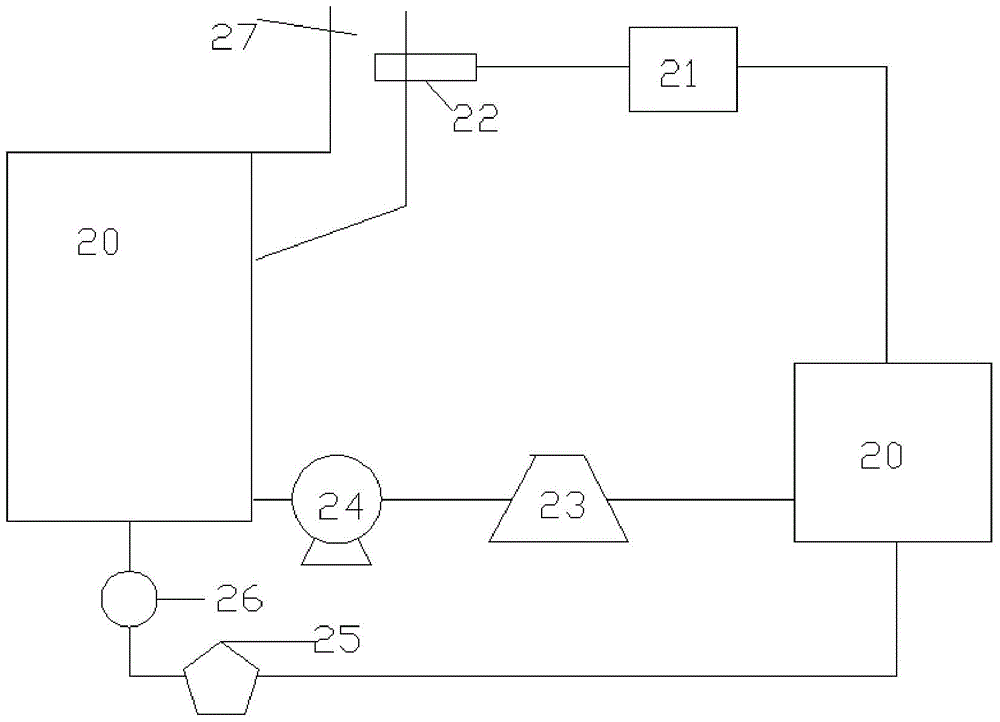

Loop circuit heat tube type solar energy system

InactiveCN104266368APromote absorptionReduce corrosionSolar heating energySolar heat devicesElectricitySolar water

The invention provides a loop circuit heat tube type solar energy system which comprises a solar water heater and a heat utilization device. The loop circuit heat tube type solar energy system comprises an auxiliary heating device and further comprises an auxiliary electric heater, wherein the auxiliary heating device is in parallel connection with pipelines of a solar water heater system, the electric heater is automatically started according to the temperature of water fed into the electric heater and heats hot water. The energy-saving loop circuit heat tube type solar water heater improves the solar heat utilization capacity.

Owner:SHANDONG UNIV

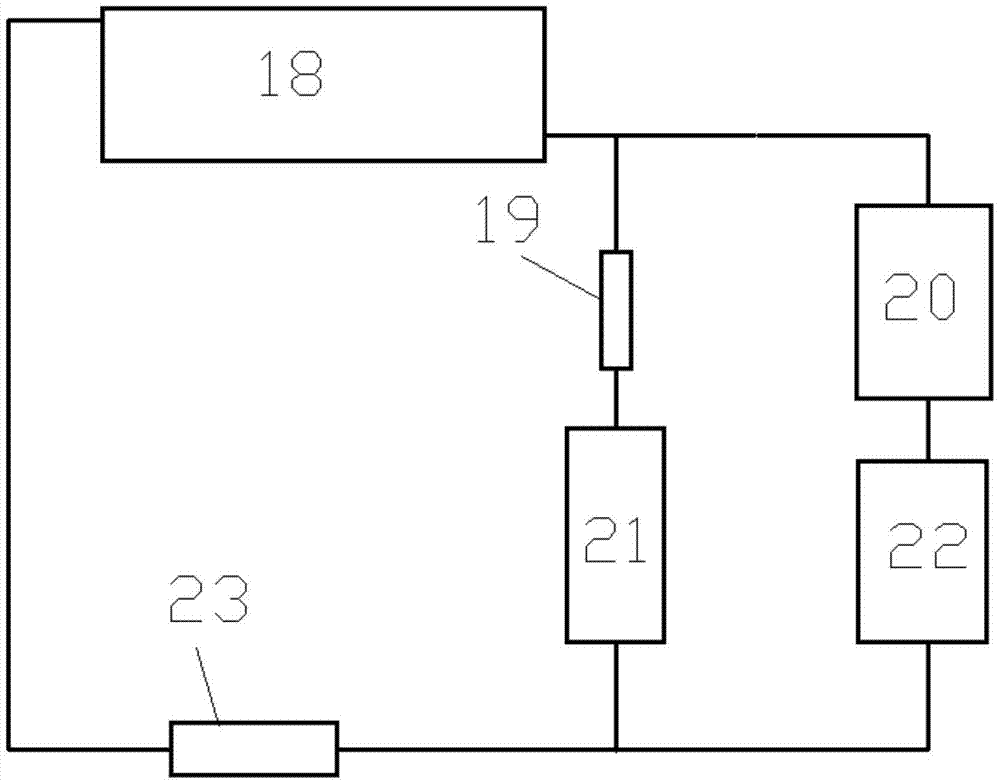

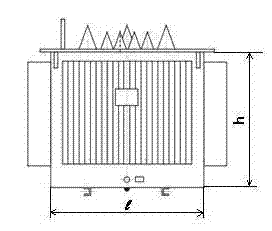

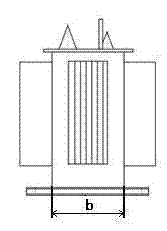

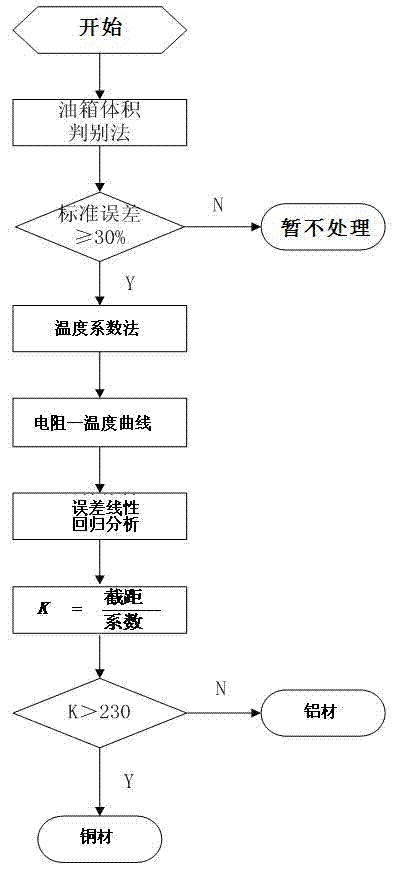

Distribution transformer coil material nondestructive testing method

ActiveCN103163185AAvoid Transformer DamageProof of accuracyMaterial resistanceElectrical resistance and conductanceDistribution transformer

The invention discloses a distribution transformer coil material nondestructive testing method, the detection method comprises a distribution transformer fuel tank volume discrimination method and a resistance temperature coefficient method. According to the invention, by a fuel tank volume for measuring distribution transform, compared with data in a routine fuel tank volume table, if the fuel tank volume for testing distribution transform exceeds the routine distribution transform by 30%, and the fuel tank is a suspected aluminum core transformer. The resistance temperature coefficient method is characterized in that a resistance temperature coefficient K value is measured and calculated to determine the coil material, on the basis of a distribution transform coil temperature model, the invention employs a multi-point linear regression method to inhibit random error generated in a test, and thereby the measure precision of K value can be increased. A multitime test result proves that a principle of the material detection method based on coil resistance temperature coefficient is correct, and the method is feasible. The invention is suitable for the nondestructive test of the distribution transformer material.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

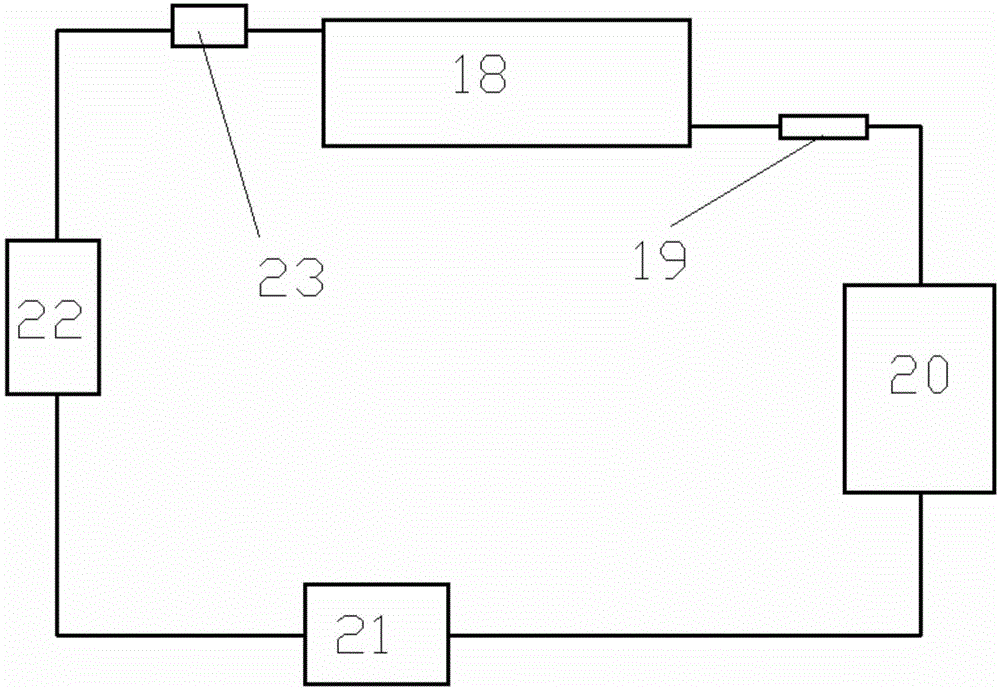

Solar heat accumulating system and seawater desalting system with heat accumulating function

InactiveCN105731573AImprove desalination efficiencyTimely supplementSolar heating energySolar heat collector controllersSeawaterDesalination

The invention provides a solar heat accumulating system and a seawater desalting system. The solar heat accumulating system comprises a heat collector, a heat accumulator and a heat using device, wherein the heat collector and the heat accumulator are communicated to form a circulating loop; the heat accumulator and the heat using device are communicated to form a circulating loop; a pipe, where the heat accumulator is located, is connected in parallel with a pipe, where the heat using device is located; the heat collector is used for absorbing energy from the sun and heating water in the heat collector; the heated water flows into the heat accumulator and the heat using device through a water outlet pipe respectively, and water flowing out of the heat accumulator and the heat using device enters the heat collector through a water return pipe for heat exchange. The invention provides the novel solar system and seawater desalting system, and the seawater desalting efficiency is improved through a heat accumulating function.

Owner:山东大学(威海)

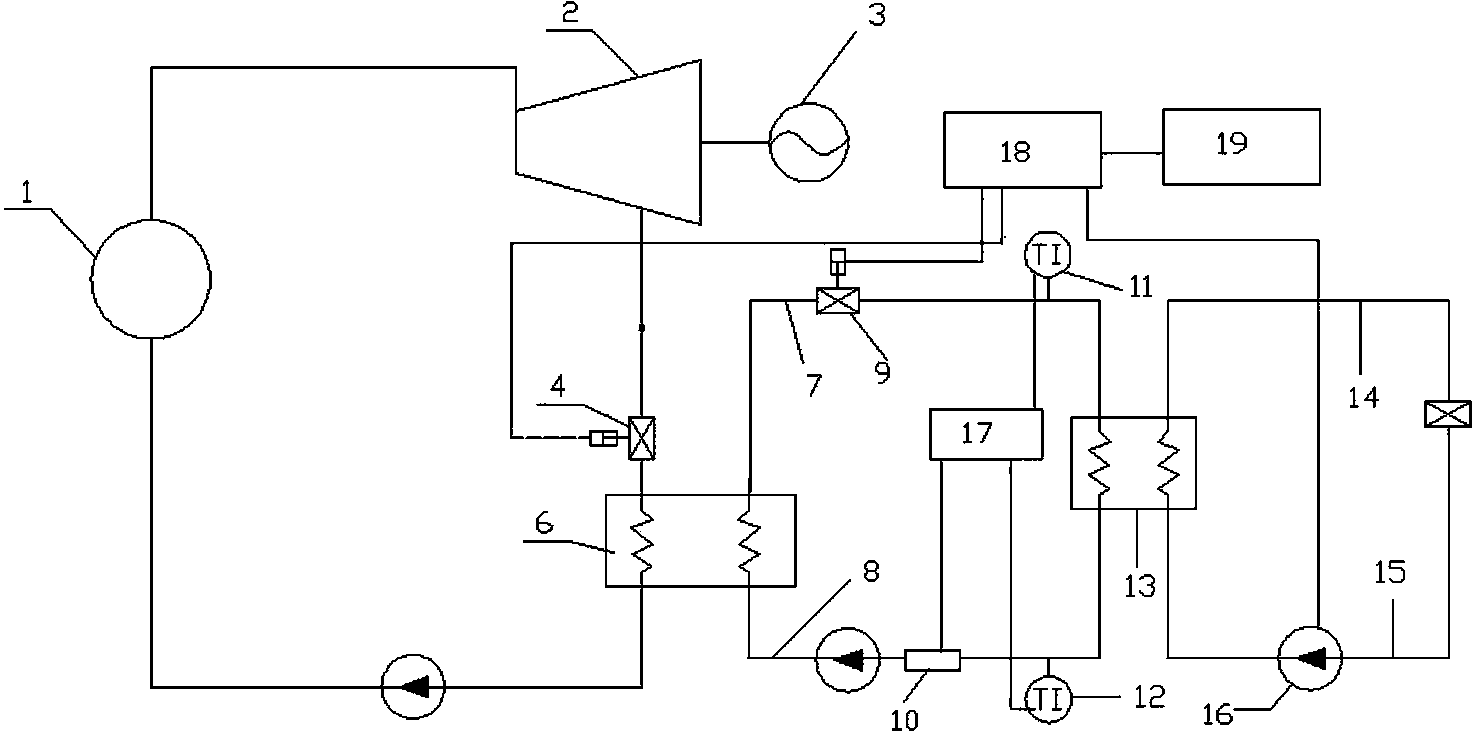

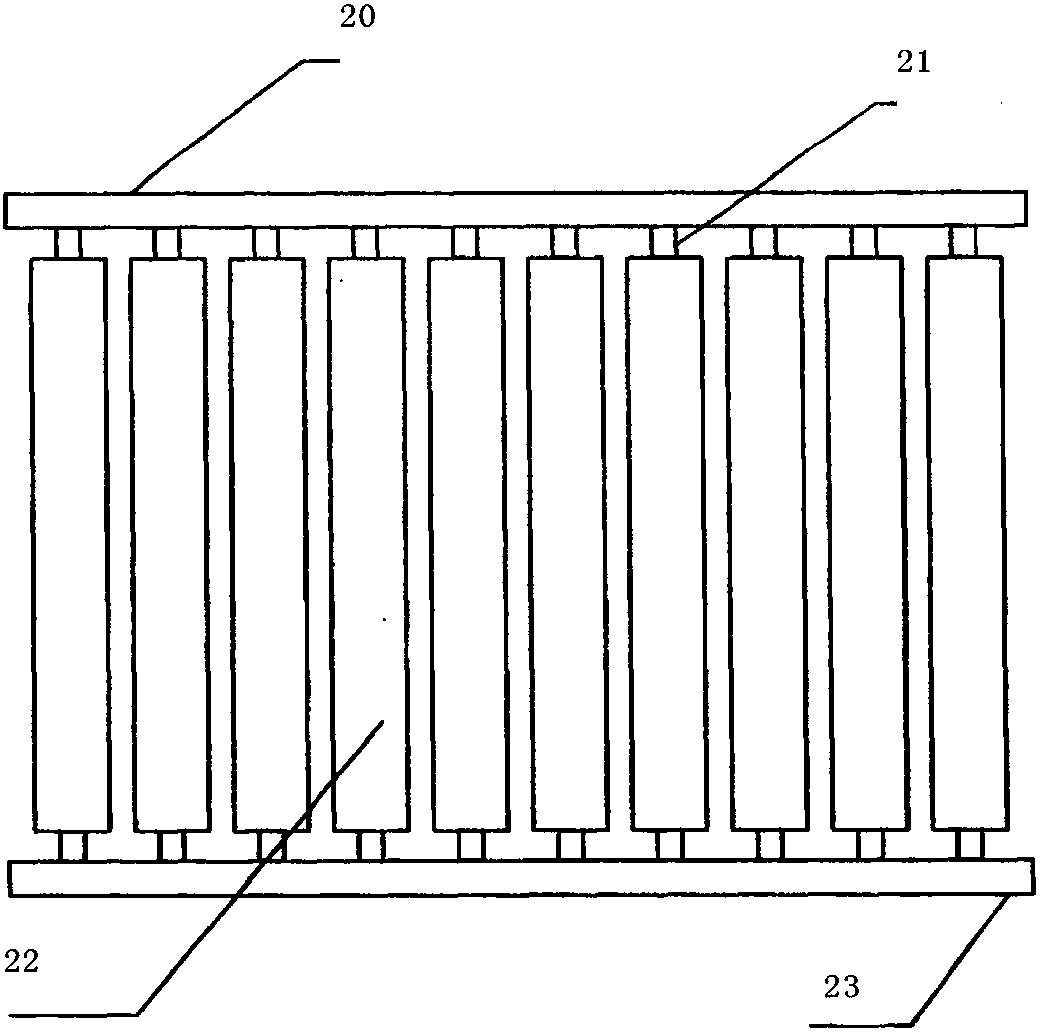

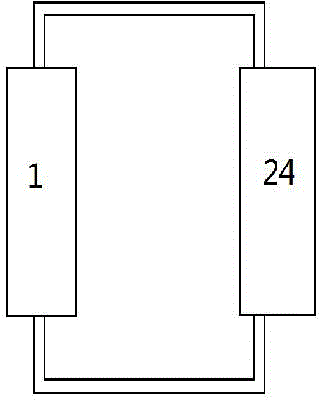

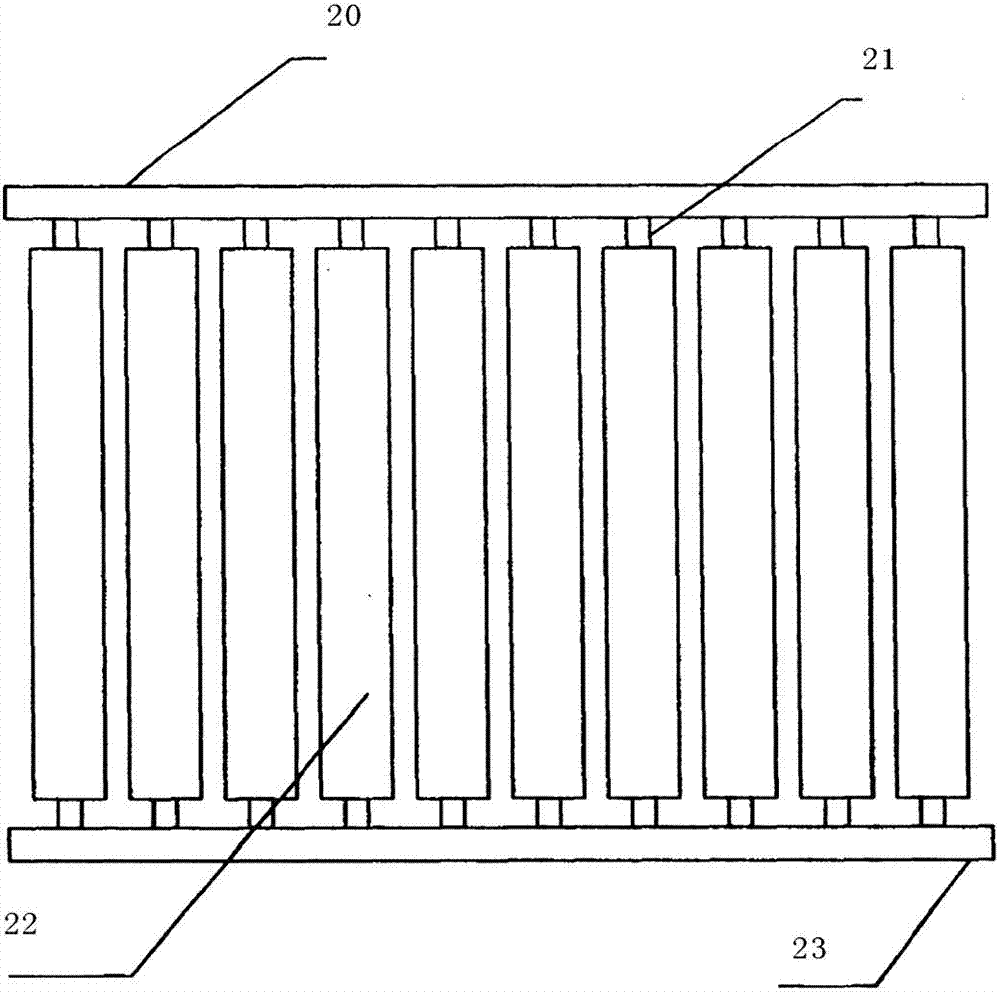

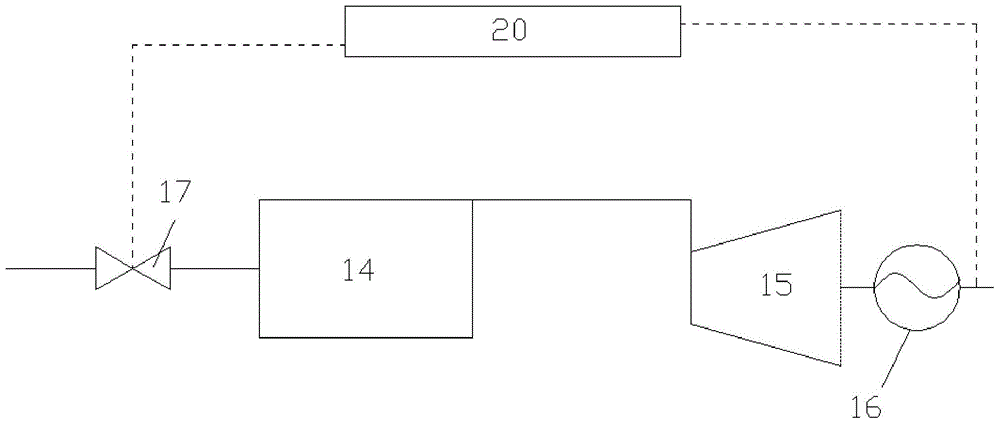

Heat radiator and combined heat and power generation system including same

InactiveCN103939979AEnhanced heat transferEnhanced chimney effectSteam useEnergy industryCogenerationHeat transfer efficiency

The invention provides a heat radiator and a combined heat and power generation system including the same. The heat radiator comprises a base tube and external fins, the external fins are sealed, the sealed external fins comprise fins and a sealing sheet for sealing the fins, and the distance between the sealing sheet and the base tube gets closer from the lower portion of the base tube to the upper portion of the base tube. According to the heat radiator and the combined heat and power generation system, the structure of the heat radiator is optimized, heat transfer efficiency of the heat radiator is maximized, energy is saved, and the purposes of environmental protection and energy saving are achieved.

Owner:ZHONGBEI UNIV

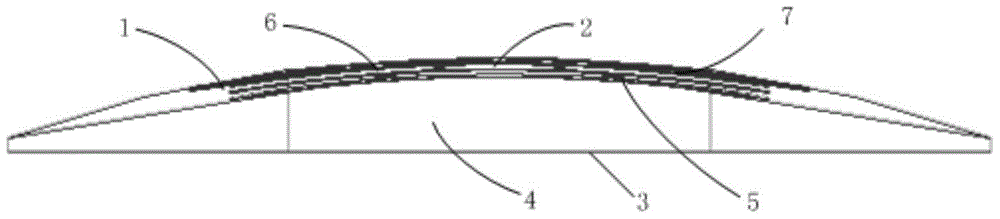

Improved solar thermal collector system

InactiveCN104048423ATake advantage ofAvoid lostSolar heating energySolar heat devicesThermodynamicsSolar heat

The invention provides a solar thermal collector system which comprises a thermal collector and a reflecting mirror. The thermal collector comprises a thermal collecting tube which is a flat tube, the flat tube is of a parabolic-shaped structure or an arc structure, the bending direction of the parabola or the arc is opposite to that of the parabolic structure of the reflecting mirror, and the focus point of the thermal collecting tube and the focus point of the reflecting mirror coincide. According to the improved solar thermal collector system, solar energy can be fully utilized, loss of solar heat is avoided, and the effect of protecting environment and saving energy is achieved.

Owner:兰州三阳自然能源科技有限责任公司

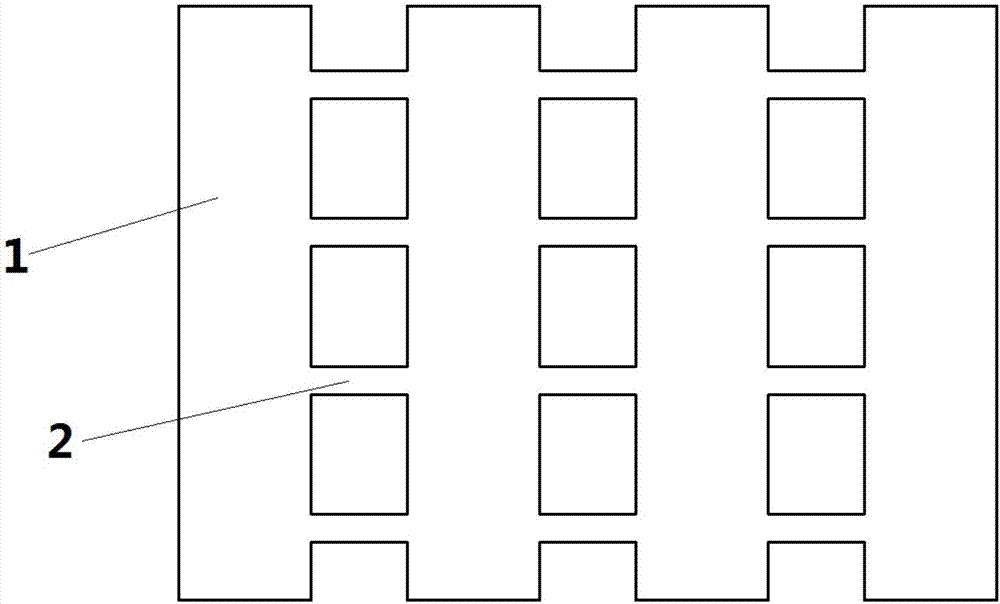

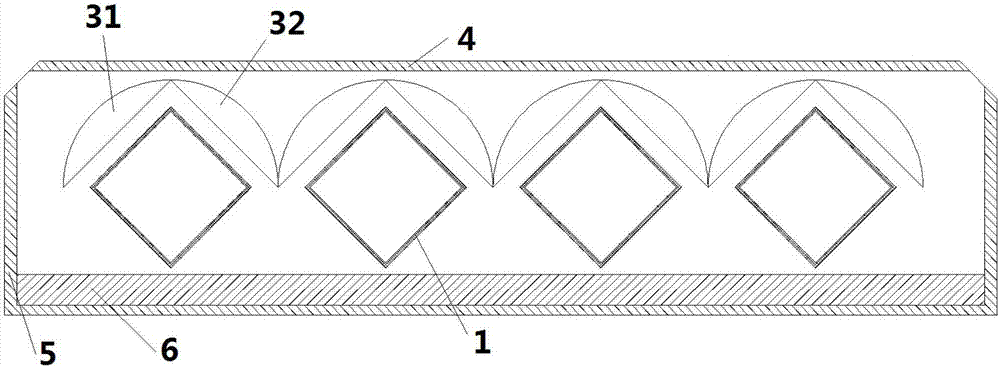

Solar heat collector and seawater desalination system comprising same

InactiveCN105588342AAvoid thermal blind spotsImprove heat absorption efficiencySolar heating energyGeneral water supply conservationSeawaterSolar thermal collector

The invention provides a solar heat collector and a seawater desalination system comprising the same. The solar heat collector comprises heat collection tubes, wherein every two adjacent heat collection tubes are connected by the aid of a heat collection plate, so that the multiple heat collection tubes and the adjacent heat collection plates form a tube-and-plate structure. A solar heat collector system comprises two tube-and-plate structures, a certain included angle is formed by the two tube-and-plate structures, the heat collection tubes have rectangular cross sections, and the heat collection plates are connected with corners of the rectangles. The novel solar heat collector and the seawater desalination system can improve the solar heat absorptivity, so that the desalination efficiency of the seawater desalination system can be improved.

Owner:山东大学(威海)

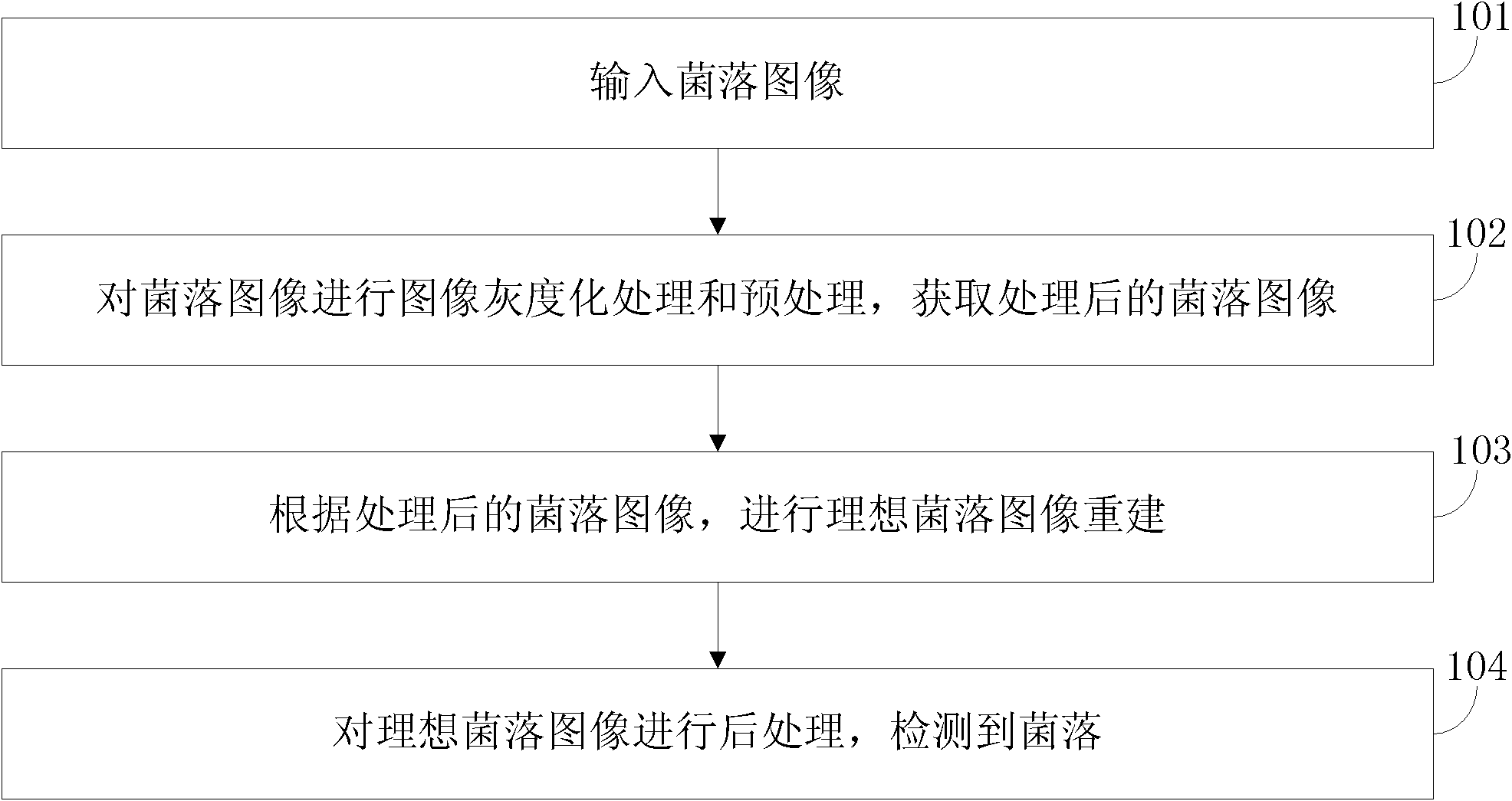

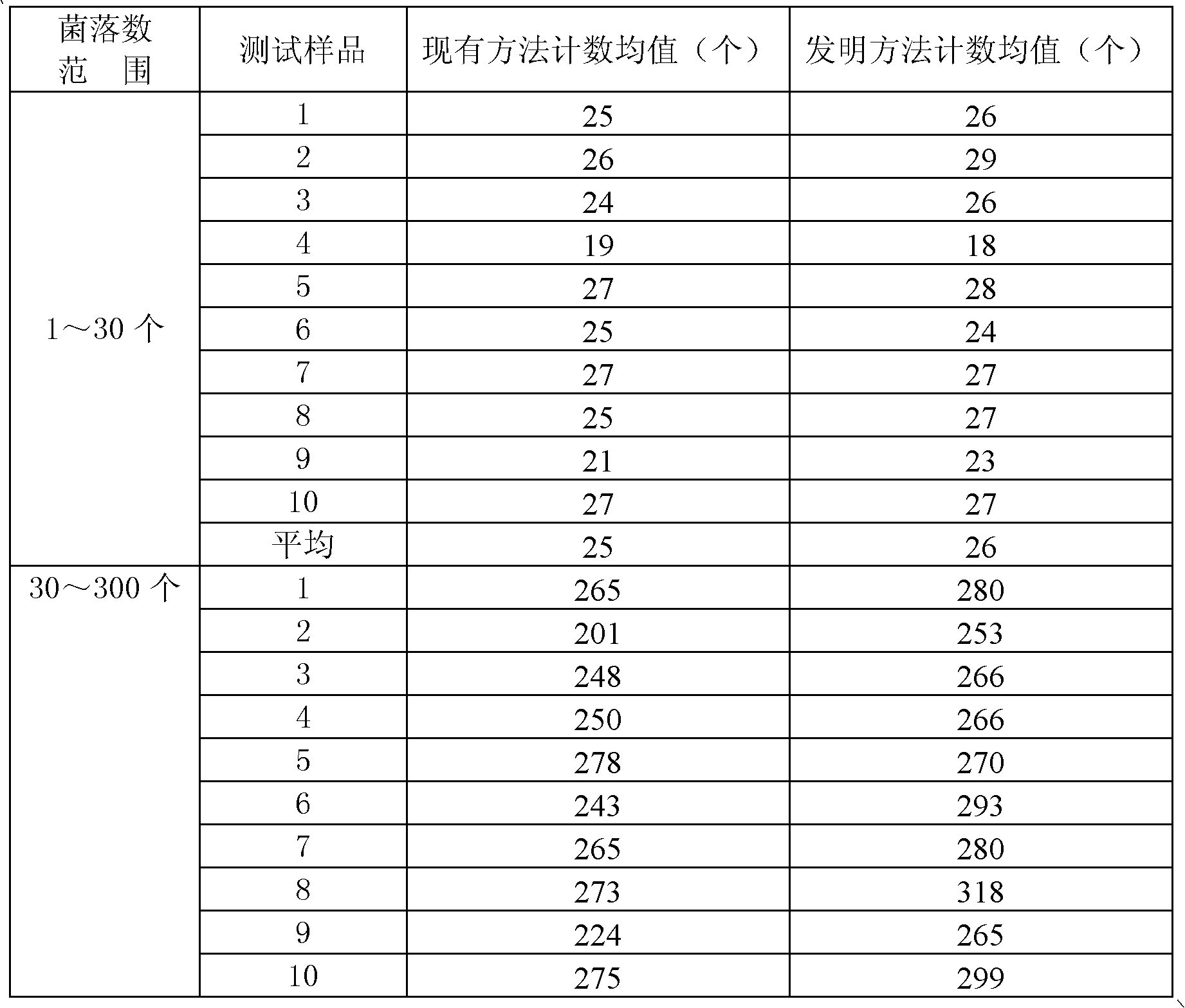

Bacterial colony automatic detection method

InactiveCN102024259AImprove universalityProof of accuracyImage enhancementImage analysisPattern recognitionImaging processing

The invention discloses a bacterial colony automatic detection method, belonging to the fields of biomedicine image processing, environment monitoring and the like. The method comprises the following steps:inputting bacterial colony images; carrying out image gradation processing and pre-processing on the bacterial colony images, and acquiring the processed bacterial colony images; carrying out ideal bacterial colony image reconstruction according to the processed bacterial colony images; and post-processing the ideal bacterial colony images, and detecting the bacterial colonies, wherein, when the bacterial colony images are acquired at different conditions, the input bacterial colony images are converted into the ideal bacterial colony images by eliminating illumination deviation, and the ideal bacterial colony images are subject to post-processing, thus the bacterial colonies are detected. The bacterial colony automatic detection method does not rely on a specific image acquiring device, bacterial colony types and external environmental conditions, and the image segmentation and bacterial colony extracting processes also do not rely on experimental threshold value or prior knowledge, Thus the bacterial colony automatic detection method has the advantages that the universality is high, the application range is enlarged; and large-scale experiments prove the accuracy and precision of the bacterial colony automatic detection method.

Owner:QIQIHAR GREEN ENVIRONMENTAL PROTECTION TECHDEV

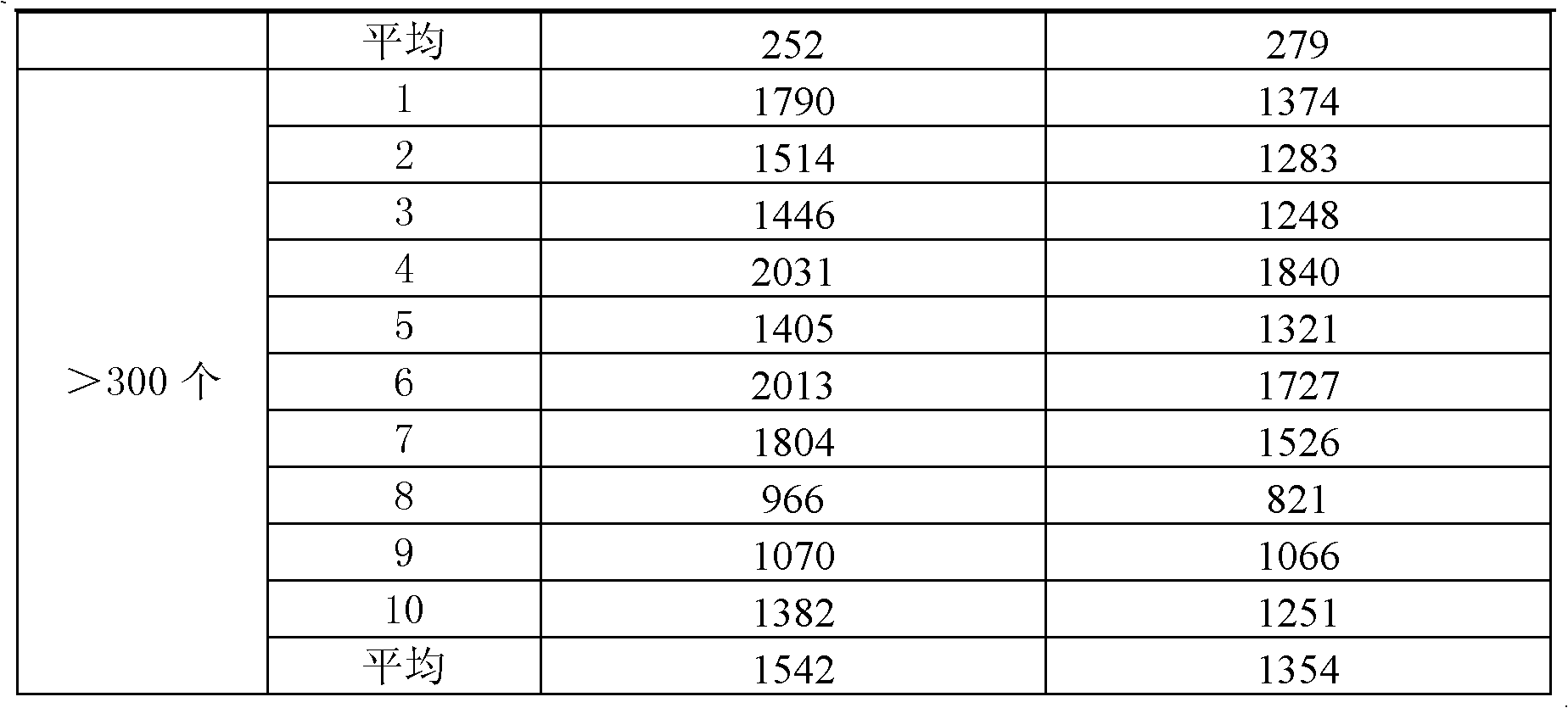

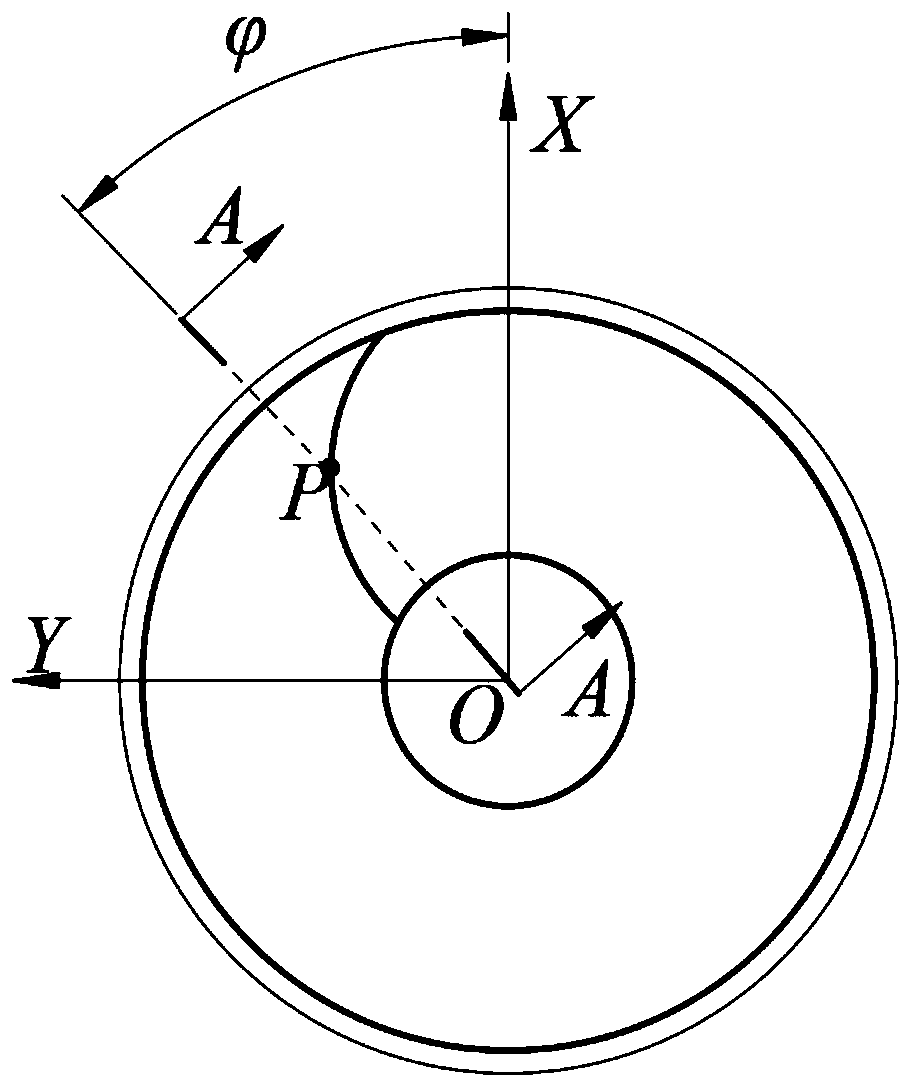

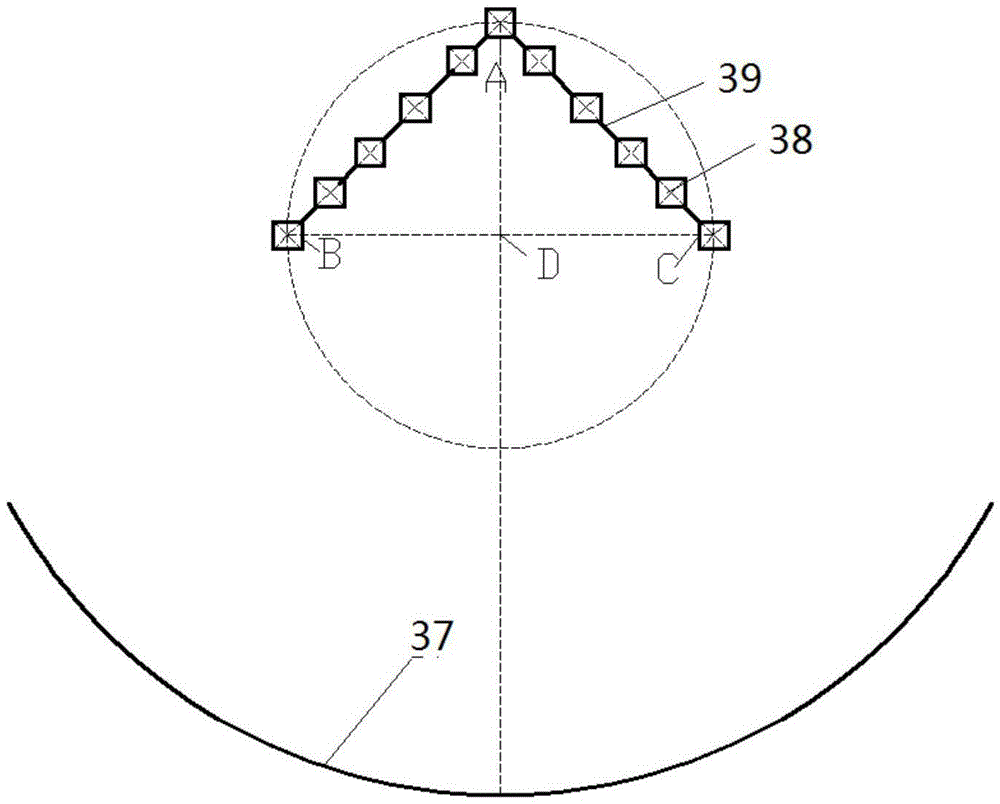

Method for solving grinding track of front tool face of arc edge of arc head end mill

The invention provides a method for solving a grinding track of a front tool face of an arc edge of an arc head end mill. The method includes the following steps: firstly, the process characteristicsof the front tool face of the arc edge are defined, and include an instantaneous front tool face of the arc edge in the grinding plane, and a track curve of knifing grinding points (simultaneously constrains the width and front angle of the arc front tool face); secondly, a grinding track and attitude of a grinding wheel in the instantaneous front tool face is calculated; and finally, through spatial coordinate transformation, an actual machining track of the grinding wheel is obtained. According to the method for solving the grinding track of the front tool face of the arc edge of the arc head end mill, a grinding method of the front tool face of the arc edge of the integral end mill is studied in a deepgoing way, and a set of arc front tool face grinding algorithm capable of satisfying smooth transition and simultaneously constraining the front angle and the width; and simulation and machining results show that the method can be effectively used in tooling, the accuracy and feasibility of the grinding method are proved, and a theoretical reference for actual production and machining of cutters is provided.

Owner:SOUTHWEST JIAOTONG UNIV

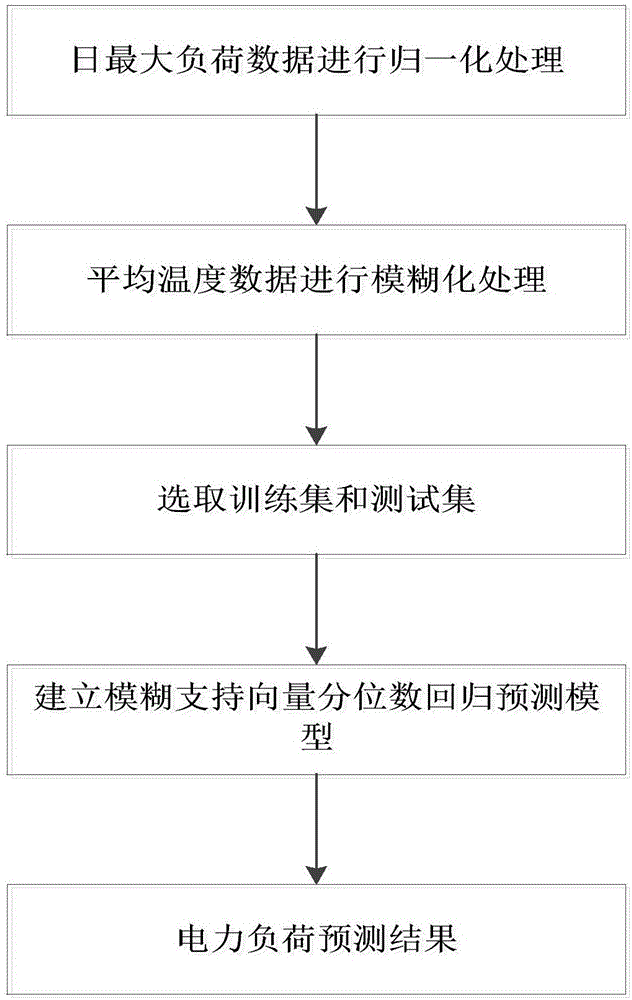

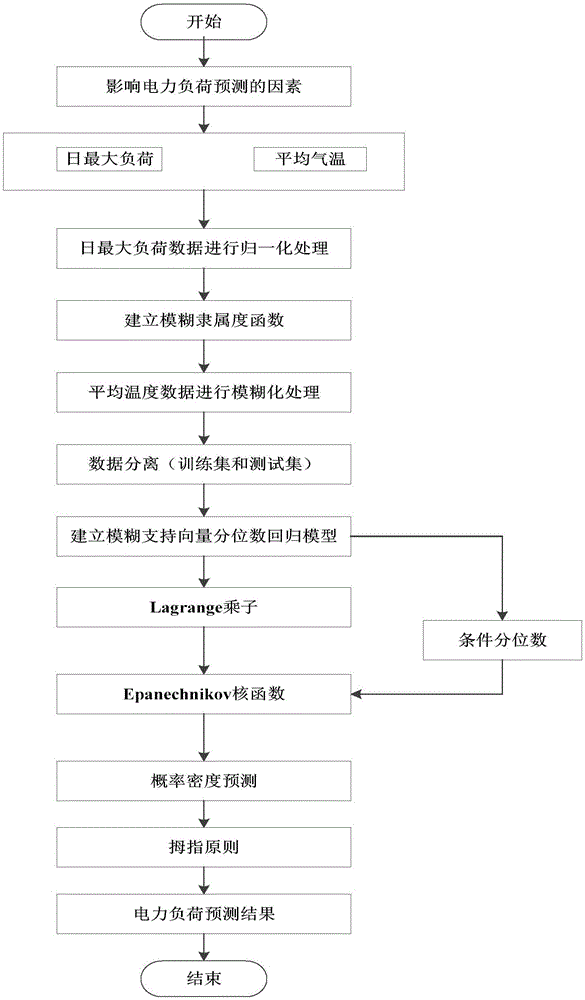

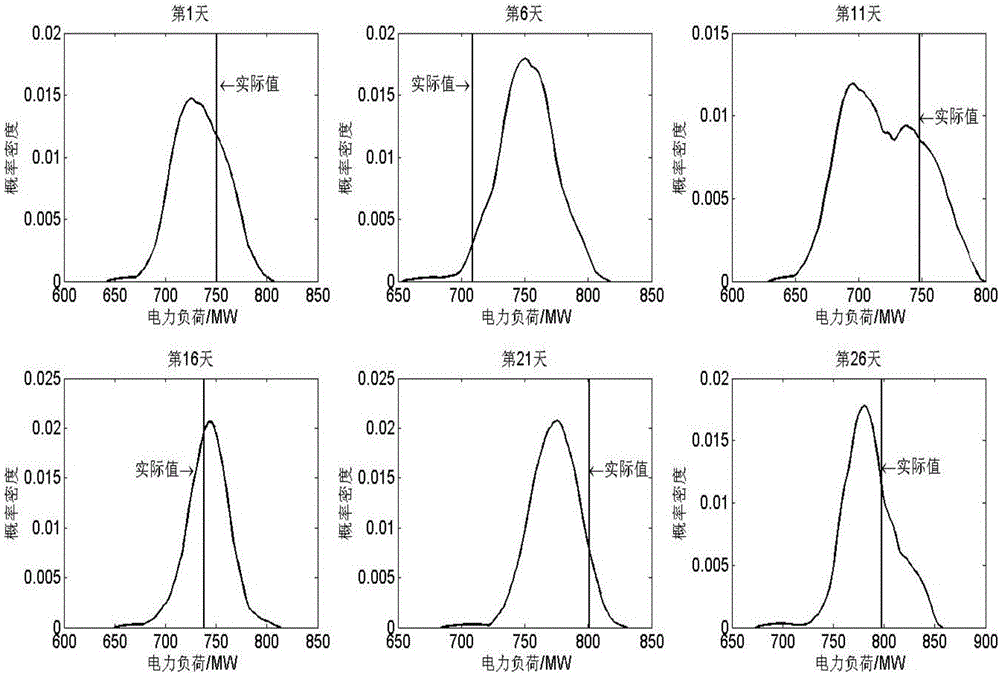

Power load probability density prediction method based on fuzzy support vector quantile regression

ActiveCN106251027AFacilitate scientific decision-makingSolve nonlinear problemsForecastingEnergy efficient computingAlgorithmPredictive methods

The invention discloses a power load probability density prediction method based on fuzzy support vector quantile regression. According to the method, maximum day load data and average temperature data before a prediction day are collected; a train set and a test set are established through adoption of history data; lagrangian multipliers and support vector subscripts of a fuzzy support vector quantile regression model are obtained through utilization of the train set; the fuzzy support vector quantile regression prediction model is established according to obtained model parameter values; the test set is substituted into the model to obtain prediction values; and probability density prediction of the maximum day load is realized through utilization of the obtained prediction values under different quantiles and through application of kernel density estimation. According to the method, prediction errors can be effectively reduced, the power load prediction precision is improved, the good prediction effect is obtained, and the relatively reliable basis is provided for a power system scheduling department to adjust power consumption plans and optimize generator set contribution.

Owner:HEFEI UNIV OF TECH

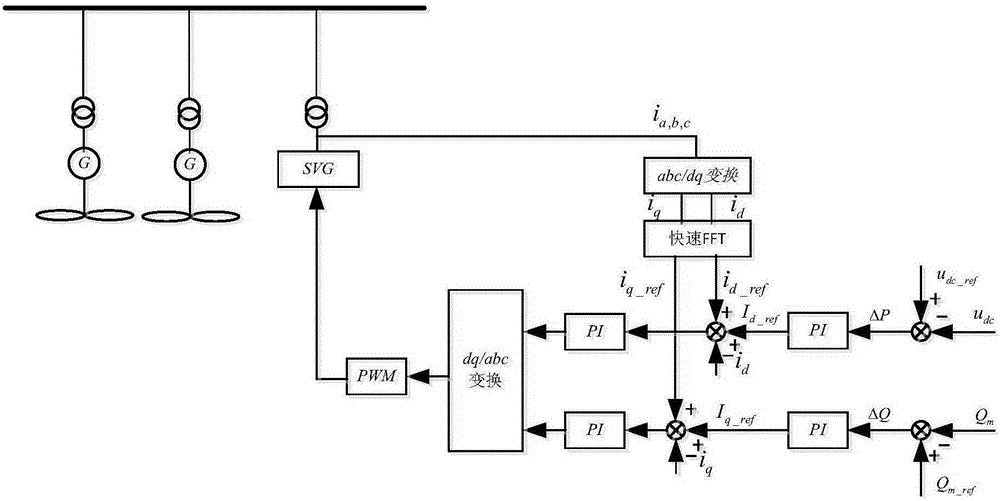

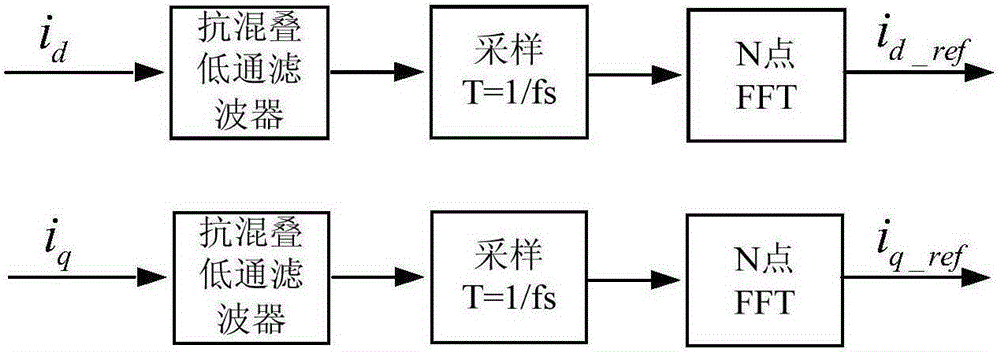

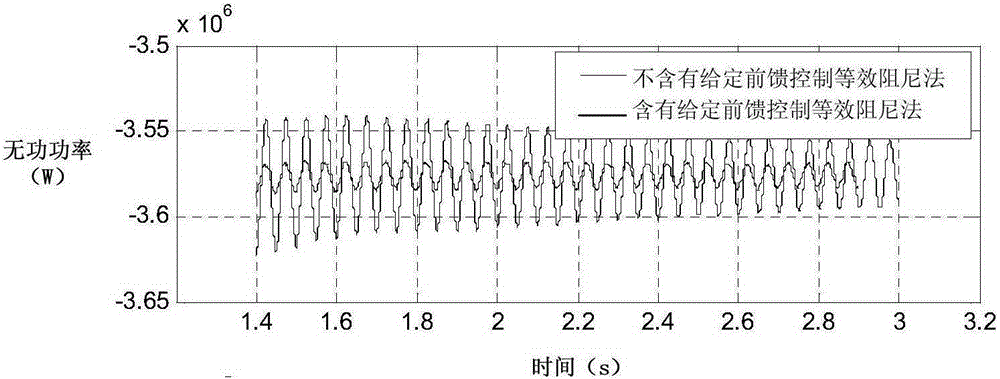

Control method for online dynamically restraining power grid low frequency oscillation and subsynchronous oscillation

InactiveCN105226679AStabilized wind power generation systemFast active and reactive powerFlexible AC transmissionReactive power adjustment/elimination/compensationDigital signal processingPower grid

The invention provides a control method for online dynamically restraining power grid low frequency oscillation and subsynchronous oscillation. Firstly, power grid voltage and current are acquired via a sensor, and after the voltage and the current are converted into signals readable by a digital processor, online real-time quick FFT is carried out via a digital signal processor (DSP); then, an SVG current control strategy is designed, and the SVG outputs accurate reactive power compensation according to a real-time power grid low frequency oscillation component and a subsynchronous oscillation component. On the basis of the original SVG control strategy, control algorithm for online dynamically restraining power grid subsynchronous oscillation is added, positive damping can be effectively provided with a wind farm, and a wind power generation system is stabilized; and compared with the existing restraining strategy, the SVG can output more accurate and quicker active power and reactive power according to the real-time power grid subsynchronous oscillation component, and the subsynchronous oscillation problem in the power grid is solved.

Owner:TBEA SUNOASIS +1

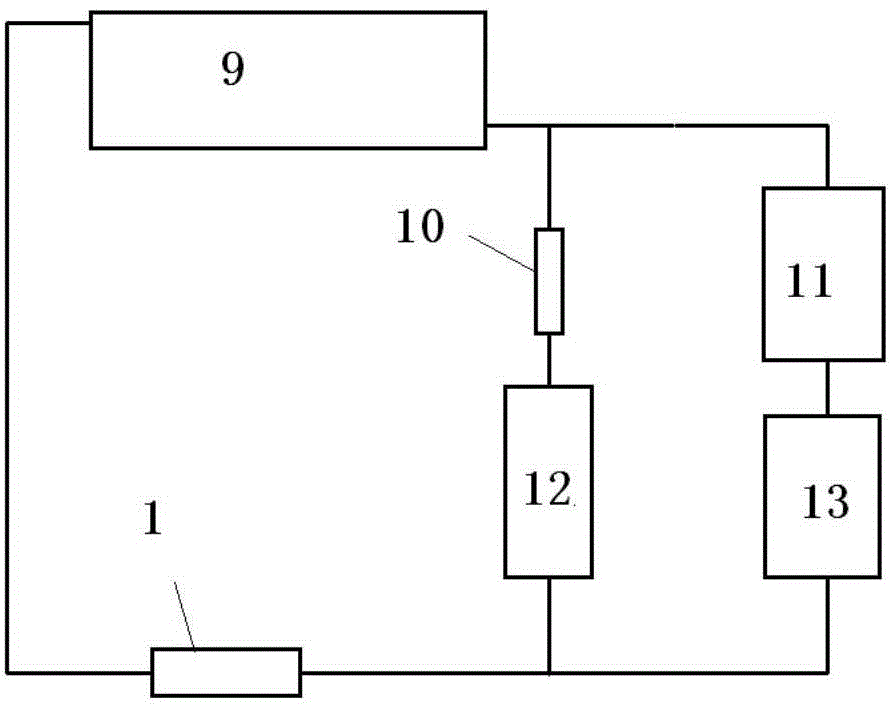

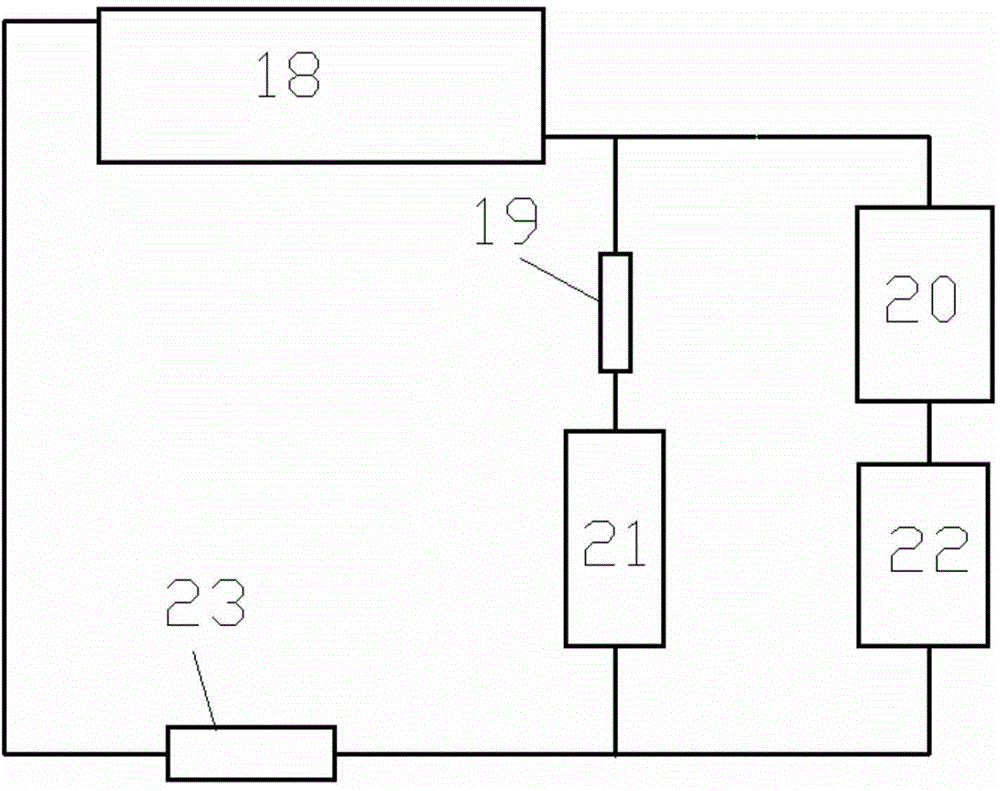

Solar heat storage system of loop heat pipe

InactiveCN105737399AAvoid wastingEven heat absorptionSolar heating energySolar heat devicesMicro-loop heat pipeEvaporation

The invention provides a solar heat storage system of a loop heat pipe. The solar heat storage system comprises a heat collector, a water tank, a heat storage device and the loop heat pipe; the condensation end of the loop heat pipe is arranged in the water tank, and the heat collector absorbs heat of solar energy to heat the evaporation end of the loop heat pipe; working liquid at the evaporation end is circulated to enter the condensation end of the loop heat pipe, and heat releasing is carried out at the condensation end to heat water in the water tank; and after heat releasing is completed at the condensation end, the working liquid is recirculated to enter the evaporation end of the loop heat pipe to conduct heating, and the water tank is connected with the heat storage device. According to the loop heat pipe solar heat storage system, by means of the loop heat pipe, the heat using capacity of solar energy is improved.

Owner:SHANDONG UNIV

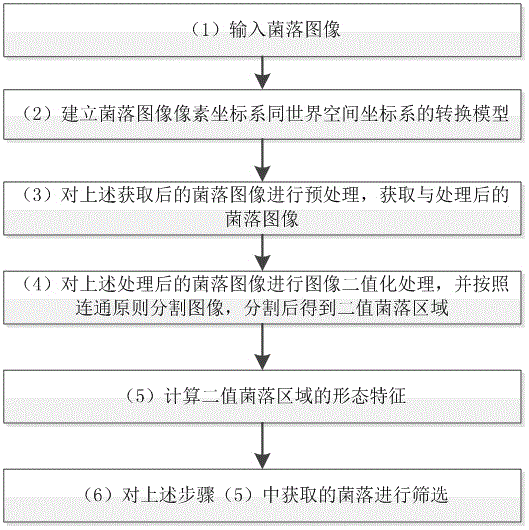

Automatic bacterial colony screening method based on bacterial colony morphological characteristics

InactiveCN105420107AGuaranteed screening accuracyProof of accuracyMicroorganismsScreening methodComputer science

The invention discloses an automatic bacterial colony screening method based on bacterial colony morphological characteristics. The method includes the steps that firstly, a bacterial colony image is input; secondly, a conversion model of a bacterial colony image pixel coordinate system and a world space coordinate system is established; thirdly, the acquired bacterial colony image is preprocessed, and the preprocessed bacterial colony image is acquired; fourthly, the preprocessed bacterial colony image is subjected to binarization processing, a binary bacterial colony image is obtained and is segmented according to the communication principle, and a binary bacterial colony area is obtained after segmentation; fifthly, the morphological characteristics of the binary bacterial colony area are calculated; sixthly, bacterial colonies obtained in the fifth step are screened. According to the method, the bacterial colonies are screened according to the morphological characteristics of the individual bacterial colonies and are compared with a morphological characteristic sample base of excellent bacterial colonies so that the screening accuracy of the bacterial colonies can be guaranteed, universality is high, and meanwhile, bacterial colony screening accuracy and precision of the method are proved through a large number of bacterial colony screening experiments performed on a bacterial colony selector.

Owner:SHANGHAI UNIV

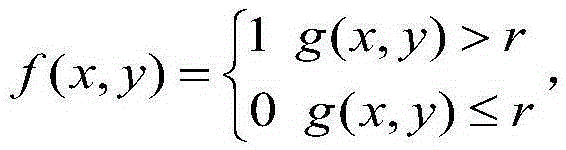

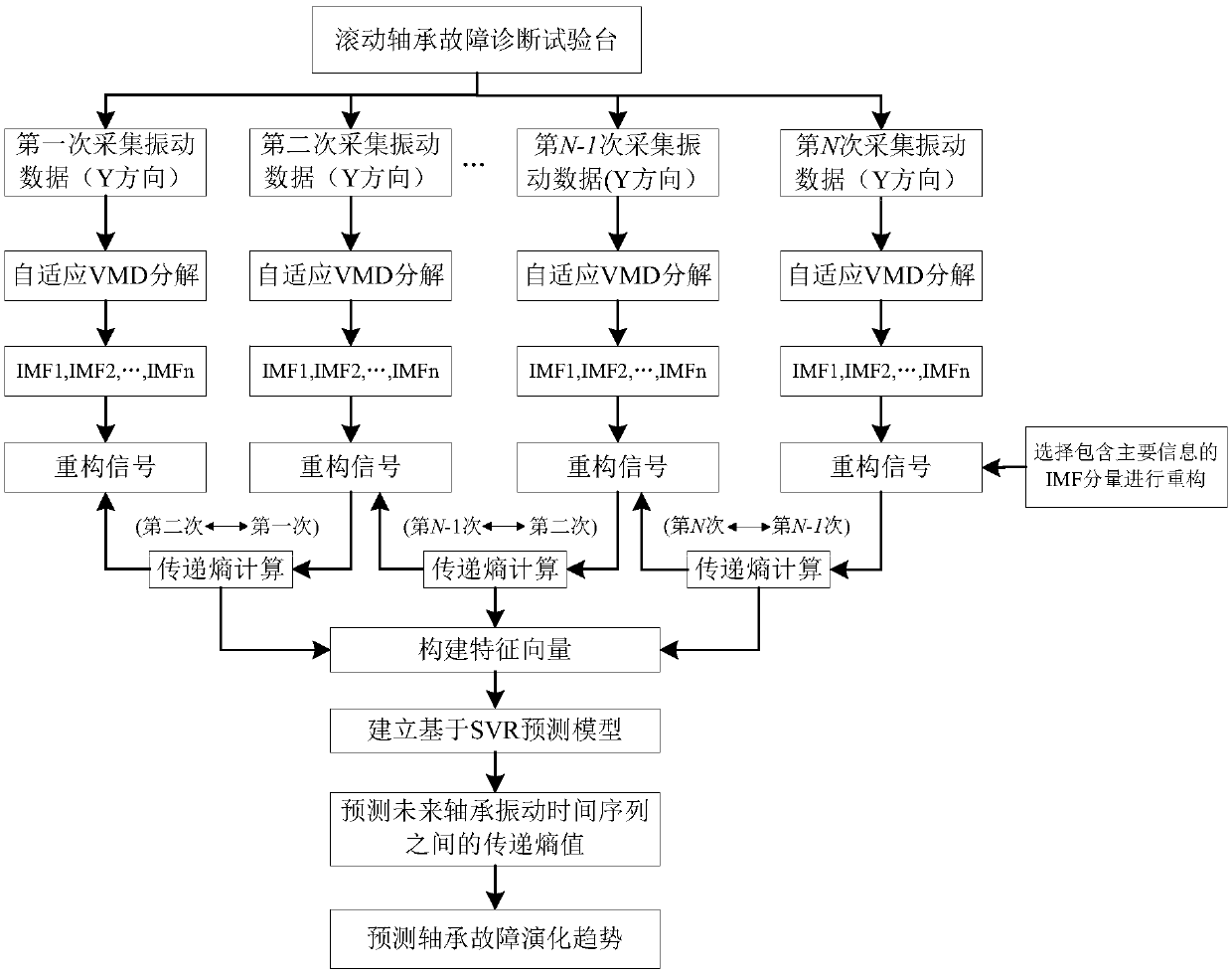

Bearing degradation state identification and predication method based on variation modal decomposition-transfer entropy

InactiveCN109580222AImprove forecast accuracyAvoid blind trial calculationsMachine bearings testingDecompositionTheory based

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

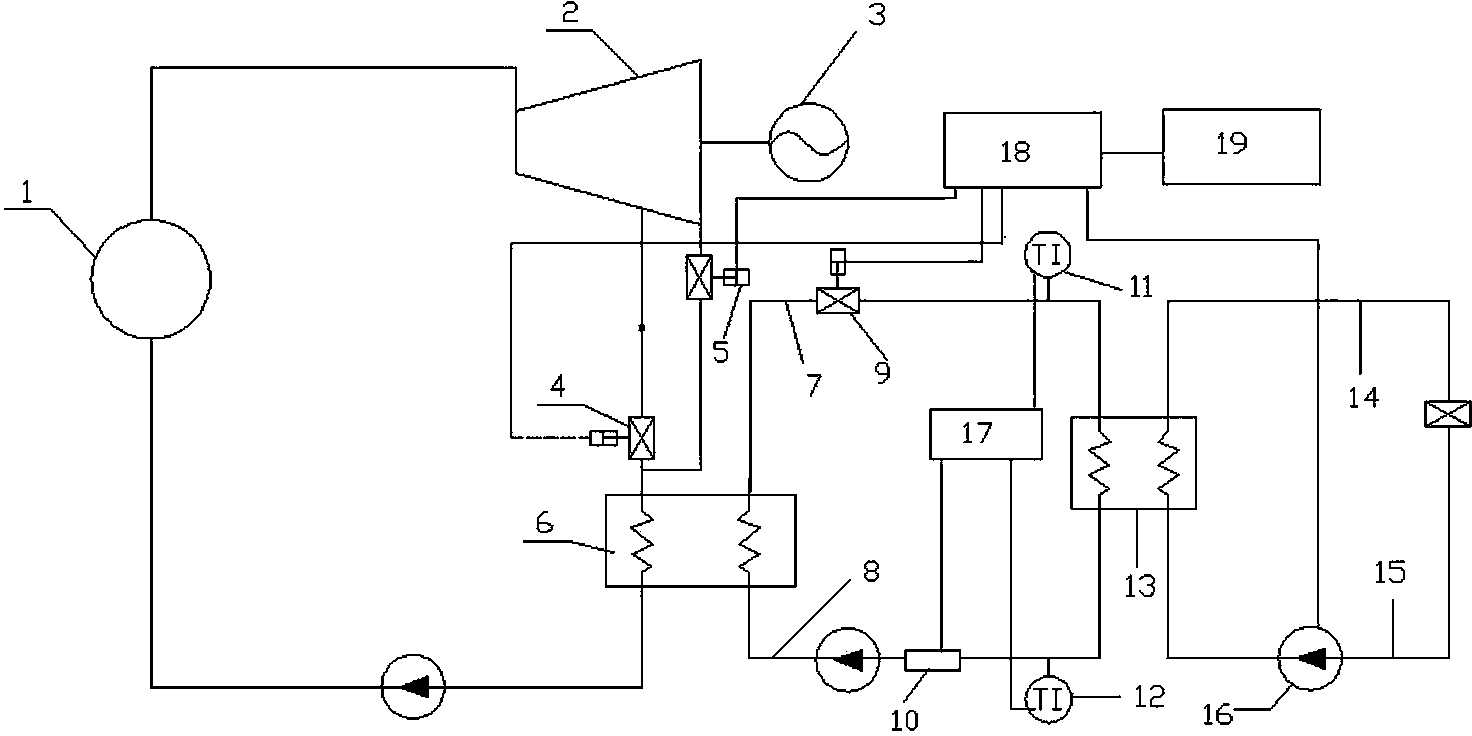

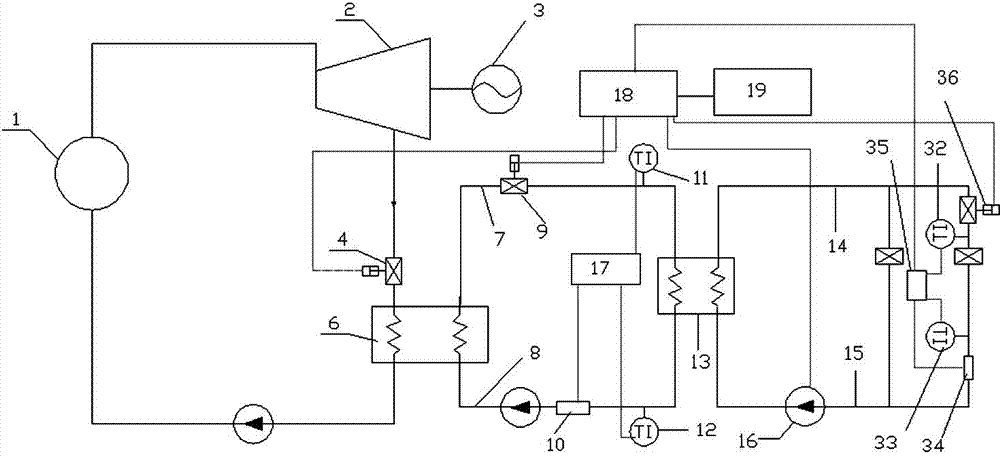

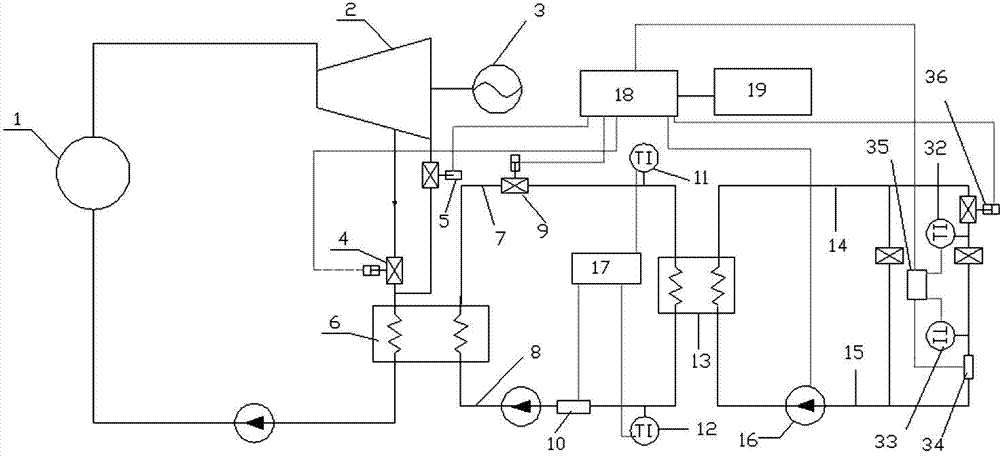

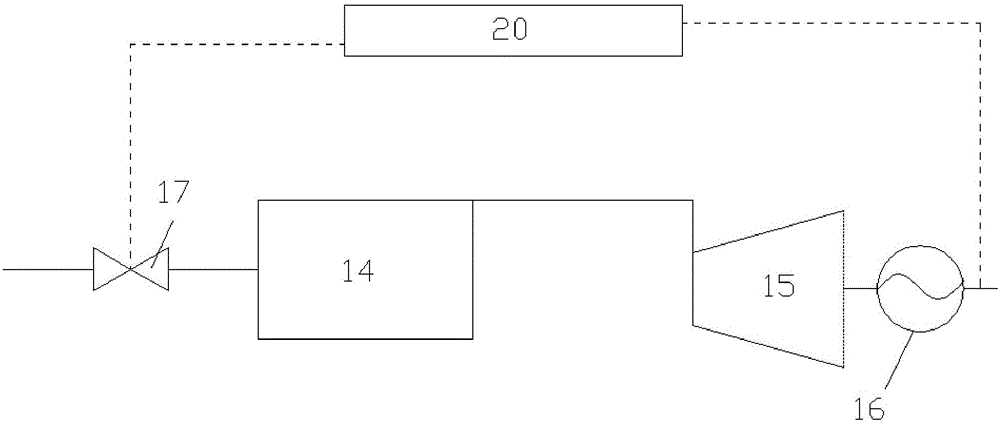

Combined heat and power generation system with regulating valves adapting to changes

InactiveCN104713388AEnhanced chimney effectGood optimization resultSteam useStationary conduit assembliesData connectionProgrammable logic controller

The invention provides a combined heat and power generation system with regulating valves adapting to changes. According to the combined heat and power generation system with the regulating valves adapting to the changes, the first regulating valve is arranged on a hot water supply pipe to regulate hot water entering into a heat exchanger; the second regulating valve is arranged on a water inlet pipeline of a radiator, data connection is conducted between a programmable logic controller and the first regulating valve as well as between the programmable logic controller and the second regulating value, and when the opening degree of the second regulating valve changes, the opening degree of the first regulating valve changes correspondingly to enable the hot water input into the heat exchanger to change correspondingly. According to the combined heat and power generation system with the regulating valves adapting to the changes, the heat exchange efficiency is maximized through the corresponding changes of the regulating valves, the energy is saved, and the purposes of protecting environment and saving energy are achieved.

Owner:ZHONGBEI UNIV

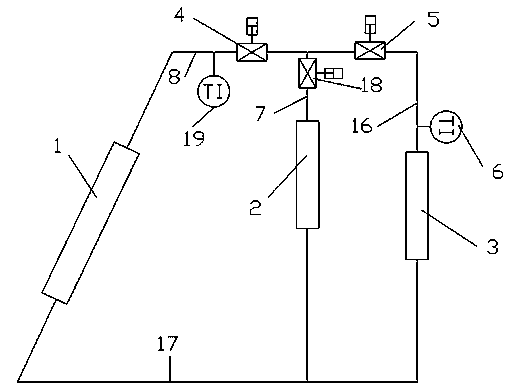

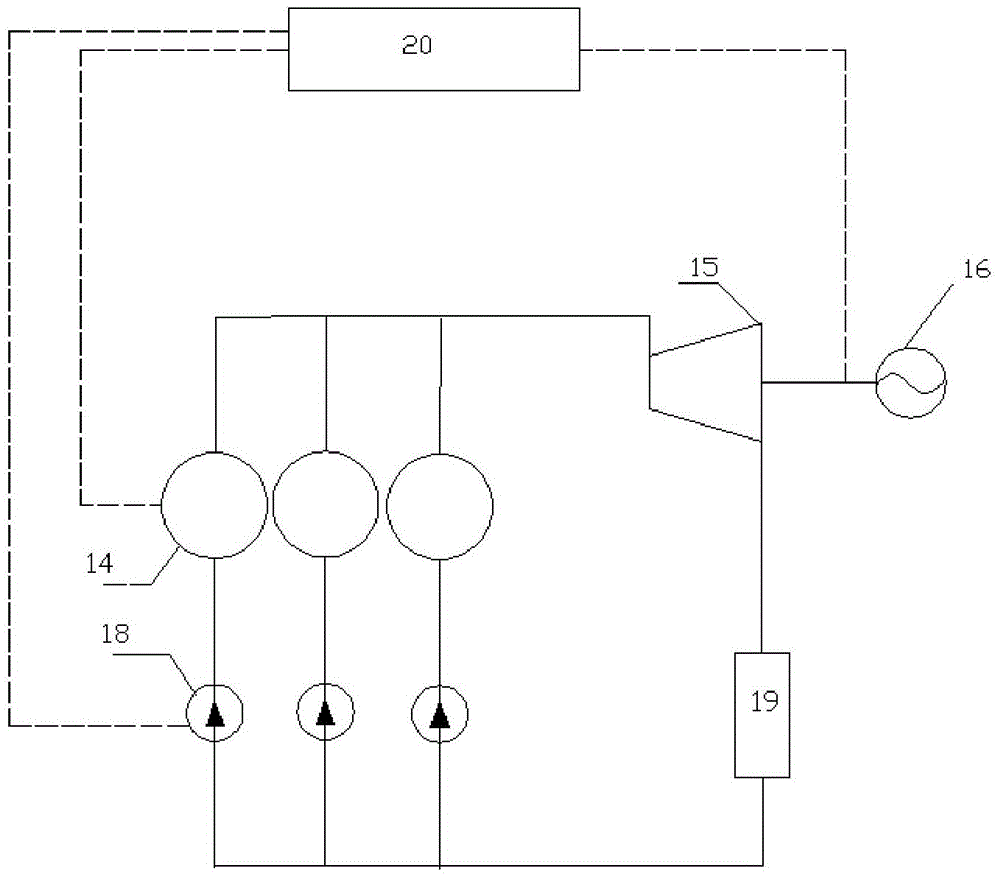

Solar water heater system

ActiveCN104061699APromote absorptionReduce corrosionSolar heating energySolar heat devicesMicro-loop heat pipeSolar water

The invention provides a loop heat pipe-type solar water heater system which comprises a thermal utilization device, wherein the thermal utilization device is hot water output equipment for providing a user with hot water and comprises a heat exchanger; the heat exchanger is connected with tap water; hot water from a solar water heater enters the heat exchanger to exchange heat with the tap water. The solar water heater provided by the invention is energy-saving, and higher in solar heat utilization capability.

Owner:SHANDONG UNIV

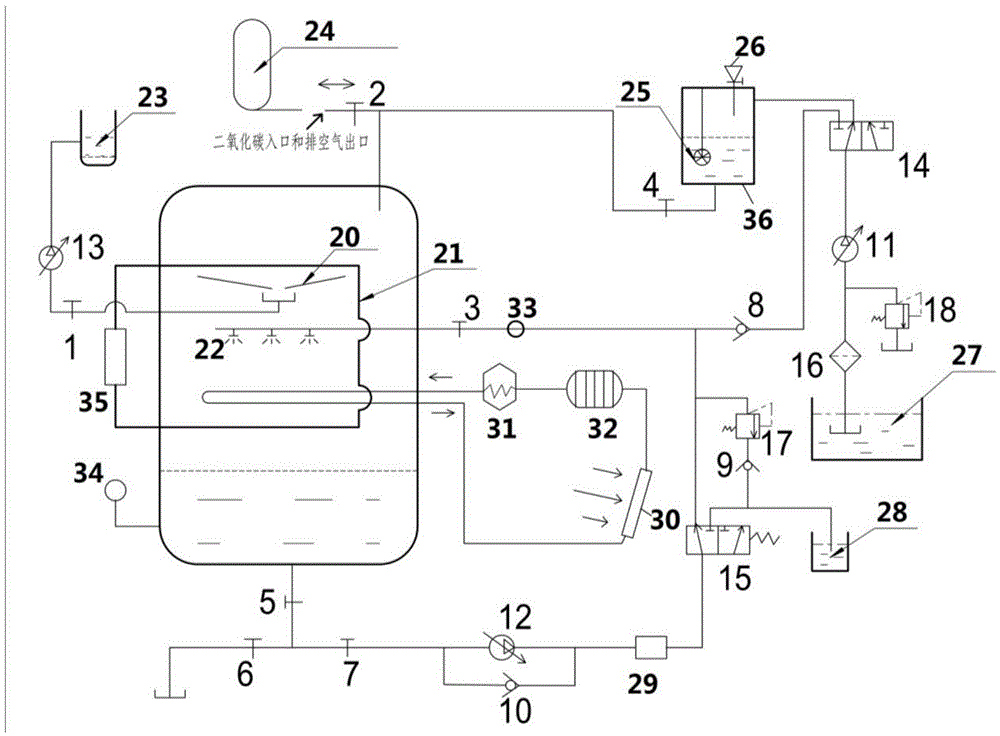

Intelligent blowdown boiler

InactiveCN104949098AAvoid wastingRealize automatic online monitoringBoiler cleaning apparatusEnergy industryThermal energyAutomatic control

The invention provides an intelligent blowdown boiler which comprises an automatic control blowdown system. The automatic control blowdown system is automatically controlled according to the amount of steam generated by the boiler and the amount of water input into the boiler. The water supply amount and the generated steam amount of each boiler are monitored in real time, so that the dynamic relation of the water supply amount and the generated steam amount is obtained, whether the blowdown system of the boiler works normally or not is judged, and waste of a large amount of heat energy waste caused by faults of the blowdown system of the boiler is avoided.

Owner:张雪原

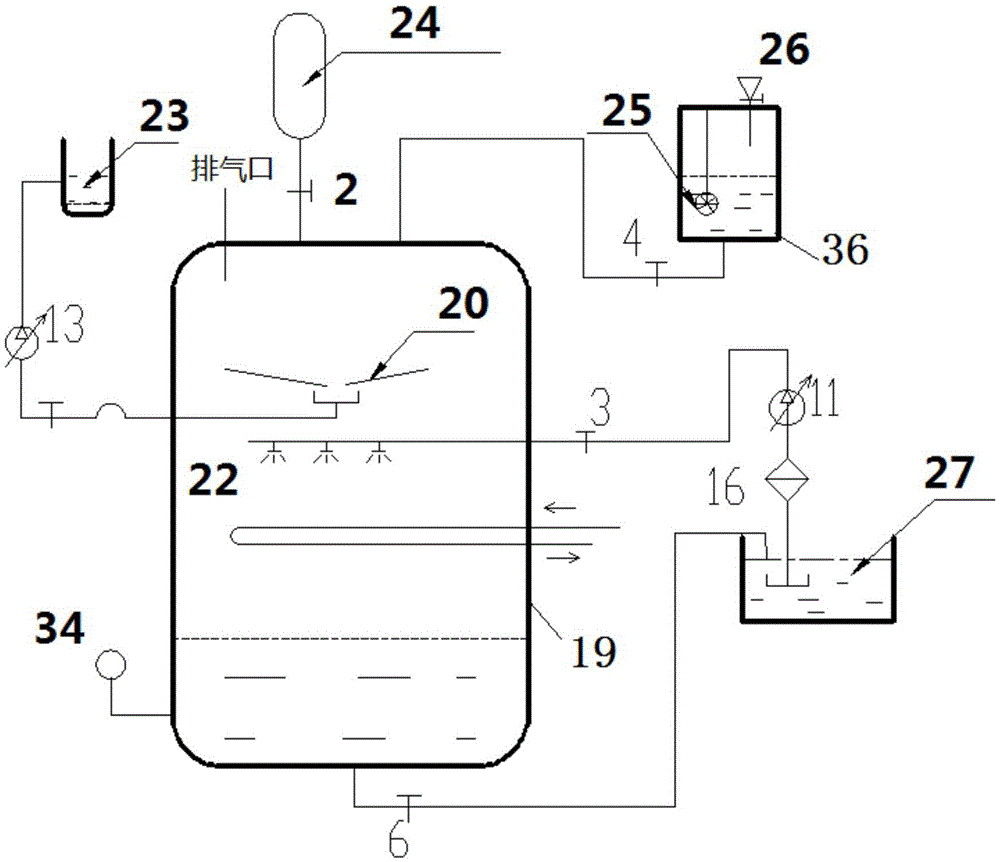

Seawater desalination system with loop heat pipe

InactiveCN105600854ASave energyImprove performanceSolar heating energyGeneral water supply conservationSeawaterProcess engineering

The invention provides a seawater desalination system with a loop heat pipe. The system comprises an evaporation chamber, an acidic gas storage tank, an alkaline solution container and a seawater storage tank. The evaporation chamber is provided with an exhaust port and is connected with the acidic gas storage tank and the alkaline solution container, a first pipeline connected with the seawater storage tank is arranged at the bottom of the evaporation chamber, the seawater storage tank is provided with a second pipeline connected with the evaporation chamber and used for conveying seawater to the evaporation chamber, the first pipeline and the second pipeline are provided with a first valve and a second valve respectively, a pipeline through which the evaporation chamber and the acidic gas storage tank is connected is provided with a third valve, and a pipeline through which the evaporation chamber is connected with the alkaline solution container is provided with a fourth valve. The evaporation chamber is vacuum in a chemical mode, cost is reduced, and seawater desalination performance and efficiency are improved.

Owner:山东大学(威海)

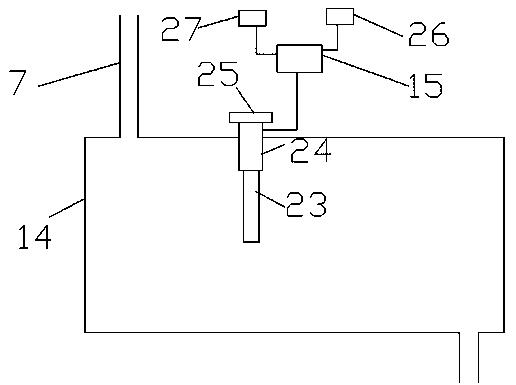

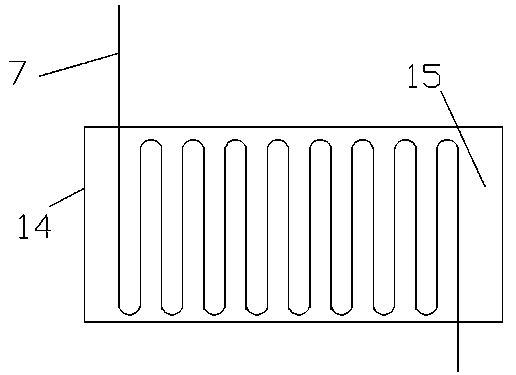

Solar heat collector detecting leakage through humidity measuring device

ActiveCN106949641AUniform pressureEvenly distributedSolar heating energySolar heat devicesData connectionControl system

The invention provides a solar flat plate type heat collector which comprises a box body and heat collecting pipes. A transparent cover plate is arranged on the top of the box body; a heat preservation layer is arranged at the bottom of the box body; and the heat collecting pipes are arranged in the box body. The solar flat plate type heat collector further comprises a humidity measuring device arranged in the box body and in data connection with a control system; and once liquid leaks, the liquid enters the box body, when the detected humidity is higher than a certain value, measurement data are abnormal, and the control system closes valves of liquid entering into the heat collecting pipes in time. The novel solar heat collector for automatically detecting leakage detects leakage by detecting the humidity of the heat collecting pipes.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

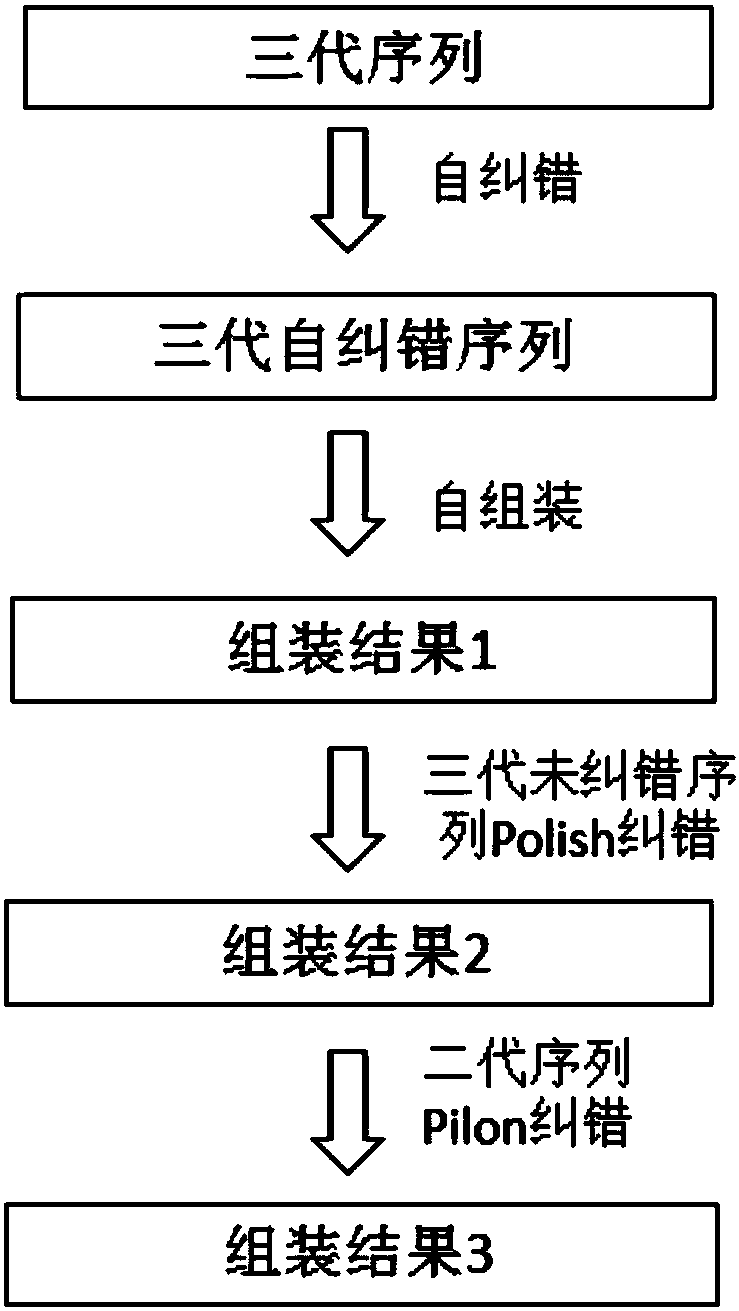

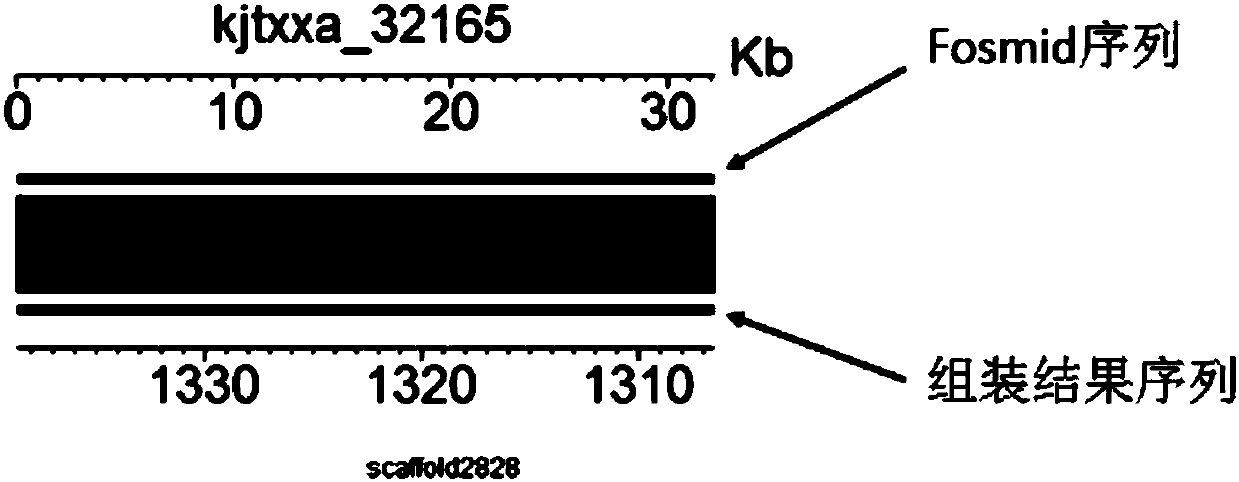

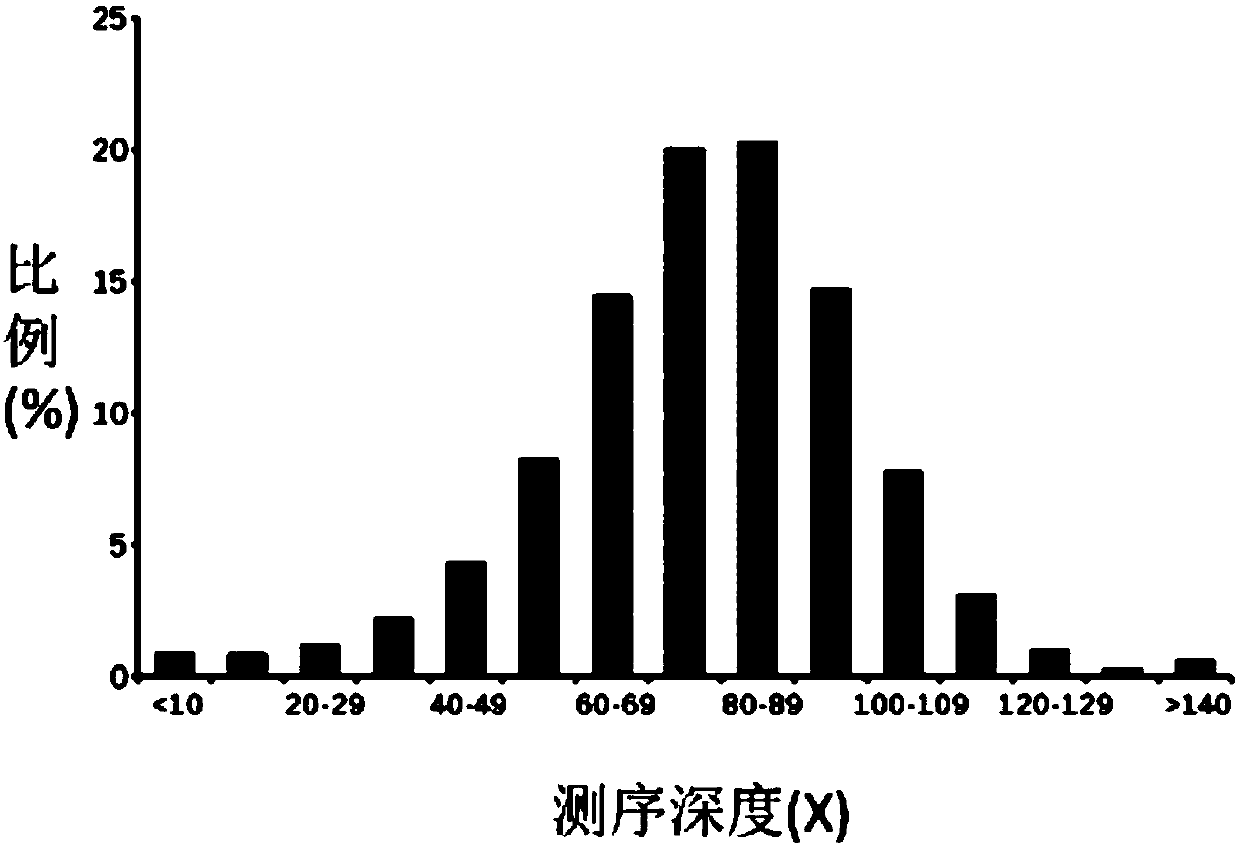

Method and device of estimating and verifying sequence assembly result of three-generation sequencing

ActiveCN107895104AProof of accuracyImprove accuracySequence analysisSpecial data processing applicationsScreening methodComputer science

The invention discloses a method and device of estimating and verifying a sequence assembly result of three-generation sequencing. The method comprises the steps of comparing a two-generation sequencewith a three-generation assembly result; extending and selecting a low cover degree area, and obtaining the extended sequence; comparing a three-generation sequence with the extended sequence; counting basic group coverage depth; marking the assembly result. The method and device can screen out the area with not too high quality from the three-generation assembly result, and mark the area. In thefollowing species research, a prompt function is provided if the area with not too high quality needs to be used, and a rapid screening method is provided for the following improvement; meanwhile, the accuracy and quality of the three-generation assembly result can be proved, and the accuracy of the assembly result can be improved.

Owner:BGI TECH SOLUTIONS

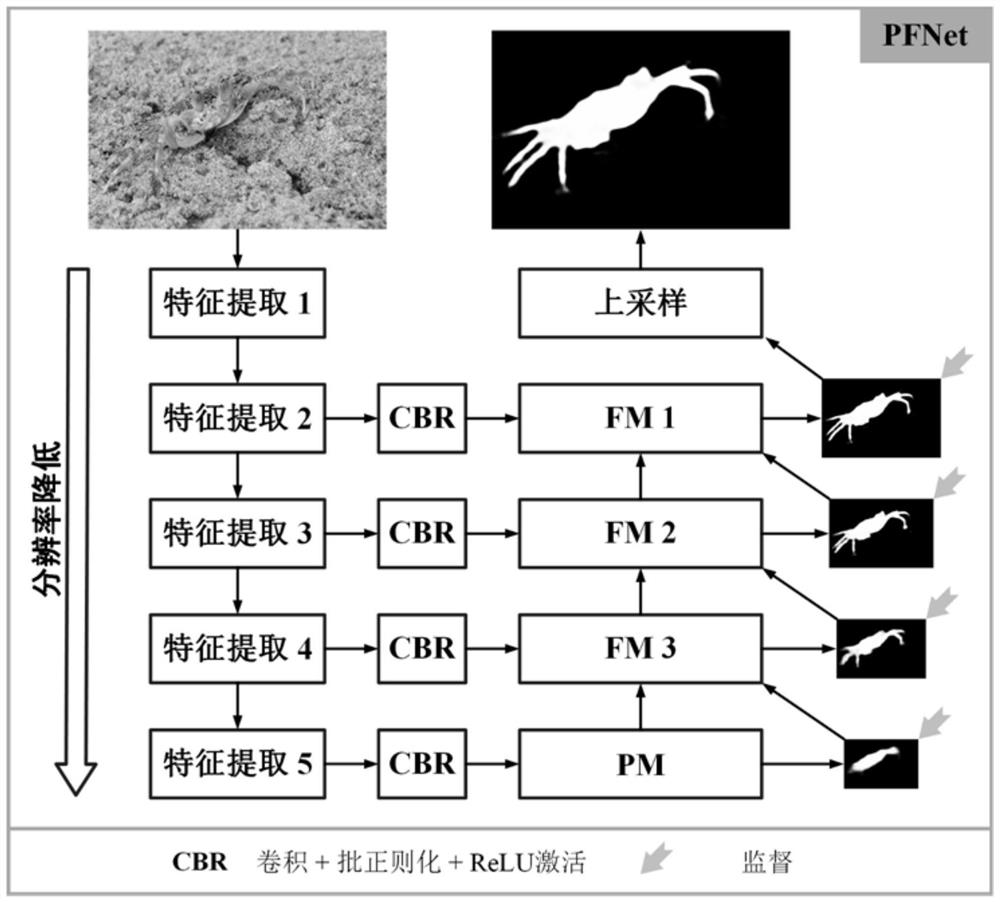

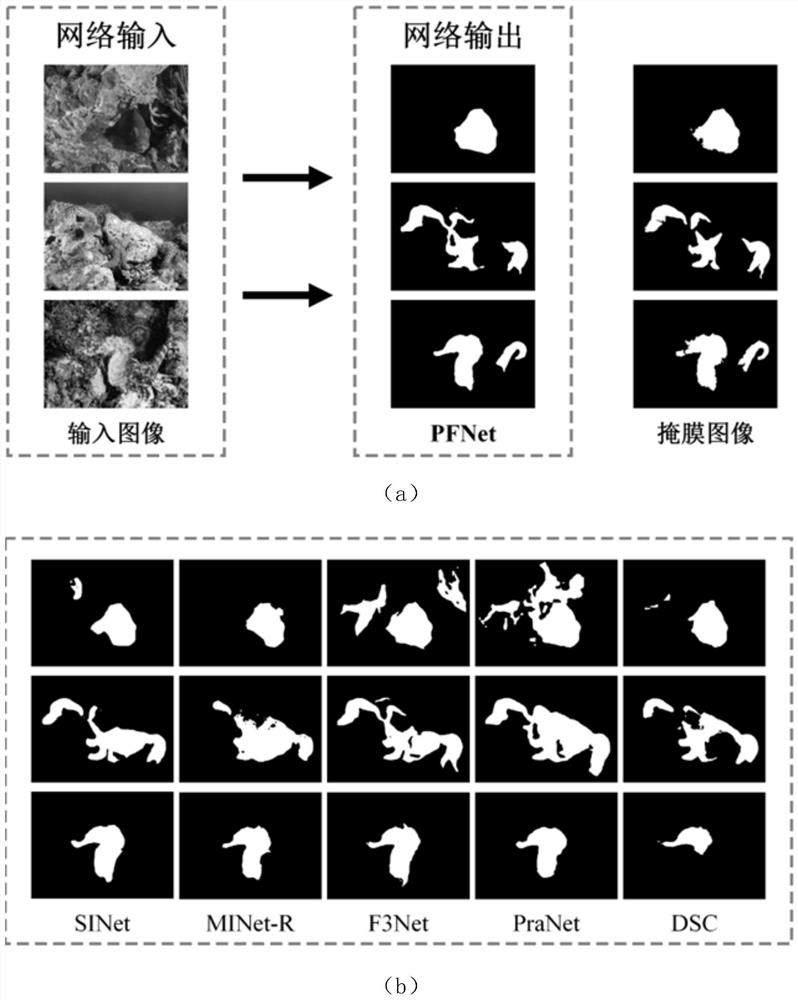

Camouflage target image segmentation method based on information mining

ActiveCN112750140ASolve the problem of camouflaged target segmentationPerfect segmentation resultsImage enhancementImage analysisScene segmentationFeature extraction

The invention belongs to the technical field of scene segmentation in computer vision, and discloses a camouflage target image segmentation method based on information mining. The PFNet sequentially comprises a multi-layer feature extractor, a positioning module and a focusing module, wherein the multi-layer feature extractor obtains context features of different levels by using a traditional feature extraction network; the positioning module firstly uses RGB feature information to preliminarily determine the position of a camouflage target in an image; and the focusing module is used for mining information and removing interference information on the basis of the RGB feature information and the preliminary position information of the image, and finally determining the boundary of the camouflage target step by step. According to the method, the concept of interference information is introduced into a camouflage target segmentation problem, a new information exploration and interference information removal strategy is developed, and segmentation of a camouflage target image is facilitated. From the perspective of the result, the PFNet segmentation result is very excellent, and the fine degree of the camouflage target boundary is also satisfactory. Meanwhile, the method is wider in applicability.

Owner:DALIAN UNIV OF TECH

Boiler thermodynamic system for conducting automatic control based on steam fuel consumption

InactiveCN105003901AGuaranteed uptimeAvoid wastingFuel supply regulationEnergy industryData connectionAutomatic control

The invention provides a boiler thermodynamic system. The boiler thermodynamic system comprises a central monitoring diagnostic system, a fuel conveying device and a plurality of boilers connected in parallel. Each boiler is in data connection with the central monitoring diagnostic system. The central monitoring diagnostic system is in data connection with each boiler and the fuel conveying device so that the fuel input amount of each boiler can be obtained in time. The central monitoring diagnostic system monitors the ton steam fuel consumption parameter of each boiler in real time according to the obtained mass of steam output by each boiler and the obtained fuel input amount of each boiler. The ton steam fuel consumption of each boiler is the ton steam fuel consumption index obtained by dividing the total amount of steam generated by the boiler during a certain period of time by the fuel input amount of the boiler during the period of time. By means of the boiler thermodynamic system, the thermodynamic system can keep running efficiently all the time, and energy waste can be avoided.

Owner:张雪原

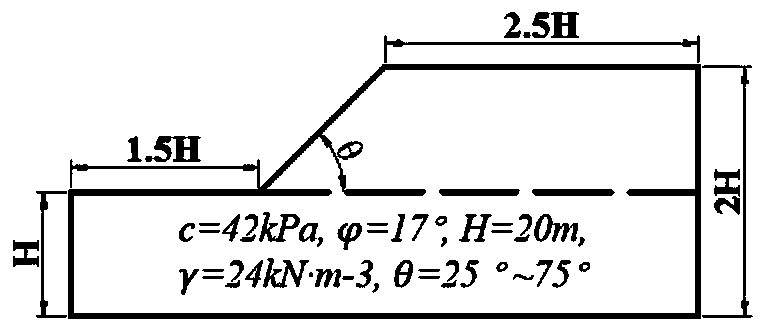

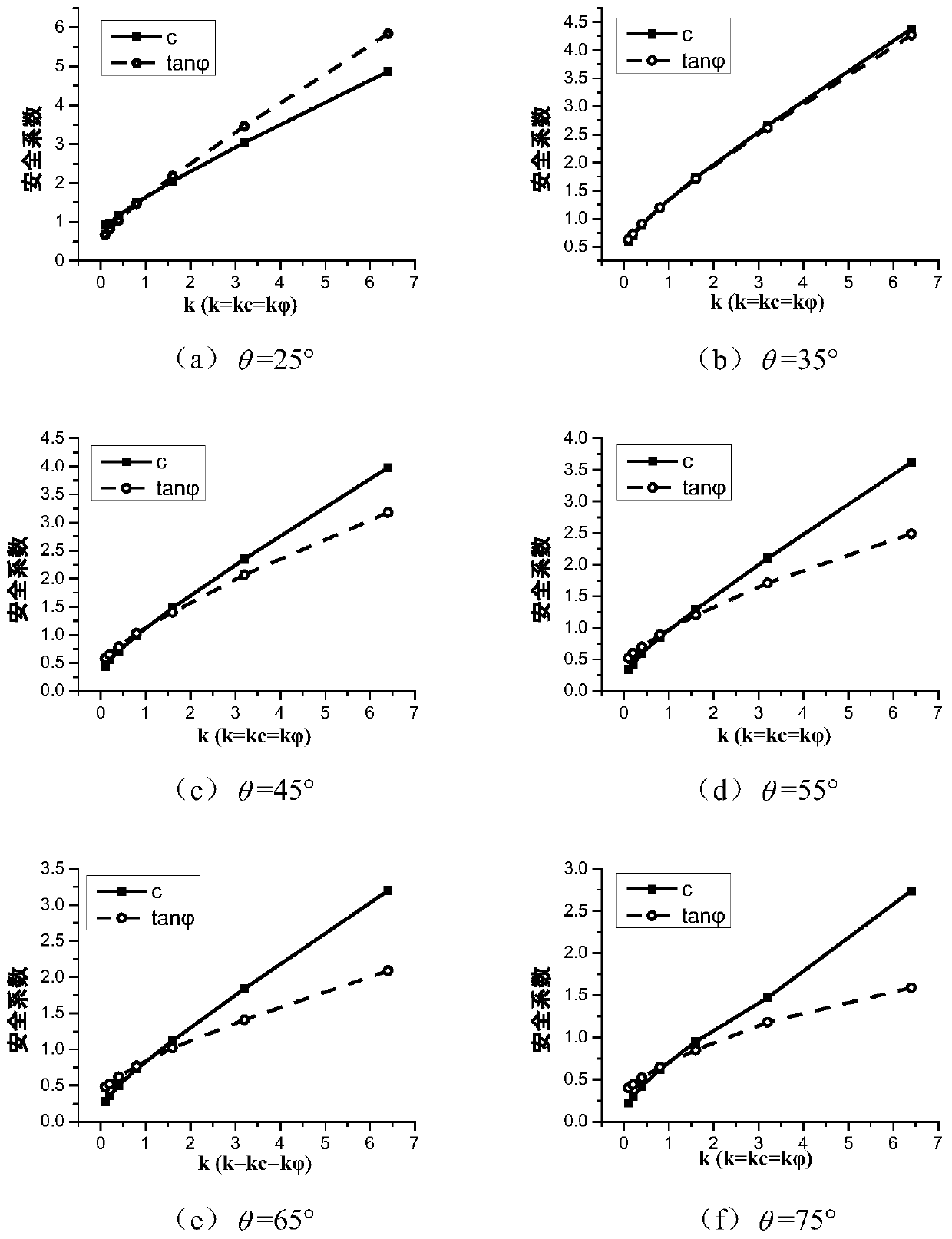

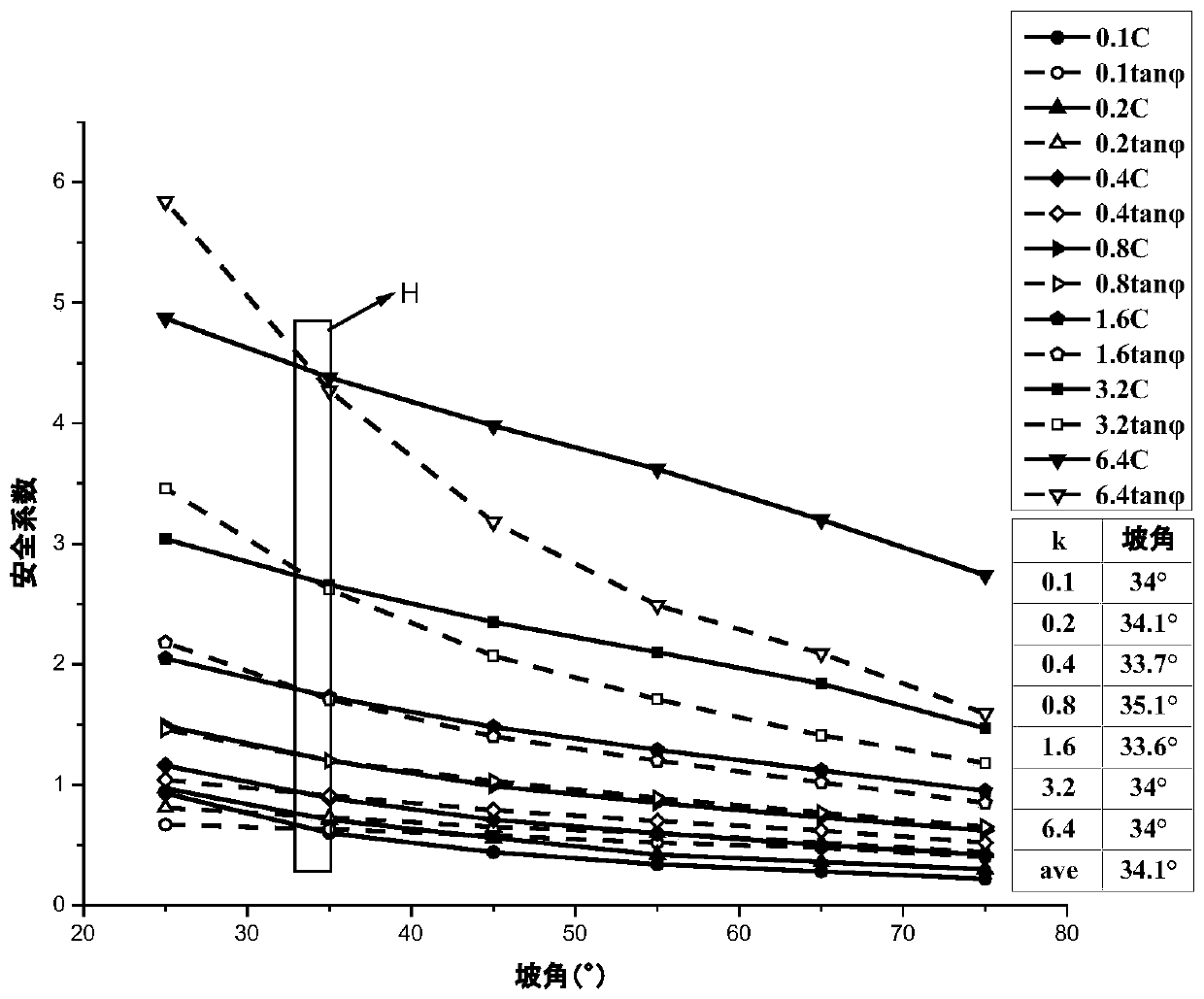

Slope safety coefficient calculation method considering cohesive force and internal friction angle contribution degree

ActiveCN111008465AProof of accuracyWell formedDesign optimisation/simulationClassical mechanicsEngineering

The invention discloses a slope safety coefficient calculation method considering cohesive force and internal friction angle contribution degree. According to the calculation method, the influence degree and the influence mechanism of the cohesive force and the internal friction angle on the slope stability are described, the form is simple and the physical significance is clear. The stability calculation result obtained through the method has quite high coincidence degree with the calculation result obtained through an existing method, it is proved that the provided double-reduction slope comprehensive safety coefficient defining method is reasonable and accurate, and problems and defects existing in an existing double-reduction slope comprehensive safety coefficient defining method can be effectively solved. According to the calculation method, the double-reduction slope comprehensive safety coefficient calculation method capable of reflecting contribution of the cohesive force and the internal friction angle to slope stability is provided, existing slope examples are analyzed through the method, and high calculation precision shows the reasonability and the correctness of the new calculation method.

Owner:CENT SOUTH UNIV

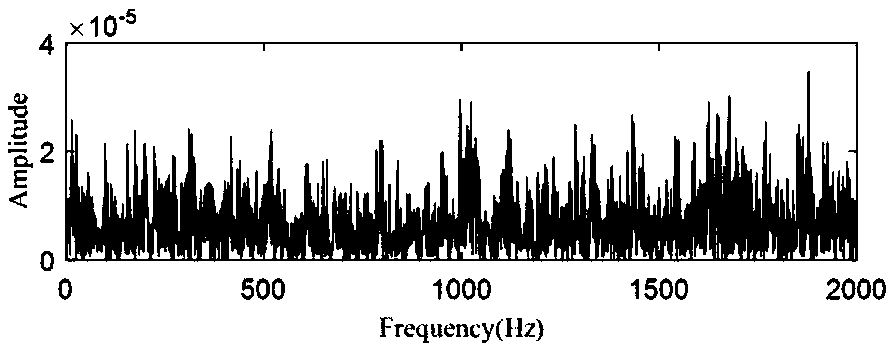

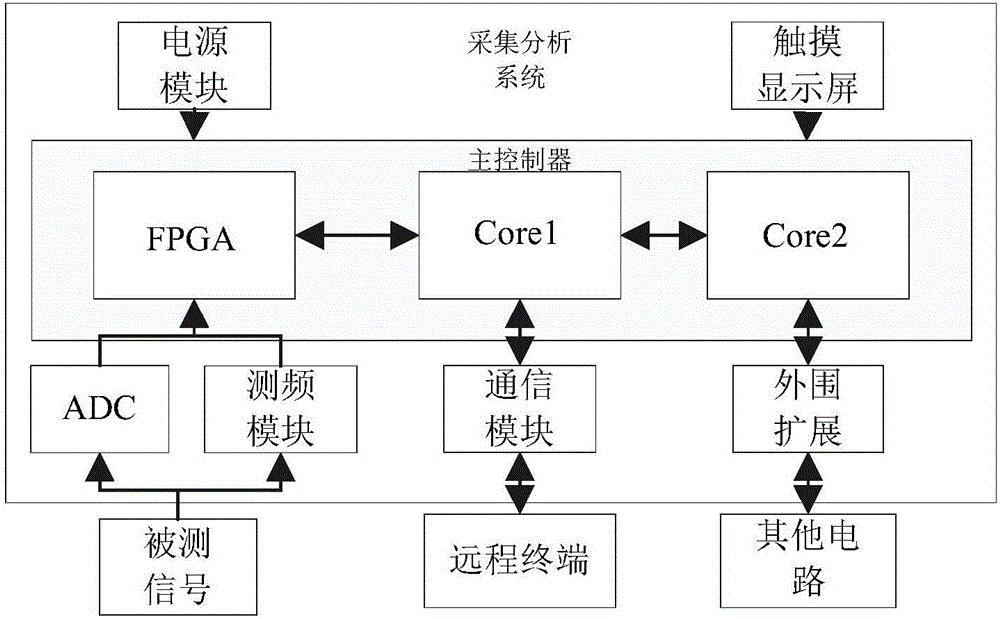

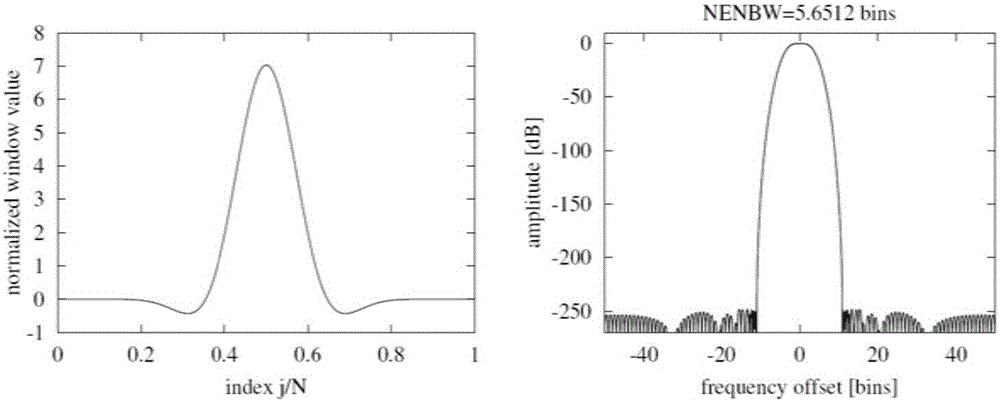

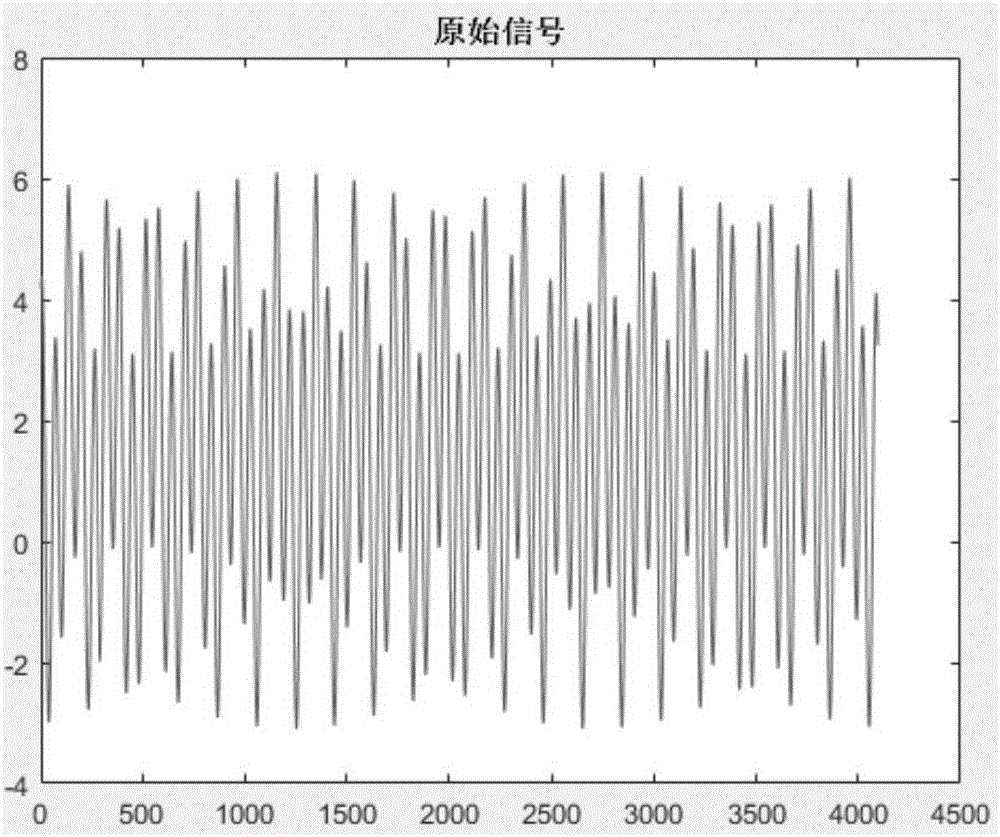

Low cost and high precision embedded type signal collection and analysis system and method

ActiveCN106645942AEasy to handleHigh speedSpectral/fourier analysisDigital variable displayLow speedFrequency measurements

A signal collection and analysis system and method are disclosed. The signal collection and analysis system comprises a main controller, a data converter ADC, a frequency measurement unit and the like. The main controller comprises a main control unit, an auxiliary control unit and a logic gate array, wherein the logic gate array is used for driving an ADC and measuring and calculating frequency of tested signals, and the main control unit is used for realizing man-machine interaction and communication with the auxiliary control unit and a host computer. The low cost and high precision embedded type signal collection and analysis system is characterized in that the logic gate array and a front end circuit can be used for accurately measuring signal frequency, a signal amplitude can be accurately calculated by the main control unit when the signal frequency is known, and the auxiliary control unit is capable of expanding other low speed demands of the main control unit.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

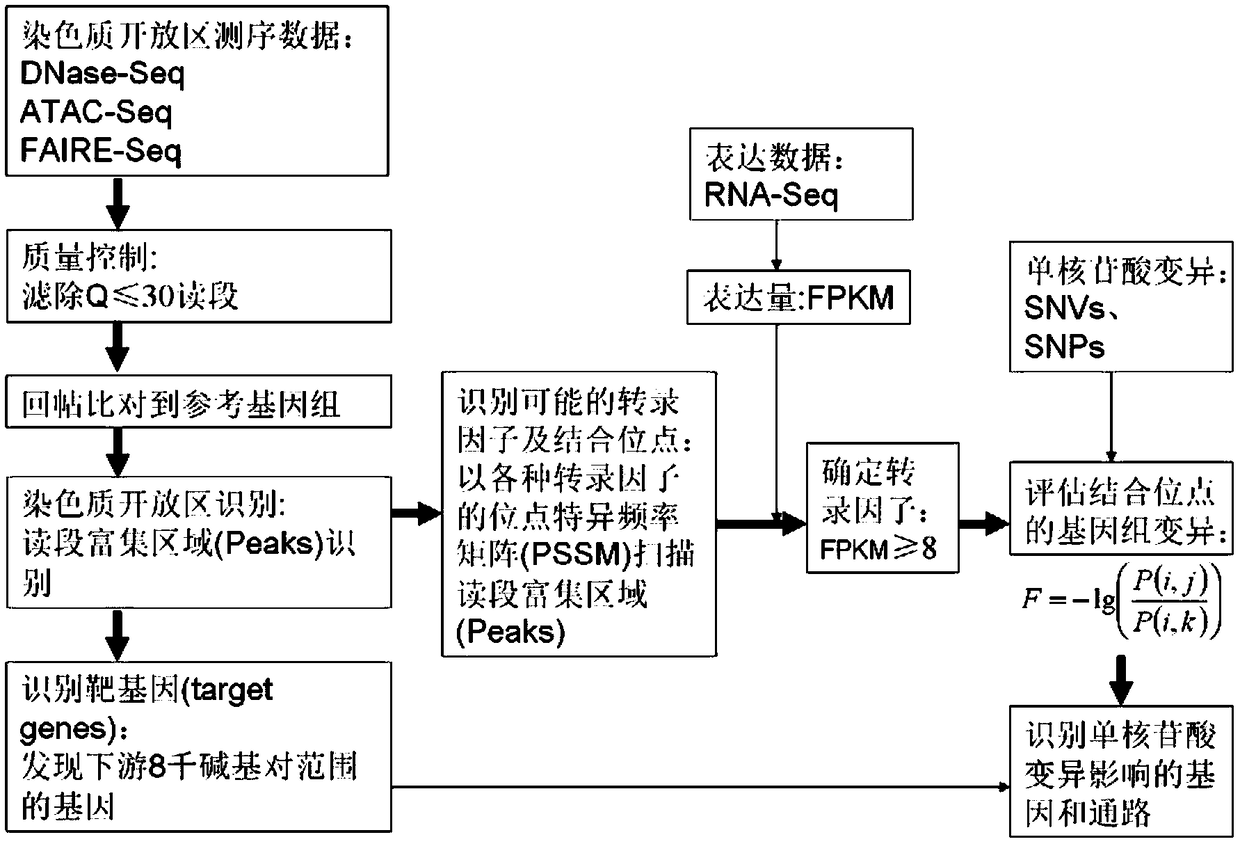

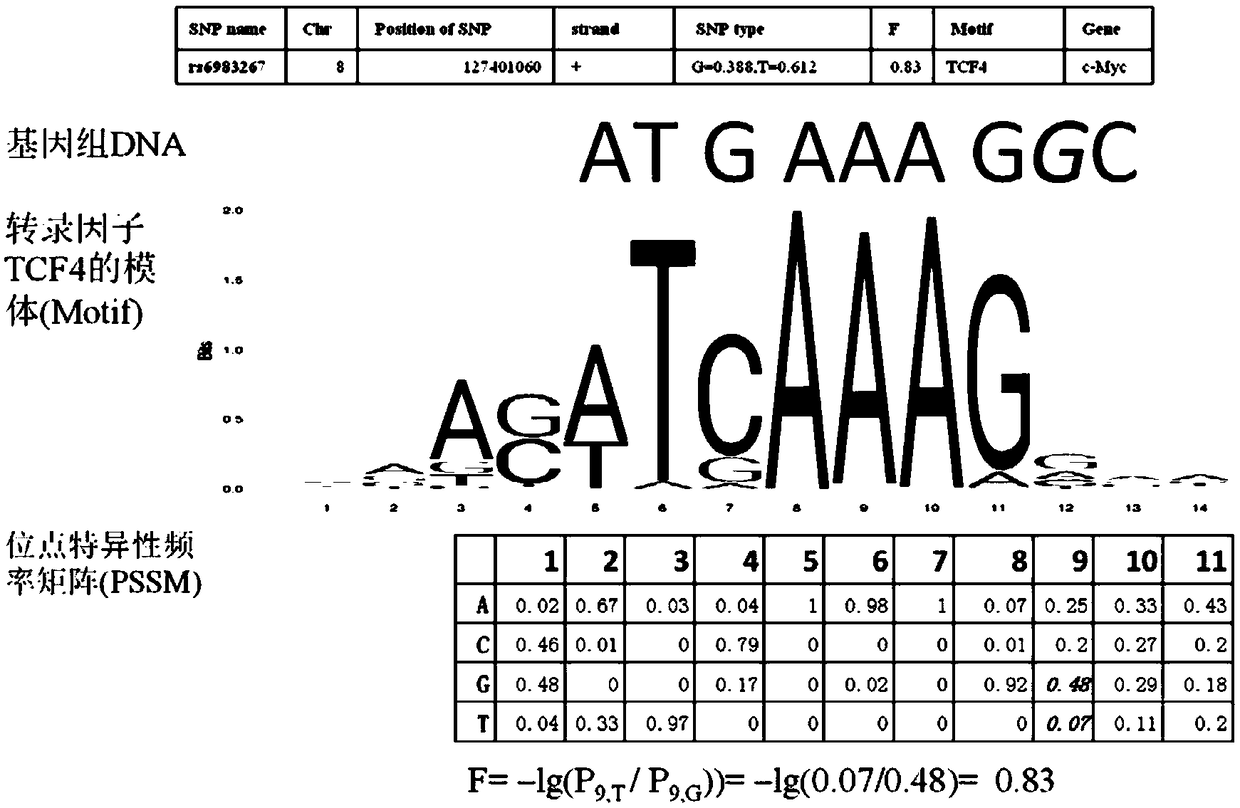

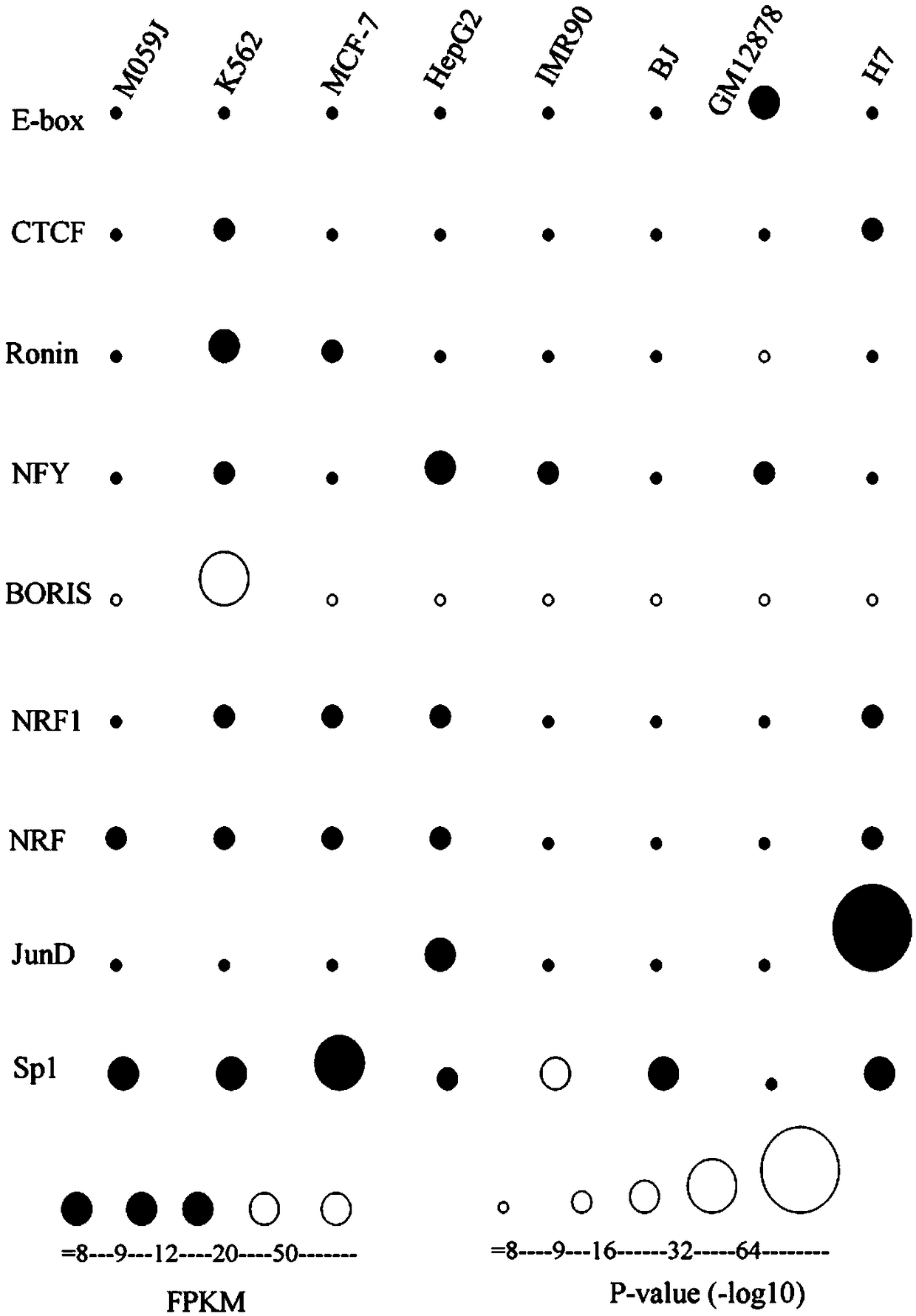

A method for functional prediction of single nucleotide genomic variation in a non-coding region

ActiveCN109033751ALow sequencing depth requirementAvoid time costSpecial data processing applicationsGenomic mutationNucleotide

The invention discloses a method for functional prediction of single nucleotide genomic variation in a non-coding region, which comprises the following steps: 1) identifying a chromatin open region; 2) identifying transcription factor bin sites; 3) assessing the role of single nucleotide variations: Based on the site-specific frequency matrix of transcription factors, the effect of single nucleotide variations in the transcription factor binding site region on transcription factor binding is calculated, and the single nucleotide variations that significantly change the binding capacity of transcription factors are identified; the role of single nucleotide variations is further evaluated by viewing the biological pathway of the target gene of the transcription factor. The method recognizesa variety of transcription factors and their binding sites at one time through chromatin open region information and gene expression information, and realizes the functional annotation of non-coding region genomic mutation.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com